Test method for prepreg resin infiltration degree

A test method and prepreg technology, applied in the field of composite materials, can solve the problems of high sampling requirements, lack of scientific standards, inability to test standards for resin infiltration degree, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

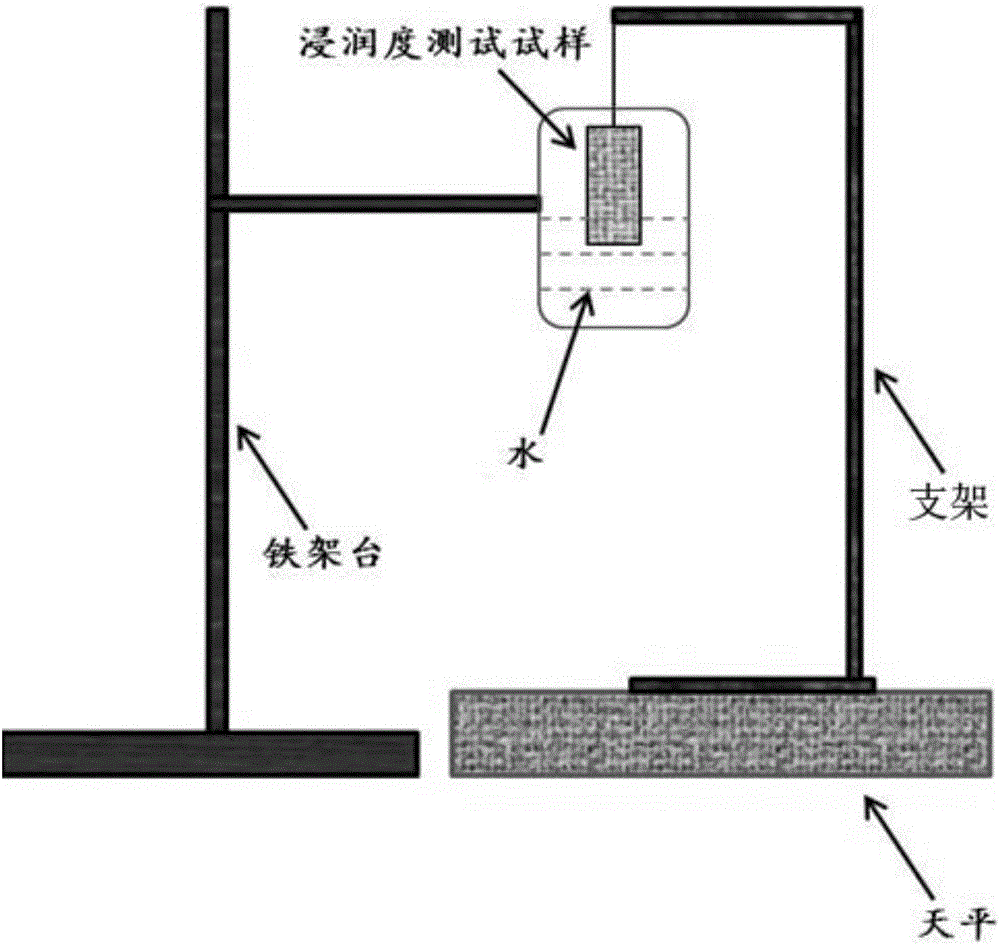

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] like figure 1 , figure 2 As shown, a partially impregnated prepreg resin impregnation test method, including:

[0024] 1. Sampling of fabric matrix and prepreg matrix: samples are taken from both sides (OS, DS) and middle (M) of the full width prepreg and fabric respectively. Dipping matrix, the size of the matrix is 100.0mm×100.0mm,

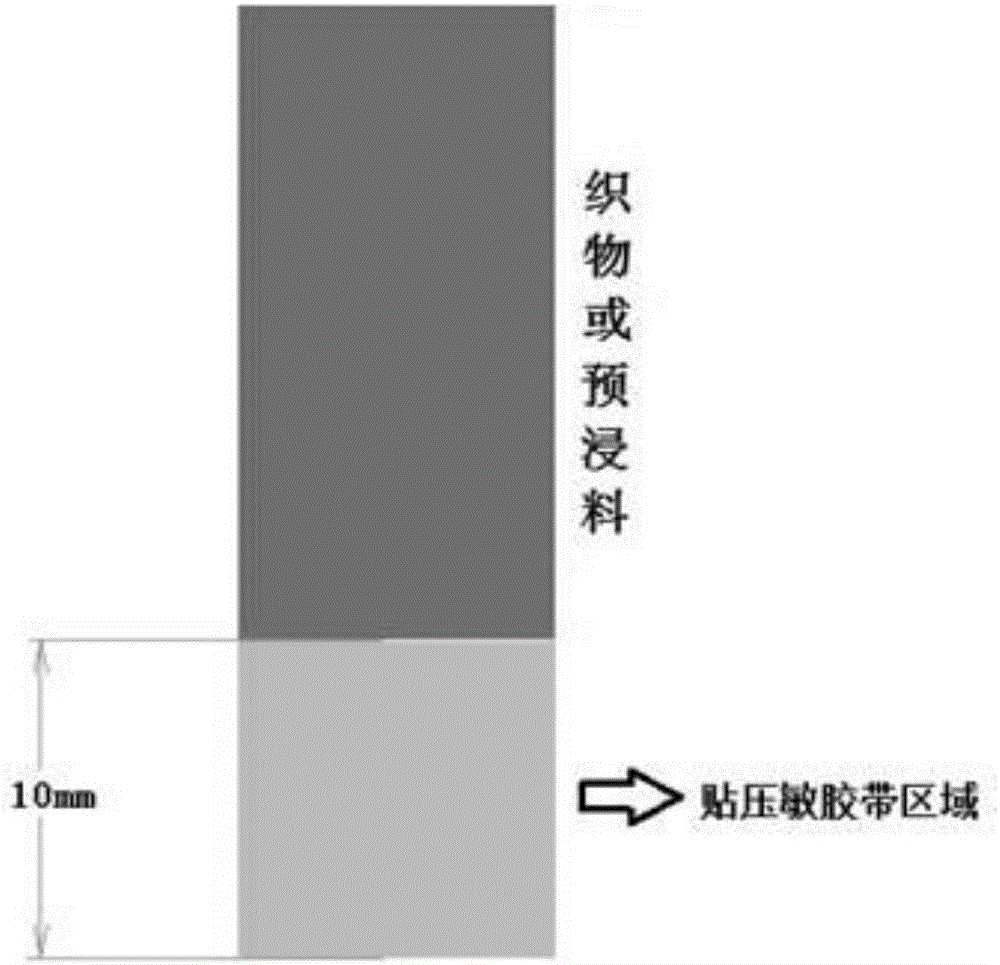

[0025] 2. Sampling of fabric samples and prepreg samples: Cut 2 fabric samples on the fabric matrix of each group, and cut 2 prepreg samples on the prepreg matrix of each group, namely 6 fabric samples, 6 prepreg samples, a total of 12 samples, the size of the test sample is 10.0mm×30.0mm;

[0026] 3. Use pressure-sensitive tape to stick on the bottom of all test samples. Both sides must be pasted with pressure-sensitive tape to ensure that the bottom of the test sample is not completely soaked when in contact wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com