Bath method of dyeing

A bath method and dyeing technology, which is applied in dyeing, textiles and paper making, can solve the problems of long process, uneven coloring, waste of water resources, etc., and achieve the effects of saving water resources, shortening production time and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

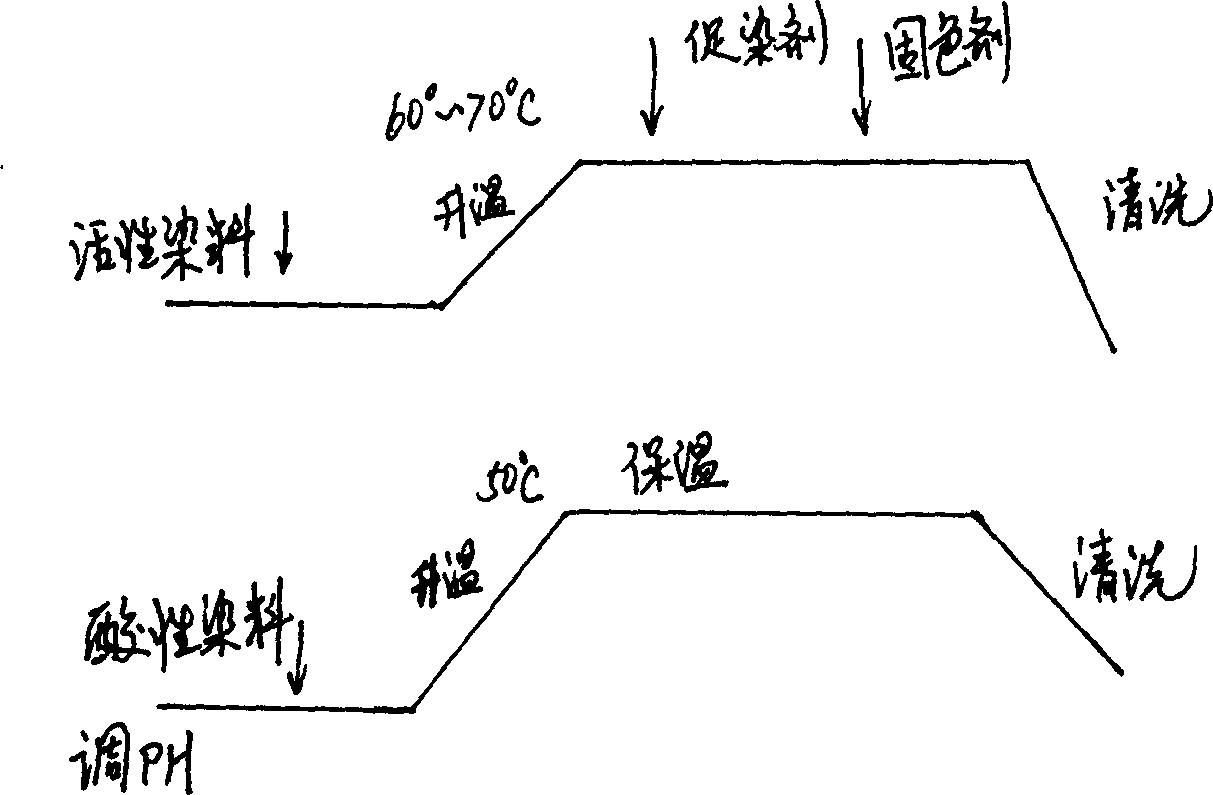

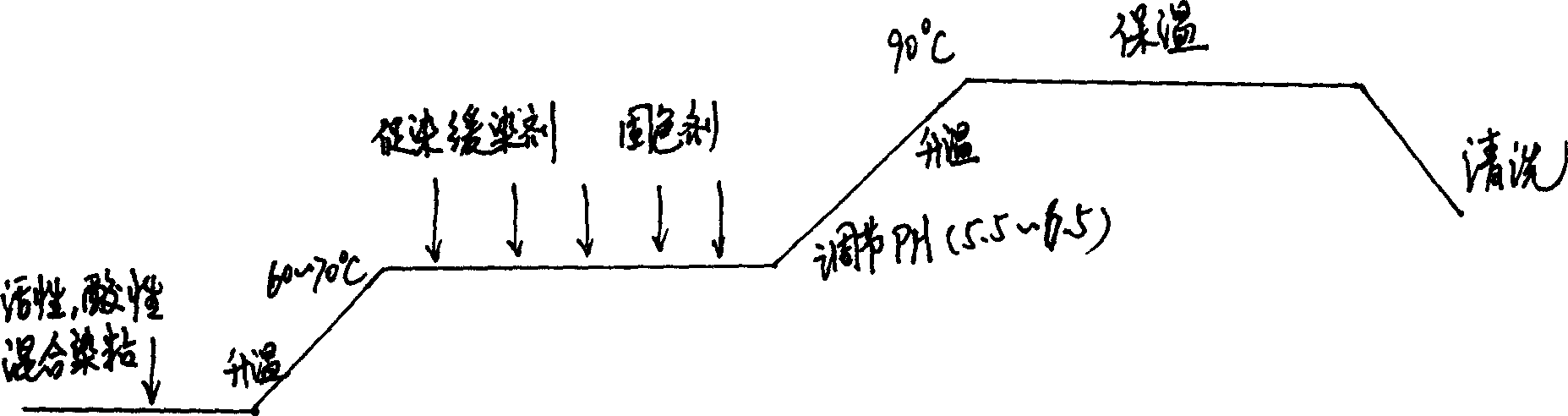

[0012] like figure 2 As shown, the process of using reactive dyes and acid dyes to dye cotton and nylon blended fabrics black in one bath:

[0013] Choose one part of reactive yellow 3RS for reactive dyes, one part of reactive red 3BS, ten parts of reactive black KN-G2RC, one part of acid black LD for acid dyes, four parts of neutral black BL, mix the dyes and dissolve them in the dyeing vat to make Dye solution at 60-70°C. Prepare 100 g / L of sodium hexametaphosphate, 30 g / L of soda ash, and 1 g / L of sodium hexametaphosphate in proportion to the volume of the dye solution. Immerse in the blended fabric to be dyed at a bath ratio of 1:20. The temperature of the dye solution is controlled at 60-70°C. After 5 minutes, add 1 / 3 part of sodium sulfate, add once every 10 minutes, and add in three times. Natalan plays a role in accelerating the dyeing of reactive dyes, promoting the combination of reactive dyes and cotton in blended fabrics, and retarding the dyeing of acid dyes, p...

Embodiment 2

[0016] The process of dyeing cotton and polyester blended fabrics with a one-bath method of bright red using reactive dyes and weak acid dyes:

[0017] For reactive dyes, choose one part of reactive scarlet 3BS, one part of reactive yellow 3RS, and one part of reactive yellow RS. Mix the dyes and dissolve them in the dye vat to make a dye solution at 50°C. Prepare 100 grams according to the volume of the dye solution. Yuanmingfen per liter, trisodium phosphate at 30 grams per liter, sodium hexametaphosphate at 1 gram per liter. Immerse in the blended fabric to be dyed at a bath ratio of 1:20. The temperature of the dye solution is controlled at about 50°C. After 5 minutes, add 1 / 3 part of sodium sulfate, add once every 10 minutes, and add in three times. Yuanming powder acts as a dyeing accelerator for reactive dyes, promoting the combination of reactive dyes and cotton in blended fabrics, and retards dyeing for acid dyes, preventing the reaction of reactive dyes and polyester...

Embodiment 3

[0020] The one-bath method of orange dyeing of cotton and nylon blended fabrics using reactive dyes and weak acid dyes:

[0021] For reactive dyes, choose one part of reactive big red yellow X3R, one part of reactive yellow X-G, and one part of weak acid orange GS. Mix the dyes and dissolve them in the dyeing vat to make a dye solution at about 35 °C. Prepare 100 g / L of table salt, 30 g / L of soda ash, and 1 g / L of sodium hexametaphosphate in proportion to the volume of the dye solution. Immerse in the blended fabric to be dyed at a bath ratio of 1:20, control the temperature of the dye solution at about 35°C, add 1 / 3 portion of salt after 5 minutes, add once every 10 minutes, and add in three times. Salt acts as a dyeing accelerator for reactive dyes, promoting the combination of reactive dyes and cotton in blended fabrics, and retards dyeing for weak acid dyes, preventing the reaction of reactive dyes and ammonium fiber in blended fabrics. After the salt is added, add soda a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com