Ammonia carbon-free synthesis system by means of nuclear energy and method thereof

A technology for synthesizing ammonia and nuclear energy, which is applied in chemical instruments and methods, ammonia compounds, inorganic chemistry, etc., can solve the problems of large cooling water consumption, multiple cooling equipment, and increased process complexity, so as to save investment, achieve good cooling effect, and reduce The effect of fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] one ,system

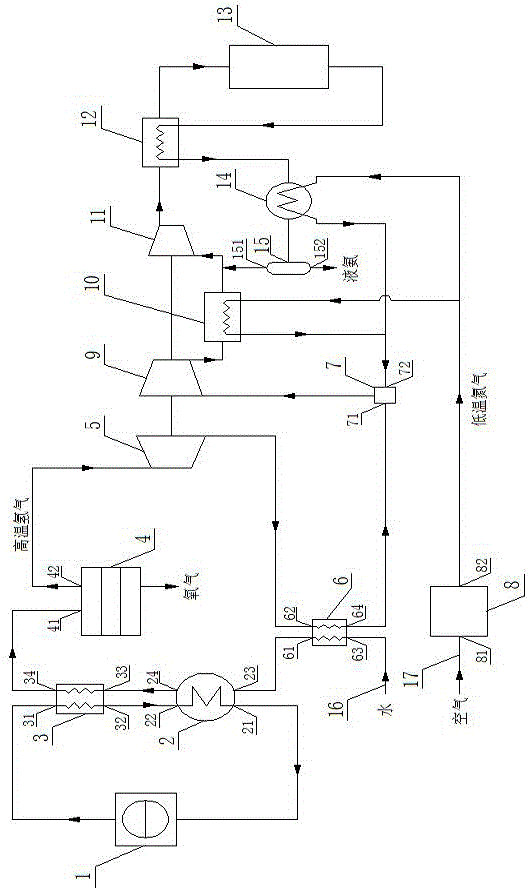

[0025] Such as figure 1As shown, the present invention is a carbon-free ammonia synthesis system utilizing nuclear energy, which includes a high-temperature gas-cooled reactor 1, a steam generator 2, a superheater 3, a solid oxide electrolyzer 4, a Stirling heat engine 5, and a heater 6 , mixer 7, cryogenic air separation unit 8, low pressure compressor 9, intercooler 10, high pressure compressor 11, preheater 12, ammonia synthesis tower 13, ammonia condenser 14, ammonia separator 15, water supply pipeline 16 , air pipeline 17; the inlet of described high-temperature gas-cooled reactor 1 is connected with the helium outlet 21 of steam generator 2, and the outlet of high-temperature gas-cooled reactor 1 is connected with the helium inlet 31 of superheater 3; described steam generation The helium gas inlet 22 of the device 2 is connected with the helium gas outlet 32 of the superheater 3, the feedwater inlet 23 of the steam generator 2 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com