Energy-saving gypsum board

A gypsum board and gypsum technology, applied in the field of gypsum board, can solve problems such as poor bending resistance of gypsum board, and achieve the effects of good mechanical properties and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

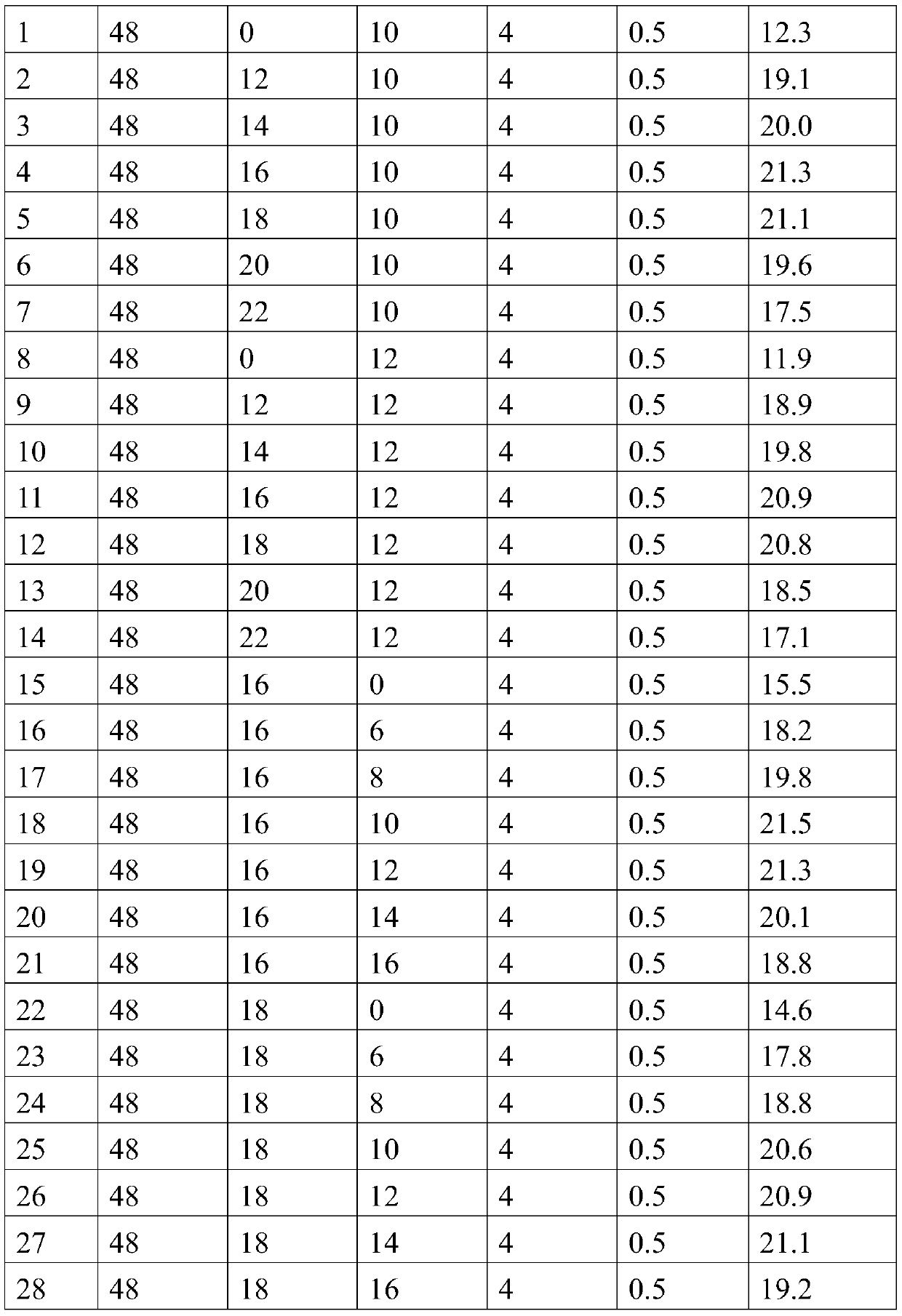

[0037] The ratio of raw materials in this embodiment is determined as follows:

[0038] (1) Gypsum: 48 parts,

[0039] (2) Sodium salt slag: 17 parts, the particle size of sodium salt slag is less than 2mm,

[0040] (3) Silica fume: 11 parts,

[0041] (4) Zeolite powder: 4 parts,

[0042] (5) Superplasticizer: 0.5 parts,

[0043] (6) Water: 19.5 parts.

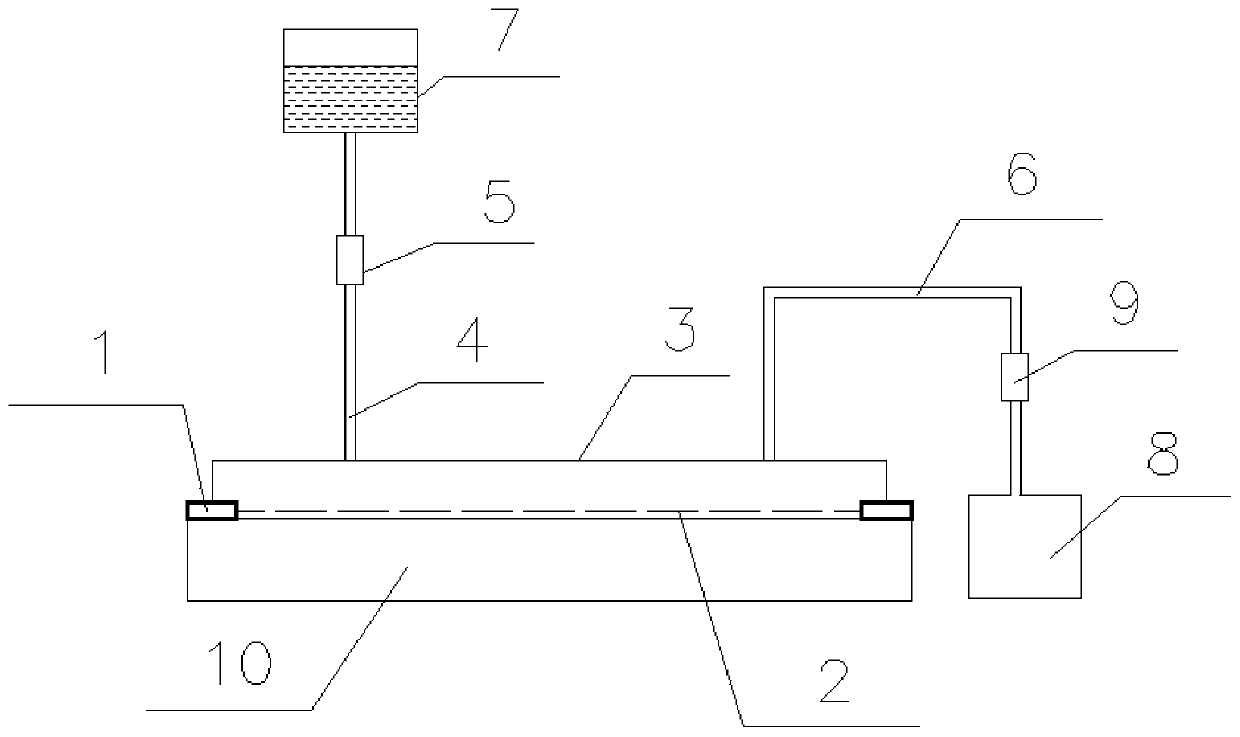

[0044] The gypsum board 10 is infiltrated with phenolic resin after molding. The infiltration adopts a special device. The special device includes a rubber suction cup 1, a flexible infiltration net 2, a flexible film 3, a feed pipe 4, a one-way valve 5, an air suction pipe 6, and an infiltration solution storage Bottle 7, air compressor 8, air pressure regulating valve 9, rubber suction cups 1 are arranged on both sides of the flexible film 3, the rubber suction cups 1 are located at the two ends of the gypsum board 10, the width of the rubber suction cups 1 is 120 mm, the flexible film 3 and the rubber suction cups 1 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com