Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Single bath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing coarse gauge double yarn galling flannel

InactiveCN101397714AImprove fluffinessReduce tensionWeft knittingHeating/cooling textile fabricsPolyesterYarn

The invention relates to a production method of a bulky double-yarn brushed flannel, which comprises the steps of the weaving and the dyeing and finishing of the bulky double-yarn brushed flannel. The steps of dyeing and finishing technique comprise dyeing, drying, surface sanding, wrong side fuzzing, combing, shearing and shaping. The method is characterized in that the weaving thereof adopts an improved three-thread interleaver fleece knitting machine in a two-way polyester face and cotton back manner for supplying yarns; the dyeing and finishing technique also comprises the steps of pre-shaping treatment before dyeing and adding an oil removing technique when dyeing is carried out; the temperature of the pre-shaping treatment is 180 DEG C to 190 DEG C and time for shaping is 30 seconds to 40 seconds; and a single bath process is adopted for the oil removal when dyeing is carried out and the temperature is controlled to be 130 DEG C to 140 DEG C. The bulky double-yarn brushed flannel produced by the method of the invention has the advantages and characteristics of rough style, compact texture and relatively light gram weight; in addition, the fabric of the brushed flannel has stable size and the surface of the fabric has good puff feeling.

Owner:SHANGHAI JIALE

Antiwear nickel phosphor functionalized gradient plate preparation method

The invention discloses a preparation method for wearable nickel phosphate function gradient plating coat, which comprises: with design idea for gradient material, using single-bath electroplating method, preparing the coat with phosphate content gradient varying by boosting current density gradually and controlling deposition time. This product has proper phosphate content gradient and thermal expansion coefficient to release the thermal stress problem and high bond strength and abrasion resistance. This method can replace current used technique.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

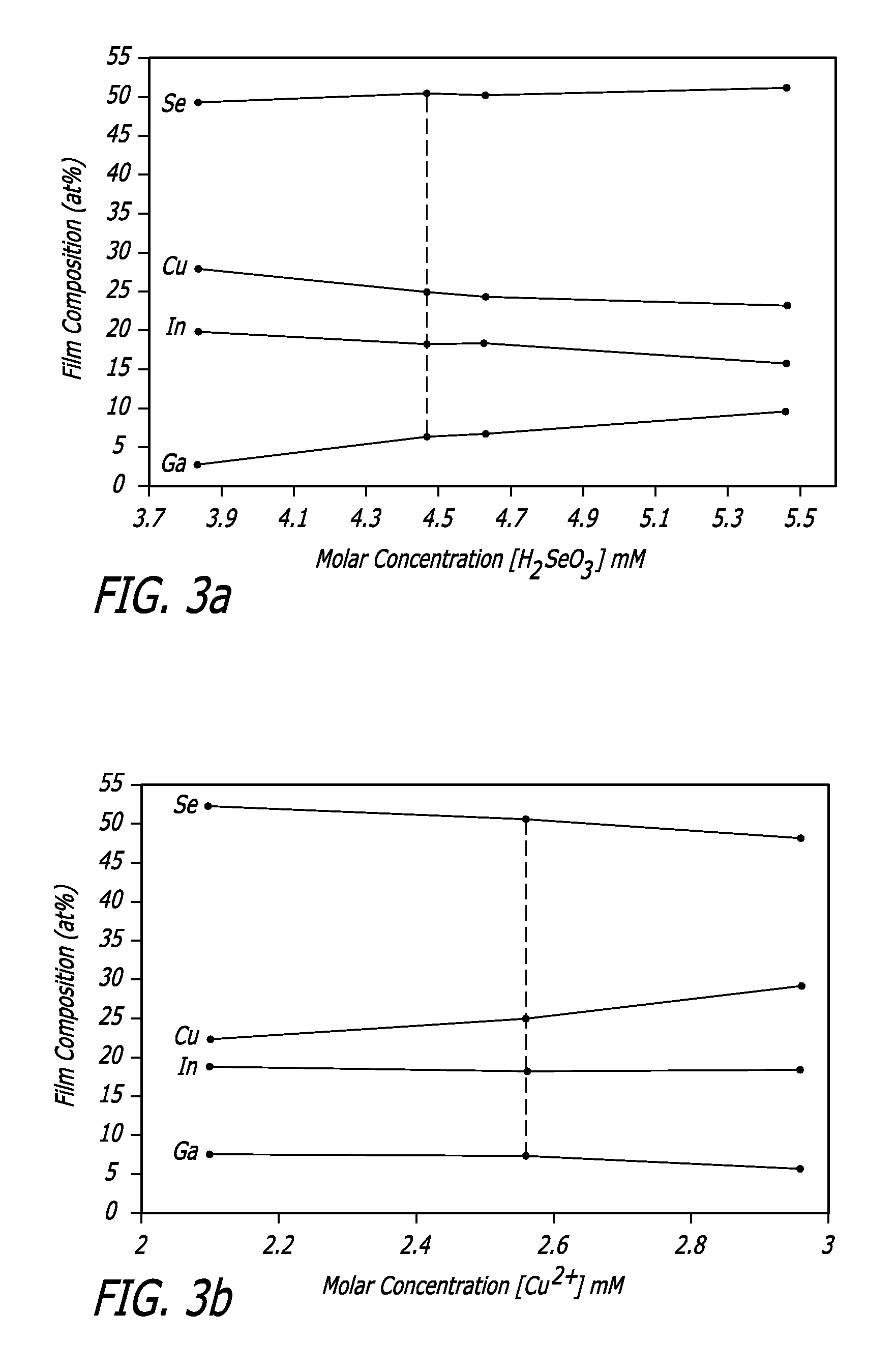

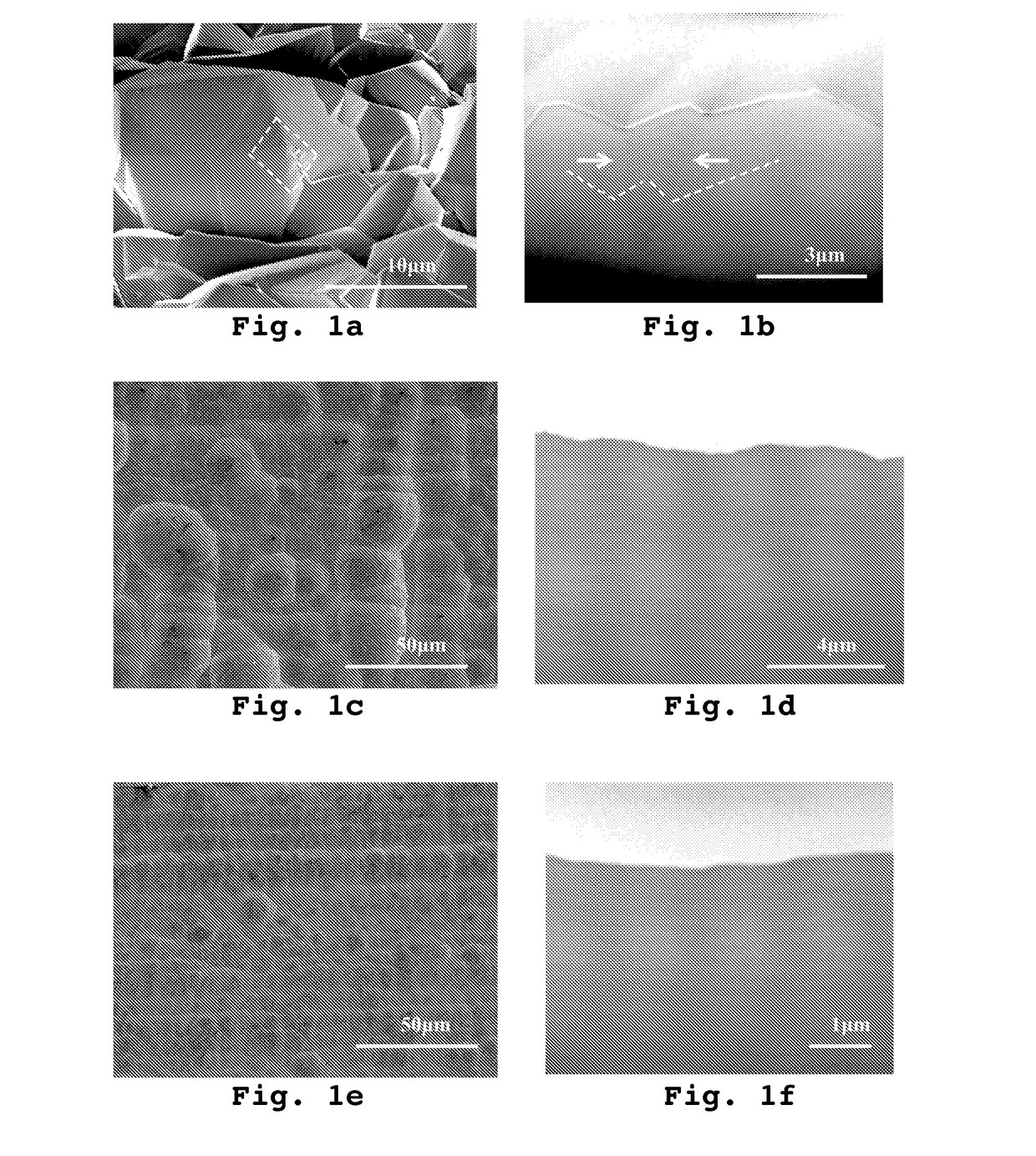

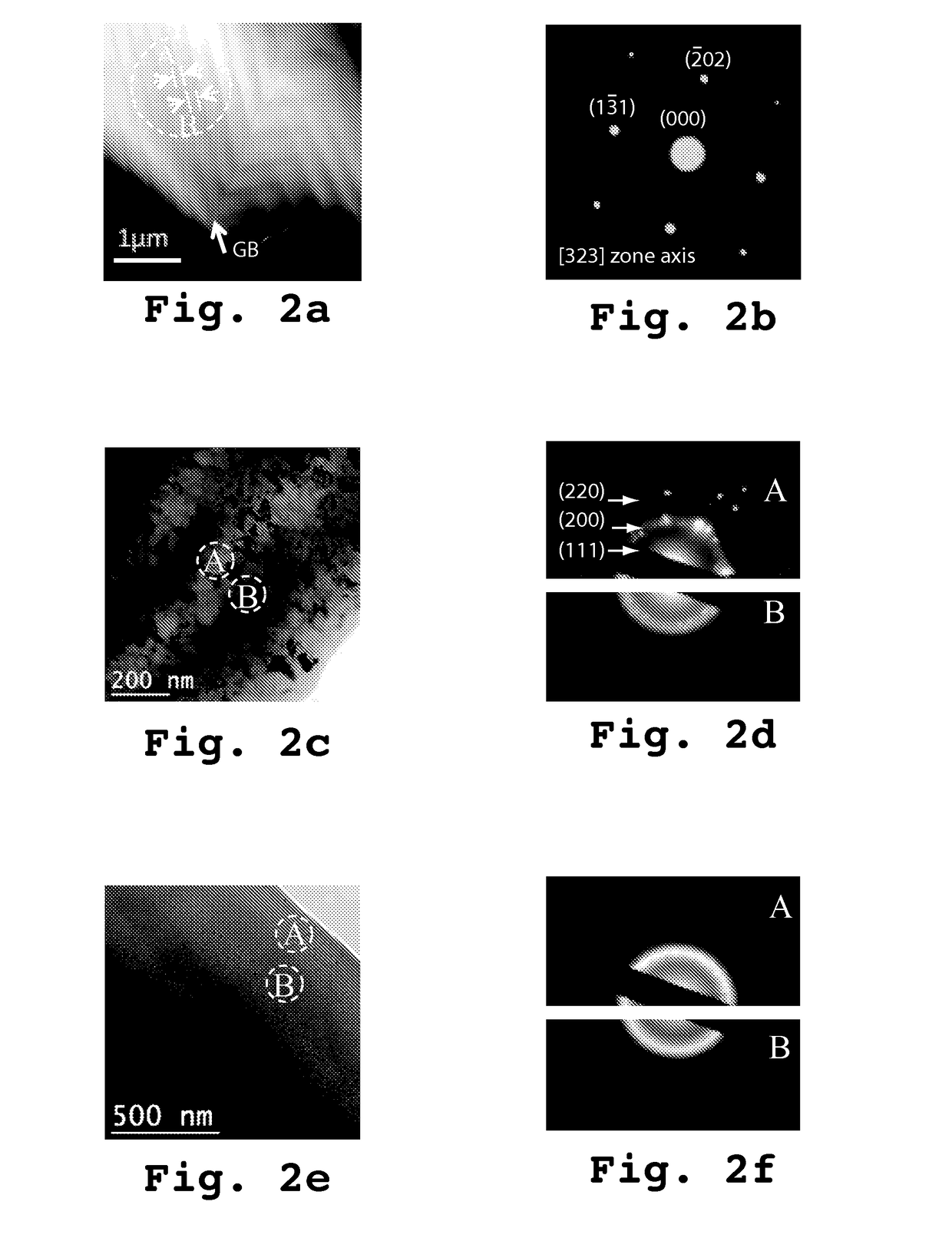

Post deposition treatments of electrodeposited cuinse2-based thin films

InactiveUS20070151862A1Easy to controlReduce crackingPhotovoltaic energy generationSemiconductor devicesCrack freeChemical measurement

Single bath electrodeposition of polycrystalline Cu(In,Ga)Se2 thin films for photovoltaic applications is disclosed. Specifically, Cu(In,Ga)Se2 was deposited onto Mo electrodes from low concentration buffered (pH 2.5) aqueous baths containing CuCl2, InCl3, GaCl3 and H2SeO3. Moreover, buffered aqueous baths are disclosed wherein Se4+ / Cu2+ concentration ratios were controlled to optimize Se and Cu levels, while In3+ concentration was adjusted to control deposited In and Ga. Further disclosed are pre- and post-deposition processing methods resulting in smooth, compact, crack-free films of near stoichiometric values. Post deposition heat treatments on electrodeposited CuInSe2-based films in selenium and sulfur containing atmosphere are described. CuInSe2-based films from a single bath deposited onto Mo electrodes from low concentration aqueous baths. Heat treatment of electrodeposited Cu(In,Ga)Se2 in H2Se producing an O-free crystalline film and annealing in Se-vapor producing crystalline CuInSe2 without loss of Ga or O).

Owner:UNIVERSITY OF DELAWARE

Desizing, boiling, bleaching and dyeing alkaline single bath dyeing method and adjuvant composition used thereby

InactiveCN101440581AIncrease productivityDry-cleaning apparatus for textilesBleaching apparatusAdjuvantSewage

The invention discloses a one alkaline bath dyeing method integrating desizing, cloth refining, bleaching and dyeing. The method comprises: (a) a step of raw material mixing, during which an auxiliary composition is added with stirring at 40 DEG C and dye is added with stirring five minutes later; (b) a step of integrated desizing, cloth refining, bleaching and dyeing, in which 1 to 3 heat-preservation stages are set according to fabric type, the dyeing temperature is 130 DEG C, the total time is kept within 30 to 60 minutes according to the fabric type, and the rate of temperature rise is adjusted within a range from 1 to 2DEG C / min; (c) a step of cooling to 70 DEG C and discharging sewage after dyeing and adding a washing agent for washing; and (d) a step of water washing. The invention also discloses an auxiliary composition used by the method. The auxiliary composition comprises an auxiliary agent for desizing, cloth refining and bleaching and an accelerating agent, wherein the auxiliary agent for desizing, cloth refining and bleaching is a surfactant compound of which the principle component is sodium persulfate, and the accelerating agent is a surfactant compound of which the principle component is 14,16-polyoxyethylene alkyl ether. The invention is applicable to dacron and has the advantages of simple processing, high quality, high efficiency, low pollution and so on.

Owner:SHENGHONG GRP CO LTD

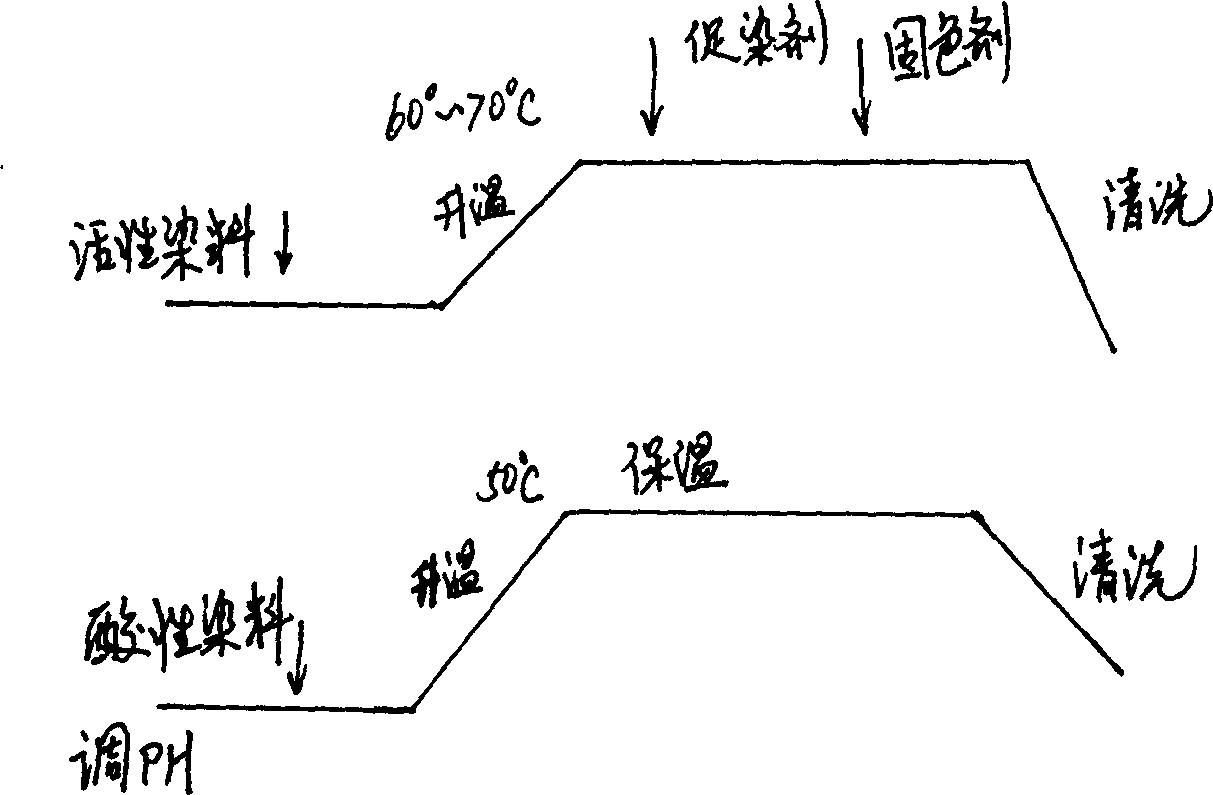

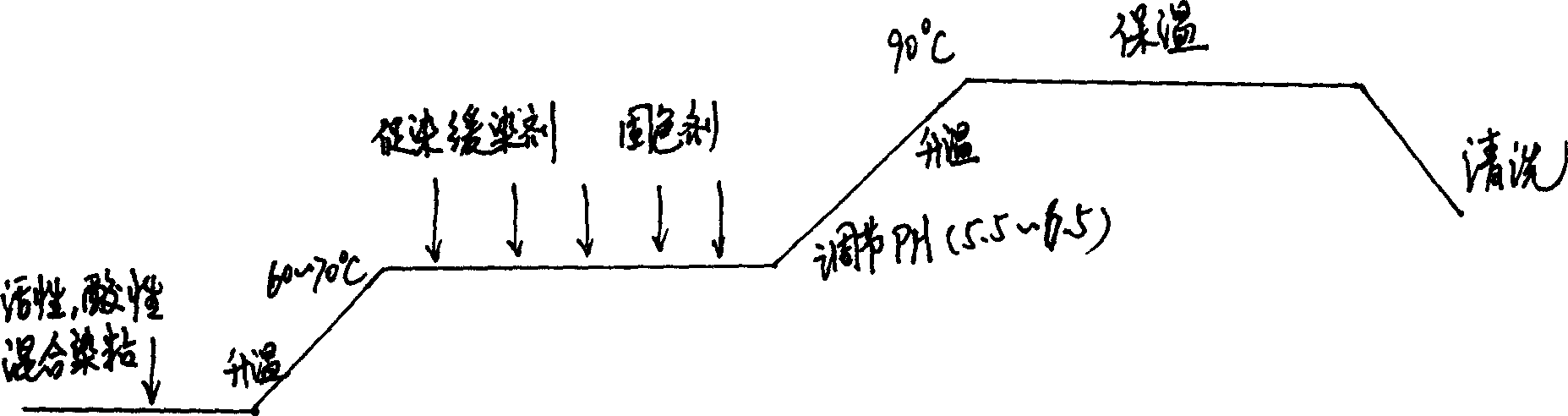

Bath method of dyeing

A single bath method for dyeing fabric includes such steps as choosing dye, mixing it with reactive dye, dissolving, regulating the dyeing condition according to the one of dye mixture, which requires lower temp. adding dyeing promoter, retarding agent and fixative, dyeing, regulating the dyeing condition according to the one of dye mixture, which requires higher temp. and dyeing, cooling and washing. Its advantages are low cost, and high dyeing quality.

Owner:张永成

Single bath finishing technology for antibacterium and dyeing of textile by natural products

InactiveCN101736605ANo pollution in the processNon-toxicDyeing processVegetal fibresNatural productFiltration

The invention provides a single bath finishing technology for antibacterium and dyeing of textile by natural products and relates to textile chemical technology. In the invention, natural products are used as raw materials to produce finishing agent. The raw material is preliminarily crushed by mini plant pulverizer into powder which is then arranged in the waterbath and stirred for some time before going through suction filtration and being produced into natural product finishing agent. The cation-modified cotton fabric is soaked in the finishing agent and treated with dyeing antibacterial finish by the single bath technology. The technology is simple and convenient to operate and energy-saving and environment-friendly. After the finishing, the fabric features good lustre, excellent antibacterial effect, and is nonhazardous to human body.

Owner:JIANGNAN UNIV

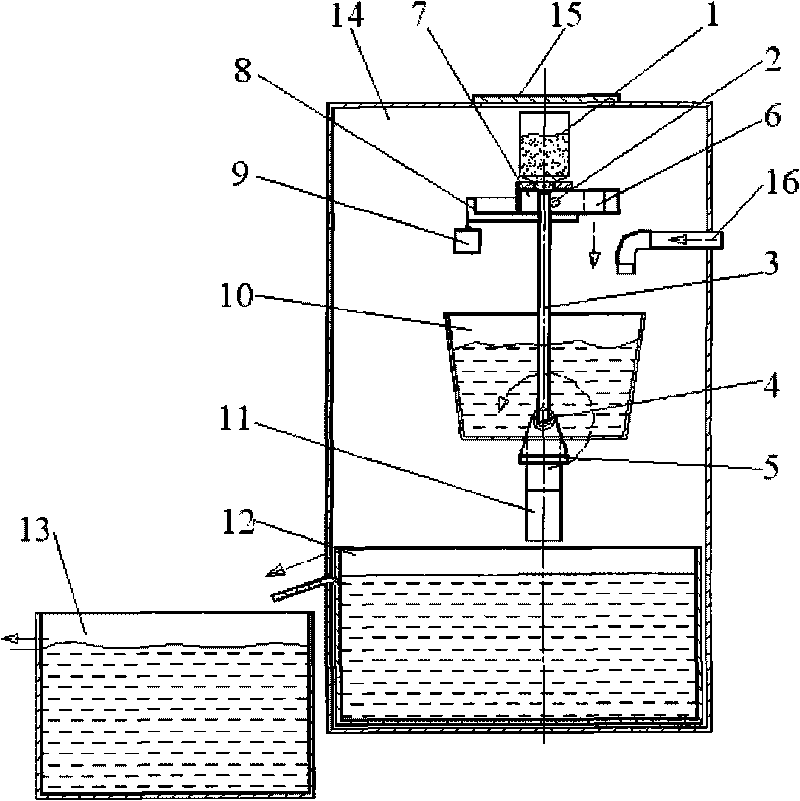

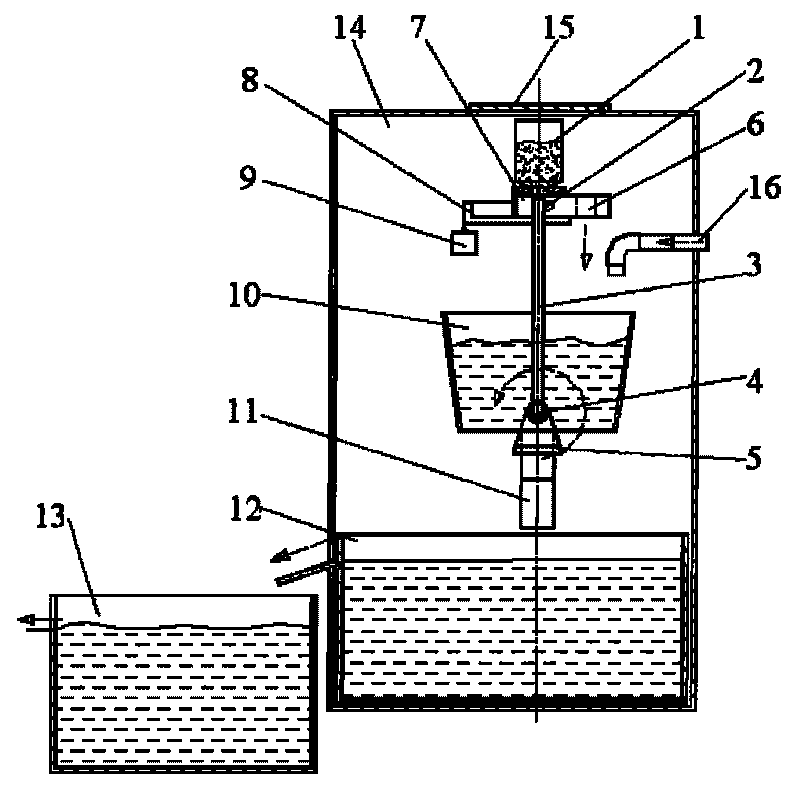

Unpowered quantitative dosing and mixed wastewater treatment device and use and adjustment methods thereof

ActiveCN101691260AReduce volumeEasy to moveMixer accessoriesMultistage water/sewage treatmentWastewaterSewage

The invention discloses an unpowered quantitative dosing and mixed wastewater treatment device, which is provided with a turnover water tank and a water tank turnover balance weight block arranged at the lower part of the water tank. When the water tank is positioned in a balanced position, the upper part of the water tank is provided with an opening, and the opening is greater than the bottom part of the water tank; a wastewater inlet is arranged above the water tank; and a quantitative dosing mechanism in turnover linkage with the water tank is also arranged above the water tank. The invention also discloses use and adjustment methods of the wastewater treatment device. The technical scheme in the invention can reduce the volume of equipment which is suitable to be used by a single restaurant or a single bath center; and the equipment is a rectangular tank body and is convenient to move and mount, can finish automatic wastewater metering, automatic quantitative dosing, automatic mixing and stirring and primary sedimentation processes without using electric power except for replacing medicament bottles manually, and adopts a secondary sedimentation tank flush with the ground so as to finish the whole process of wastewater treatment.

Owner:南通迪特金属制品有限公司

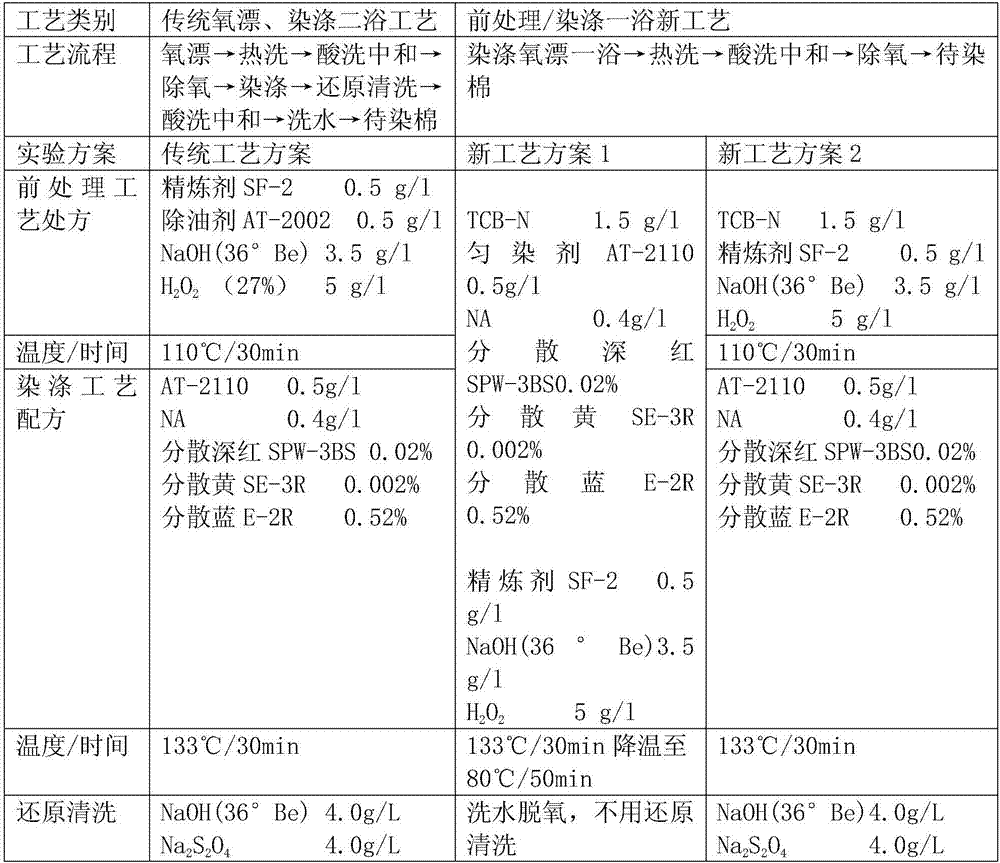

Novel dyeing process of polyester/cotton knitted fabric

The invention relates to a novel dyeing process of a polyester / cotton knitted fabric. The process is characterized by comprising the following steps: pre-treatment / washing in a single bath; pickling and neutralizing; deoxygenating; cotton dyeing; water washing; acid passing; TCW cleaning; hot washing; water washing; and color fixing. Compared with a conventional process, a single bath agent Yakesai TCB-N is adopted to combine pre-treatment and dyeing, so that the oxygen bleaching and dyeing in the single bath can be realized technically; after washing, no cleaning is performed, and meanwhile, the hot washing numbers of time and two times of reductive cleaning are reduced, and cotton dyeing is directly performed, so that the process is shortened; after cotton dyeing, a TCW environmental cleaning process is adopted to replace a conventional two-time soaping step at 95 DEG C, and meanwhile, the hot washing numbers of time is reduced, so that the process is relatively environment-friendly, COD is low, the sewage treatment burden is alleviated, the benefit is increased, the pollution discharge is reduced, and an effect of saving energy and reducing emission is achieved.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Tuning nano-scale grain size distribution in multilayered alloys electrodeposited using ionic solutions, including Al—Mn and similar alloys

Owner:MASSACHUSETTS INST OF TECH

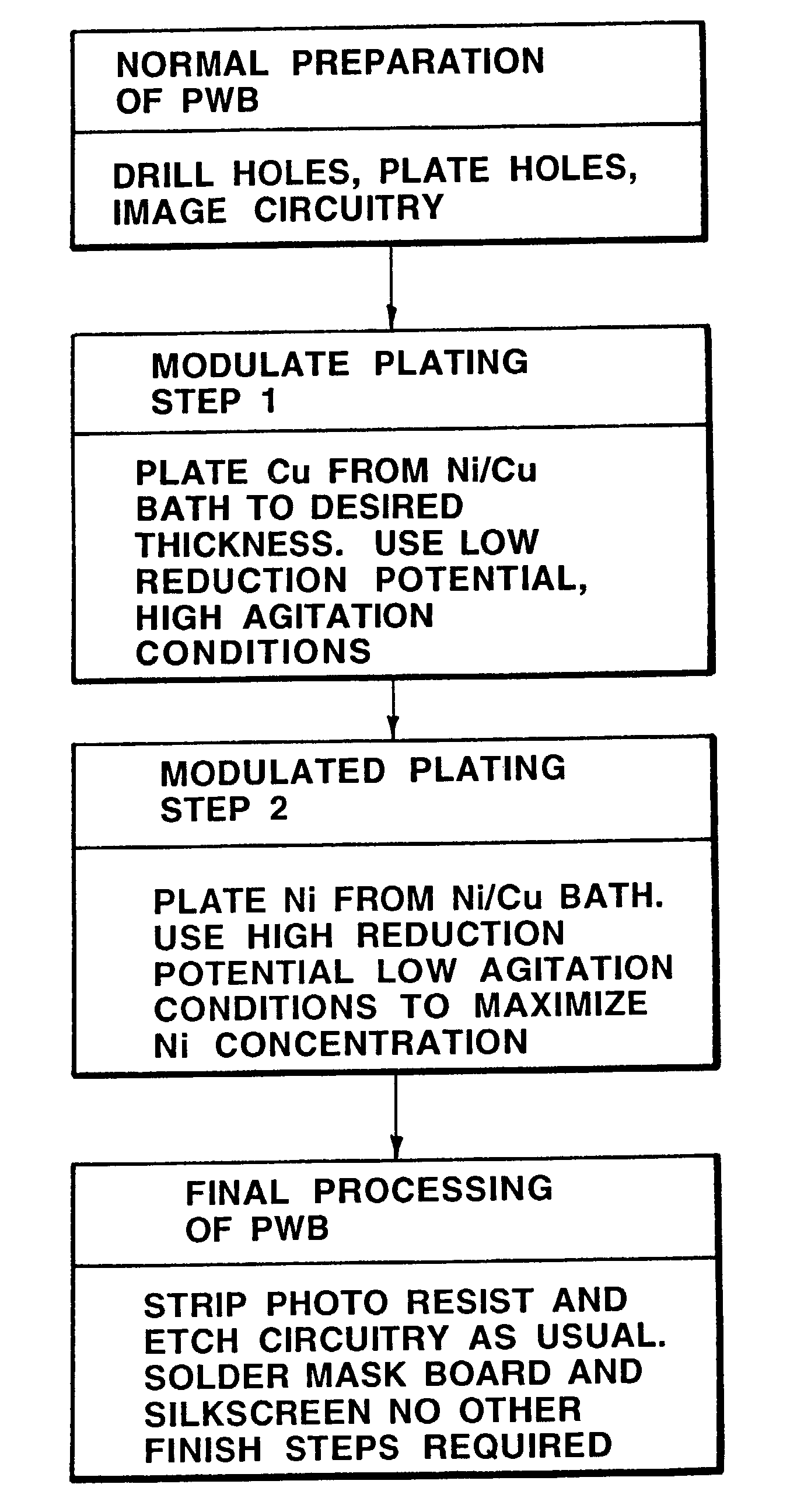

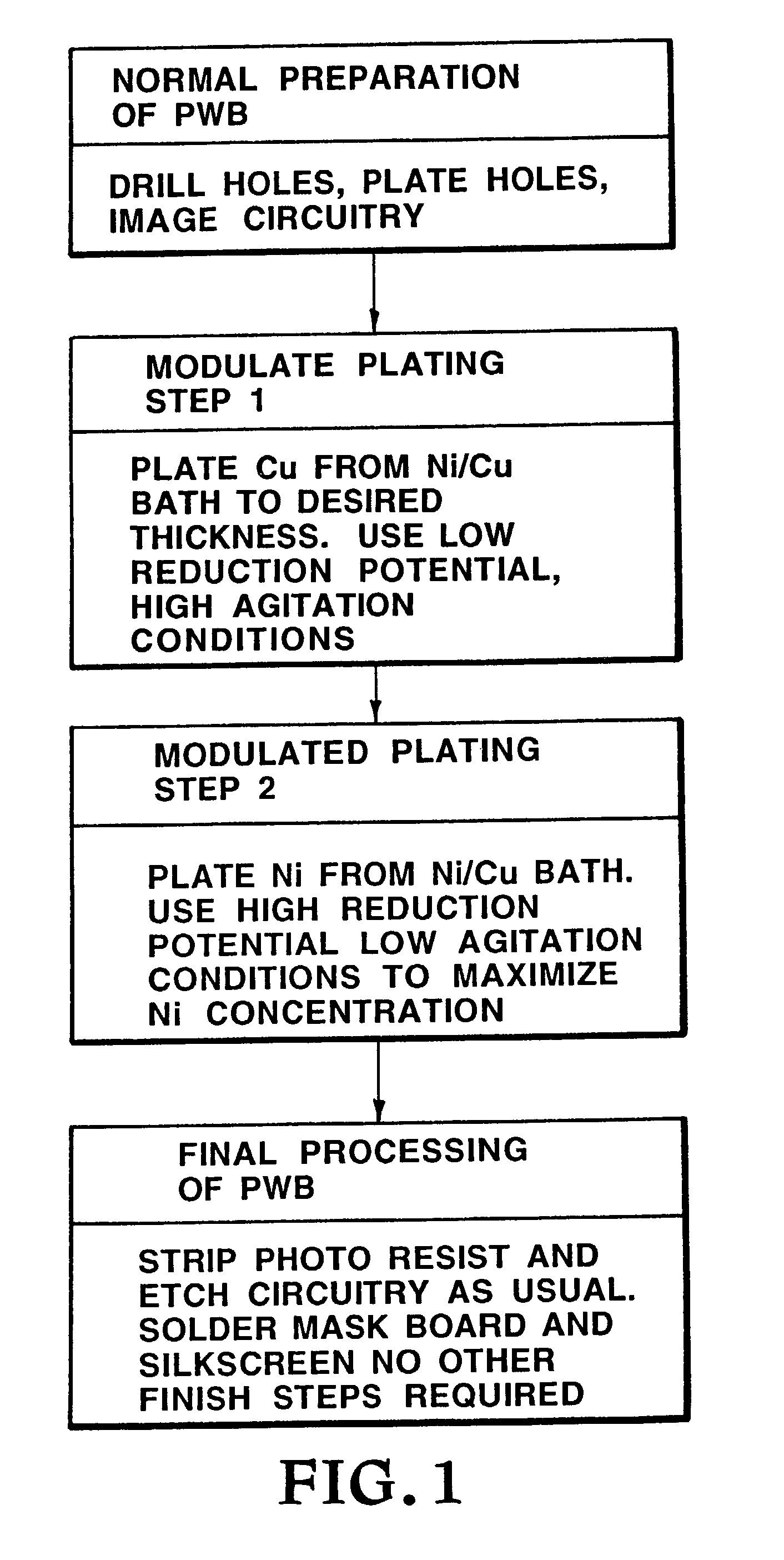

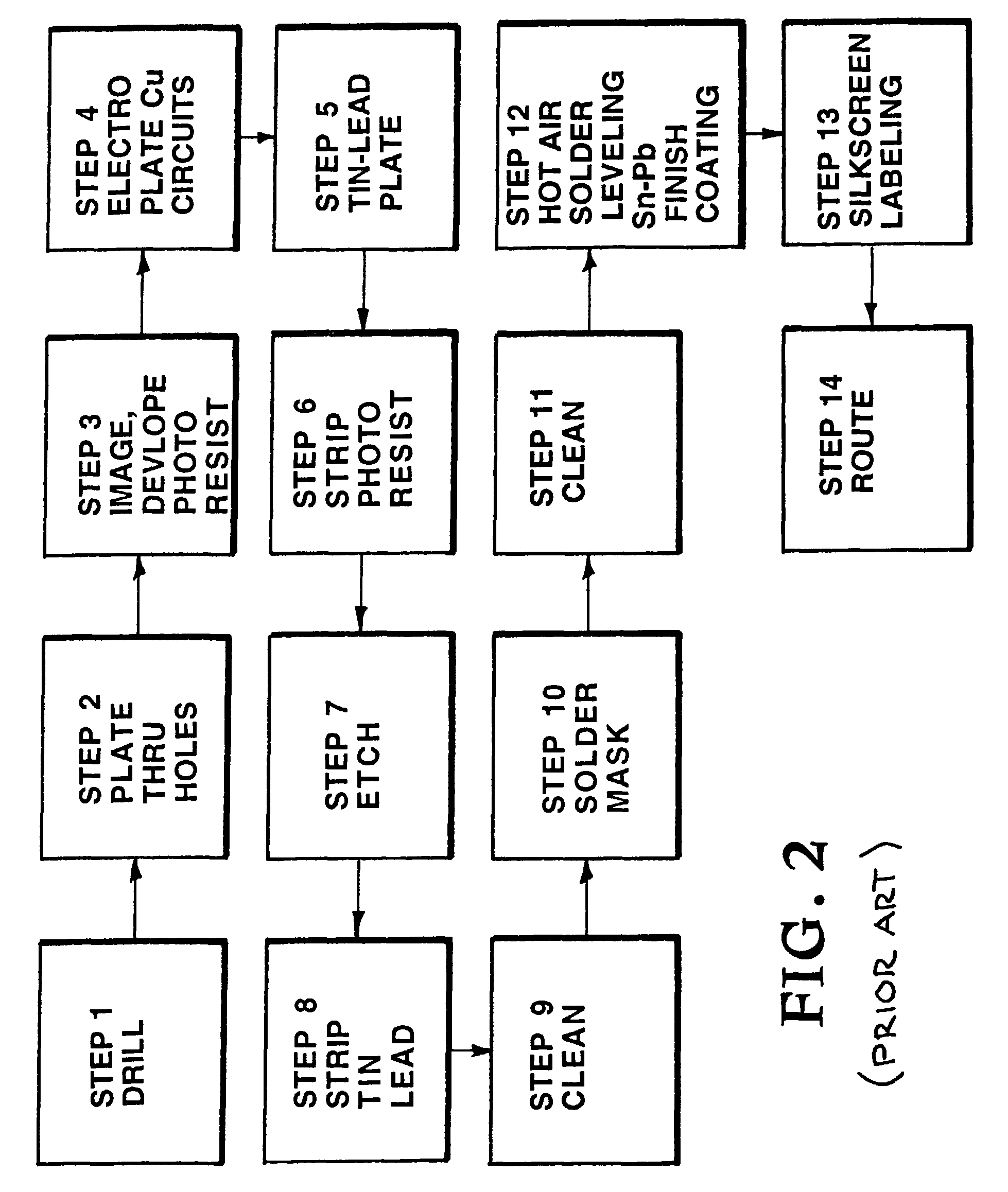

Processing a printed wiring board by single bath electrodeposition

InactiveUS7846317B2Improve conditionsLower conditionsConductive material chemical/electrolytical removalConductive pattern reinforcementEngineeringCopper

A method of processing a printed wiring board. Initial processing steps are implemented on the printed wiring board. Copper is plated on the printed wiring board from a bath containing nickel and copper. Nickel is plated on the printed wiring board from a bath containing nickel and copper and final processing steps are implemented on the printed wiring board.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

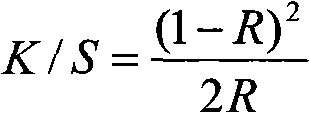

Single-bath dyeing and finishing process for blended knitting fabrics containing protein fibers

ActiveCN103122589AChange gray effectChange flatnessAnimal materialDyeing processColour fastnessMoisture absorption

The invention discloses a dyeing and finishing technology, and in particular relates to a production technology for dyeing and finishing blended fabrics of protein fibers and plants. The invention aims at providing a single-bath dyeing and finishing process of the blended knitting fabrics containing the protein fibers, which is consistent in dye-uptake rate, good in evenness, and free of flower ash and dyeing effect, and can ensure the color fastness. According to the single-bath dyeing and finishing process of the blended knitting fabrics containing the protein fibers obtained by the invention, silk cotton is dyed by the method, so that the cotton is consistent with real silk in color and has comfortable sensation just as the real silk, and in addition, the cotton has the function of natural moisture absorption, so that the flower ash effect and the uneven phenomenon of a common dye method of the real silk and the cotton are changed; the defect of poor dyeing color fastness of an original process is improved; consumption of water, electricity and gas is greatly reduced; and the single-bath dyeing and finishing process plays roles in saving and reducing emission.

Owner:ZHEJIANG JIAMING DYEING & FINISHING CO LTD

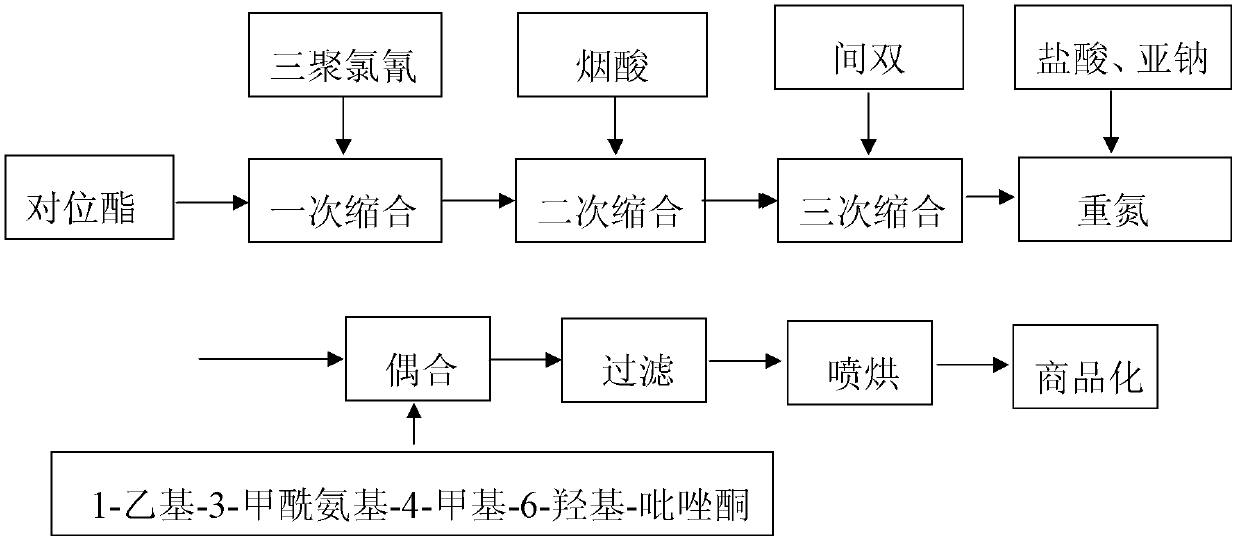

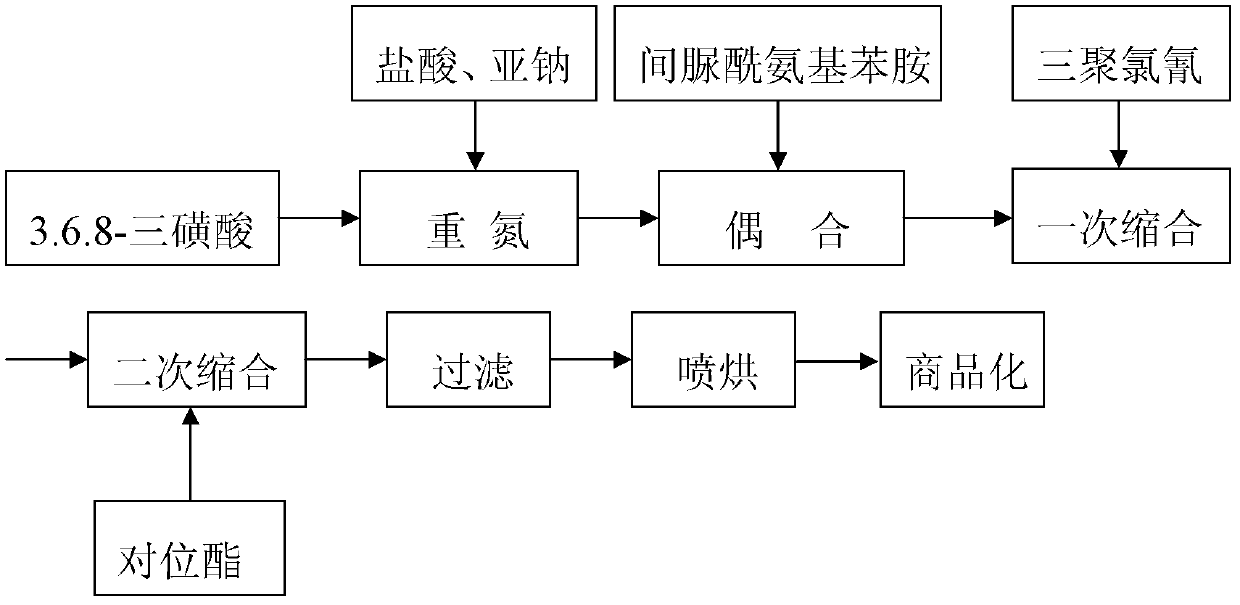

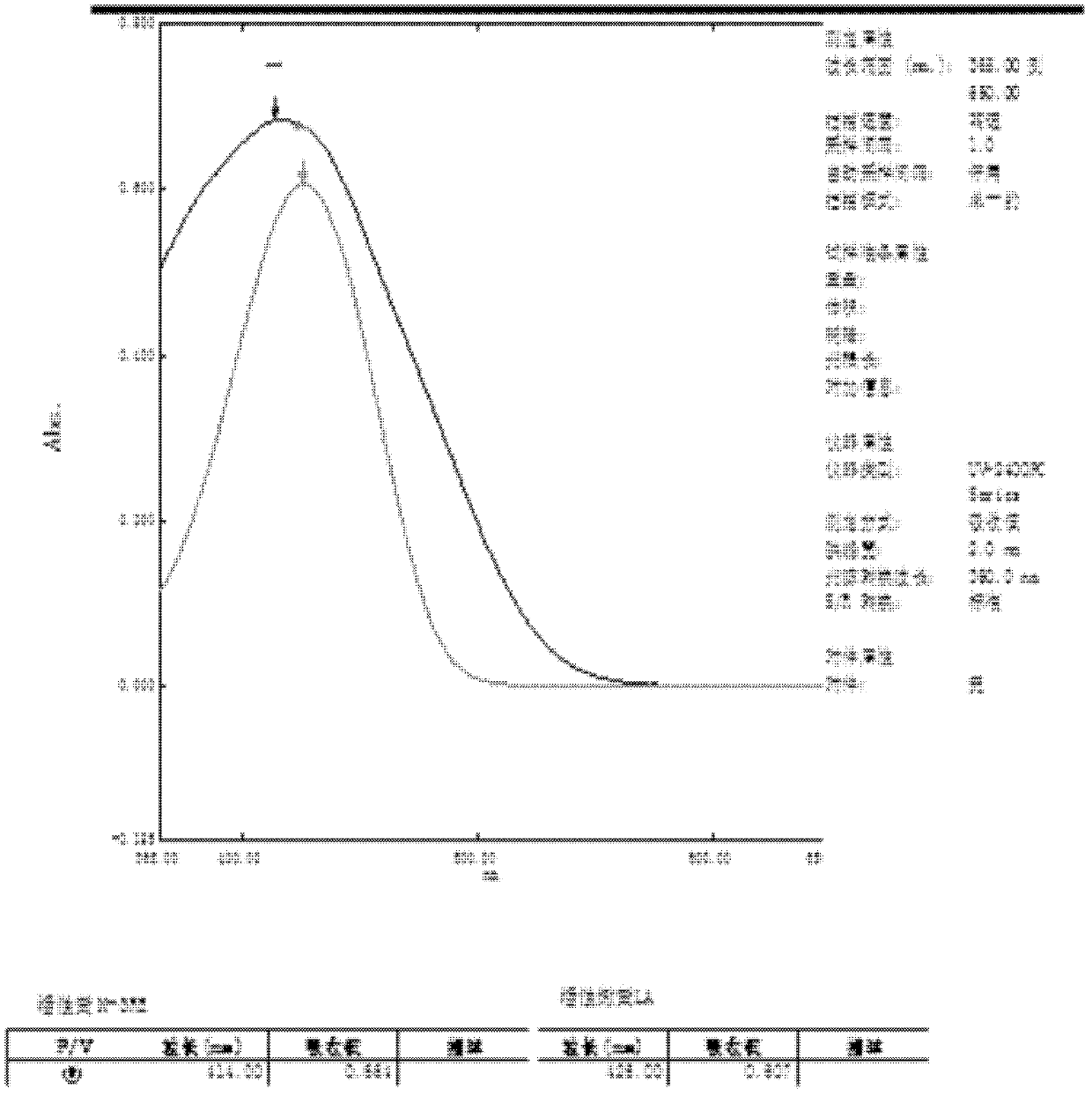

Active light yellow LA and preparation process thereof

ActiveCN102584794AImprove conversion rateHigh yieldOrganic chemistryReactive dyesSolubilityDisperse dye

The invention discloses active light yellow LA and a preparation process thereof. The active light yellow LA has a formula (I) structure. Active light yellow LA synthetized by the invention, and active black LA and active brown LA prepared can be dyed with disperse dyes through a single bath process, and the dyes conduct alkaline color fixation. The invention has the advantages that the pure caustic soda consumption is one eighth to one twentieth of the traditional consumption, the dyeing rate is low, dyeing defects are not easily caused, the dyeing temperature and the PH value are low, the hydrolysed dyes are less, the various fastnesses can be improved, the cloth cover cleaning property is high, the waste water discharging amount is less, the solubility is high, the substantivity is high, excellent compatibility and dyeing stability are achieved, the reproduction quality and the once dyeing rate are ensured, particularly, the absolute color fixation rate is higher than that of the active yellow M-3RE5 by 5% to 10%, and the light resistance, the washability and the fastness to rubbing are higher than those of the conventional variety by 1 to 2 grades.

Owner:TAIXING JINYUN DYESTUFF

Method of dyeing with reactive dye

A method of dyeing with one or more reactive dyes either a single material selected between polyamide fibers and cellulose fibers or a composite material comprising a material selected among synthetic polyamide and natural polyamide fibers and a material selected among cellulose, polyacrylic, and polyester fibers, characterized in that the reactive dyes are selected based on a classification of reactive dyes by the ratio of the color density of dyed synthetic polyamide fibers to that of cellulose fibers dyed in the same bath as the synthetic polyamide fibers and on color differences for correction, and that the work is dyed with the reactive dyes or with a combination of the reactive dyes and one or more dyes selected among metal-containing acid dyes, disperse dyes, etc., all the dyes to be used being dissolved in a single bath.

Owner:DAIICHI KASEI CO LTD

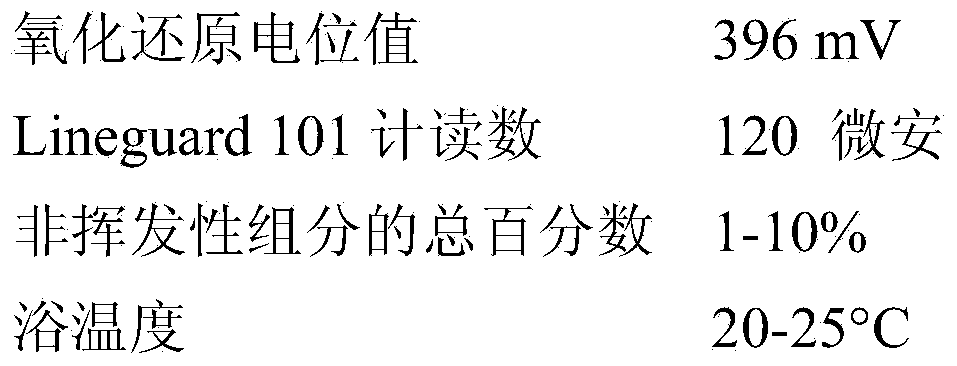

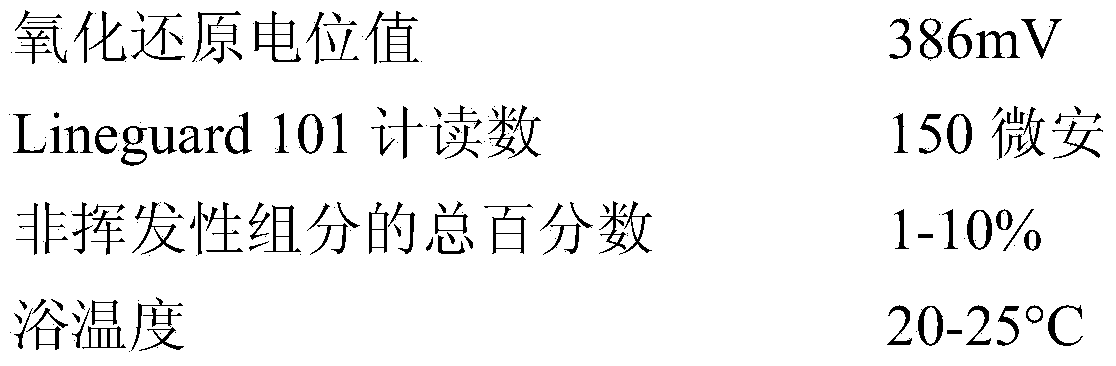

Single bath autodeposition coating for combination metal substrates and methods therefor

This invention relates to an autodeposition bath composition comprising a nitrogen containing compound, said bath being suitable for generating a uniform autodeposition coating on two or more of ferrous, aluminum, magnesium and zinciferous multi-metal substrate surfaces, treated either sequentially or simultaneously. The invention also provides autodeposition concentrate compositions for use in the bath, methods of making and using the concentrate and bath, as well as metal articles comprising an autodeposition coating according to the invention.

Owner:HENKEL KGAA

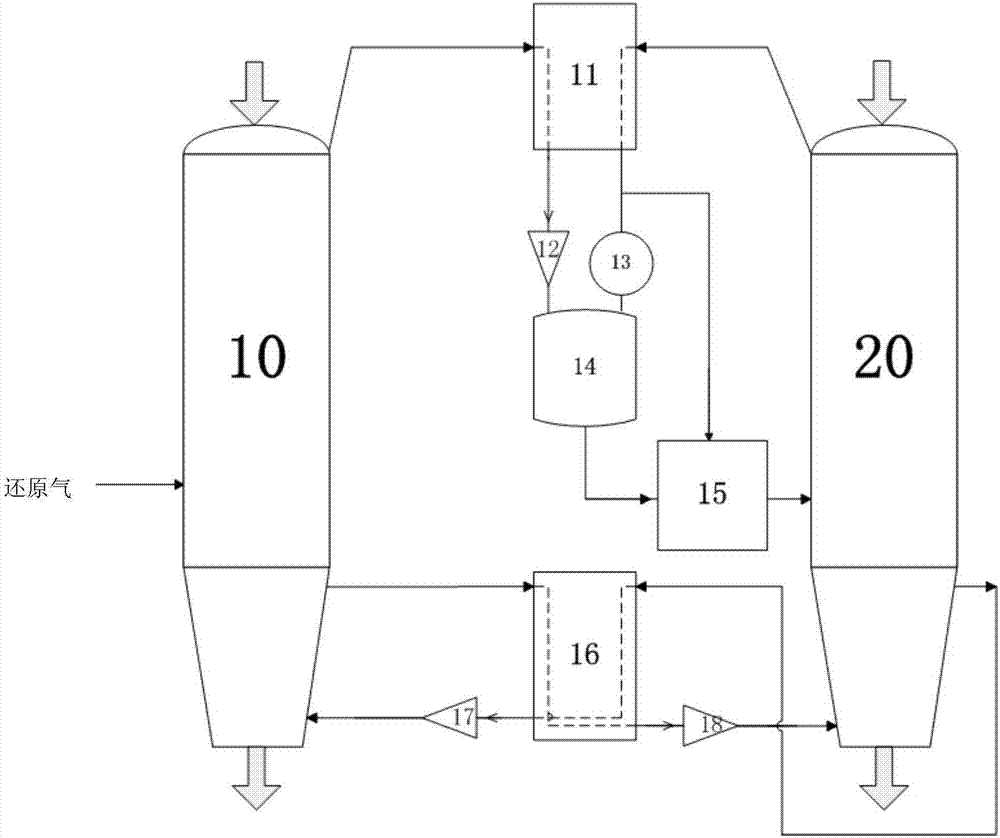

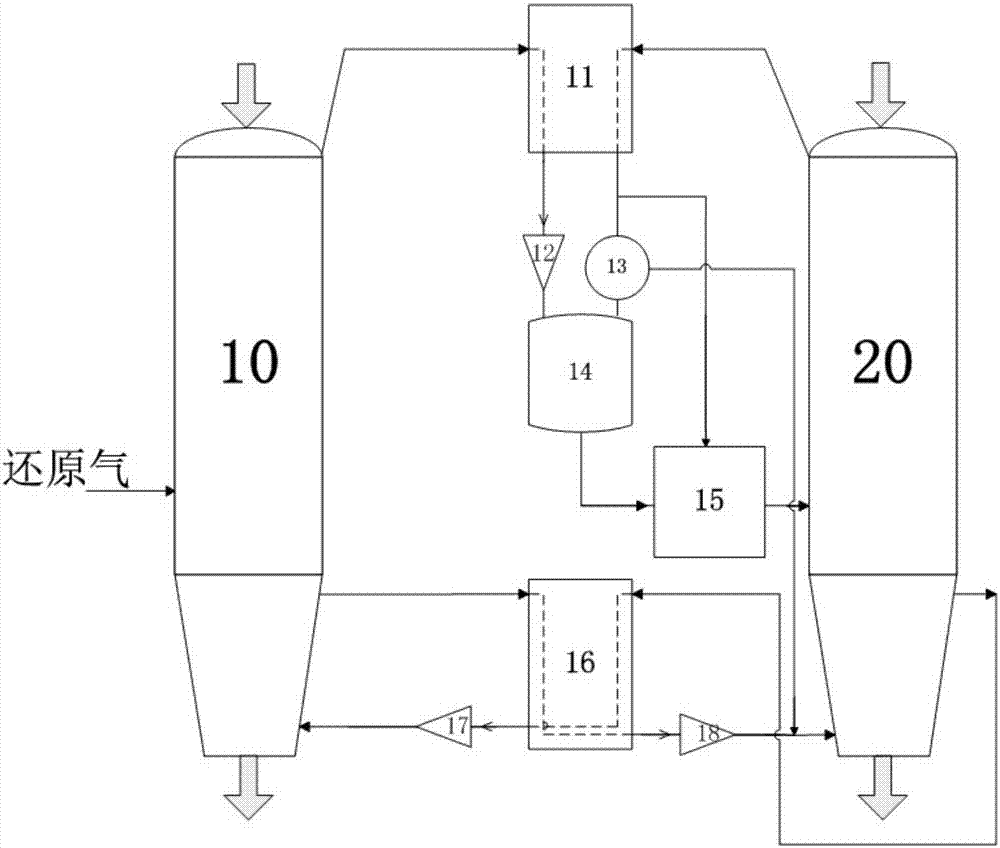

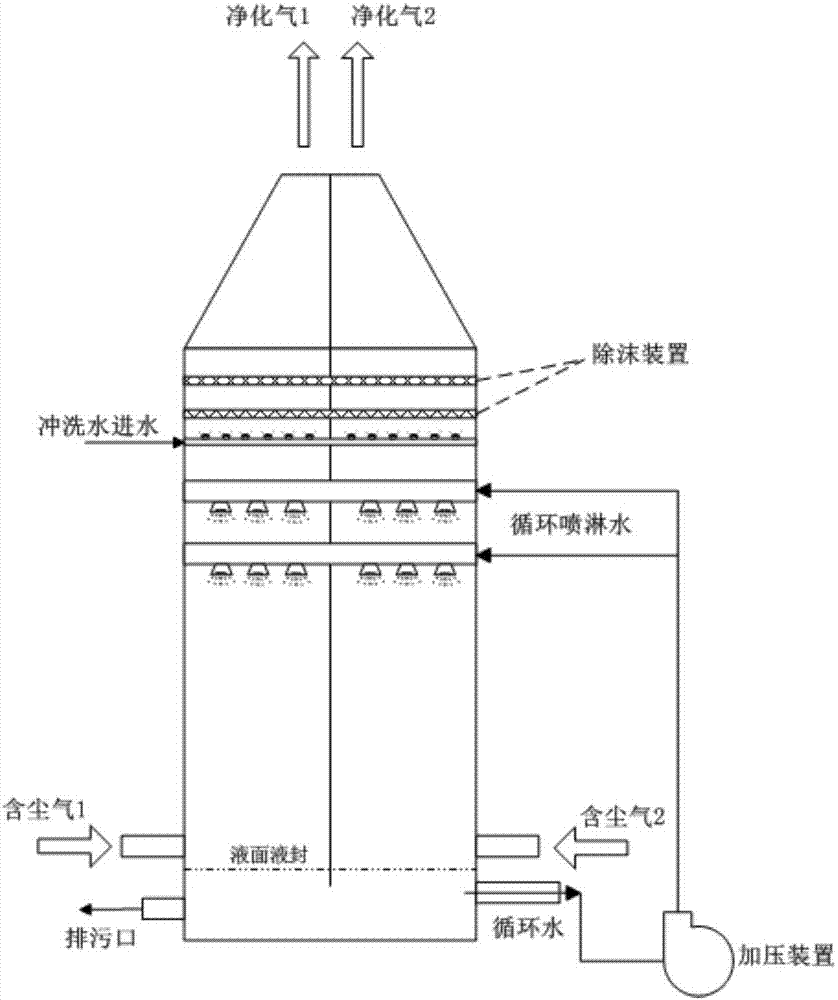

Double-shaft-furnace joint production system and method for treating two paths of gas with single bath towers

PendingCN107513597AImplement Gradients usingIncrease profitShaft furnaceGas emission reductionTitaniumEngineering

The invention discloses a double-shaft-furnace joint production system for treating two paths of gas with single bath towers. The system comprises a first shaft furnace, the top gas bath tower, a first pressure reducing device, a CO2 remover, a mixing tank, a heating furnace, a second shaft furnace, the cooling gas bath tower, a second pressure reducing device, a pressure boosting device and connecting pipelines between all the parts. Meanwhile, the invention discloses a method for joint production of iron-containing products with the system. According to the double-shaft-furnace joint production system, the sefstromite shaft furnace and the iron ore concentrate shaft furnace are coupled, the pressure difference of the two shaft furnaces and the H2 / CO ratio difference of two reducing gas ingredients are fully utilized in the production process, pressure and ingredient gradient utilization is realized, the utilization rate of resources and energy is increased, and vanadium-and-titanium-enriched sponge iron and sponge iron products are produced; and in addition, the same bath tower device is adopted according to the design of the two shaft furnaces, matched equipment investment is reduced while top gas and cooling gas are treated, and system equipment is effectively simplified.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

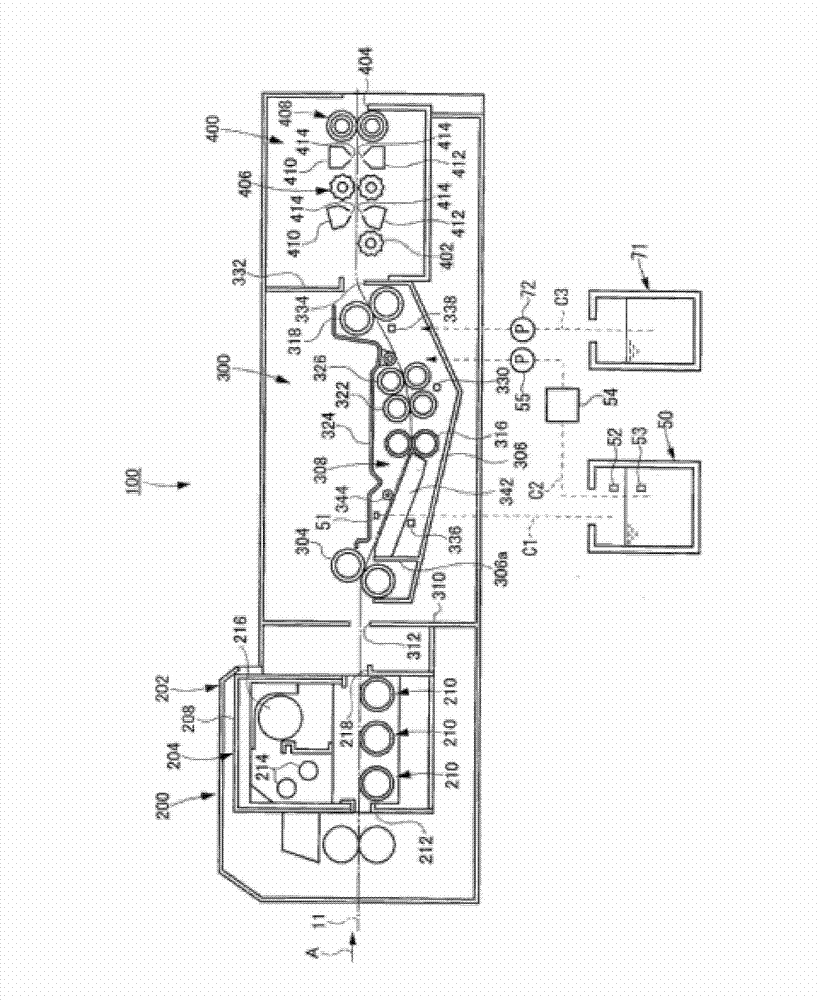

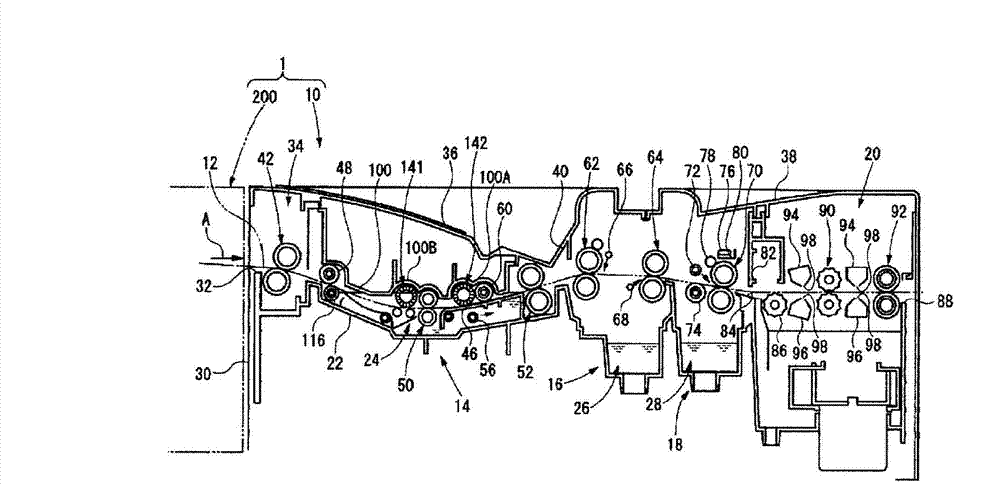

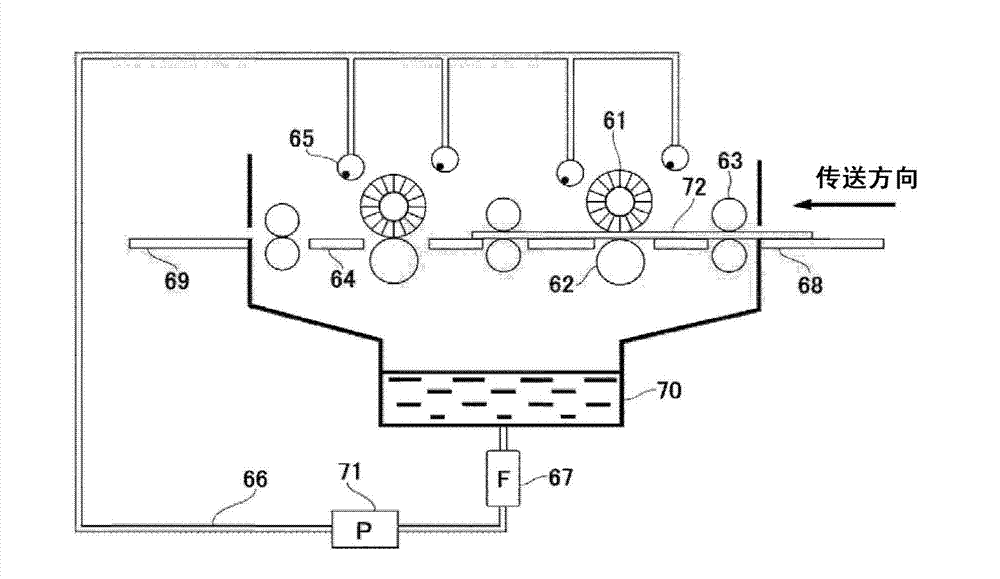

Method for manufacturing lithographic printing plates

ActiveCN103176352AIncreased durabilityImprove pollutionPhotosensitive material processingOrganic solventImage formation

Provides is a method for manufacturing lithographic printing plates with good print durability and print staining properties, in which the content of organic solvents with pH levels close to neutral is small, the quantity of chemicals employed is low, the quantity of waste solution generated is small, and processing can be conducted in a single bath. The method for manufacturing lithographic printing plates comprises (A) exposing to a negative-type lithographic printing plate precursor comprising an image-forming layer that is curable by exposure to light on a support having a hydrophilic surface; (B) developing with a developer having a pH of 4 to 10 the negative-type lithographic printing plate precursor that has been exposed; (C) treating with a burning surface-treatment liquid the negative-type lithographic printing plate precursor that has been developed; and (D) subjecting the negative-type lithographic printing plate precursor to a burning treatment; and by an interval between the developing (B) and the treating with a burning surface-treatment liquid (C) of from 1 minute or more to 10 hours or less, during which time no water-washing or gumming is incorporated.

Owner:FUJIFILM CORP

Preparation of cellulosic materials

InactiveCN1723272AReduce outflowHigh moisture absorptionPhysical treatmentNon-surface-active detergent compositionsFiberEnzyme system

The present invention provides methods and compositions for desizing, scouring and bleaching of cellulosic materials, which are carried out by contacting the cellulosic materials simultaneously or sequentially in a single-bath process with an enzyme system and a bleaching system comprising hydrogen peroxide or at least one peroxy compound which generates hydrogen peroxide when dissolved in water, or combinations thereof, and at least one bleach activator.

Owner:NOVOZYMES NORTH AMERICA INC

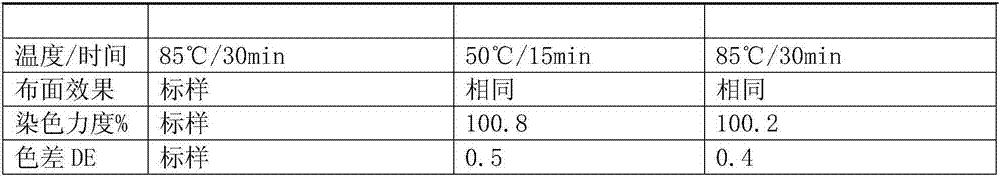

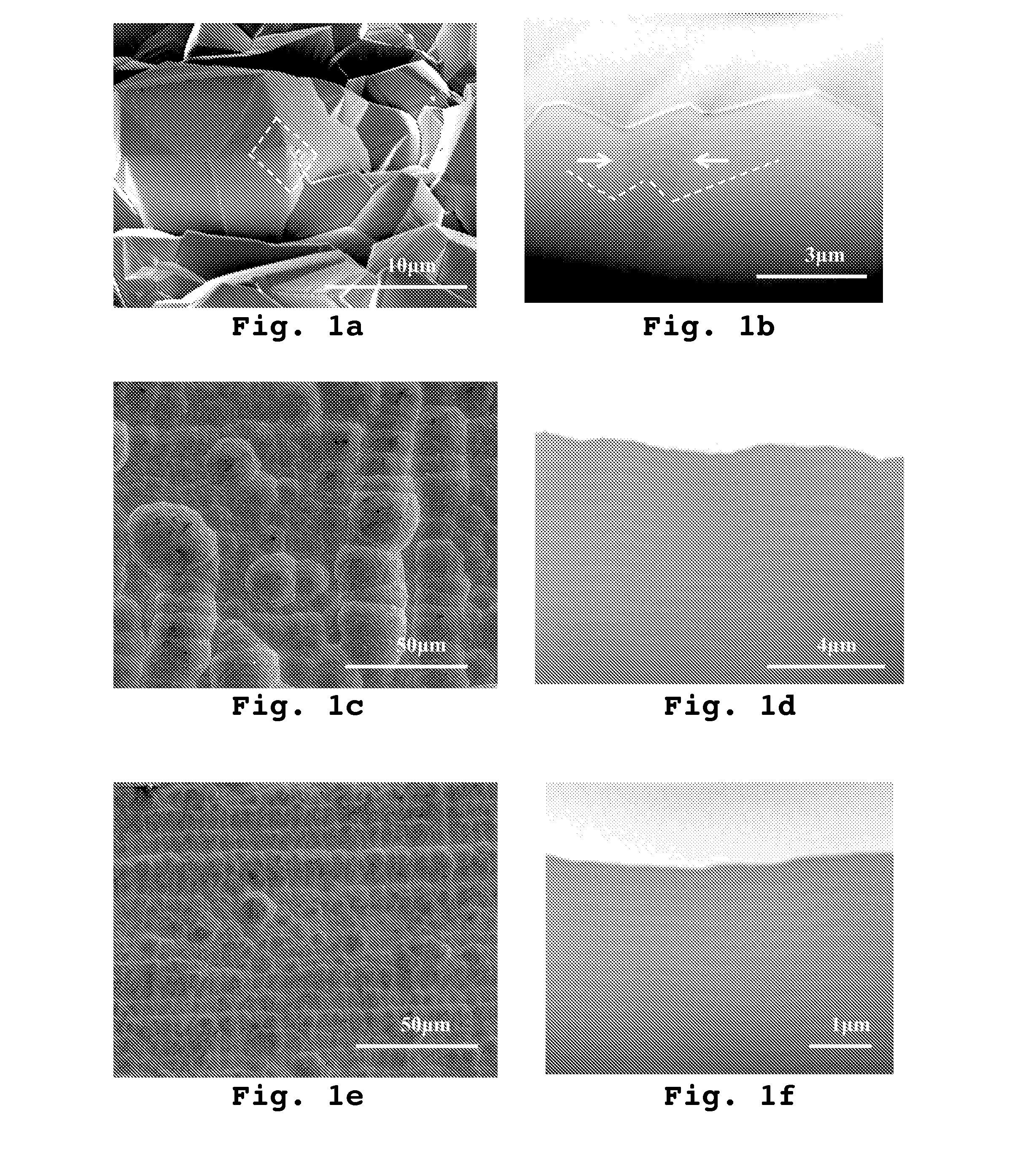

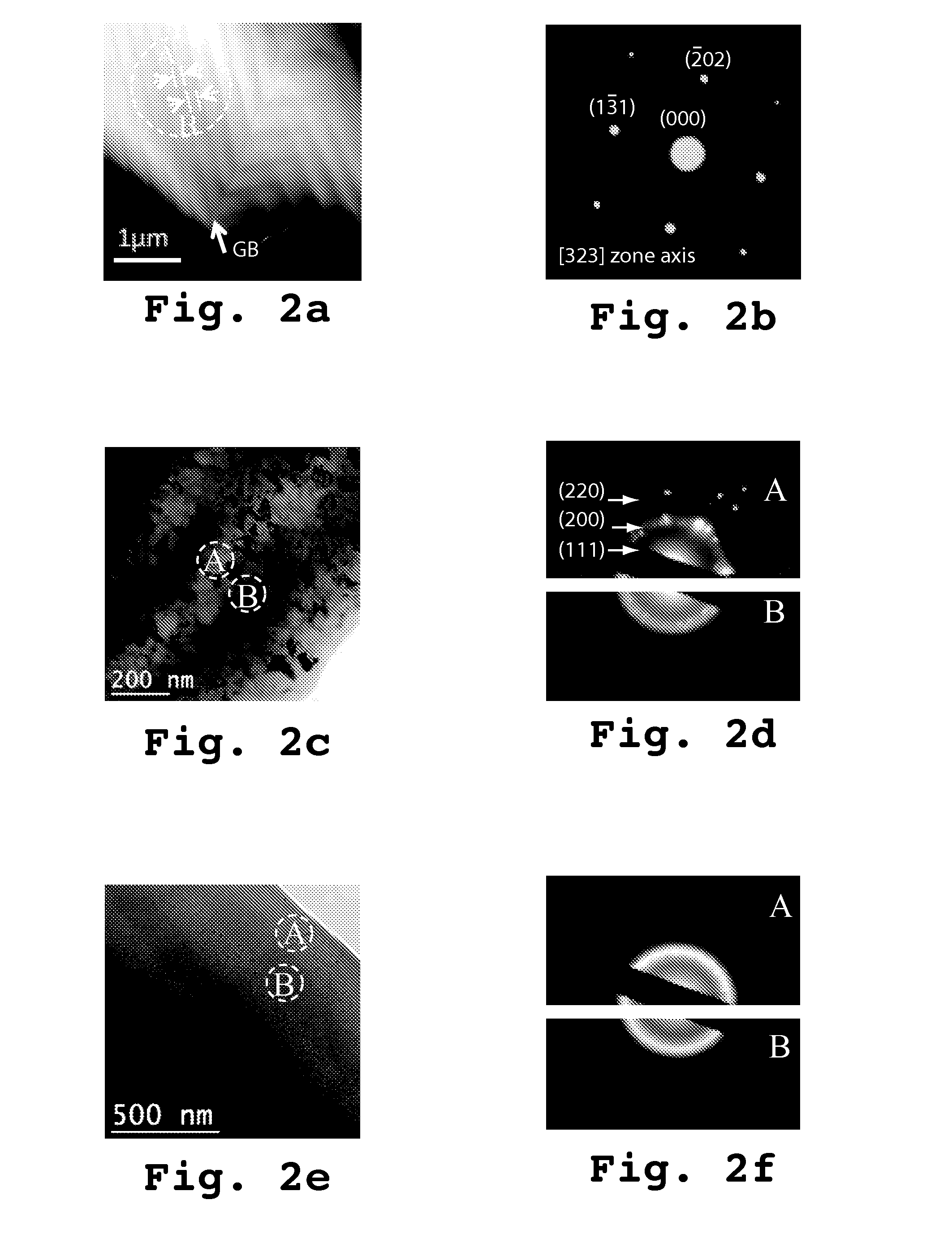

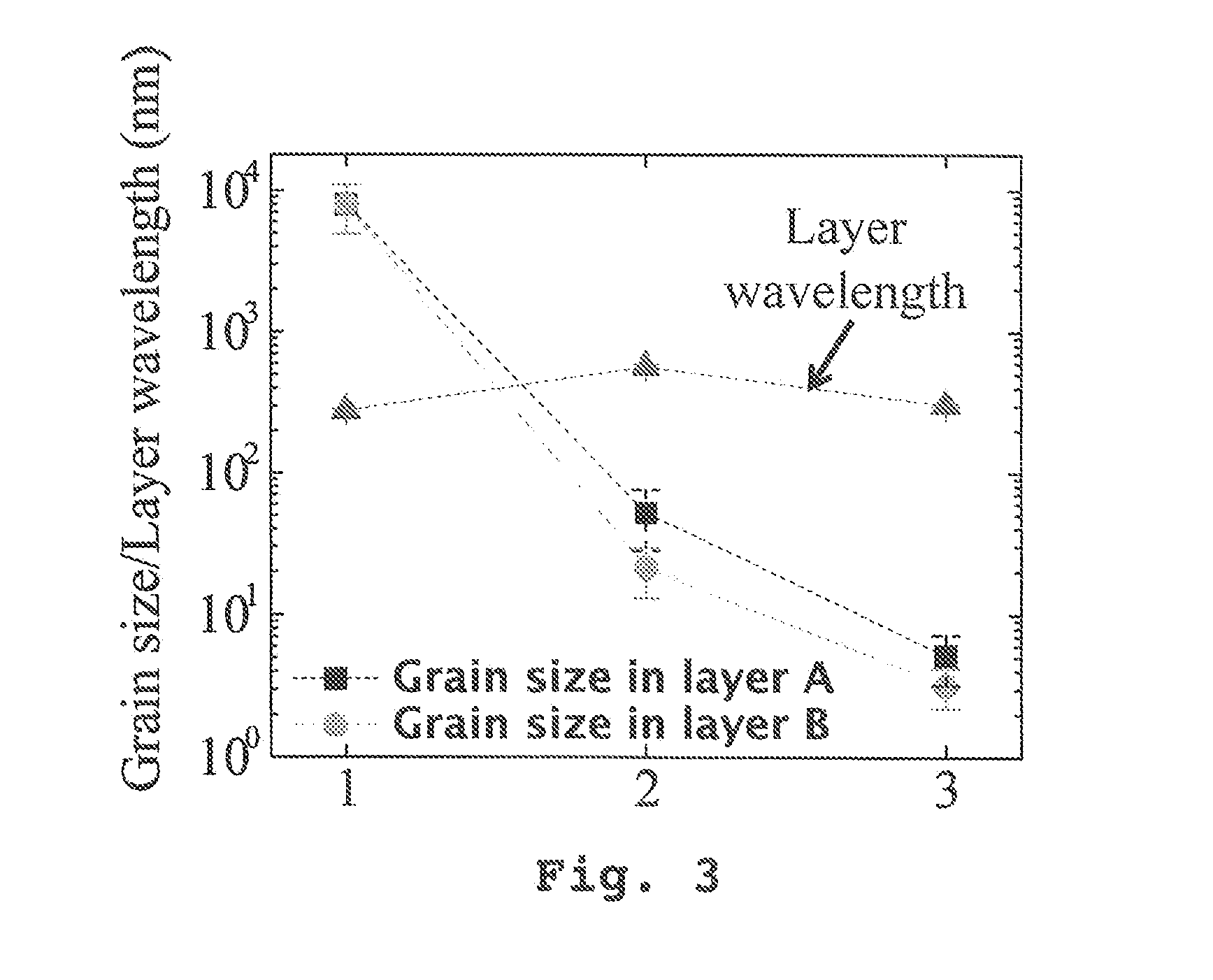

TUNING NANO-SCALE GRAIN SIZE DISTRIBUTION IN MULTILAYERED ALLOYS ELECTRODEPOSITED USING IONIC SOLUTIONS, INCLUDING Al-Mn AND SIMILAR ALLOYS

Al—Mnx / Al—Mny multilayers with a wide range of structures ranging from microcrystalline to nanocrystalline and amorphous were electrodeposited using a single bath method under galvanostatic control from room temperature ionic liquid. By varying the Mn composition by −1-3 at. % between layers, the grain sizes in one material can be systematically modulated between two values. For example, one specimen alternates between grain sizes of about 21 and 52 nm, in an alloy of average composition of 10.3 at. % Mn. Nanoindentation testing revealed multilayers with finer grains and higher Mn content exhibited better resistance to plastic deformation. Other alloy systems also are expected to be electrodeposited under similar circumstances.

Owner:MASSACHUSETTS INST OF TECH

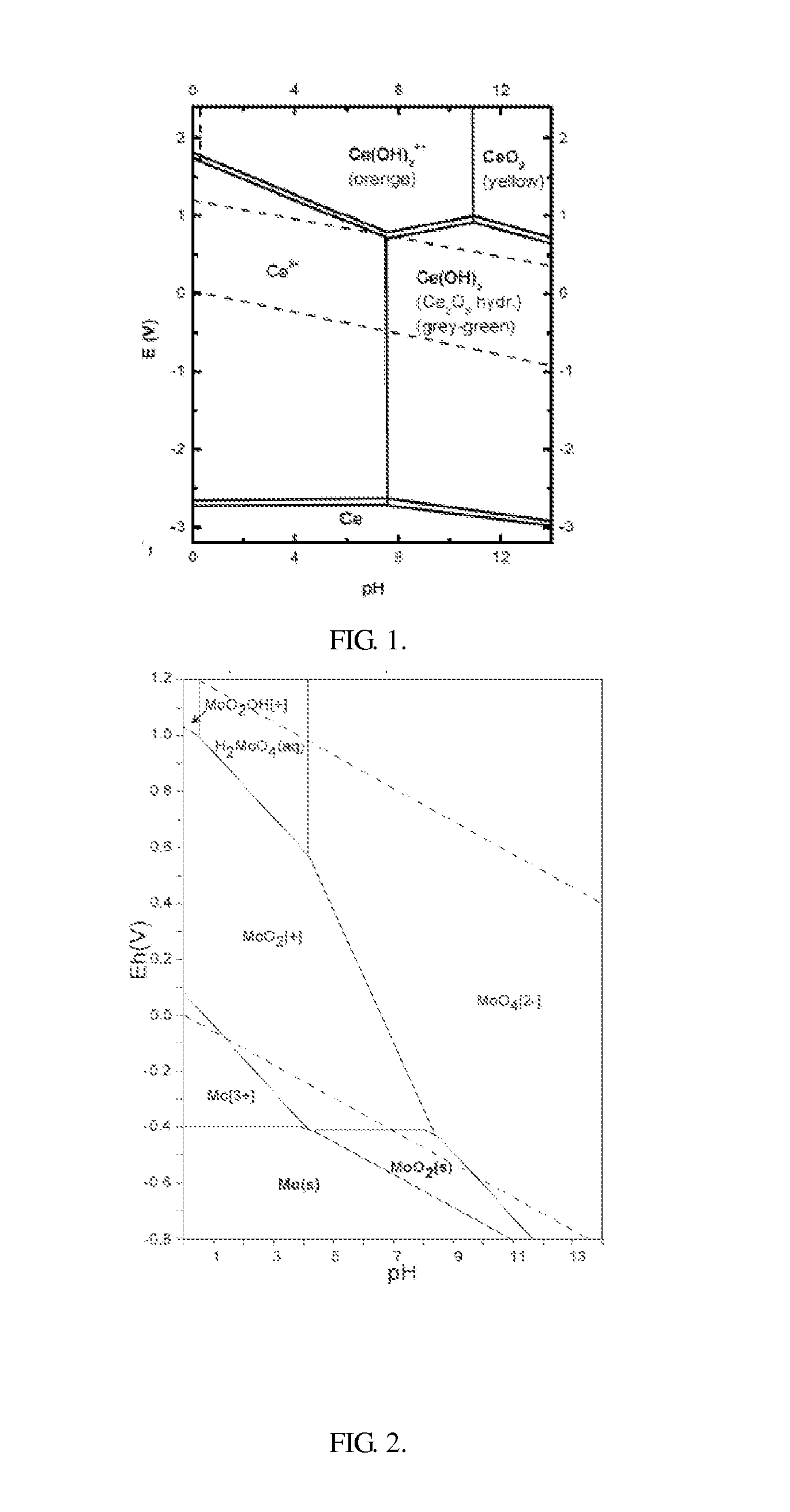

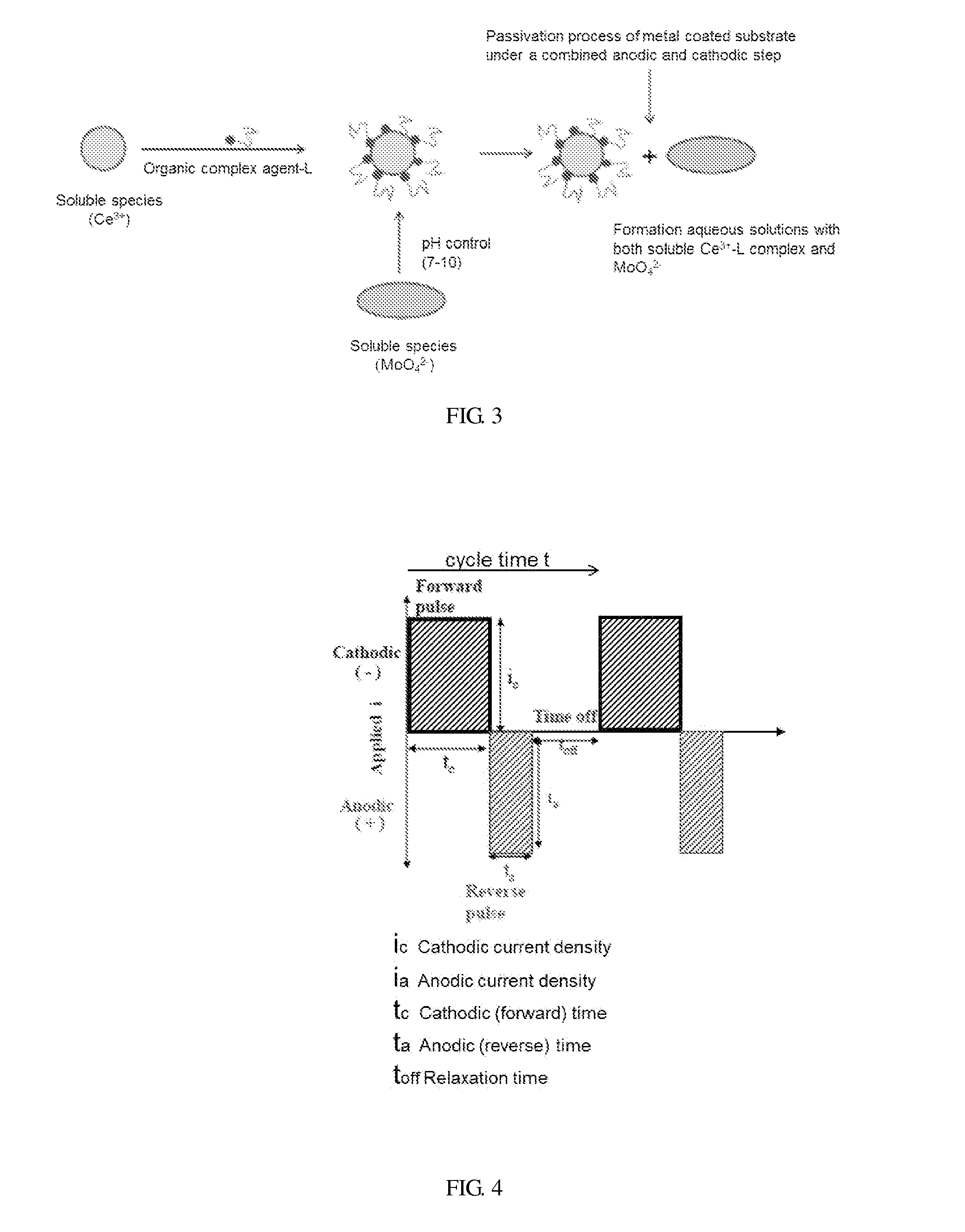

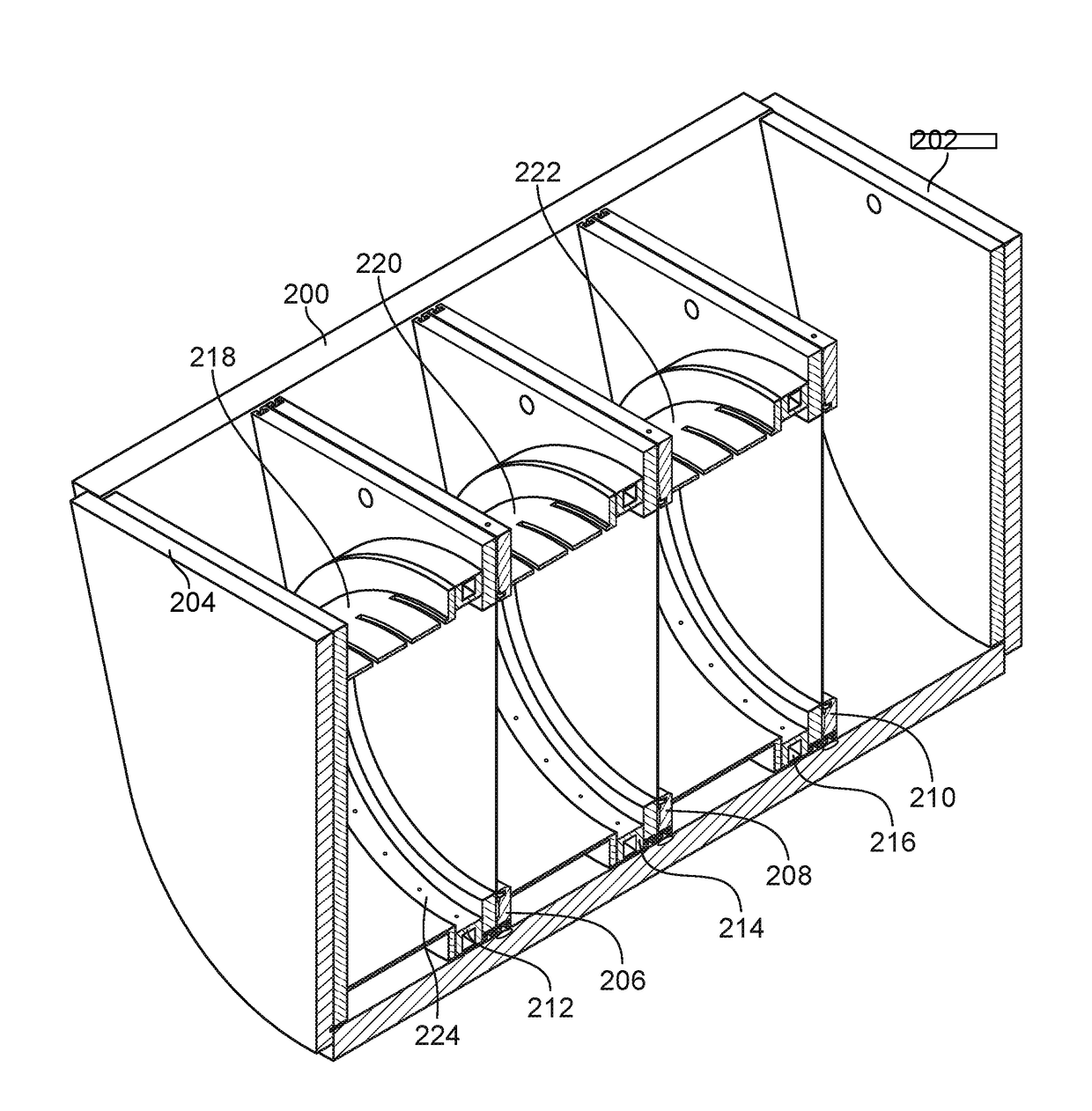

Methods for passivating a metal substrate and related coated metal substrates

Disclosed are methods for passivating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods comprise the steps of autodepositing copper, silver, a IIIB metal and / or IVB metal onto at least a portion of the substrate, and simultaneously and / or immediately subsequently electrophoretically depositing on the substrate a curable, electrodepositable coating composition; wherein the copper, silver, IIB metal and / or IVB metal and the curable, electrodepositable coating composition are both contained within a single bath composition. The present invention also relates to coated substrates produced by the above methods.

Owner:PPG IND OHIO INC

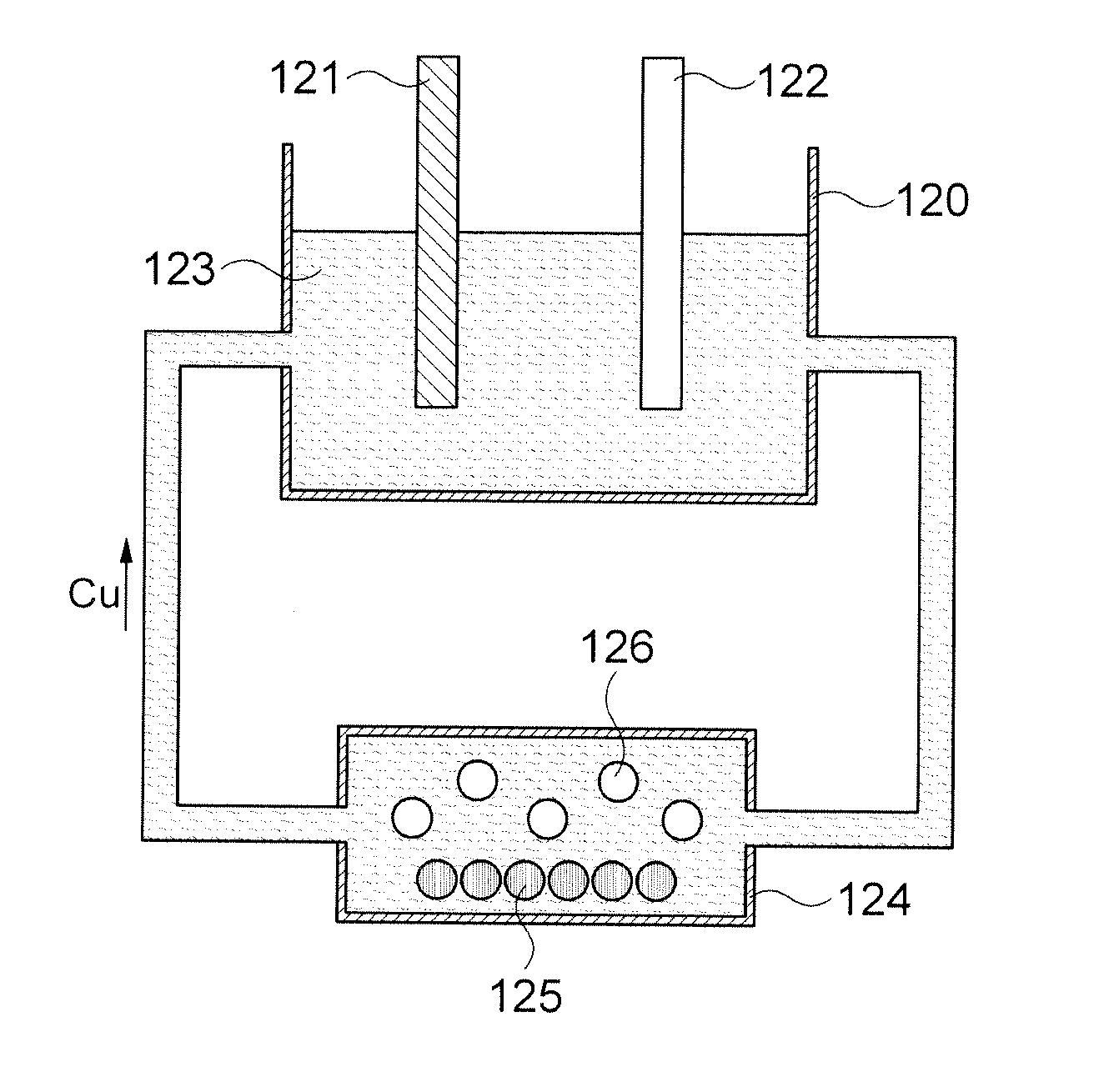

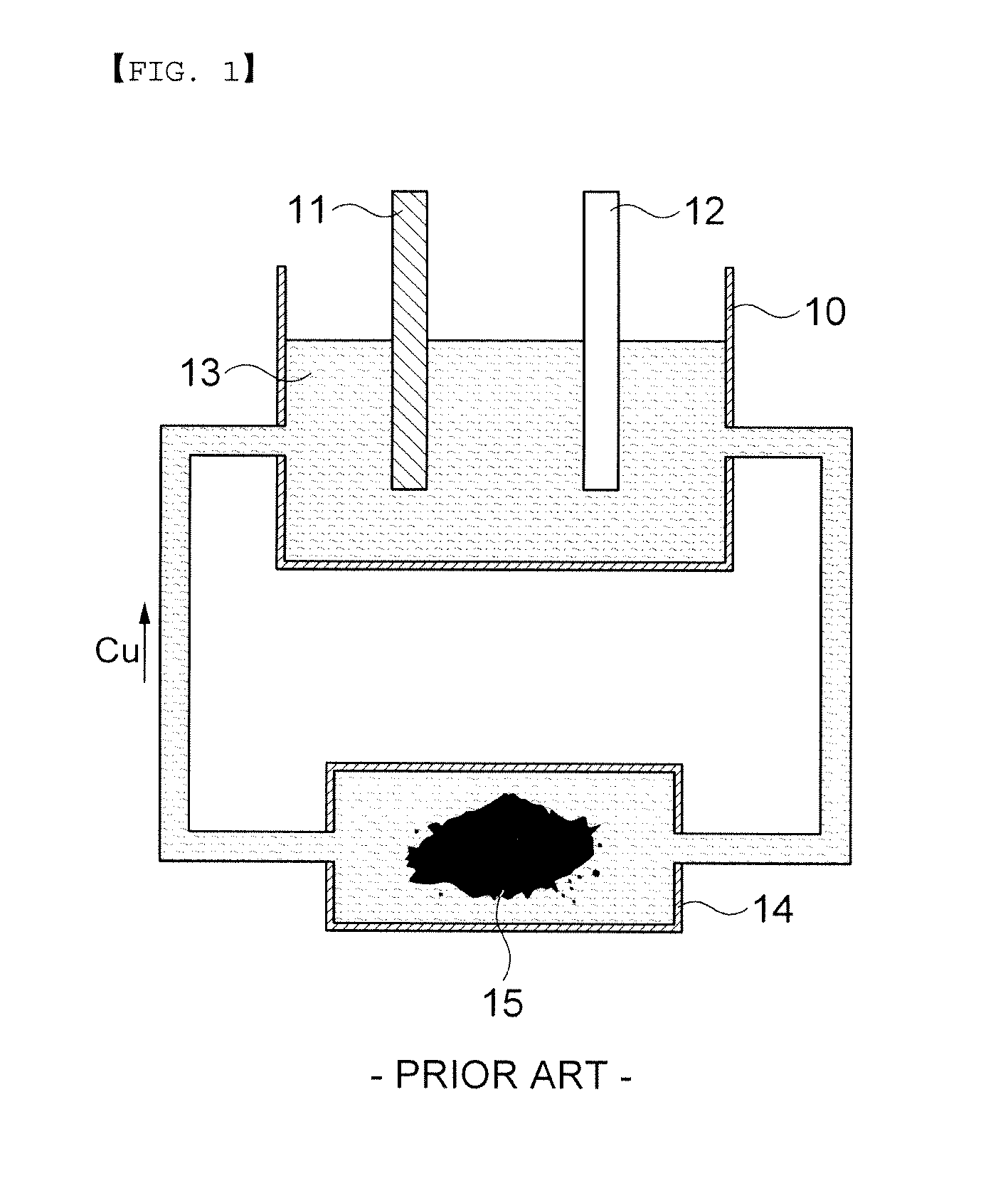

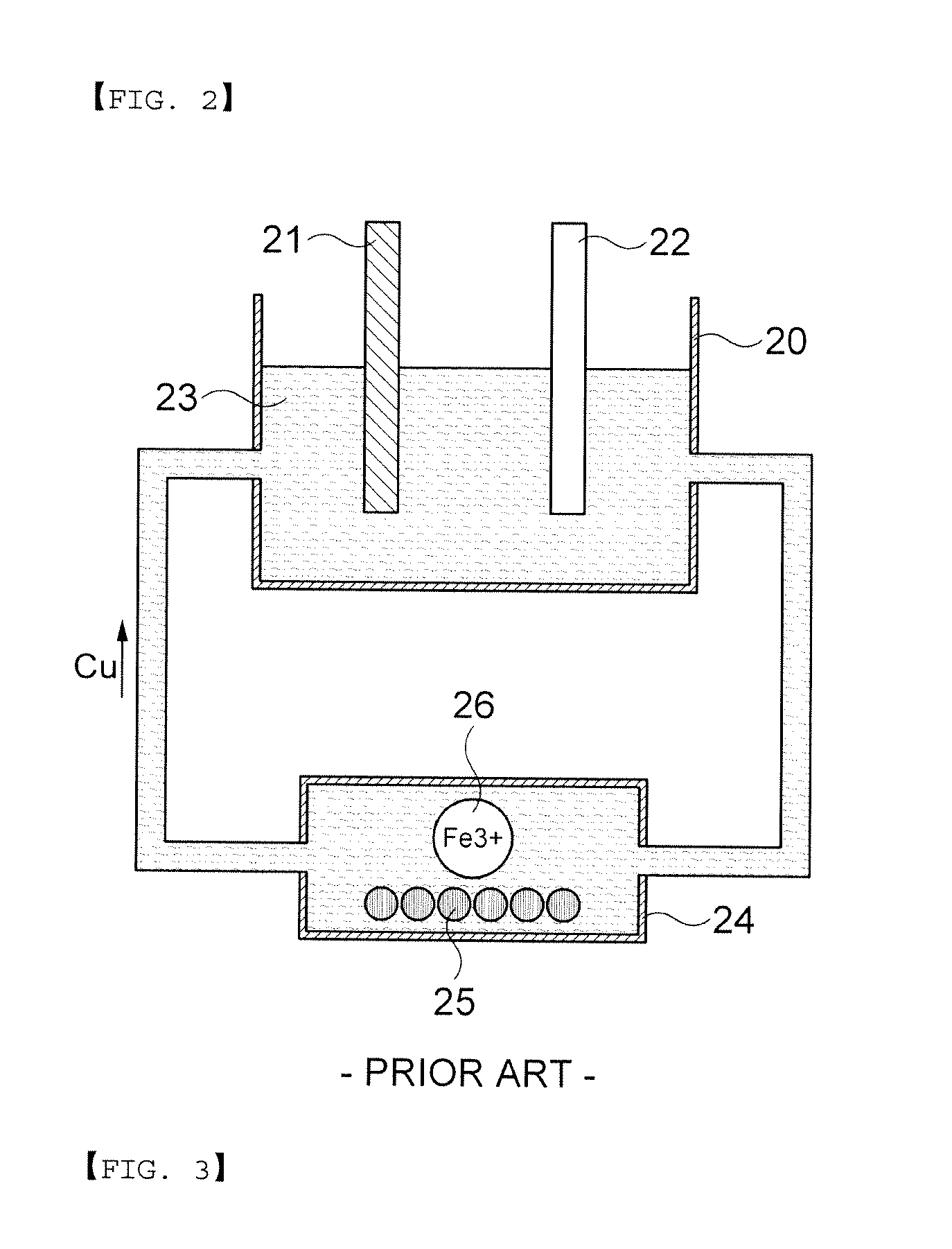

Electro-copper plating apparatus

Disclosed herein is an electro-copper plating apparatus in which a cathode, an insoluble anode, a copper ball, and a plating solution are included in a single bath, wherein the plating solution includes manganese oxide; or an electro-copper plating apparatus including: a main bath including a cathode, an insoluble anode, and a plating solution; and a dissolution bath including a copper ball, and manganese oxide. According to the present invention, the manganese oxide having higher oxidation-reduction potential instead of using Fe3+ of the related art as the copper source in the electro-copper plating apparatus may be used to obtain a high effect in suppressing surface plating even at a low concentration.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

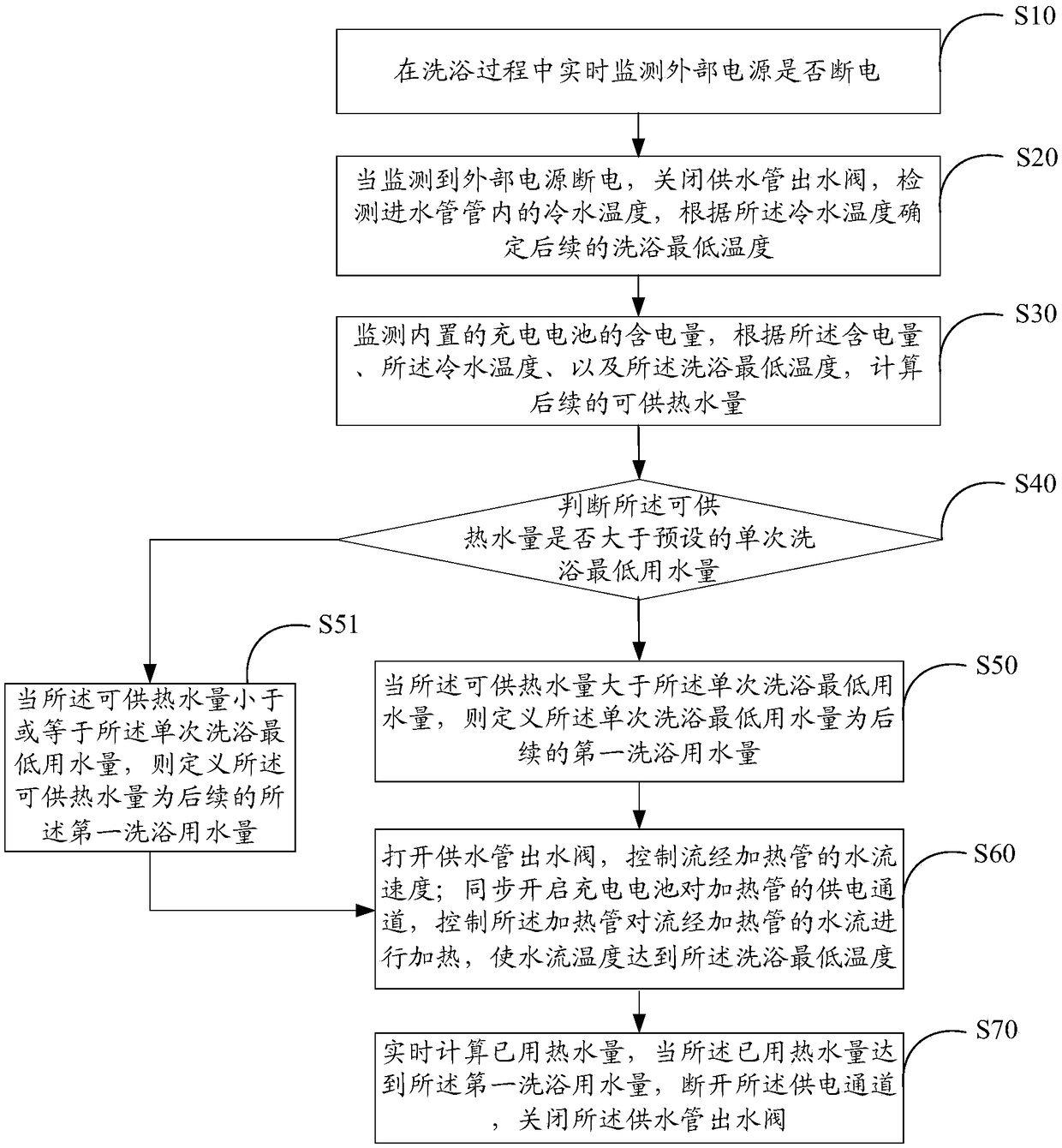

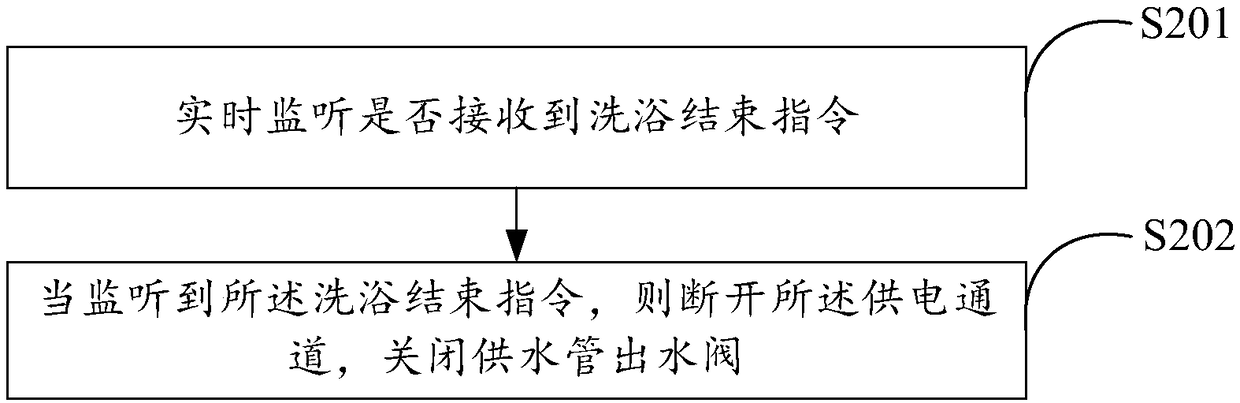

Control method of instant-heating electric water heater, electronic equipment and storage medium

The invention discloses a control method of an instant-heating electric water heater. The control method comprises the following steps that whether an external power supply is powered off in real timein a bathing process is monitored; when the external power supply is monitored, the water outlet valve of a water supply pipe is closed, the temperature of cold water is detected, and the lowest temperature of the subsequent bathing is determined; the electric quantity of a rechargeable battery is monitored, and the subsequent heat supply amount is calculated; whether the heat supply water quantity is larger than the preset single-time bath minimum water consumption is judged; if yes, the lowest water consumption of the single bath is defined as the follow-up first bathing water consumption;the water outlet valve of the water supply pipe is opened, and the water flow speed flowing through a heating pipe is controlled; the power supply channel of a charging battery to the heating pipe issynchronously started, and the heating pipe is controlled to heat the water flow, so that the water flow temperature reaches the bath lowest temperature; and the used hot water quantity is calculatedin real time, when the water consumption reaches the first bathing water consumption amount, the power supply channel is disconnected, and the water outlet valve of the water supply pipe is closed. According to the control method of the instant-heating electric water heater, the external power supply can supply hot water after being powered off, so that the bathing safety and the health of a userare ensured.

Owner:SHENZHEN SAIYI TECH DEV

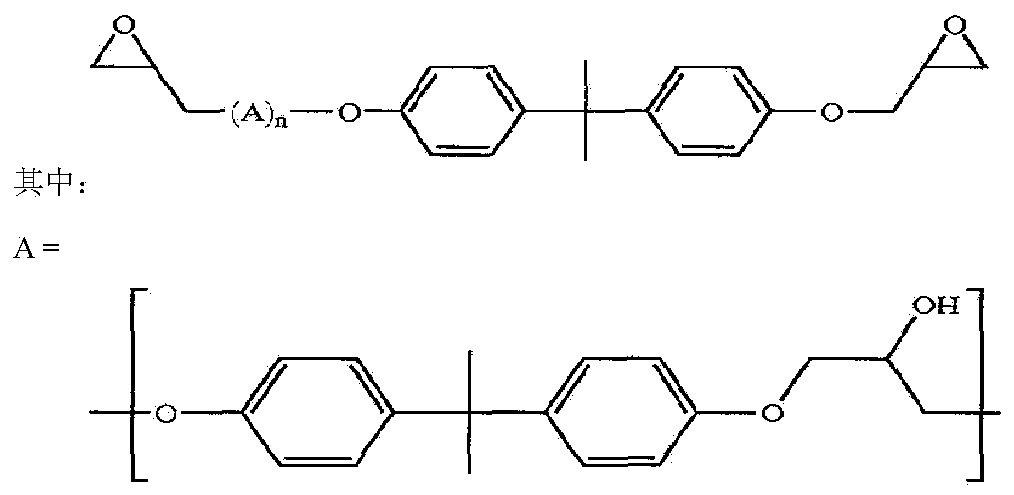

Dipping solution used for producing dipped polyester canvas by single bath method and preparation method thereof

The invention provides a dipping solution used for producing dipped polyester canvas by a single bath method and a preparation method thereof. The dipping solution comprises the following components in parts by mass: 140-170 parts of soft water, 10-12 parts of resorcinol, 13-15 parts of formaldehyde, 15-20 parts of p-chlorophenol, 250-350 parts of styrene-butadiene-vinylpyridine copolymer latex, 10-15 parts of ammonia water, 18-20 parts of an isocyanate solution, and 0.3-1 part of sodium hydroxide. The phenolic resin containing a p-chlorophenol solution is used to form tight chemical bond between the resin and the fabric produced by the fiber by dipping the polyester fiber fabric and drying at a high temperature, the chemical bonding strength of a polyester fiber-based skeleton material isenhanced, the strength of the polyester fiber is improved, and the preparation method is provided, the preparation efficiency of the dipping solution is increased, and the quality of the dipping solution is improved.

Owner:WUHU SHZ IND FABRIC

Method for dyeing a nonwoven fabric and apparel formed therefrom

A method is provided for dyeing a nonwoven fabric comprising a blend of fibers to a single color shade. The method includes selecting a nonwoven fabric formed of a blend of polyester and nylon fibers, where the polyester fibers comprise about X percent by weight of the fabric and the nylon fibers comprise about Y percent by weight of the fabric. A single bath is formulated having about X percent by weight disperse dye and about Y percent by weight acid dye, adjusted for the desired color shade / depth. The nonwoven fabric is then dyed to obtain a dyed fabric having a single color shade of at least Grade 4 when measured in accordance with AATCC Test Method 153 and a colorfastness of at least Grade 4 when measured in accordance with AATCC Test Method 61.

Owner:HBI BRANDED APPAREL ENTERPRISES

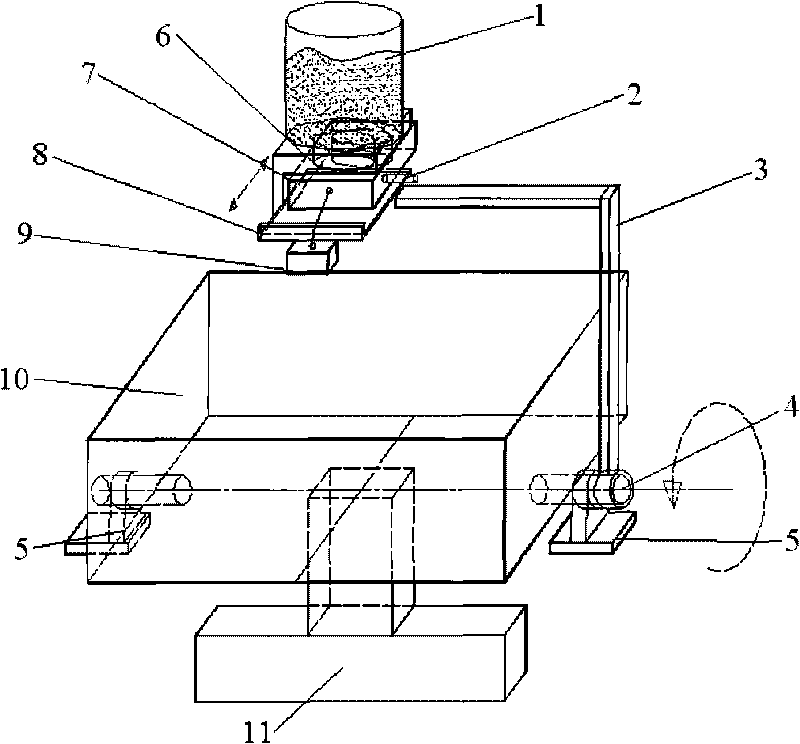

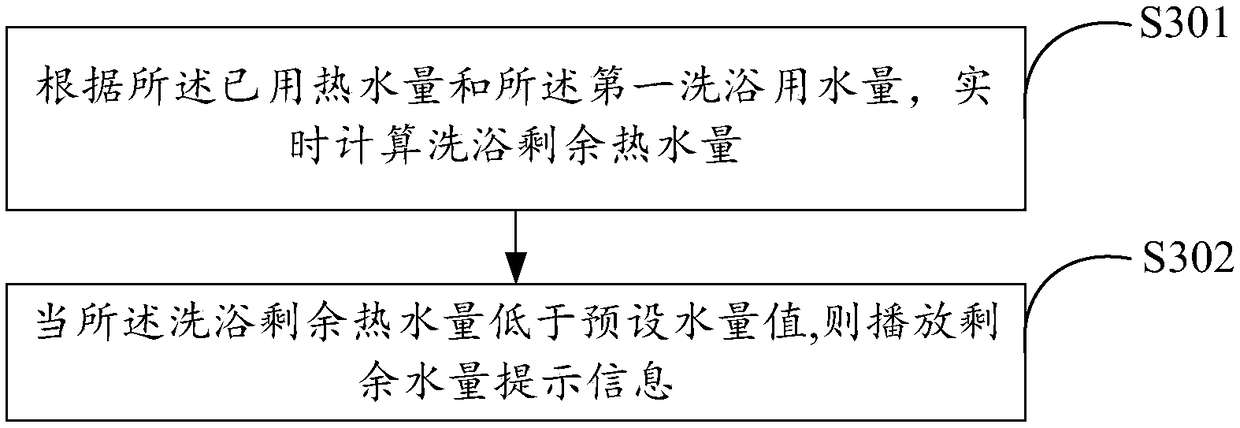

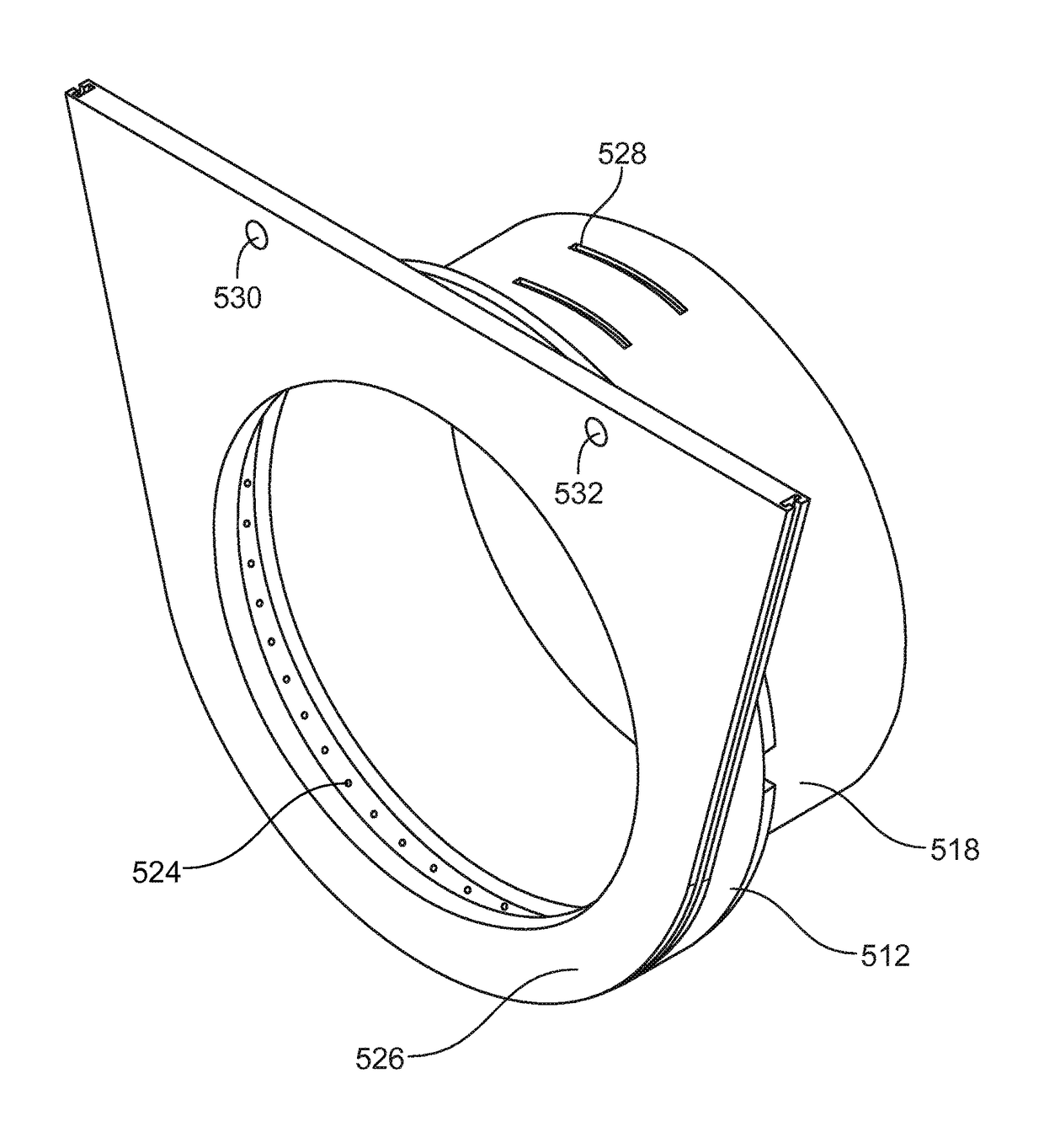

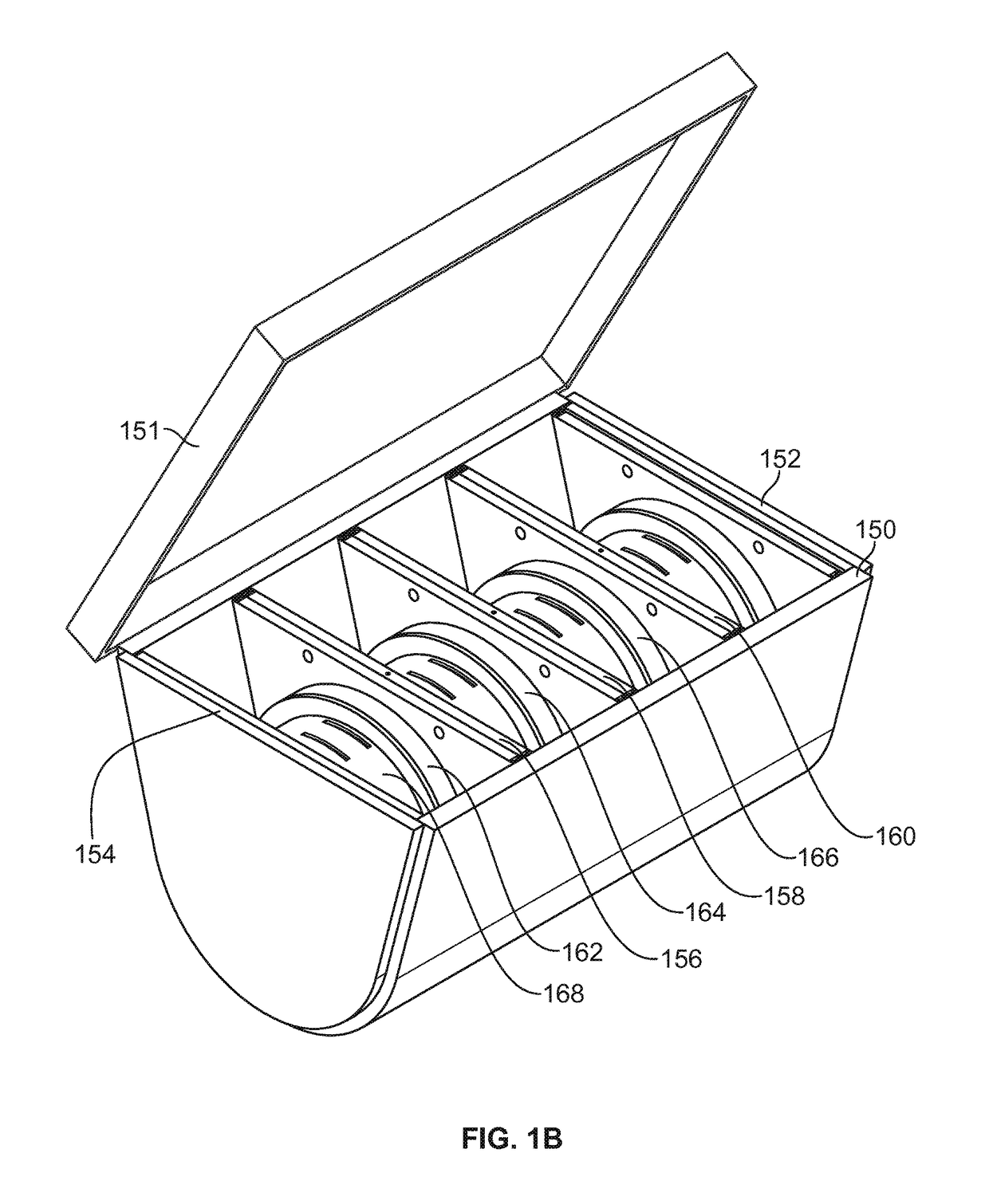

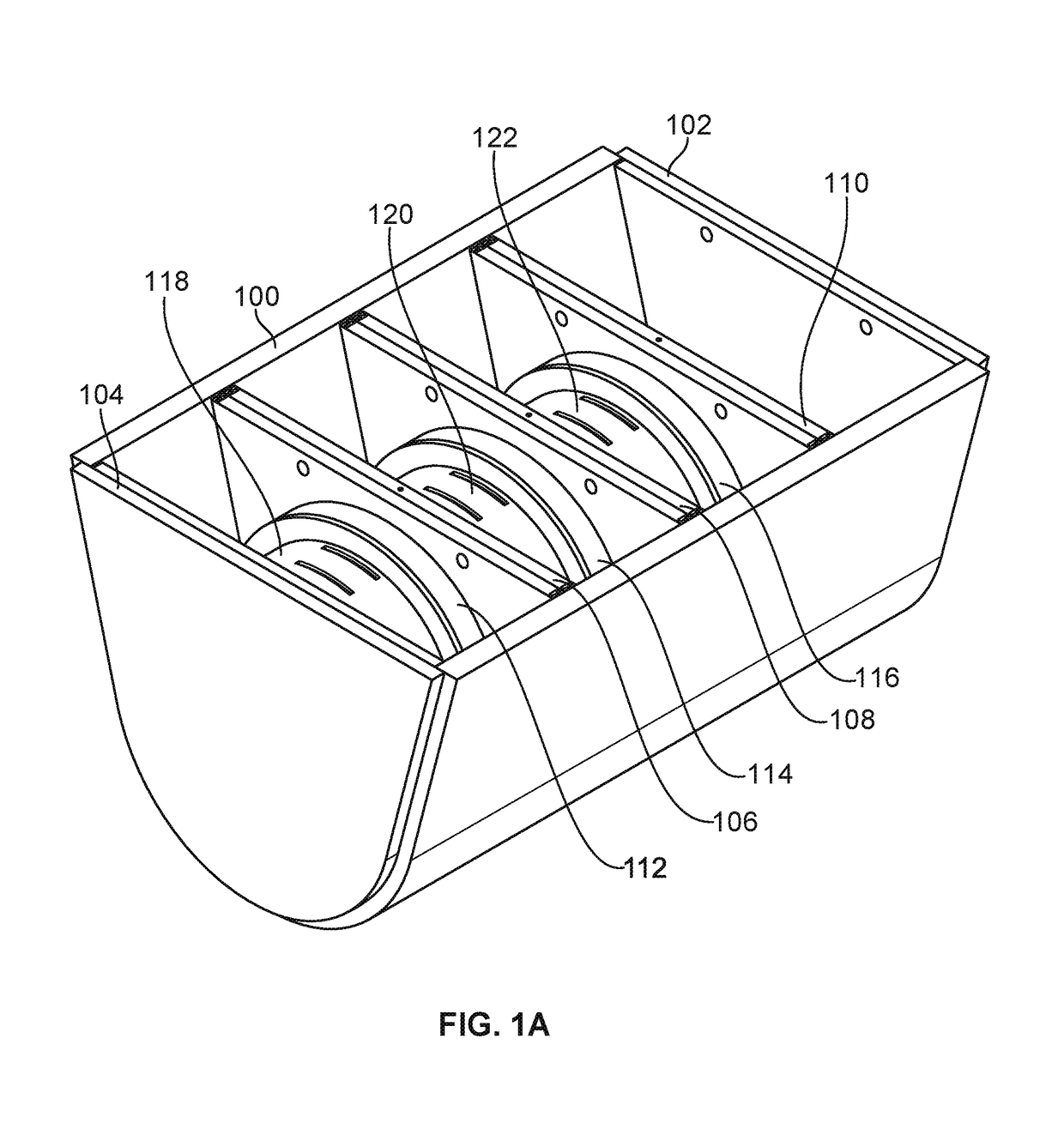

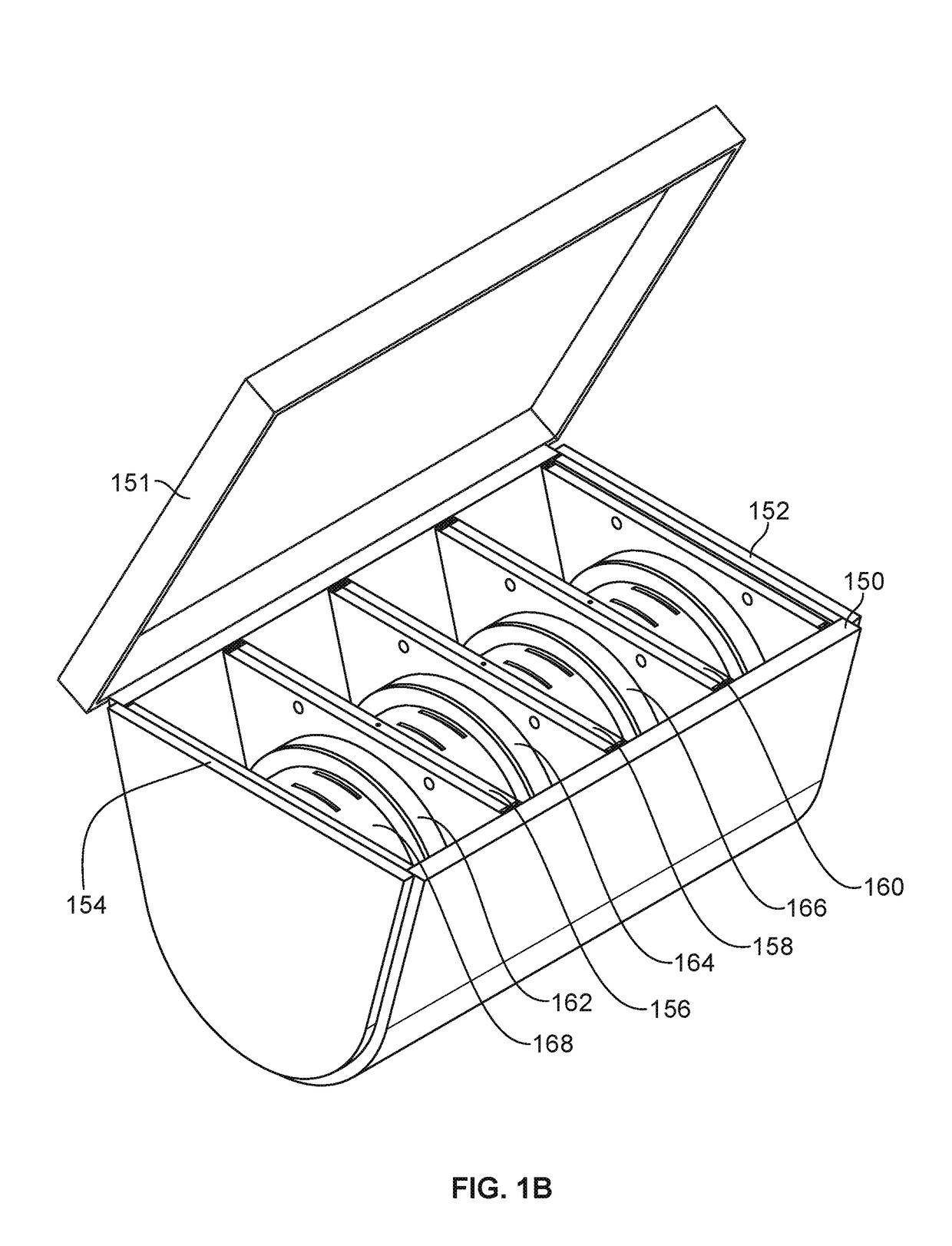

Multiple wafer single bath etcher

An etcher comprises a bath, a plurality of blades, and a tunnel. The bath includes a first electrode at a first end and a second electrode at a second end. The plurality of blades is configured to fit in the bath. At least one blade of the plurality of blades holds a wafer. At least one tunnel is configured to fit between adjacent blades of the plurality of blades in the bath.

Owner:TRUTAG TECH

Moisture absorption and quick dry sportswear polyamide yarn-pure cotton yarn mixed fabric producing method

The invention discloses a moisture absorption and quick dry sportswear polyamide yarn-pure cotton yarn mixed fabric producing method. The method comprises a dyeing technology which comprises the steps of dye liquor dyeing, color fixing, washing, soap boiling, hot water washing, cold water washing and airing, wherein a fabric is wetted before dye liquor dyeing, and dye liquor adopted in the dye liquor dyeing process consists of neutral dye, reactive dye, a catalyst HR-1, a moisture absorption and quick dry agent HV, anhydrous sodium sulphate and water. The optimum dyeing of a single bath process and the single bath processing with the moisture absorption and quick dry finishing agent are realized through controlling technological conditions, so that the fabric has high soaping resistance and rub resistance, the dyeing time is greatly shortened, the yield increases, the energy consumption is reduced, and the production cost is lowered; moreover, the alkali content of sewage is reduced, so that the method is contributed to environmental protection and achieves the effects of energy conservation and emission reduction.

Owner:南通曙光染织有限公司

Solution composition and method for single-bath post treatment of substrate

ActiveUS20160002808A1Electrolytic inorganic material coatingDuplicating/marking methodsPolymerSolution composition

Disclosed is a solution composition which may be used for a single-bath electrochemical passivation and a method using the same. The solution composition includes a metal cation, a metal-oxide anion; and an organic ligand, and optionally includes a non-metallic oxide anion or a polymer. The solution composition may prevent undesired precipitation of metal oxides before performing passivation. In addition, the method of passivation using the solution composition in a single-bath use is also provided.

Owner:RTX CORP

Method for making high-imitation washed cotton bedding fabric

The invention discloses a method for making a high-imitation washed cotton bedding fabric. The method comprises the following steps: a, performing carbon sanding on a polyester tatting sanded cloth fabric of which the gram weight is 90-130g / m<2>; b, desizing, removing oil and dirt, and performing whitening single bath; c, performing heating treatment; d, performing cooling treatment; e, performing dehydration washing treatment; f, performing shaping treatment; g, performing magnetic bar printing; h, performing long loop steaming; I, performing continuous countercurrent water washing; j, performing high-temperature shaping at 190-200 DEG C; k, performing high-temperature cylinder shrinking in a cylinder; I, performing rope-like untwisting, spreading and dehydration; and m, loosening, shaping and drying. The high-imitation washed cotton bedding fabric produced by using the method has an old wrinkle feeling same as that of washed cotton, and is relatively gentle in gloss, soft in hand feeling and low in price; and compared with a conventional washed cotton production process, the method is simple in production procedure and relatively energy-saving and environmental-friendly.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

Single bath dipping solution for polyester dipped canvas for high temperature resistant conveyor belt and preparation method thereof

The invention relates to a single bath dipping solution for a polyester dipped canvas for a high temperature resistant conveyor belt and a preparation method thereof, and belongs to the technical field of composite materials in industrial fabrics. The dipping solution comprises carboxyl butadiene-acrylonitrile latex, acrylate, deionized water, and a RP adhesive, and is prepared by fully mixing andstirring the components mentioned above. A polyester dipped canvas, which is dipped in the dipping solution, is used to produce a conveyor belt; at a high temperature, the dipping solution can guarantee the bonding force between the dipped canvas and ethylene propylene rubber; at the same time, the aminolysis speed of the main enhancing material namely polyester fibers of the dipped canvas is largely reduced; and thus the service life is extended and safety coefficient of the heatproof conveyor belt is improved.

Owner:无锡宝强工业织造有限公司

Multiple wafer single bath etcher

An etcher comprises a bath, a plurality of blades, and a tunnel. The bath includes a first electrode at a first end and a second electrode at a second end. The plurality of blades is configured to fit in the bath. At least one blade of the plurality of blades holds a wafer. At least one tunnel is configured to fit between adjacent blades of the plurality of blades in the bath.

Owner:TRUTAG TECH

Single-bath dyeing and finishing process for blended knitting fabrics containing protein fibers

ActiveCN103122589BChange flatnessReduce consumptionAnimal materialDe-gumming silkColour fastnessElectricity

The invention discloses a dyeing and finishing technology, and in particular relates to a production technology for dyeing and finishing blended fabrics of protein fibers and plants. The invention aims at providing a single-bath dyeing and finishing process of the blended knitting fabrics containing the protein fibers, which is consistent in dye-uptake rate, good in evenness, and free of flower ash and dyeing effect, and can ensure the color fastness. According to the single-bath dyeing and finishing process of the blended knitting fabrics containing the protein fibers obtained by the invention, silk cotton is dyed by the method, so that the cotton is consistent with real silk in color and has comfortable sensation just as the real silk, and in addition, the cotton has the function of natural moisture absorption, so that the flower ash effect and the uneven phenomenon of a common dye method of the real silk and the cotton are changed; the defect of poor dyeing color fastness of an original process is improved; consumption of water, electricity and gas is greatly reduced; and the single-bath dyeing and finishing process plays roles in saving and reducing emission.

Owner:ZHEJIANG JIAMING DYEING & FINISHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com