Fabrics and method for producing fabrics

A fabric and roving technology, applied in textiles and papermaking, chemical instruments and methods, fabrics, etc., to reduce costs, improve absorbency, and improve resin impregnation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The composite fabric of the present invention comprises layers that are stitched together to form a unitary product. These layers include chopped fiberglass mat, at least one layer of long fiberglass rovings, and a tissue paper backing layer. Composite fabric has many uses, but it is especially useful in the manufacture of composite products made from thermoplastic or thermosetting resins, where the fabric forms a support layer, reinforcement or substrate for the plastic product in a manner known in the art .

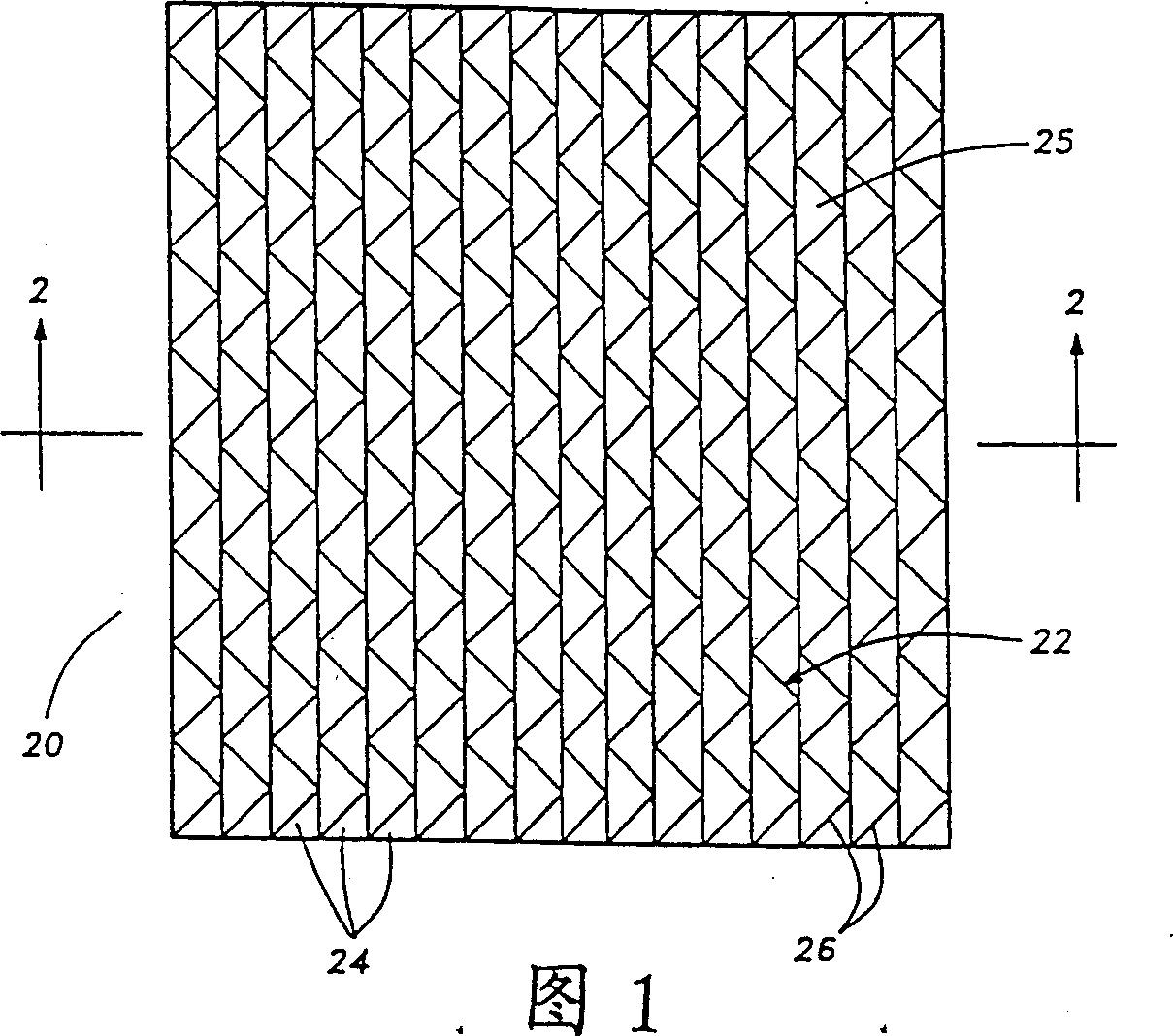

[0017] Referring to the drawings, wherein like numerals indicate like parts throughout the several views, there is generally shown a preferred embodiment of the composite fabric 20 of the present invention. The composite fabric 20 includes a number of layers including an upper layer 22 of fiberglass rovings, layers 28, 30, 32 of fiberglass rovings. The composite web 20 also includes a chopped glass fiber strand mat layer 34 and a tissue paper back layer 36 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com