Gradient electrode and solid oxide battery

A solid oxide, gradient technology, applied in electrodes, fuel cells, battery electrodes, etc., can solve problems such as unfavorable long-term battery operating life, affecting operating efficiency, and differences in battery planar performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation of the above-mentioned gradient electrode can be achieved by adjusting different particle diameters or different mass fractions of the electrode catalyst at different positions on the electrode surface, adding another single-phase or composite-phase nano electrocatalytic particles, etc.

[0060] Gradient electrode is realized by particle size distribution, that is, the particle size of the catalyst gradually decreases along the direction of the flow field, so that the catalytic surface area, the length of the three-phase boundary of the catalytic reaction, or the number of the three-phase boundary gradually increases.

[0061] The catalyst mass fraction control can be achieved by changing the supported content of the active catalyst to achieve the gradient, that is, changing the ratio of the active catalyst in the composite electrode (composite of the active catalyst + the catalyst carrier, that is, the ion conductor).

[0062] Adding another single-phase or com...

Embodiment 1

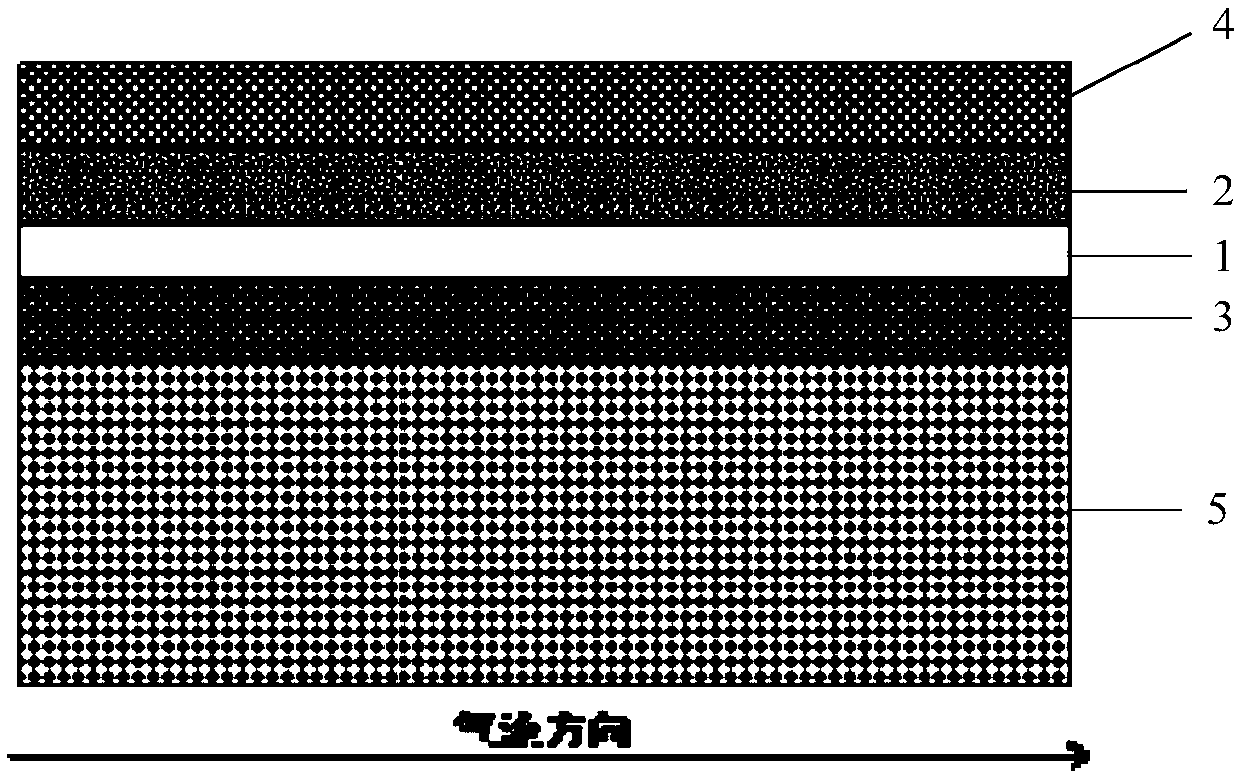

[0081] Non-gradient-designed electrode-supported solid oxide battery: 300μm thickness Ni-YSZ support|15μm thickness Ni-YSZ fuel electrode|10μm thickness YSZ electrolyte|20μm thickness LSM-YSZ oxygen electrode, operating temperature 870℃, average current density 1.5 A / cm 2 , Electrolysis gas is 45% CO 2 +45%H 2 O+10%H 2 The conversion rate of the mixed gas is 45%, and the current collecting layer is approximately equipotential, that is, the voltage is equal everywhere V=1.4 volts.

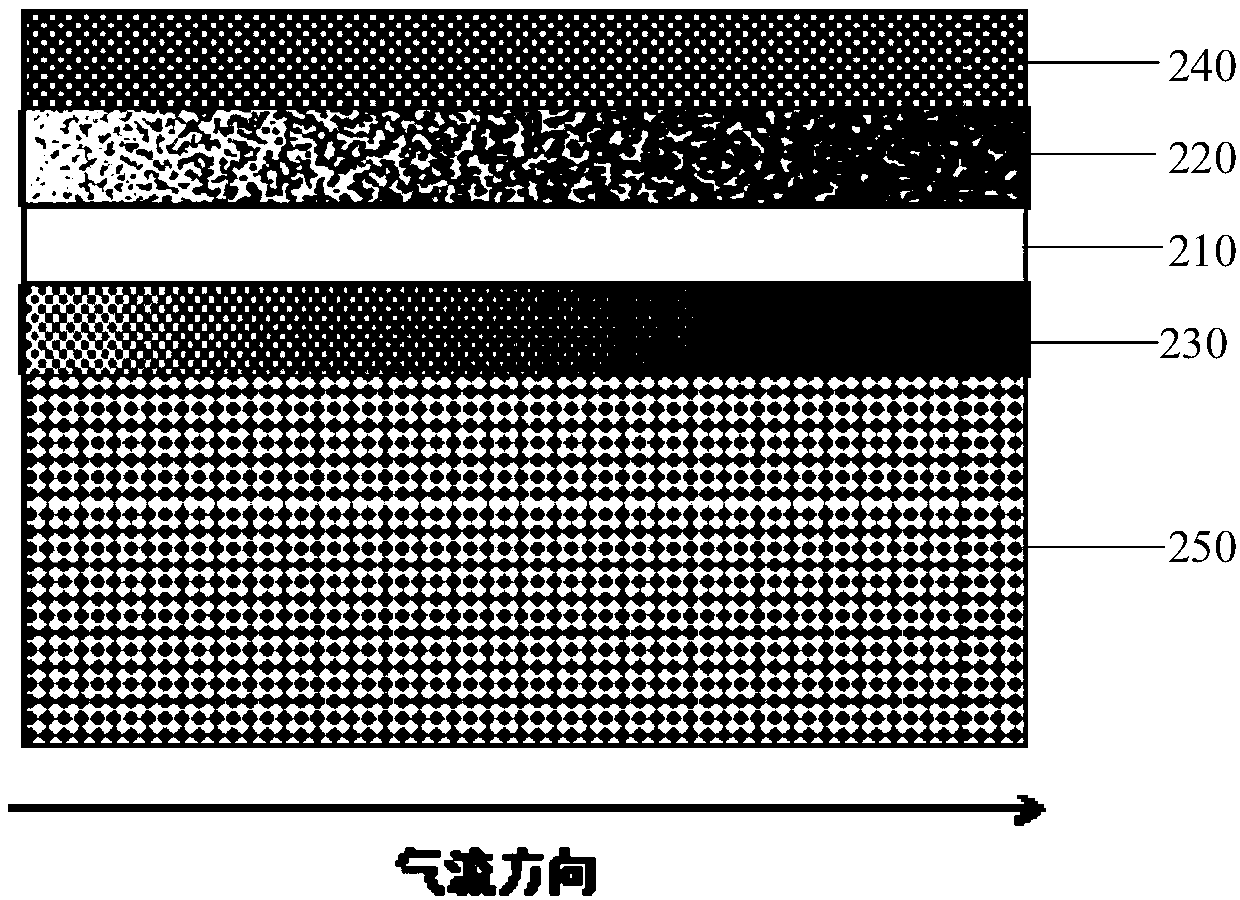

[0082] By adjusting the particle size of the Ni catalyst in the Ni-YSZ fuel electrode and the ion conductor 8YSZ, and using a step gradient from the upstream to the downstream of the airflow, the electrode is gradually refined, that is, the battery is divided into 4 rectangular areas along the direction of the airflow and connected to each other. There is no gap, and the distance between the adjacent boundary and the inlet accounts for 25%, 50% and 75% of the total length of the flow field respectively....

Embodiment 2

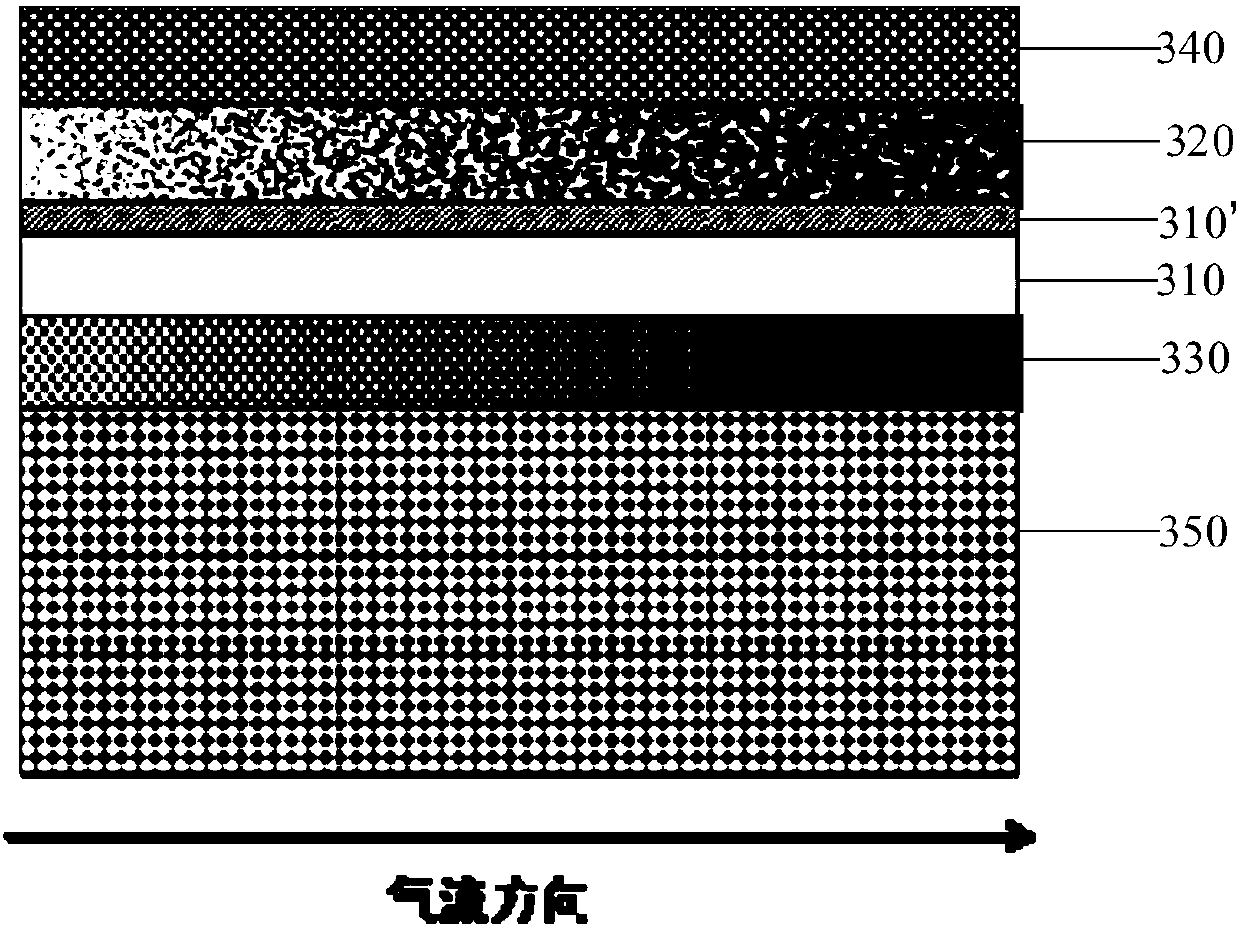

[0085] The difference from Example 1 is that the basic structure of the solid oxide battery is 300μm thick Ni-YSZ support|15μm thick Ni-SSZ fuel electrode|10μm thick SSZ electrolyte|5μm thick GDC barrier layer|20μm thick LSCF-GDC oxygen electrode, The porosity of LSCF-GDC is 35%-50%. By adding a new catalyst to the LSCF-GDC oxygen electrode and adjusting its content to obtain a smooth gradient, the electrochemical catalytic performance from the inlet to the outlet of the gas flow is enhanced. Specifically, a liquid microinjection method is used to apply La on the surface and inside of the electrode. 0.6 Sr 0.4 CoO 3-δ CeO 2 Corresponding to the metal ion nitrate precursor solution, the substance content is controlled by the injection speed, so that the increase relative to the entrance is increased from 0 to 15% (near the exit), slowly dried and decomposed and heated to 650-850 ℃ for processing to obtain high activity Nano La 0.6 Sr 0.4 CoO 3-δ CeO 2 (Weight ratio 3:2) cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com