Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Solid oxide electrolyser cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

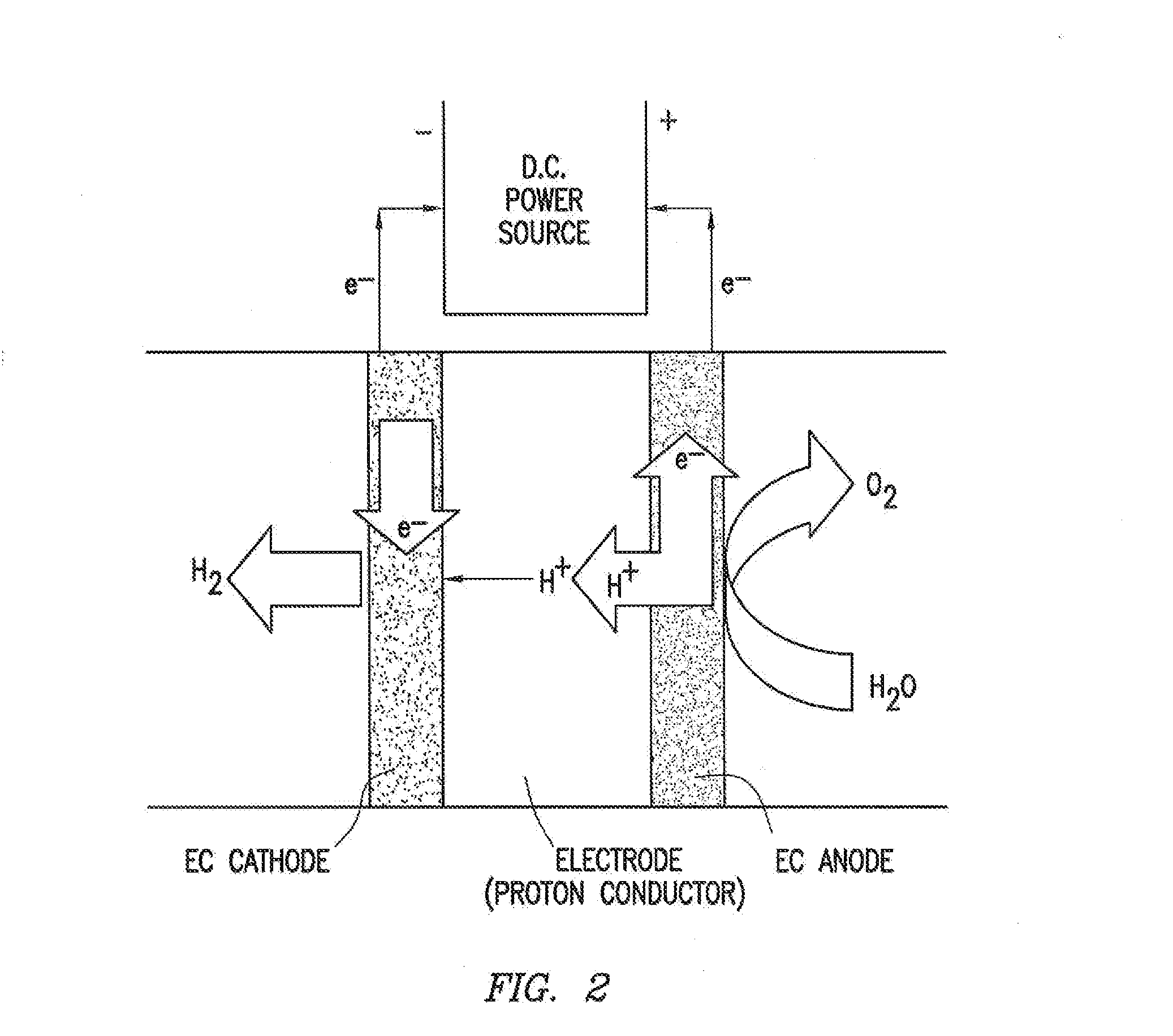

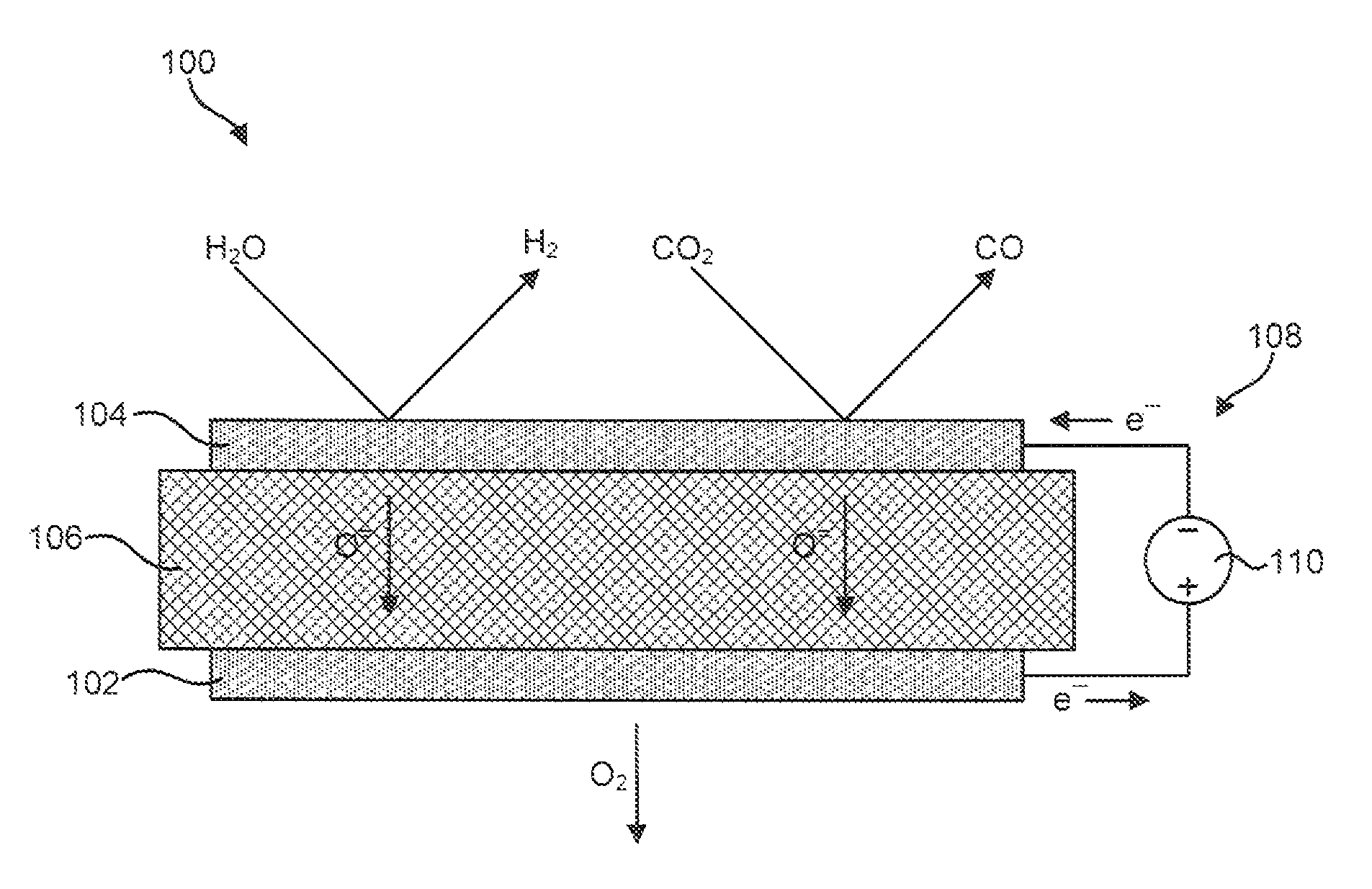

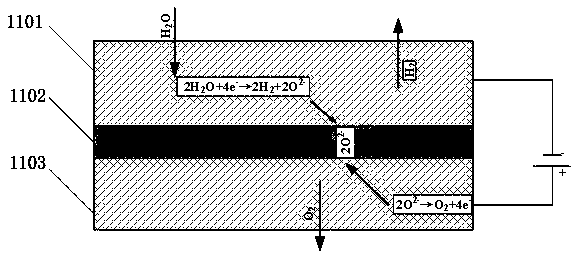

A solid oxide electrolyzer cell (SOEC) is a solid oxide fuel cell that runs in regenerative mode to achieve the electrolysis of water (and/or carbon dioxide) by using a solid oxide, or ceramic, electrolyte to produce hydrogen gas (and/or carbon monoxide) and oxygen. The production of pure hydrogen is compelling because it is a clean fuel that can be stored easily, thus making it a potential alternative to batteries, which have a low storage capacity and create high amounts of waste materials. Electrolysis is currently the most promising method of hydrogen production from water due to high efficiency of conversion and relatively low required energy input when compared to thermochemical and photocatalytic methods.

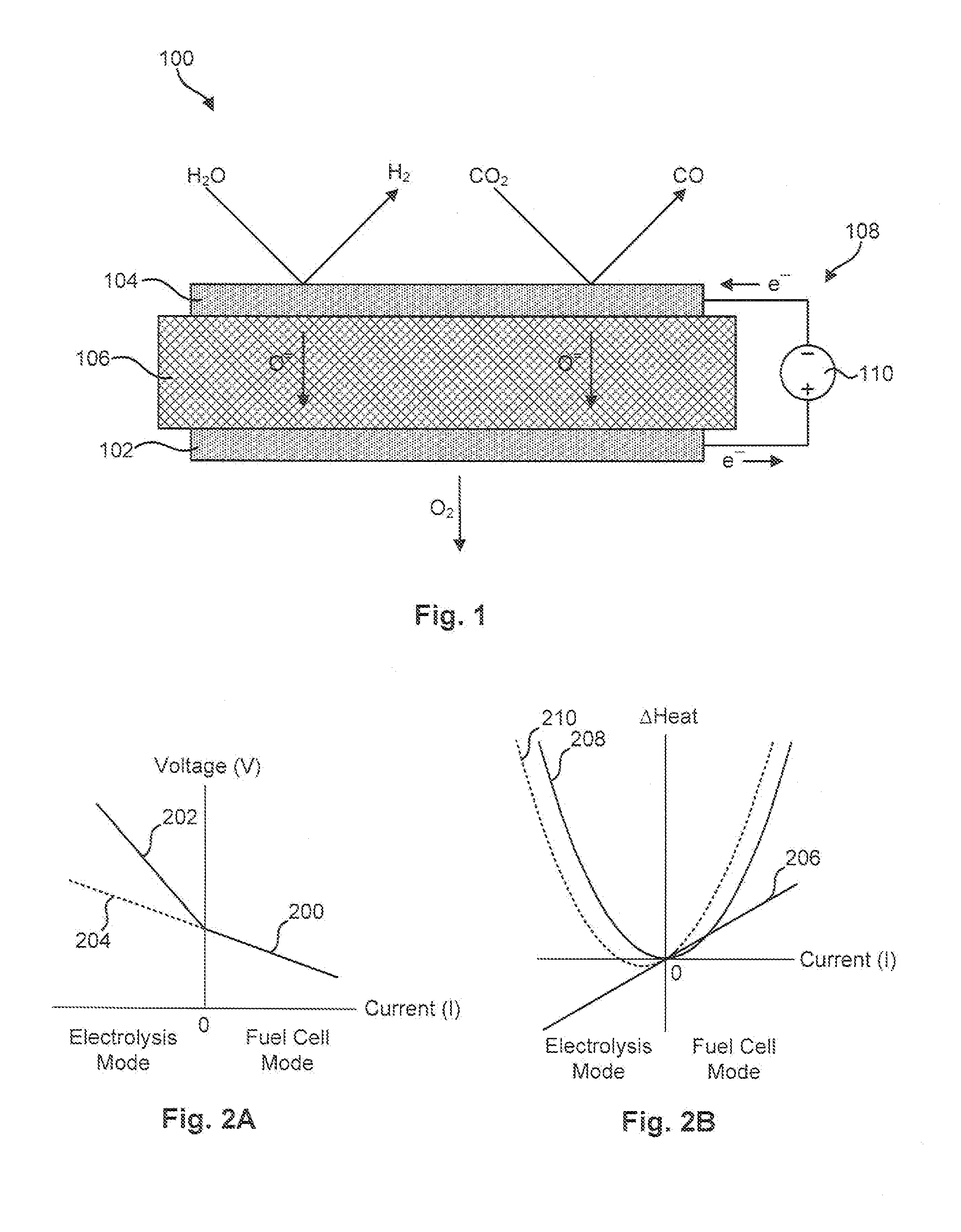

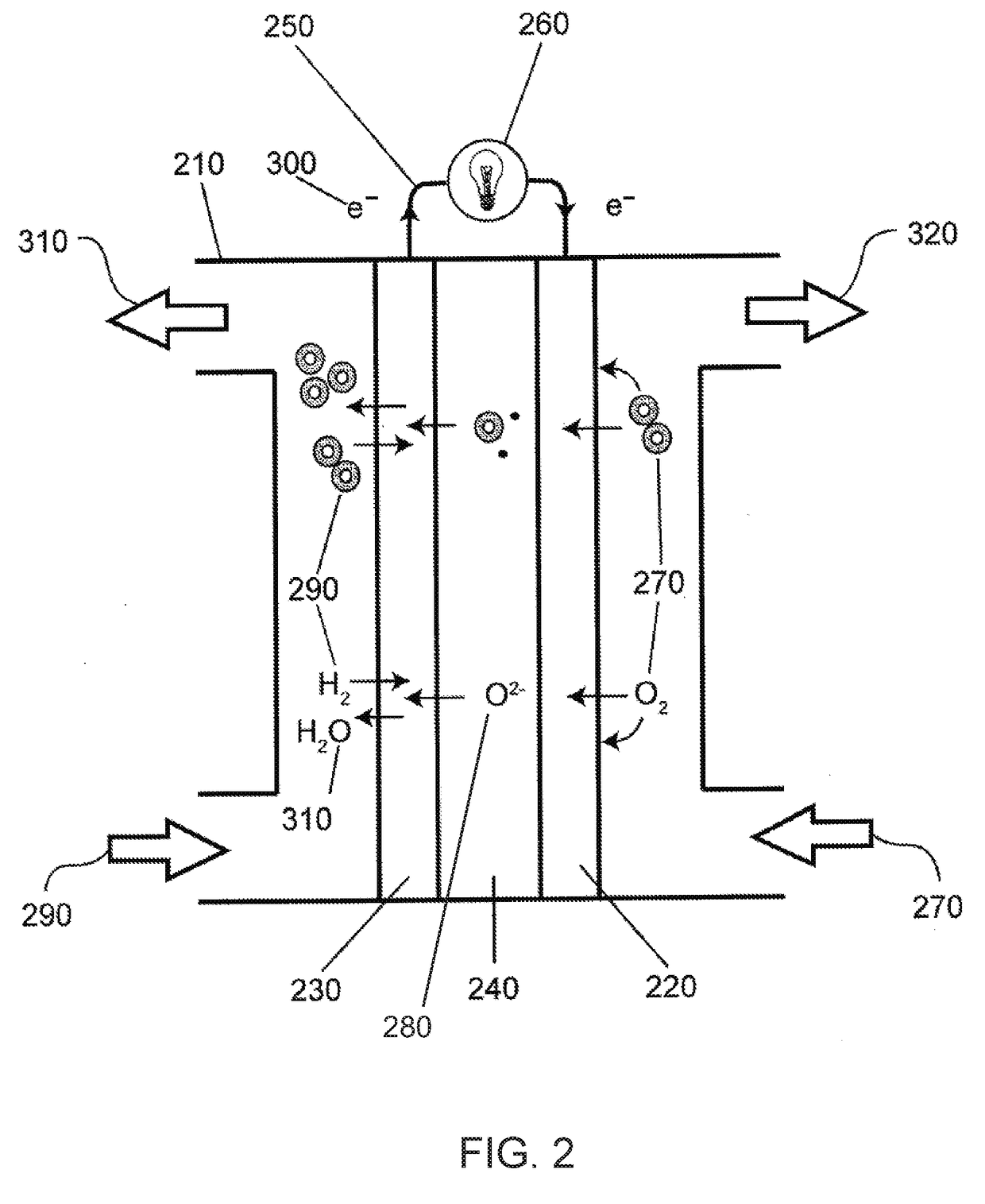

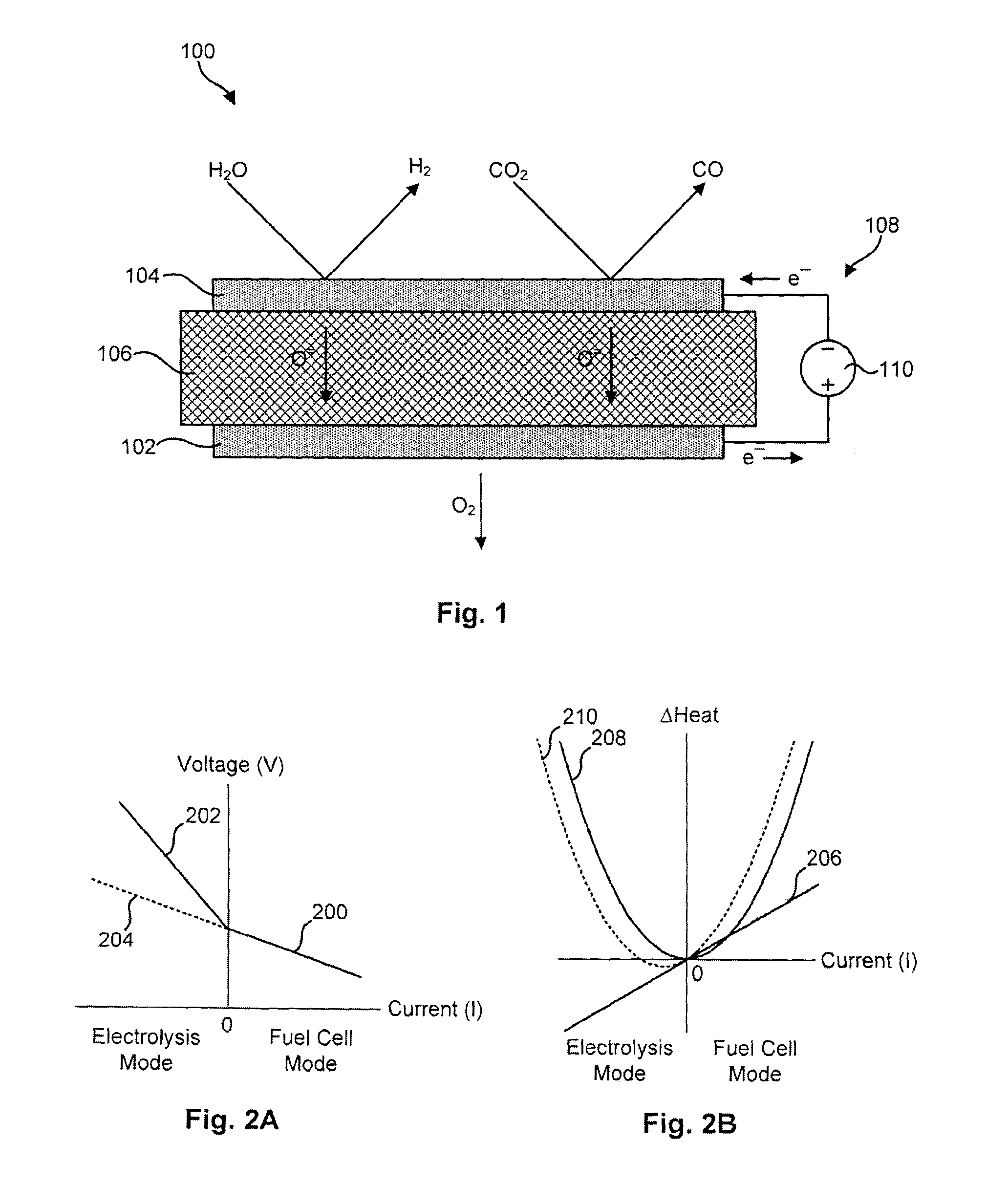

Efficient Reversible Electrodes For Solid Oxide Electrolyzer Cells

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0≦x≦0.5, 0≦y≦0.5, and 0.8≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:COORSTEK INC

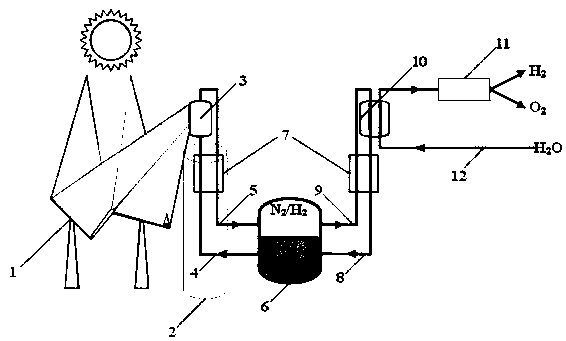

Carbon dioxide conversion to hydrocarbon fuel via syngas production cell harnessed from solar radiation

ActiveUS20140194539A1Solar heating energyLiquid hydrocarbon mixture productionThermal energyChemistry

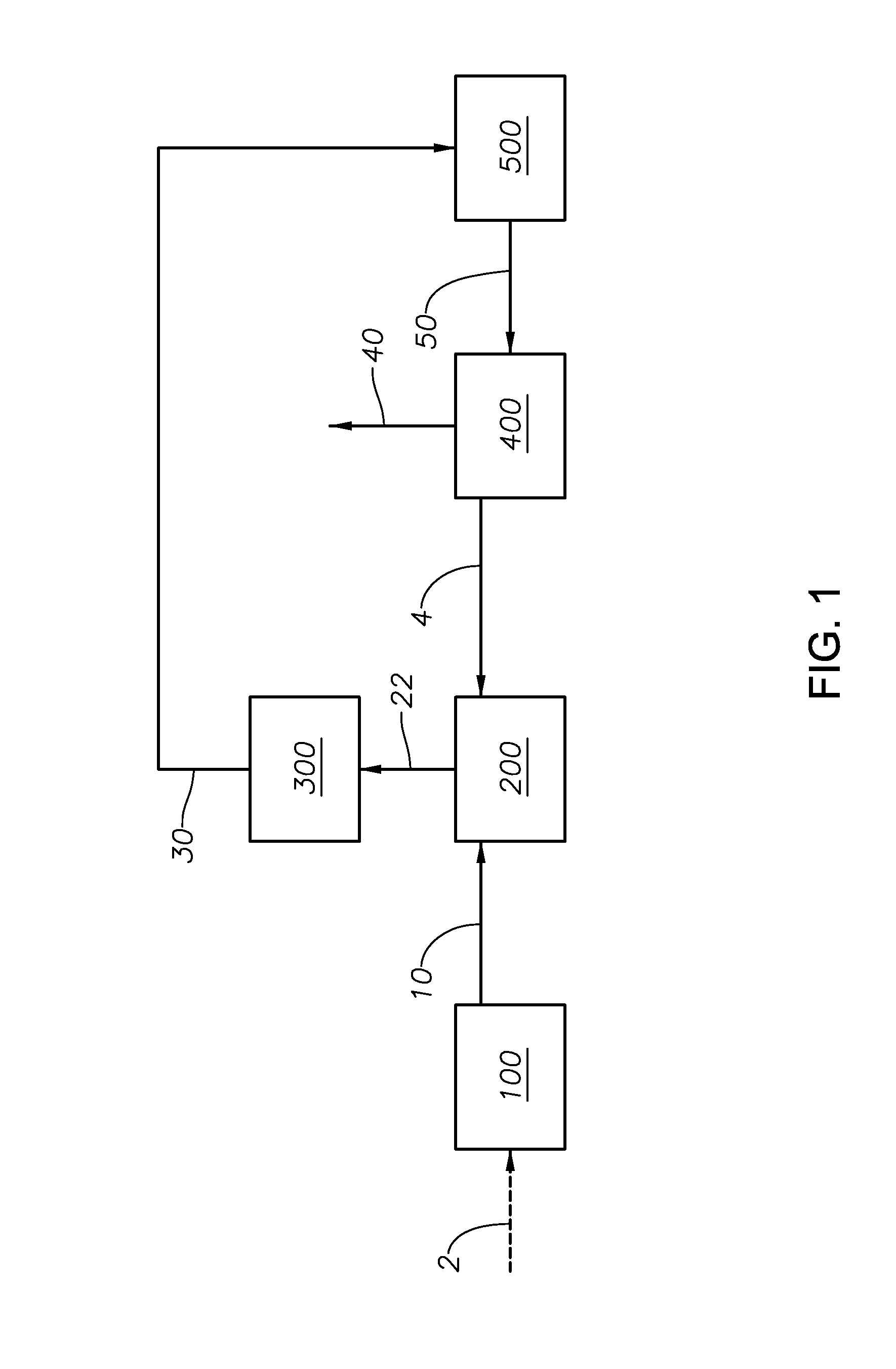

A process for converting carbon dioxide to hydrocarbon fuels using solar energy harnessed with a solar thermal power system to create thermal energy and electricity, using the thermal energy to heat a fuel feed stream, the heated fuel feed stream comprising carbon dioxide and water, the carbon dioxide captured from a flue gas stream, converting the carbon dioxide and water in a syngas production cell, the syngas production cell comprising a solid oxide electrolyte, to create carbon monoxide and hydrogen, and converting the carbon monoxide and hydrogen to hydrocarbon fuels in a catalytic reactor. In at least one embodiment, the syngas production cell is a solid oxide fuel cell. In at least one embodiment, the syngas production cell is a solid oxide electrolyzer cell.

Owner:SAUDI ARABIAN OIL CO

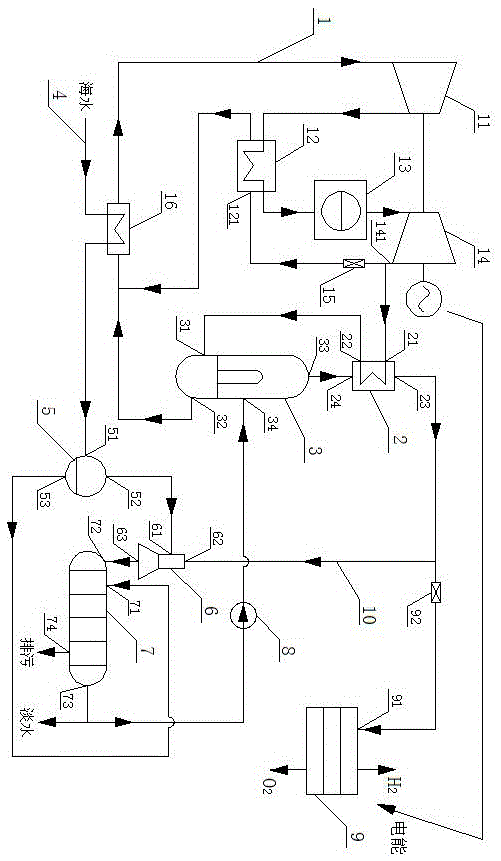

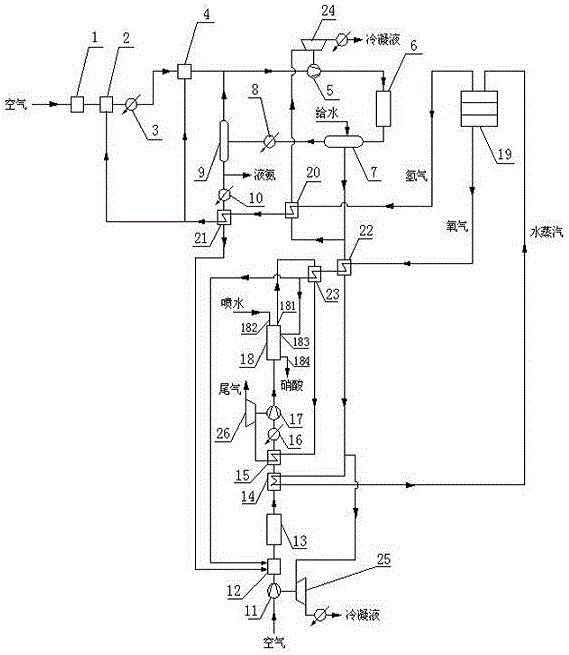

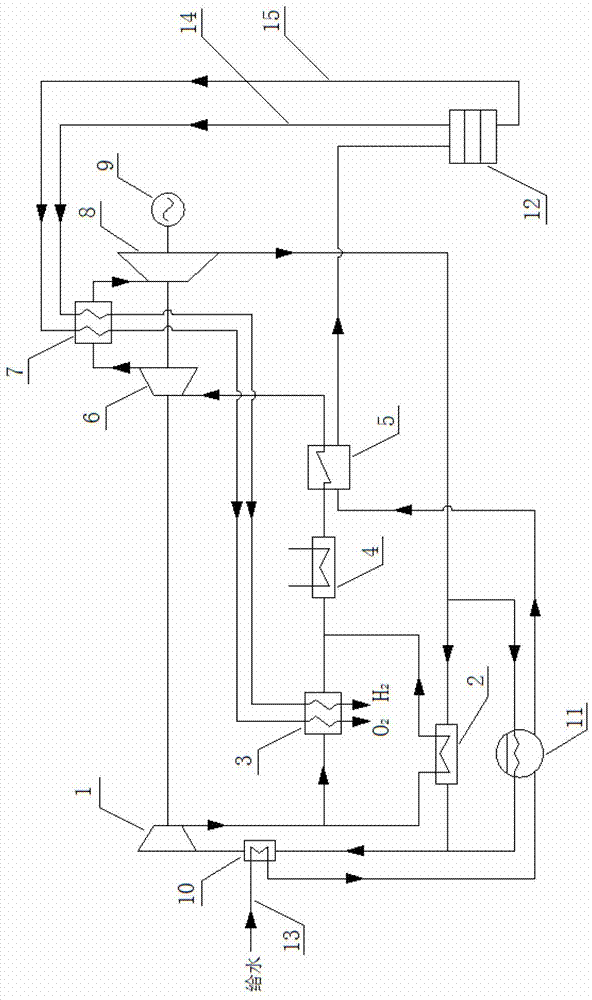

Tri-cogeneration system and tri-cogeneration method for generating power, producing hydrogen and producing fresh water by aid of high-temperature gas-cooled reactor of nuclear power plant

InactiveCN105645499AImprove cycle thermal efficiencyMeet the changing requirements of different needsGeneral water supply conservationSeawater treatmentNuclear powerSuperheater

The invention discloses a tri-cogeneration system and a tri-cogeneration method for generating power, producing hydrogen and producing fresh water by the aid of a high-temperature gas-cooled reactor of a nuclear power plant. The tri-cogeneration system comprises a closed helium circulating system of the nuclear power plant, a superheater, a steam generator, a raw seawater pipeline, a flash evaporator, a steam ejector, a seawater desalting device, a water feeding pump, a solid oxide electrolytic tank and an auxiliary steam pipeline. The tri-cogeneration system and the tri-cogeneration method have the advantages that the circulating system of the nuclear power plant, steam electrolysis and hydrogen production processes and distillation seawater desalination processes are coupled with one another, the power is generated by the aid of a helium gas turbine at first, waste heat of partial exhaust gas of the helium gas turbine is used for electrolyzing steam and producing the hydrogen, low-temperature waste heat cooling water of a cooler is used for carrying out distillation seawater desalination by means of coupled flash evaporation and steam injection, and accordingly diversified water, power and hydrogen tri-cogeneration modes can be implemented; the electric power and the fresh water which are required for steam electrolysis and hydrogen production can be provided by means of seawater desalination and nuclear power generation, accordingly, the tri-cogeneration system is high in circulating heat efficiency and good in adjustment performance and has a good economic benefit, the reliability of equipment can be improved, environmental pollution can be reduced, the tri-cogeneration system and the tri-cogeneration method have excellent application prospects, and the like.

Owner:陈志强

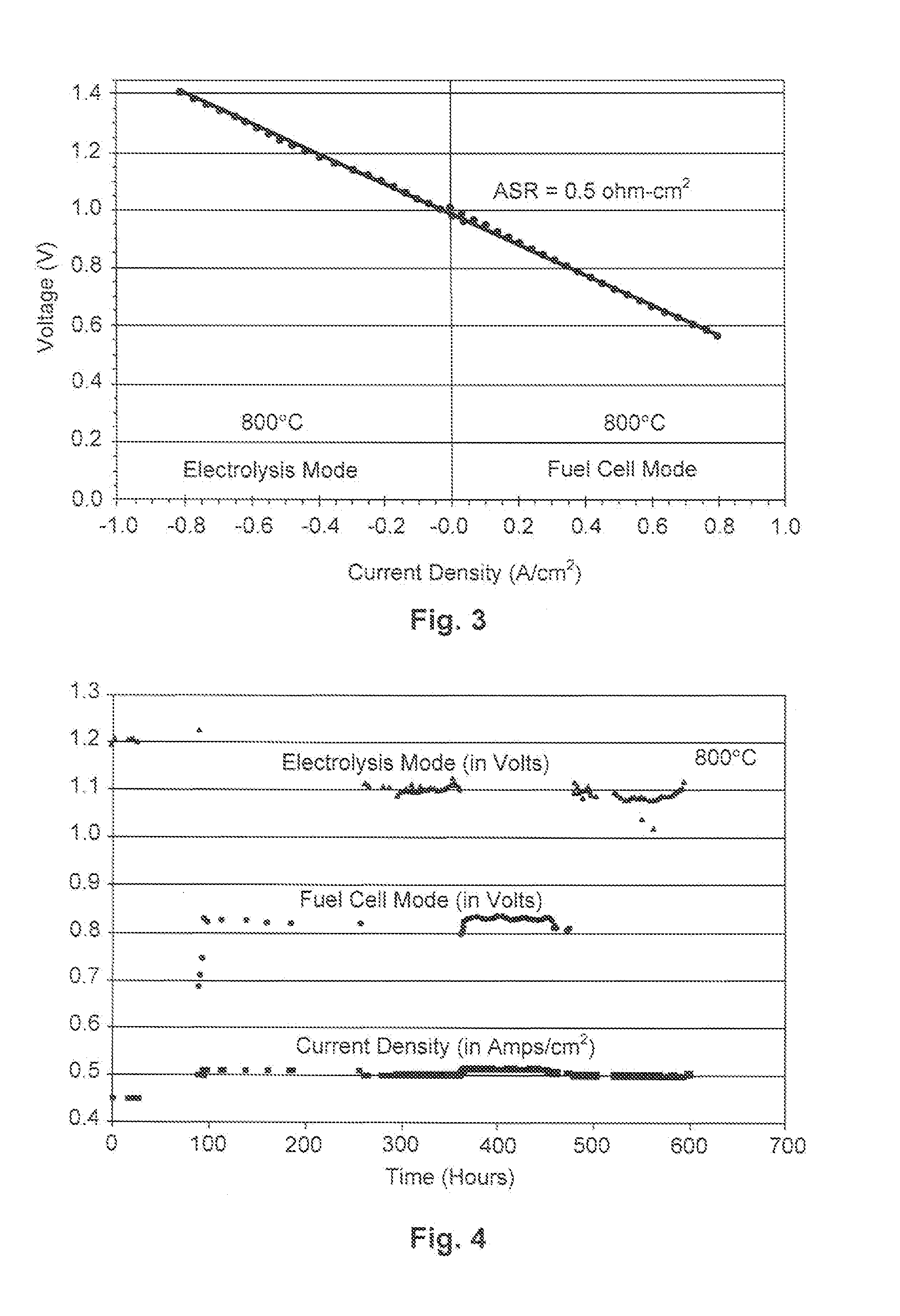

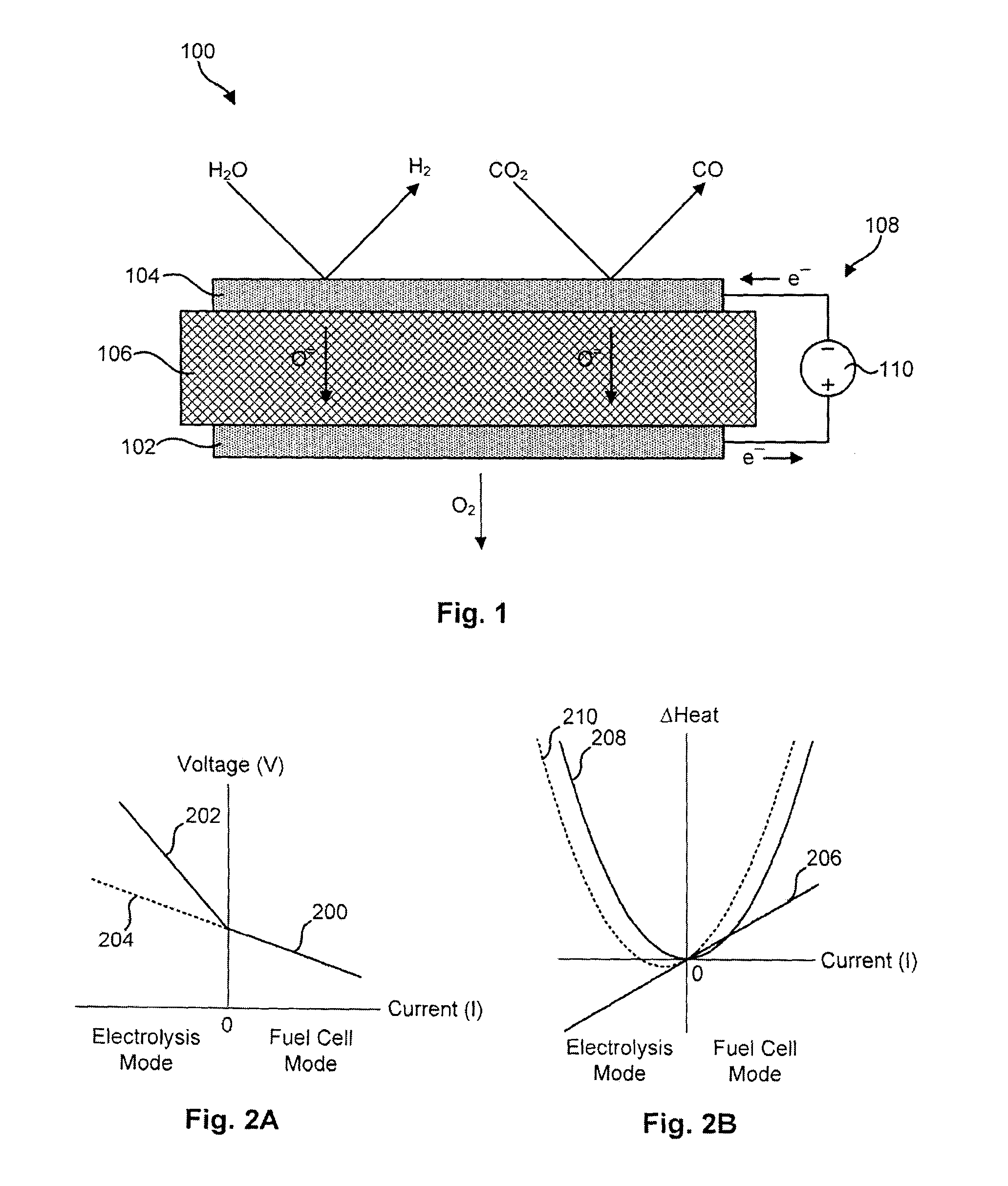

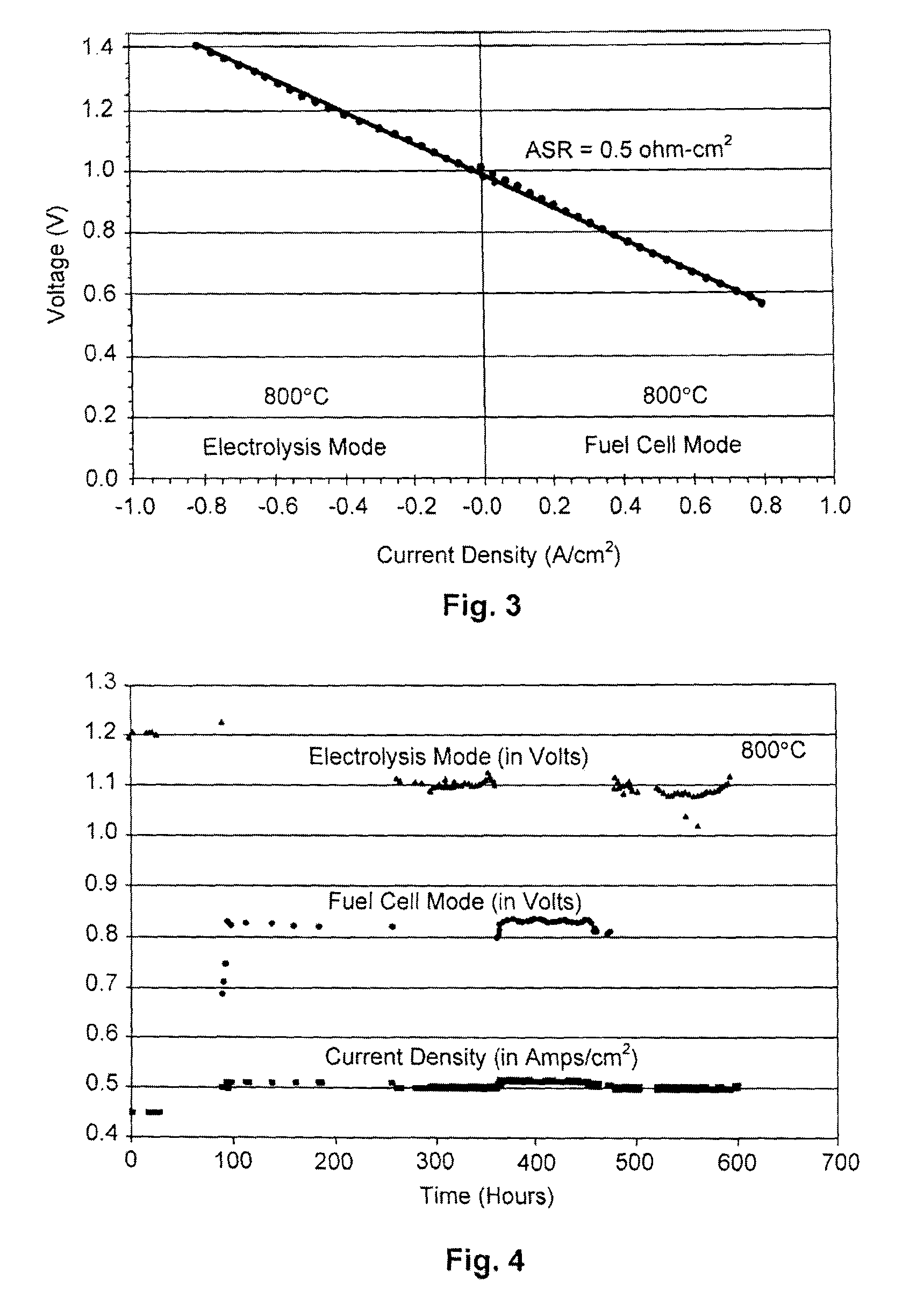

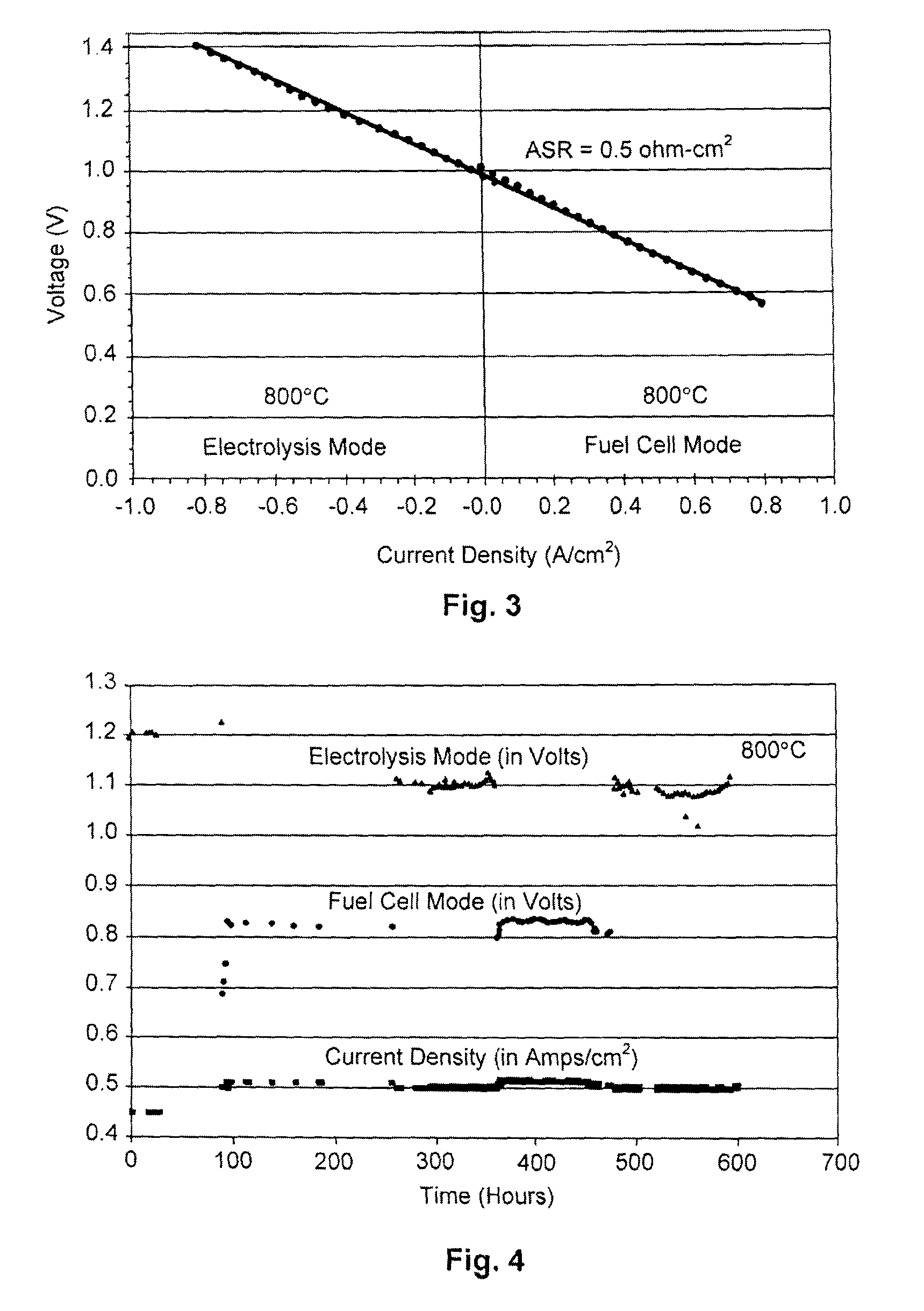

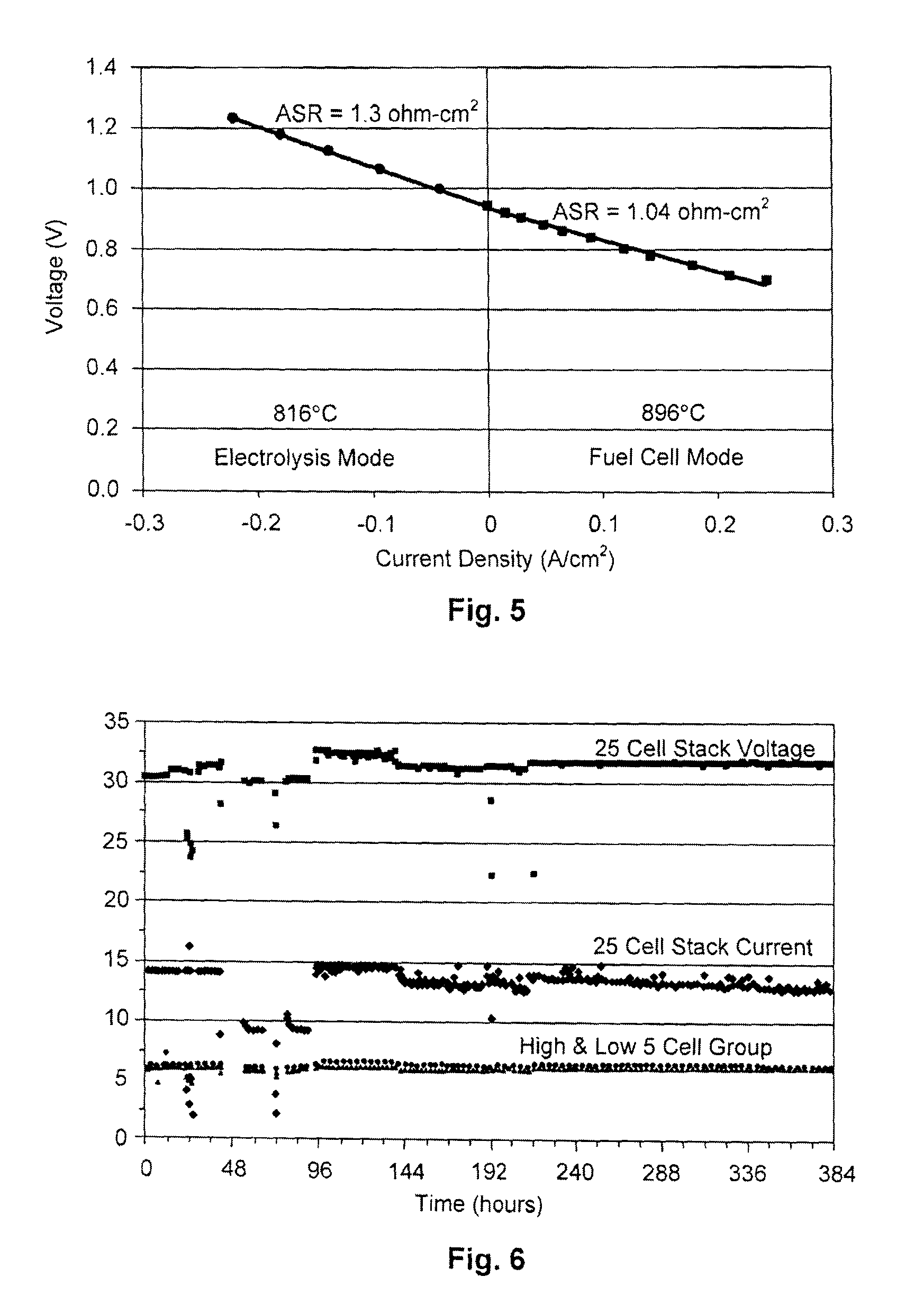

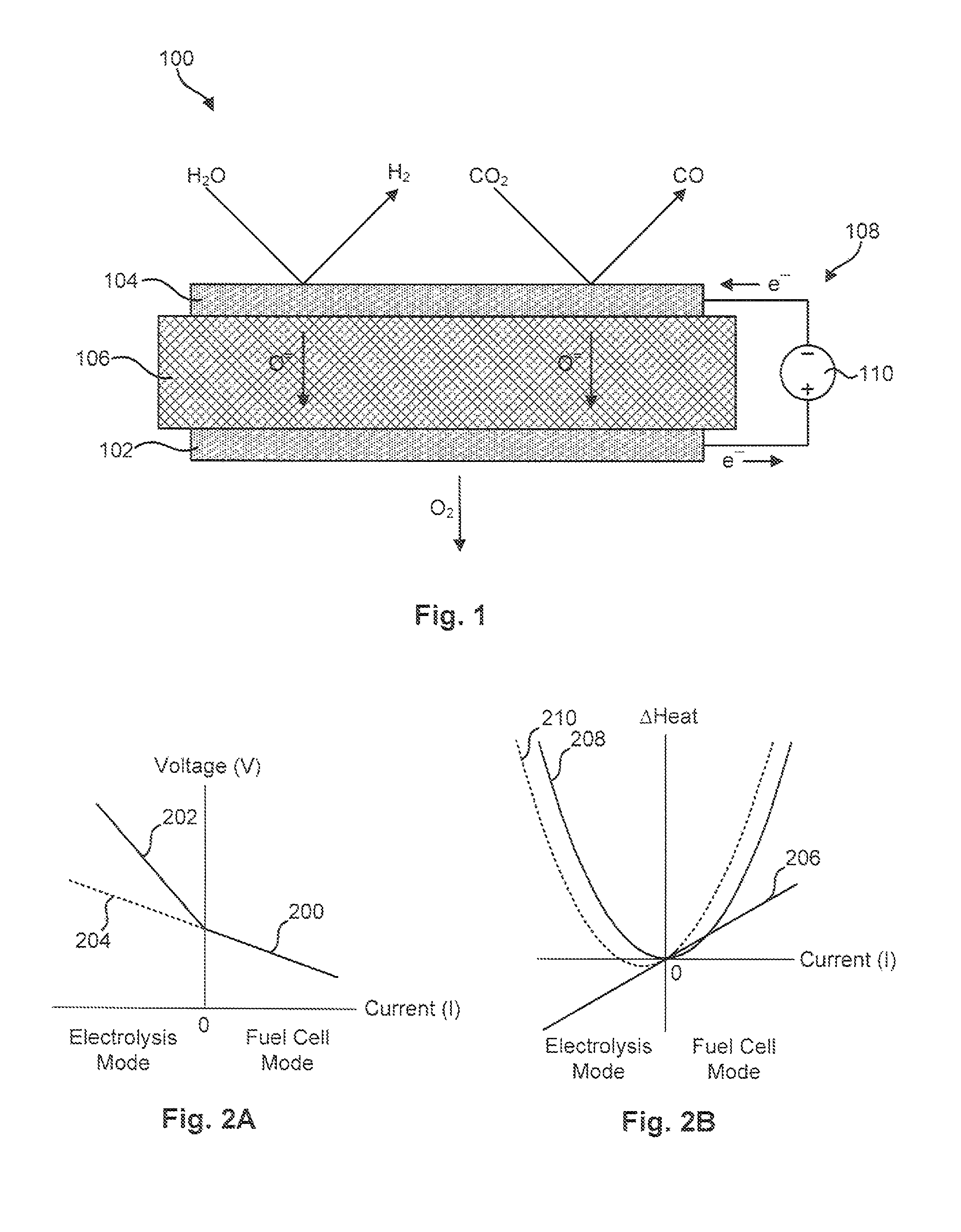

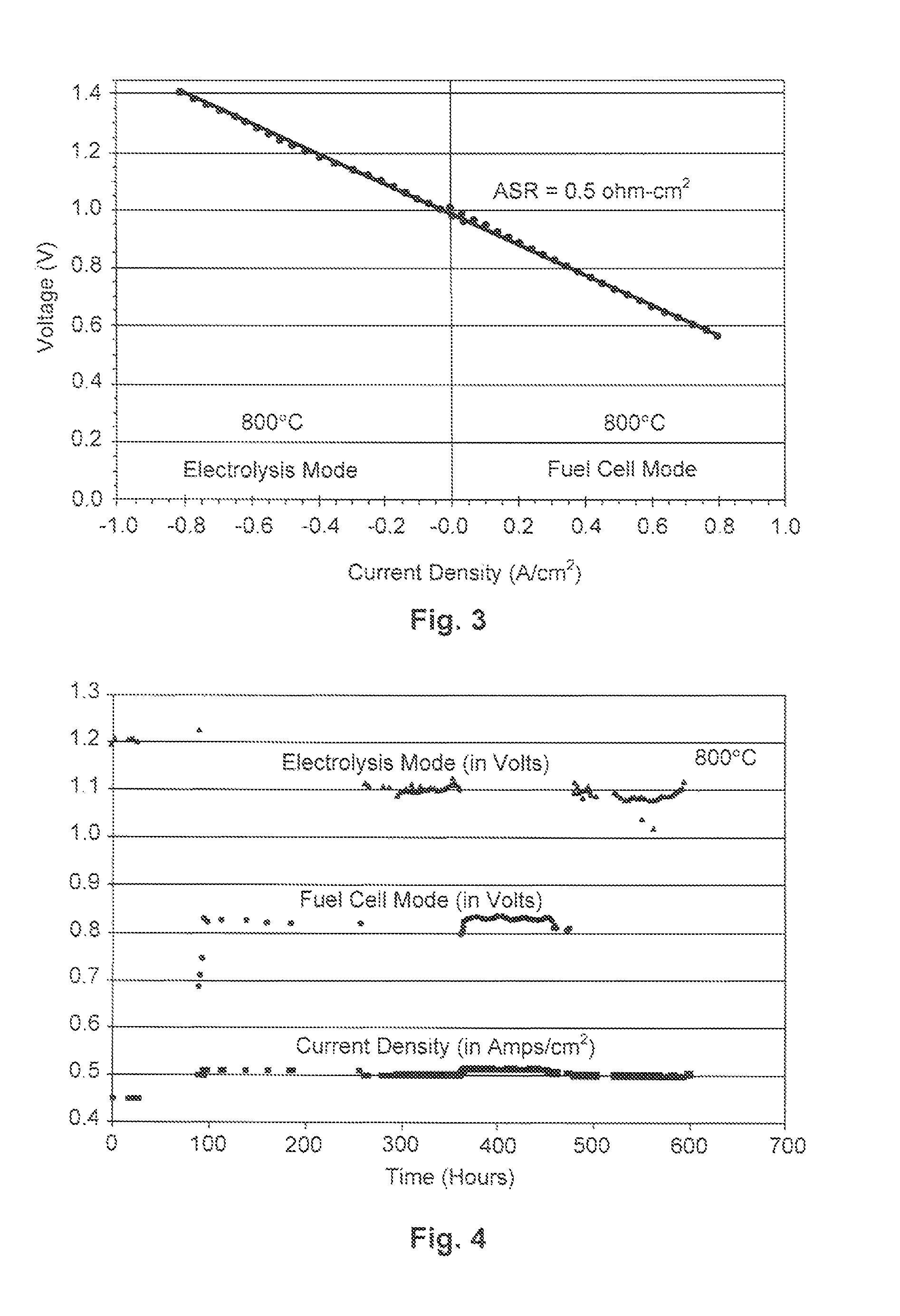

Method for improving the efficiency and durability of electrical energy storage using solid oxide electrolysis cell

ActiveUS20120003552A1Improve system efficiencyOvercome limitationsElectrolysis componentsPhotography auxillary processesElectrical batteryThermal energy storage

A method for improving the efficiency and durability of reversible solid oxide cells during electrical energy storage is disclosed. The method utilizes a specific set of operating conditions that produces a storage chemistry where approximately thermal-neutral operation can be achieved at low cell over-potentials. Also disclosed are reversible solid oxide cell energy storage system configurations, including one that utilizes storage in natural gas and water storage / distribution networks, thereby reducing storage cost.

Owner:NORTHWESTERN UNIV

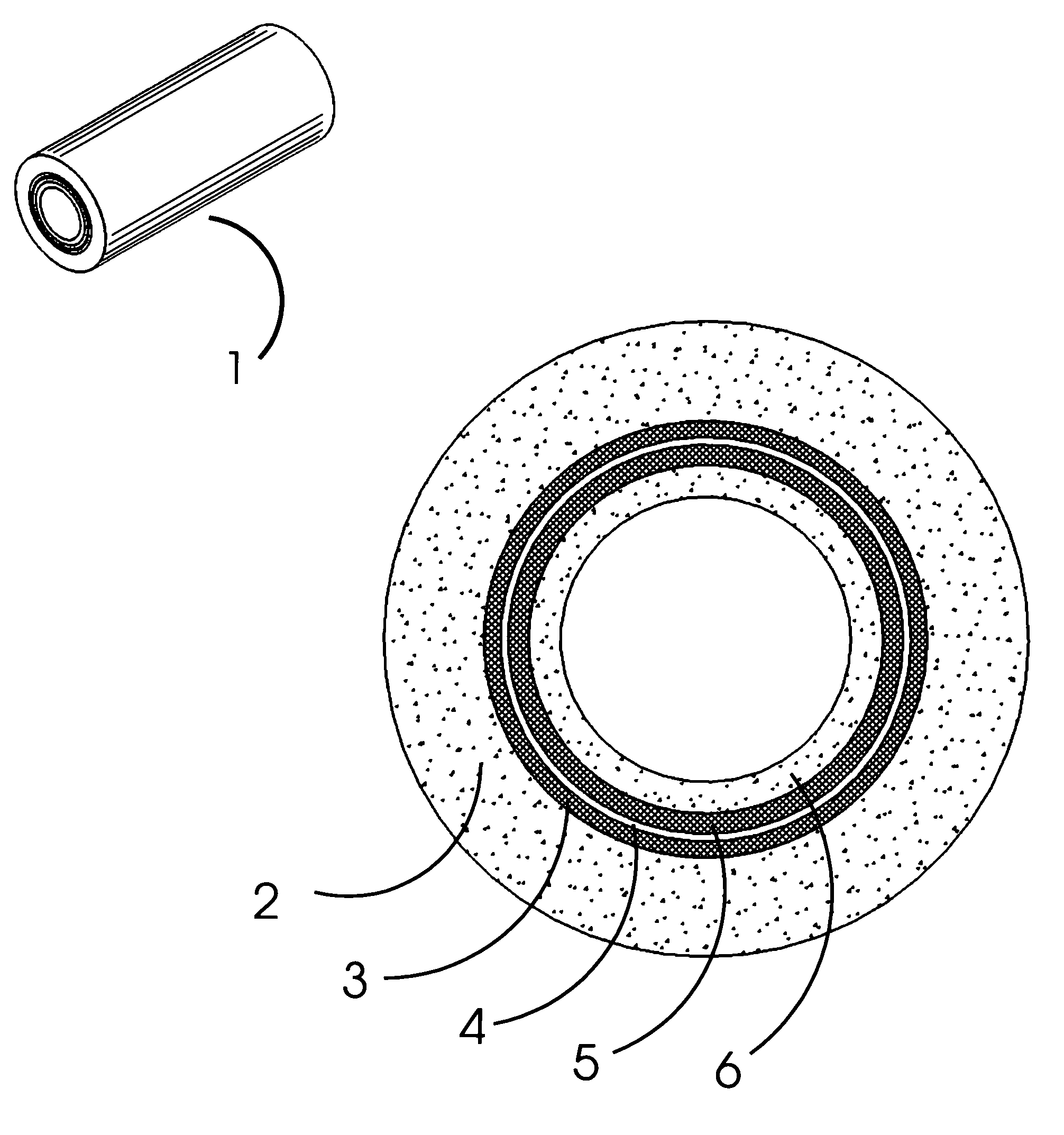

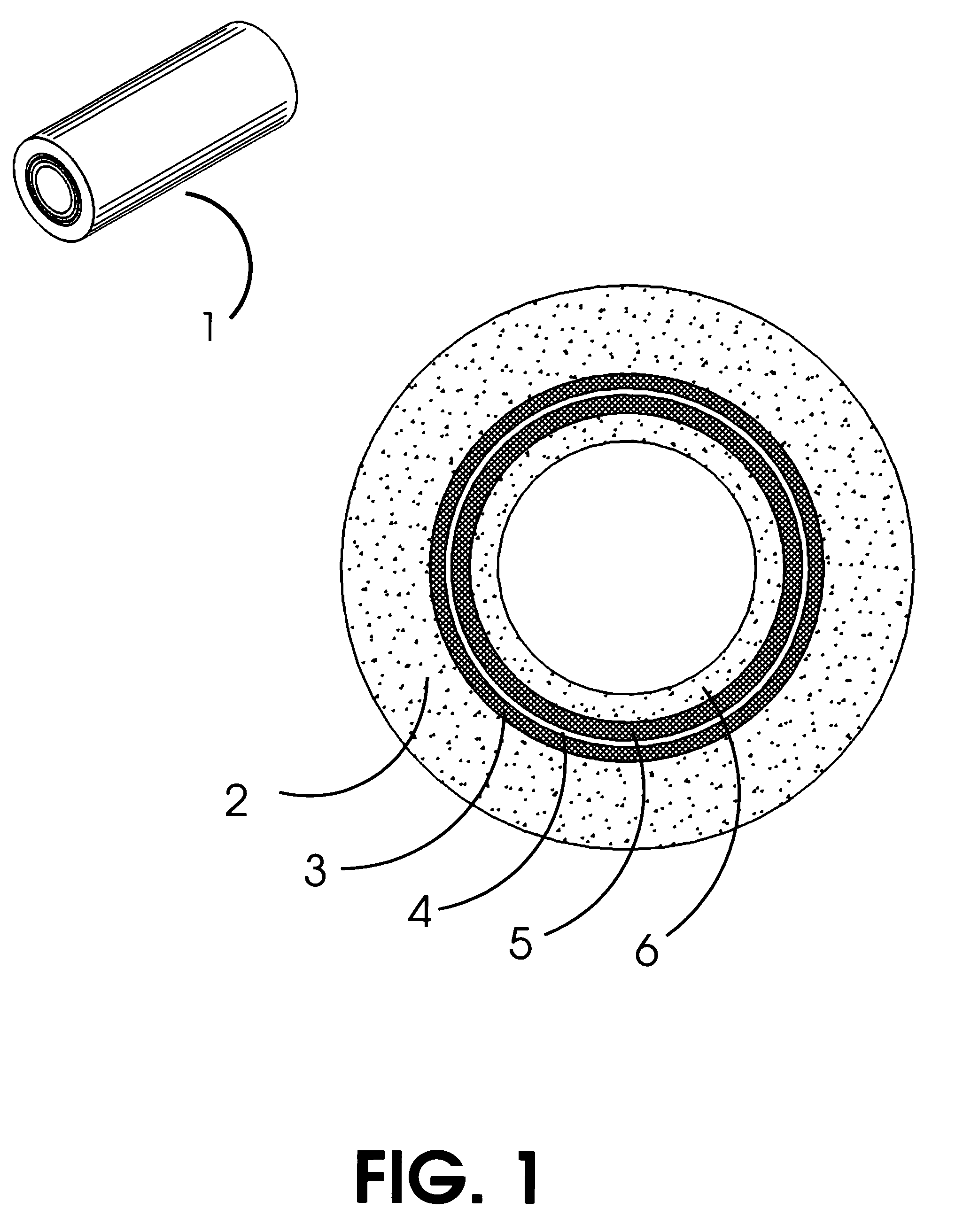

Porous bi-tubular solid state electrochemical device

A low cost, robust bi-tubular solid state electrochemical device including a first porous, sintered support tube of a non-noble transition metal, a non-noble transition metal alloy and a cermet incorporating one or more of a non-noble transition metal and a non-noble transition metal alloy and having successive layers of a first porous electrode, a dense electrolyte and a second porous electrode, said successive layers disposed radially on the interior surface of said first porous, sintered support tube or disposed radially on the exterior surface of the first porous, sintered support tube and a second porous, sintered tubular member of a non-noble transition metal, a non-noble transition metal alloy and a cermet incorporating one or more of a non-noble transition metal and a non-noble transition metal alloy formed, deposited, or placed in electrical contact with the second porous electrode. The bi-tubular device of the present invention may comprise a solid oxide fuel cell or a solid oxide electrolyzer cell.

Owner:RGT UNIV OF CALIFORNIA +1

Solid oxide reversible fuel cell with improved electrode composition

A solid oxide electrolyzer cell or a solid oxide reversible fuel cell includes a solid oxide electrolyte. It may also include at least one of a first gadolinia doped ceria interfacial layer in contact with a first side of the electrolyte and a second gadolinia doped ceria interfacial layer in contact with a second side of the electrolyte. It may also include a fuel electrode including a cermet containing nickel and one or both of a doped zirconia and gadolinia doped ceria. It may also include an oxidant electrode including an LSM and one or both of a doped zirconia and gadolinia doped ceria.

Owner:BLOOM ENERGY CORP

Process for enabling carbon-capture from existing combustion processes

ActiveUS20140076213A1Enhanced feedingElectrolysis componentsUsing liquid separation agentFlue gasSolid oxide electrolyser cell

A process of producing a feed from a solid oxide electrolysis cell. A first portion of the flue gas produced from a combustion process is directed to the anode side of the solid oxide electrolysis cell. The feed and a second portion of the flue gas are then mixed to produce an enhanced feed. The enhanced feed is then mixed with fuel and combusted in the combustion process to produce flue gas. The flue gas comprises greater than 50 wt % CO2 and less than 1 wt % N2.

Owner:PHILLIPS 66 CO

Cathode material used for solid oxide electrolytic cell and application of cathode material

The invention provides a cathode material used for a solid oxide electrolytic cell and application of the cathode material. The chemical constitution of the cathode material is Sr2Fe1-xMxMoO6-Delta, wherein x is larger than or equal to 0 and smaller than or equal to 1; M is one or more selected from Mg, Zn, Ni, Co, Cu and Mn; an SrMoO3 phase is not contained in the cathode material. The cathode material does not comprise the SrMoO3 phase, adopts a single perovskite phase structure, can effectively solve the problem that the electrochemical performance of the Sr2Fe1-xMxMoO6-Delta is undesirable due to existence of the SrMoO3 phase, has favorable electrochemical performance, and can effectively improve hydrogen manufacturing efficiency of the solid oxide electrolytic cell.

Owner:TSINGHUA UNIV

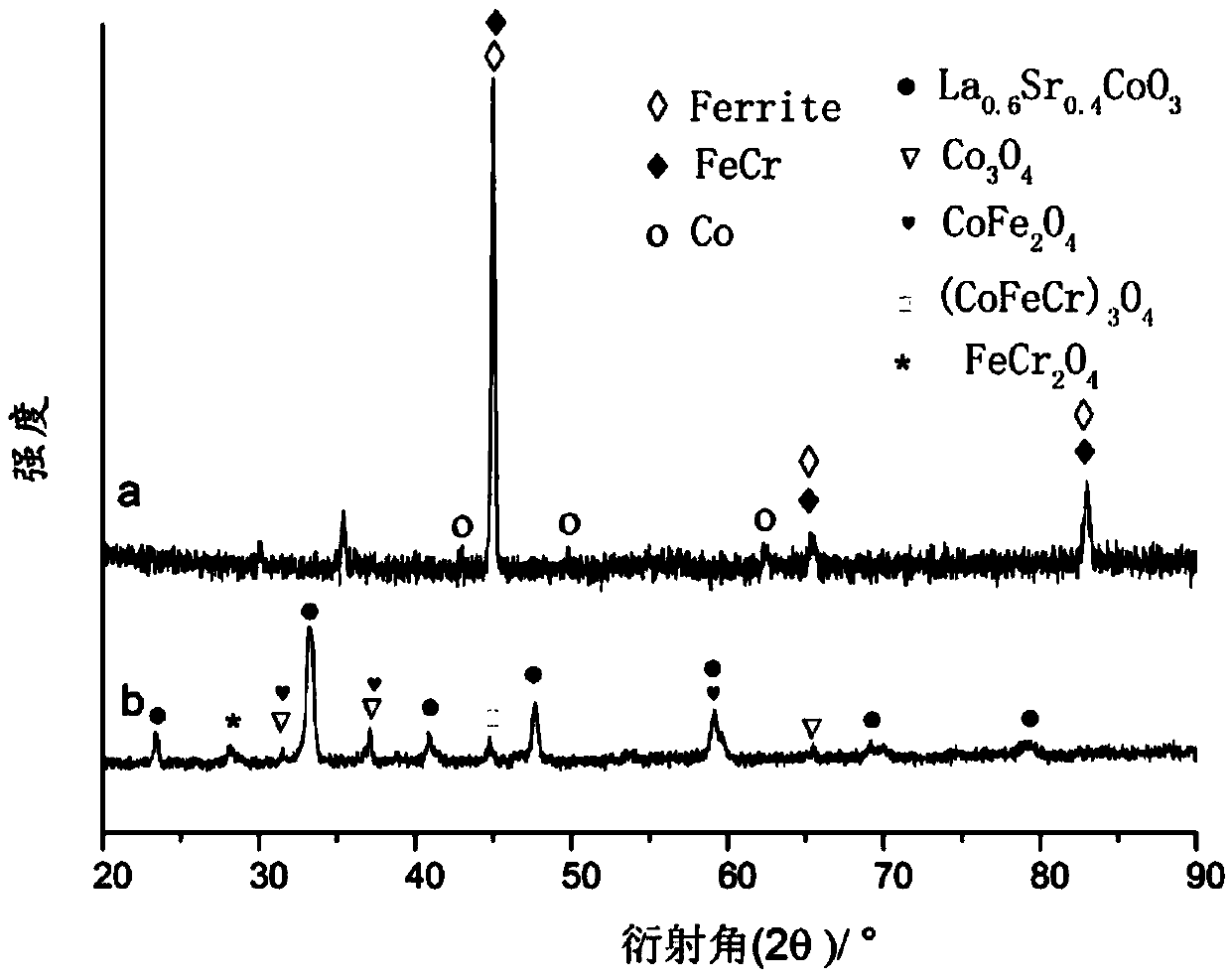

Double-layer coating on metal connector surface of high-temperature solid oxide cell and preparation method thereof

InactiveCN103746128AImprove bindingWell bonded and denseCell component detailsSolid electrolyte fuel cellsOxide compositeContact resistance

The invention discloses a double-layer coating on the metal connector surface of a high-temperature solid oxide cell and a preparation method of the double-layer coating. The coating comprises a first coating facing the metal connector surface and a second coating facing the environment, wherein the first coating consists of a main-phase oxide spinel structure and a first-phase composite oxide; the second coating consists of a main-phase composite oxide and a second-phase composite oxide. The first coating of the double-layer coating is bonded to a metal connector well and densely; the diffusion of chromium to an SOFC (solid oxide fuel cell) cathode or an SOEC (solid oxide electrolyser cell) anode can be effectively prevented; the main-phase composite oxide powder in the second coating adopts a precursor, high-temperature sintering can be realized in an non-oxidizing atmosphere to avoid excessive oxidation of the metal connector; the second coating is bonded well with the first coating; the phasing of the main-phase oxide composite is realized at low temperature before the cell is operated; high electric conductivity is obtained, and meanwhile, high thermochemical compatibility and low contact resistance between the coating and the SOFC cathode or the SOEC anode are realized.

Owner:SHANGHAI JIAO TONG UNIV

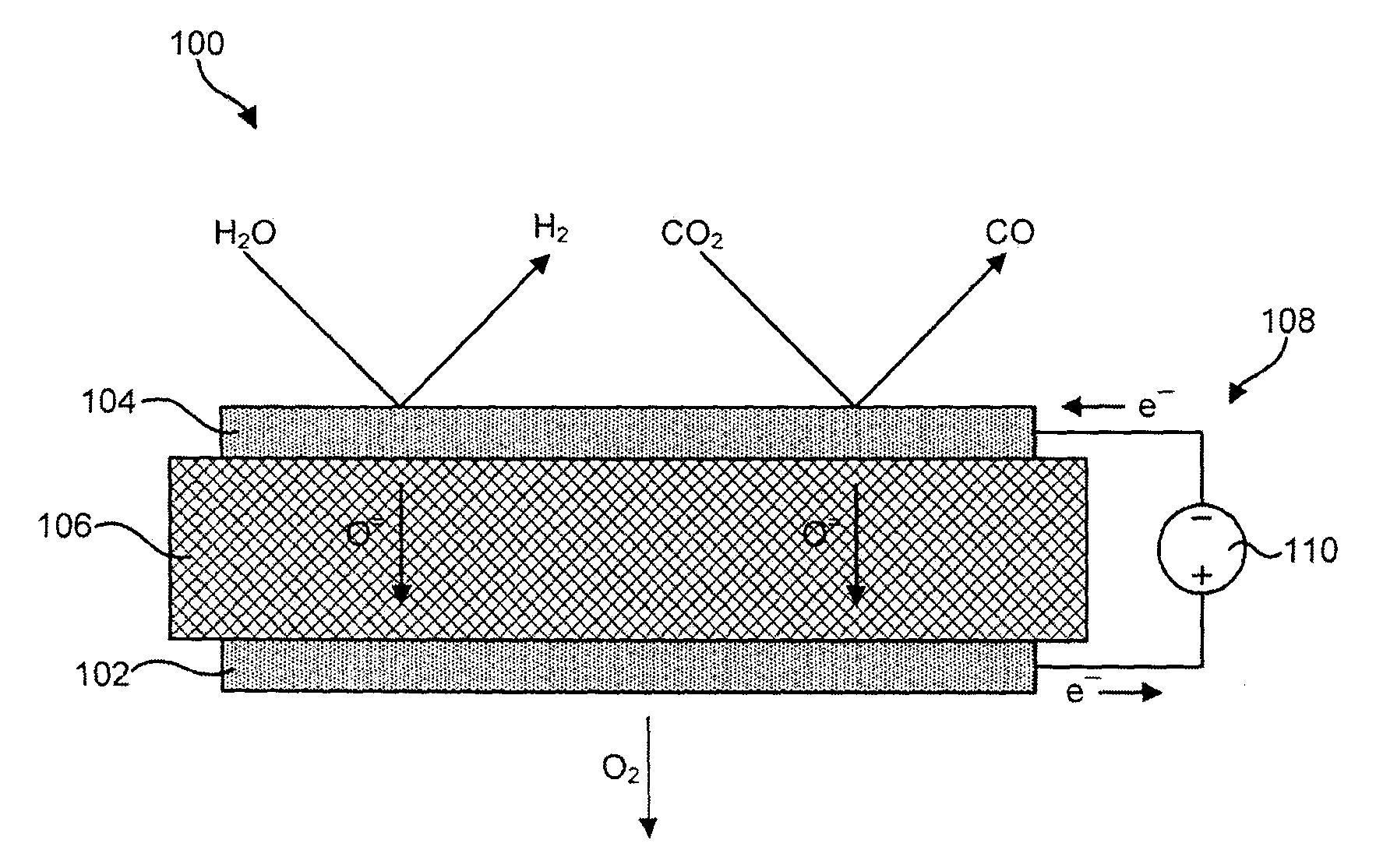

Efficient reversible electrodes for solid oxide electrolyzer cells

InactiveUS20110062017A1Improve electrochemical efficiencyImprove efficiencyCellsActive material electrodesOxygen ionsElectron

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0<x<1, 0≦y≦0.5, and 0.8 ≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:CERAMTEC

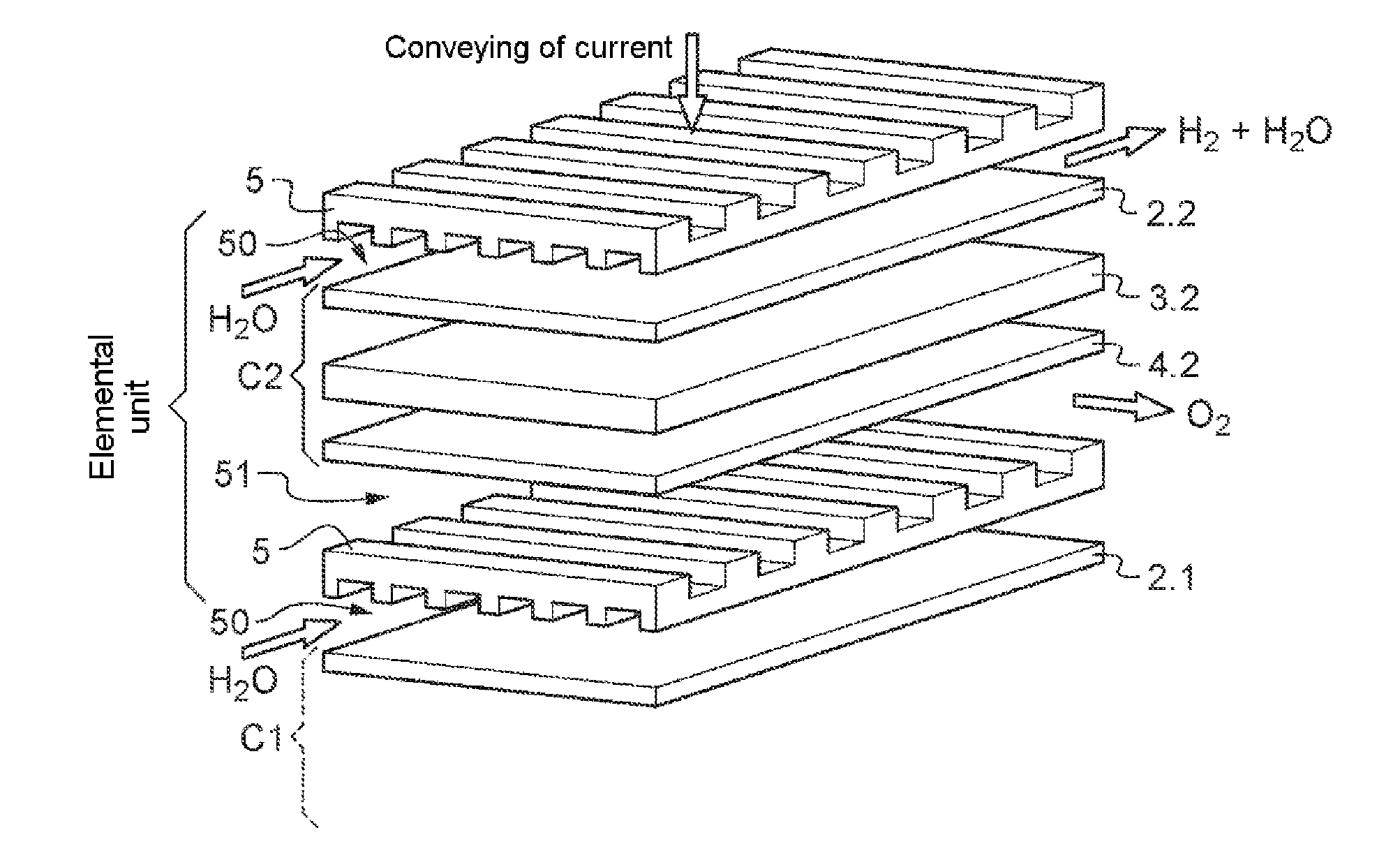

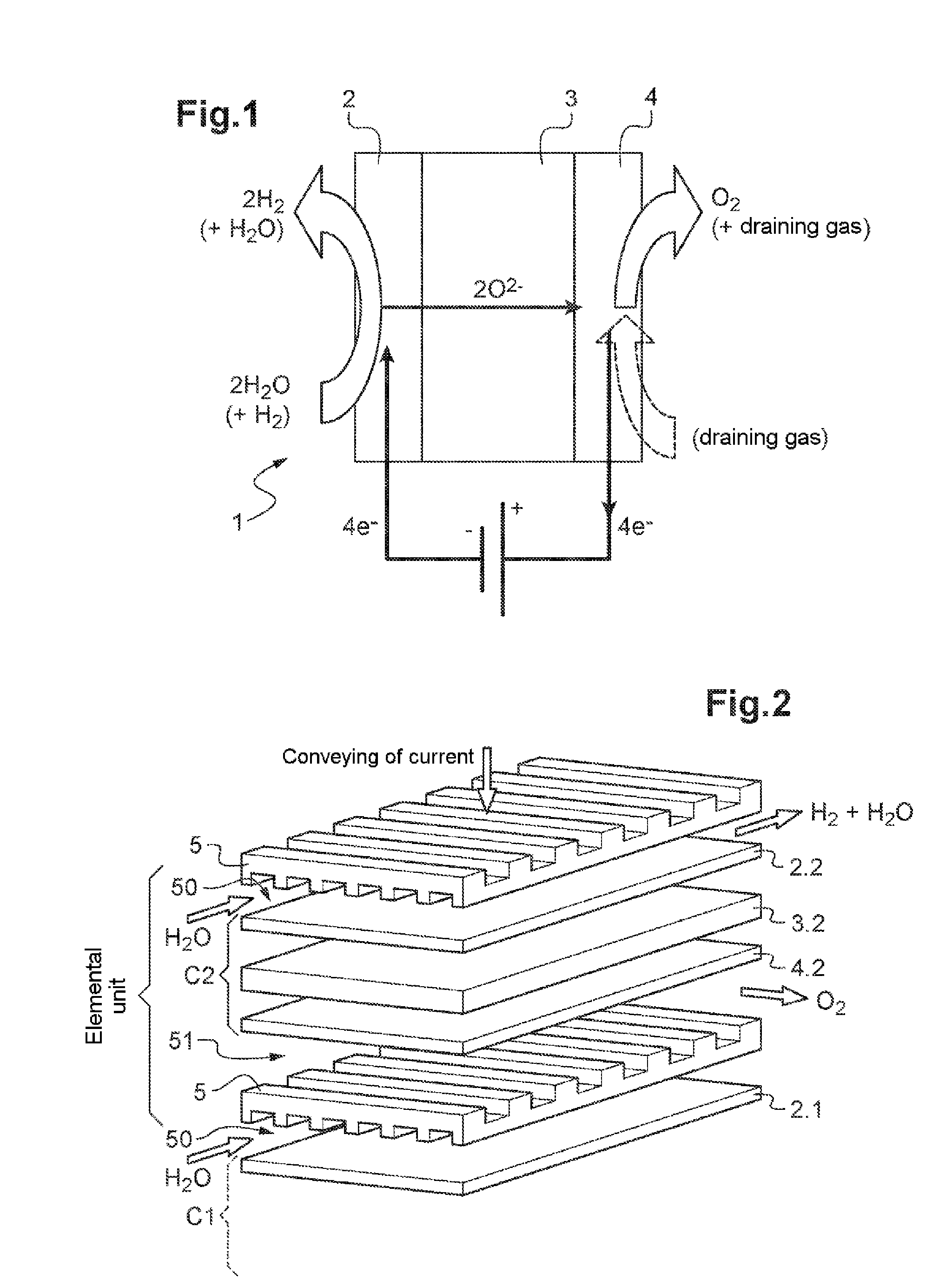

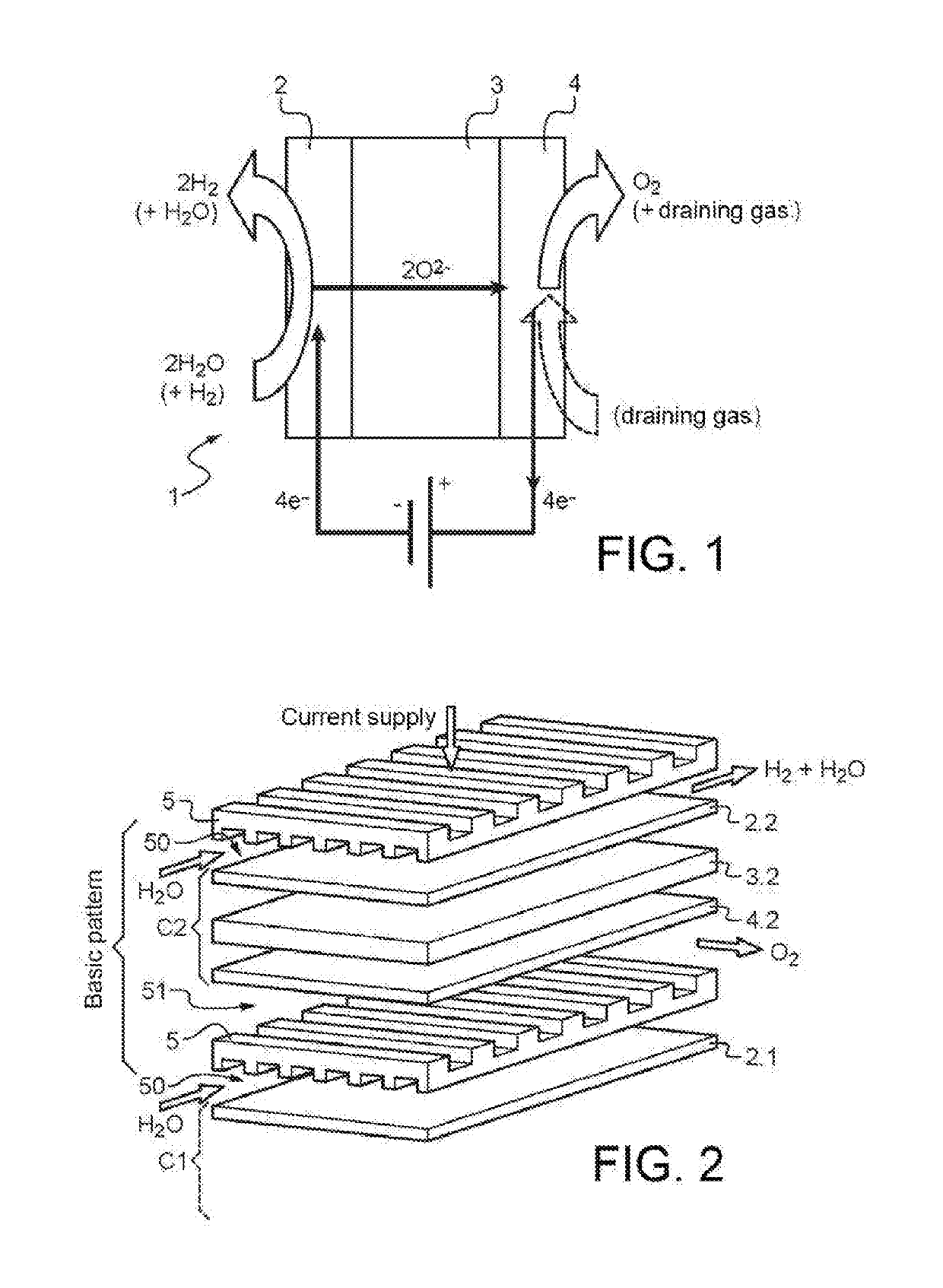

Method for operating an soec-type stack reactor for producing methane in the absence of available electricity

ActiveUS20160355932A1Speed up the processImproved thermal managementCellsGaseous fuelsElectricitySyngas

A method for the operation of an SOEC stack reactor (Solid Oxide Electrolyser Cell), according to which, in the absence of electricity, synthesis gas H2+CO or a mixture H2+CO2 is injected at the cathode inlet of the reactor in such a way as to produce methane inside the reactor. Since the catalytic methanation reaction is exothermic, the stack reactor can therefore be held at temperature, without loss of fuel. The fuel used for the methanation (synthesis gas or hydrogen) can advantageously be that which has been previously produced during the operating phases with available electricity.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

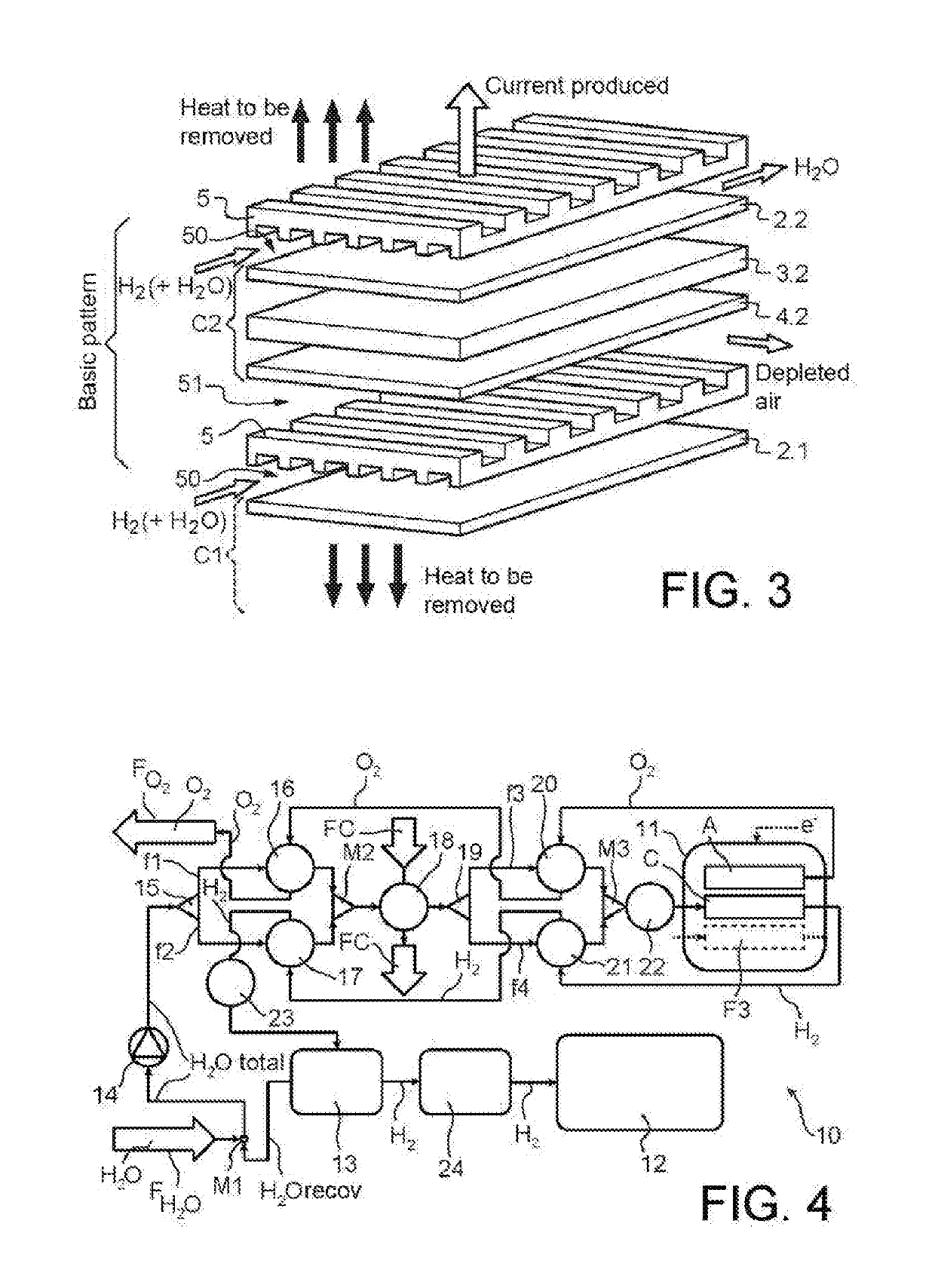

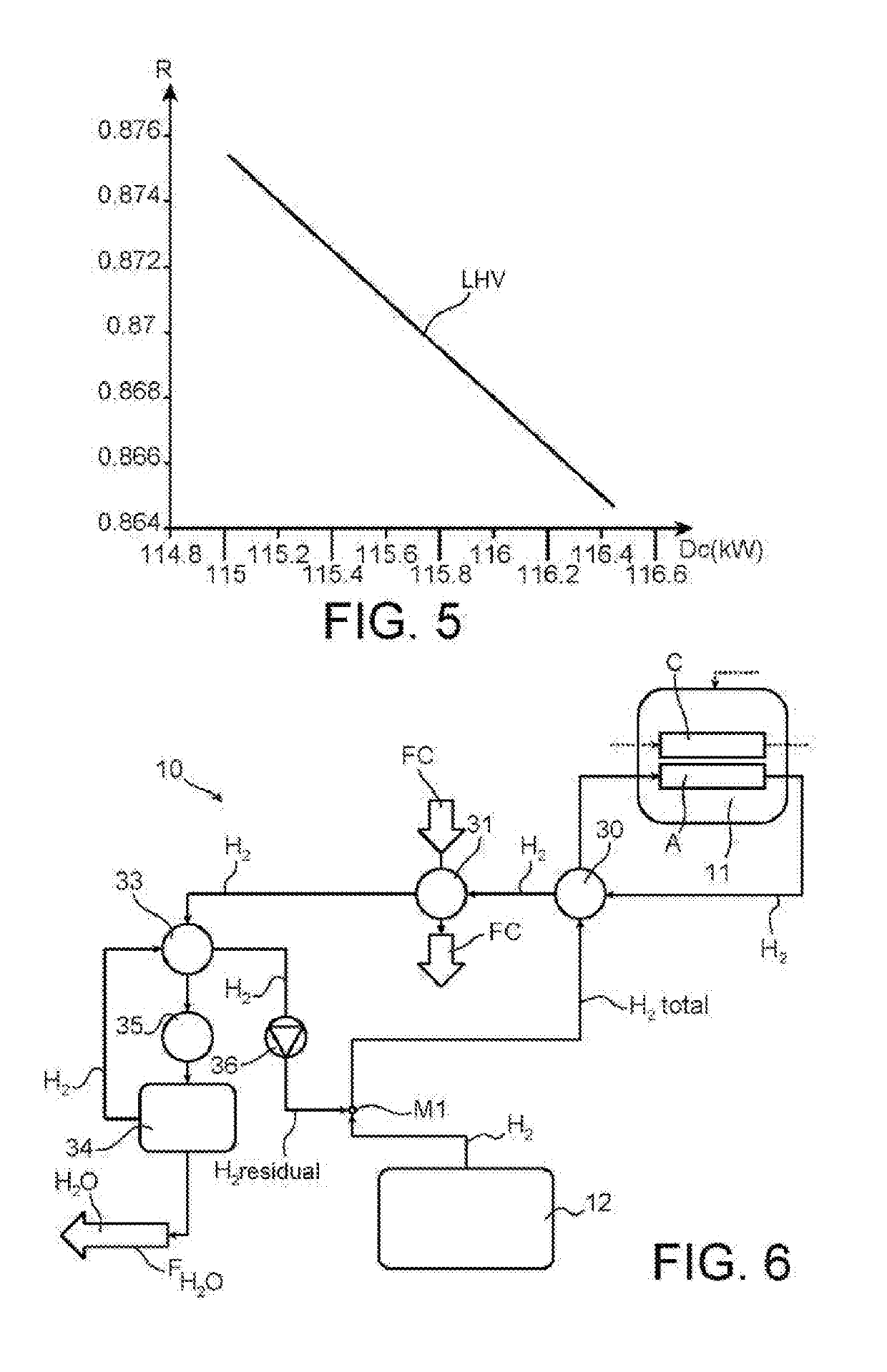

System for high-temperature reversible electrolysis of water comprising a hydride tank coupled with the electrolyser

ActiveUS20190245224A1Improve efficiencyImprove performanceCellsFuel cell heat exchangeElectricityHydrogen

A system for high-temperature reversible electrolysis of water, characterised in that it includes: a high-temperature reversible electrolyser, configured to operate in SOEC (solid oxide electrolyser cell) mode to produce hydrogen and store electricity, and / or in SOFC (solid oxide fuel cell) mode to withdraw hydrogen and produce electricity; a hydride tank, thermally coupled with the reversible electrolyser, the system being configured to allow the recovery of heat released by the hydride tank during hydrogen absorption in order to produce pressurised steam intended for entering the reversible electrolyser in SOEC mode, and to allow the recovery of heat released by the one or more outgoing streams from the reversible electrolyser in SOFC mode so as to allow the desorption of hydrogen from the hydride tank.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

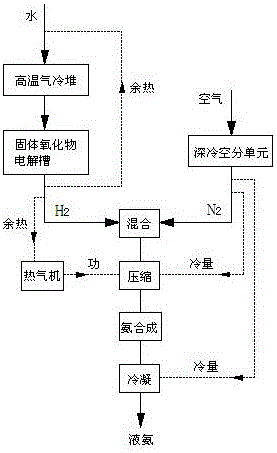

Water vapor electrolytic process based system for joint production of ammonia and nitric acid

ActiveCN106185984ARealize joint productionNot affected by market pricesElectrolysis componentsEnergy inputWater vaporEmission standard

The invention belongs to the technical field of chemical engineering and particularly relates to a water vapor electrolytic process based system for joint production of ammonia and nitric acid. The system comprises a nitrogen generation unit, an ammonia synthesis unit, a nitric acid generation unit, and a solid oxide electrolyzer. The ammonia synthesis unit is used to provide the material ammonia and process vapor for the nitric acid generation unit, no ammonia is externally purchased for the nitric acid generation unit, meanwhile, a heat recovery boiler is eliminated. The reaction heat of the ammonia synthesis unit and the nitric acid generation unit is used to produce high temperature vapor, the high temperature vapor is applied to the solid oxide electrolyzer, the solid oxide electrolyzer produces hydrogen and oxygen, the hydrogen and the oxygen are applied to the ammonia synthesis unit and the nitric acid generation unit, so that a mode of joint production of ammonia and nitric acid by taking air and water as raw materials is achieved, no materials or fuels are externally purchased, only electric energy is used, so that the system has the characteristics of high integration, low production cost, single and convenient energy consumption, reasonable recovery of energy, less environment pollution, conformity to the international emission standard and the like, and has an excellent economic benefit and an excellent application prospect.

Owner:陈志强

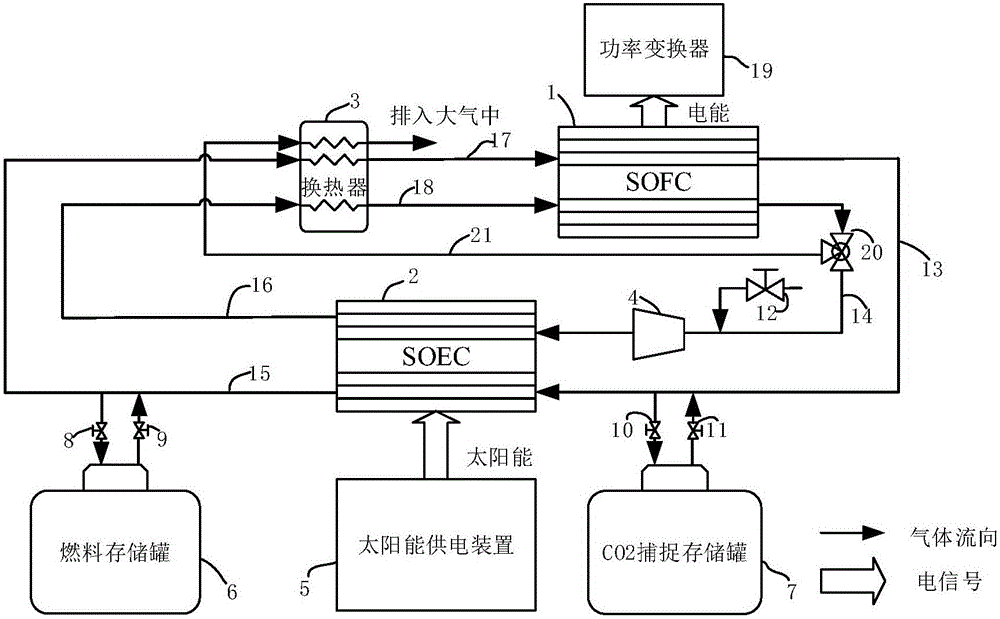

Solid oxide fuel cell and solid oxide electrolysis cell combined power generation system

The invention discloses a solid oxide fuel cell and solid oxide electrolysis cell combined power generation system, which comprises a solid oxide fuel cell stack unit, a solid oxide electrolysis cell stack unit, a solar power supply device, a power converter, a fuel storage tank and corresponding inlet and outlet channels and flow control valves, a CO2 capture storage tank and corresponding inlet and outlet channels and flow control valves, a heat exchanger unit, an air exhaust bypass control valve, an air inlet control valve and an air compressor. By the solid oxide electrolysis cell stack unit, CO2 and H2O can be converted into fuel gases CH4, H2 and the like by externally supplied electric energy (for example, solar energy and the like) in a high-pressure environment, so that fuel exhaust and air exhaust discharged from a solid oxide fuel cell are introduced into an electrolysis cell; reaction is carried out by the solar power supply device to generate a new fuel gas; and the new fuel gas is introduced into a fuel cell stack again for power generation.

Owner:HUAZHONG UNIV OF SCI & TECH

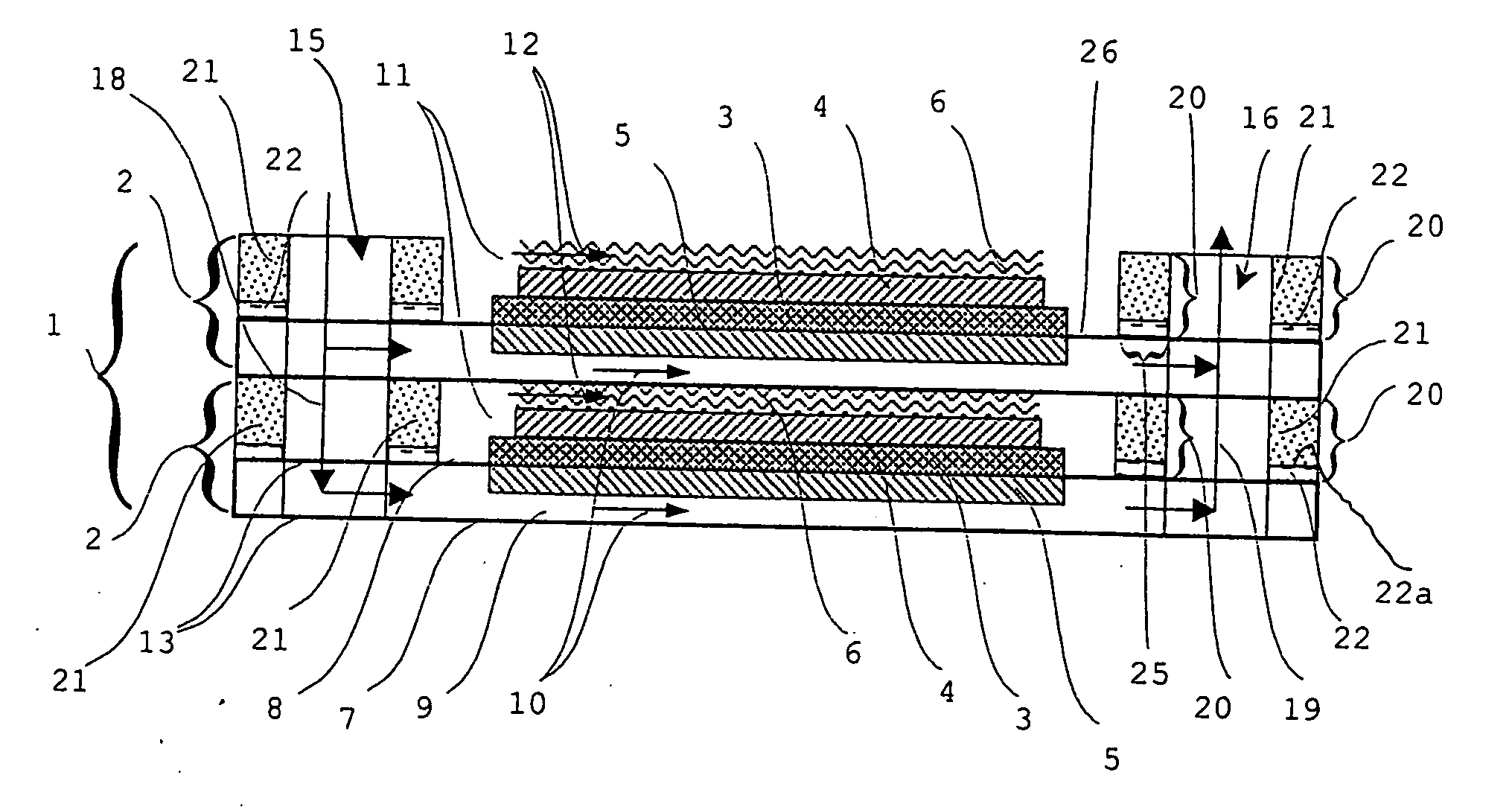

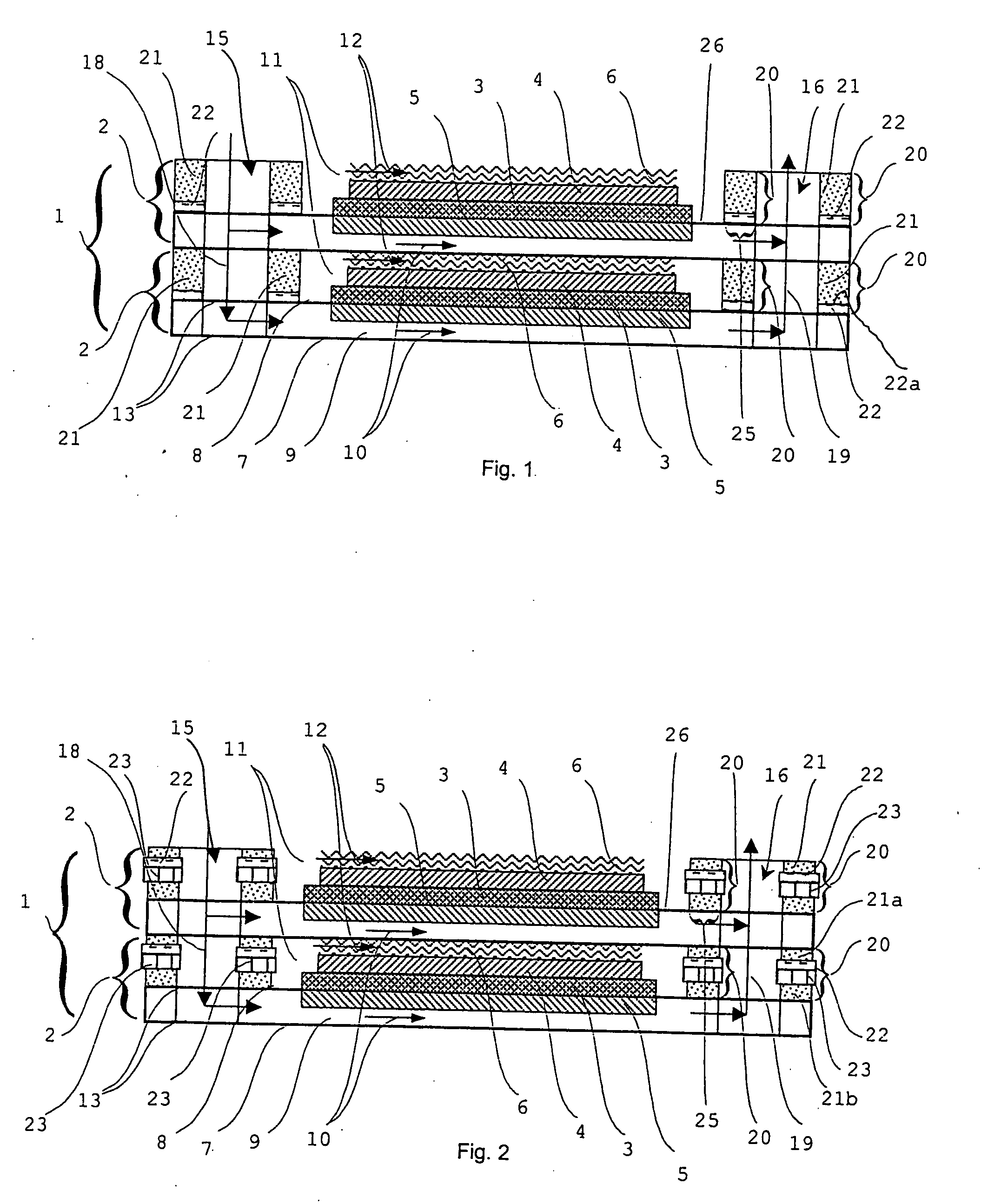

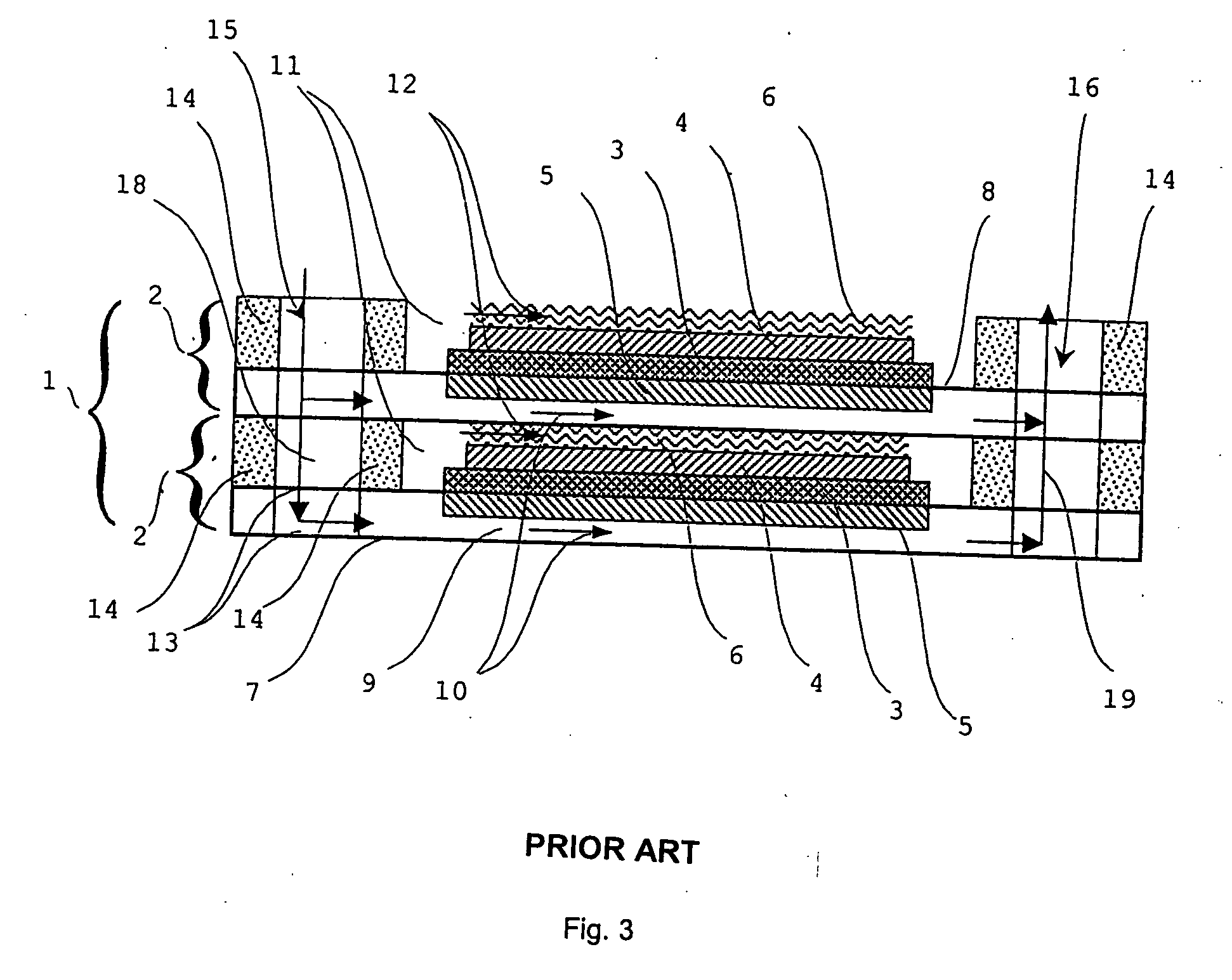

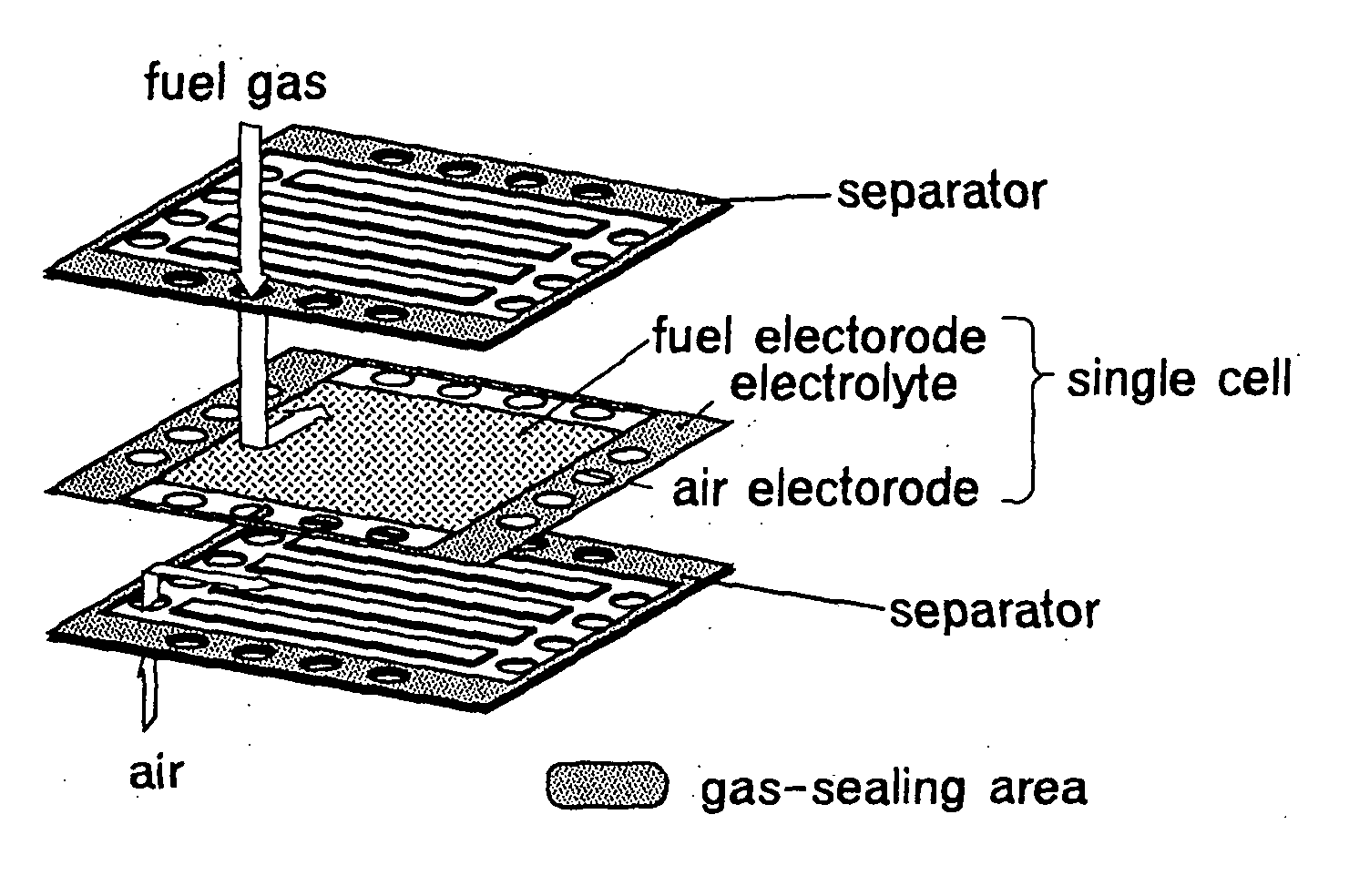

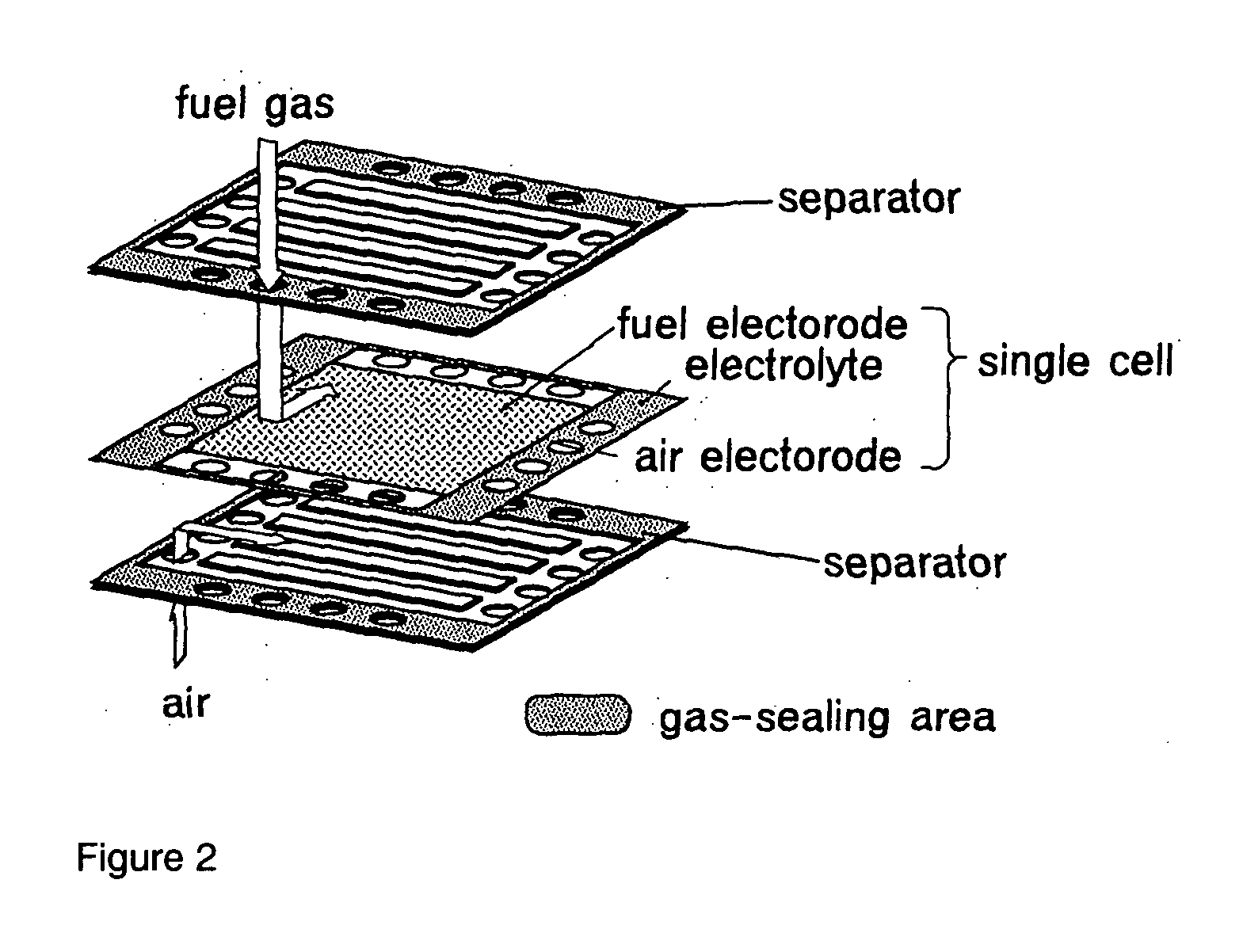

Seal construction for a fuel cell electrolyser and process for making a fuel cell with same

InactiveUS20050186463A1Facilitated and particularly more process-secure mountingSimple and cost-effectiveFuel cells groupingFinal product manufactureFuel cellsEngineering

A sealing structure in a fuel cell and / or an electrolyzer (particularly a solid-oxide fuel cell and / or a solid-oxide electrolyzer) is arranged between neighboring separator plates of a cell stack. The sealing structure is constructed in at least two layers, including at least one insulating layer and at least one sealing layer.

Owner:BAYERISCHE MOTOREN WERKE AG +1

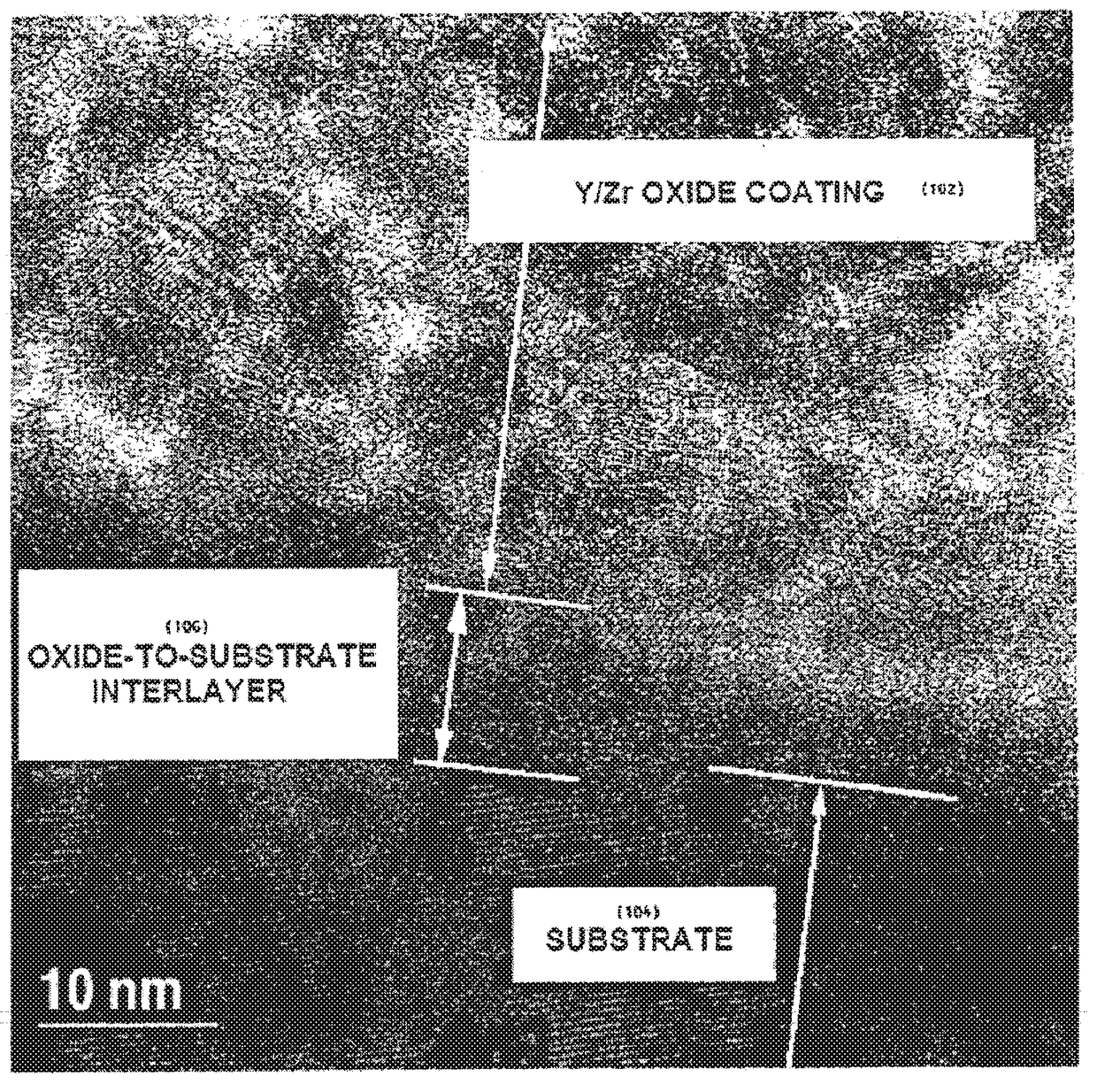

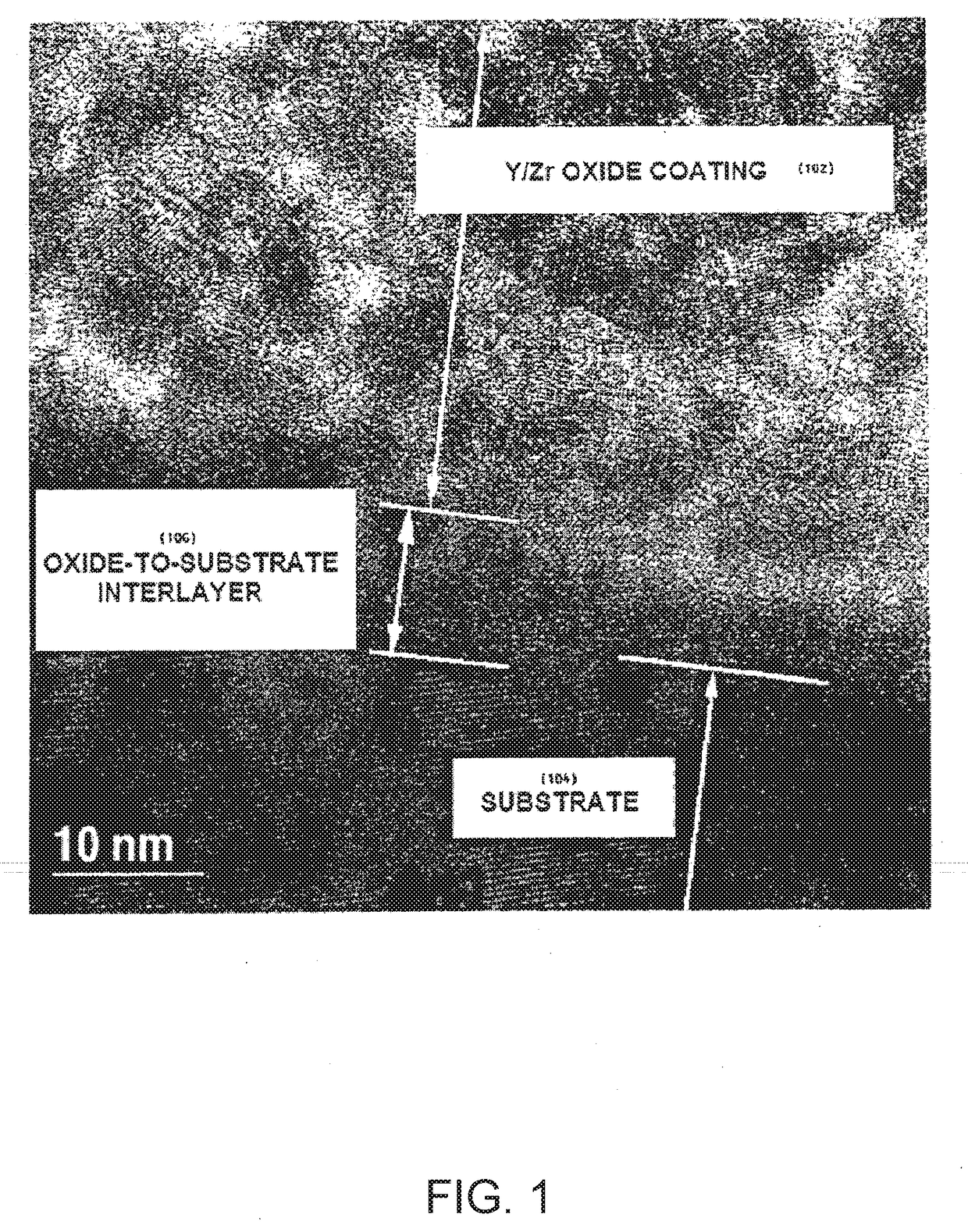

Solid Oxide Fuel Cells, Electrolyzers, and Sensors, and Methods of Making and Using the Same

InactiveUS20170146481A1Tolerate high temperatureHigh operating temperatureCellsFinal product manufactureElectrical batteryEngineering

The present invention provides solid oxide fuel cells, solid oxide electrolyzer cells, solid oxide sensors, components of any of the foregoing, and methods of making and using the same. In some embodiments, a solid oxide fuel cell comprises an air electrode (or cathode), a fuel electrode (or anode), an electrolyte interposed between the air electrode and the fuel electrode, and at least one electrode-electrolyte transition layer. Other embodiments provide novel methods of producing nano-scale films and / or surface modifications comprising one or more metal oxides to form ultra-thin (yet fully-dense) electrolyte layers and electrode coatings. Such layers and coatings may provide greater ionic conductivity and increased operating efficiency, which may lead to lower manufacturing costs, less-expensive materials, lower operating temperatures, smaller-sized fuel cells, electrolyzer cells, and sensors, and a greater number of applications.

Owner:FCET

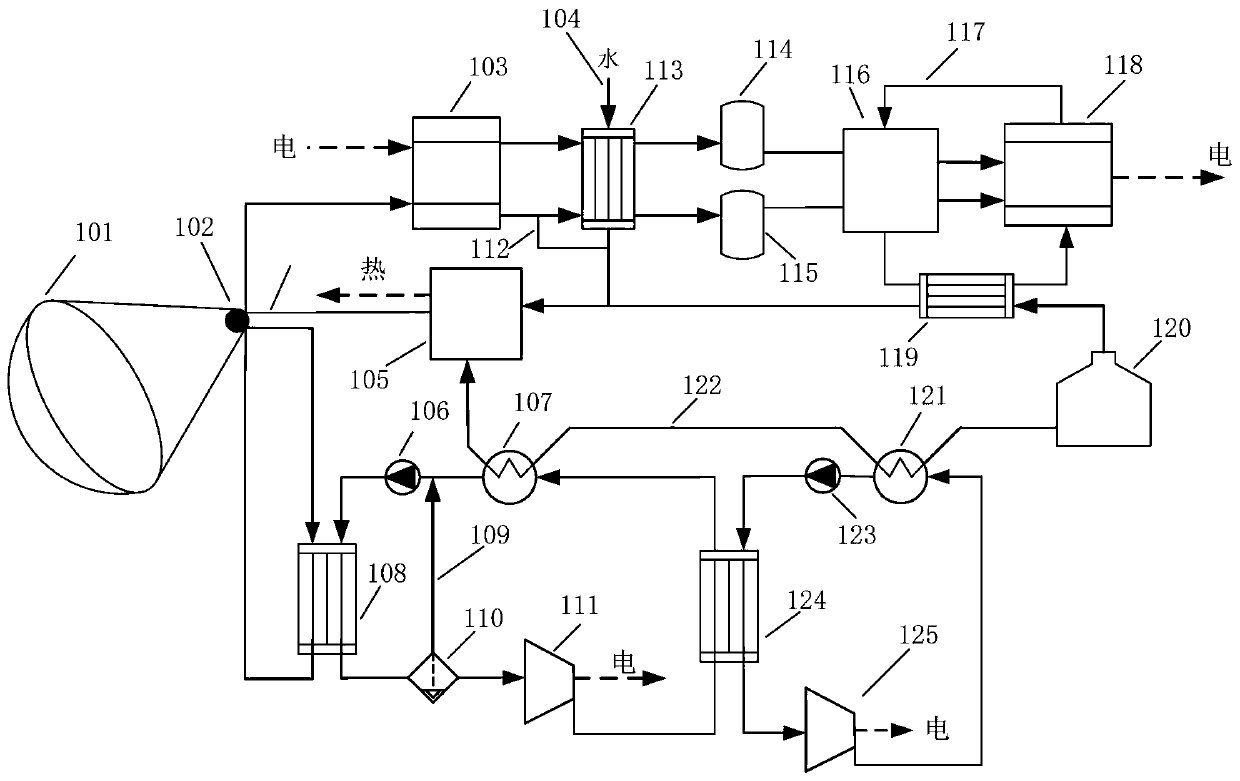

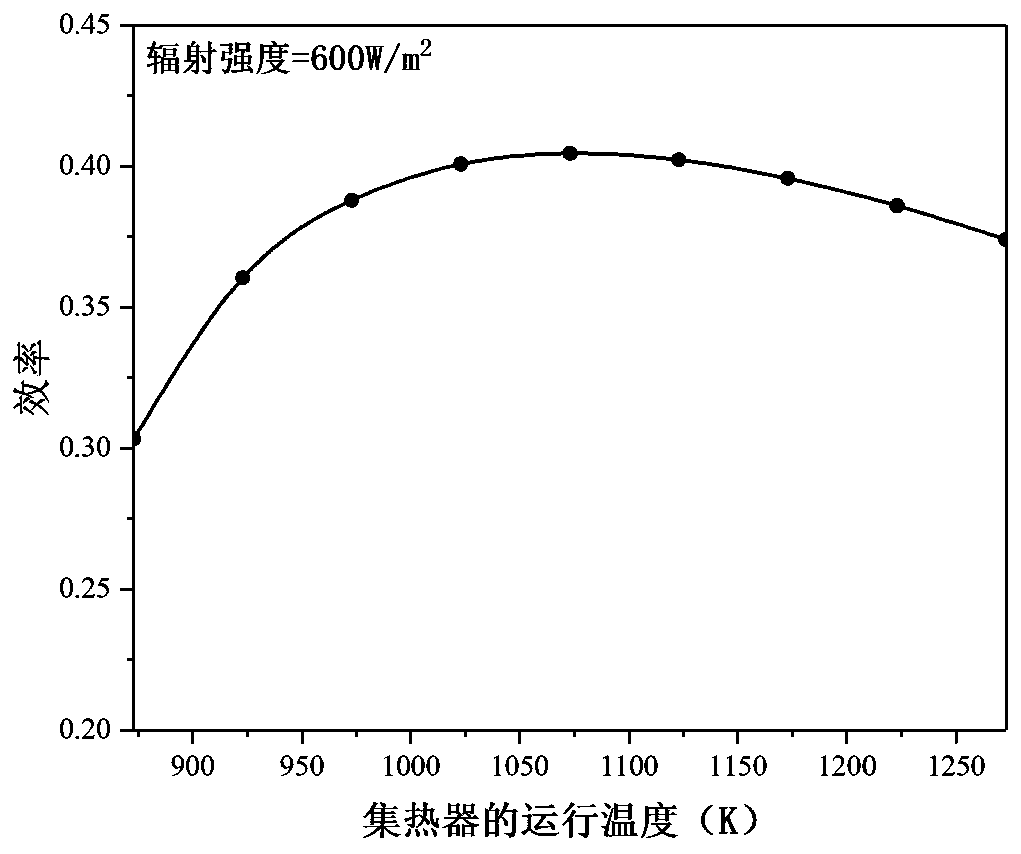

Solar supercritical carbon dioxide cycle power generation and steam electrolysis hydrogen production coupled system

ActiveCN107100808AReduce power generation costsReduce the cost of hydrogen productionSolar heating energyElectrolysis componentsHigh concentrationThermal energy

The invention discloses a solar supercritical carbon dioxide cycle power generation and steam electrolysis hydrogen production coupled system comprising a compressor, a heat regenerator, a preheater, a high-concentration solar energy receiver, a steam superheater, a high-pressure carbon dioxide turbine, a reheater, a low-pressure carbon dioxide turbine, a generator, a cooler, a steam generator and a solid oxide electrolytic bath. The solar thermal power generation system adopts a supercritical carbon dioxide cycle and provides a high-temperature heat source and low-cost electricity for steam electrolysis hydrogen. Waste heat of steam electrolysis hydrogen production is recycled through the reheater and the preheater, so that the cycle thermal efficiency of the solar thermal power generation system is improved, and the grade of the thermal energy output by the solar thermal power generation system is improved. In addition, the gas flow entering the regenerator is reduced in a flow distributing manner, and the problem that the regenerator generates a heat exchange pinch point because the specific heat capacities of the fluid on the high-pressure side and the fluid on the low-pressure side are different is solved. The solar supercritical carbon dioxide cycle power generation and steam electrolysis hydrogen production coupled system has the advantages of being high in cycle thermal efficiency, high in energy utilization rate, low in hydrogen production cost and low in power generation cost.

Owner:JIMEI UNIV

Preparation method of ordered solid oxide membrane electrode

ActiveCN103474675ALower polarization resistanceReach controllableCell electrodesVoid ratioReaction rate

The invention belongs to the technical field of an electrode preparation method, and in particular relates to a preparation method of an ordered solid oxide membrane electrode. In the method, a supporter array solid oxide bar of a catalyst can be prepared by a template method, and can be roasted and integrally fused with a compact solid oxide electrolyte membrane. The highly ordered array solid oxide bar defines the electrode void ratio and the catalyst surface size in the ordered solid oxide membrane electrode, so as to realize the controllable preparation of the ordered electrode. An anode catalyst and a cathode catalyst are prepared respectively on the array solid oxide bar, the catalysts are combined on the surface of the solid oxide bar in a nano- or micro-particle state to form a catalysis layer, the catalyst particles are communicated with each other and are connected to a collector, and the catalyst particles are dispersed highly and have higher specific surface area and catalysis activity, therefore, the three-phase reaction interface of an SOFC (solid oxide fuel cell) and an SOEC (solid oxide electrolysis cells) is increased greatly, the polarization resistance of the electrode is reduced, and consequently, the reaction rate of the fuel and the raw material gas reducing transforming rate are improved.

Owner:TSINGHUA UNIV

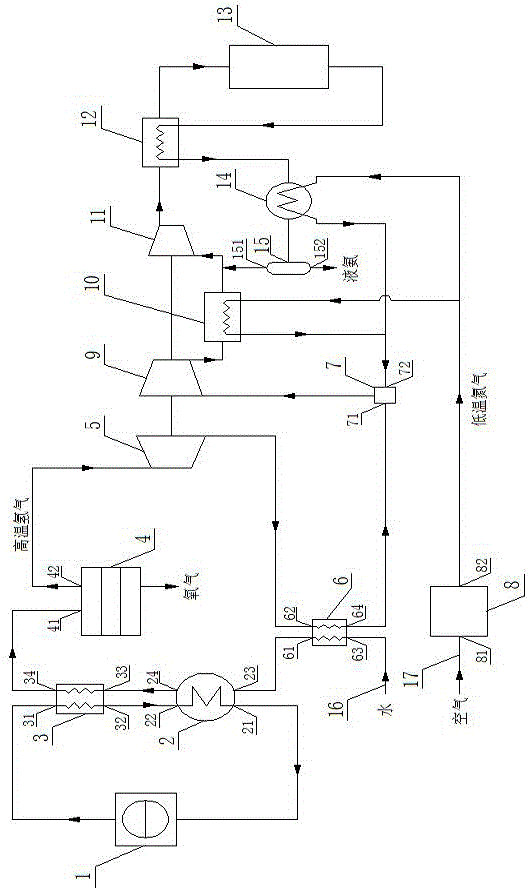

Ammonia carbon-free synthesis system by means of nuclear energy and method thereof

InactiveCN105836759AGet rid of dependenceLower fuel costsEnergy inputAmmonia preparation/separationIntercoolerSuperheater

The invention discloses an ammonia carbon-free synthesis system by means of nuclear energy and a method thereof .The system comprises a high-temperature gas cooled reactor, a steam generator, an overheater, a solid oxide electrolytic cell, a Stirling hot air engine, a heater, a mixer, a deep cooling air separation unit, a low-pressure compressor, an intercooler, a high-pressure compressor, a preheater, an ammonia synthesis tower, an ammonia condenser, an ammonia separator, a water supply pipeline and an air pipeline .The nuclear energy serves as fuel, air and water serve as raw materials, and the ammonia synthesis system which does not depend on fossil energy or generate pollutants is achieved jointly through the high-temperature gas cooled reactor in cooperation with a steam electrolysis method and a deep cooling air separation method .Waste heat of high-temperature hydrogen generated through the steam electrolysis method is used for driving the Stirling hot air engine to drive the compressors to act, low-temperature nitrogen of the deep cooling air separation unit serves as a cooling medium of the ammonia condenser and the intercooler, the advantages of comprehensively utilizing energy, saving water, simplifying the technological process and the like are achieved, and therefore high economic and environment-friendly value and good application prospects are achieved .

Owner:陈志强

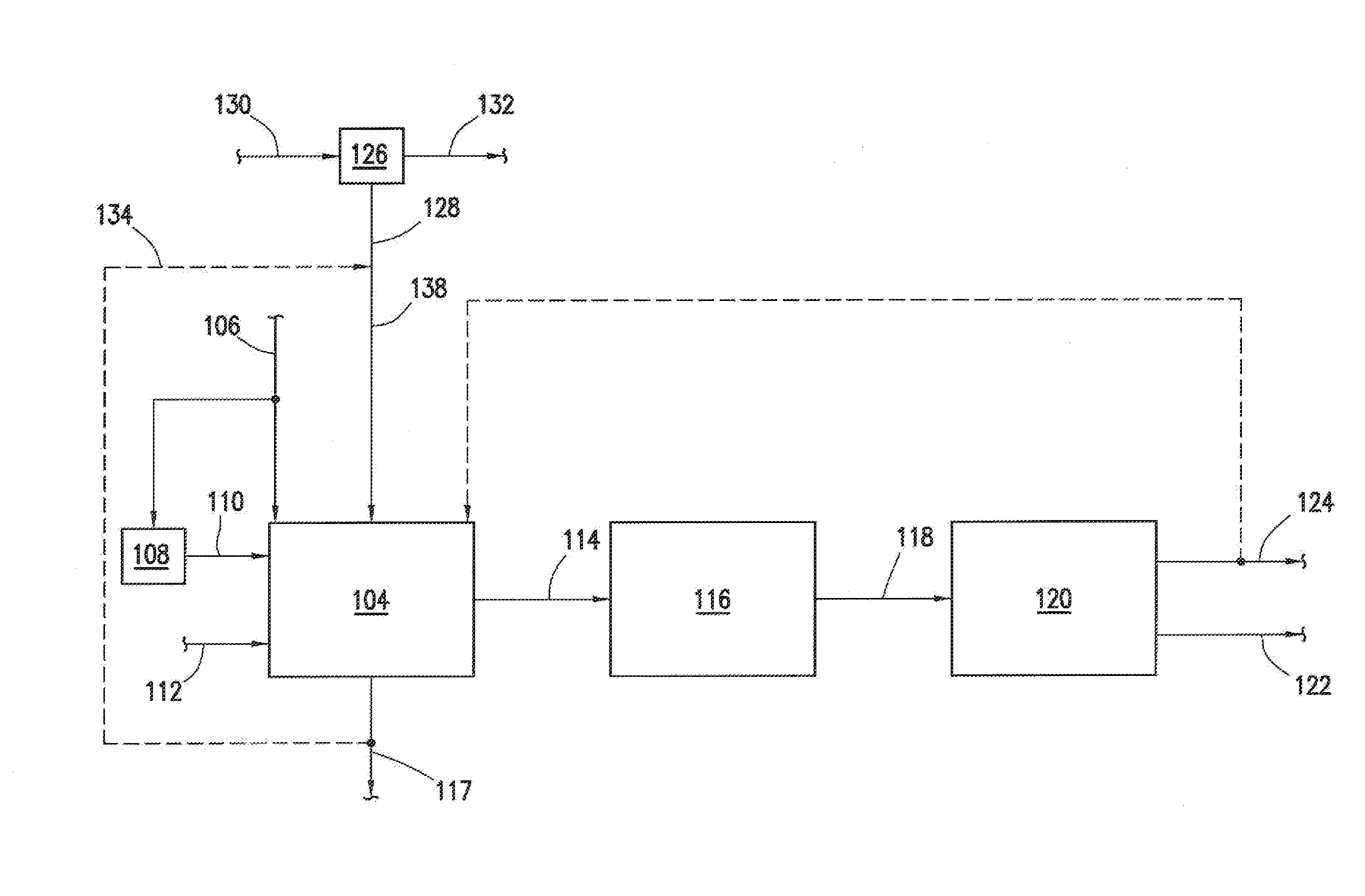

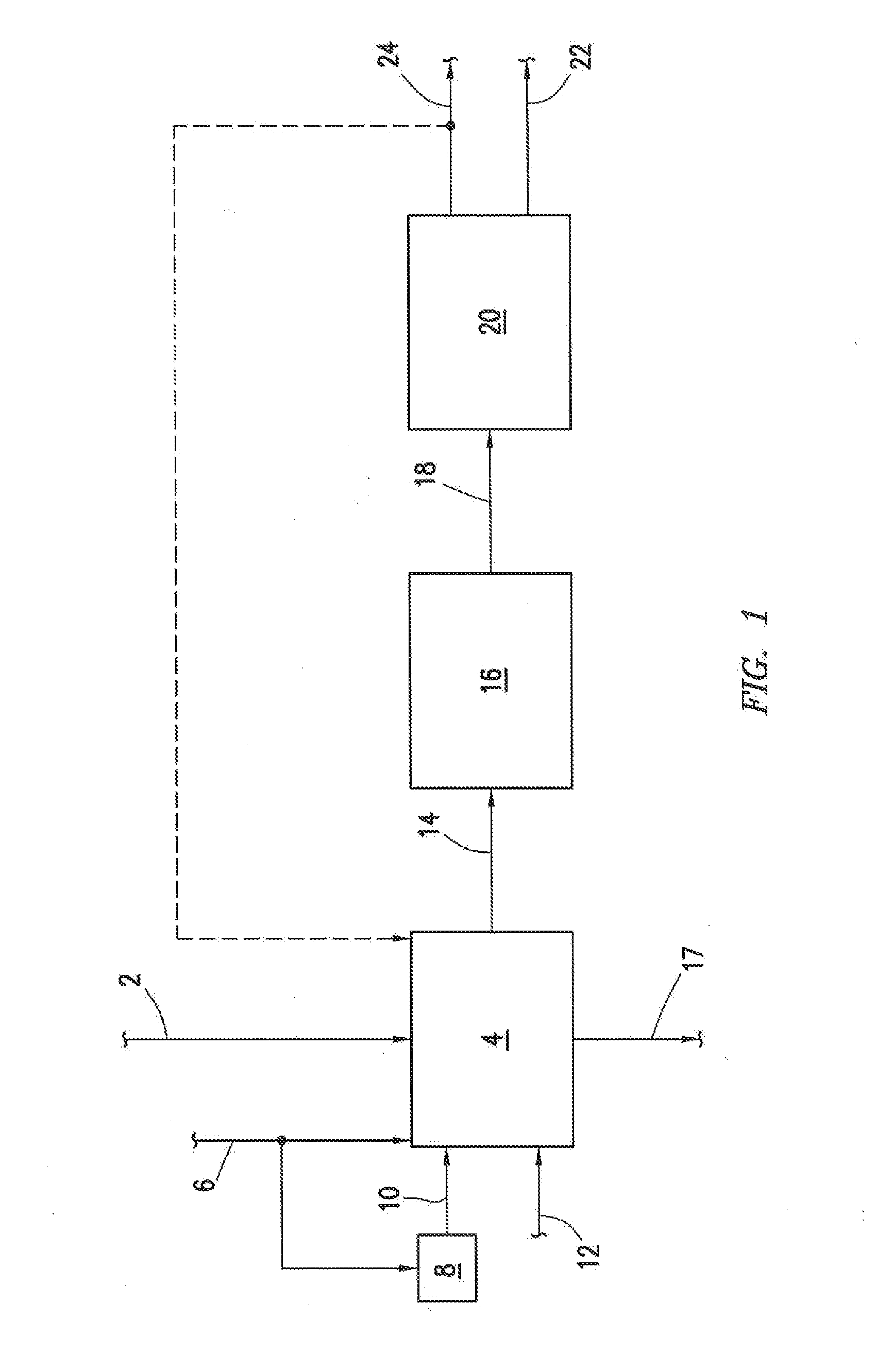

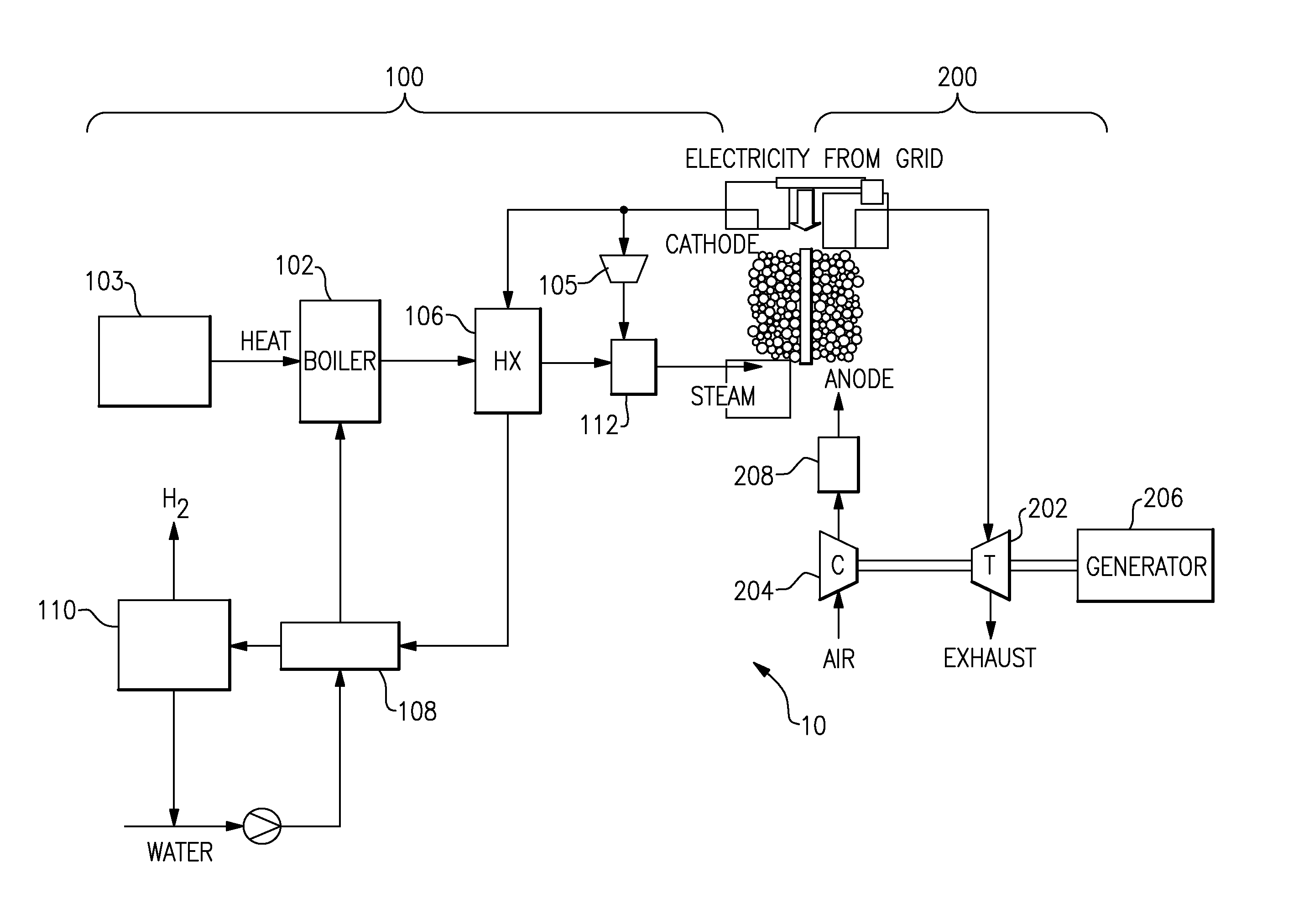

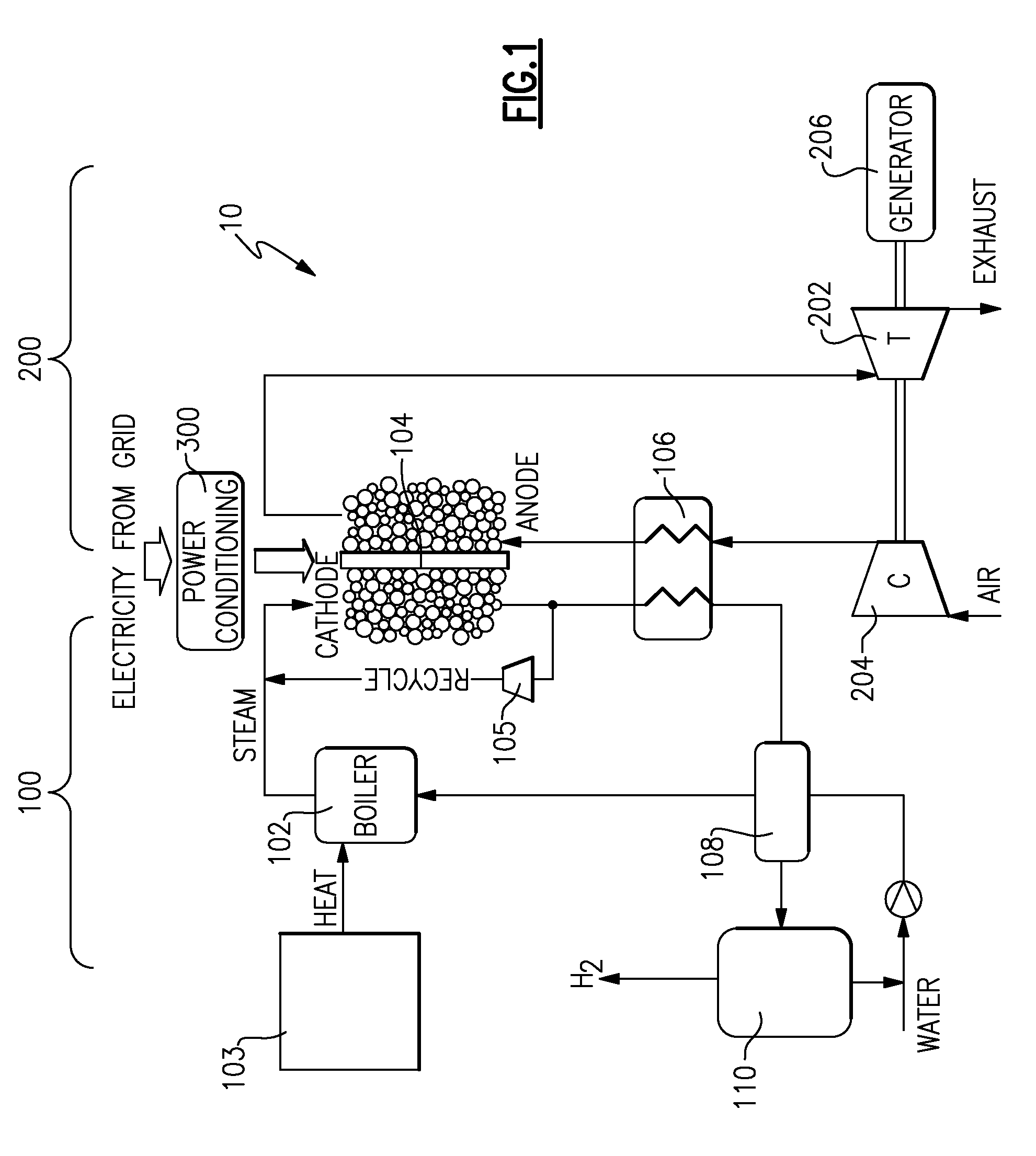

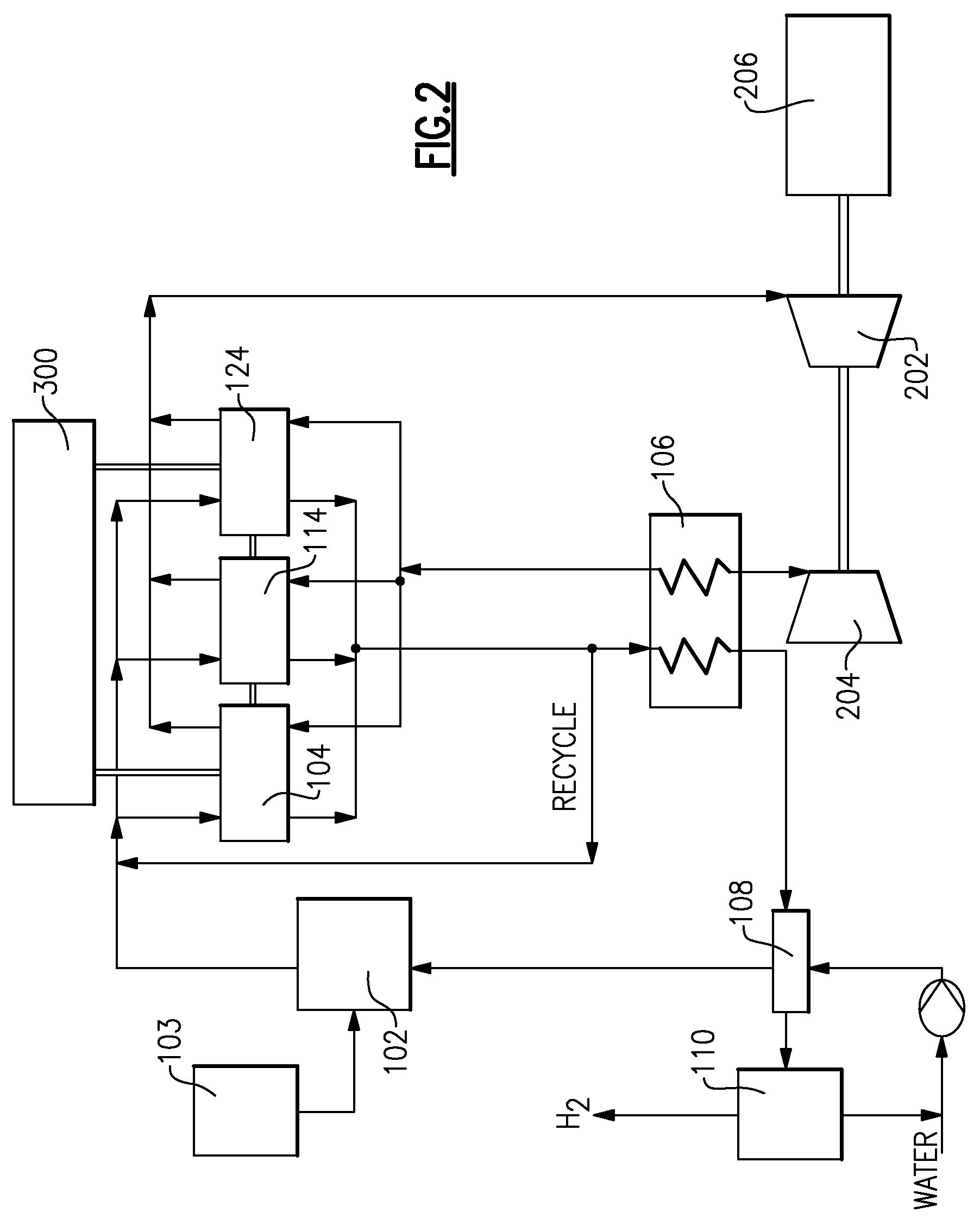

System and method for the production of hydrogen

Disclosed herein are a system and a method for the production of hydrogen. The system advantageously combines an independent high temperature heat source with a solid oxide electrolyzer cell and a heat exchanger located between the cathode inlet and the cathode outlet. The heat exchanger is used to extract heat from the molecular components such as hydrogen derived from the electrolysis. A portion of the hydrogen generated in the solid oxide electrolyzer cell is recombined with steam and recycled to the solid oxide electrolyzer cell. The oxygen generated on the anode side is swept with compressed air and used to drive a gas turbine that is in operative communication with a generator. Electricity generated by the generator is used to drive the electrolysis in the solid oxide electrolyzer cell.

Owner:GENERAL ELECTRIC CO

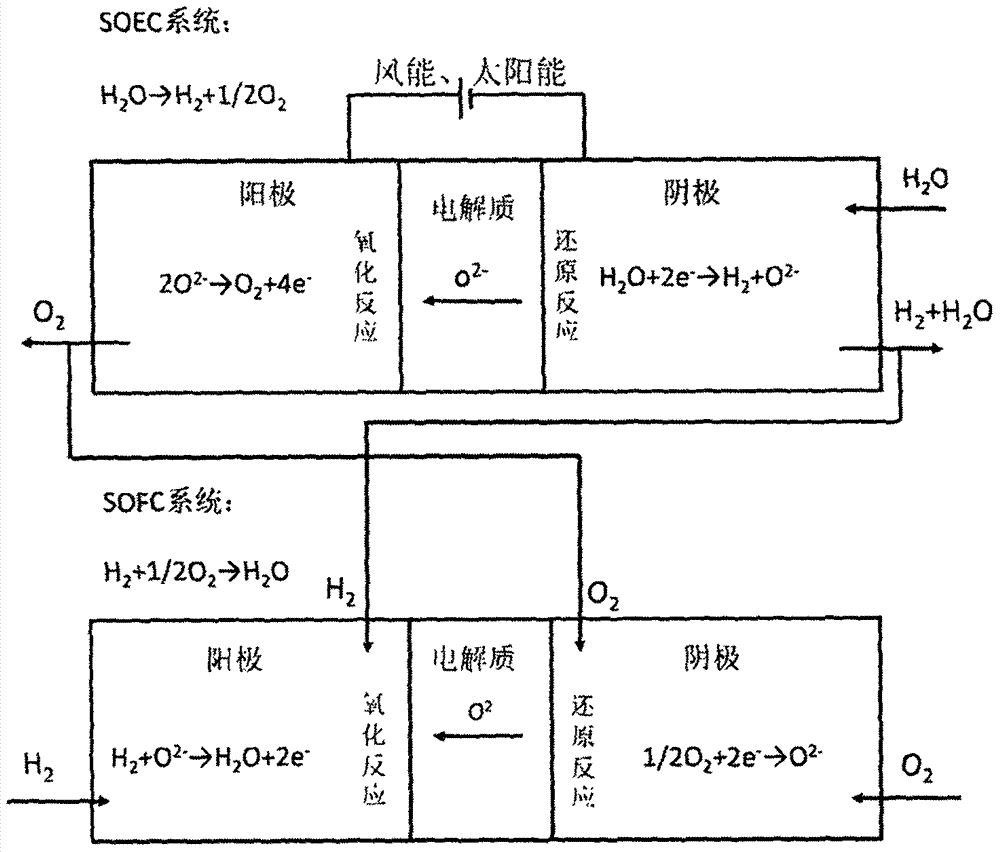

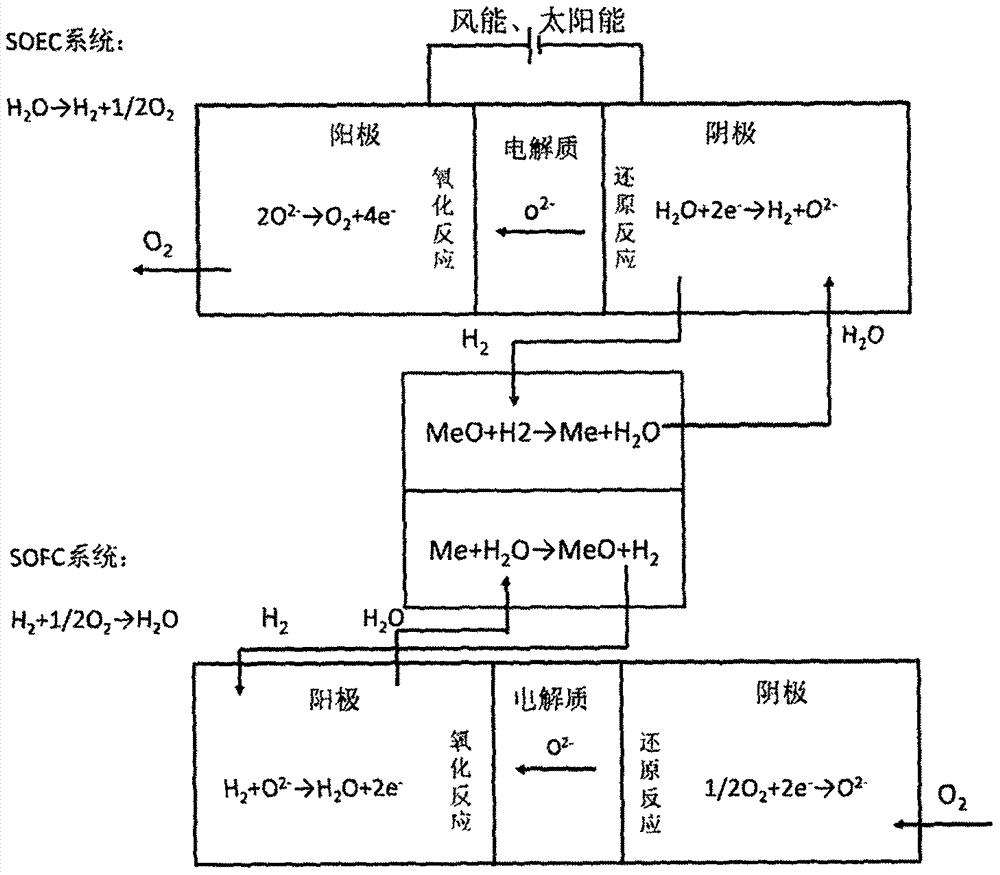

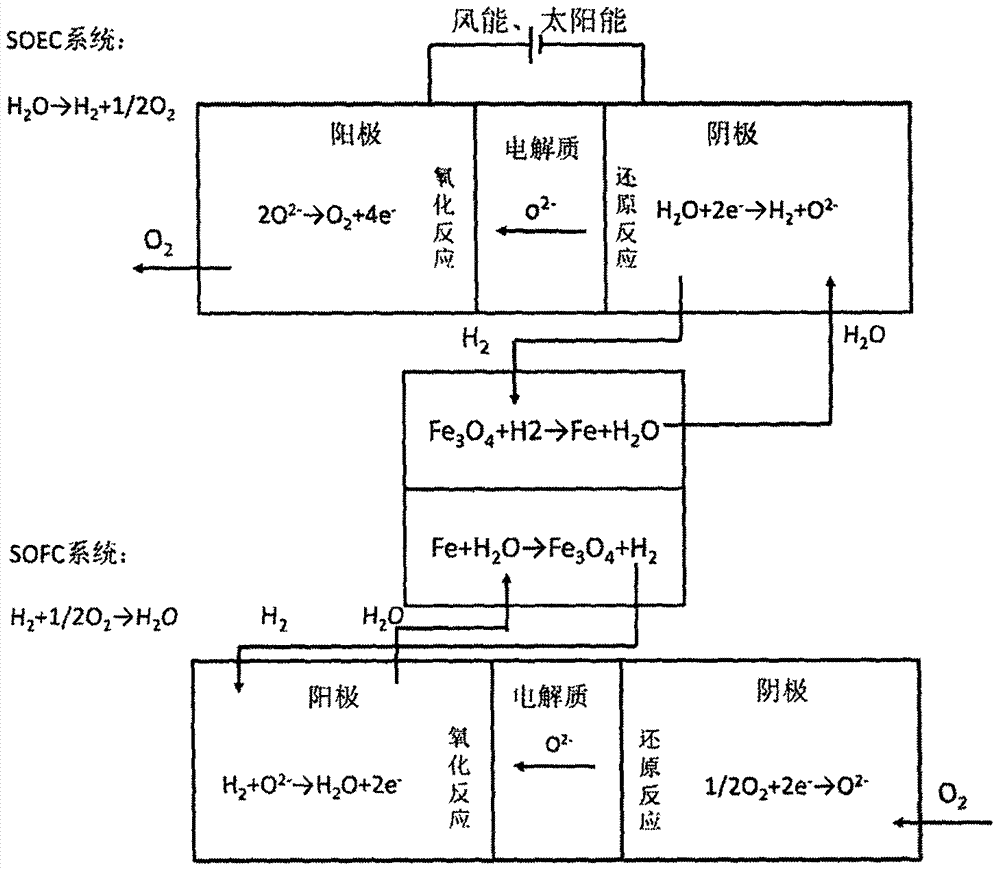

Energy storage and conversion system based on solid oxide cells

PendingCN106876752AAvoid damage to the batteryFinal product manufactureWater management in fuel cellsEngineeringProduced water

A solid oxide cell (SOC) system composed of a solid oxide fuel cell (SOFC) and a solid oxide electrolysis cell (SOEC) produces water while generating power in an SOFC working mode, water reacts with a nanocrystalline metal on a carrier to produce hydrogen, and the hydrogen is supplied to the SOFC for working; and in an SOEC working mode, the water is electrolyzed by the electric energy from a solar wind energy cell to produce the hydrogen, the hydrogen reacts with the nanocrystalline metal on the carrier to produce water, and the water is supplied to the SOEC for electrolysis. As the metal and a metallic oxide are used as intermediate conversion material to recycle the fuel, so that the fuel does not need to be frequently injected, the purpose of continuous seal is achieved, and meanwhile the phenomenon that the fuel is loaded for multiple times to cause a lot of impurities to lead to damage to the cells is avoided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

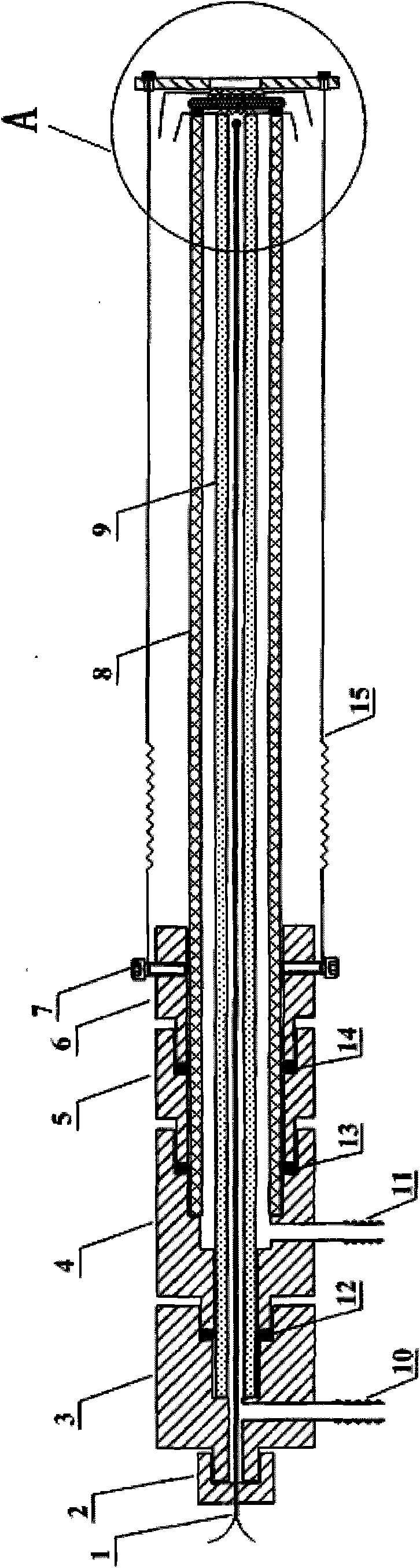

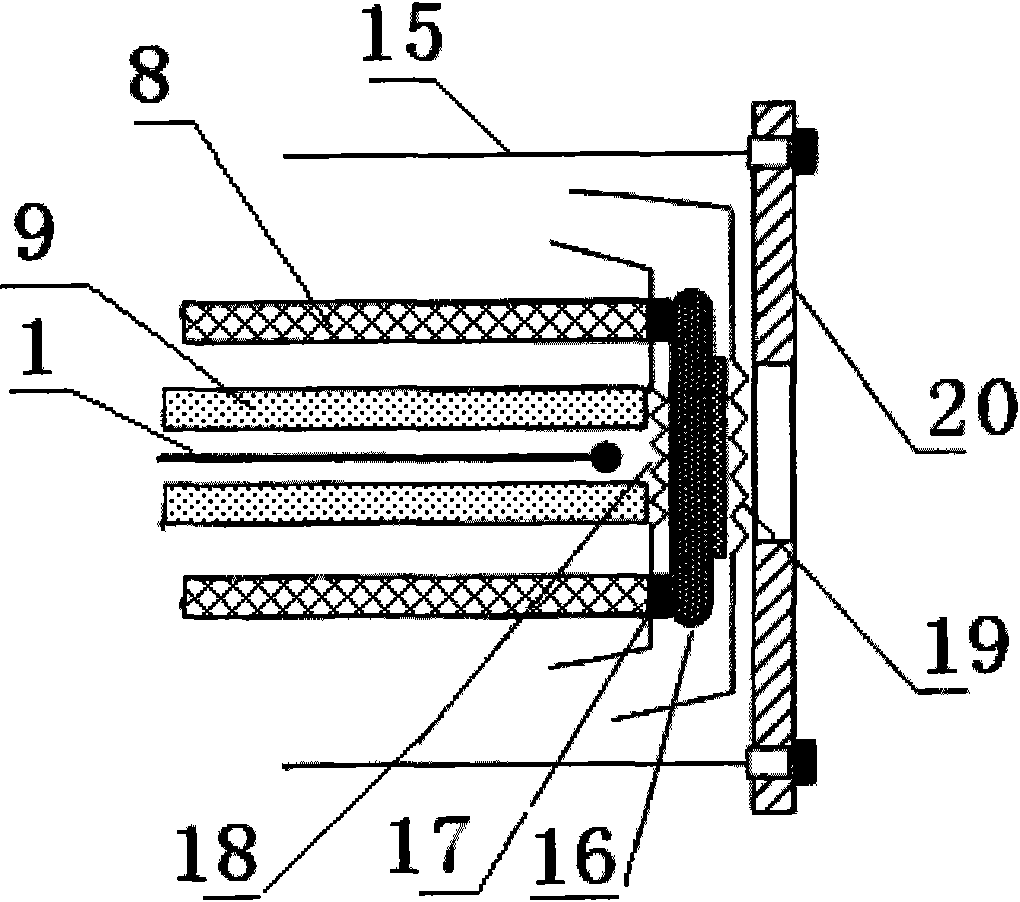

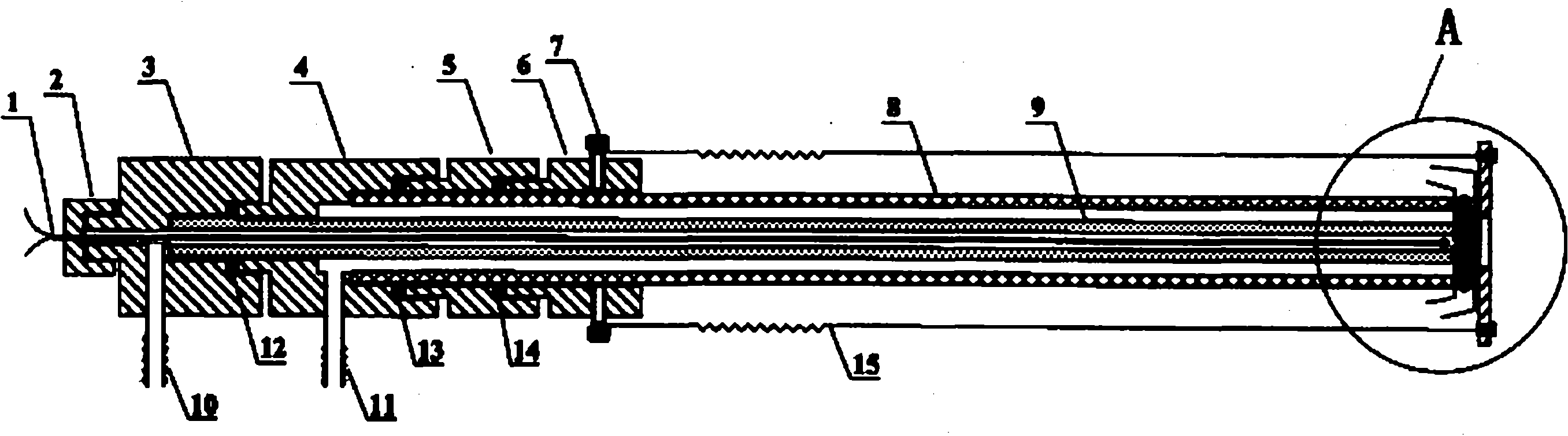

Solid oxide electrolytic cell testing bracket

ActiveCN101980009AImprove sealingSolve the sealing problemMaterial electrochemical variablesWorking temperatureSealant

The invention belongs to the field of high-temperature steam electrolysis hydrogen production, and particularly relates to a solid oxide electrolytic cell testing bracket. A design mode of combining a ceramic material and a stainless steel material is adopted in the testing bracket, a solid oxide electrolytic cell and a hydrogen electrode air chamber ceramic tube are sealed by using glass or glass-ceramic sealant in a high-temperature area, and a hydrogen electrode air chamber ceramic tube and a stainless steel sealing cutting sleeve are sealed by using silicon rubber sealant in a low-temperature area; the solid oxide electrolytic cell is arranged on the end face of the hydrogen electrode air chamber ceramic tube and fixed by using a pull lead to ensure that the electrode of the electrolytic cell is tightly contacted with a collector net; a hydrogen electrode collector net lead passes out of a glass sealing ring to avoid hydrogen brittleness; and a thermocouple is arranged in an air inlet tube to monitor the working temperature of the electrolytic cell. The testing bracket solves the problems of sealing of the electrolytic cell in the high-temperature area and transition sealing from the electrolytic cell to an air path system, can run stably for a long term under a high-temperature and high-humidity environment, and has the advantages of simple assembly, convenience for operation, good sealing performance and the like.

Owner:TSINGHUA UNIV

Efficient reversible electrodes for solid oxide electrolyzer cells

InactiveUS8354011B2Improve efficiencyReduce coarseningCellsActive material electrodesOxygen ionsElectron

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0<x<1, 0≦y≦0.5, and 0.8≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:CERAMTEC

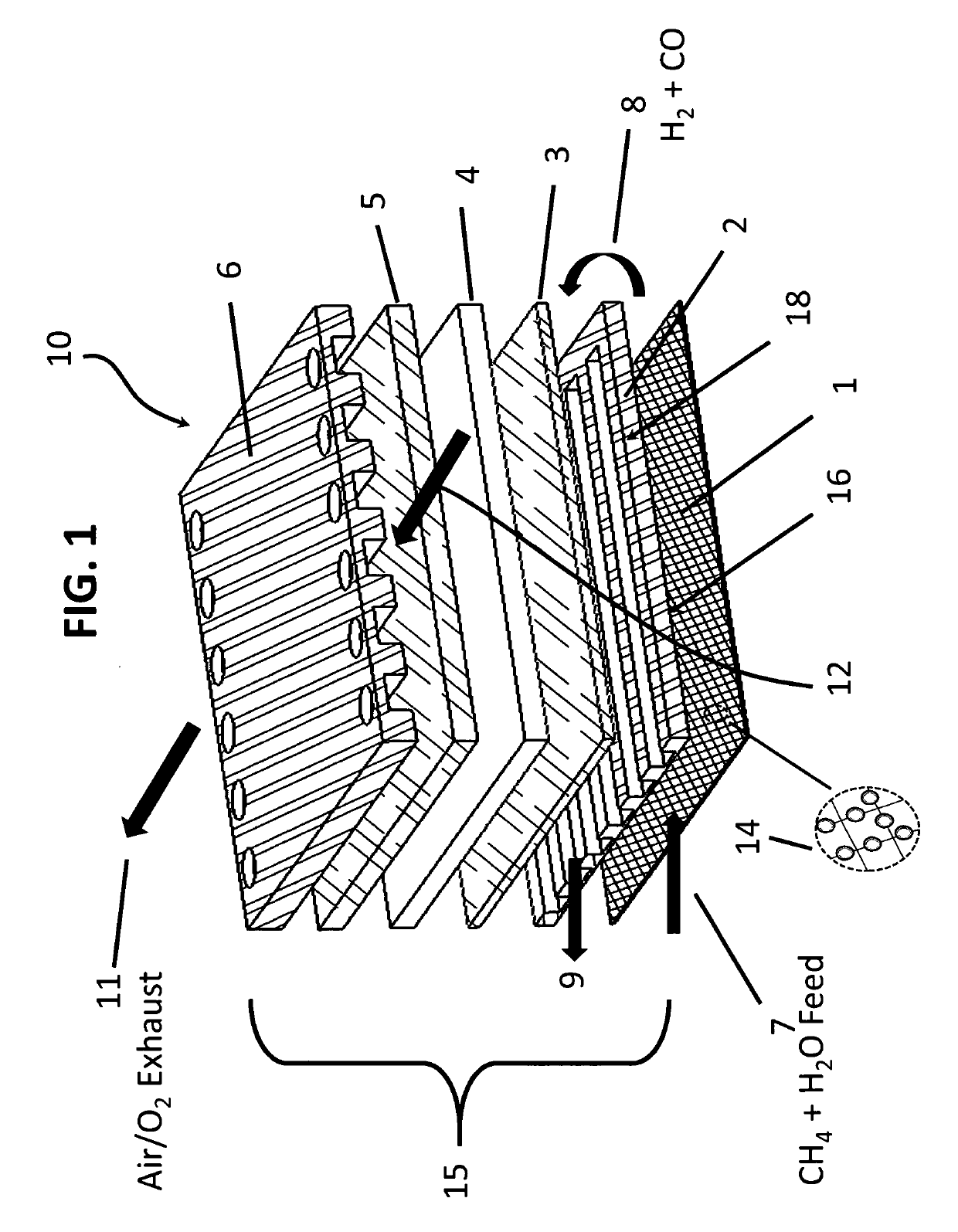

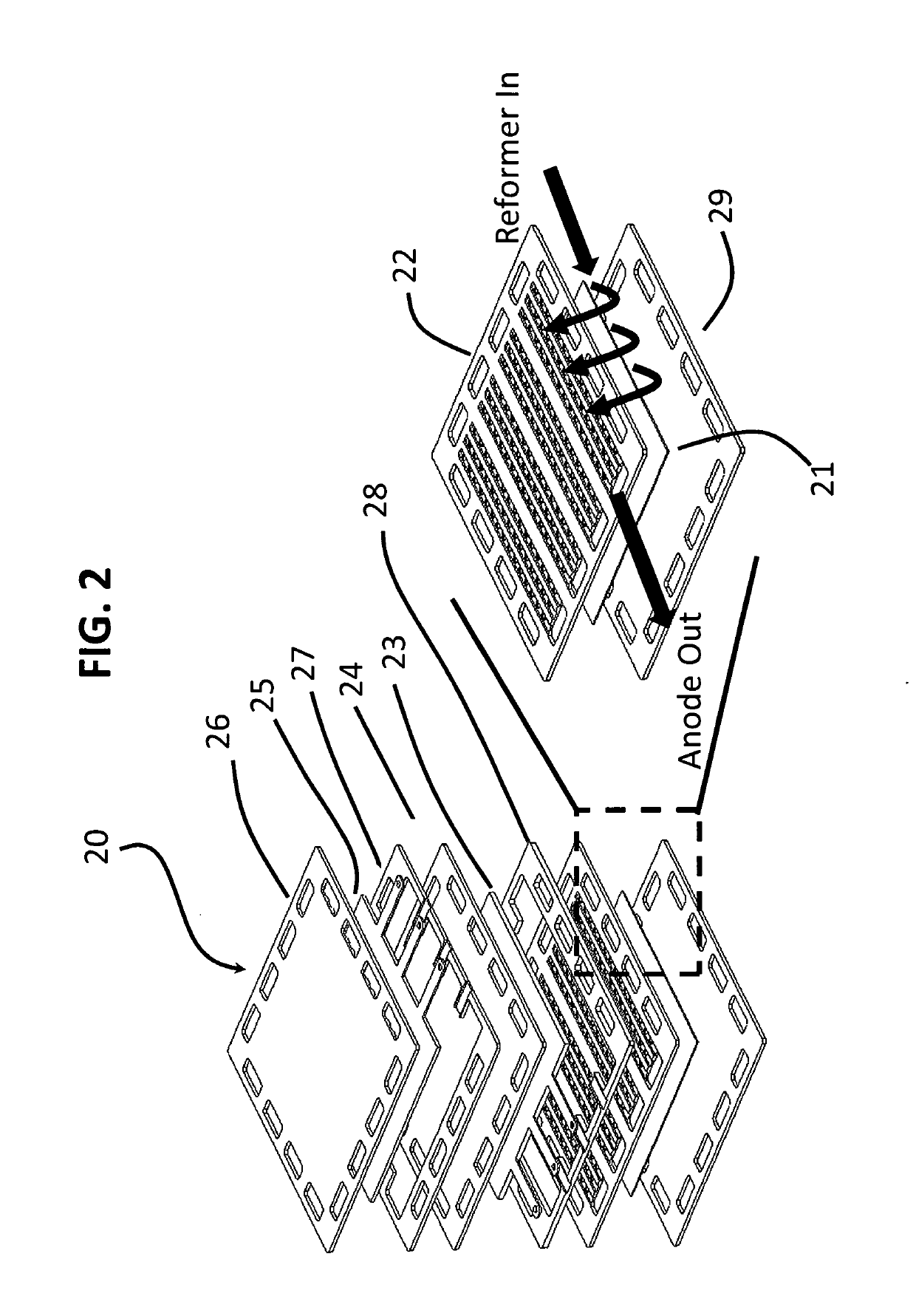

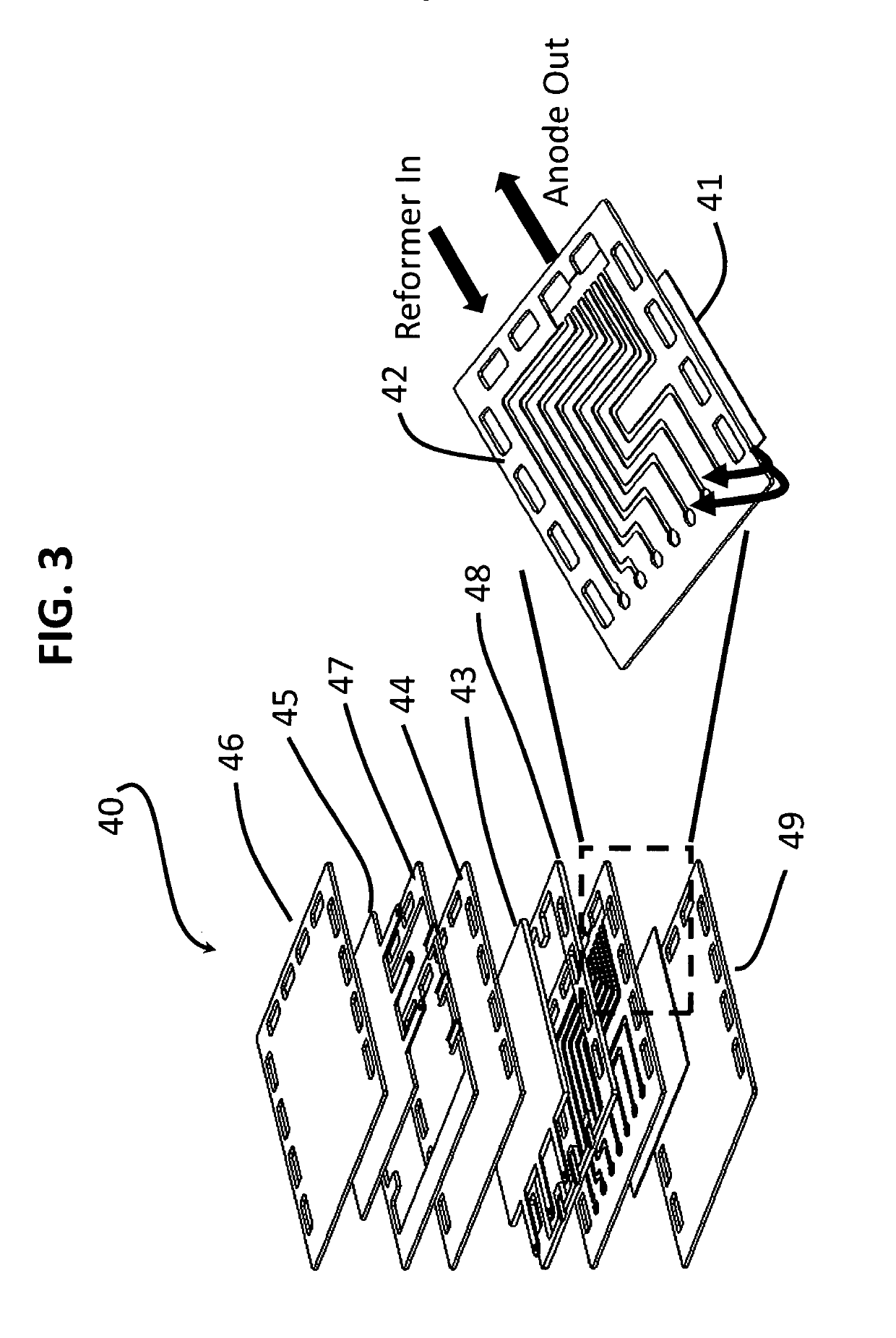

Solid oxide fuel cell with internal reformer

ActiveUS20190226101A1Reduce weightReducing dimensionCellsFuel cell heat exchangeSteam reformingPartial oxidation

An individual solid oxide cell (SOC) constructed of a sandwich configuration including in the following order: an oxygen electrode, a solid oxide electrolyte, a fuel electrode, a fuel manifold, and at least one layer of mesh. In one embodiment, the mesh supports a reforming catalyst resulting in a solid oxide fuel cell (SOFC) having a reformer embedded therein. The reformer-modified SOFC functions internally to steam reform or partially oxidize a gaseous hydrocarbon, e.g. methane, to a gaseous reformate of hydrogen and carbon monoxide, which is converted in the SOC to water, carbon dioxide, or a mixture thereof, and an electrical current. In another embodiment, an electrical insulator is disposed between the fuel manifold and the mesh resulting in a solid oxide electrolysis cell (SOEC), which functions to electrolyze water and / or carbon dioxide.

Owner:PRECISION COMBUSTION

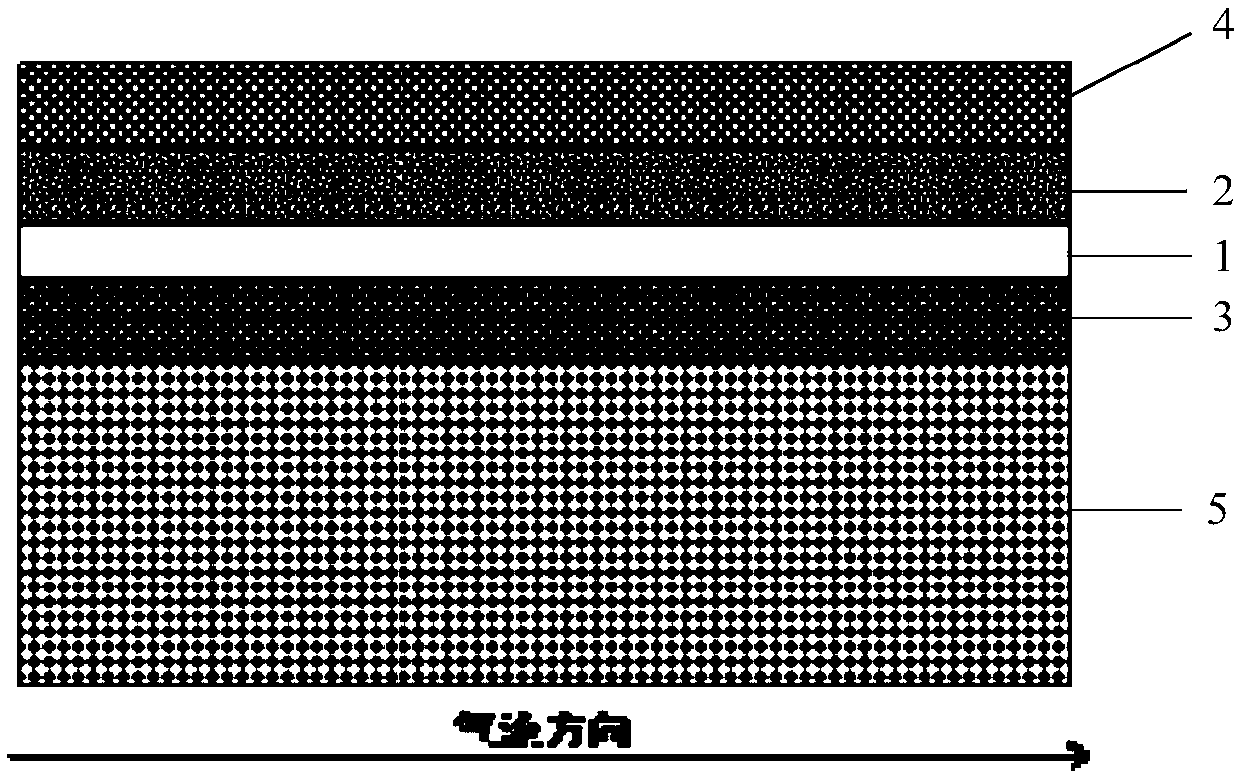

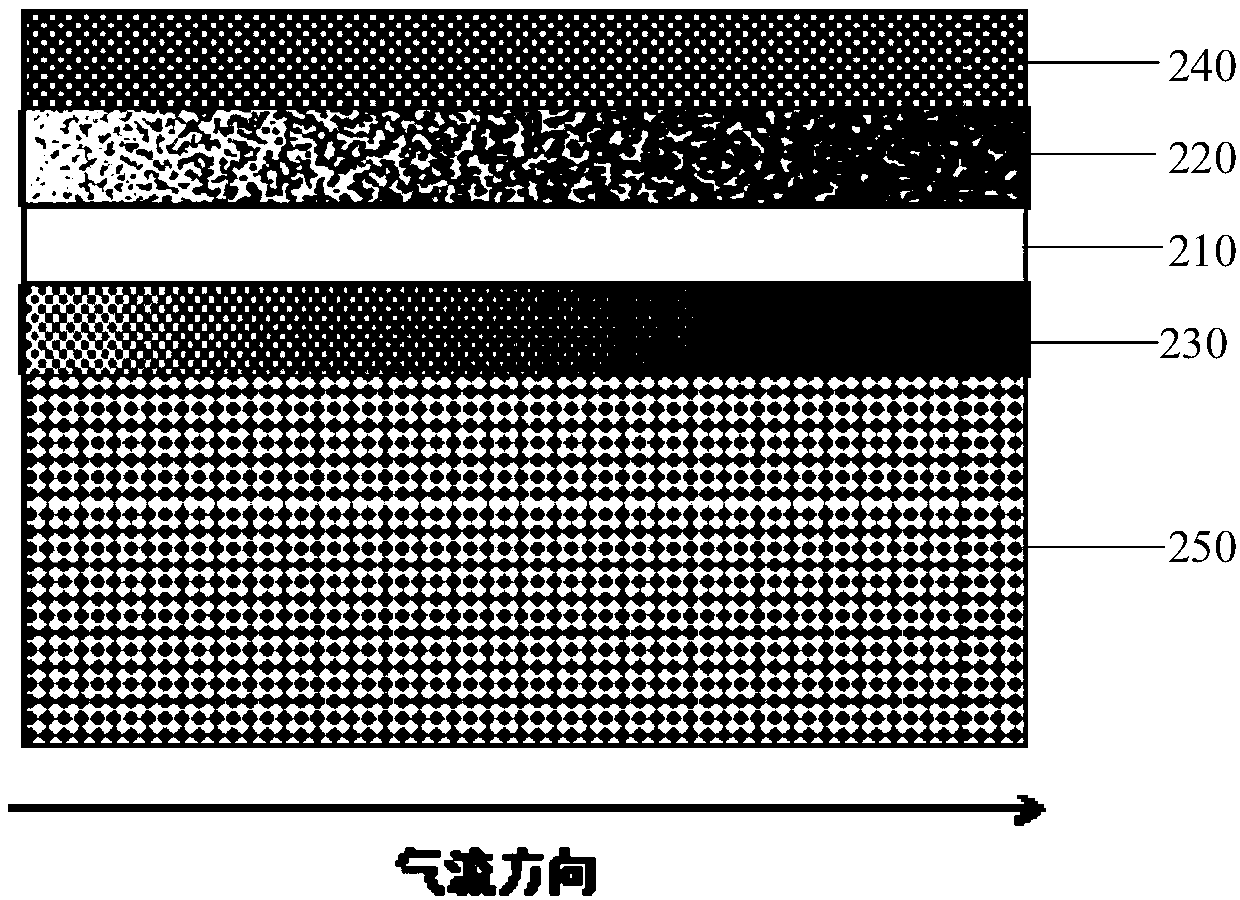

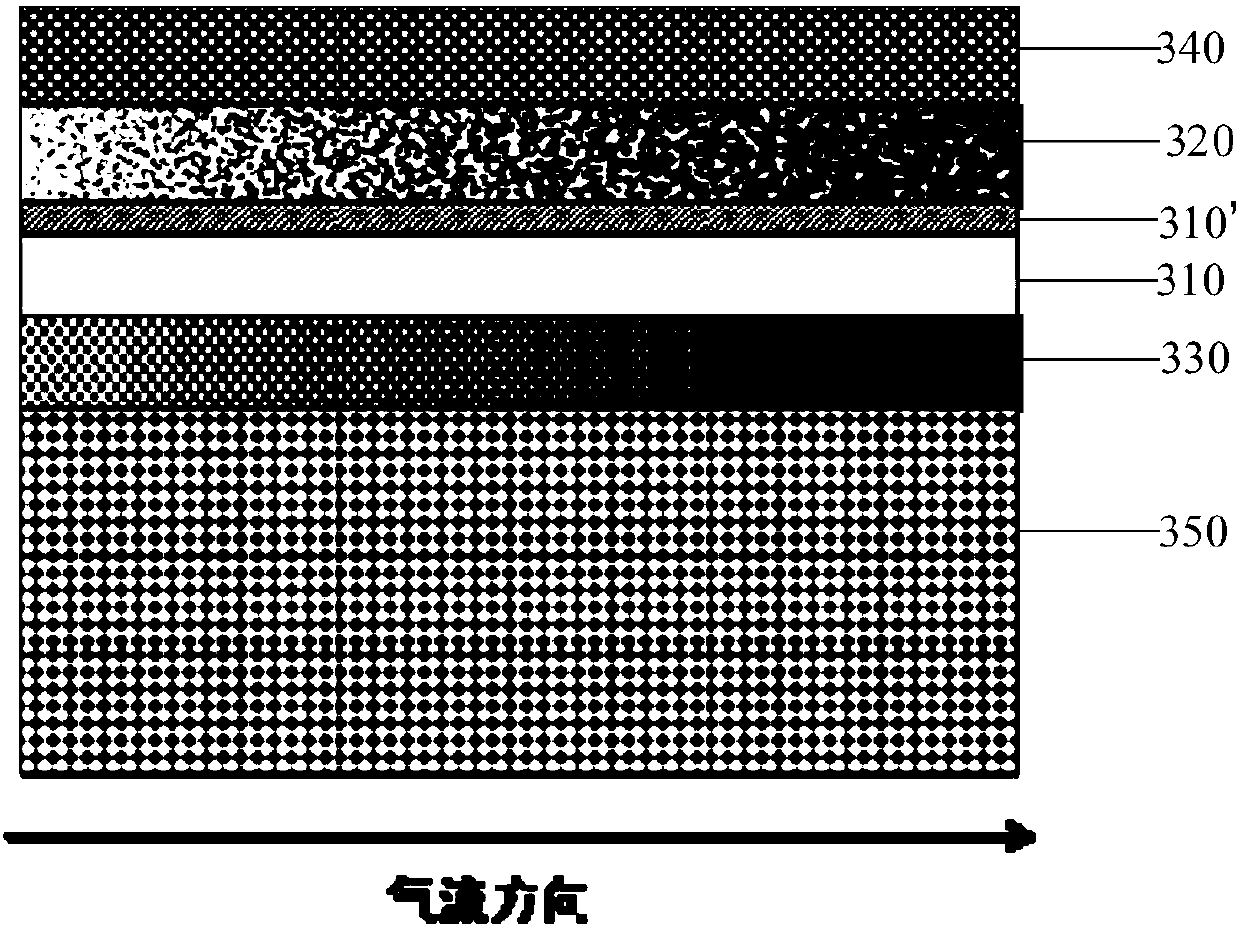

Gradient electrode and solid oxide battery

PendingCN107732257AGuaranteed operating efficiencySmall attenuationCell electrodesElectrode shape/formsUltrasound attenuationFuel cells

The invention discloses a gradient electrode and a solid oxide battery. The gradient electrode is used for a solid oxide fuel battery or a solid oxide electrolytic cell, and the reaction activity of the gradient electrode is increased in a gradient way along the air flow direction. The gradient electrode and the solid oxide fuel battery or the solid oxide electrolytic cell containing the gradientelectrode have the advantages that the distribution difference of polarizing property of the electrode along the air flow direction can be avoided or effectively reduced, so that the running efficiency of the electrode is ensured, and the attenuation of the battery is relieved.

Owner:SHENZHEN UNIV

Efficient reversible electrodes for solid oxide electrolyzer cells

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0≦x≦0.5, 0≦y≦0.5, and 0.8≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:COORSTEK INC

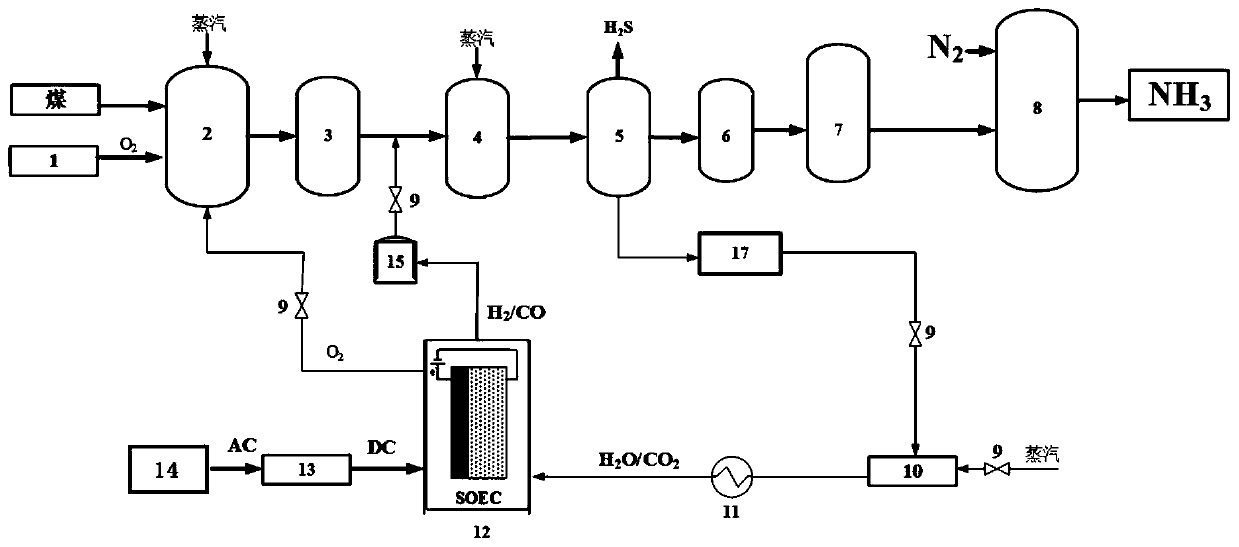

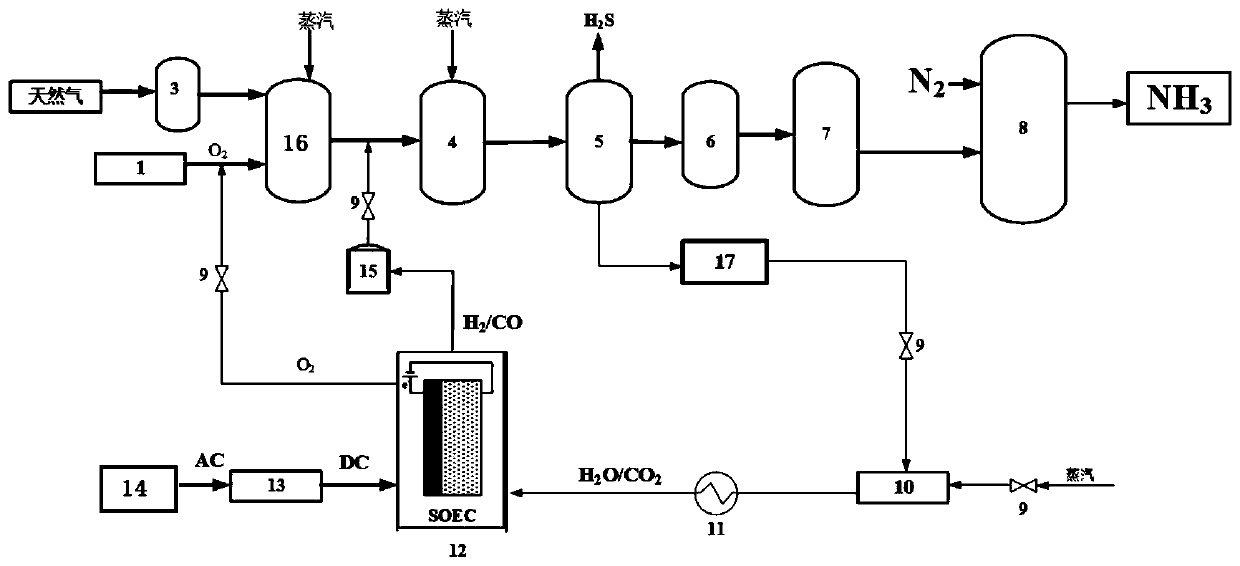

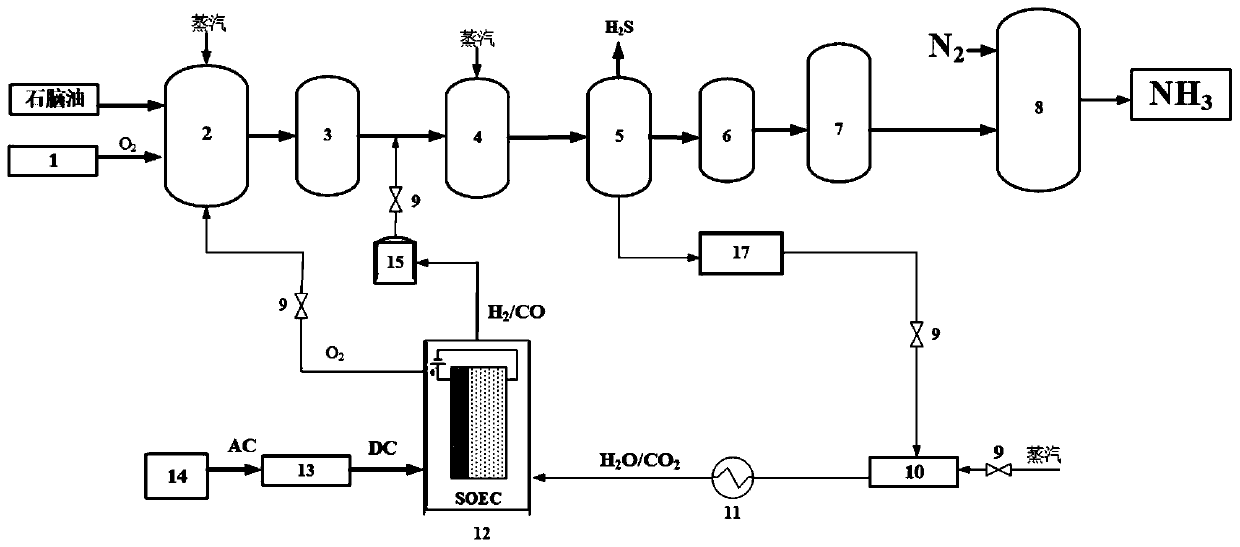

Ammonia synthesis method by coupling solid oxide electrolysis with fossil fuel ammonia synthesis

ActiveCN110156047AAchieve recyclingRealize recycling of resourcesHydrogenEnergy inputWater vaporSynthesis methods

The invention belongs to the technical field of synthetic ammonia, and particularly relates to an ammonia synthesis method by coupling a solid oxide electrolytic tank with a fossil fuel ammonia synthesis system. The method comprises the following steps: preparing hydrogen by taking fossil fuel as a raw material, then mixing the hydrogen with nitrogen to carry out an ammonia synthesis reaction, then collecting carbon dioxide gas generated in the hydrogen production step, mixing the carbon dioxide gas with water vapor, introducing the mixed gas into a solid oxide electrolytic tank to carry out electrolysis, and returning the generated gas to the hydrogen production step for cyclic utilization. According to the invention, the fossil fuel ammonia synthesis system is coupled with the solid oxide electrolytic tank, so that carbon dioxide gas generated in the process of hydrogen production by fossil fuel is effectively utilized, cyclic utilization of carbon dioxide is realized, and carbon emission is reduced.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

Thermoelectricity and hydrogen multi-combination-supply system based on solar energy

InactiveCN111089001AIncrease profitMeet the conditions for high temperature operationSolar heating energyElectrolysis componentsProton exchange membrane fuel cellBattery (electricity)

The invention relates to a thermoelectricity and hydrogen multi-combination-supply system based on solar energy. The system comprises a disc-type solar condenser, a solid oxide electrolytic tank, a proton exchange membrane fuel battery, a dual-level Rankine cycle, heat exchangers, a humidifier, a cold water tank and a hot water tank. The solid oxide electrolytic tank is a solid oxide electrolysiselectric pile, the proton exchange membrane fuel battery is a proton exchange membrane fuel battery electric pile, and the dual-level Rankine cycle is used by combining a high-temperature Rankine cycle and a low-temperature Rankine cycle and mainly comprises the heat exchangers, pumps, condensers, turbines and a flash evaporator. According to the thermoelectricity and hydrogen multi-combination-supply system based on the solar energy, the disc-type solar condenser takes the solar energy as a driving heat source, through the Rankine cycle, water electrolysis and a fuel battery power generationtechnology, continuous electric power, heating and hot water are provided for users, and clean and efficient utilization for the solar energy is achieved. The thermoelectricity and hydrogen multi-combination-supply system based on the solar energy is suitable for a distributed energy system, the demands of the users for multiple kinds of energy are met, and the utilization rate of the combination-supply system is further increased.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

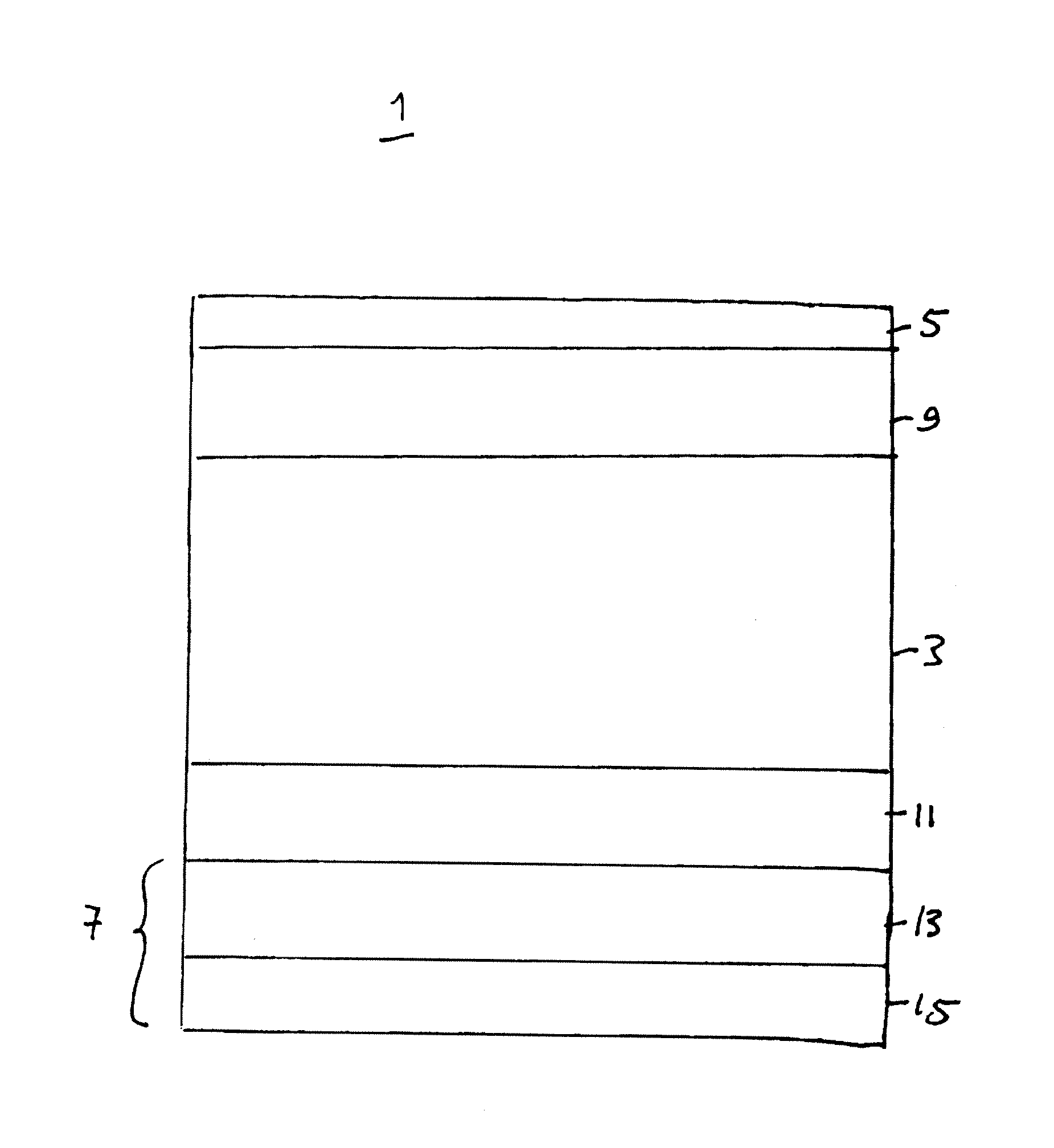

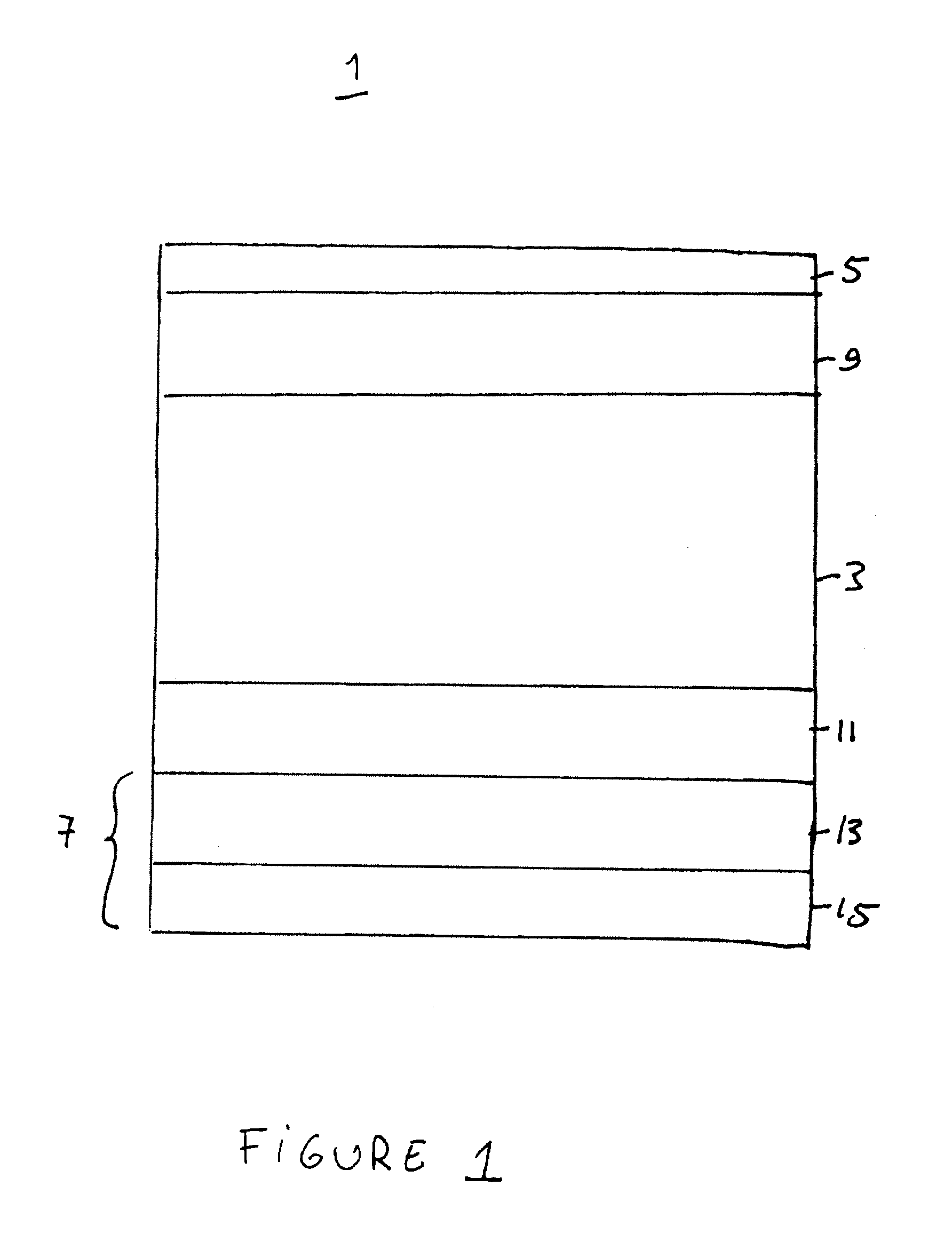

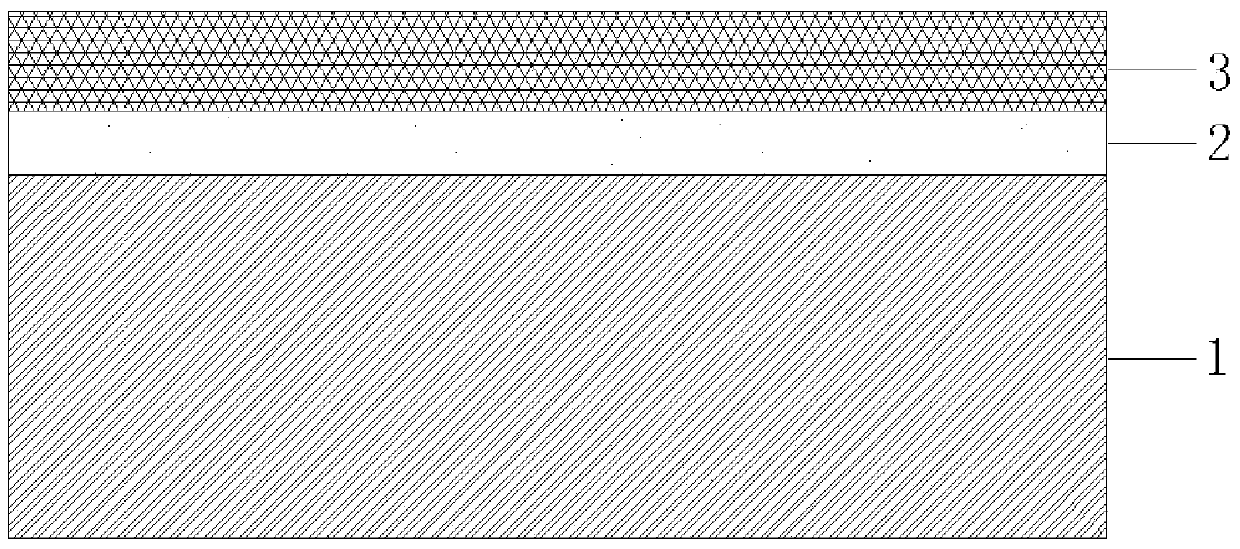

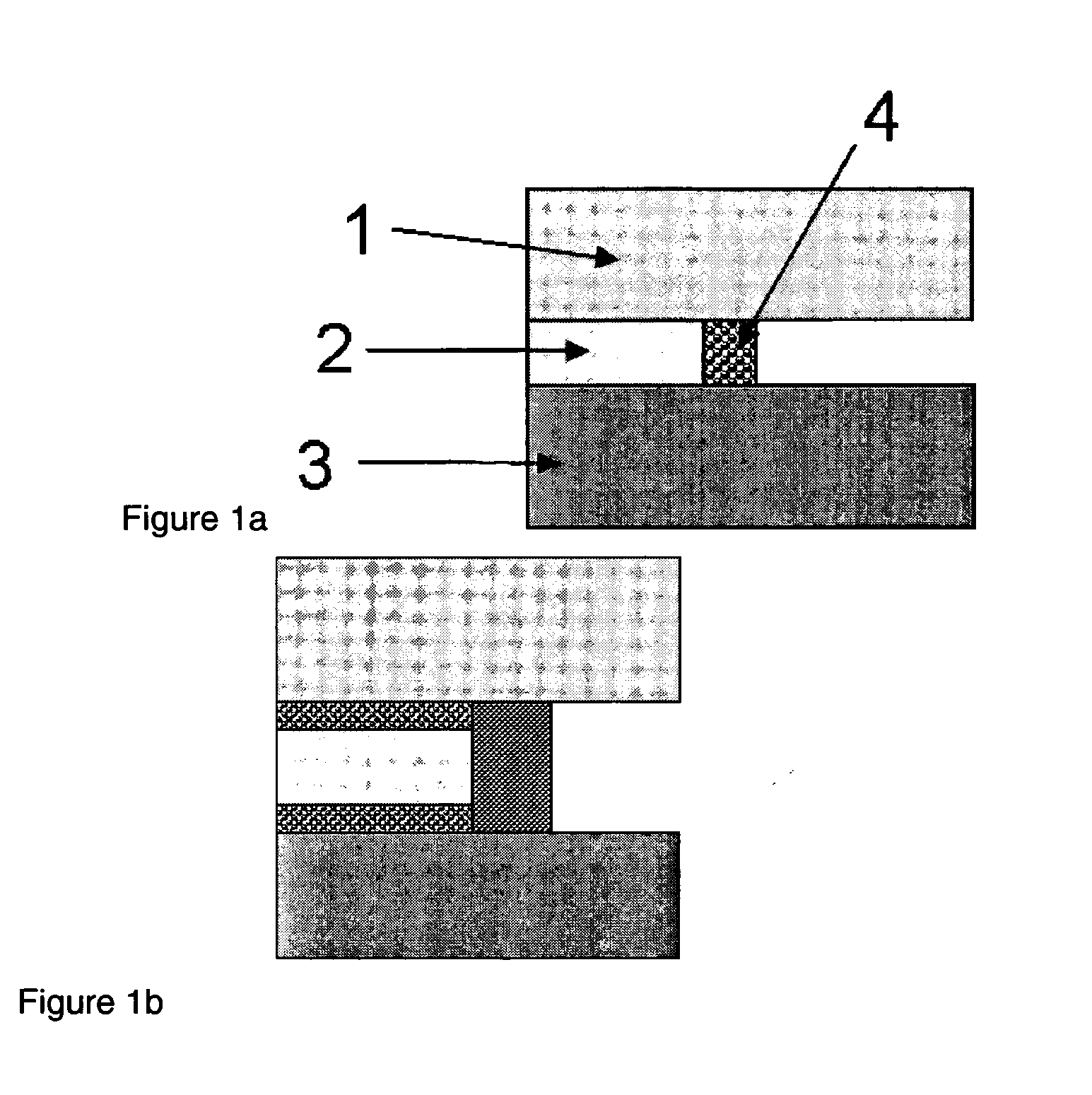

Composite glass seal for a solid oxide electrolyser cell stack

InactiveUS20110100805A1Increased durabilityExtended service lifeCellsLamination ancillary operationsMetalMaterials science

The present invention provides a solid oxide cell stack, comprising: —at least two cells which each comprise a first electrode layer (1), an electrolyte layer (2), a second electrode layer (3), —gas passage ways, and —sealing components (4), wherein the sealing components (4) comprise a glass component (4a) and a component comprising a metal oxide or metal oxide precursor (4b), and wherein the component comprising the metal oxide or metal oxide precursor (4b) is located at least in between the glass component (4a) and a gas passage way. The present invention further provides a method of producing the above solid oxide cell stack, comprising the steps of: —providing at least two SOC cells comprising each a first electrode layer or electrode precursor layer (1), an electrolyte layer (2), a second electrode layer or electrode precursor layer (3); —stacking at least two cells so as to form a cell stack including gas passage ways; and —sealing said cell stack with sealing components (4), wherein the sealing components (4) comprise a glass component (4a) and a component comprising a metal oxide or metal oxide precursor (4b), and wherein the component comprising the metal oxide or metal oxide precursor (4b) is at least located in between the glass component (4a) and a gas passage way.

Owner:DANMARKS TEKNISKE UNIV

Amino solar thermal chemical solid oxide electrolysis water hydrogen production system

The invention discloses an amino solar thermal chemical solid oxide electrolysis water hydrogen production system, which comprises a heliostat field, an ammonia decomposition reactor, a normal temperature pressure storage tank, an ammonia synthesis reactor and a solid oxide electrolysis cell, wherein a first liquid conveying pipe is connected to the bottom inlet of an ammonia decomposition reactor, a first gas conveying pipe is connected to the top outlet of the ammonia decomposition reactor, a second liquid conveying pipe is connected to the bottom outlet of the ammonia synthesis reactor, a second gas conveying pipe is connected to the top inlet of the ammonia synthesis reactor, the solid oxide electrolysis cell is connected to a water conveying pipeline, the water conveying pipeline penetrates through the ammonia synthesis reactor, and the heliostat field can heat the ammonia decomposition reactor. According to the present invention, the system solves the problems of low electrolysisefficiency, high electrolysis cost, high operating temperature and the like of the conventional electrolysis cell by using the advantages of high energy density, low energy loss and low storage temperature of the ammonia synthesis reaction.

Owner:ZHEJIANG UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com