Novel dyeing process of polyester/cotton knitted fabric

A technology of knitted fabric and new technology, applied in the field of dyeing technology, can solve the problems of water consumption, high production cost, energy consumption, etc., achieve the effect of reducing pollution discharge, reducing the number of hot washing, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

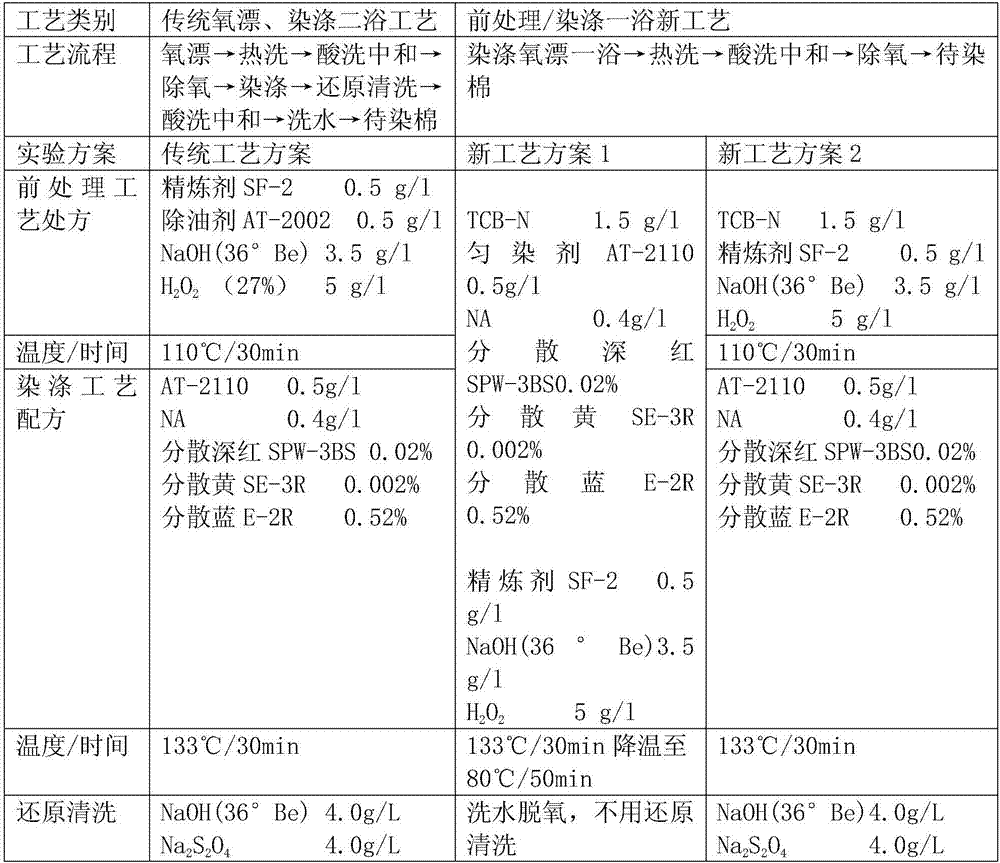

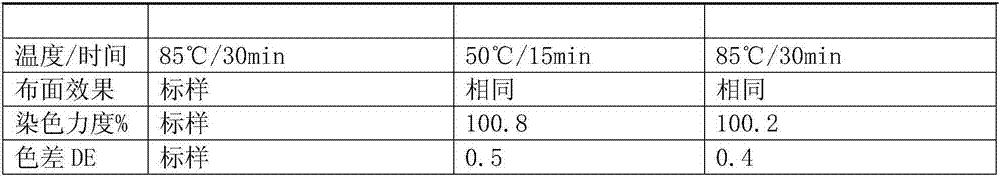

Method used

Image

Examples

Embodiment 1

[0027] A new dyeing process for polyester-cotton knitted fabrics, comprising the following steps:

[0028] Pretreatment / dyeing and washing in one bath→acid washing and neutralization→deoxidation→dyeing cotton→washing→acid neutralization→TCW cleaning→hot washing→washing→fixation

[0029] Specifically, the pretreatment / dyeing and washing one bath includes: adding water, raising the room temperature to 35°C, adding Acosel TCB-N and dyes, then raising the temperature to 125°C at 1.5°C / min, keeping it warm for 35 minutes, and then heating at 0.8°C / min min to 75°C, add liquid caustic soda and hydrogen peroxide, keep warm for 55 minutes, turn on the water, and then wash with clean water. Further, the dosage of Acces TCB-N is 1g / L, and the bath ratio of pretreatment / dyeing and washing is 1:4 , using the one-bath agent Yakesa TCB-N to combine the pretreatment with dyeing and washing, realizing one bath of oxygen bleaching, dyeing and washing from the process, no washing after dyeing an...

Embodiment 2

[0038] A new dyeing process for polyester-cotton knitted fabrics, comprising the following steps:

[0039] Pretreatment / dyeing and washing one bath→acid washing and neutralization→deoxidation→dyeing cotton→washing→peracid→TCW cleaning→hot washing→washing→fixation

[0040] Specifically, the pre-treatment / dyeing and washing one bath includes: adding water, raising the room temperature to 45°C, adding Acosel TCB-N and dyes, then raising the temperature to 135°C at 1°C / min, keeping it warm for 25 minutes, and then heating at 1.5°C / min min to 85°C, add liquid caustic soda and hydrogen peroxide, keep warm for 45 minutes, turn on the water, and then wash with clean water. Further, the dosage of Acces TCB-N is 2g / L, and the bath ratio of pretreatment / dyeing and washing is 1:6 , using the one-bath agent Yakesa TCB-N to combine the pretreatment with dyeing and washing, realizing one bath of oxygen bleaching, dyeing and washing from the process, no washing after dyeing and washing, and r...

Embodiment 3

[0049] A new dyeing process for polyester-cotton knitted fabrics, comprising the following steps:

[0050] Pretreatment / dyeing and washing one bath→acid washing and neutralization→deoxidation→dyeing cotton→washing→peracid→TCW cleaning→hot washing→washing→fixation

[0051] Specifically, the pretreatment / dyeing and washing one bath includes: adding water, raising the room temperature to 40°C, adding Acces TCB-N and dyes, then raising the temperature to 133°C at 1.2°C / min, keeping it warm for 30 minutes, and then increasing the temperature at 1°C / min min to 80°C, add liquid caustic soda and hydrogen peroxide, keep warm for 50 minutes, turn on the water, and then wash with clean water. Further, the dosage of Acces TCB-N is 1.5g / L, and the bath ratio of pretreatment / dyeing and washing is 1: 5. The one-bath agent Yakesai TCB-N is used to combine the pretreatment with dyeing and washing, which realizes one bath of oxygen bleaching, dyeing and washing in terms of technology, and does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com