Single bath autodeposition coating for combination metal substrates and methods therefor

A technology of self-deposition and substrate, applied in metal material coating process, coating, transportation and packaging, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

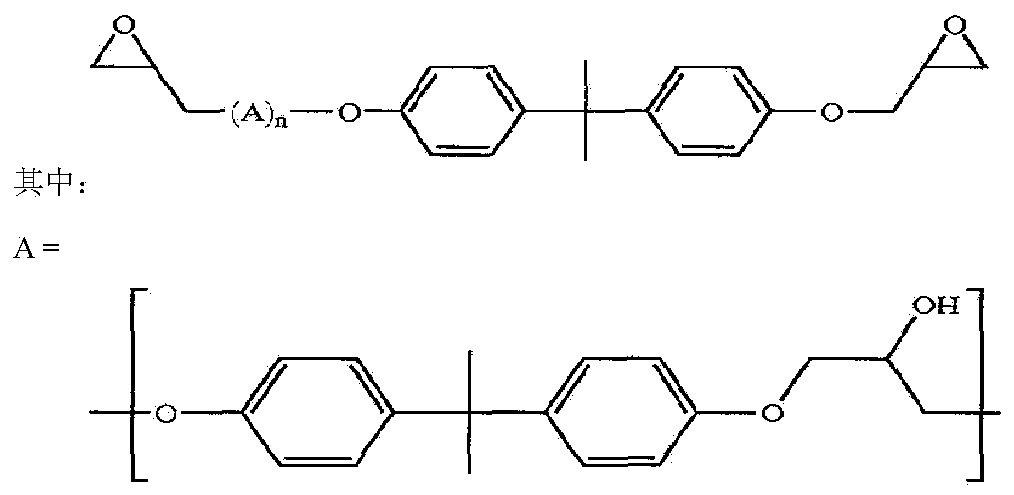

Method used

Image

Examples

Embodiment 1

[0097] Nitroethane added after polymerization

[0098] The modified autodeposition coating bath was prepared as follows: In a 1 liter container, 130.21 g of 930 Make-up (available from the Surface Technologies Division of Henkel Corporation's self-deposition coating concentrate, which is described as an epoxy / acrylic copolymer, a blocked crosslinker, and a water-based dispersion of carbon black pigment) with 15.0 g Starter 300 (a product available from the Surface Technologies Division of Henkel Corporation containing an autodeposition promoter and other components), 854.8 g deionized water, 0.027 g HF, and 2.0 g nitroethane were mixed.

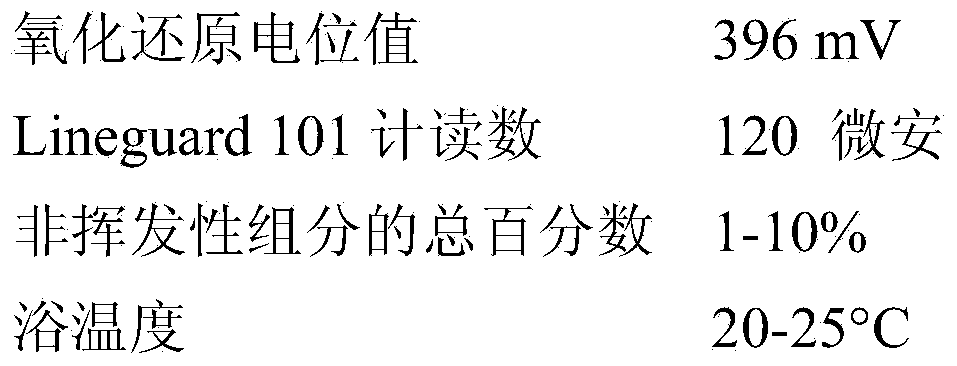

[0099] The bath was mixed for 1 hour and the bath was kept stirring. Note that the bath does not condense, separate or settle. Measure and adjust bath parameters.

[0100] Oxidation-reduction potential (Redox) value 372mV

[0101] Lineguard101 meter reads 150 microamps

[0102] Bath temperature 20-25°C

[0103] The redox potential v...

Embodiment 2

[0114] Addition of nitroethane before polymerization

[0115] In a process utilizing a microemulsion polymerization step, a modified self-depositing microemulsion dispersion is prepared as follows by using nitroethane as a prepolymerization additive:

[0116] Into a clean 2 liter 4 necked flask equipped with stirrer, nitrogen inlet, condenser and addition funnel was charged a) 167.8 g of epoxy resin and b) 20.5 g of blocked isocyanate. To this flask was charged c) 174.5 g of ethylenically unsaturated monomer, d) 7.3 g of ester alcohol (2,2,4-trimethyl-1,3-pentanediol monoisobutyrate propionic acid) and e) 9.0 g of a homogeneous mixture of nitroethane and mix it until the epoxy resin and blocked isocyanate are dissolved. A homogeneous mixture of f) 16.2 g of anionic surfactant 28% NV and g) 600 g of deionized water was added and mixed within 10 minutes. Remove the crude dispersion from the flask and pass it through the M-110F to form a fine particle dispersion microemulsi...

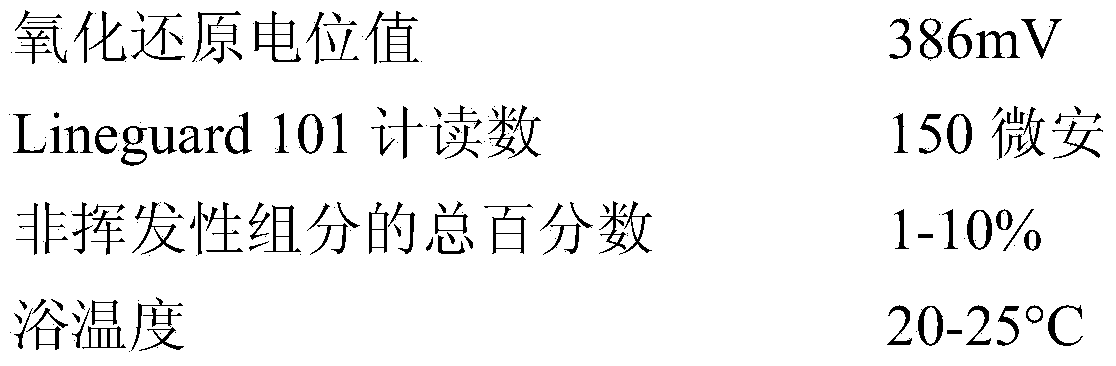

Embodiment 3a

[0118] Autodeposition composition concentrate prepared using the dispersion of Example 2

[0119] An autodeposition composition concentrate comprising an anionically stabilized emulsion of the nitroethane-modified epoxy / acrylic acid of Example 2 was prepared by adding a carbon black pigment slurry as follows: In a 1.5 liter vessel, 166.0 g of The dispersion of Example 2 at 35.96% solids was combined with 6.0 g of carbon black pigment slurry (40.5% solids) and the material was allowed to mix for 10-60 minutes. No condensation or precipitation was noted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com