Resin infiltration zero-dimensional/one-dimensional porous ceramic composite material for dental restoration, and a preparation method thereof

A technology of resin infiltration and dental restoration, applied in ceramic products, dental preparations, applications, etc., can solve the problems of increasing difficulty and extremely high equipment requirements, and achieve the effect of improving fracture resistance, increasing bulk density, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

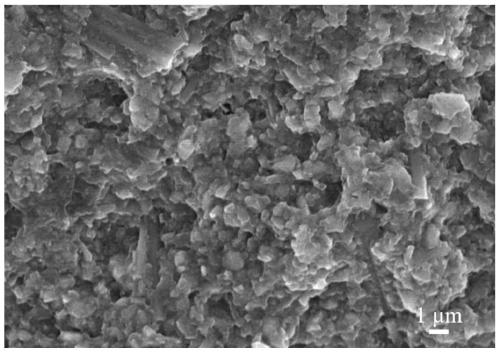

[0029] (1) Preparation of silylated hydroxyapatite nanowires: at 40°C, 24g of oleic acid and 24g of absolute ethanol were stirred and mixed evenly, and then 40mL of sodium hydroxide aqueous solution (50g / L) was sequentially added to the solution, 40mL calcium chloride aqueous solution (11g / L), 20mL calcium dihydrogen phosphate aqueous solution (24g / L), continue to stir for 2h, then transfer the solution into a hydrothermal kettle, react at 180°C for 24h and collect to obtain hydroxyapatite nanowires , after being washed and purified by ethanol, suspended in a mixture of KH570, deionized water, absolute ethanol and tetraethyl orthosilicate (the mass ratio of the four is 1:2:2:4), and heated to 50°C for 12 hours. The silylated hydroxyapatite nanowires were collected by filtration, washed with ethanol and dried in vacuum for later use. The aspect ratio of the product was greater than or equal to 50.

[0030] (2) Preparation of resin system: after mixing bisphenol A-glycidyl metha...

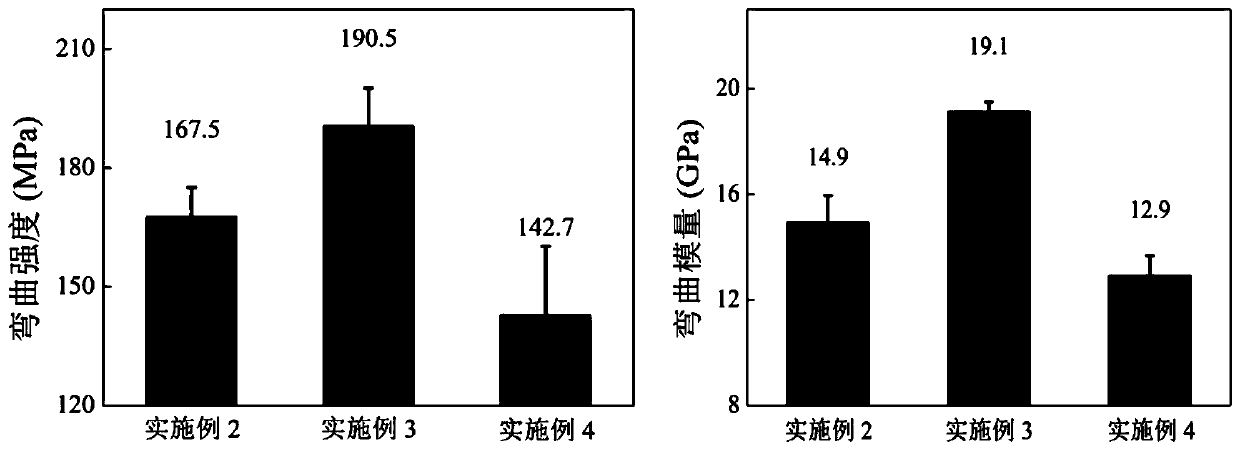

Embodiment 2

[0035] (1) Preparation of silylated hydroxyapatite nanowires: at 40°C, 24g of oleic acid and 24g of absolute ethanol were stirred and mixed evenly, and then 40mL of sodium hydroxide aqueous solution (50g / L) was sequentially added to the solution, 40mL calcium chloride aqueous solution (11g / L), 20mL calcium dihydrogen phosphate aqueous solution (24g / L), continue to stir for 2h, then transfer the solution into a hydrothermal kettle, react at 180°C for 24h and collect to obtain hydroxyapatite nanowires , washed with ethanol, purified, and dried, placed in a muffle furnace to raise the temperature to 700°C at a rate of 5°C / min and keep the temperature constant for 12h. Suspend the sintered hydroxyapatite nanowires in a mixture of KH570, deionized water, absolute ethanol and tetraethylorthosilicate (the mass ratio of the four is 1:2:2:4), and heat up to 50 After reacting at ℃ for 12 hours, the silylated hydroxyapatite nanowires were collected by filtration, washed with ethanol, and...

Embodiment 3

[0041] (1) Preparation of silylated hydroxyapatite nanowires: same as step (1) in Example 2.

[0042] (2) Preparation of resin system: same as step (2) of Example 1.

[0043] (3) Preparation of porous ceramic preform: Weigh an equal amount of silanized barium glass-ceramic powder with a particle size of 0.4, 0.7 and 1.0 μm, 4.75 g in total, and 0.25 g of silanized hydroxyapatite prepared in step (1) After the stone nanowires are mixed evenly by two-way rotation (revolution: 2000rpm; rotation: 300rpm), add absolute ethanol (0.5g) to infiltrate evenly, then transfer to a steel mold, apply 2MPa pressure, press for 1min, and form after the ethanol volatilizes The porous ceramic prefabricated body has a porosity of 20±3%.

[0044] (4) Resin system permeates the porous ceramic preform: same as step (4) of Example 1.

[0045] (5) Curing molding of resin-infiltrated ceramic matrix composite material: same as step (5) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com