Surface modified carbon fiber prepreg based on graphene oxide and preparation method of carbon fiber prepreg

A carbon fiber prepreg and surface modification technology, which is applied in the field of graphene oxide-based surface modified carbon fiber prepreg and its preparation, can solve the problems of increasing process difficulty and cost, agglomeration affecting material performance, and low surface activity. The effect of improved interface performance, good wettability, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

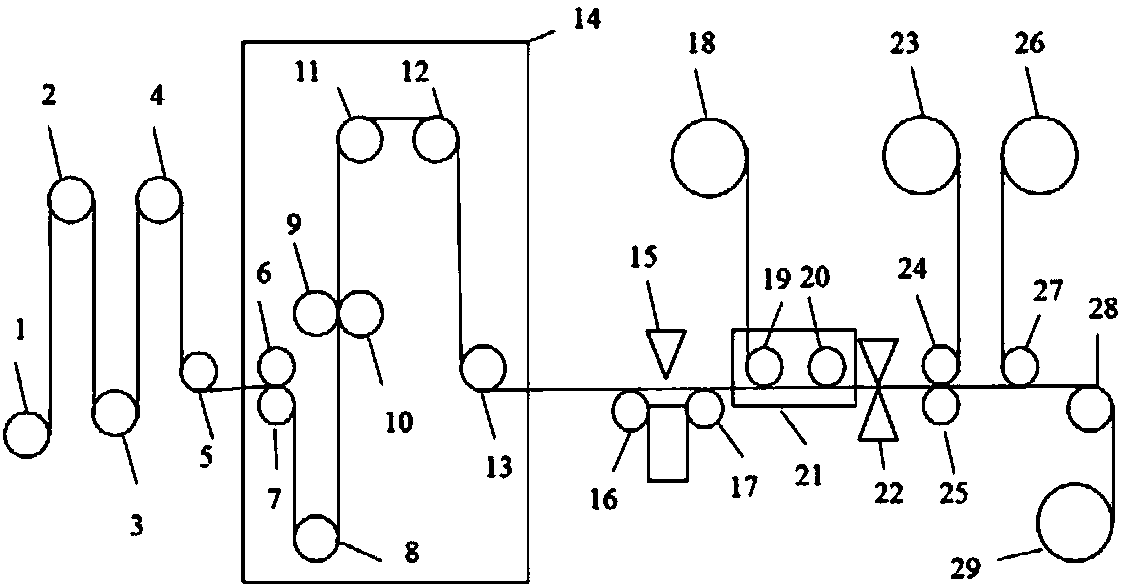

[0035] The preparation method of the surface-modified carbon fiber prepreg based on graphene oxide comprises the following steps:

[0036] 1) Preparation of carbon fiber prepreg: The carbon fiber prepreg is a mixed system composed of graphene oxide, epoxy resin, and organic solvent. The graphene oxide aqueous solution is obtained by the Hummers method, and the degree of oxidation is controlled to realize the control of graphene oxide. The total content of oxygen-containing groups is between oxygen atom / carbon atom (O / C)=(1 / 2)~(1 / 10) (atom number ratio), and the number of dispersion layers in acetone solvent is controlled to be 1~ 10 layers; at the same time, use ultrasonic dispersion to control the number of dispersed layers of graphene oxide in acetone solvent to be between 1 and 10 layers; filter the graphene oxide aqueous solution to remove water, then directly dissolve it in acetone solution, and centrifuge at low speed The precipitate was removed to obtain the upper liqui...

Embodiment 1

[0043] The graphene oxide aqueous solution is obtained by the Hummers method, wherein by controlling the degree of oxidation, the total content of the oxygen-containing groups of the graphene oxide is controlled at oxygen atom / carbon atom (O / C)=(1 / 2)~(1 / 10 ) (ratio of atomic number). At the same time, ultrasonic dispersion is used to control the number of dispersion layers of the graphene oxide in the acetone solvent to be between 1 and 10 layers. The graphene oxide aqueous solution was suction filtered to remove water, then directly dissolved in the acetone solution, and the precipitate was removed by low-speed centrifugation to obtain the graphene oxide acetone solution as the upper liquid. The concentration of the graphene oxide acetone solution can be controlled to be 6-8 mg / mL by rotary evaporation and other technical methods.

[0044] Prepare an acetone solution of graphene oxide, ultrasonic 10min, to obtain mixed solution A; dissolve the epoxy resin in the acetone solu...

Embodiment 2

[0047] The graphene oxide aqueous solution is obtained by the Hummers method, wherein by controlling the degree of oxidation, the total content of the oxygen-containing groups of the graphene oxide is controlled at oxygen atom / carbon atom (O / C)=(1 / 2)~(1 / 10 ) (ratio of atomic number). At the same time, ultrasonic dispersion is used to control the number of dispersion layers of the graphene oxide in the acetone solvent to be between 1 and 10 layers. The graphene oxide aqueous solution was suction filtered to remove water, then directly dissolved in the acetone solution, and the precipitate was removed by low-speed centrifugation to obtain the graphene oxide acetone solution as the upper liquid. The concentration of the graphene oxide acetone solution can be controlled to be 6-8 mg / mL by rotary evaporation and other technical methods.

[0048] Prepare an acetone solution of graphene oxide, ultrasonic 10min, to obtain mixed solution A; dissolve the epoxy resin in the acetone solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com