Amino solar thermal chemical solid oxide electrolysis water hydrogen production system

A solid oxide, solar thermal technology, applied in the field of electrolysis of water, can solve the problems of low economic benefit, large energy consumption of electrolyzed water, low electrolysis efficiency, etc., and achieve the effects of less energy loss, low electrolysis efficiency and high energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings of the description.

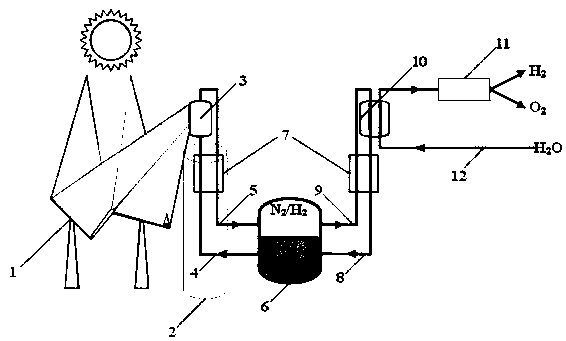

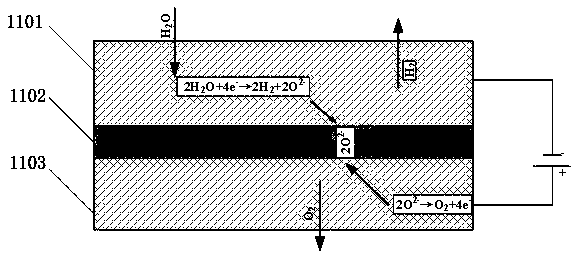

[0014] Such as Figure 1-2 As shown in the amino solar thermochemical solid oxide water electrolysis hydrogen production system, the heliostat field 1 is placed at a certain angle to reflect sunlight to the ammonia decomposition reactor 3 (endothermic reaction); the ammonia decomposition reactor 3 is a tank-shaped structure, its two ends are spherical arc surfaces, and the bottom end of the ammonia decomposition reactor 3 is connected to the heat exchanger 7 through two conduits of the first gas delivery pipe 4 and the first liquid delivery pipe 5 (the function of the heat exchanger here is to absorb H 2 , N 2 heat, preheating liquid ammonia), the ammonia decomposition reactor 3 and the heat exchanger 7 are supported by the steel structure of the heat collection tower 2, and the heat exchanger 7 is connected to the normal temperature through the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com