Carbon fiber shell surface penetration type pore and crack repairing structure and process

A carbon fiber and pore technology, applied in the field of repairing structure and repairing process, can solve the problems of limitation, difficulty in immersing into the deep layer of carbon fiber shell, easy occurrence of pores and cracks, etc., and achieve the effect of small weight gain, strong applicability and application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

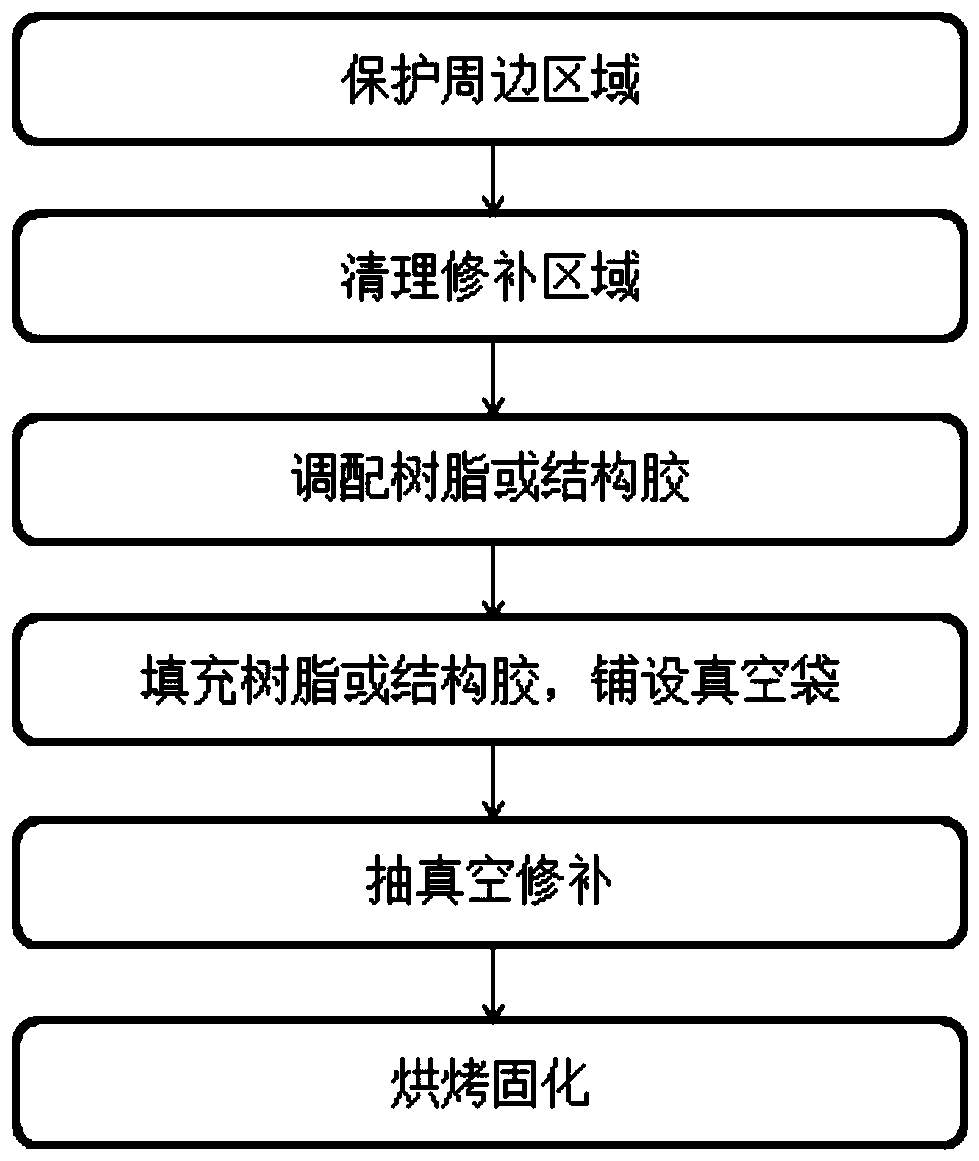

[0053] (1) Use masking tape to protect the inner and outer surfaces near the place to be repaired, and use sealing tape to block the threaded holes near the repaired place;

[0054] (2) Dip the paint remover with a cotton swab and apply it on the inner and outer surfaces of the part to be repaired, let it stand for 2 minutes, scrape off the paint surface gently with a blade, and then use 400# sandpaper to roughen the inner and outer surfaces;

[0055] (3) Prepare 3g of resin according to the ratio of resin:curing agent=2:1, wherein the resin is a medium-temperature curing epoxy resin, the curing temperature is 80°C, add 0.1g of carbon powder, and mix thoroughly until the color of the resin is black;

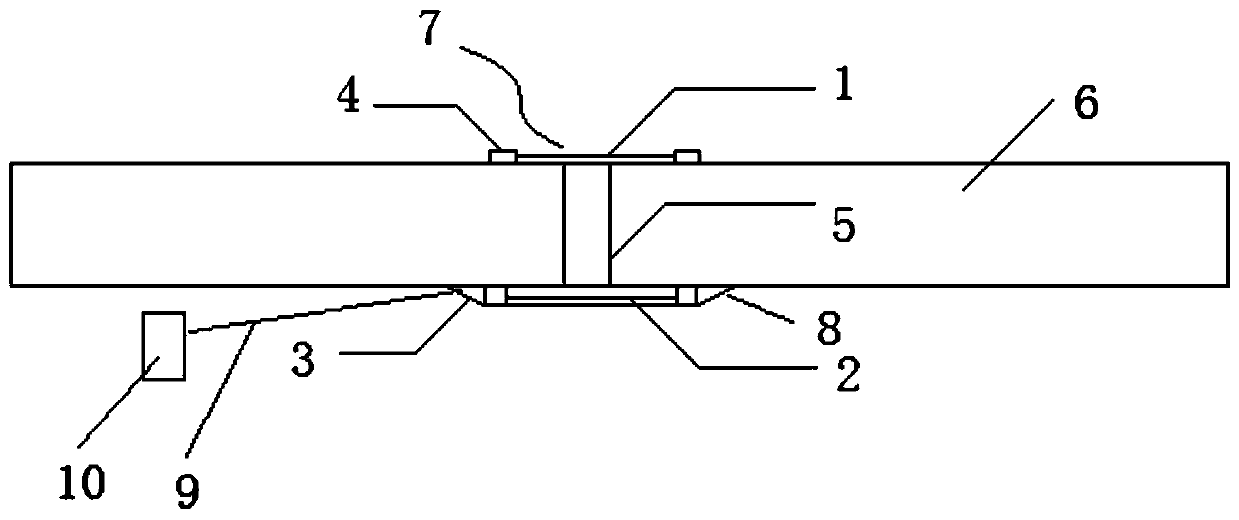

[0056] (4) Apply the prepared resin on the inner surface of the repaired part, install an air nozzle on the outer surface, and spread a vacuum bag on the outer surface;

[0057] (5) Use an air pump to vacuum for 1 minute, observe that the resin has penetrated into the outer surfa...

Embodiment 2

[0060] (1) Use masking tape to protect the inner and outer surfaces near the place to be repaired, and use sealing tape to block the threaded holes near the repaired place;

[0061] (2) Dip the paint remover with a cotton swab and apply it on the inner and outer surfaces of the part to be repaired, let it stand for 2 minutes, scrape off the paint surface gently with a blade, and then use 400# sandpaper to roughen the inner and outer surfaces;

[0062] (3) Prepare 3g of resin according to the ratio of resin:curing agent=2:1, wherein the resin is a medium-temperature curing epoxy resin, the curing temperature is 80°C, add 0.1g of carbon powder, and mix thoroughly until the color of the resin is black;

[0063] (4) Fill the prepared resin into the inner surface of the repaired part, install an air nozzle on the outer surface, and spread a vacuum bag on the outer surface;

[0064] (5) Use an air pump to vacuum for 1 minute, observe that the resin has penetrated into the outer surf...

Embodiment 3

[0067] (1) Use masking tape to protect the inner and outer surfaces near the place to be repaired, and use sealing tape to block the threaded holes near the repaired place;

[0068] (2) Dip the paint remover with a cotton swab and apply it on the outer surface of the part to be repaired, let it stand for 2 minutes, scrape off the paint surface gently with a blade, and then use 400# sandpaper to roughen the inner and outer surfaces;

[0069] (3) Prepare 3g of resin according to the ratio of resin:curing agent=2:1, wherein the resin is a medium-temperature curing epoxy resin, the curing temperature is 80°C, add 0.1g of carbon powder, and mix thoroughly until the color of the resin is black;

[0070] (4) Apply the prepared resin on the inner surface of the repaired part, install air nozzles on the outer surface, and spread vacuum bags on the inner and outer surfaces;

[0071] (5) Use an air pump to vacuum for 1 minute, observe that the resin has penetrated into the outer surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com