Cement-based composite rod

A composite rod, cement-based technology, applied in building types, buildings, towers, etc., can solve the problems of heavy weight, heavy steel bar, poor freeze-thaw resistance, etc., and achieve the effect of novel structure, wood saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

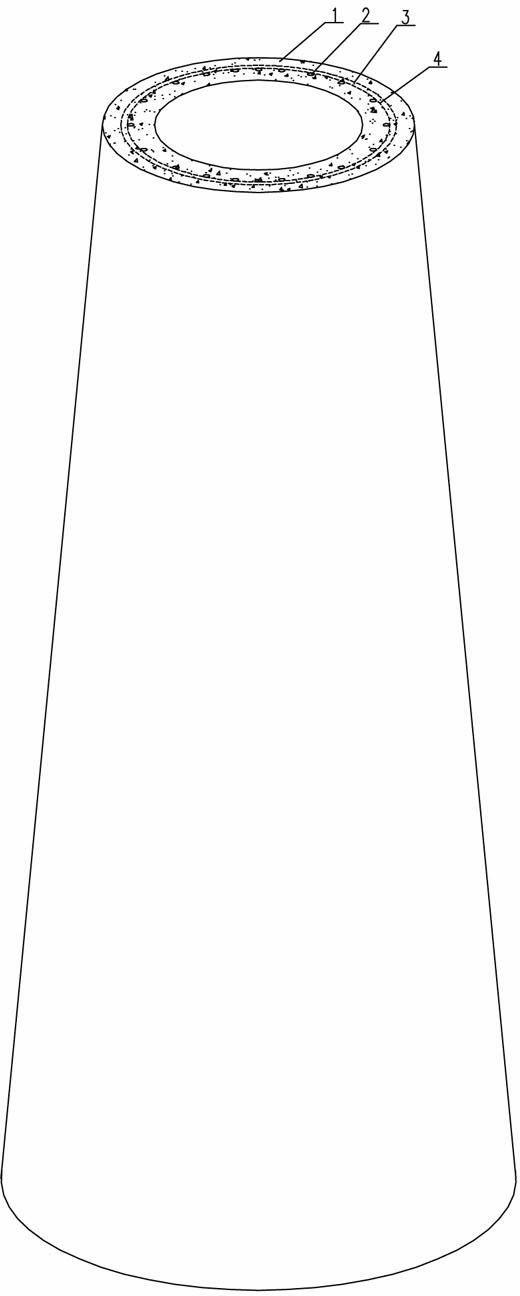

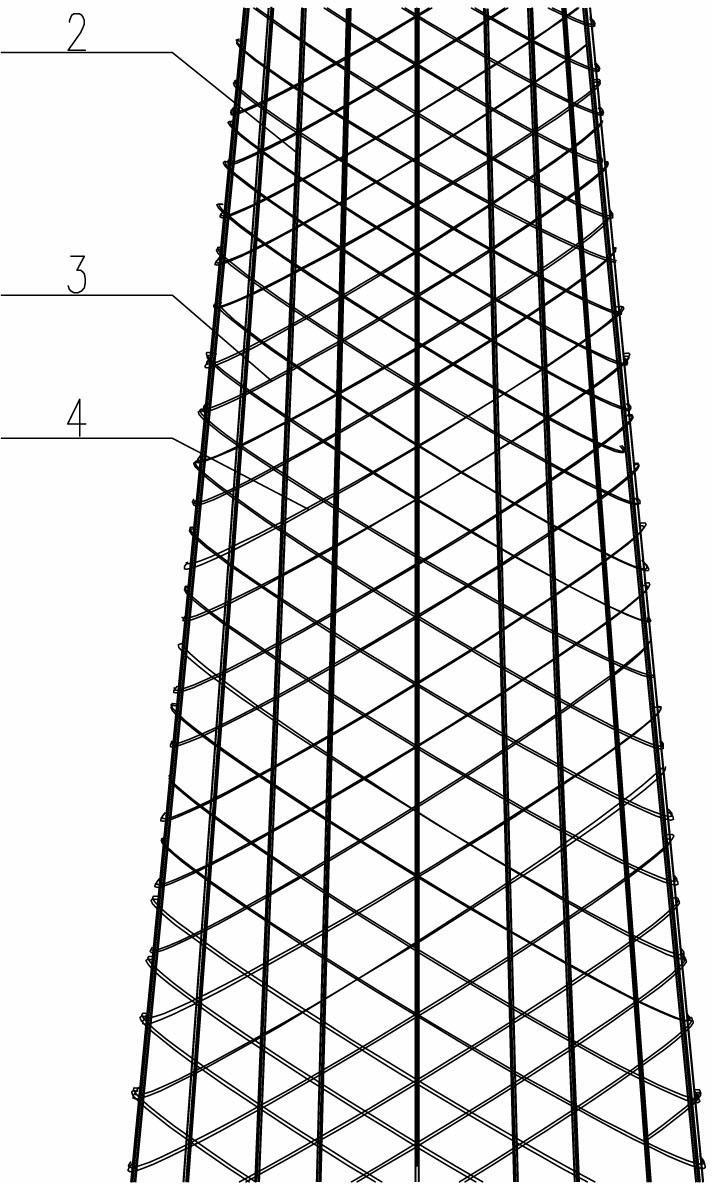

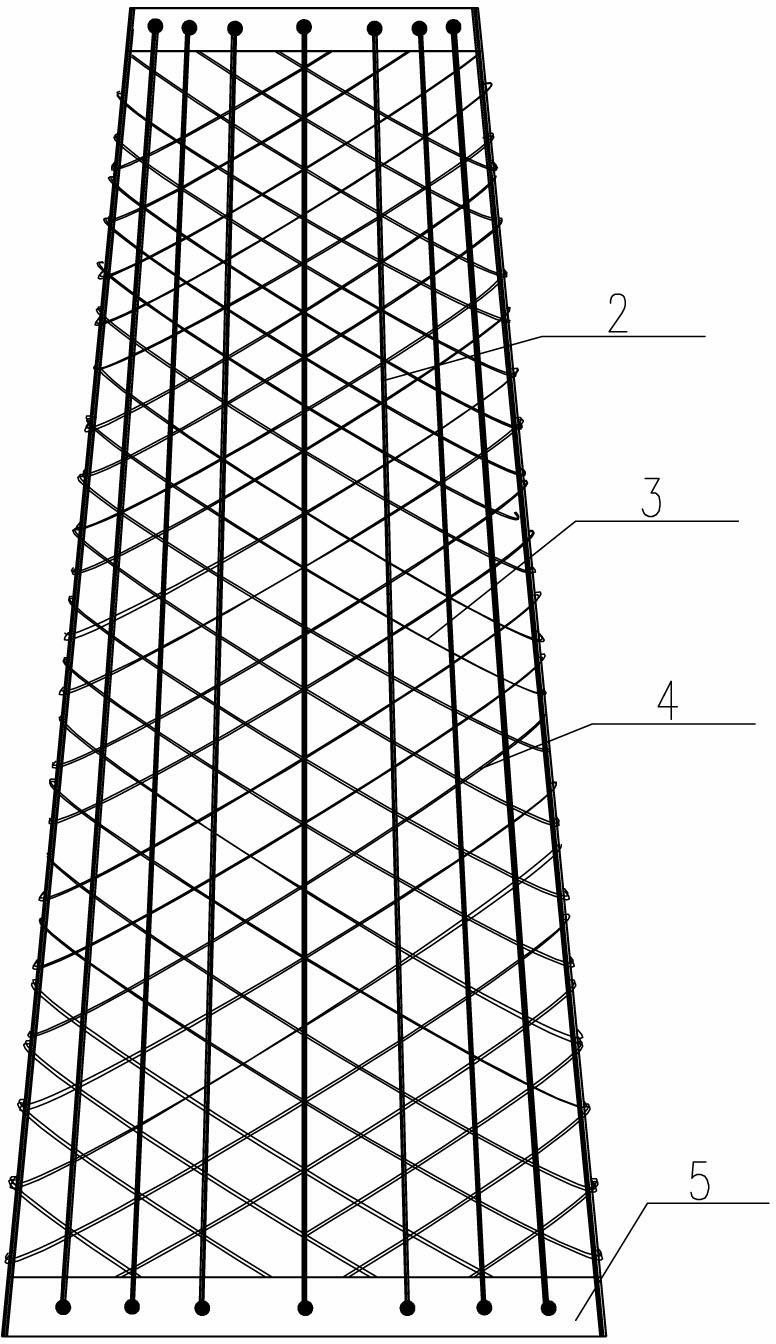

[0025] Such as figure 1 , figure 2 , image 3 As shown, the cement-based composite rod of the present invention is characterized in that the cone-shaped rod body is formed by solidification of the cone-shaped grid skeleton and the cement mortar that wraps the outer surface of the cone-shaped grid skeleton and fills the voids of the grid skeleton. 1, the cone-shaped grid skeleton is composed of at least one layer of longitudinally impregnated resin-impregnated fiber strips 2 uniformly arranged along the circumferential direction and impregnated resin wound along the left helical direction cross-connected with the longitudinally impregnated resin-impregnated fiber strips A group of helically intersecting fiber strips composed of fiber strips 3 and resin-impregnated fiber strips 4 wound in the right-hand helical direction are solidified to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com