Method for manufacturing lithographic printing plates

A technology of lithographic printing plate and original plate, which is applied in the direction of photographic plate-making process, instrument, optics, etc. on the pattern surface, and can solve the problems of pollution resistance degradation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 27 and comparative example 1 to 15

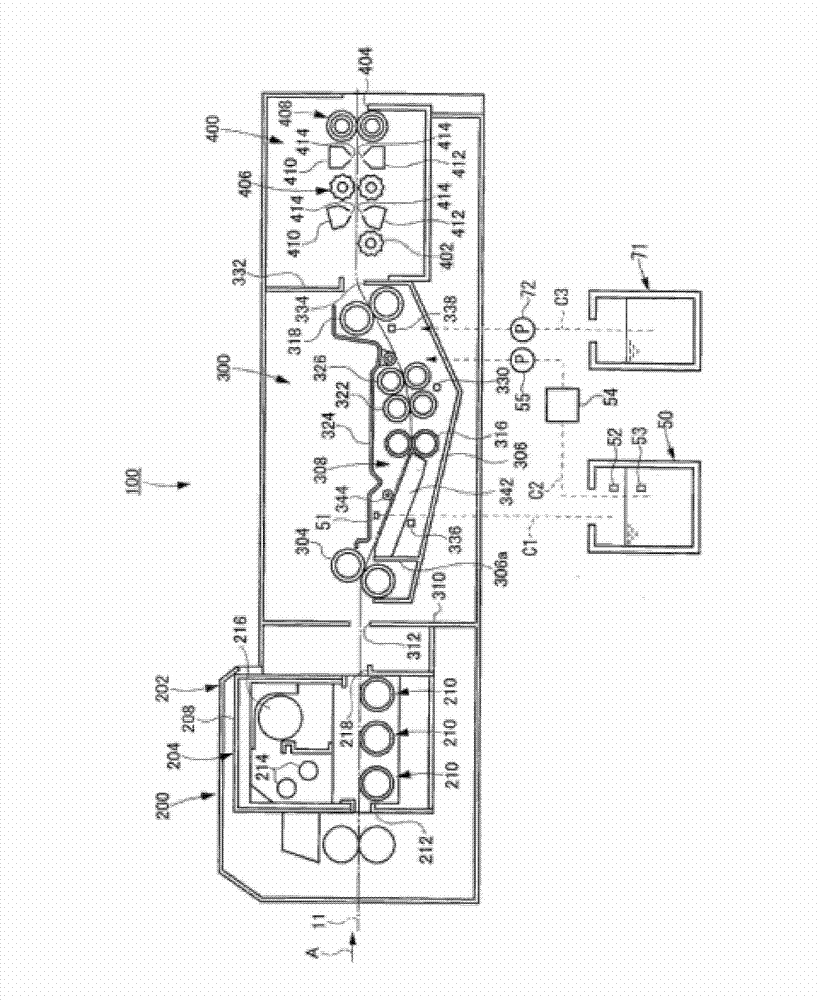

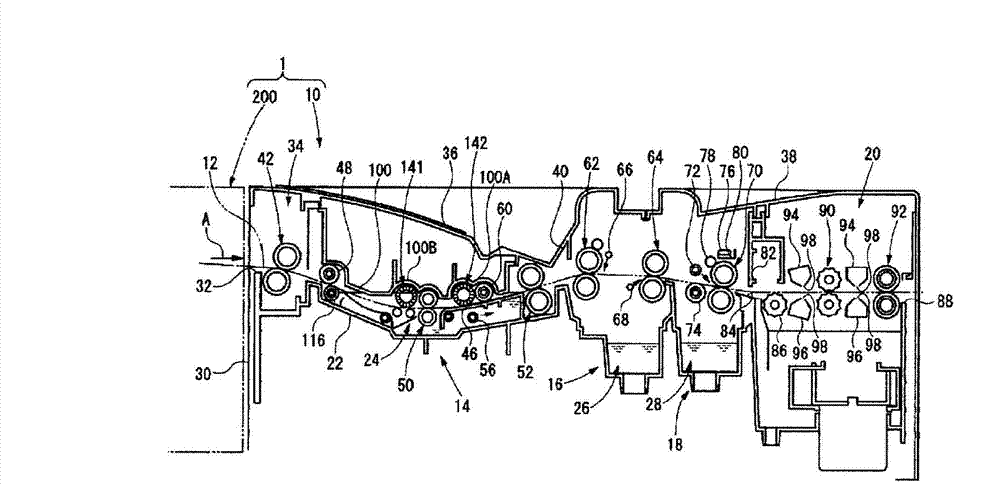

[0443] (Preparation of Lithographic Printing Plate Precursor (1))

[0444]

[0445] An aluminum sheet (material 1050, heat-refined H16) of 0.24 mm thickness was dipped in a 5% aqueous sodium hydroxide solution kept at 65° C., subjected to degreasing treatment for 1 minute, and washed with water. The degreased aluminum flakes were then dipped in 10% aqueous hydrochloric acid for one minute to neutralize them, and then washed with water. Next, the surface of the aluminum sheet is subjected to AC current at 25°C and 100A / dm 2 Electrolytic roughening was performed in a 0.3% by weight hydrochloric acid aqueous solution for 60 seconds under the condition of a current density of , and then a desmutting treatment was performed in a 5% sodium hydroxide aqueous solution maintained at 60° C. for 10 seconds. For decontamination and roughened aluminum sheet at 10A / dm 2 Anodization was performed in 15% sulfuric acid aqueous solution at 25° C. at a current density of 15 V, and then made ...

Embodiment 28 to 159 and comparative example 1 to 39

[0513] (Preparation of Lithographic Printing Plate Precursor (2))

[0514]

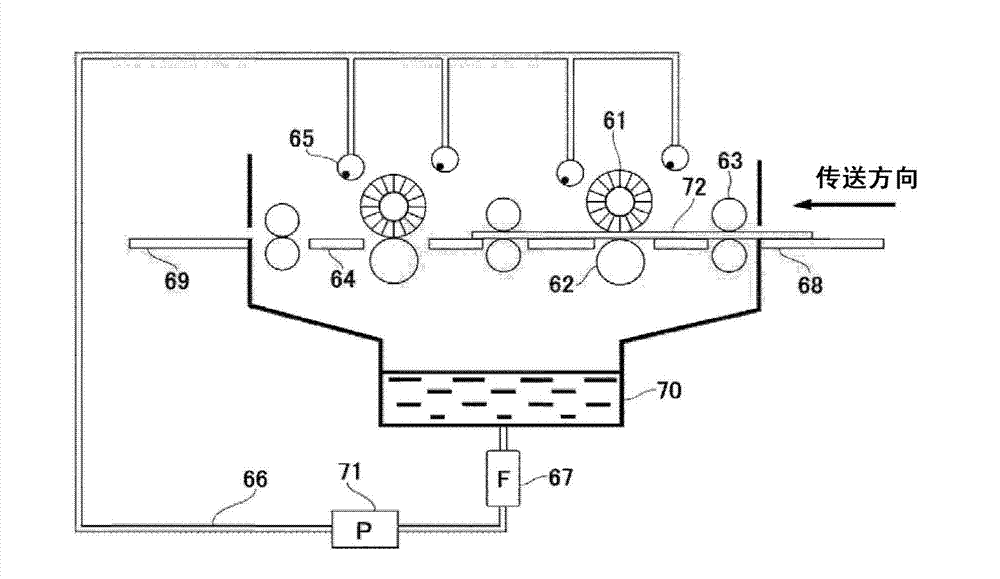

[0515] A degreasing treatment was performed at 50° C. for 30 seconds using a 10% by weight aqueous solution of sodium aluminate to remove rolling oil from the surface of an aluminum sheet (material JIS A 1050) having a thickness of 0.3 mm. Subsequently, three nylon brushes planted with bristle tufts with a diameter of 0.3 mm and a pumice stone with a median diameter of 25 μm (specific gravity: 1.1 g / cm 3 ) to grit the aluminum surface, after which it was thoroughly washed with water. Thereafter, the sheet was etched by immersing it in a 25% by weight aqueous sodium hydroxide solution at 45° C. for 9 seconds. After washing with water, the pieces were dipped in 20% by weight aqueous nitric acid solution for a further 20 seconds at 60° C. and washed with water. At this time, the etching degree of the grained surface is about 3g / m 2 .

[0516] Next, electrochemical surface roughening was performed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com