Solid oxide electrolytic cell testing bracket

A solid oxide and electrolytic cell technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of inability to achieve accurate monitoring of the atmosphere temperature on the hydrogen electrode side, short service life of electrode leads, and reduced sealing effect, and achieve easy processing and operation. , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

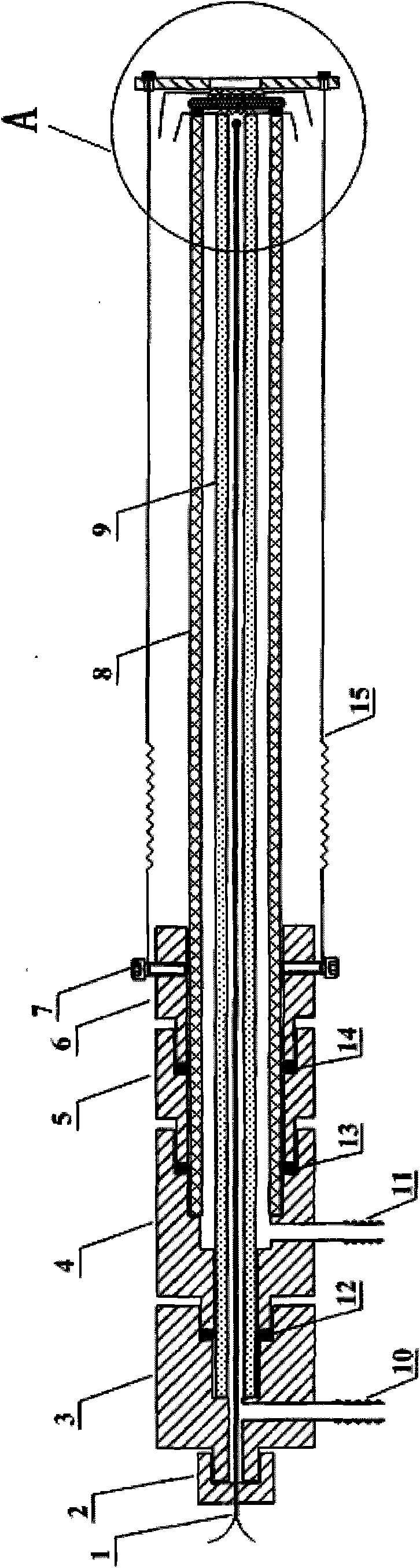

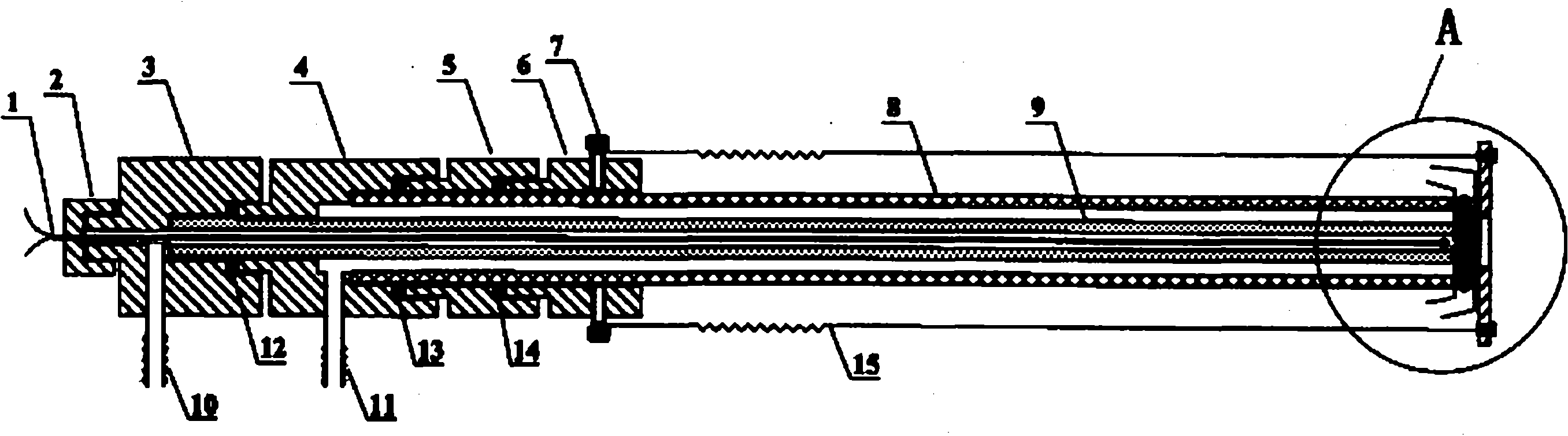

[0019] Below in conjunction with accompanying drawing and embodiment specify the specific structure and operation method of test support of the present invention:

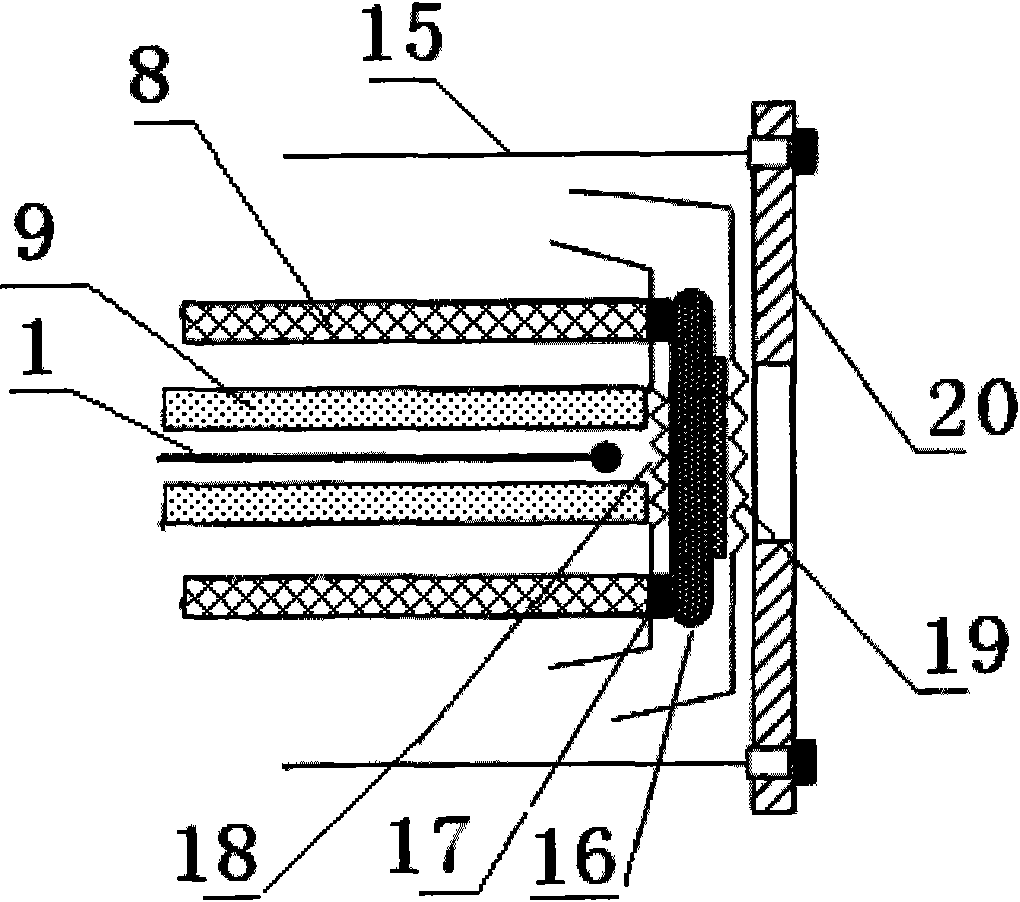

[0020] figure 1 It is a schematic structural diagram of an embodiment of a solid oxide electrolytic cell test support. From left to right, the first stainless steel ferrule 3, the second stainless steel ferrule 4, the third stainless steel ferrule 5 and the fourth stainless steel ferrule 6 are sequentially connected by threads to form a sealed ferrule; the left end of the intake ceramic tube 9 is embedded in the first stainless steel ferrule Inside the ferrule 3 and the second stainless steel ferrule 4, the hydrogen electrode gas chamber ceramic tube 8 is set outside the intake ceramic tube 9 and is coaxial with it, and the left end of the hydrogen electrode gas chamber ceramic tube 8 is embedded in the second stainless steel ferrule 4 and the third stainless steel ferrule 4. In the stainless steel ferrule 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com