Double-faced melt impregnation method and device for continuous long fiber reinforced thermoplastic resin

A technology of reinforced thermoplastic and melt impregnation, applied in the direction of coating, etc., can solve the problems of affecting fiber content and product appearance, non-uniformity of melt feeding, difficult to coat and infiltrate fiber bundles, etc. Uniform, avoid lax coating, balanced impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

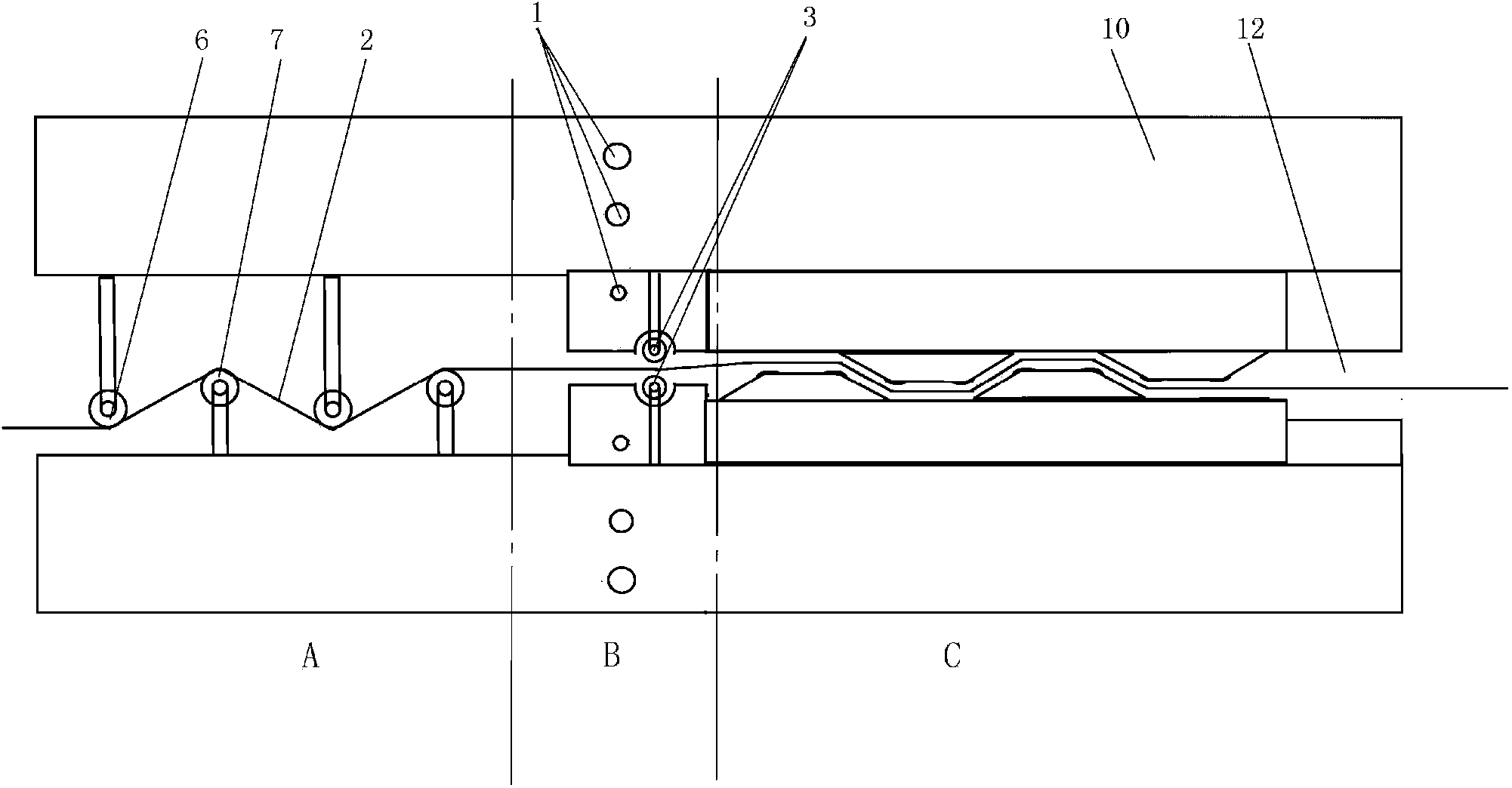

[0047] In this embodiment, a method for double-sided melt impregnation of continuous long fiber reinforced thermoplastic resin comprises the following steps:

[0048] (1) After the continuous long fiber enters the fiber channel, it first enters the fiber pre-dispersion area, and the continuous long fiber is pre-dispersed and pre-heated by the pre-dispersion device;

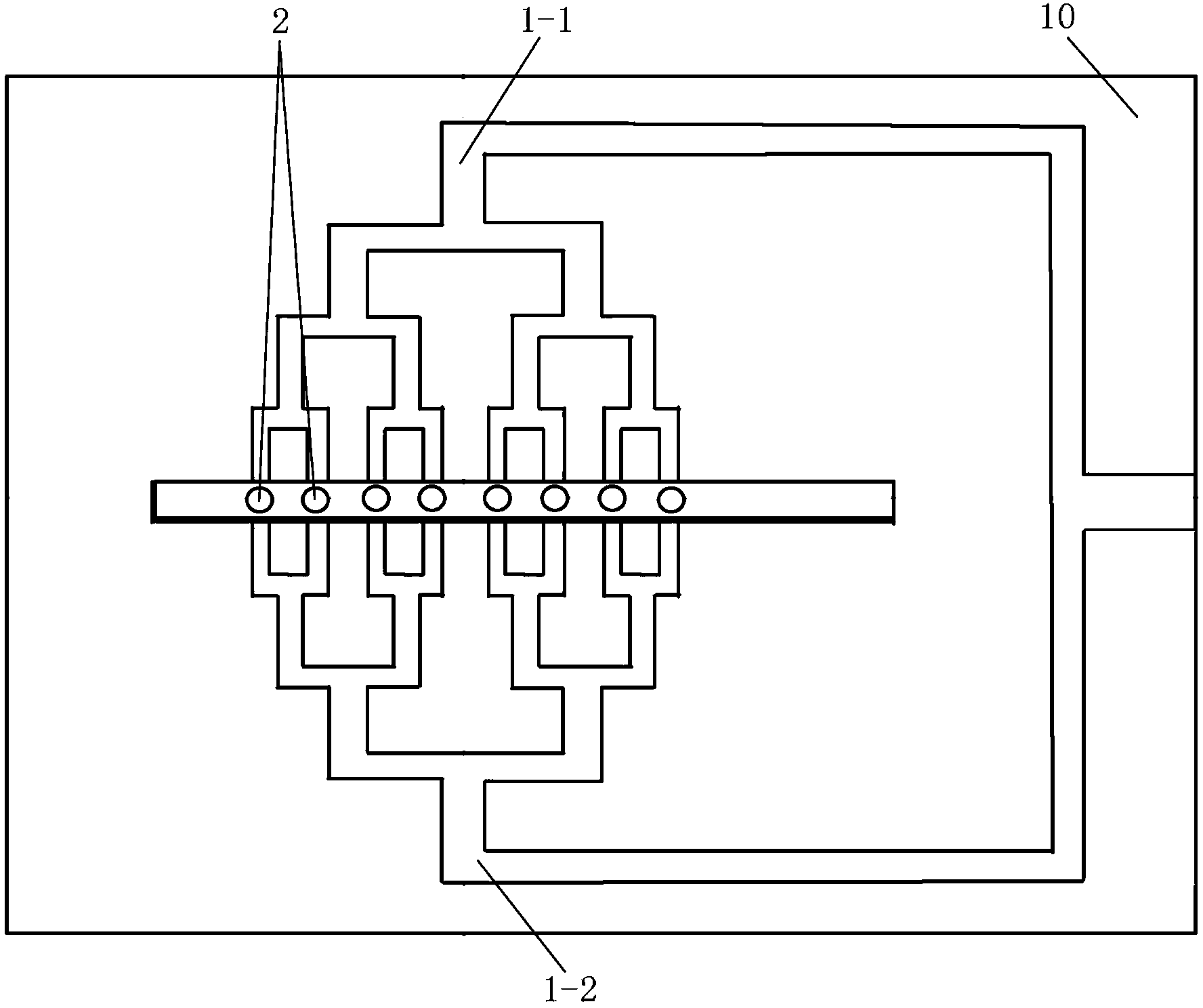

[0049] (2) The pre-dispersed and pre-heated continuous long fibers enter the resin-impregnated fiber area, and the resin melt flows out from the double-sided distribution channel, and simultaneously infiltrates and penetrates the continuous long fibers from the upper and lower sides, so that the continuous long fibers are melted by the resin. The body is fully wrapped and infiltrated, and then the resin melt content of the continuous long fiber is smoothed and balanced by the calender roll group;

[0050] (3) The impregnated continuous long fiber enters the fiber redispersion zone, and the fiber is dispersed again...

Embodiment 2

[0067] This embodiment is a double-sided melt impregnation equipment for continuous long fiber reinforced thermoplastic resin. Compared with Embodiment 1, the difference is that: Figure 4 As shown, in the fiber redispersion zone, the redispersing device includes an upper dispersing roller 8 and a lower dispersing roller 9, the upper dispersing roller is arranged above the continuous long fiber, the lower dispersing roller is arranged below the continuous long fiber, the upper dispersing roller and the lower dispersing roller are arranged. The dispersing rollers are alternately distributed and arranged at equal intervals, and the fiber channel is wavy;

[0068] The upper dispersing roller and the lower dispersing roller have the same structure, both are smooth rollers with a square cross-section, the length of each side of the square is 5-60mm, and the corners of each square are rounded at 90-150°; each upper dispersing roller and lower dispersing roller There are electric hea...

Embodiment 3

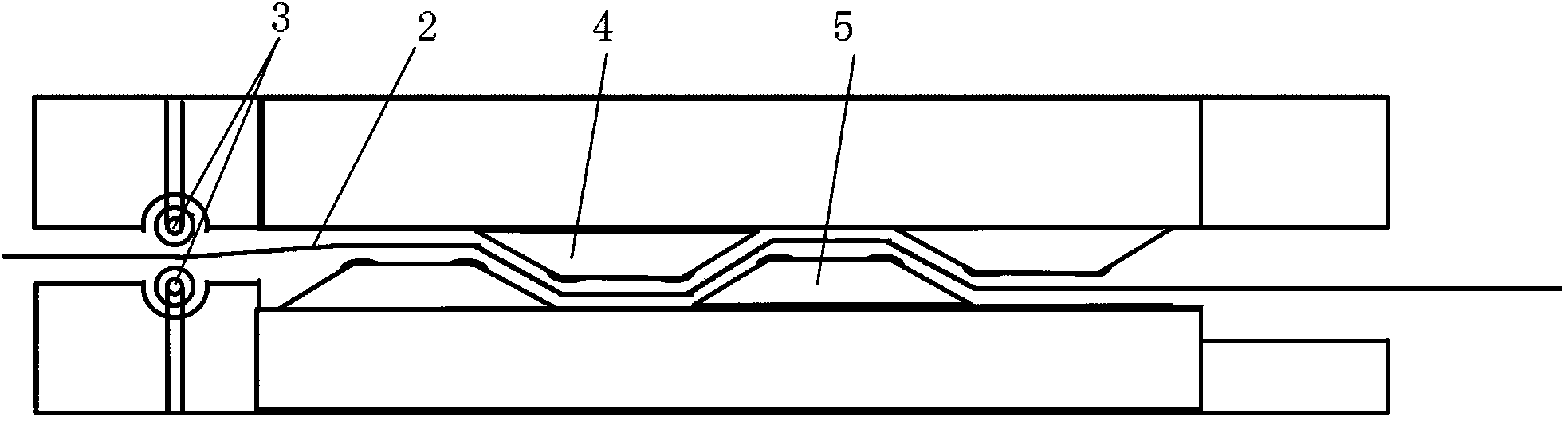

[0070] This embodiment is a double-sided melt impregnation equipment for continuous long fiber reinforced thermoplastic resin. Compared with Embodiment 1, the difference is that: Figure 5As shown, in the fiber redispersion zone, the redispersing device includes an upper dispersing roller 8 and a lower dispersing block 5, an upper dispersing roller is provided above the continuous long fiber, a lower dispersing block is provided below the continuous long fiber, and the upper dispersing roller and the lower dispersing block are arranged. The dispersing blocks are distributed alternately and arranged at equal intervals, the fiber channel is wavy, the upper dispersing roller is placed in the trough, and the distance between the outer edge and the trough is 1-15mm;

[0071] Among them, the upper dispersing roller is a smooth roller with a square cross-section, the length of each side of the square is 5-60mm, and the corners of each square are rounded corners of 90-150°; each upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com