Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Resin infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepreg with moderate-temperature cured epoxy resin as substrate material and preparation method thereof

The invention relates to a prepreg with moderate-temperature cured epoxy resin as a substrate material and a preparation method of the prepreg, relates to a prepreg and a preparation method of the prepreg, and is used for solving the problems that the prepreg is prepared at the curing temperature higher than 120 DEG C, so that the product is high in energy consumption and the dimensional accuracy of the product is difficult to control. The prepreg with moderate-temperature cured epoxy resin as the substrate material is composed of an epoxy resin mixture, a curing agent system mixture and a moderate-temperature cured epoxy resin infiltration reinforcing material prepared by a toughening agent, wherein the epoxy resin mixture is composed of solid or semisolid epoxy resin and liquid epoxy resin, and the curing agent system mixture is composed of a curing agent and a promoter. The preparation method comprises the steps of: (1) preparing the epoxy resin mixture; (2) preparing the curing agent system mixture; (3) preparing the moderate-temperature cured epoxy resin; and (4) preparing the prepreg. The prepared product can be used for preparing planes, spacecrafts, yachts, golf rods and the like, and has important commercial value.

Owner:HARBIN FRP INST

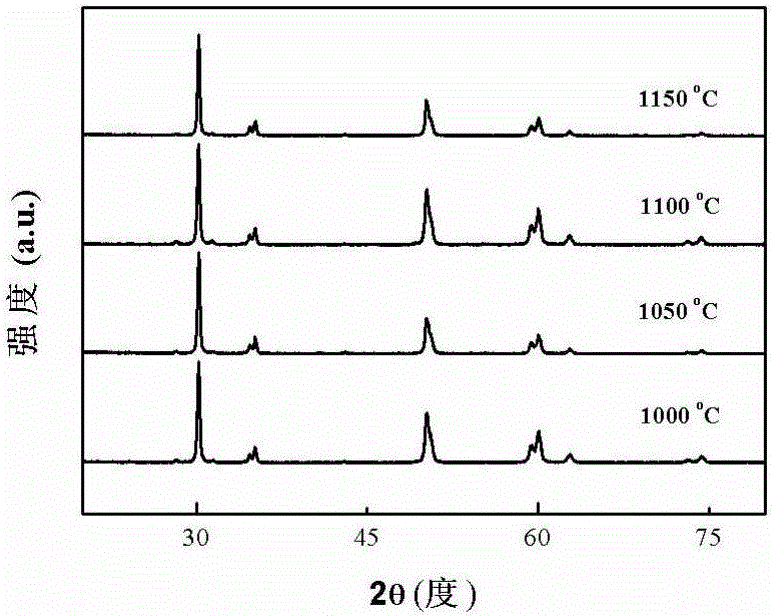

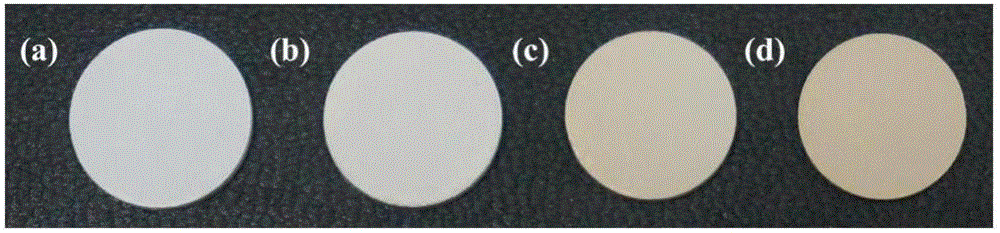

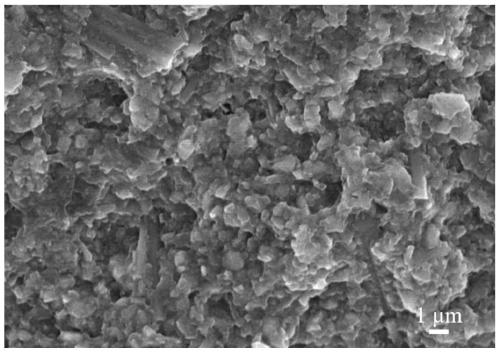

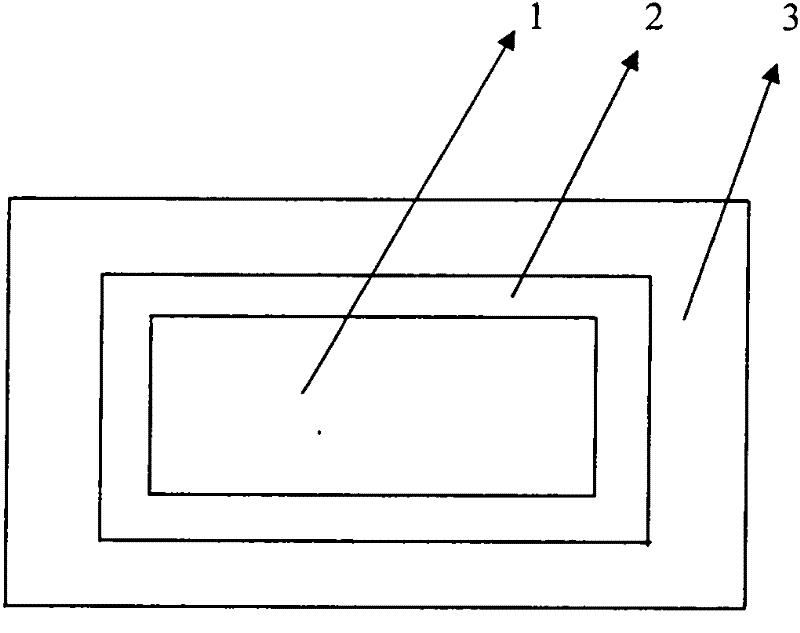

Resin-permeable ceramic composite and preparation method thereof

ActiveCN106007802AInhibition of volume changeImprove bending strengthImpression capsDentistry preparationsMethacrylateCeramic composite

The invention provides a resin-permeable ceramic composite which is formed by curing a ceramic body and mixed resin permeating in the porous network structure of the ceramic body, wherein the ceramic body has a porous network structure and comprises yttria-stabilized tetragonal phase zirconia; and the mixed resin comprises a mixture of methacrylate compounds and a thermal curing agent. The resin-permeable ceramic composite provided by the invention is composed of a porous ceramic network structure and resin permeating in the ceramic network structure; by adopting the ceramic as a matrix, the volume change of the composite in the curing process can be effectively avoided, and the defects that traditional particle reinforcing resin-based composite is easily cured and shrunk and consequently residual stress is introduced are overcome; and through the permeation way, the mixed resin can form a resin network structure penetrating through the ceramic network structure, and a ceramic-based composite with excellent mechanical properties is obtained.

Owner:TSINGHUA UNIV

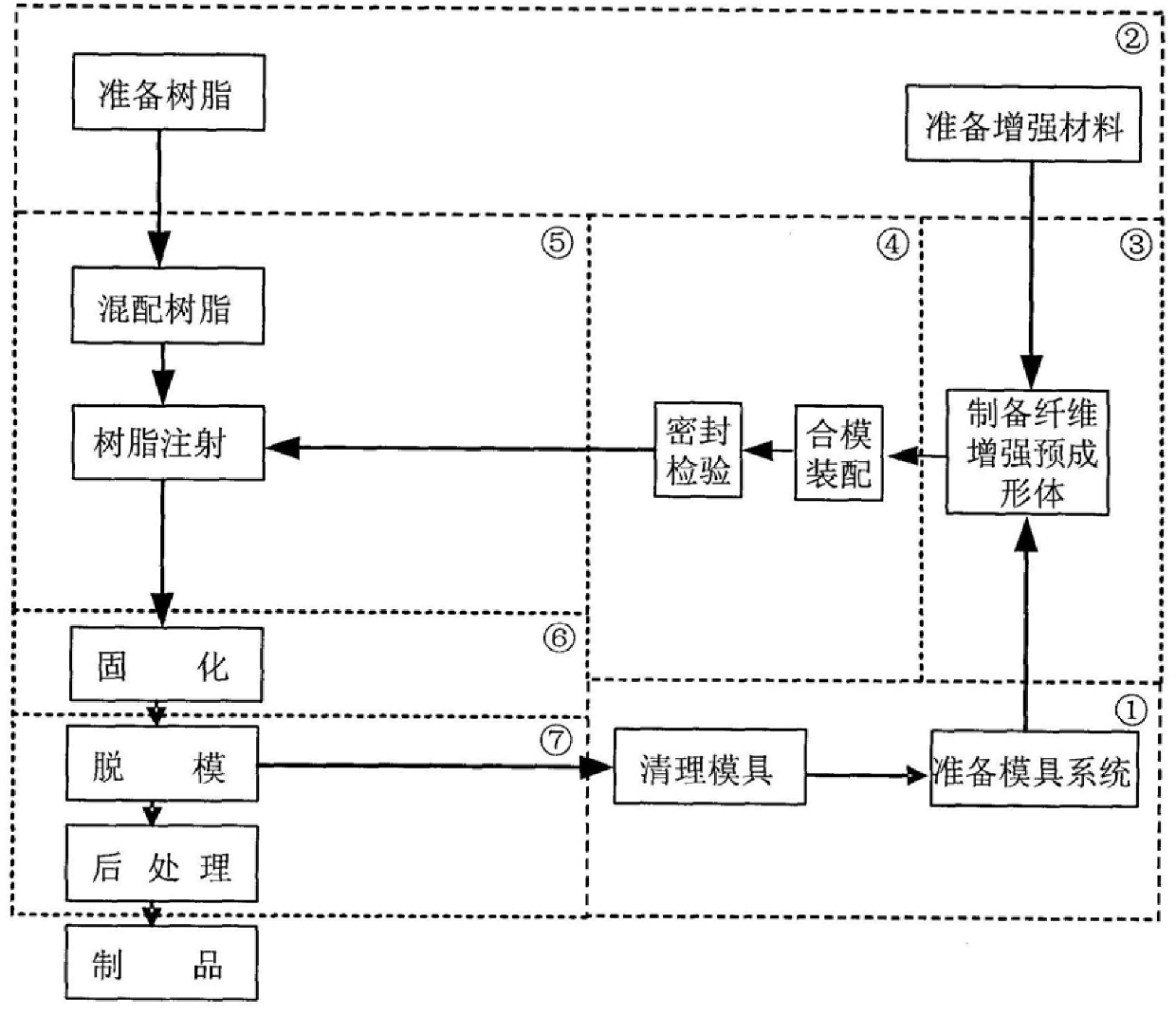

Resin infiltration transfer technique

InactiveUS7628942B1Desired loading levelQuality improvementLaminationWood working apparatusCeramic compositeCrack free

A process has been developed for fabricating composite structures using either reaction forming or polymer infiltration and pyrolysis techniques to densify the composite matrix. The matrix and reinforcement materials of choice can include, but are not limited to, silicon carbide (SiC) and zirconium carbide (ZrC). The novel process can be used to fabricate complex, net-shape or near-net shape, high-quality ceramic composites with a crack-free matrix.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

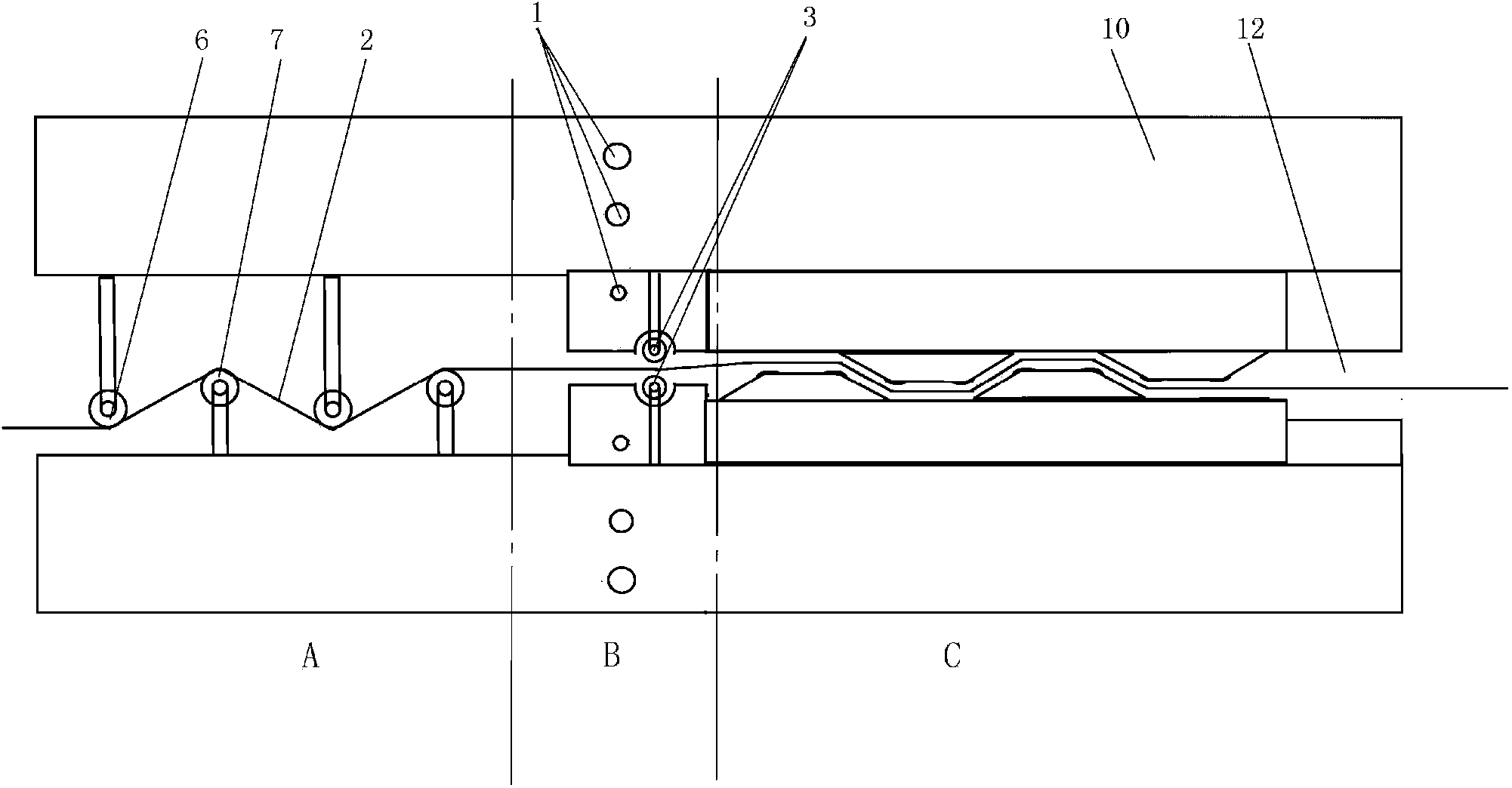

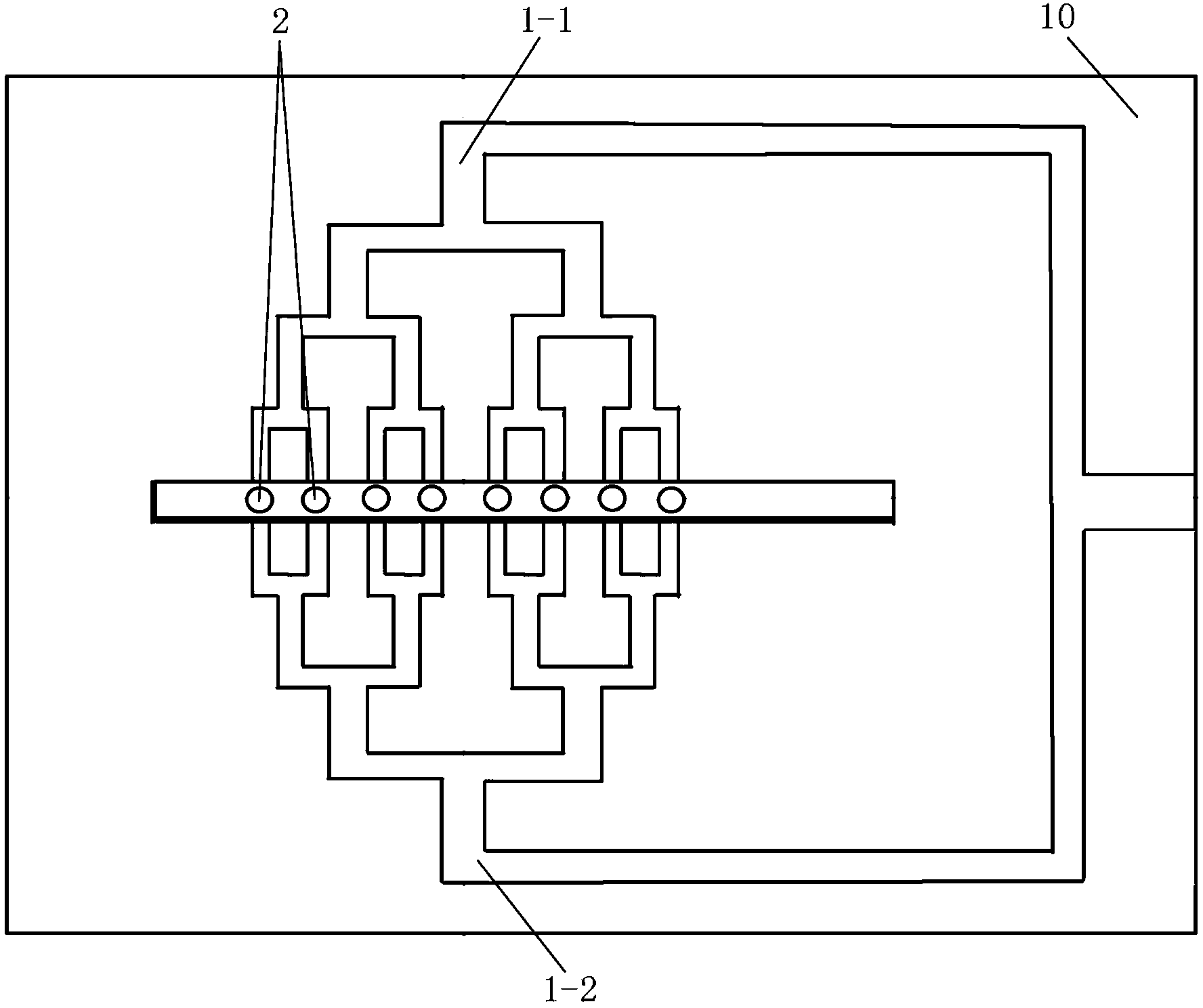

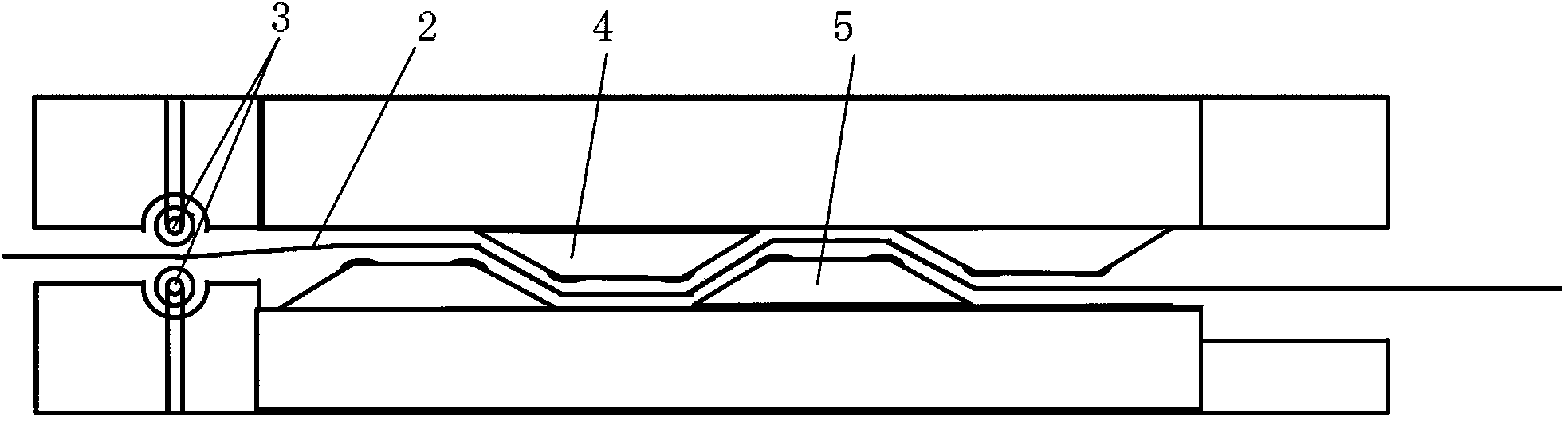

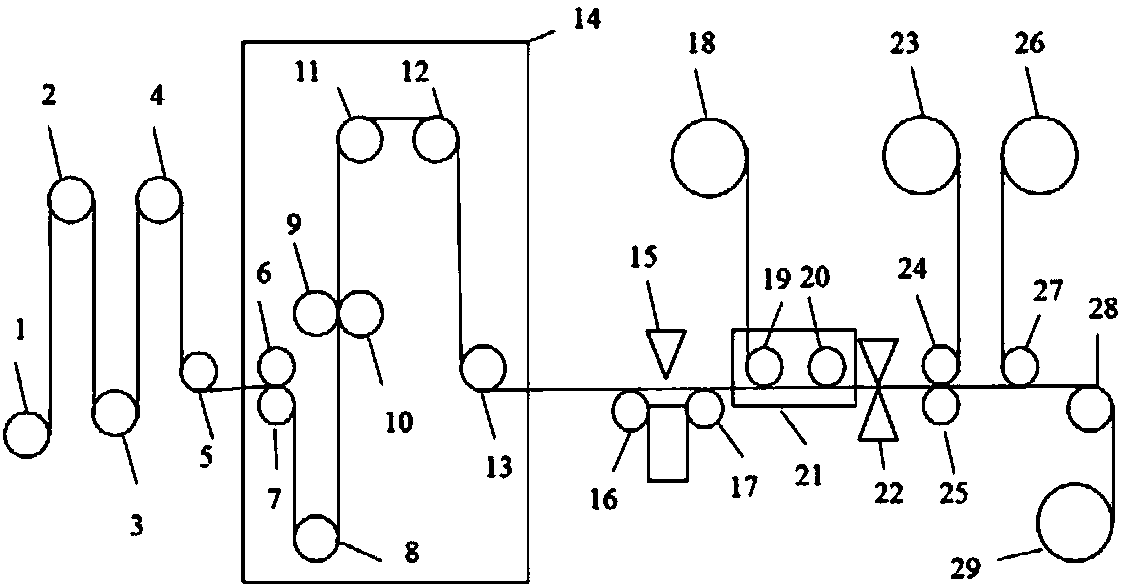

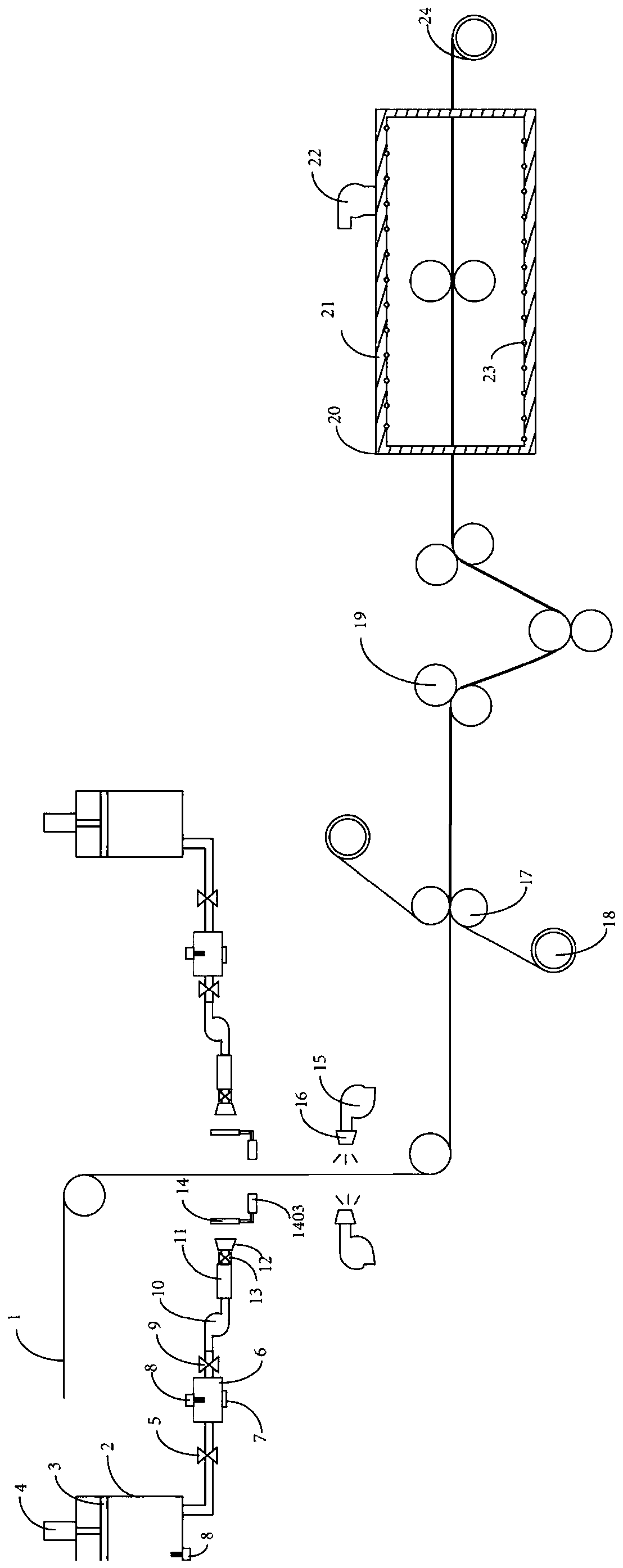

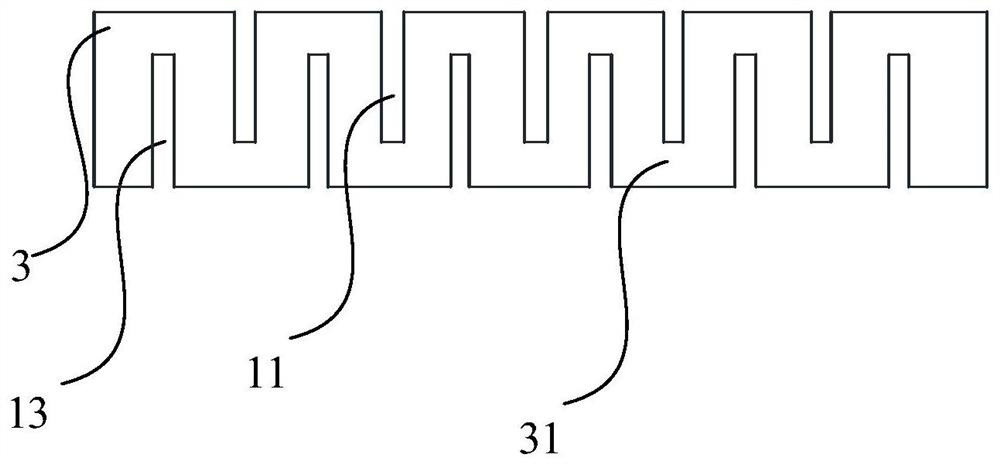

Double-faced melt impregnation method and device for continuous long fiber reinforced thermoplastic resin

The invention discloses a double-faced melt impregnation method and device for continuous long fiber reinforced thermoplastic resin. The method comprises the steps of firstly carrying out pre-dispersion and preheating on continuous long fibers, then carrying out comprehensive packaging and infiltration by virtue of a double-faced distribution runner, carrying out fiber re-dispersion processing, and sending the treated fibers out of a fiber channel. The device is characterized in that a fiber pre-dispersion region, a resin-infiltration fiber region and a fiber re-dispersion region are arranged in the fiber channel in a melt impregnation machine head, wherein the double-faced distribution runner is arranged in the resin-infiltration fiber region and comprises an upper-layer distribution runner and a lower-layer distribution runner which are structurally symmetrical; a pre-dispersion device is arranged in the fiber pre-dispersion region, and a re-dispersion device is arranged in the fiber re-dispersion region. According to the double-faced melt impregnation method and device, an impregnation effect of resin melt to continuous long fiber bundles is balanced, purposes of complete cladding, permeation and infiltration are achieved, a phenomenon that the single sides of the fibers are not tightly clad is avoided, the long-time continuous stable production is realized, and the yield and the quality of a product are substantially improved.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

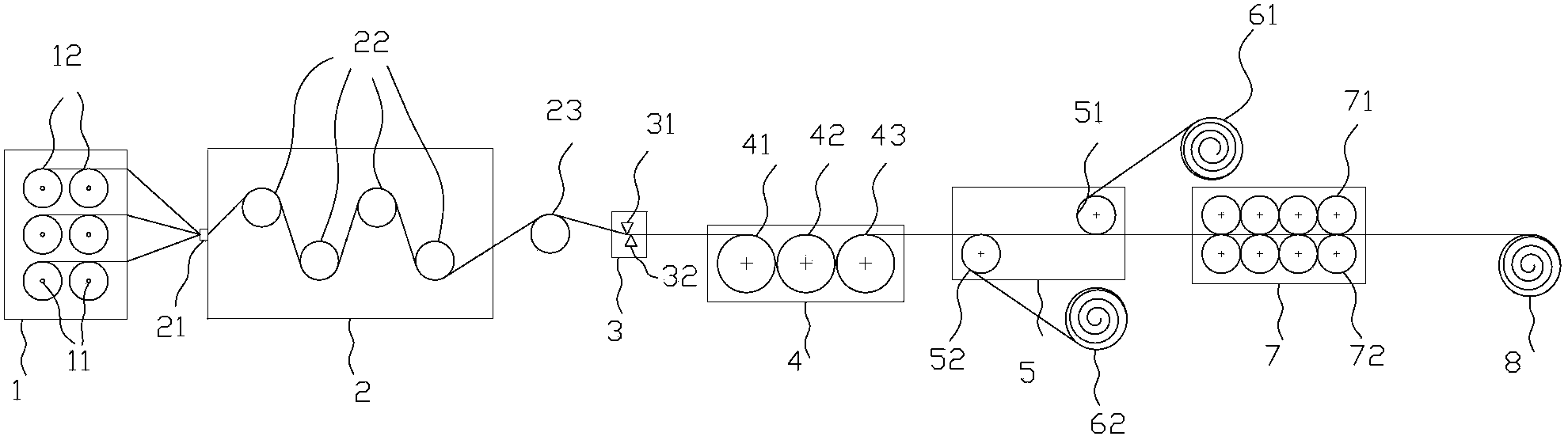

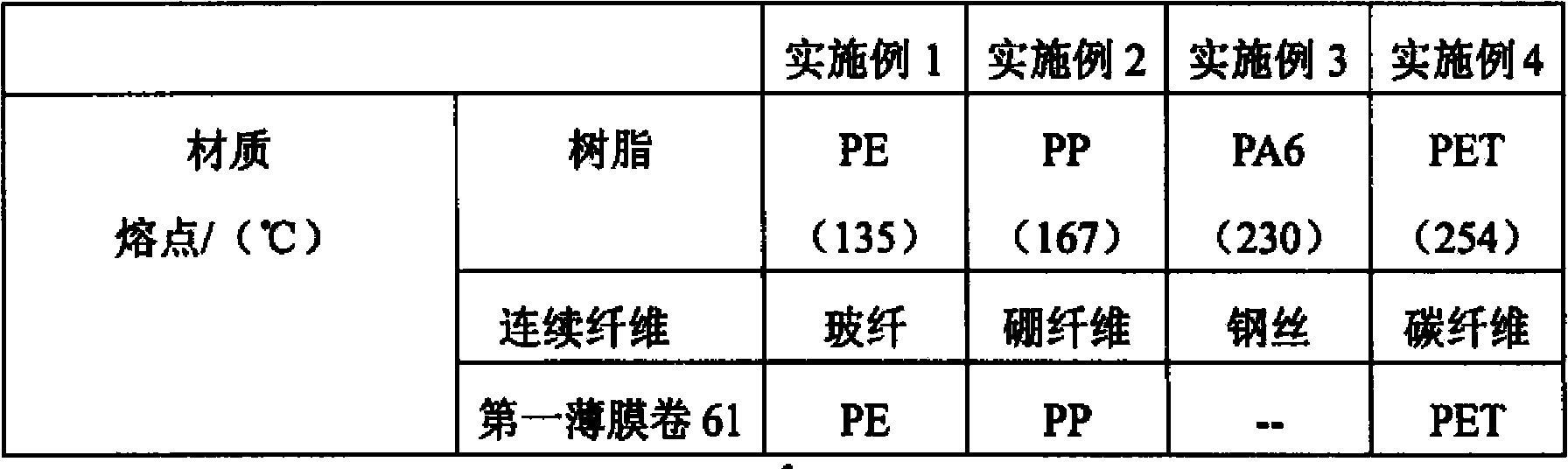

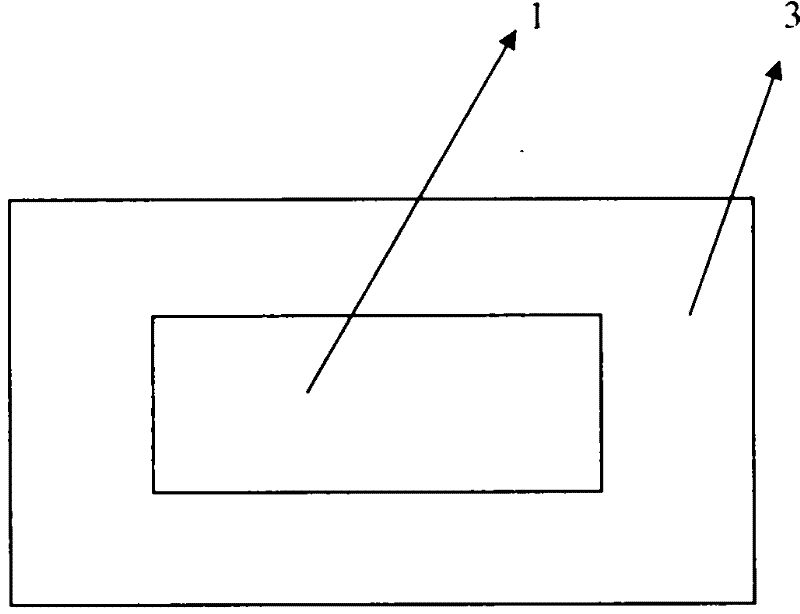

Equipment for producing continuous fiber-reinforced thermoplastic resin prepreg tapes and application of equipment

The invention relates to equipment capable of laminating on line for producing continuous fiber-reinforced thermoplastic resin prepreg tapes and a method for producing prepreg tapes by applying the equipment. The equipment comprises a creel (1), a tension regulating device (2), a dual-extrusion die head (3), a three-roller dipping device (4), a cooling and rolling device (7), a traction and reeling device (8), a laminating and rolling device (5), a first film reel (61) and a second film reel (62), wherein the first film reel (61) and the second film reel (62) are arranged on the upper side and the lower side of the laminating laminating and rolling device (5), respectively, and provide films for being laminated on the upper surface and the lower surface of each prepreg tape, and the upper surface and the lower surface of each prepreg tape are laminated by the laminating laminating and rolling device (5) so as to obtain laminated prepreg tapes. Compared with the prior art, the equipment has the advantage that the phenomena of tearing, fiber exposure and the like are prevented due to the adoption of a direct laminating technology; the problem of poor resin infiltration caused by inorganic filler and pigment is prevented; accurate color blending is realized.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

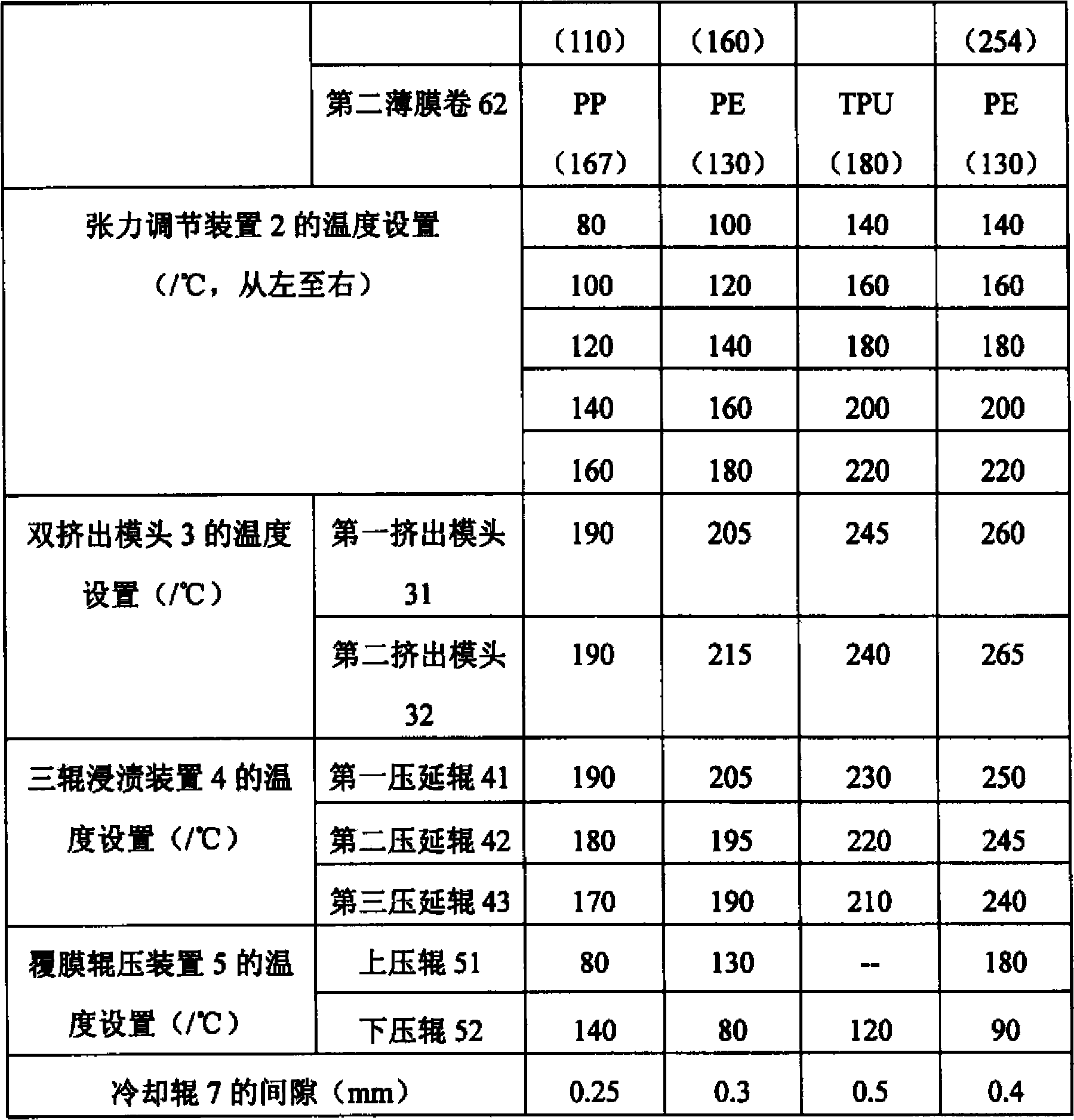

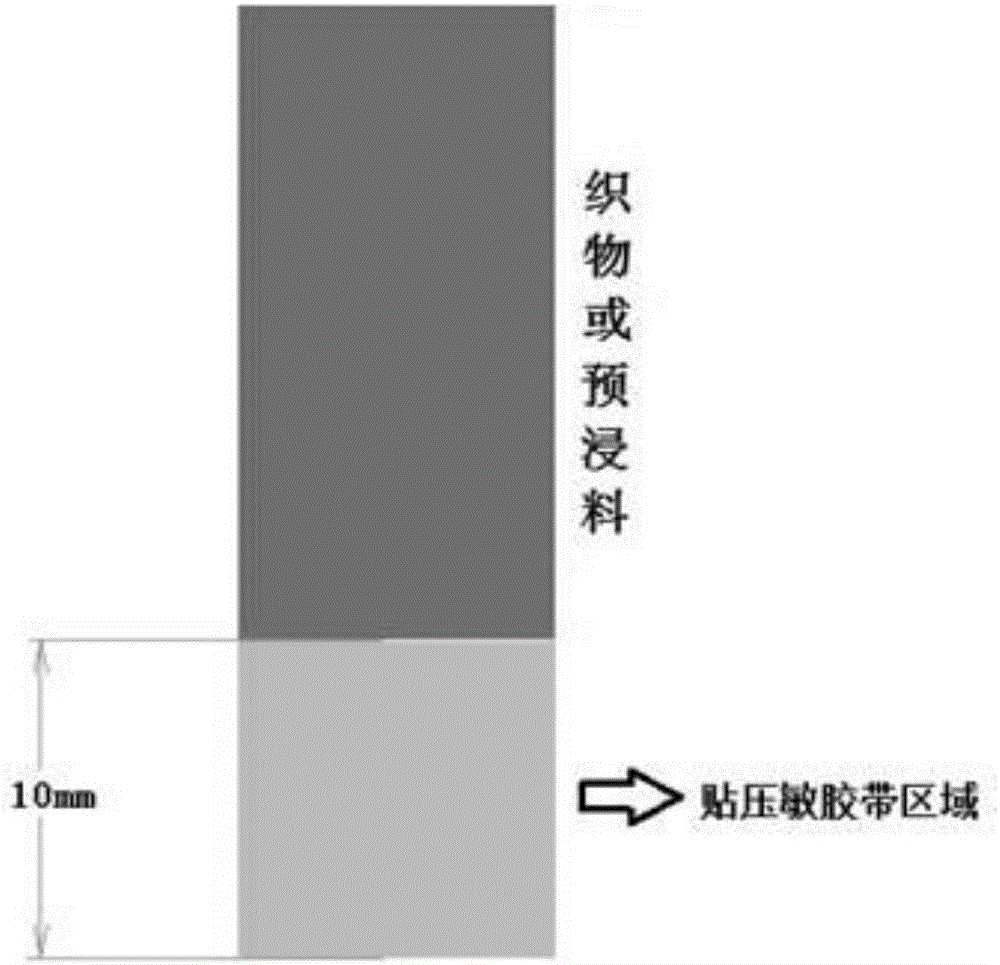

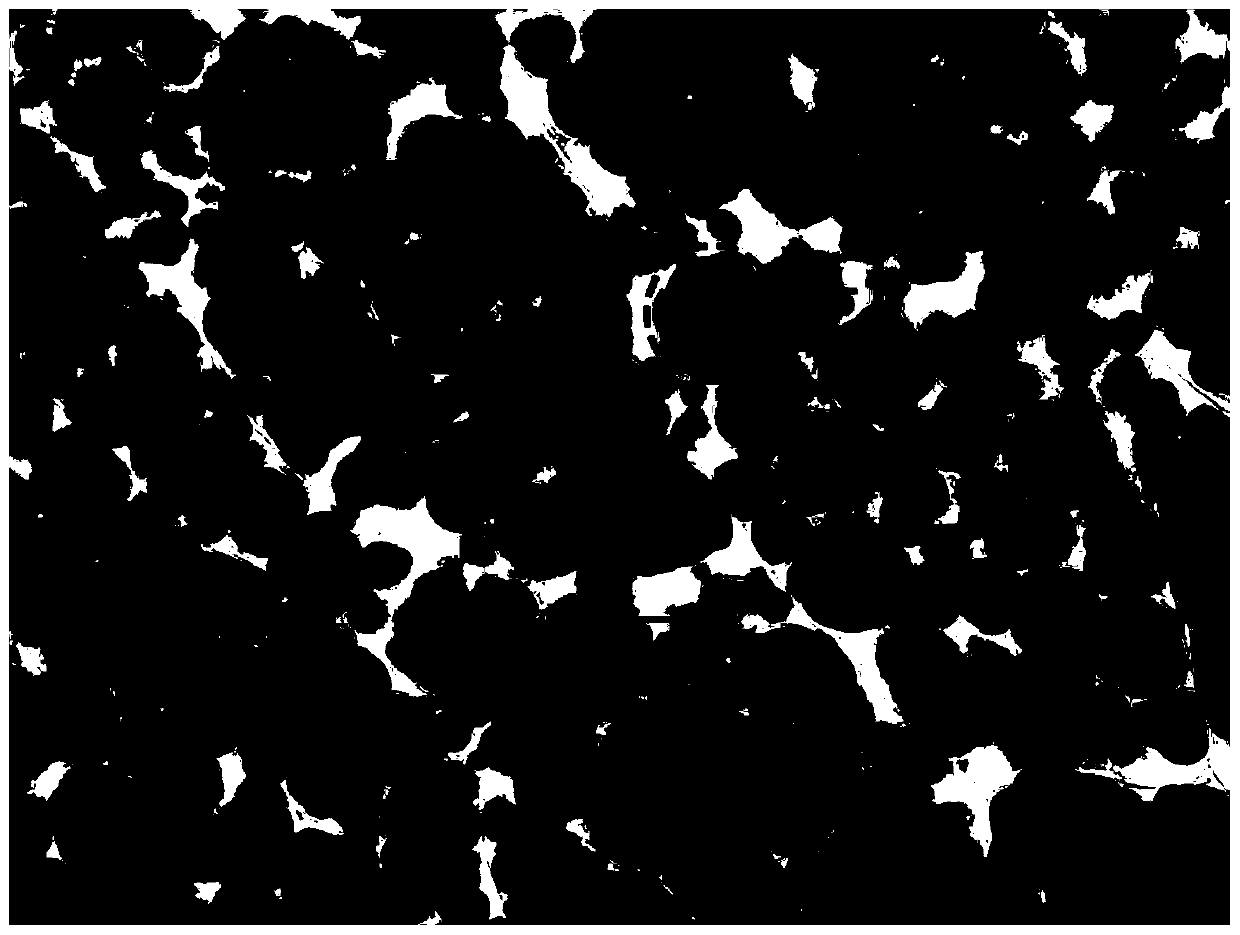

Test method for prepreg resin infiltration degree

ActiveCN105938076AControl saturated water absorption timeSimple and fast operationWeighing by absorbing componentCapillary water absorptionFiber bundle

The invention provides a test method for prepreg resin infiltration degree. The method is mainly for testing the impregnation degree of a vacuum bag molded oven cured prepreg. The method utilizes the capillary water absorption phenomenon occurred during contact of dry fiber and water, and water rises along the capillary between fiber bundles and infiltrates the fiber till reaching a saturated water absorption capacity. The resin infiltrated interfibre capillary channel is closed, capillary action cannot occur to absorb water, so that the water absorption capacity can be utilized to judge the content of dry fiber in the impregnated prepreg, thus testing the impregnation degree of the prepreg.

Owner:HENGSHEN

Surface modified carbon fiber prepreg based on graphene oxide and preparation method of carbon fiber prepreg

The invention discloses a surface modified carbon fiber prepreg based on graphene oxide and a preparation method of the carbon fiber prepreg and relates to preparation of the carbon fiber prepreg. Thesurface modified carbon fiber prepreg based on graphene oxide is prepared from, in parts by mass, 100 parts of carbon fiber and a prepreg solution containing 40%-60% of resin, wherein the prepreg solution is prepared from, in parts by mass, 100 parts of epoxy resin, 50-150 parts of acetone and 0.05-5 parts of graphene oxide. Graphene oxide is uniformly dispersed in an epoxy resin prepreg solution, carbon fiber is soaked in the epoxy resin prepreg solution containing graphene oxide, and a graphene oxide / epoxy resin infiltration layer is formed on the surface of the carbon fiber, the purpose ofimproving the interface performance of the carbon fiber and an epoxy resin matrix is achieved, and a graphene oxide / carbon fiber / epoxy resin prepreg and a composite product thereof are obtained and are convenient to operate, require simple equipment and are suitable for industrial production.

Owner:XIAMEN UNIV

Wind generating set blade core materials and processing method

PendingCN107718598AEvenly pour the core materialPromote infiltrationLamination ancillary operationsLaminationEngineeringResin infiltration

The invention provides wind generating set blade core materials which comprise a core plate, wherein a main resin pouring groove is formed in the front surface of the core plate. An auxiliary resin pouring groove is formed in the back surface of the core plate, an anti-overflow layer which is laid on the back surface of the core plate is arranged above the auxiliary resin pouring groove, and the main resin pouring groove is communicated with the secondary resin pouring groove. The main resin pouring groove and the secondary resin pouring groove are arranged on the front surface and the back surface of the core plate, and gridding cloth is arranged on the back surface of the core plate, so that resin is more uniformly poured in the core plate, the phenomena of poor resin infiltration, resinwaste and the like are reduced, and the quality and the performance of the core materials is improved.

Owner:GUODIAN UNITED POWER TECH LIANYUNGANG CO LTD

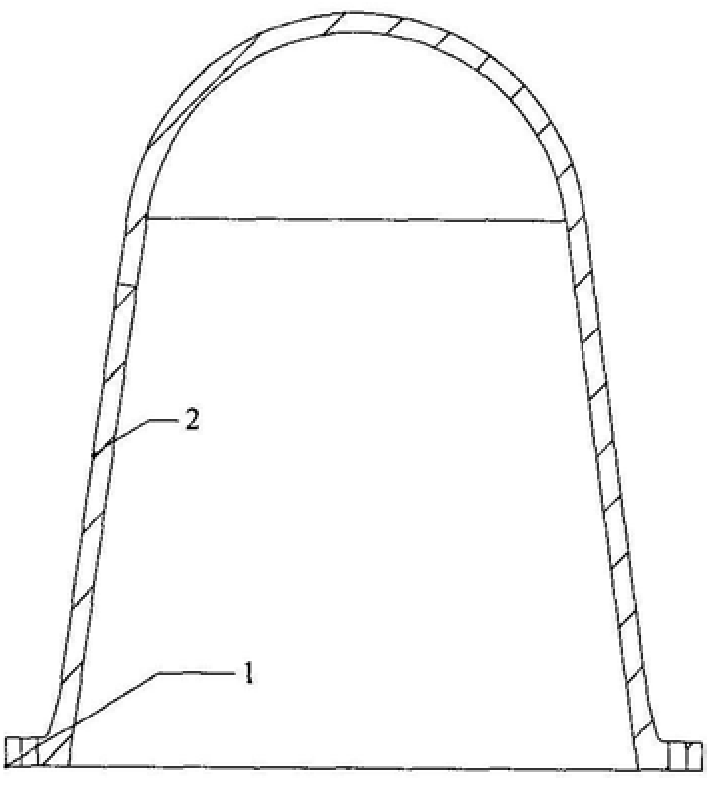

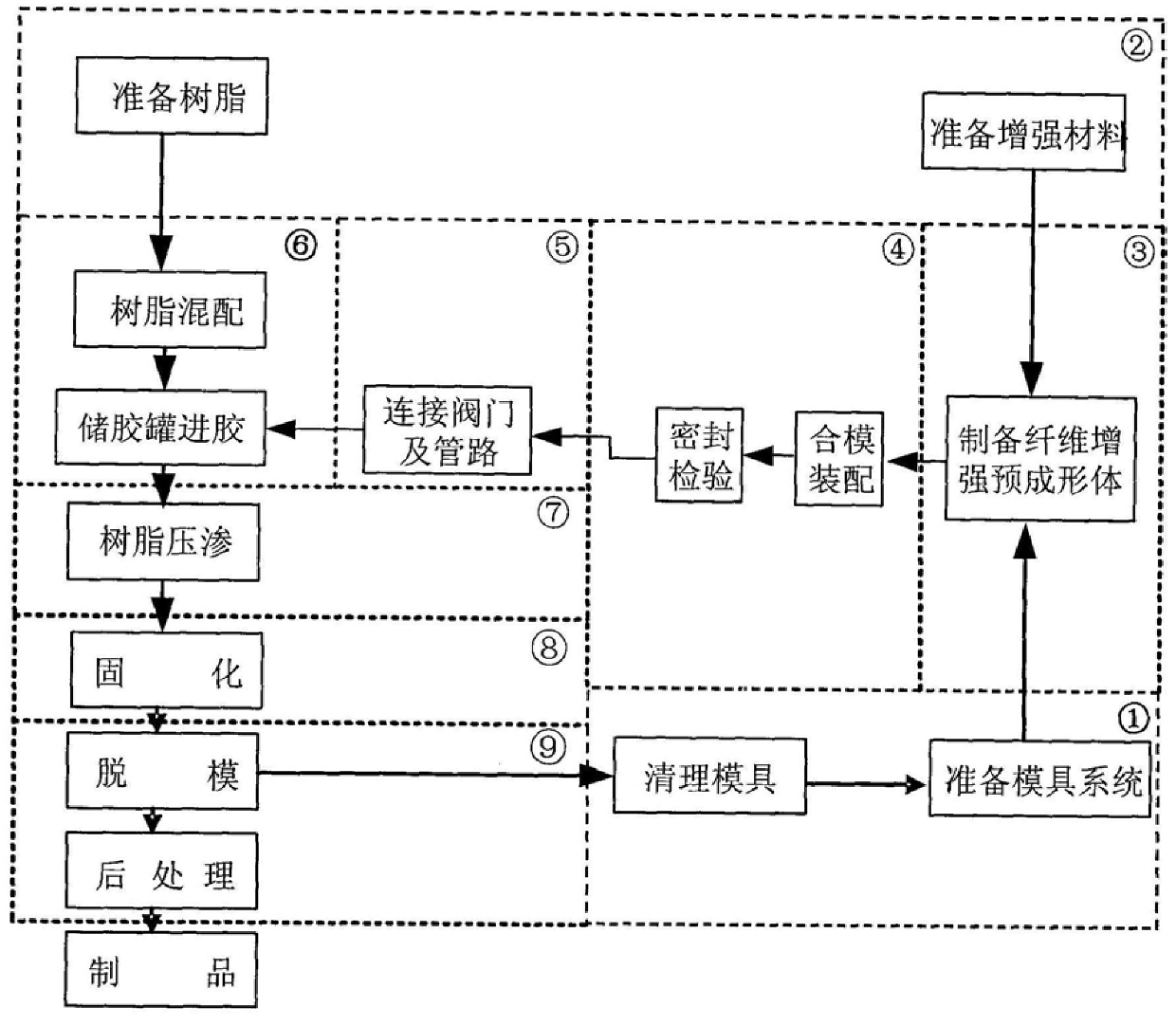

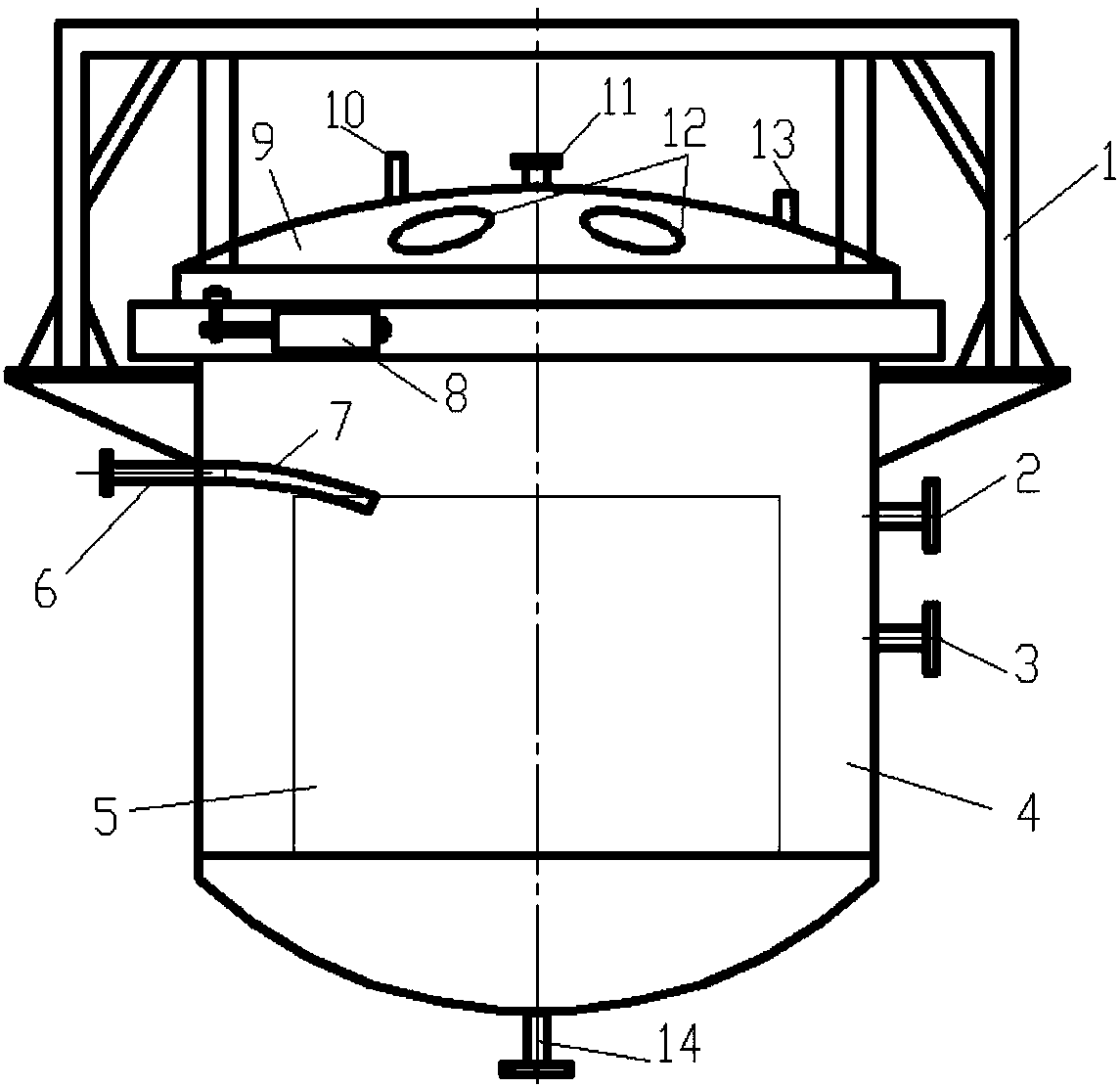

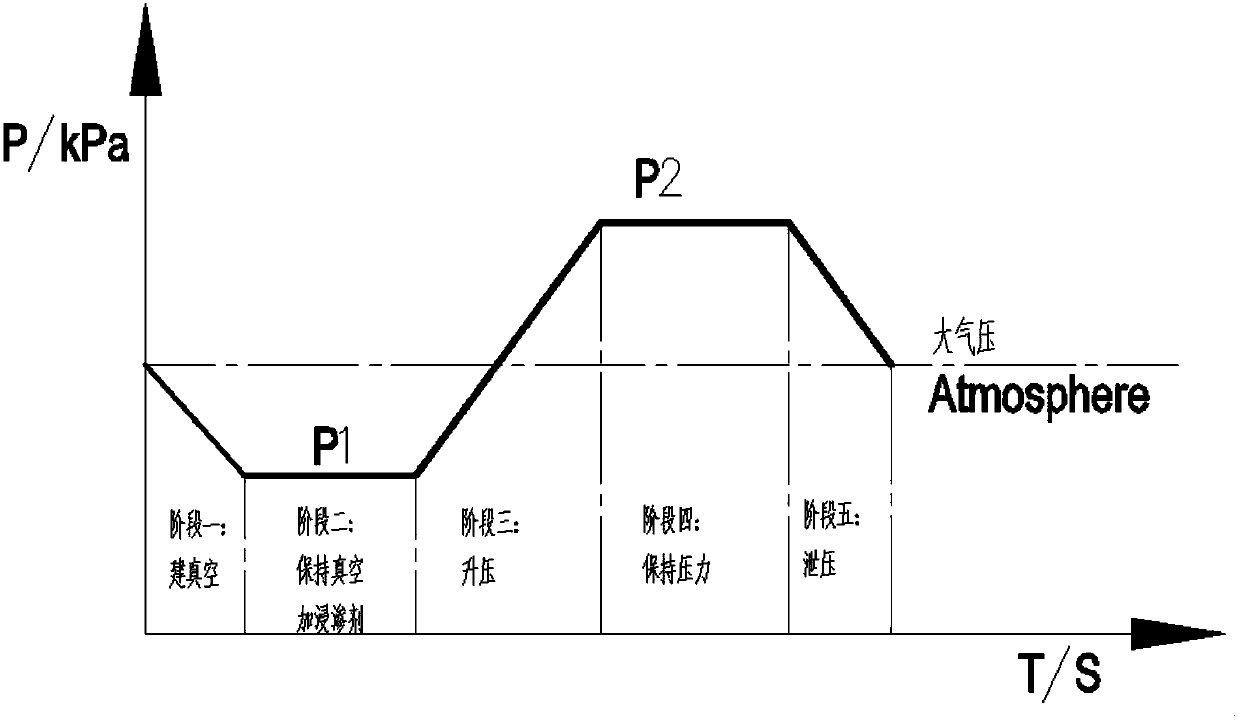

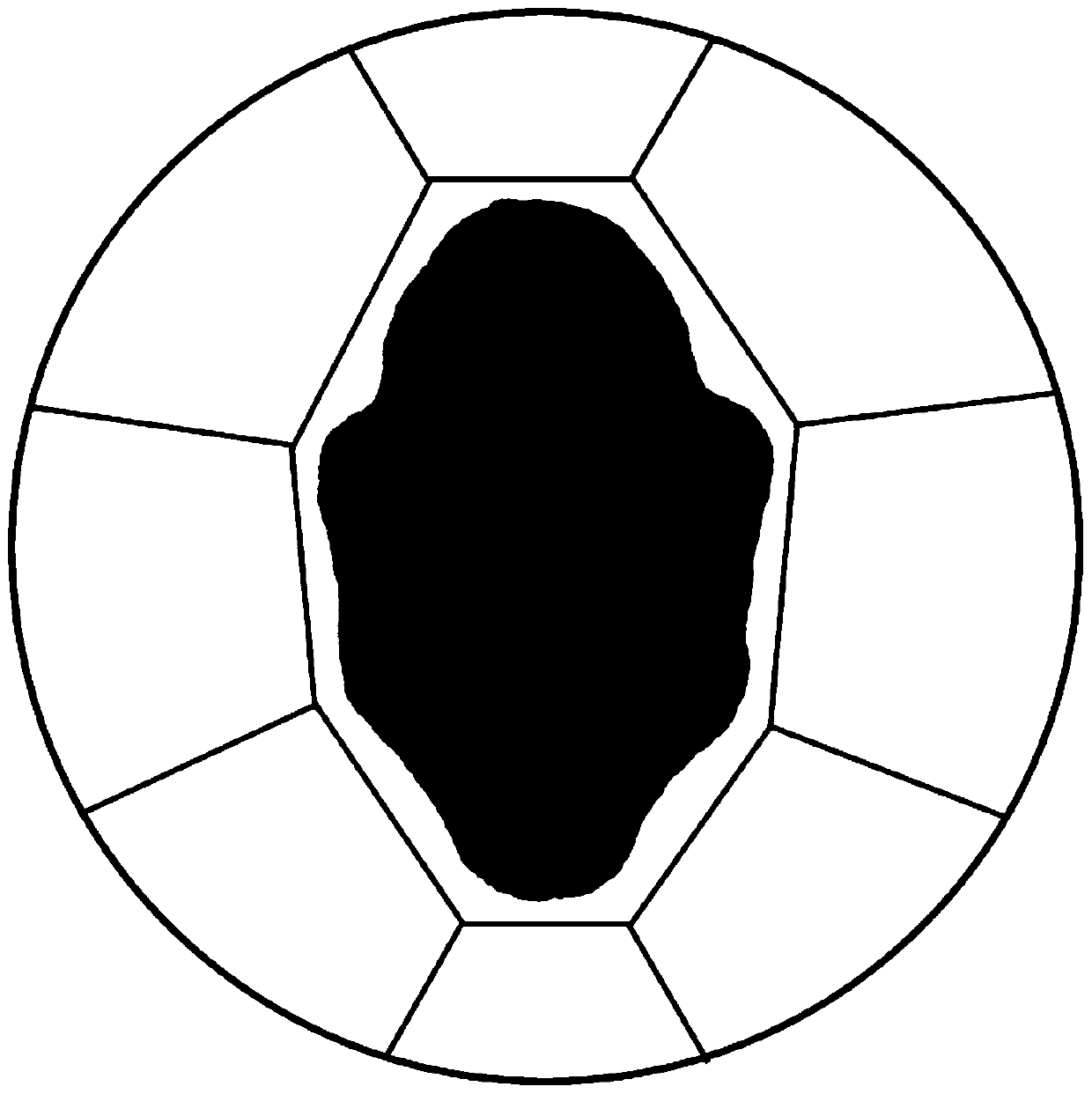

Pressure Infiltration Forming Method of Latent Composite Radome

InactiveCN106507737BSimple and fast operationLow costRadiating element housingsThick wallAtmospheric pressure

The invention discloses a piezo-infiltration molding method for latent composite material radome. The technical problem to be solved is to provide a low-cost overall preparation method for composite material radome, so that the prepared composite material radome has strict dimensions and wall thickness. Uniform, smooth inner and outer surfaces, excellent dielectric properties, and high overall load-bearing performance. The technical solution is to prepare the mold and materials first, then prepare the fiber-reinforced preform, close the mold and seal it, then connect the valve and pipeline, carry out resin mixing, glue storage tank, and then carry out resin pressure infiltration, including normal pressure impregnation. Infiltration and pressure infiltration, and finally curing and demoulding and post-treatment. The preparation of the composite material radome by the present invention is easy to operate and low in cost; it can flexibly adjust the pressurization speed of the resin glue liquid to the mold cavity, and the adjustment range is large, which is especially beneficial to the slow impregnation and integral molding of the composite material radome with a thick-walled structure. .

Owner:NAT UNIV OF DEFENSE TECH +1

Process for manufacturing fibre three-dimensional reinforced hollow composite material

InactiveCN101474867AImproved height dimension accuracyImprove the defect of poor wetting uniformityFlat articlesState of artFiber

The invention relates to a process for manufacturing a fiber three dimensional reinforced hollow composite material. The process comprises: firstly, controlling the temperature of a horizontal mold plate to be between 25 and 35 DEG C, carrying out the first resin injection on the horizontal mold plate, and spreading a fiber three dimensional woven fabric on the horizontal mold plate so as to make the resin infiltrate the woven fabric; secondly, carrying out mechanical rolling, after the first rolling, carrying out the second resin injection, and repeating the mechanical rolling after the injection; and finally, sucking the infiltrated woven fabric through a vacuum sucking device to adjust the height of the woven fabric, and obtaining a product through heating, curing and molding. Compared with the prior art, the process is simple and favorable for environmental protection. The product has the advantages of high production efficiency, good precision of finished products, uniform resin infiltration and the like.

Owner:苏州美克思科技发展有限公司

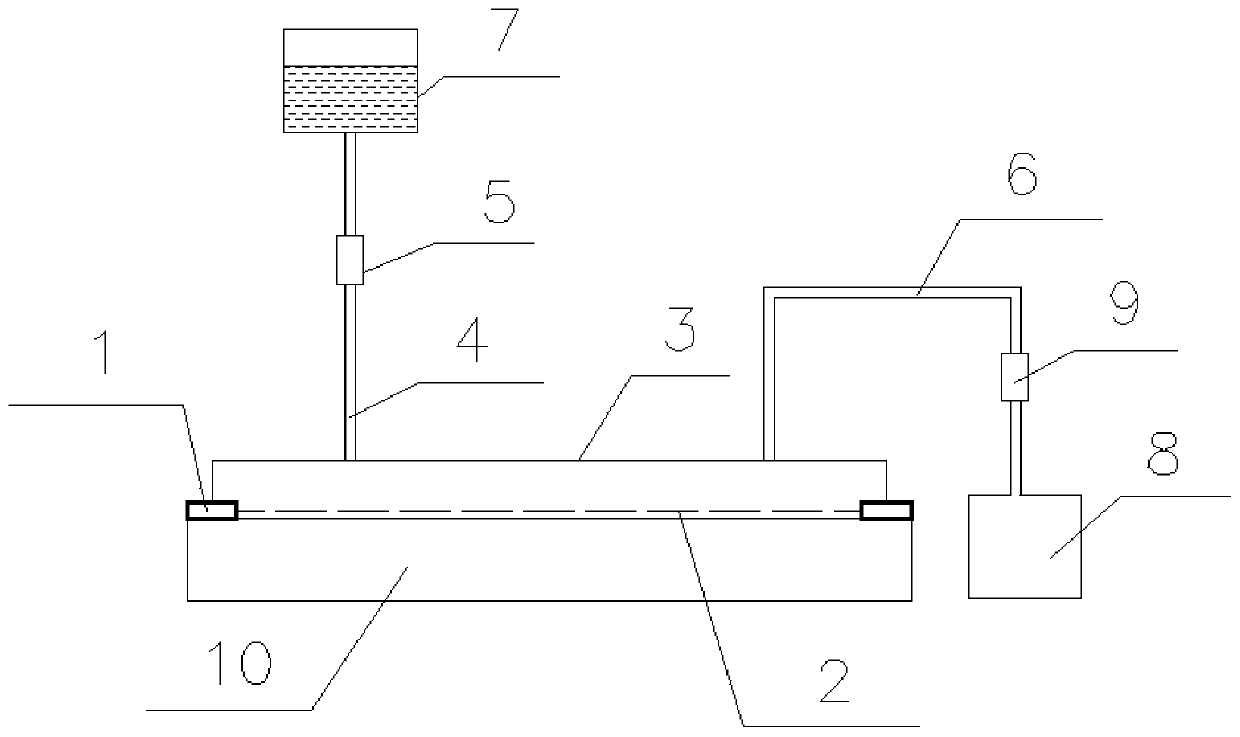

Novel device and technology for manufacturing ultra-thick composite plate by means of vacuum infusion

InactiveCN105563855ASolve the difficult realization of ultra-thick composite sheetSolve technical problems in product preparationFiberInfusion method

The invention provides a novel device and technology for manufacturing an ultra-thick composite plate by means of vacuum infusion, and aims at solving the problem that the ultra-thick composite plate is hard to manufacture by means of vacuum infusion. The thickness of the composite plate is larger than 8 mm. According to the scheme, a layer of flow guide medium is laid on the upper surface of a pre-forming body, and a layer of flow guide medium is laid on the lower surface of the pre-forming body; after resin is poured, the resin on the upper surface of the pre-forming body downwards permeates into fibers through gravity and surface acting force, and the resin on the lower surface of the pre-forming body upwards permeates into the fibers through surface acting force; and the distance of a resin infiltration reinforcement body is shortened, the resin pouring time is shortened, the defects of the composite plate are reduced, and the success rate of the composite plate is increased. The technical problem that the ultra-thick composite plate or product is hard to manufacture by means of a vacuum infusion method is solved, the application range of the vacuum infusion method is widened, and meanwhile a thought is provided for low-cost manufacturing of the ultra-thick composite plate or product.

Owner:HENGSHEN

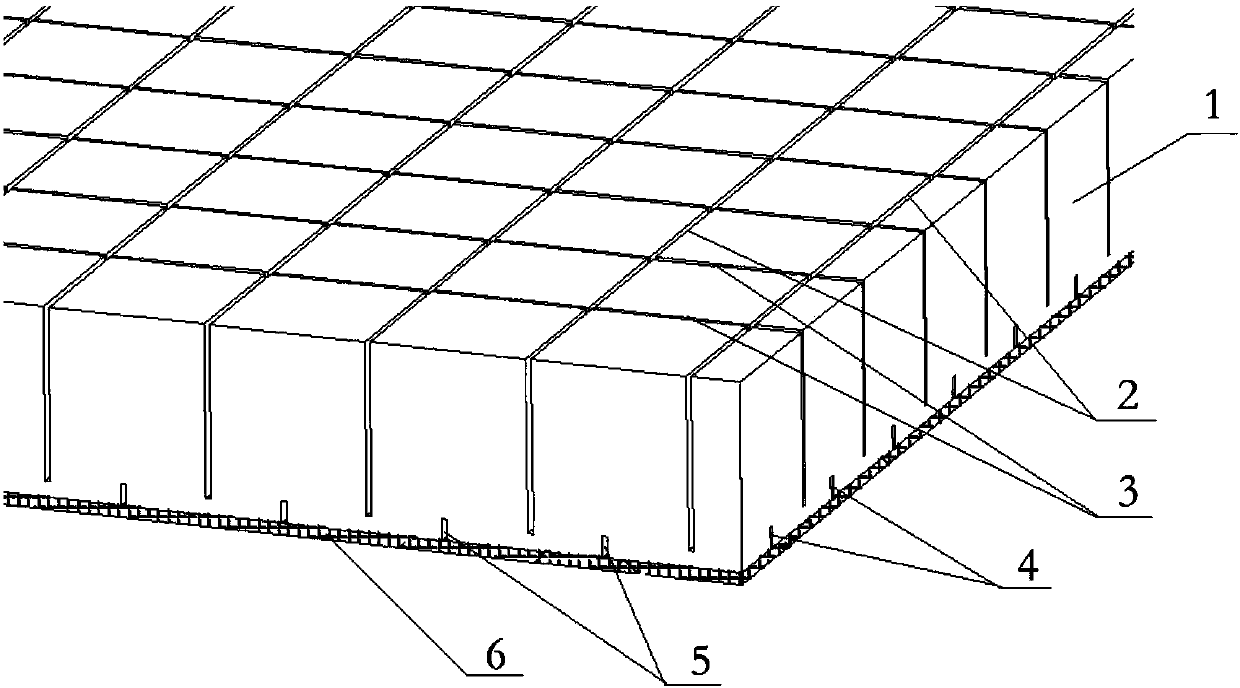

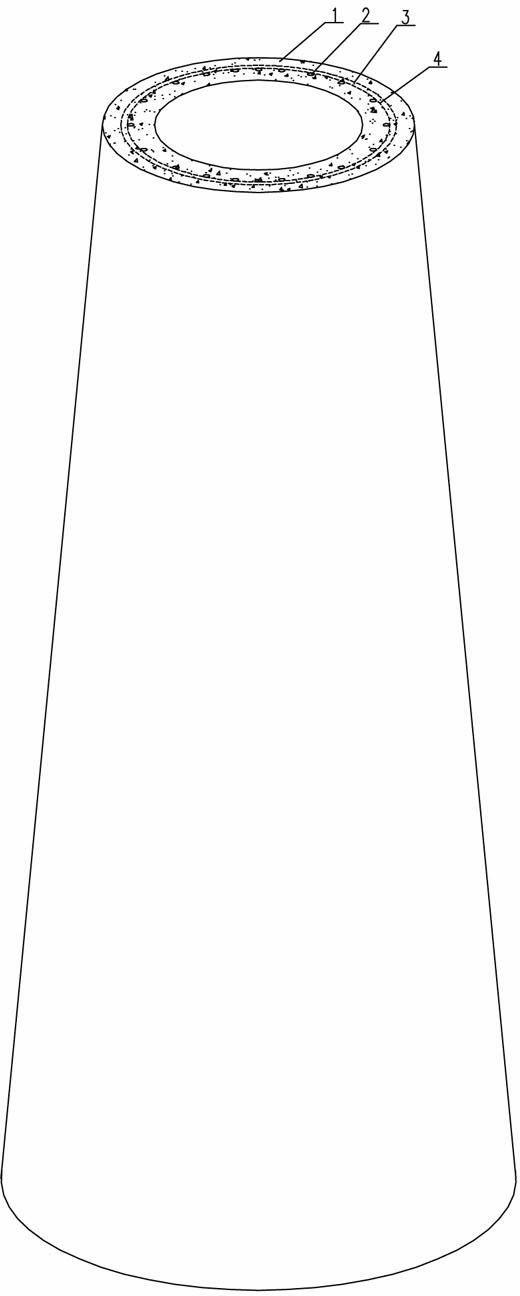

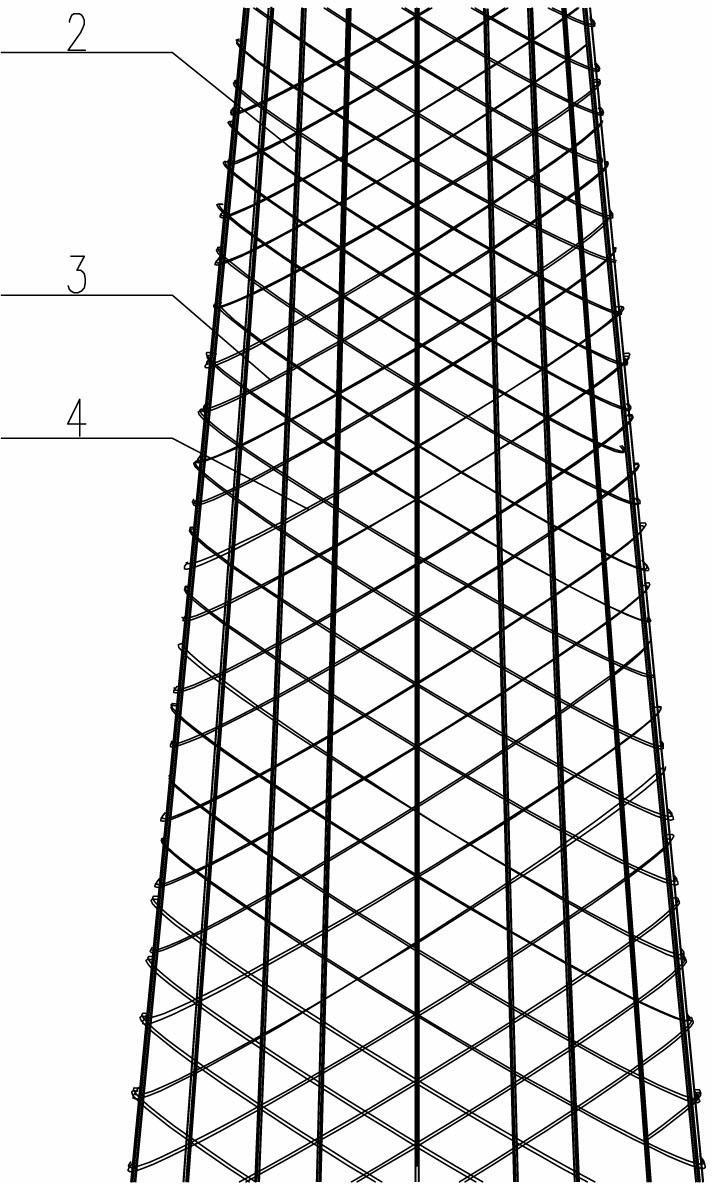

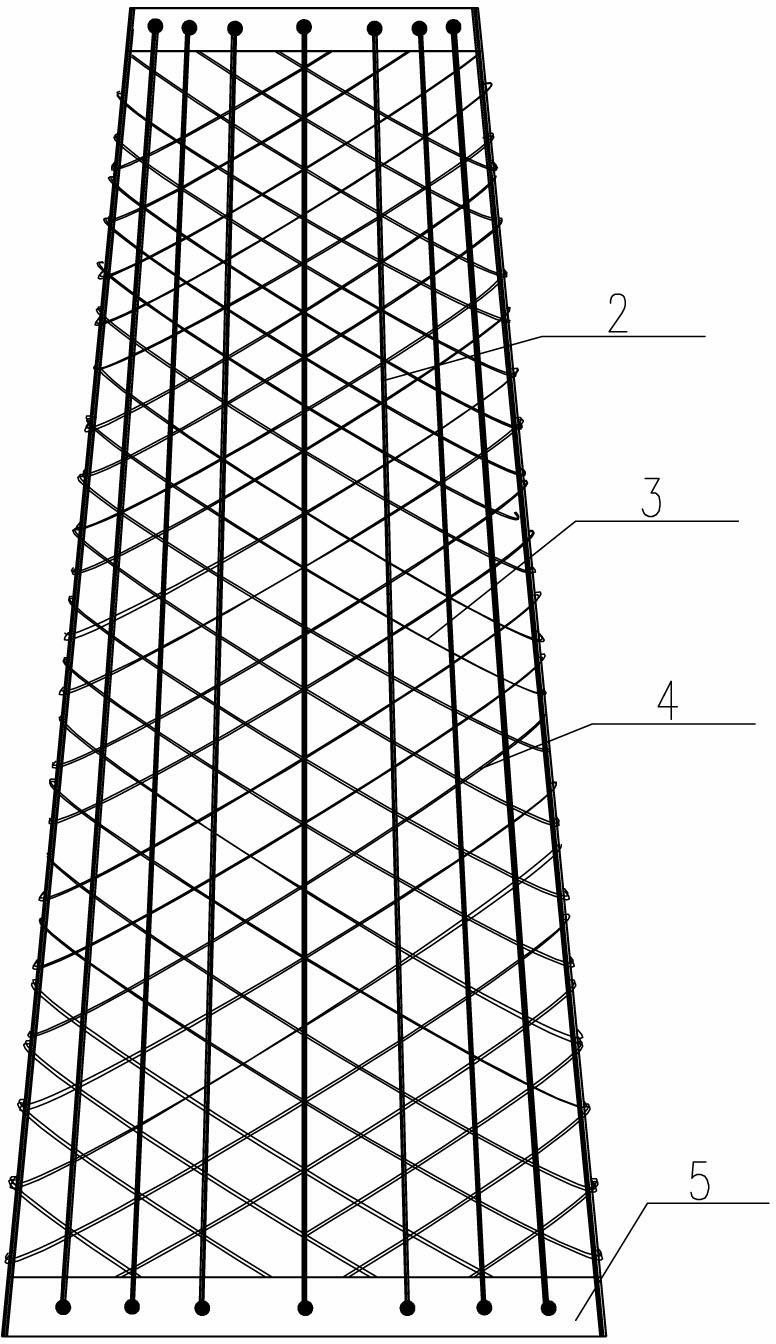

Cement-based composite rod

The invention relates to a cement-based composite rod. The cement-based composite rod is characterized by consisting of a conical cylindrical grid framework and a conical cylindrical rod body which is wrapped on the outer surface of the conical cylindrical grid framework and is formed by solidifying cement mortar filled in gaps of the grid framework, wherein the conical cylindrical grid framework is formed by solidifying at least one layer of longitudinal resin infiltration fiber strips which are uniformly arranged along the circumferential direction together with spiral cross fiber strips formed by resin infiltration fiber strips which are connected with the longitudinal resin infiltration fiber strips in an intersection mode and are wound along the left spiral direction and resin infiltration fiber strips which are wound along the right spiral direction. The cement-based composite rod in the structure has the characteristics of light weight, high intensity, corrosion resistance, impact resistance, long service life and the like, has a novel structure and low cost, saves wood and steel and is the optimal substitute for electric rods, communication rods and lamp rods which are made of cement, the wood and the steel.

Owner:祁锦明

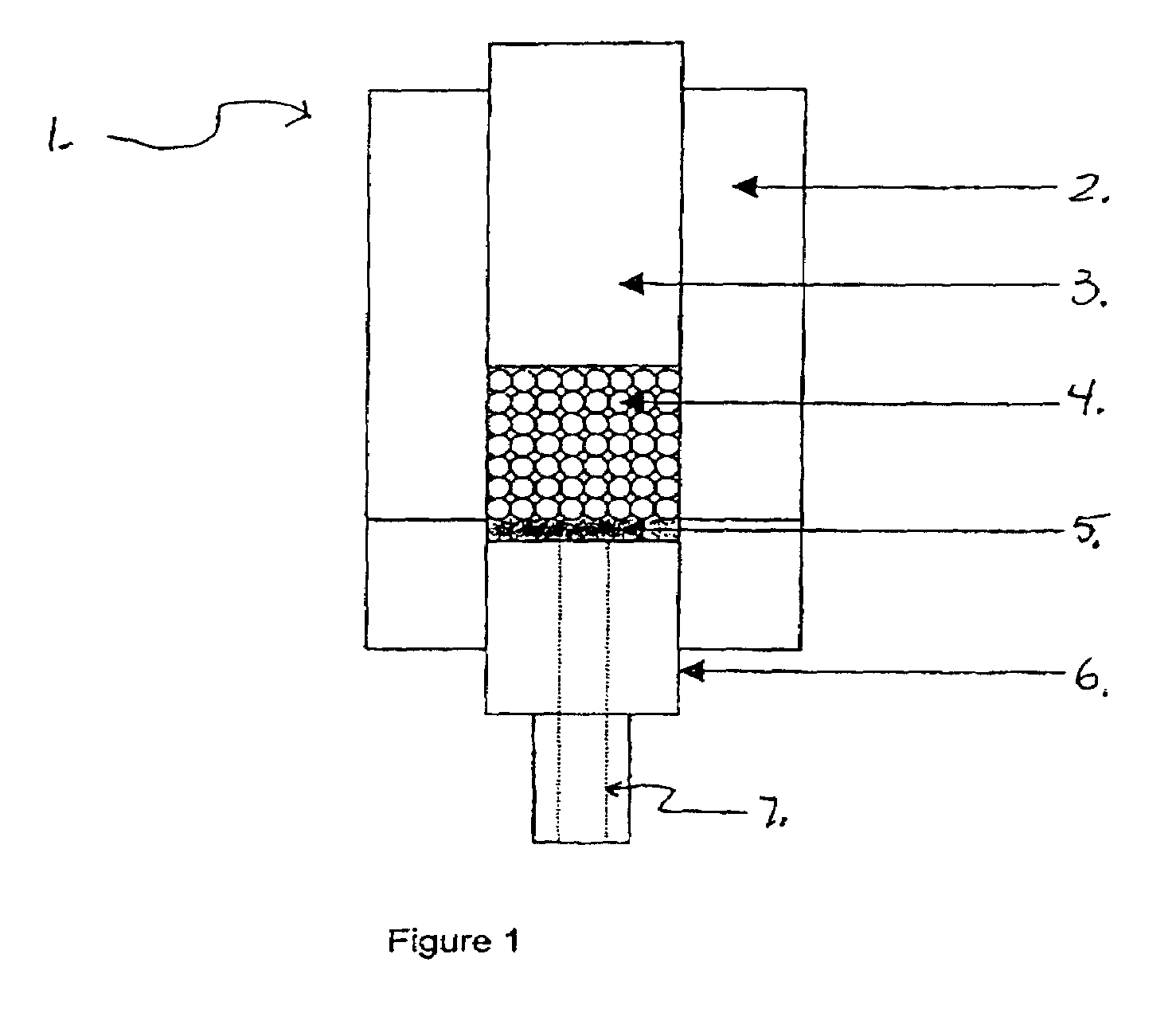

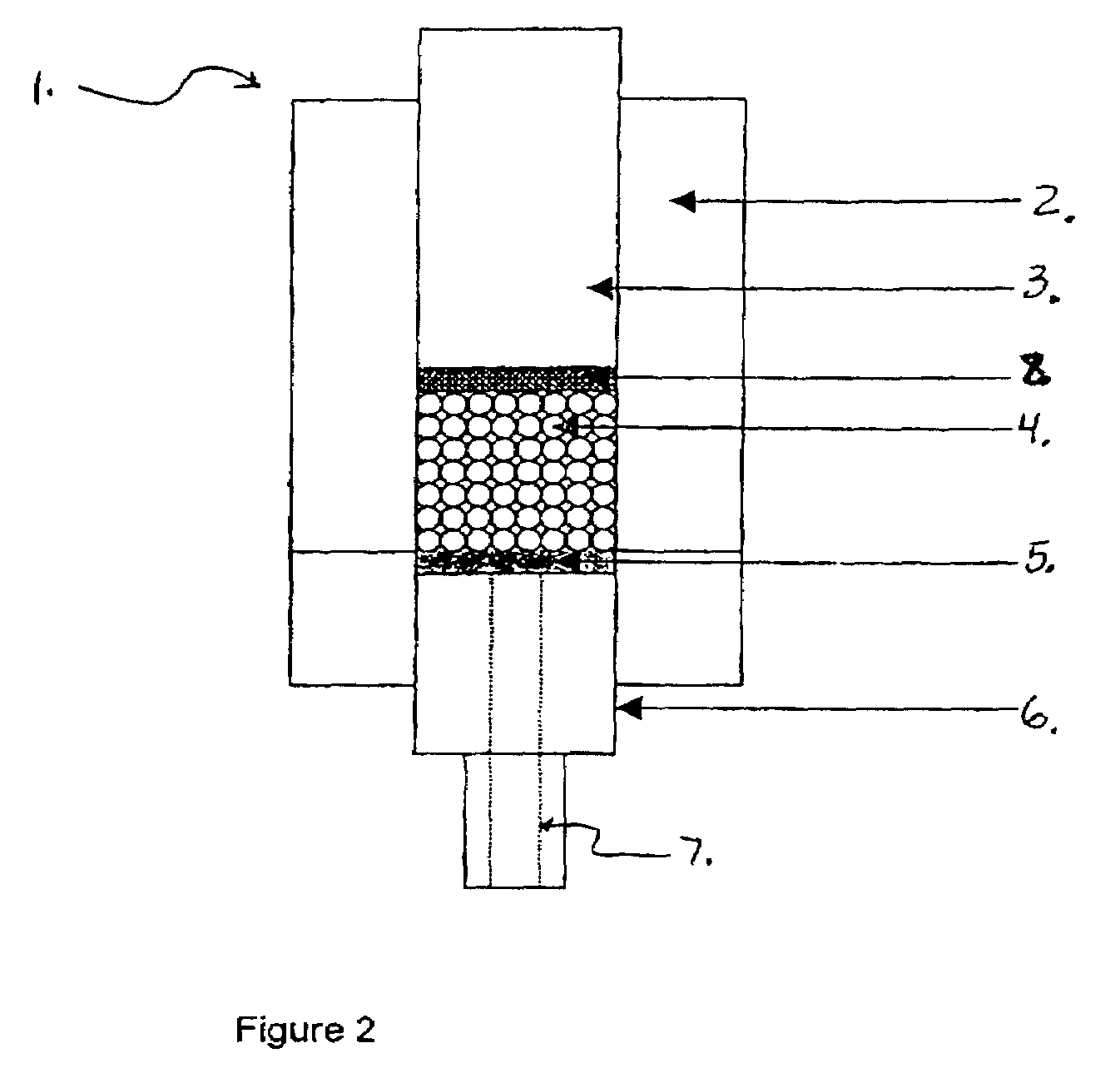

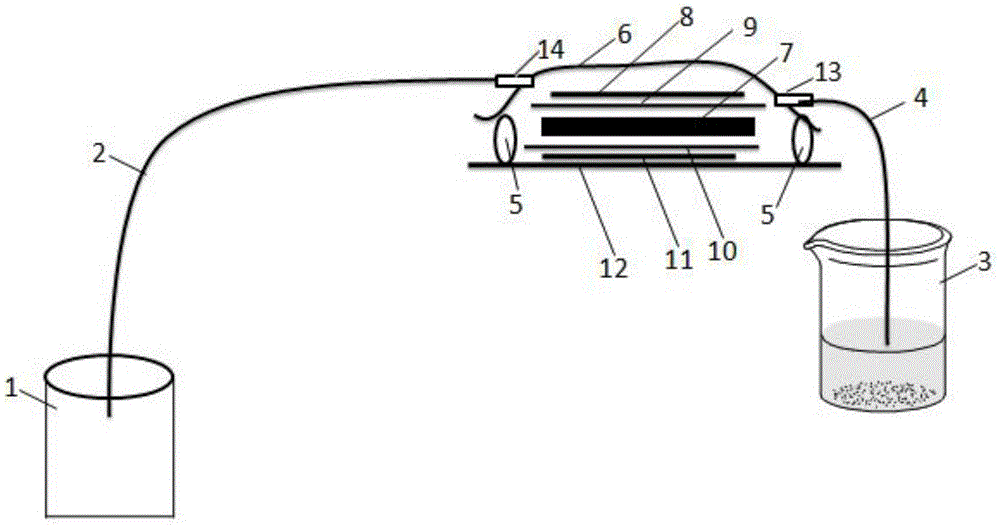

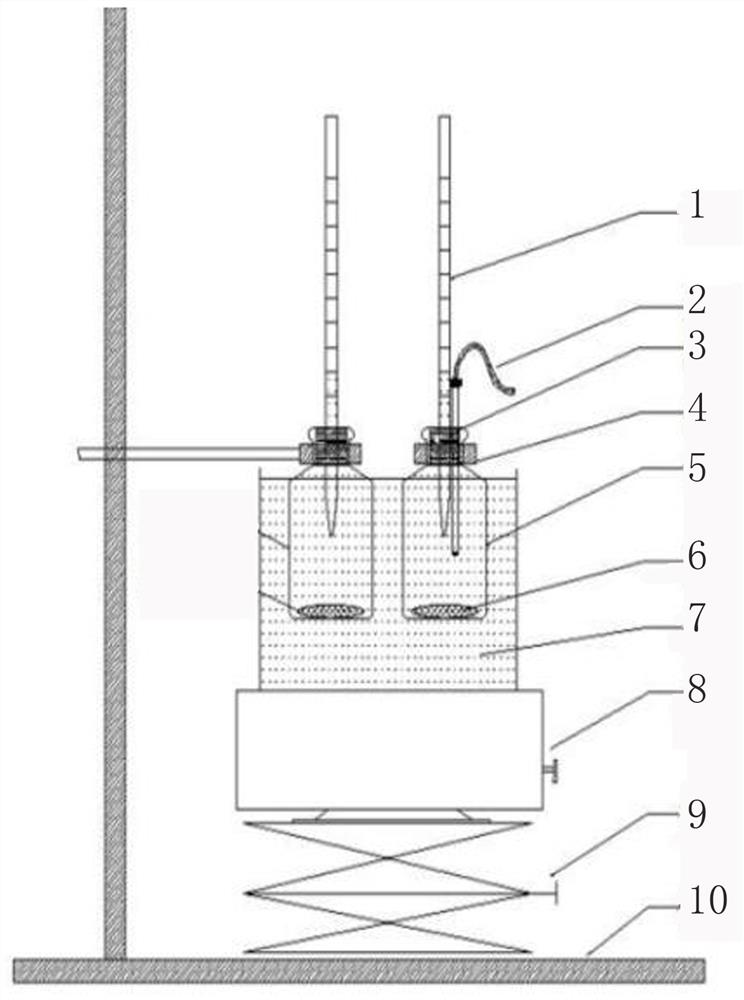

Sintered model resin infiltration method and vacuum infiltration device

InactiveCN107650375AEliminate dustEliminate gasAdditive manufacturing apparatusManufacturing material handlingPolystyreneProper time

The invention provides a polystyrene sintered model resin infiltration method and a production device on the basis of vacuum filling and pressure curing technological principles and provides a novel method aiming at the problem of the poor effect of aftertreatment in an existing coating mode. The polystyrene sintered model resin infiltration method comprises the specific steps that a polystyrene model which is sintered by a laser is placed in a sealed cavity, air in the cavity is pumped, a vacuum environment with the absolute pressure smaller than 40 KPa is established, and an infiltration agent is injected to enable the model to make contact with the infiltration agent sufficiently; and the pressure in the sealed cavity is rapidly increased to be larger than 150 KPa, the proper time is kept to enable the infiltration agent to enter the model under the pressure effect, and after a solidification reaction, the quality and mechanical performance of the surface of the model are improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Preparation method of rock wool/corn straw fiber composite heat insulation material

A preparation method of a rock wool / corn straw fiber composite heat insulation material comprises the following steps: respectively compacting rock wool and corn straw fibers to prepare tablets, arranging the obtained rock wool and corn straw fiber sheets on a pendulum machine in an interval lamination manner to form superposed cotton layers, adding the superposed cotton layers into a pleating machine, carrying out extrusion pleating, impregnating, and curing to prepare the rock wool / corn straw fiber composite heat insulation material. A mass ratio of the rock wool to the corn straw fibers in the material is 70%:30%-85%:15%. The above product prepared through the method can substitute traditional rock wool heat insulation materials widely used at present, the resin infiltration speed and the interface compatibility of the product are effectively improved without influencing the heat insulation performance of the product, the mechanical performances of the product are improved, the specific gravity and the production cost of the product are reduced, and a new approach is provided for comprehensive utilization of corn straws.

Owner:NANJING NORMAL UNIVERSITY

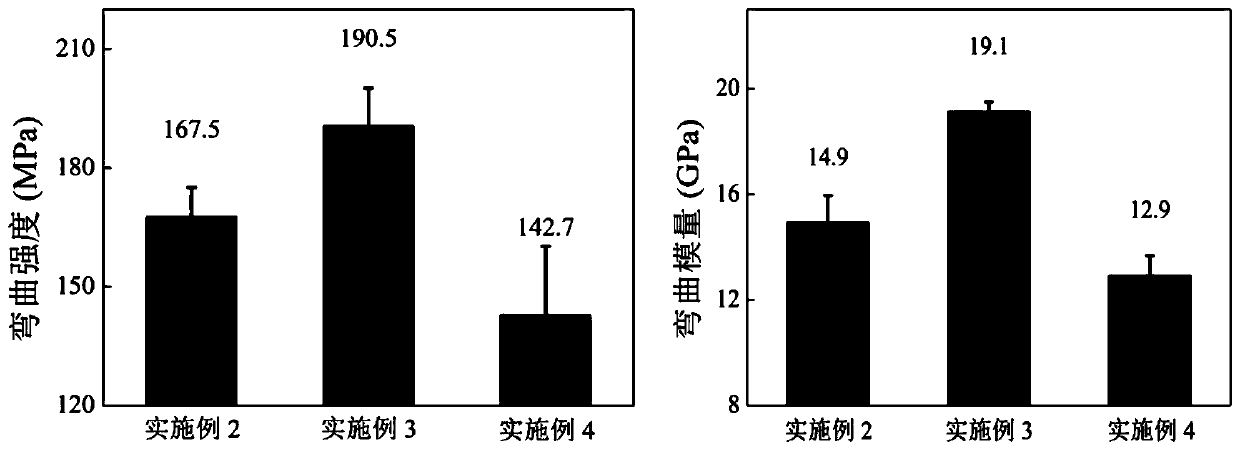

Resin permeable silicate composite material and preparation and application thereof

InactiveCN108524291AEasy to prepareProcess parameters are easy to controlImpression capsDentistry preparationsFlexural strengthTransmittance

Owner:TSINGHUA UNIV

Chrysotile nanofiber and resin composite transparent film, and preparation method and application thereof

InactiveCN103331967ARefractive index adjustmentLow viscositySynthetic resin layered productsSolid-state devicesComposite filmUV curing

A chrysotile nanofiber and resin composite transparent film, and a preparation method and application thereof. The film includes a layer of chrysotile nanofiber layer with pores; the nanofiber layer is wrapped between an upper resin layer and a lower resin layer; and the resin is infiltrated into the pores of the fiber layer. The content of chrysotile nanofiber is 20wt%-75wt%, and the thickness of the transparent composite film is 70-150 mum. The method is as below: adding chrysotile nanofiber into water, adding a polymer binder, and forming a uniform colloidal solution through mechanical stirring and ultrasonic; filtering the colloidal solution with a microfiltration membrane, and drying the obtained filter membrane to form a white chrysotile nanofiber film; and impregnating the chrysotile nanofiber film in vacuum in a UV curing resin, taking out the film, leveling and forming, curing with the UV to obtain the chrysotile nanofiber and resin composite film. The composite transparent film can be applied to substrate materials of organic electroluminescent devices.

Owner:CENT SOUTH UNIV

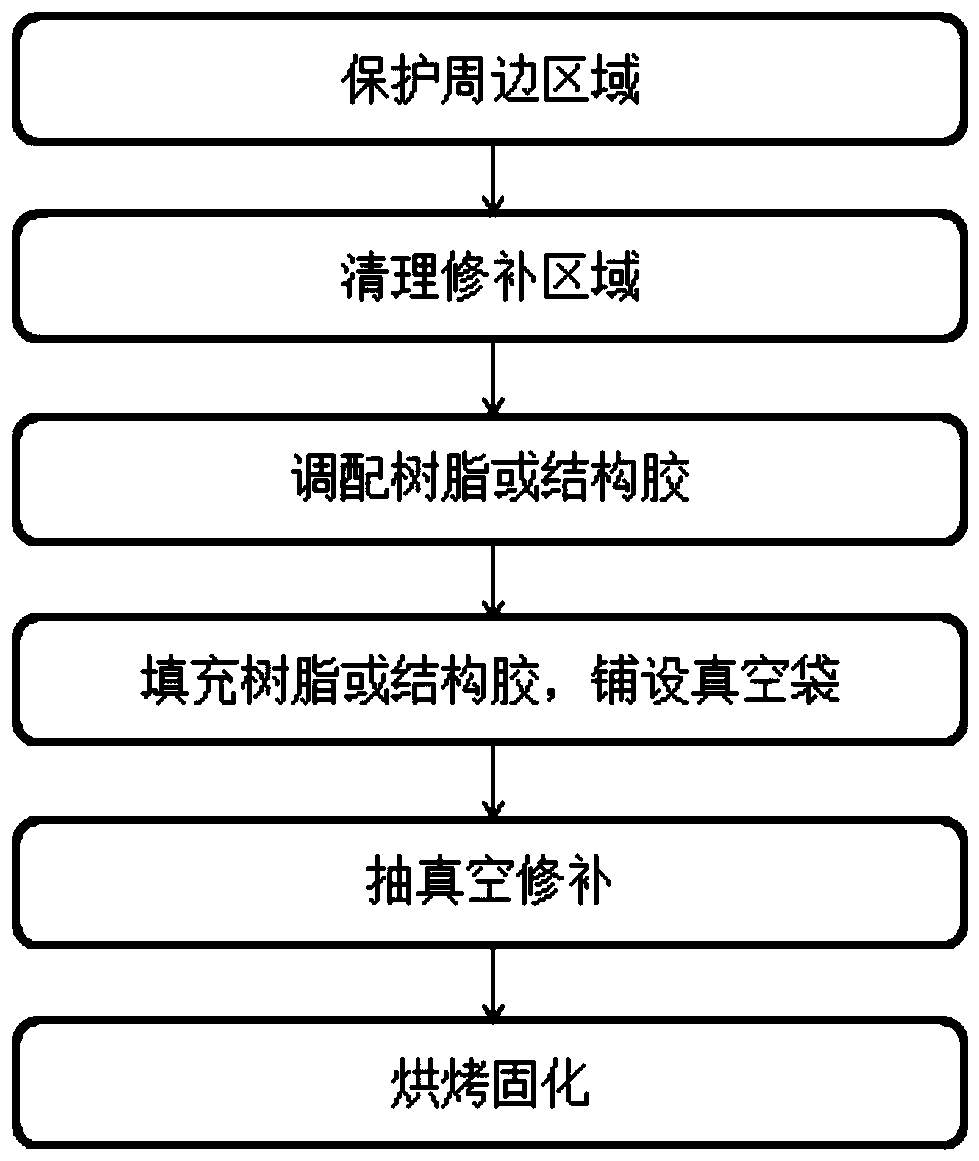

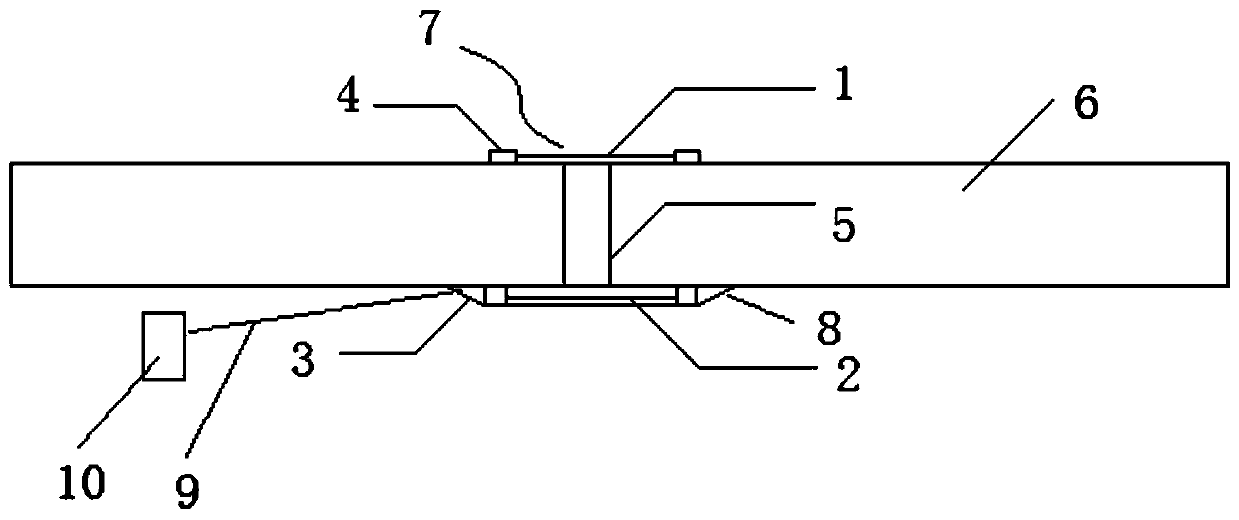

Carbon fiber shell surface penetration type pore and crack repairing structure and process

The invention relates to a carbon fiber shell surface penetration type pore and crack repairing structure and process. The repairing structure comprises carbon fibers to be repaired, pores to be repaired, vacuum bags, glue absorbing cotton, shielding adhesive tape, resin or structural glue, sealing rubber strips and the like. The repairing process comprises the following steps of 1, shielding thesurface around the repaired area by using the shielding adhesive tape, and filling holes nearby by using the sealing rubber strips; 2, removing the paint surface of the repaired area by using a paintremover; 3, blending resin or structural glue according to a certain proportion; 4, coating the inner surface of the repaired area with resin or structural glue, and laying a vacuum bag on the outer surface; 5, connecting a vacuum pump, vacuumizing the repaired position, and removing redundant resin after finishing; and 6, placing a shell in an oven to be baked to completely cure the resin. The negative pressure brought by vacuumizing is used for enabling the resin to penetrate into the carbon layer so as to repair cracks and pores in the carbon layer, and meanwhile it is ensured that the repaired position has certain strength.

Owner:上海伽材新材料科技有限公司

Manufacturing method for light plastic packing boxes

The invention discloses a manufacturing method for light plastic packing boxes. The method includes: firstly, utilizing a light board to make a packing box body with two sides open; secondly, preheating the periphery of a bottom cover of the box body, coating the bottom cover with hot melt adhesive prior to continuous heating, and then rapidly combining the bottom cover on one opening of the packing box body to seal the opening; thirdly, after the hot melt adhesive is cooled to normal temperature, coating gap positions inside the packing box body with the hot melt adhesive; fourthly, fixedly mounting stainless steel seal edges on all ridges outside the packing box body, and hinging an end cover at the other opening, wherein the end cover is in seal fit with the packing box body when closed. The light board is composed of a middle core layer of a hexagonal honeycomb structure and surface layers, the surface layers are arranged on two side faces of the middle core layer, the middle core layer is composited by polypropylene and glass fibers and is of the hexagonal honeycomb structure by injection molding, the surface layers are made of polypropylene resin infiltration glass fiber cloth via hot pressing compositing, and the surface layer, the middle core layer and the surface layer are laid between two pressing boards to composite the light board.

Owner:余姚中国塑料城塑料研究院有限公司

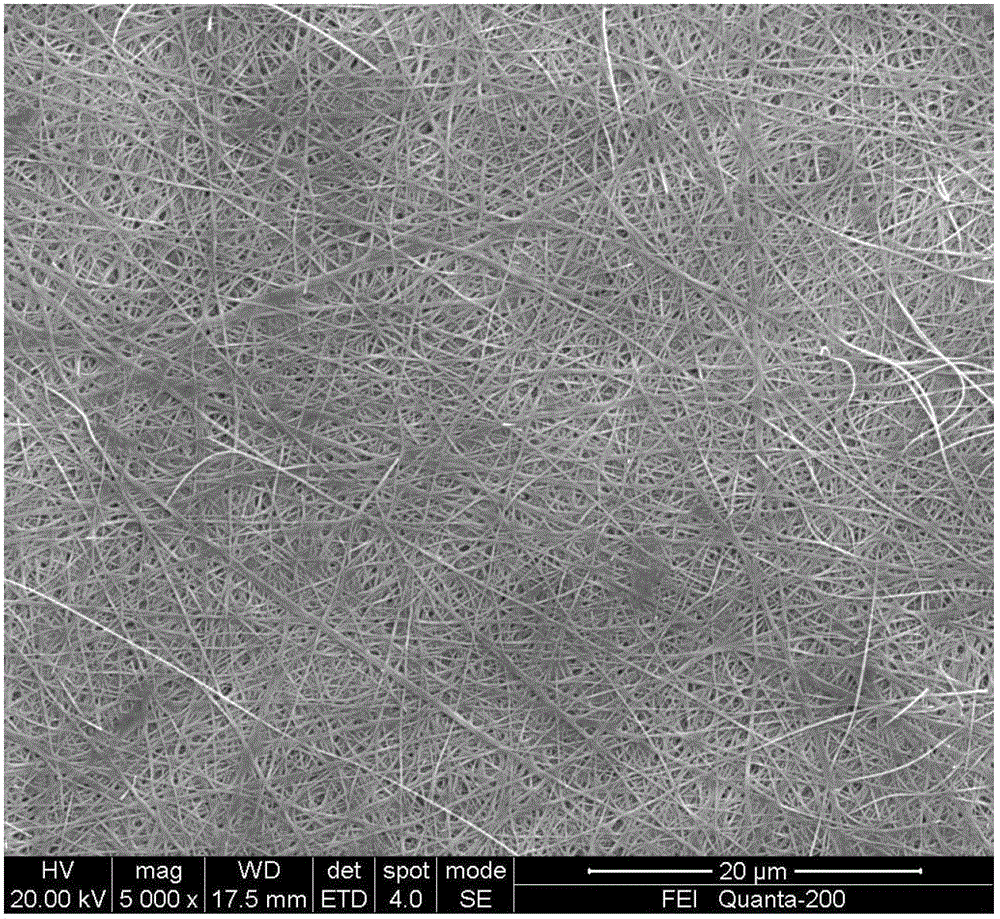

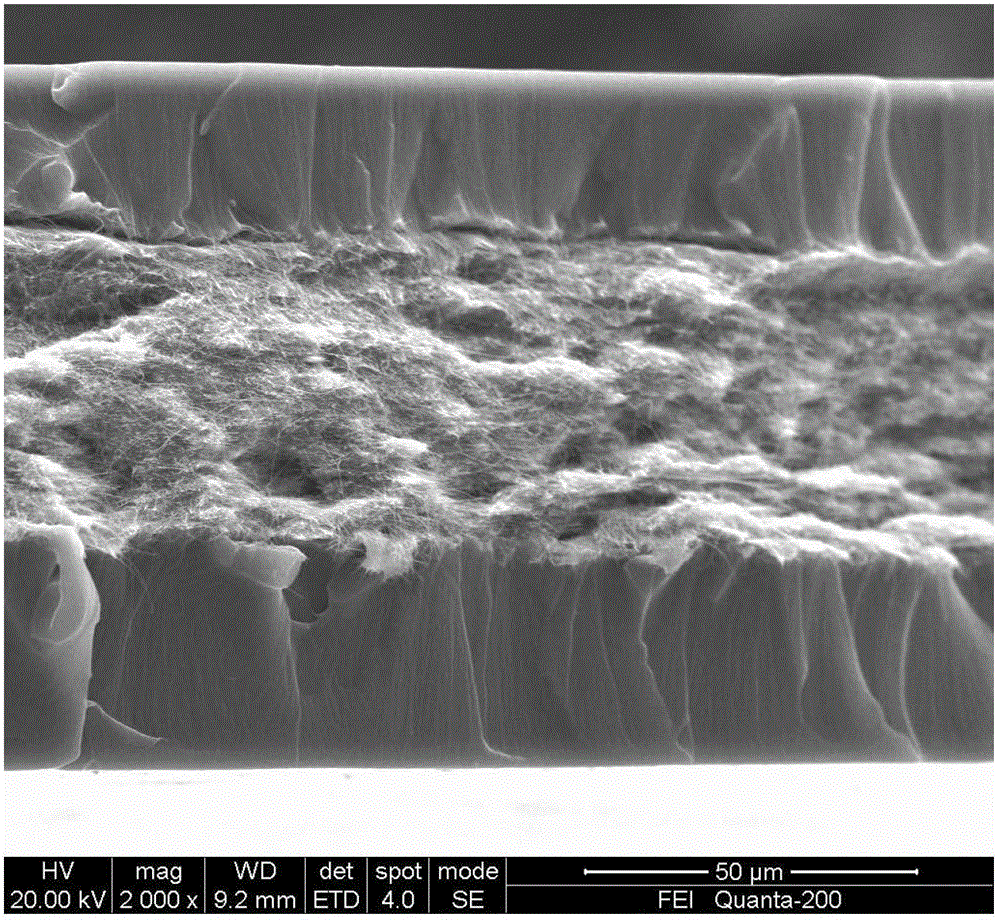

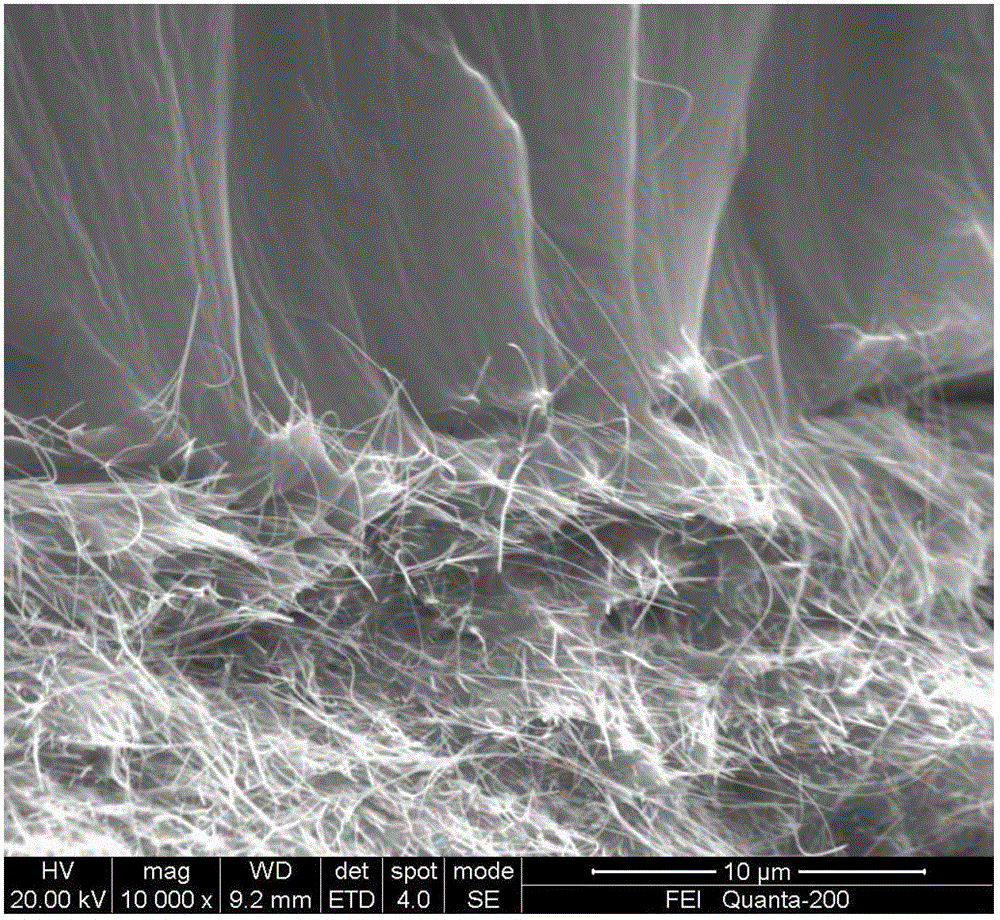

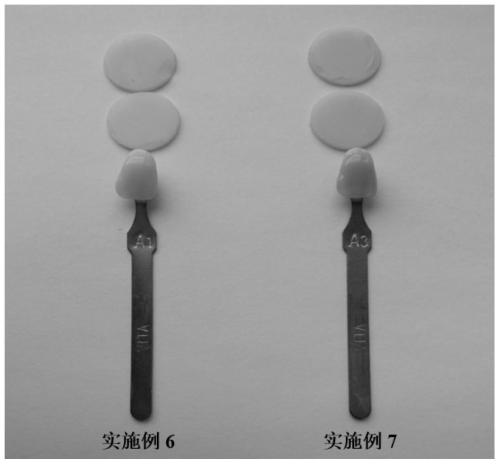

Resin infiltration zero-dimensional/one-dimensional porous ceramic composite material for dental restoration, and a preparation method thereof

InactiveCN110028333ARaw materials are easy to getEasy to makeImpression capsDentistry preparationsNatural toothFiber

The invention relates to a resin infiltration zero-dimensional / one-dimensional porous ceramic composite material for dental restoration, and a preparation method thereof, and belongs to the field of dental restoration materials. According to the present invention, a dental restoration material with performances well matched with natural human teeth is designed and prepared; the guiding ideology isbased on the principle of multi-scale and multi-dimensional reinforcement and toughening; a porous ceramic preform is prepared by mixing preparing zero-dimensional ceramic powder and one-dimensionalceramic nano-wires / fibers, and a dental restoration material having a good resin and ceramic double-interpenetrating cross-linking network structure, capable of being using for CAD / CAM technology cutting and having mechanical properties matched with natural teeth and excellent cutability is prepared by using a vacuum-assisted resin infiltration technology and a thermal curing technology; and the bridging effect of the one-dimensional nanometer filler can effectively prevent the occurrence and development of cracks so as to improve the mechanical properties of the restored body and can effectively reduce the wear loss of the ceramic powder.

Owner:BEIJING UNIV OF CHEM TECH +1

Composite sleeper with wooden inner core

A composite sleeper with a wooden inner core that can be used to support railway rails, the inner core of the sleeper is a wooden material, and glass fiber roving soaked with unsaturated polyester resin is longitudinally wound on the outside of the wooden material. The outermost layer of the composite sleeper is a glass fiber multi-axial cloth after surface treatment with a coupling agent and then infiltrated with a polyurethane resin. The composite sleeper of the invention will not be damaged by interlayer shear force when the sleeper is bent under force, and has high safety and long service life. In addition, the outer layer of the composite sleeper is still polyurethane composite material, so it has the excellent characteristics of hydrolysis resistance, oil resistance, and weather resistance unique to weathering environment; To a certain extent, the demand for polyurethane is saved, the cost of this type of composite sleeper is reduced, and the performance of the sleeper is not affected at the same time.

Owner:北京交跃通达检测科技有限公司

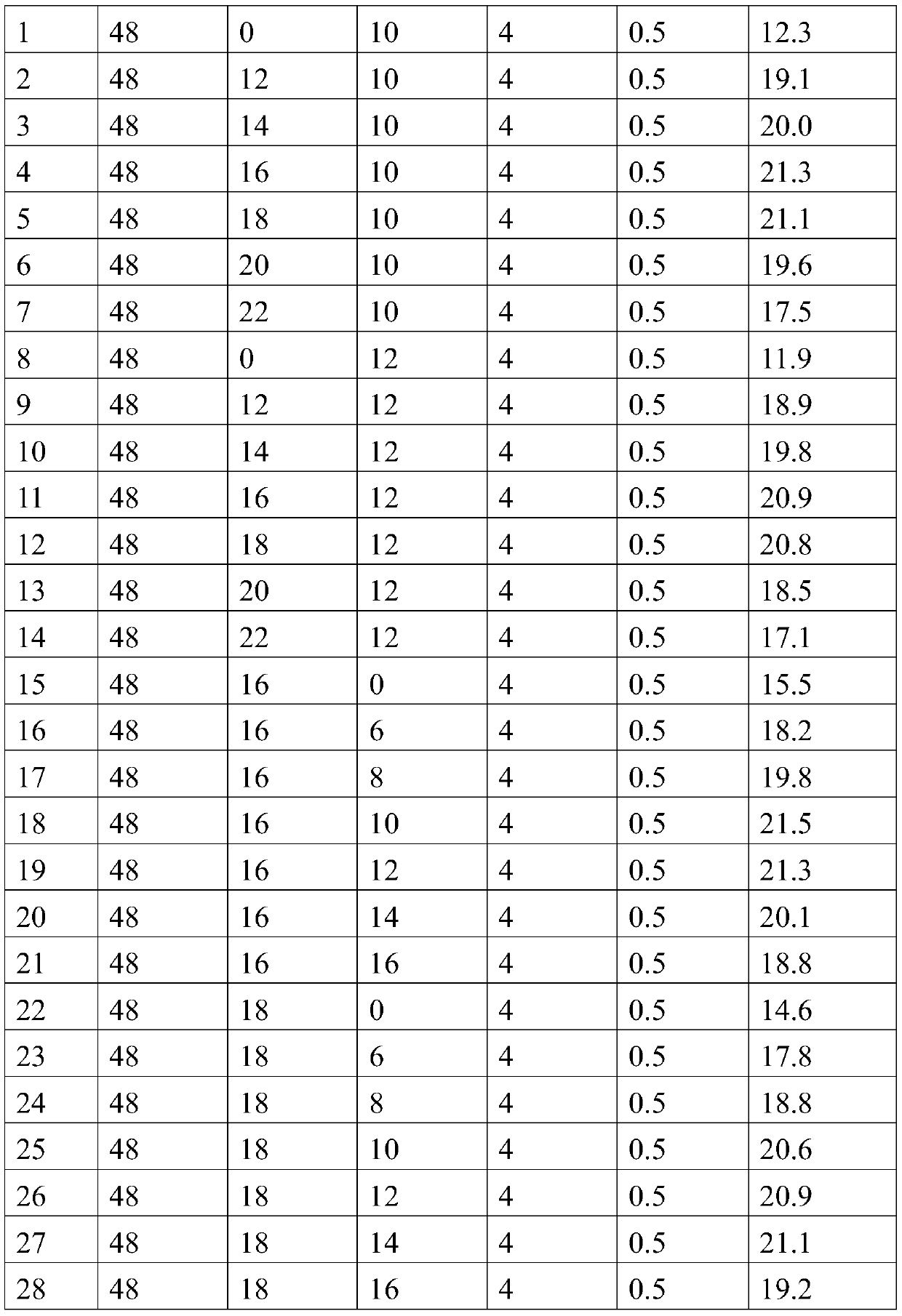

Energy-saving gypsum board

The invention discloses an energy-saving gypsum board. The energy-saving gypsum board is characterized by comprising the following raw material: 48 parts of gypsum, 17 parts of sodium salt slag with aparticle size of less than 2mm, 11 parts of silica fume, 4 parts of zeolite powder, 0.5 part of a superplasticizer, and 19.5 parts of water. The gypsum board is subjected to phenolic resin infiltration treatment. The energy-saving gypsum board provided by the invention has the advantages of good mechanical properties, green and environmental protection.

Owner:叶香竹

a composite sleeper

ActiveCN101851879BThere will be no interstory shear failureImprove securityBallastwayGlass fiberResin-Based Composite

Owner:北京交跃通达检测科技有限公司

Method for making resin slices of mature grain seeds

InactiveCN104374601BCreate slice making methodBuild methodWithdrawing sample devicesPreparing sample for investigationEmbedding AgentPolymerization

Owner:YANGZHOU UNIV

Resin adhesive for bonding thermosetting plastics and thermoplastic plastics and preparation method and application thereof

ActiveCN103450820AGreat ability to resist ground subsidenceStrong ability to resist ground subsidenceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveThermoplasticAcrylonitrile

The invention relates to an adhesive and particularly discloses a resin adhesive for bonding thermosetting plastics and thermoplastic plastics and a preparation method and application thereof. The resin adhesive for bonding the thermosetting plastics and the thermoplastic plastics is prepared from the following raw materials in parts by weight: 800-1,000 parts of o-xylene or m-xylene, 280-450 parts of chlorinated polypropylene, 15-42 parts of styryl diethoxysilane, 2-6 parts of acrylonitrile, 1-3.5 parts of di-tert-butyl ether peroxide, 5-15 parts of acrylic acid and 4-6 parts of dimethacrylate-diester. The resin adhesive and the preparation method thereof have the beneficial effects that the raw materials are easily purchased, the cost is low, the toxicity is low, the use is convenient, the bonding is firm, a glass fiber reinforced plastic pipe which is formed through winding glass fibers after the glass fibers are subjected to resin infiltration is tightly combined with an inner pipe so as to form an integer, the split slippage of the inner pipe and an outer pipe is avoided, the coefficient of heat conductivity is large, and the heat resistance is good, so that the problem of bonding between the thermosetting plastics and the thermoplastic plastics is solved effectively, and the resin adhesive is used for bonding the thermosetting plastics (especially glass fiber reinforced plastics) and the thermoplastic plastics (especially polypropylene materials).

Owner:山东呈祥电气有限公司

Chlorinated polyvinyl chloride resin and preparation method thereof

ActiveCN109517100AHigh softening temperatureImproved dynamic heat resistanceState of artPolymer science

The invention discloses a chlorinated polyvinyl chloride resin and a preparation method thereof. The preparation method comprises the following steps: a step of suspension preparation and PVC (Polyvinyl Chloride) resin infiltration, a chlorination process step, a deacidification step, a neutralization step, a centrifugation step and a drying step, wherein the chlorination process step is in an anaerobic atmosphere; chlorine is introduced into the chlorination process step according to a chlorination program; and a chlorine introduction manner is to introduce liquid chlorine into the bottom ofa chlorination kettle. The chlorine content of the prepared product chlorinated polyvinyl chloride resin reaches 66-72%, the tensile strength is more than or equal to 50MPa, the Vicat softening temperature is more than or equal to 120 DEG C, and the dynamic thermal stabilization time is more than or equal to 25 minutes. Compared with the prior art, the chlorinated polyvinyl chloride resin disclosed by the invention has the advantages that the Vicat softening temperature is improved by 5-10 DEG C, the dynamic heat resistance is improved by 5-15 minutes, and the comprehensive performance is excellent; the reaction time is shortened, the production efficiency is improved by 25-50%, and the service life of the equipment is prolonged by 50-200%; and hydrochloric acid and condensate water neededin preparation of the suspension come from the chlorination process and the drying process, recycling of the hydrochloric acid is realized, the heat value of the condensate water is effectively utilized, comprehensive utilization of heat and water resources is realized, and the chlorinated polyvinyl chloride resin is energy-saving and environmental-friendly.

Owner:山东高信化学股份有限公司

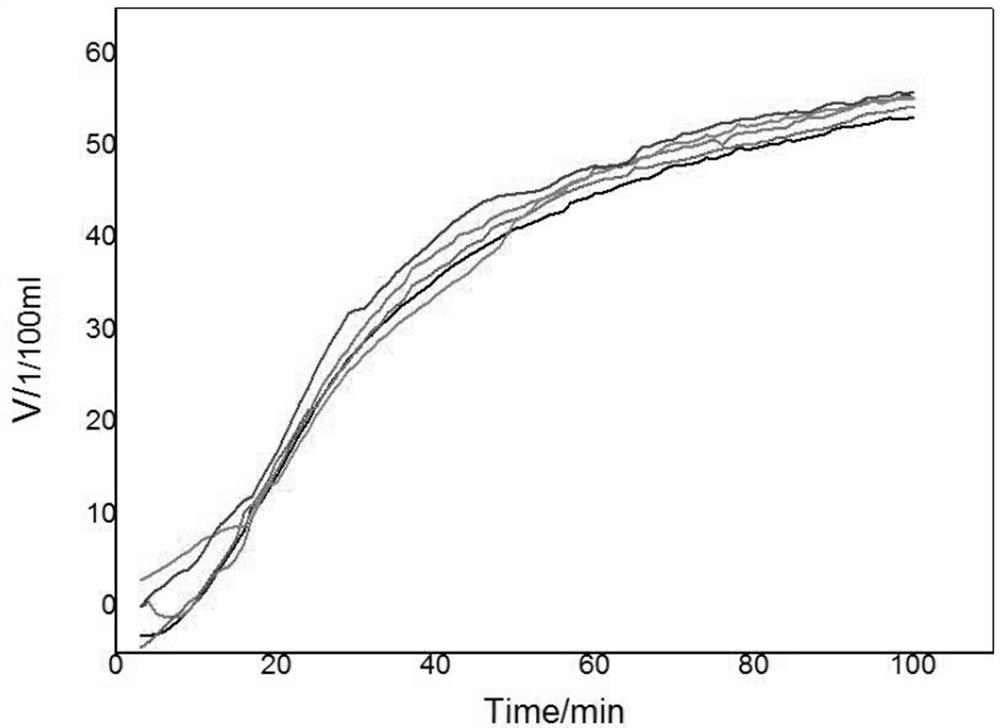

Method for testing resin curing shrinkage volume and fiber-resin contact angle

The invention provides a method for testing resin curing shrinkage volume and fiber-resin contact angle, which comprises the following steps of: 1, uniformly mixing a resin curing system to be tested according to a proportion, vacuumizing, filling a sample bottle with accurate scales, filling another same sample bottle with resin with equal weight and without a curing agent as a control group, 2, fixing pipettes and a temperature sensor at the bottleneck of a sample bottle through a rubber plug, 3, adjusting the height of a liquid column in the pipettes, and respectively putting two same fiber bundles into the two pipettes, 4, heating the sample at the moment when the fiber bundles contact the liquid level, and timing, respectively making reaction time-volume change curve graphs of the group to be detected and the control group; observing and shooting the fiber-resin infiltration angle. According to the method, the resin curing shrinkage volume and the change of the fiber-resin contact angle in the curing process can be obtained at the same time through one experiment, and compared with a traditional testing method, the testing device is simple, and the testing precision is high.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Manufacturing method of no-skeleton muscle specimen

ActiveCN109003524ALow costRich display countDead animal preservationEducational modelsAnatomical structuresDissection

The invention provides a manufacturing method of a no-skeleton muscle specimen. The manufacturing method comprises the following steps: selecting an object; skin stripping; dissection; dissection of muscles, nerves and blood vessels; dehydration, degreasing and resin infiltration; manufacturing of the muscle specimen; and repair, solidification and cleaning. The limitation of skeleton and muscle attachment can be overcome and the skeleton and the muscle can be independently displayed and move so as to save the cost of raw materials; the display number and the content of individual raw materialmanufacturing specimen can be enriched; and the autologous skeleton and muscle of the same specimen can be simultaneously, deeply, visually and completely displayed so that the anatomical structure and adjacent position of the skeleton and the muscle of the same individual can be displayed in vitro, and the anatomical structure and the functional relationship can be more visual.

Owner:DALIAN HOFFEN BIO TECHN

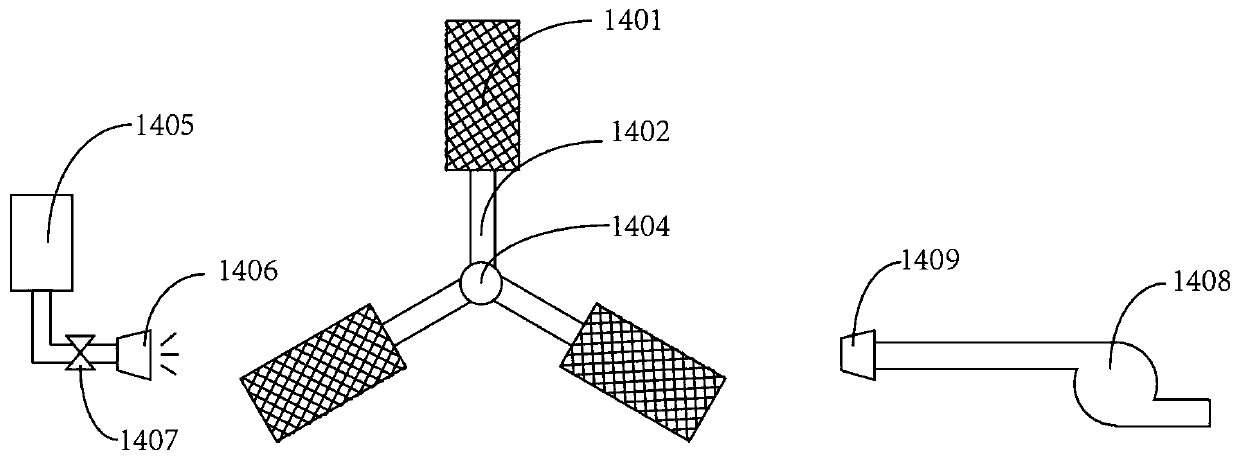

Novel carbon fiber prepreg system and manufacturing method of novel carbon fiber prepreg

PendingCN110052355AImprove wettabilityAvoid blowingLamination ancillary operationsLaminationFiber bundleCarbon fibers

The invention provides a novel carbon fiber prepreg system and a manufacturing method of novel carbon fiber prepreg. The novel carbon fiber prepreg system comprises high-pressure resin nozzles, wherein the high-pressure resin nozzles are symmetrically arranged on the front side and the back side of a carbon fiber bundle, one ends of the high-pressure resin nozzles are connected with a metering device, one end of the metering device is connected with a stock bin, the stock bin communicates with the metering device and the high-pressure resin nozzles in sequence, a first electromagnetic valve isarranged between the stock bin and the metering device, a second electromagnetic valve is arranged between the metering device and the high-pressure resin nozzles, a heating mechanism is further arranged in the metering device, and an adhesive amount adjusting device is further arranged between the high-pressure resin nozzles and the carbon fiber bundle, and is used for adjusting the amount of adhesives sprayed onto the carbon fiber bundle by the high-pressure resin nozzles. According to the novel carbon fiber prepreg system and the manufacturing method of novel carbon fiber prepreg, a two-side spraying structure is adopted for resin infiltration on the carbon fiber bundle, so that the infiltration effect is good.

Owner:汉硕高新材料(天津)有限公司

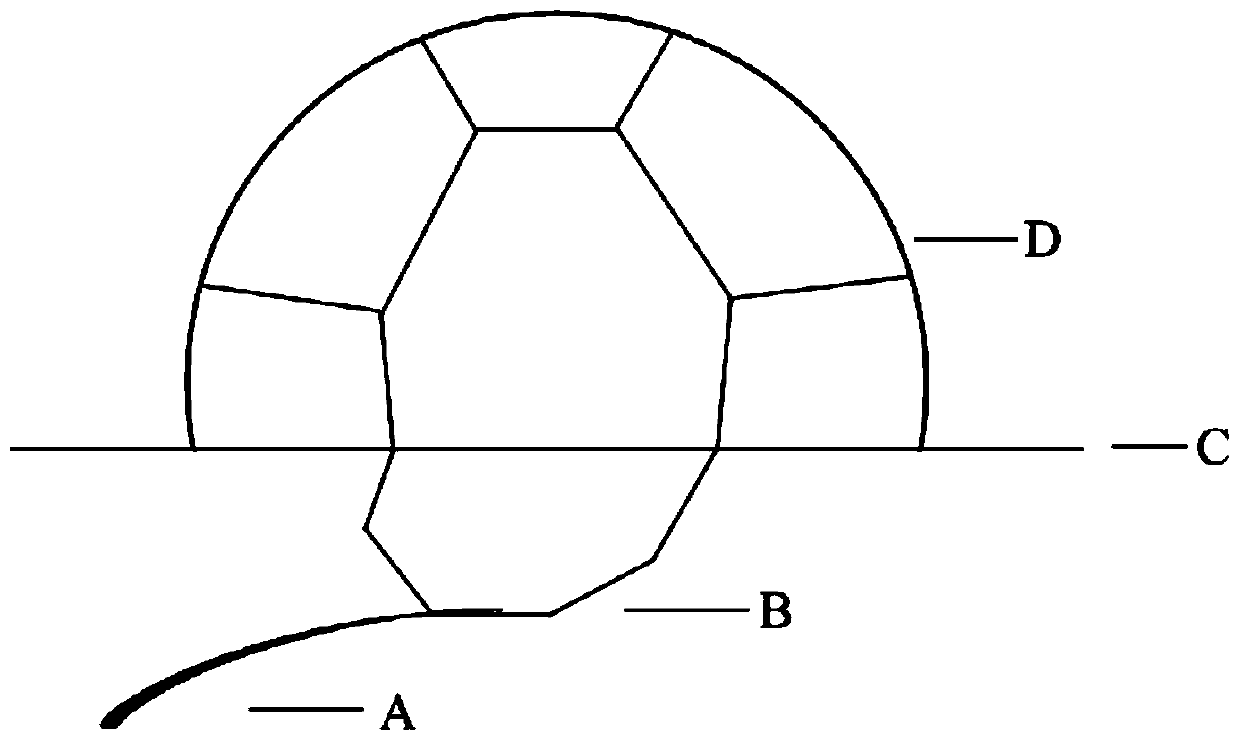

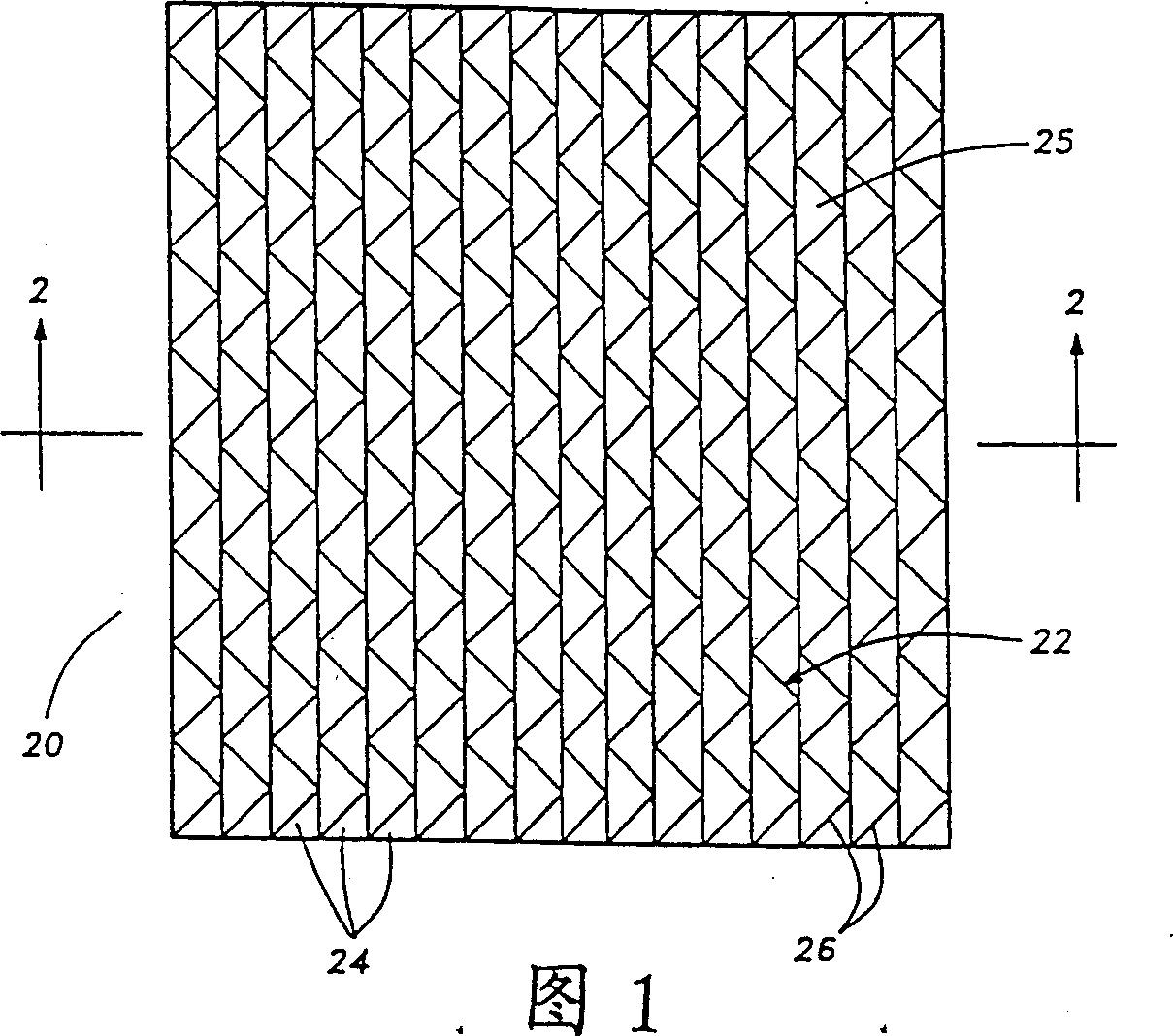

Fabrics and method for producing fabrics

InactiveCN1089678CPromote absorptionPromote infiltrationLaminationPaper/cardboard layered productsGlass fiberFiber

A chopped fiberglass tow mat (34), at least one layer of long fiberglass rovings (22, 28, 30, 32) and a porous tissue paper bottom layer (36) are formed into a multilayer fabric ( 20). A tissue (36) is placed on the first side of the chopped tow mat (34). Layers of rovings (22, 28, 30, 32) are superimposed on one opposing side of the mat (34). The layers are stitchbonded together to form a composite fabric that has favorable resin wetting properties when used as reinforcement in composite products.

Owner:OWENS CORNING FIBERGLAS ESPANA SA

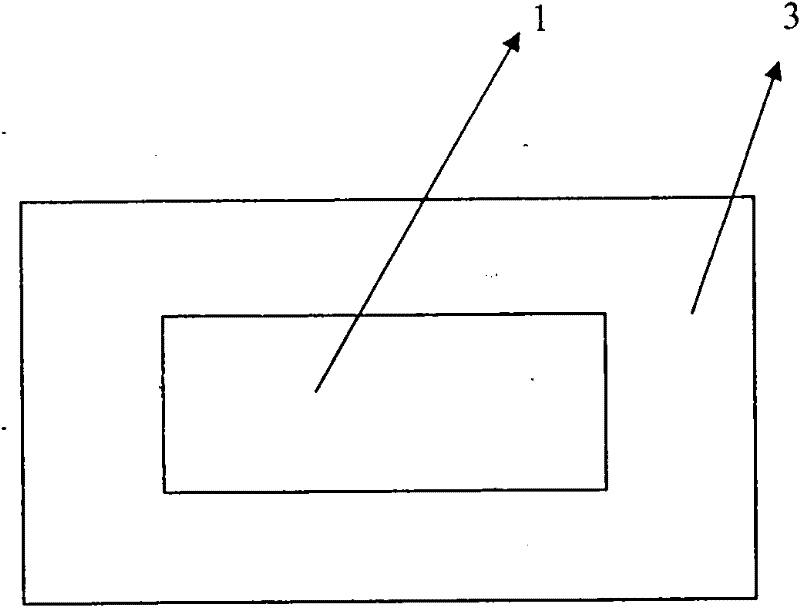

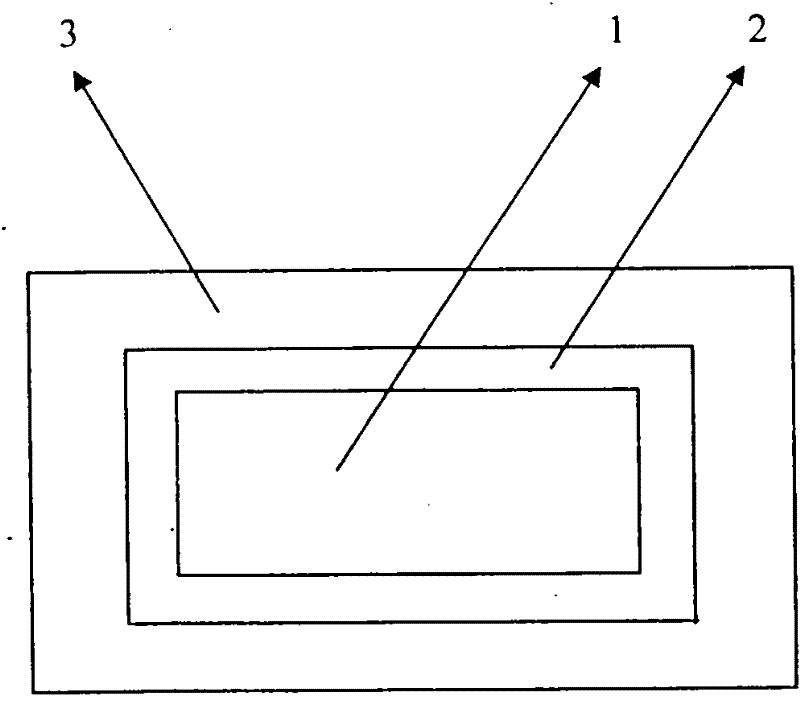

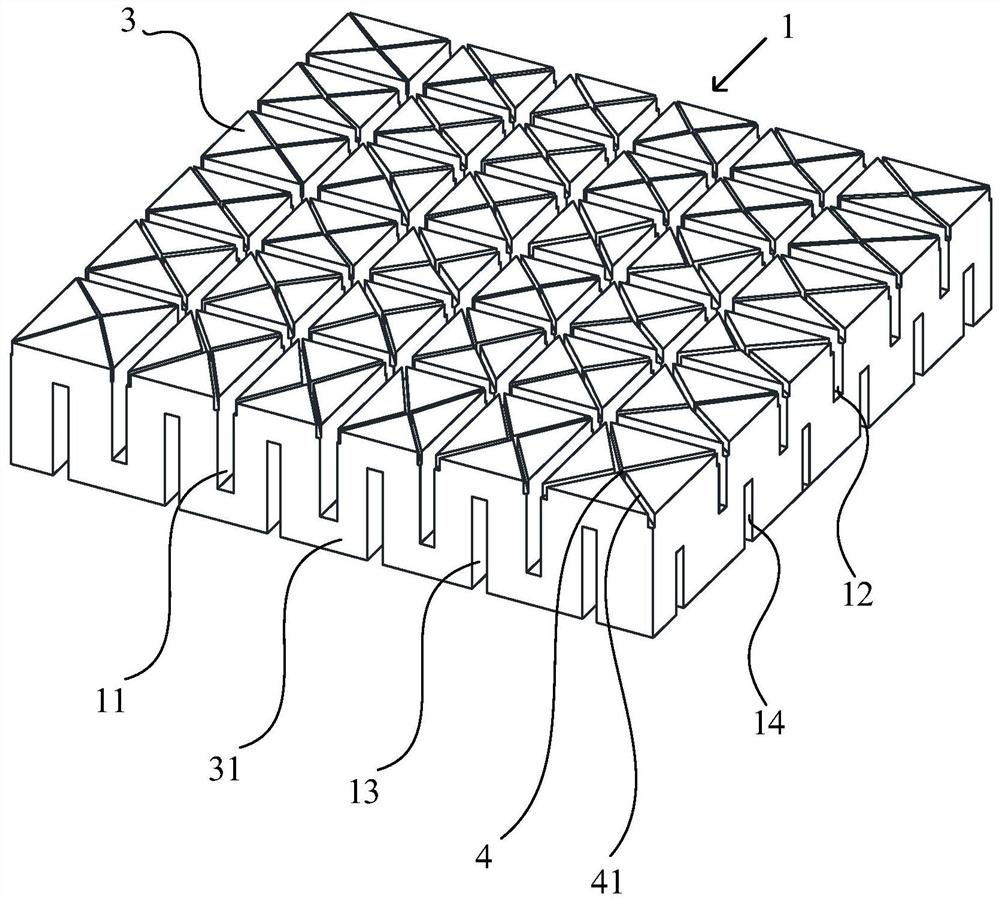

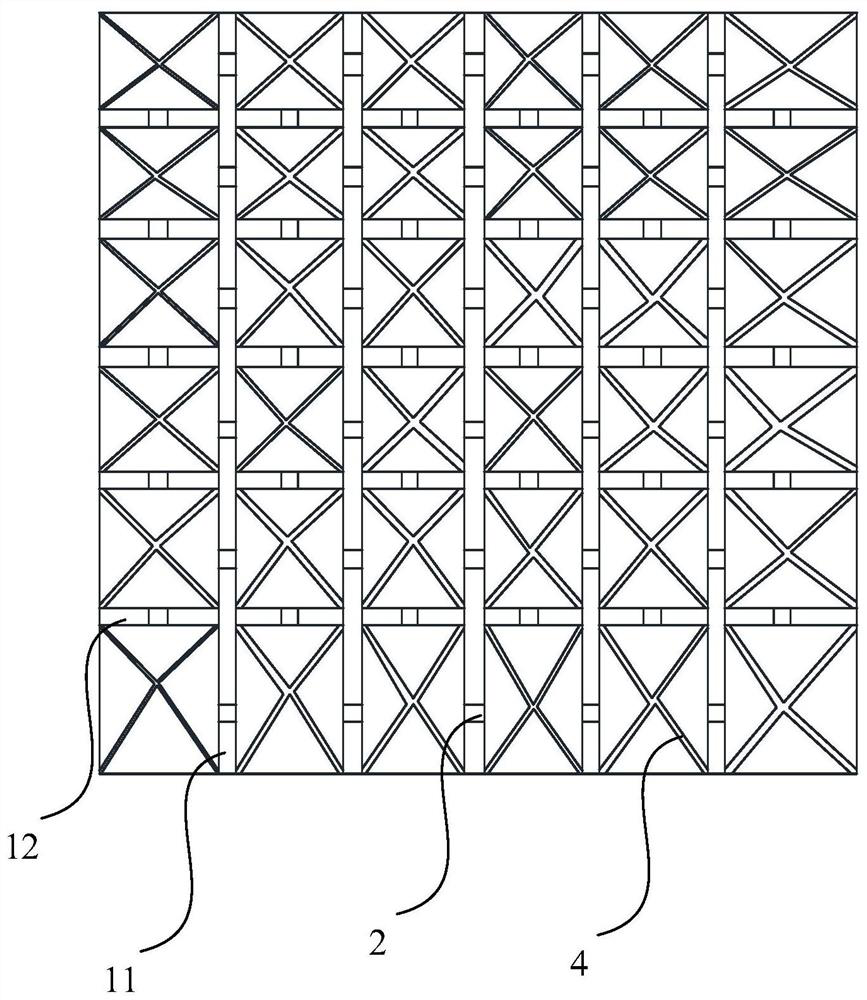

Core material, blade and blade forming method

PendingCN113738603AImproved ability to wet out resinHigh resin contentMachines/enginesEngine componentsFiberEngineering

The invention discloses a core material, a blade and a blade forming method. At least one first deep groove and at least one first shallow groove which are in communication with each other are formed in the upper surface of the core material, the first deep grooves and the first shallow grooves are formed in different directions of the upper surface and extend to the edge of the upper surface, the lower surface of the core material is provided with at least one second deep groove and at least one second shallow groove which are in communication with each other, the second deep grooves and the second shallow grooves are arranged in different directions of the lower surface and extend to the edge of the lower surface, the depth of the first deep grooves and the depth of the second deep grooves are 1 / 3-4 / 5 of the thickness of the core material, and the depth of the first shallow grooves and the depth of the second shallow grooves are smaller than those of the first deep grooves and the second deep grooves. The grooves are formed in the upper surface and the lower surface of the core material in different directions, so that the resin infiltration capacity of the core material is improved, the fixing and bonding performance of the core material and reinforced fibers is improved, the resin content in the core material can be improved, waste of resin raw materials can be avoided, the core material in the scheme is good in flow guide effect, and meanwhile the core material can be freely bent.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com