Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "P-chlorotoluene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

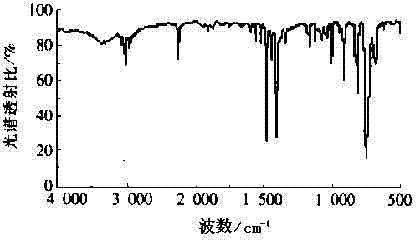

Catalyzer for liquid-phase catalytic oxidation producing of chlorobenzaldehyde by using p-chlorotoluene

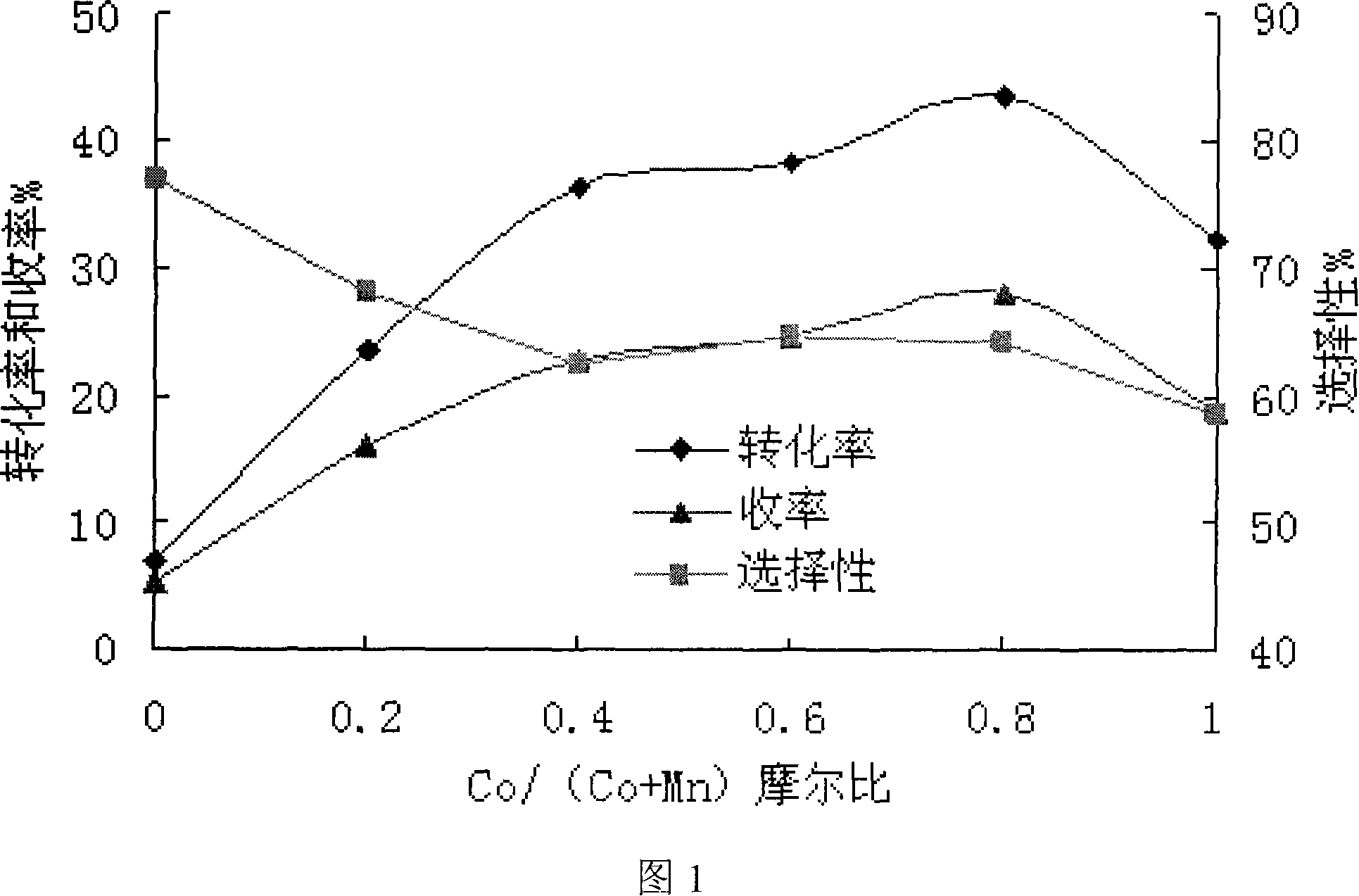

InactiveCN101138729AHigh activityHigh selectivityOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationChlorobenzeneP-chlorobenzaldehyde

The present invention relates to a catalyst for preparation of p-chlorobenzaldehyde through liquid phase catalytic oxidation. The catalyst is a compound catalyst, which is formed by loading an element provided with catalytic activity on a carrier of aluminum oxide. Active componentS of the catalyst of the present invention are cobalt and manganese, which are loaded on the carrier of the aluminum oxide. The molar ratio of cobalt and manganese is 0.1-5. In addition, the active components of the present invention can also comprise nickel, copper, iron, cerium, lanthanum, magnesium or zirconium and bromine, besides cobalt and manganese. The catalyst of the present invention is applied the reaction course for preparation of p-chlorobenzaldehyde, and is characterized by the simple technique, the high p-chlorobenzaldehyde reaction yield ratio, the low reaction temperature, the simple catalyst separation, and so on.

Owner:天津佰腾生产力促进中心有限公司

Production method of para chlorotoluene

ActiveCN1903814AHigh purityReduce contentHalogenated hydrocarbon preparationMolecular sievePotassium

The present invention relates to a production method of high-purity p-chlorotoluene. Said method includes the following steps: using L-type zeolite molecular sieve as catalyst, using low-grade halogenated saturated alkanol or low-grade halogenated saturated fully acid or its potassium and sodium salt as cocatalyst, making toluene and chlorine gas be fully reacted, then aerating, removing chlorine gas and hydrogen chloride from reaction solution, rectifying to remove unreacted toluene and tolylchloride, then more adding L-type zeolite molecular sieve catalyst, continuously introducing chlorine gas to make reaction, after said reaction is completed, aerating, removing chlorine gas and hydrogen chloride, further making rectification and separation so as to obtain high-purity p-chloro to luene.

Owner:ZHEJIANG WEIHUA NEW MATERIAL CO LTD

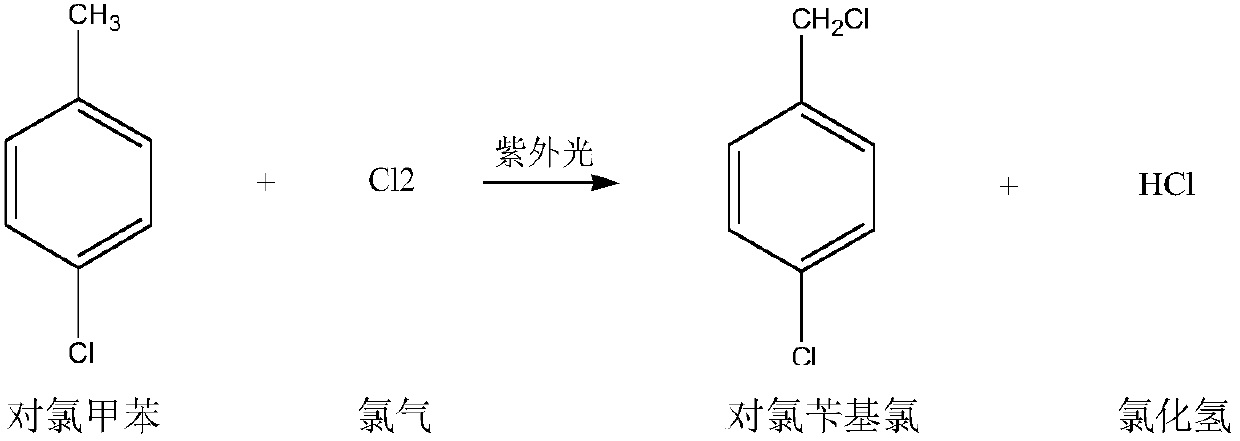

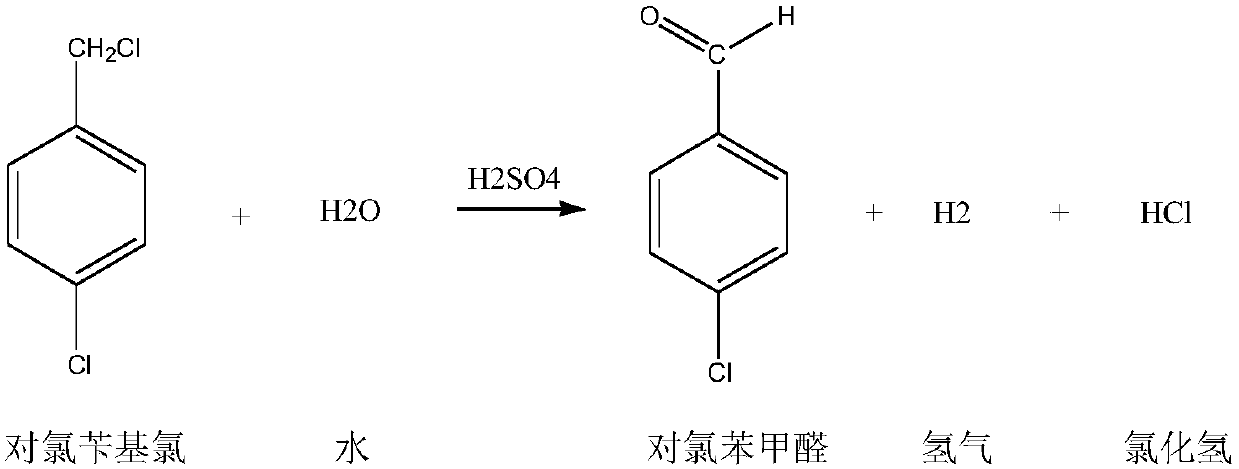

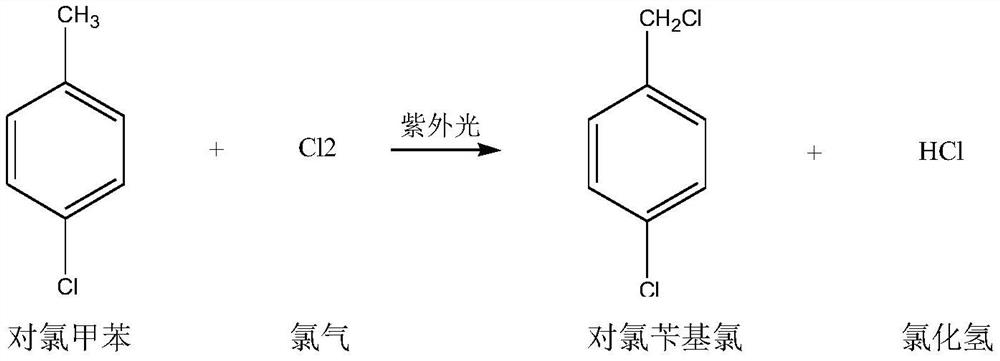

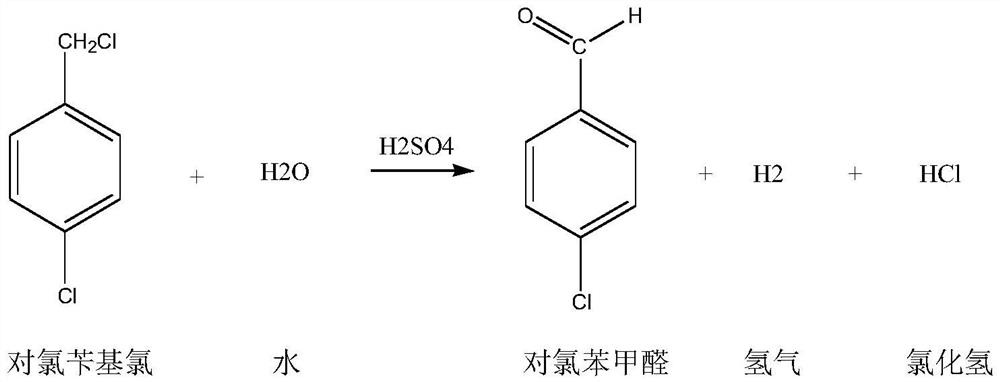

Synthetic method of p-chlorobenzaldehyde

InactiveCN104447251AGood choiceHigh yieldCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationChlorobenzeneP-chlorobenzaldehyde

The invention discloses a synthetic method of p-chlorobenzaldehyde. The synthetic method comprises the following steps: performing illumination and chlorine reaction on p-chlorotoluene in the presence of a phosphorus trichloride initiator to generate p-chlorobenzal chloride, refining, and then performing catalytic hydrolysis for 6-12 hours to obtain p-chlorobenzaldehyde. The synthetic method of p-chlorobenzaldehyde, disclosed by the invention, is good in selectivity and high in yield.

Owner:CHANGSHU XINHUA CHEM

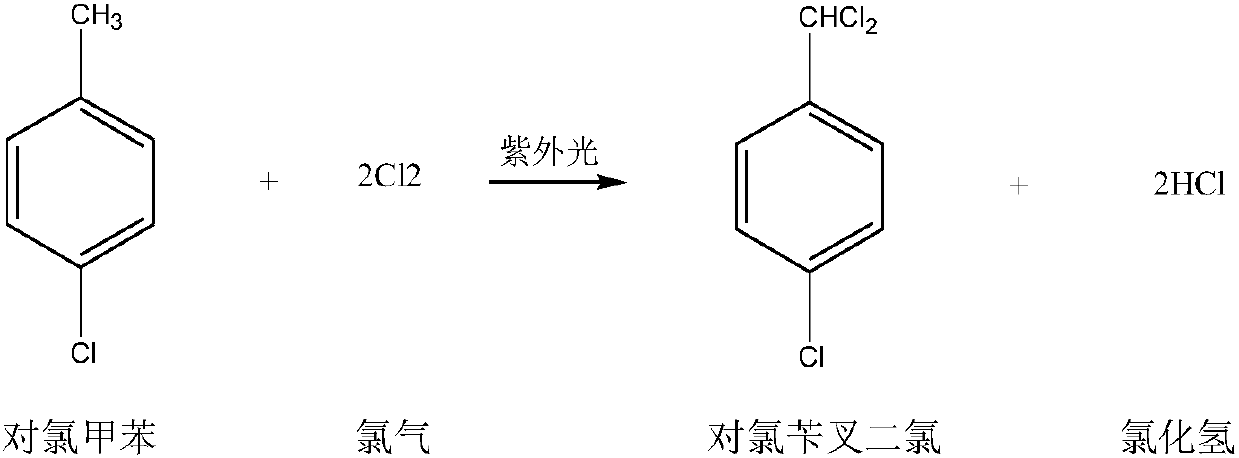

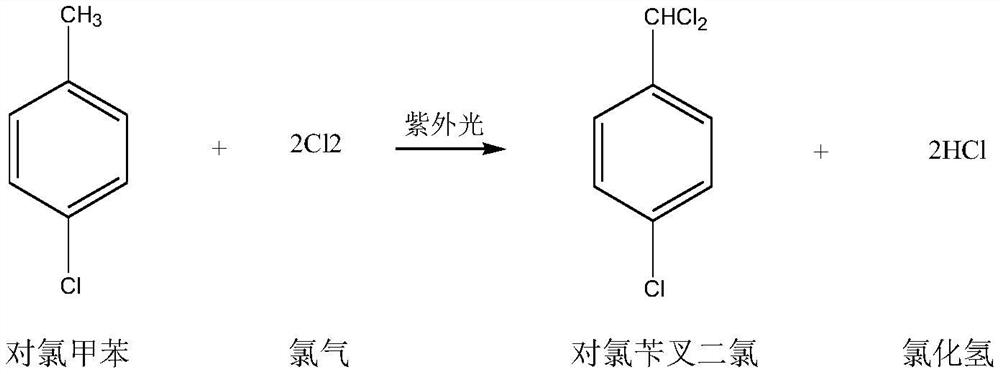

Preparation method for p-chlorobenzaldehyde

ActiveCN109651111ALower the temperature of the substitution reactionHigh selectivityCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationBenzeneP-chlorobenzaldehyde

The invention discloses a preparation method for p-chlorobenzaldehyde. P-chlorotoluene can be taken as a raw material to perform substitution reaction with chlorine under the action of a catalyst so that a mixture of 4-chlorobenzyl chloride and 4-chloro-1-(dichloromethyl)benzene; and p-chlorobenzaldehyde can be obtained by the mixture of the 4-chlorobenzyl chloride and the 4-chloro-1-(dichloromethyl)benzene under the action of the catalyst through hydrolysis reaction and air catalytic oxidation reaction. Through the action of the catalyst, the reaction temperature of the substitution reactioncan be reduced, and the selectivity of the substitution reaction can be enhanced; the yield of the p-chlorobenzaldehyde can be enhanced by adopting a mode of combining the hydrolysis reaction and aircatalytic oxidation reaction; and the wastewater quantity of the hydrolysis reaction can be reduced through the mode of applying the catalyst.

Owner:烟台舜康生物科技有限公司

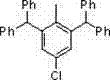

Separation method of p-chlorotoluene and o-chlorotoluene

ActiveCN110092706AReduce manufacturing costImprove stabilityHalogenated hydrocarbon preparationP-chlorotolueneO-chlorotoluene

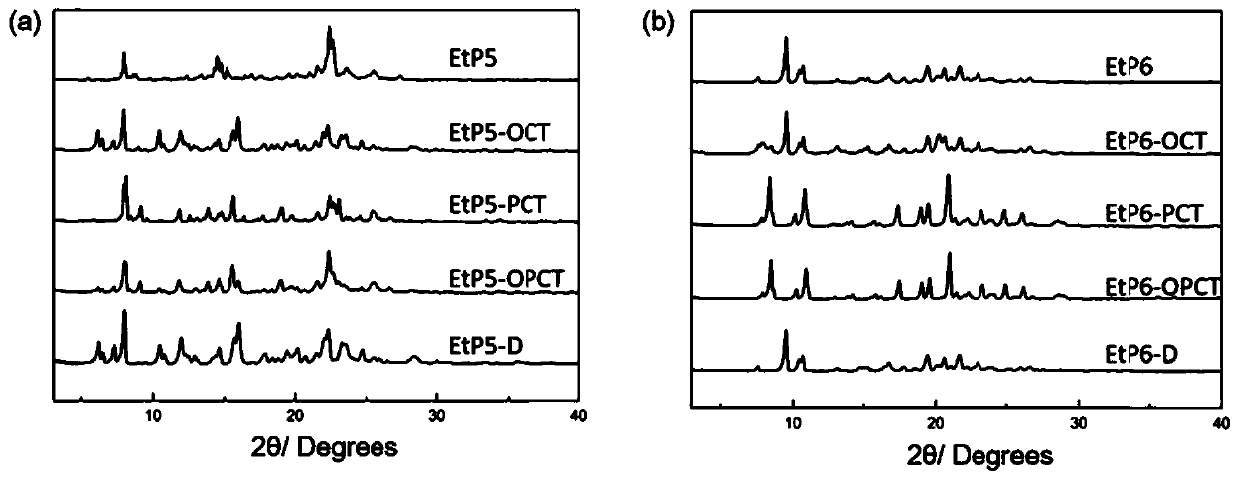

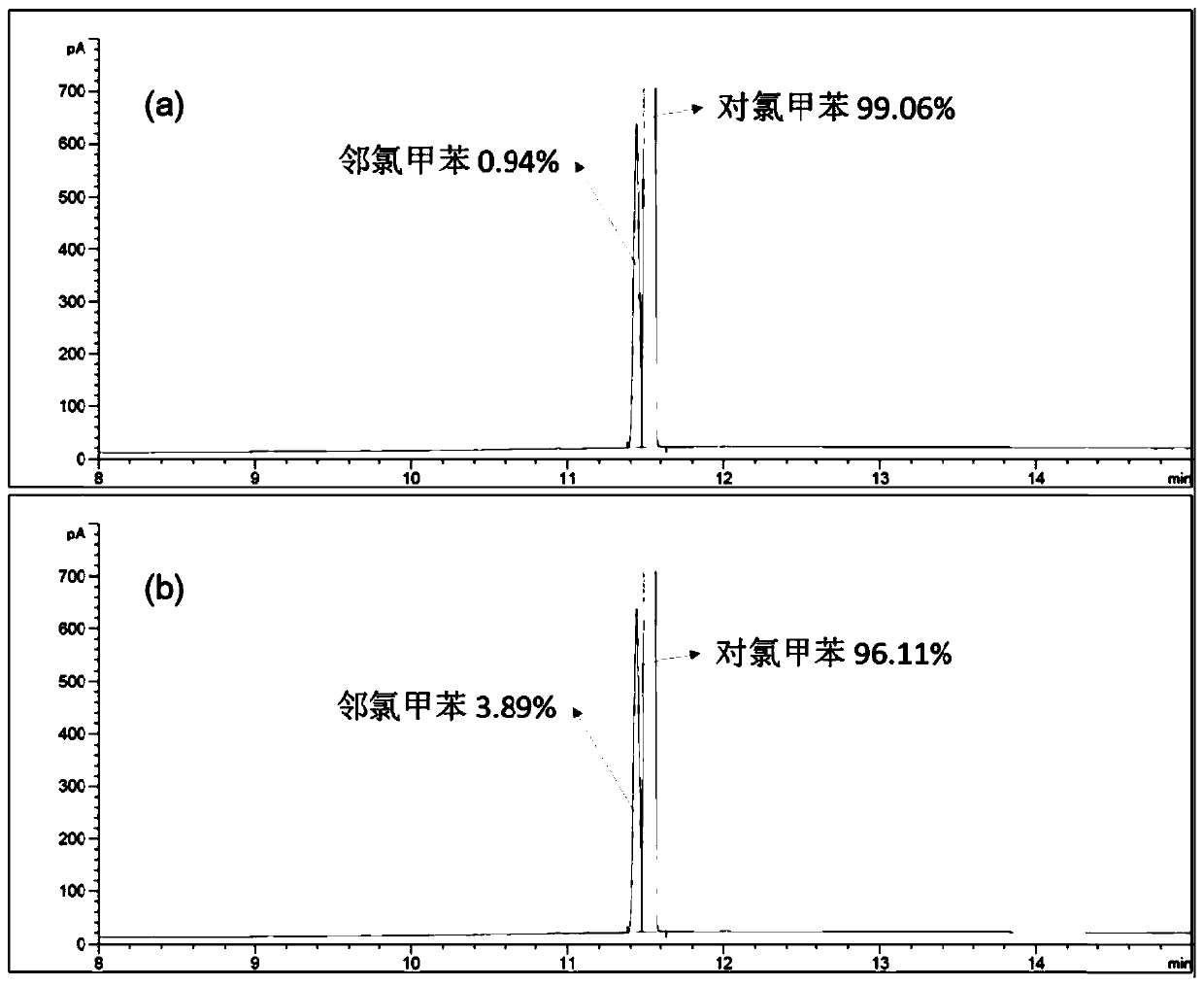

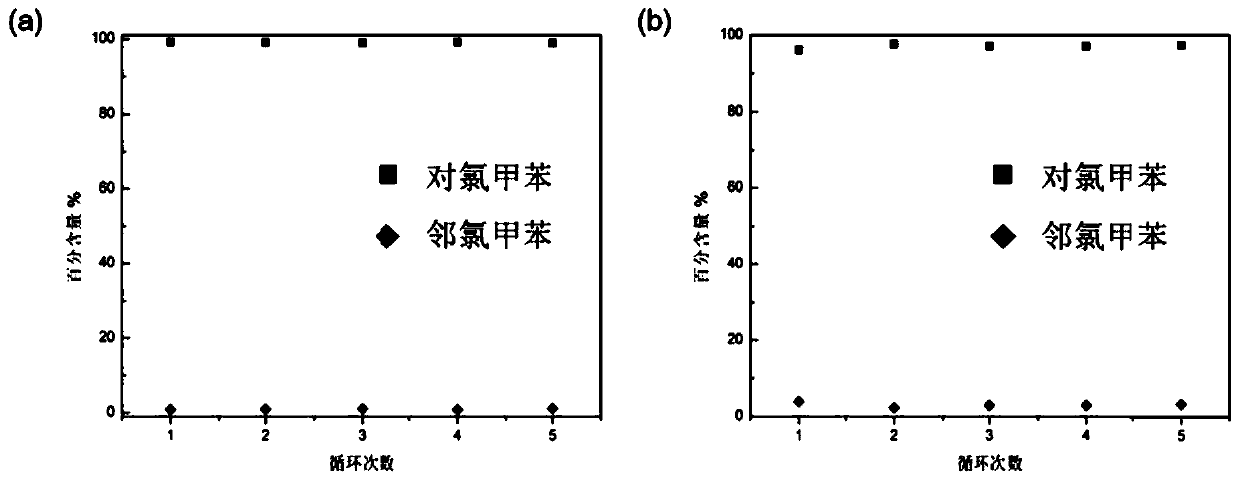

The invention discloses a separation method of p-chlorotoluene and o-chlorotoluene. A bis-diethoxy column [n] arene crystal material is utilized to adsorb and separate a p-chlorotoluene and o-chlorotoluene mixture, and the chemical structural formula of the bis-diethoxy column [n] arene crystal material is as shown in the specification, wherein n is 5 or 6. The separation method has simple separation process operation and low equipment requirement. No rectification operation is required in the separation process, the energy consumption is low, the energy is saved, and the production cost of the p-chlorotoluene is reduced. The crystal material used has high stability, and can be recycled, and the separation effect cannot be reduced.

Owner:ZHEJIANG UNIV

Anticorrosive self-cleaning paint

InactiveCN104479550ANo shrinkageNo exothermAntifouling/underwater paintsPaints with biocidesDisiloxanePtru catalyst

The invention relates to a self-cleaning paint, particularly an anticorrosive self-cleaning paint. The anticorrosive self-cleaning paint is prepared from the following raw materials in parts by weight: 20-30 parts of tetramethyldivinyl disiloxane, 25-40 parts of methylethoxy silicon oil, 10-15 parts of hydroxy hydrogenous silicon oil, 15-20 parts of chlorotoluene, 1-5 parts of ethanedioic acid, 0.1-0.5 part of cyclopentanol and 0.3-0.7 part of catalyst. The anticorrosive self-cleaning paint can not generate shrinkage or release heat, and has the advantages of moderate hardness, favorable thermal conductivity, favorable electric insulativity and high sealability.

Owner:JIANGSU NUOFEI NEW MATERIAL TECH

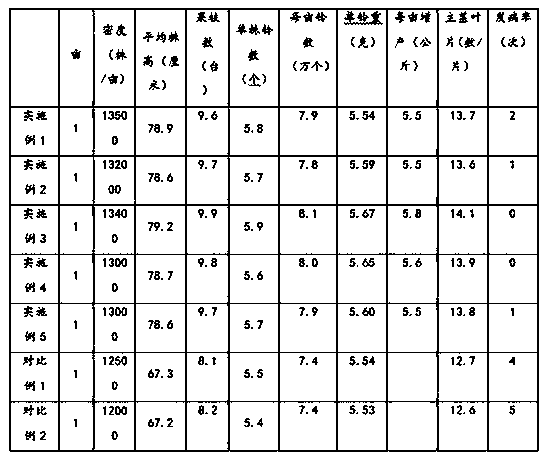

Cotton topping agent and preparation method thereof

InactiveCN110199997AEffectively control prosperityControl prosperityPlant growth regulatorsBiocidePaichongdingSulfonate

The present invention provides a cotton topping agent, which comprises, by weight, 0.8-2 parts of paichongding, 0.8-2 parts of hydroxypropylmethylcellulose, 3-6 parts of beta-methylnaphthalene, 5-10 parts of fosamine-ammonium, 10-15 parts of isonicotinic acid, 10-15 parts of iodophenoxyacetic acid, 15-20 parts of p-chlorotoluene, and 15-20 parts of sodium disec-octyl maleate sulfonate. According to the present invention, the cotton topping agent is organically dissolved, such that the cotton top can be killed, the cotton length can be effectively controlled, the ideal plant type can be shaped,the flower and the bud can be retained, the photosynthesis of cotton can be enhanced, the cotton boll can be increased, the diseases can be prevented and controlled, the boll opening early maturity can be achieved in advance by more than seven days, the micronaire value of cotton is not affected, and the purposes of high yield and stable production are achieved.

Owner:高俊毅

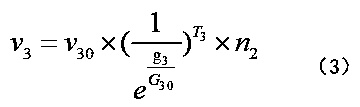

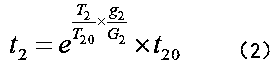

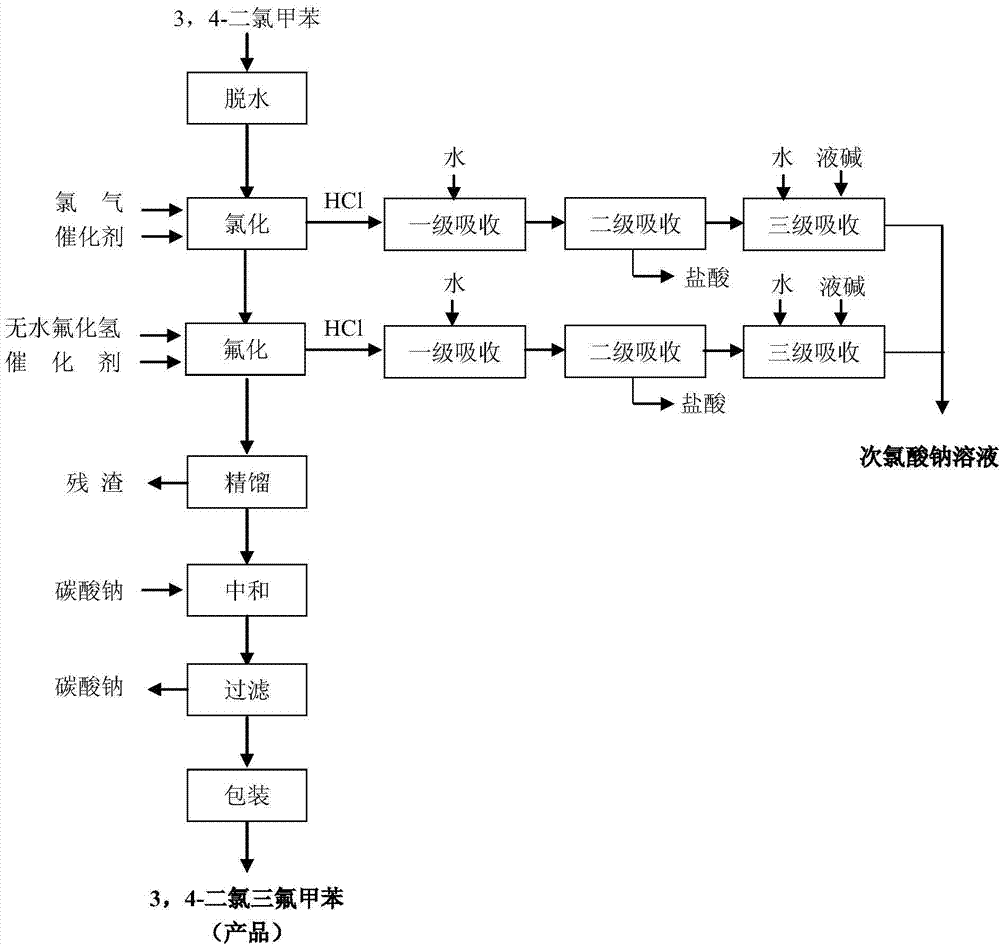

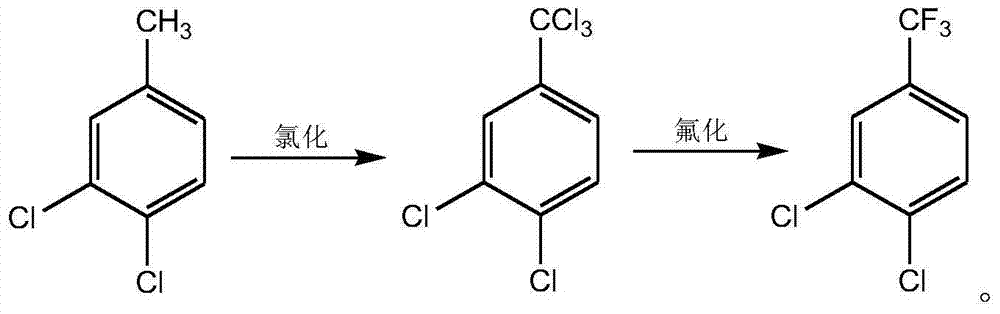

Method for preparing 3, 4-dichlorobenzotrifluoride

InactiveCN103896728AWide variety of sourcesLow pricePreparation by halogen replacementFiltrationDistillation

The invention discloses a method for preparing 3, 4-dichlorobenzotrifluoride. The method comprises the following steps: performing chlorination, fluorination, distillation, neutralization and filtration to obtain a finished product of 3, 4-dichlorobenzotrifluoride. In the method disclosed by the invention, 3, 4-dichlorotoluene is used as a raw material, 3, 4-dichlorobenzotrifluoride is synthesized by two steps of chlorination and fluorination, a chlorination reaction is decreased compared with the existing step by step reaction with p-chlorotoluene as a raw material, the new process is simple and convenient to operate and small in equipment corrosion, byproducts and exhaust emission generated by the chlorination reaction in the production are greatly reduced, and the pollutant emission in the production process is reduced. No isomer 2, 4-dichlorobenzotrifluoride of 3, 4-dichlorobenzotrifluoride is generated in the reaction process, so that the product yield is high.

Owner:JIANGSU FENGHUA CHEM IND

Production method of p-chlorotoluene

InactiveCN102603468AHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideO-chlorotoluene

The invention discloses a production method of p-chlorotoluene, comprising the steps of chloridizing toluene, removing toluene and rectifying mixed chlorotoluene. Toluene is chloridized by the steps of placing toluene in a chlorination kettle and adding a catalyst in the chlorination kettle, and feeding chlorine at 40-60 DEG C and carrying out a chlorination reaction. The catalyst used in the chlorination reaction is prepared by the steps of reacting alumina, silicon oxide and sodium oxide react at 120-150 DEG C for 6-8 hours and activating in a high-temperature activation furnace at 800 DEG C for 4-6 hours. The production method provided by the invention is simple and convenient and is easy to operate. In the total content of p-chlorotoluene and o-chlorotoluene in final products, the content of p-chlorotoluene is up to above 80%. After rectification, the content of p-chlorotoluene is up to above 99.5%.

Owner:江苏优普生物化学科技股份有限公司

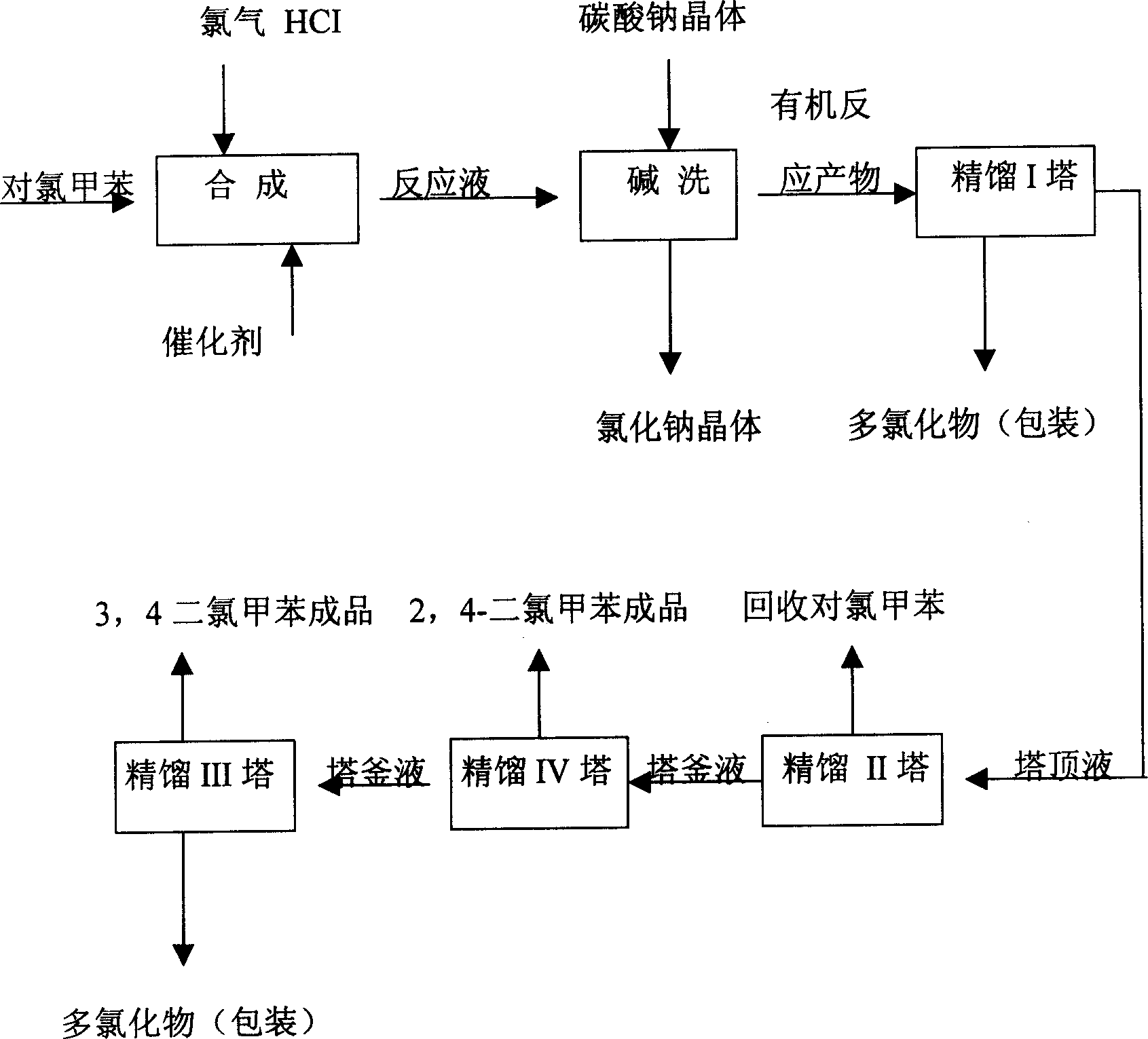

Method for preparing 2,4-toluene dichloride

InactiveCN1546443AReduce pollutionHigh yieldHalogenated hydrocarbon preparationReaction temperatureP-chlorotoluene

The invention relates to a process for preparing 2, 4-dichlorotoluene by using p-chlorotoluene, chlorine as raw material for synthesizing 2, 4-dichlorotoluene through catalyzed chloridization, which comprises the steps of synthesizing, alkaline cleaning, rectifying, the synthesizing reaction temperature is between 35-45 deg. C, the alkaline cleaning agent for washing synthetic reaction product in the alkaline cleaning step is sodium carbonate crystal containing crystal water. The invention increases the yield of 2, 4-dichlorotoluene and improves the chlorine distribution status during reaction.

Owner:株洲化工集团诚信有限公司

Method for preparing p-chlorobenzaldehyde

InactiveCN104557492ASimple processEase of industrial productionCarbonyl compound preparation by hydrolysisChlorobenzeneP-chlorobenzaldehyde

The invention discloses a method for preparing p-chlorobenzaldehyde, which comprises the following steps: reacting p-chlorotoluene with chlorine in the presence of an initiator under the irradiation of a mercury lamp at the chlorination temperature of 90-140 DEG C to obtain a p-chlorobenzyl chloride / p-trichlorotoluene mixture; and while controlling the average chlorination degree at 1.4-1.6, carrying out catalytic hydrolysis in a 3-6 wt% nitric acid solution for 6-12 hours to obtain the p-chlorobenzaldehyde. By using the method disclosed by the invention, the next hydrolysis step can be directly carried out without separating the intermediate; and thus, the method is simple in technique and can easily implement industrialized production.

Owner:CHANGSHU XINHUA CHEM

Method for selectively preparing o-chlorotoluene

InactiveCN103613482AHigh selectivityPhysical/chemical process catalystsHalogenated hydrocarbon preparationIron powderIodine

The invention provides a novel method for preparing o-chlorotoluene through chlorinating toluene. The technical scheme is as follows: the method comprises the steps of taking a mixture of elemental iodine and iron powder as a catalyst under dark conditions, adding the catalyst into a toluene solution, slowly introducing chlorine gas, controlling the temperature of a whole chlorination process to be 40-50 DEG C, and controlling an introduced chlorine gas volume so as to enable the toluene conversion ratio to be not lower than about 99%. According to the method, after the catalyst is applied to toluene chlorination, the percent content of o-chlorotoluene in a product is increased effectively, the content ratio of o-chlorotoluene to p-chlorotoluene reaches 2.0, the content of m-chlorotoluene is lower than 0.2%, and the total content of poly-chlorotoluene is lower than 5.0%.

Owner:SOUTHEAST UNIV

Production method of p-trifluoromethyl chlorobenzene

InactiveCN102603471AEasy to operateHigh content of finished productsPreparation by halogen replacementChlorobenzeneP-chlorotoluene

The invention discloses a production method of p-trifluoromethyl chlorobenzene, which comprises the following steps: adding p-chlorotoluene in a chlorinating reactor, introducing chlorine gas to perform chlorination at 90-100 DEG C for 16-20 hours, and performing aeration to remove hydrogen chloride after the chlorination is finished, and obtaining p-chlorotrichlorotoluene; and adding obtained p-chlorotrichlorotoluene into a high pressure fluorinating reactor, introducing HF, performing fluoridation at 100 DEG C and under a pressure of 1.5MPa for 6-8 hours, and obtaining p-trifluoromethyl chlorobenzene. The production method of trifluoromethyl chlorobenzene disclosed by the invention is simple and convenient, and easy to operate, and the product content after rectification is up to over 99.5%.

Owner:江苏优普生物化学科技股份有限公司

Preparation method of carbon based nano-iron alloy water treatment material

InactiveCN105461042AReduce secondary pollutionReductive degradation of polluting organic matter is acceleratedWater/sewage treatment by irradiationWater contaminantsActivation methodIron salts

The invention belongs to the field of water treatment technologies, relating to a preparation method of a carbon based nano-iron alloy water treatment material by utilizing carbon based nano-iron alloy to activate hypochlorous acid and hypochlorite, and generate chlorine radical and hydroxyl radical to remove p-chlorotoluene. The preparation method comprises the following steps: 1) an activation process of granular active carbon; the granular active carbon is activated by adopting a boiling water activation method; 2) nano-iron alloy is loaded in the activated granular active carbon; inorganic iron salt and activated active carbon are mixed according to the iron-carbon mass ratio of (1:1) to (1:5), nickel chloride or palladium acetate is mixed with the inorganic iron salt, and the molar ratio of the nickel chloride or the palladium acetate to iron in ferric salt is (1:5) to (1:10), then iron alloy is produced by being reduced by adopting a potassium borohydride liquid phase method and is loaded on the granular active carbon. The material obtained by the invention has less secondary pollution in a water treatment process, good treatment effect, and is liable to be realized.

Owner:ZHENJIANG RUNNING WATER CO

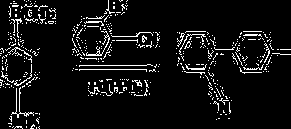

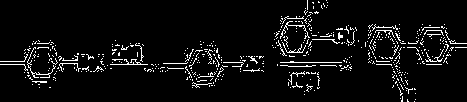

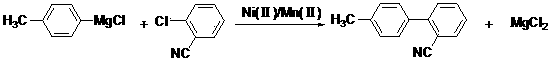

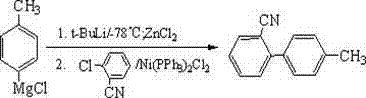

Preparation method for 2-cyano-4'-methylbiphenyl

InactiveCN103467341ALow costHigh activityCarboxylic acid nitrile preparationOrganic compound preparationBenzeneNitrogen

The invention discloses a preparation method for 2-cyano-4'-methylbiphenyl. The invention adopts the following technical scheme: the preparation method comprises the following steps: taking p-chlorotoluene as a raw material for Grignard reaction with magnesium powder in a solvent in the absence of water under nitrogen protection, and coupling a reaction product with chlorobenzonitrile under the catalytic effect of a nickel-manganese composite catalyst to prepare 2-cyano-4'-methylbiphenyl. A Ni (II) / Mn (II) composite catalyst is added into a 2-cyano-4'-methylbiphenyl synthesis reaction system, so that the reaction activity is enhanced and the reaction selectivity is improved; the catalyst is lower in price and easy to recover, so that the postprocessing difficulty is lowered and the production cost is reduced; a recrystallization method is adopted in postprocessing and refining processes, so that the product purity is further improved, a white product is obtained, and the industrialization operation is more convenient.

Owner:HENAN NORMAL UNIV

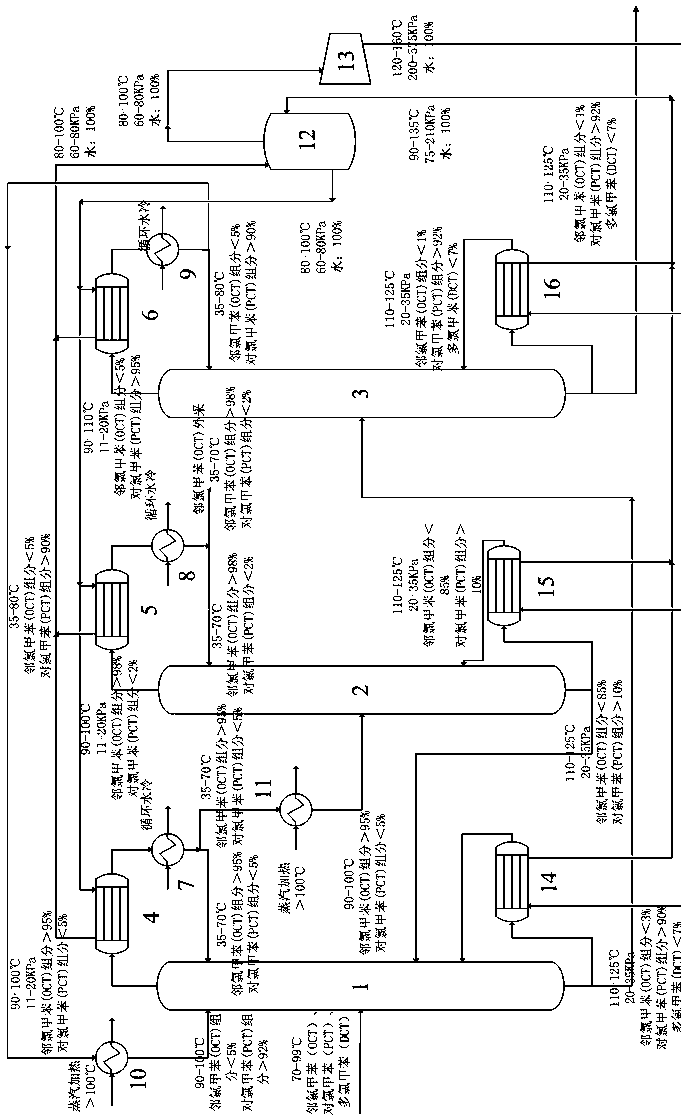

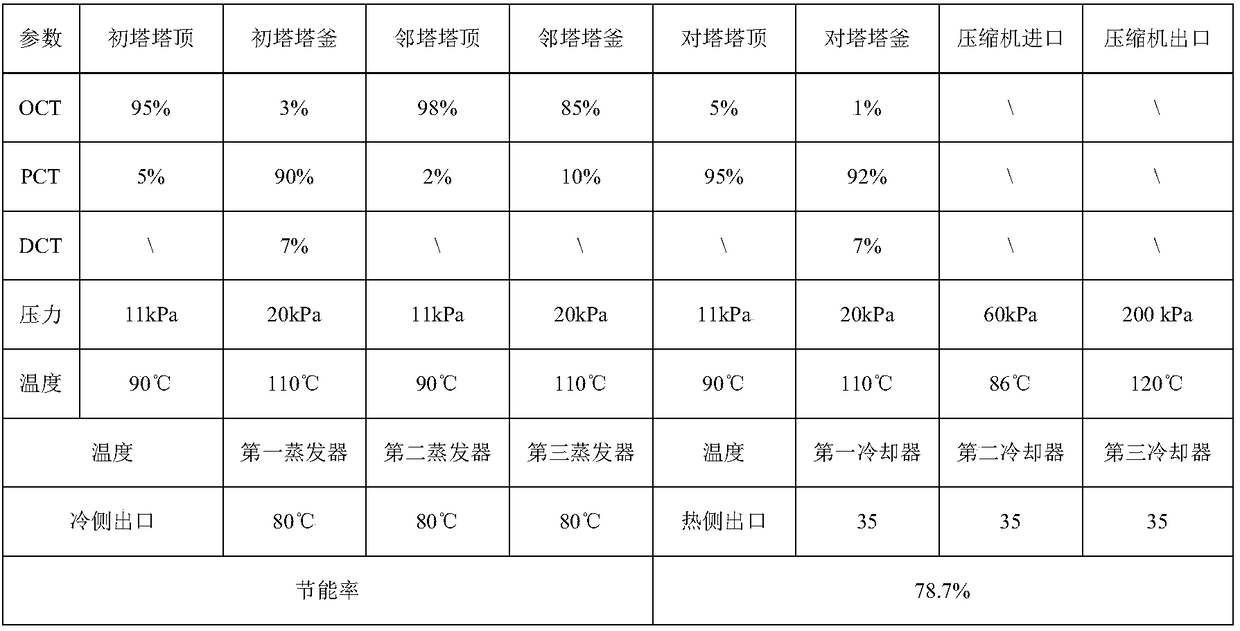

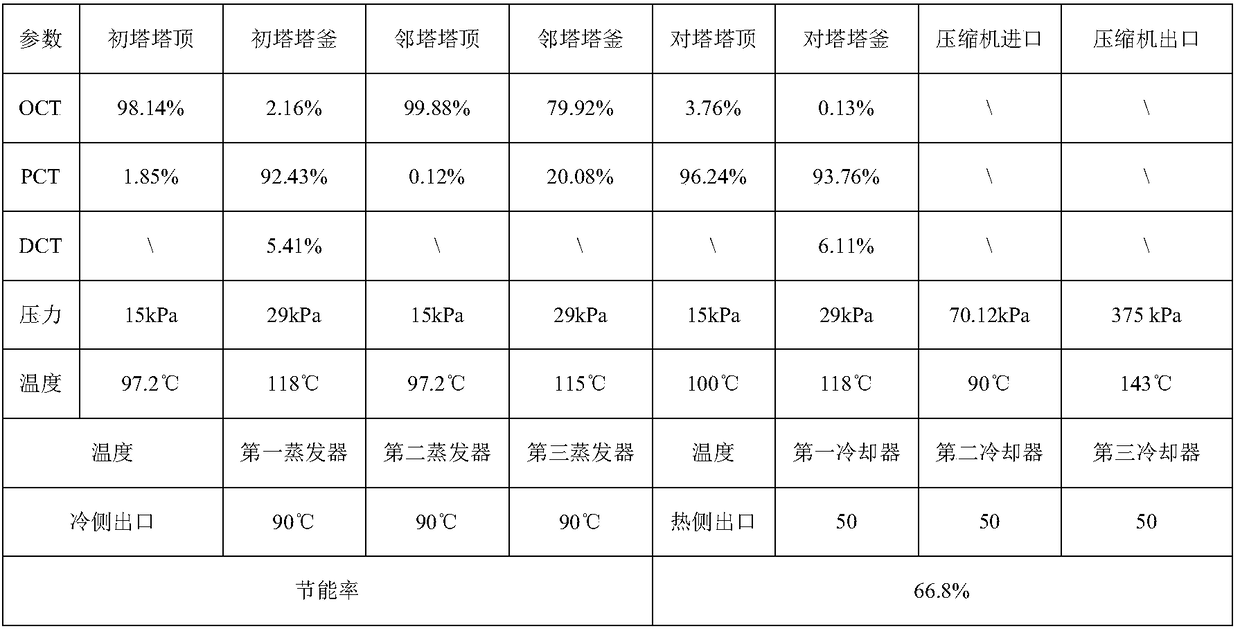

Mixed chlorotoluene MVR (mechanical vapor recompression) rectification system and method

PendingCN109134189AChemical industryHalogenated hydrocarbon separation/purificationChemical industryLiquid water

The invention belongs to the field of chemical industry and relates to a mixed chlorotoluene MVR (mechanical vapor recompression) rectification system and method. The system herein comprises a primarycolumn, an ortho-column, a para-column, evaporators, a cooler, a gas-liquid separation tank, a vapor compressor, reboilers and the like. The system is characterized in that continuous rectification via the primary column, ortho-column and para-column by means of rectification is carried out; mixed chlorotoluene mother liquor that is preheated is processed via the primary column to obtain crude o-chlorotoluene and p-chlorotoluene; the crude o-chlorotoluene and p-chlorotoluene are fed respectively into the ortho-column and the para-column for continued rectification; o-chlorotoluene with purityof higher than 98% is acquired from the top of the ortho-column; p-chlorotoluene with purity of higher than 92% is acquired from the bottom of the ortho-column; distillates from the three columns aresubjected to heat exchanging with liquid water in respective top evaporators; the liquid water absorbs heat and evaporates into water vapor; the water vapor is separated and purified by the gas-liquid separation tank before the resultant is heated and pressurized in the vapor compressor; the pressurized material enters the reboilers at the bottoms of the three columns to release latent heat to heat part of the bottom distillates. The system and method herein have the advantages of high separation efficiency, low energy consumption, low operation cost and the like.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

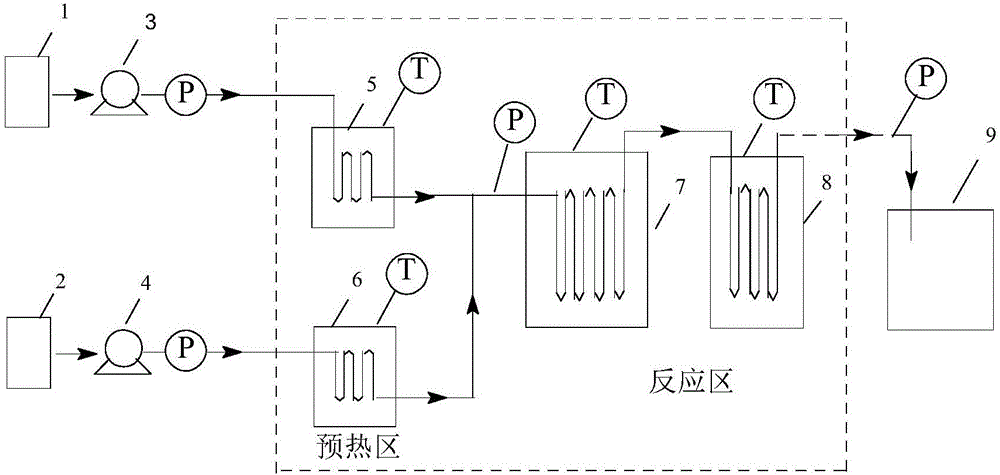

Method for preparing p-chlorobenzaldehyde through continuous oxidization of p-chlorotoluene

InactiveCN106748685AShort reaction timeMild reaction conditionsCarbonyl compound preparation by oxidationChemical/physical/physico-chemical stationary reactorsP-chlorobenzaldehydeOrganic synthesis

The invention relates to a method for preparing p-chlorobenzaldehyde through continuous oxidization of p-chlorotoluene and belongs to the technical field of organic synthesis processes. The method is a process technology for preparing p-chlorobenzaldehyde by continuously oxidizing p-chlorotoluene in a tubular reactor with a p-chlorotoluene compound as a raw material, one or more metal ion complexes of cobalt, molybdenum and bromine as a catalyst, hydrogen peroxide as an oxidizing agent and acetic acid as a solvent. The method has mild conditions and takes short time, the utilization rate of the raw material is high, effective control in the reaction process can be realized, safe, stable and continuous operation is realized, and the production efficiency is high.

Owner:CHANGZHOU UNIV

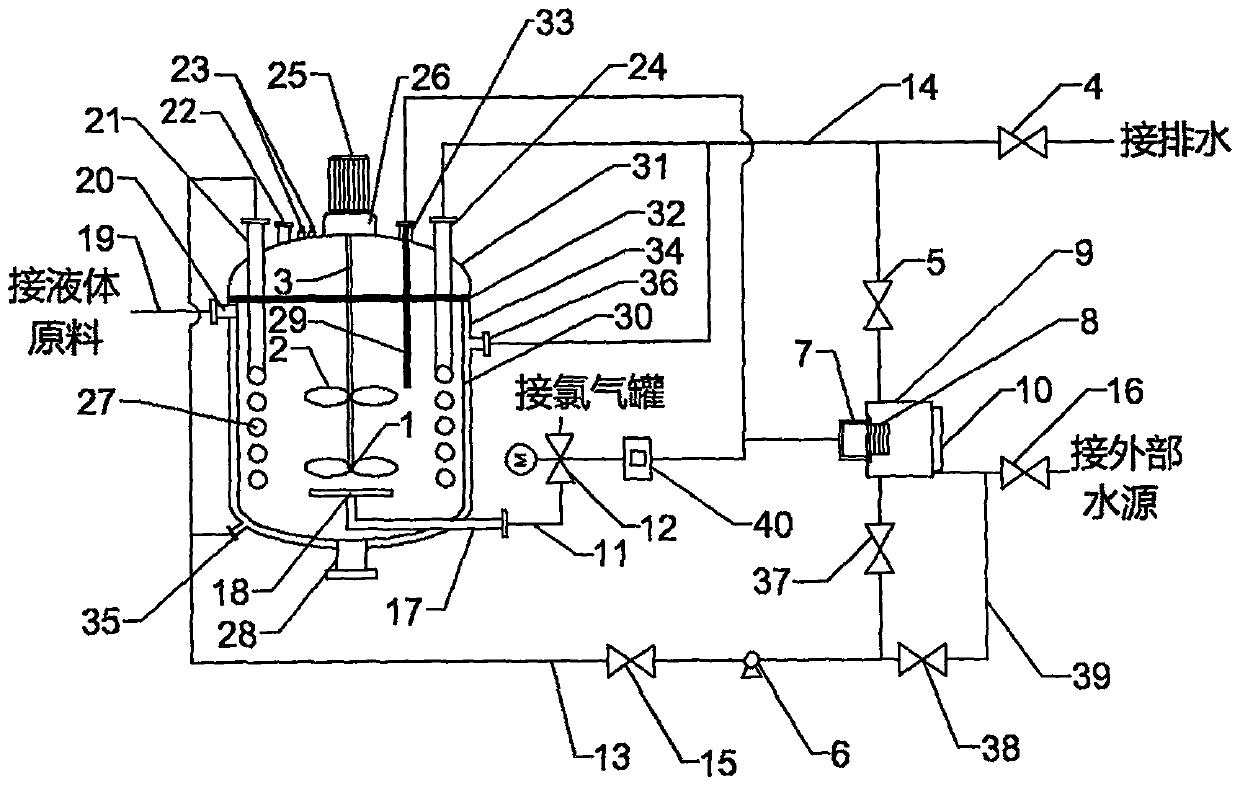

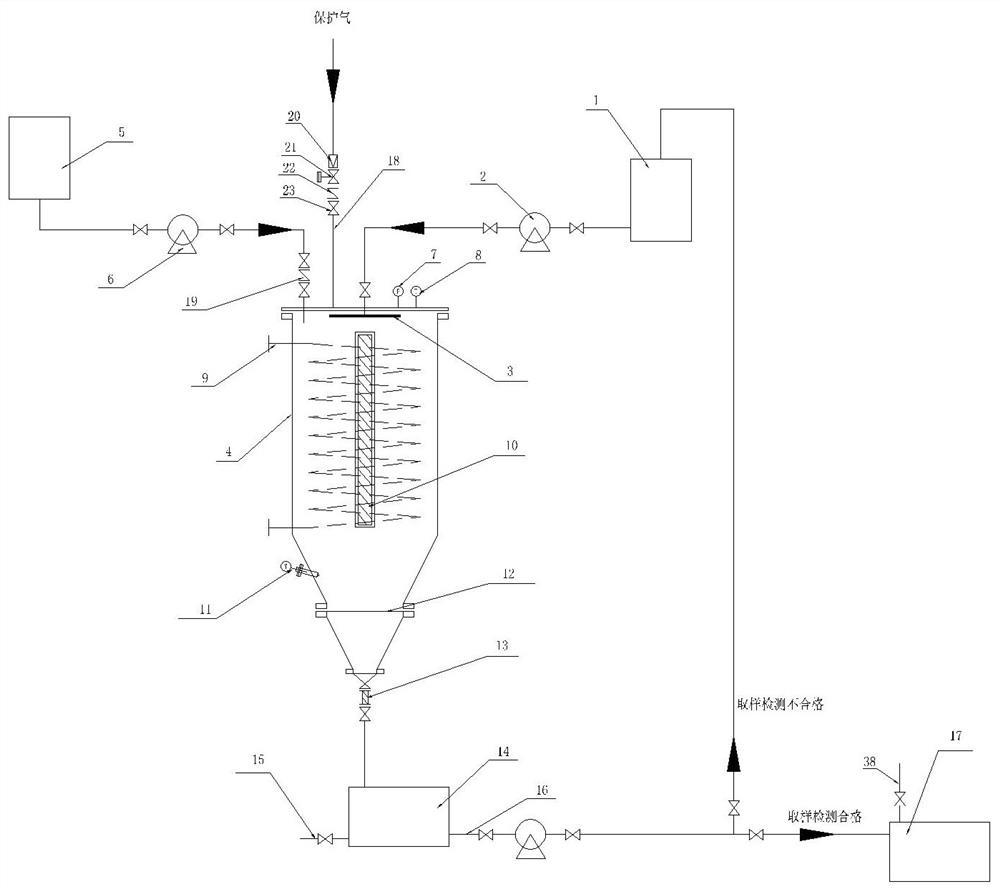

Automatic temperature control reaction kettle for synthesizing p-chlorotoluene

InactiveCN109603710AFacilitate directed synthesisStable temperatureChemical/physical/physico-chemical stationary reactorsHalogenated hydrocarbon preparationInlet valveReaction temperature

The invention discloses an automatic temperature control reaction kettle for synthesizing p-chlorotoluene. The reaction kettle comprises a lower-part stirring paddle, an upper-part stirring paddle, astirring shaft, a water drainage valve, a circulating water valve, a water pump, a controller 1, a heating water tank, an air inlet pipe, an electric valve, a water inlet pipe, a water outlet pipe, afirst water inlet valve, a second water inlet valve, a chlorine gas inlet, a gas distributor, a material inlet pipe, a liquid raw material inlet, a coil water inlet, a gas outlet, a safety valve, a coil water outlet, a motor, a motor reducer, a coil, a liquid outlet, a temperature sensing device, a reaction kettle body, a sealing cover, a sealing ring, a mounting mouth, a jacket, a jacket water inlet, a jacket water outlet, a hot water valve, a cold water valve, a cold water inlet pipe and a controller 2. An automatic temperature control device including the jacket and the coil is adopted by the reaction kettle, so that the problems of too low selectivity caused by excessively high reaction temperature and a too-low conversion rate caused by excessively low reaction temperature are solved,and meanwhile full contact of reactants are achieved through adoption of the two stirring paddles and the gas distributor.

Owner:NINGBO UNIV

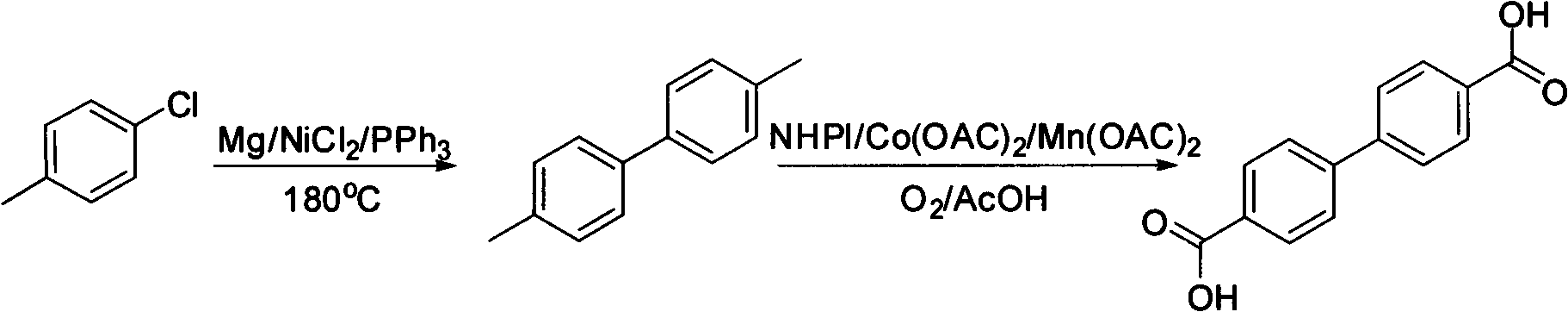

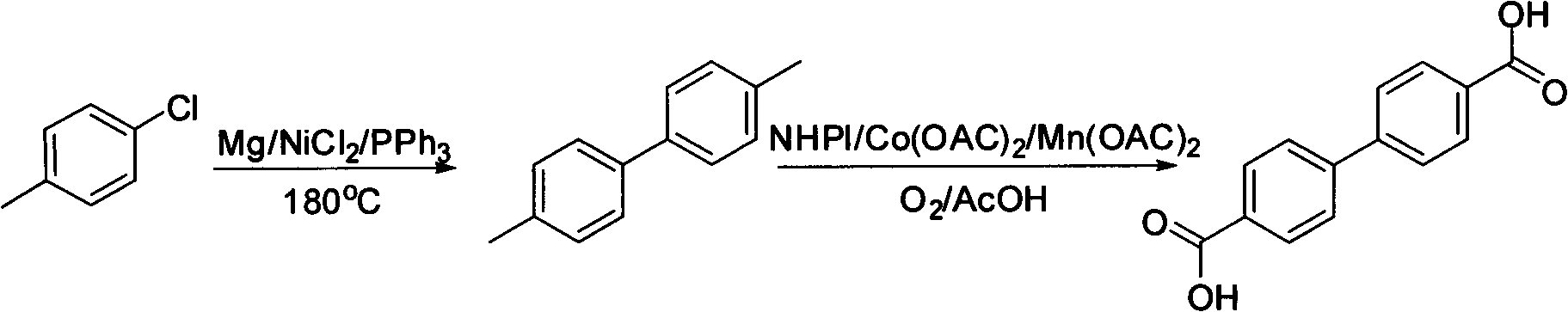

Method for synthesizing biphenyl 4,4'-dicarboxylic acid from p-chlorotoluene

InactiveCN103012121ALow priceLow costOrganic compound preparationCarboxylic compound preparationOrganic synthesisSolvent free

The present invention provides a method for preparing biphenyl 4,4'-dicarboxylic acid, and belongs to the technical field of organic synthesis. The method comprises: adopting p-chlorotoluene as a raw material, adding a metal magnesium, a catalyst and a ligand, and synthesizing 4,4'-dimethylbiphenyl through a one-pot method; and introducing oxygen to the 4,4'-dimethylbiphenyl to carry out oxidation, adding a certain amount of the catalyst, adopting acetic acid as a solvent, heating, evaporating the solvent after completing the reaction, and carrying out water washing and drying to obtain the biphenyl 4,4'-dicarboxylic acid. According to the present invention, the p-chlorotoluene is adopted as the starting material, the solvent-free one-pot method is adopted to synthesize the 4,4'-dimethylbiphenyl so as to provide advantages of low cost, high yield, simple operation and easy purification; free radical oxidation of oxygen molecules is adopted in oxidation of aromatic hydrocarbon alkyl into aromatic carboxylic acid, such that reaction conditions are relatively mild, and corrosion on the equipment is reduced; and the method is suitable for industrial production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Production technology for preparing p-chlorotoluene by methylbenzene directional chlorination

PendingCN109734551AReduce generationIncrease profitHalogenated hydrocarbon preparationRefluxO-chlorotoluene

The invention relates to the technical field of chemical raw material preparation, in particular to a production technology for preparing p-chlorotoluene by methylbenzene directional chlorination. Theproduction technology includes the steps: chlorination: adding catalysts into a reaction vessel, adding methylbenzene into the reaction vessel, leading in inert gas, discharging air in the reaction vessel, placing the reaction vessel into a constant temperature device after shading treatment, leading chlorine into a constant temperature device, performing chlorination reaction and chromatographicanalysis and accordingly judging reaction endpoints to obtain chlorinated mixture for standby application; rectification: adjusting reflux ratio to be 10:1 and collecting fraction with the temperature of 158-162 DEG C to obtain o-chlorotoluene and p-chlorotoluene mixed solution for standby application; primary purification; secondary purification. The production technology solves the problems ofpoor methylbenzene chlorination directional selectivity and high cost in the prior art, and is high in p-chlorotoluene yield and conversion rate, good in para-position directional selectivity and reasonable in technological cost.

Owner:JIANGSU QIHENG AGRI & CHEM TECHCO

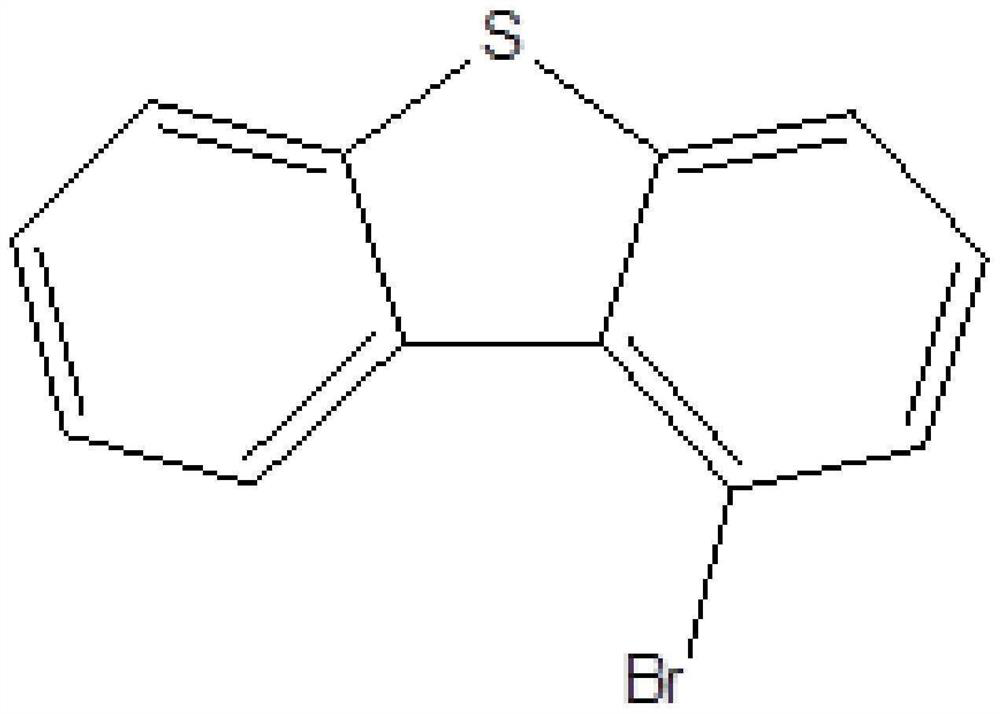

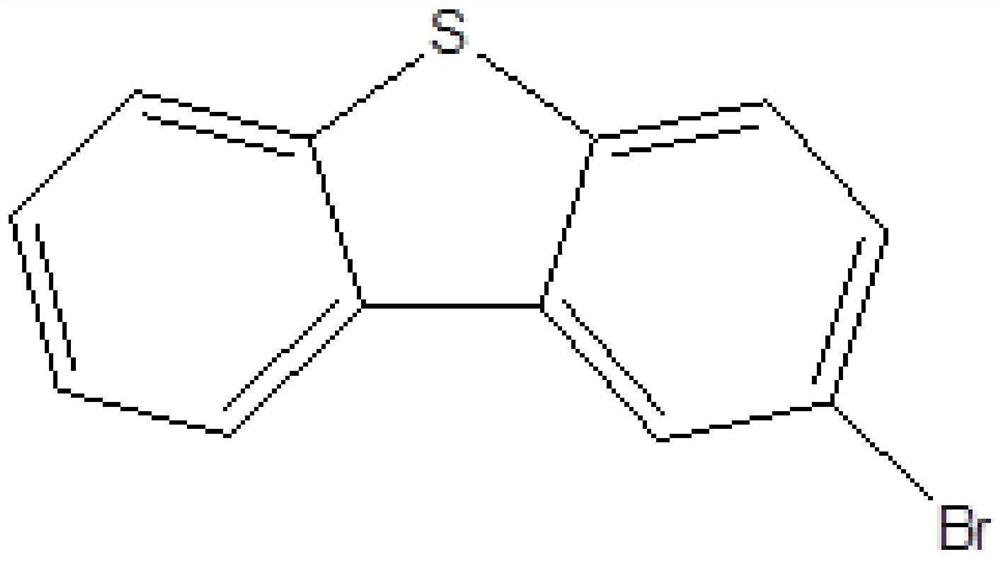

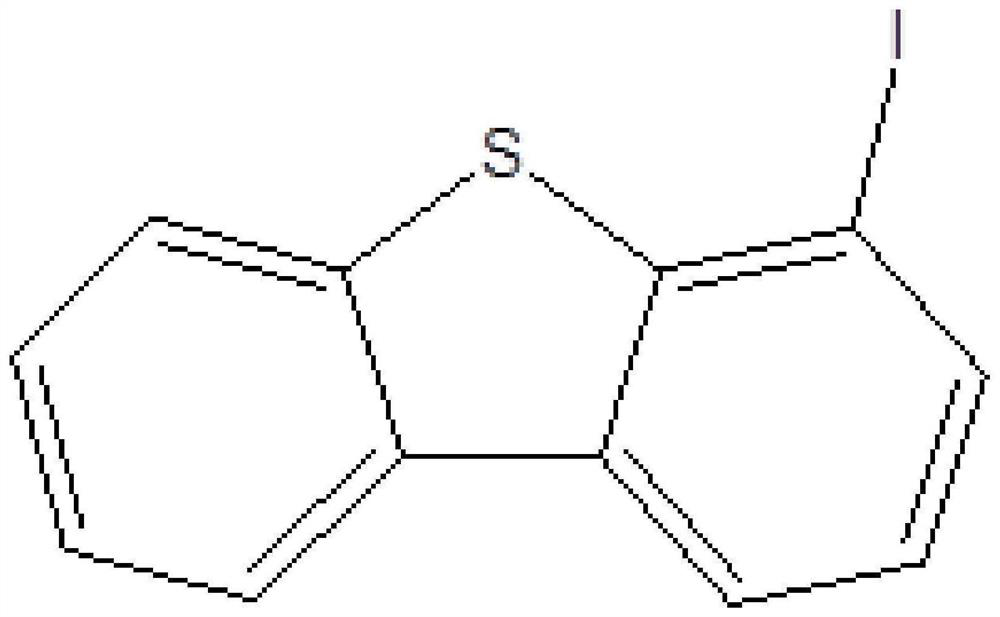

Method for selectively preparing o-chlorotoluene

ActiveCN113896612AHigh selectivityHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method for selectively preparing o-chlorotoluene, which is characterized in that a mixture of iron powder and a dibenzothiophene compound is used as a combined catalyst, and chlorine is introduced into toluene under a dark condition to obtain o-chlorotoluene. The temperature in the chlorination process is controlled to be 30-50 DEG C, and the conversion rate of toluene is 98-100% by controlling the chlorine introduction amount. The chlorination liquid obtained after the catalyst is applied to toluene chlorination takes o-chlorotoluene as a main product, the percentage content of o-chlorotoluene is effectively increased, the highest content of o-chlorotoluene reaches 68.50%, the content of m-chlorotoluene is smaller than 0.15%, the content of total dichlorotoluene is smaller than 2.21%, and the mass ratio of o-chlorotoluene to p-chlorotoluene reaches 2.28.

Owner:常州新东化工发展有限公司

Synthesis method of sartan anti-hypertensive medicament intermediate 2-cyan-4'-methyl diphenyl

InactiveCN102964271AReduced activityReduce productionCarboxylic acid nitrile preparationOrganic compound preparationPharmaceutical drugCatalytic effect

The invention provides a synthesis method of sartan anti-hypertensive medicament AIIRA intermediate 2-cyan-4'-methyl diphenyl. O-chlorobenzonitrile and p-chlorotoluene react for one step under the catalytic action of a Pd complex so that high-purity 2-cyan-4'-methyl diphenyl is obtained. The synthesis method has the advantages of fewer reaction steps, easily controlled reaction condition, low price, low raw material price, available raw materials and the like, and is simple to operate.

Owner:QILU UNIV OF TECH

Method for synthesizing p-chlorobenzaldehyde from p-chlorotoluene

InactiveCN104447250ASave raw materialsSimple and fast operationCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationChlorobenzeneP-chlorobenzaldehyde

The invention discloses a method for synthesizing p-chlorobenzaldehyde from p-chlorotoluene. The method comprises the steps of reacting the p-chlorotoluene with chlorine for 3-8 hours at 160-180 DEG C in the presence of an initiator to generate p-chlorobenzyl chloride, and then performing catalytic hydrolysis for 6-12 hour to obtain p-chlorobenzaldehyde. The method for synthesizing p-chlorobenzaldehyde from p-chlorotoluene is cheap in raw material and simple and convenient in operation.

Owner:CHANGSHU XINHUA CHEM

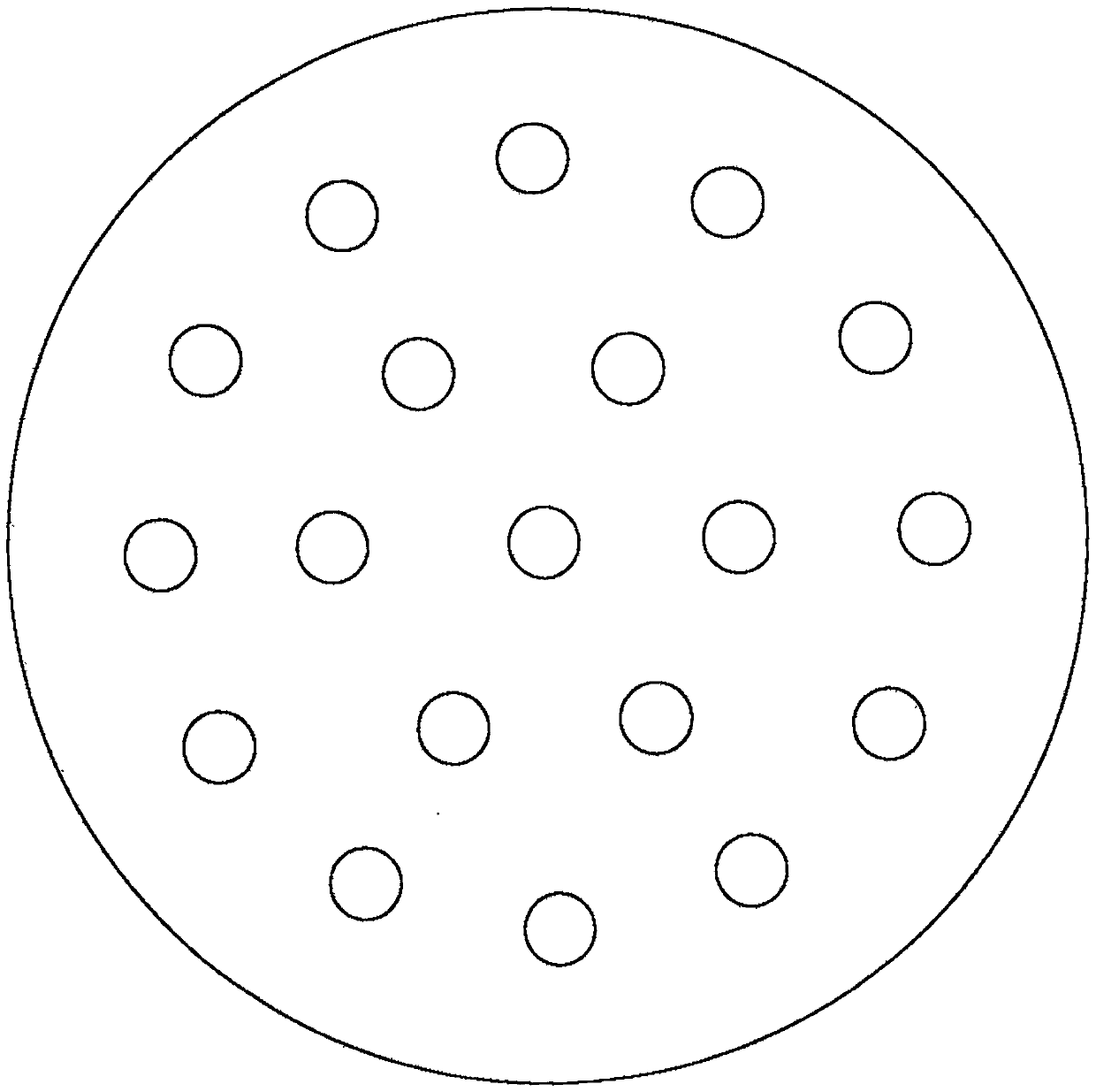

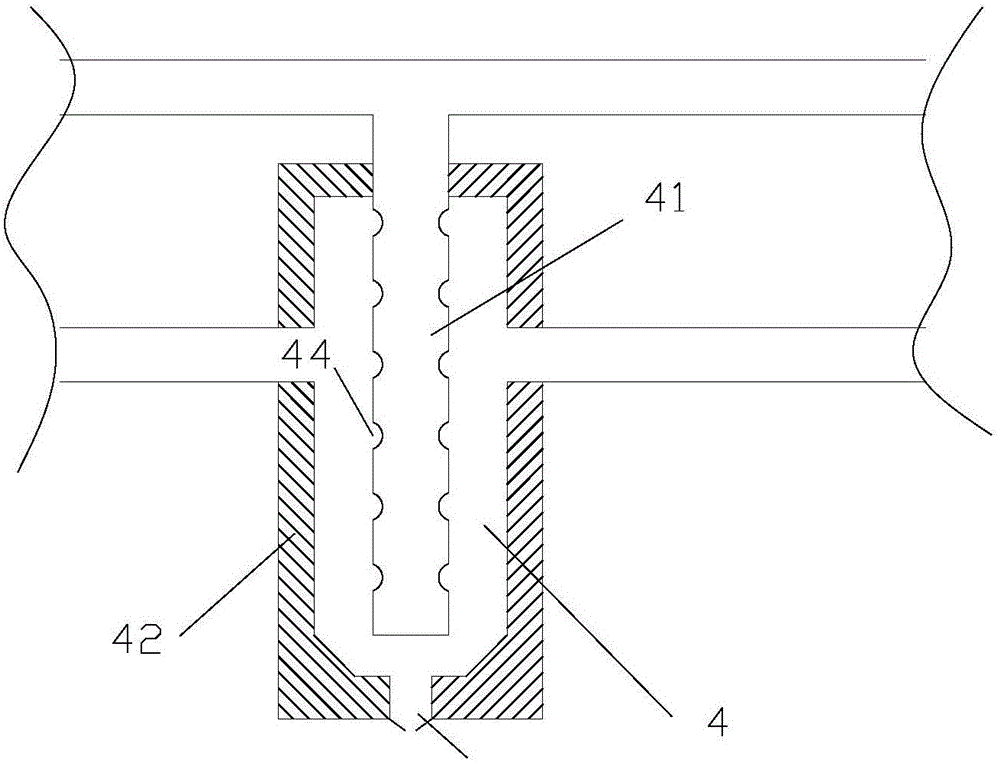

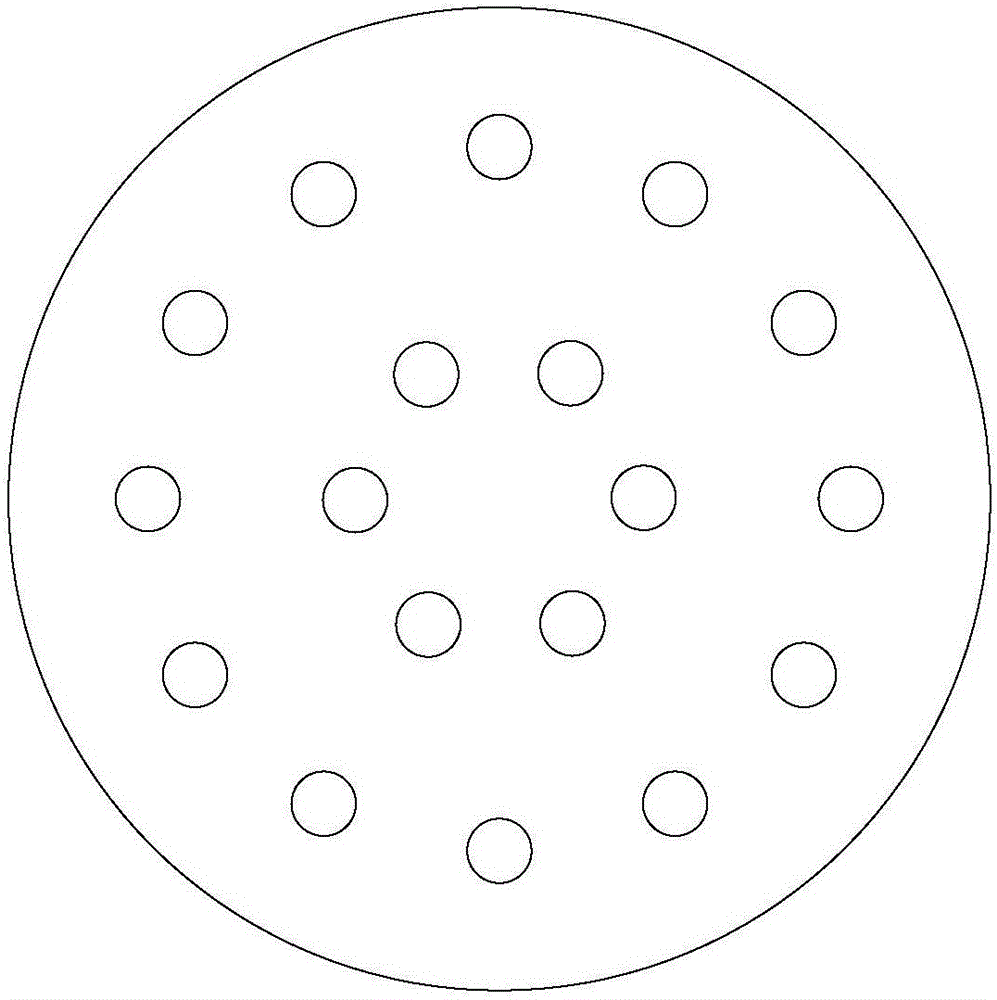

Special reactor for oriented synthesis of p-chlorotoluene

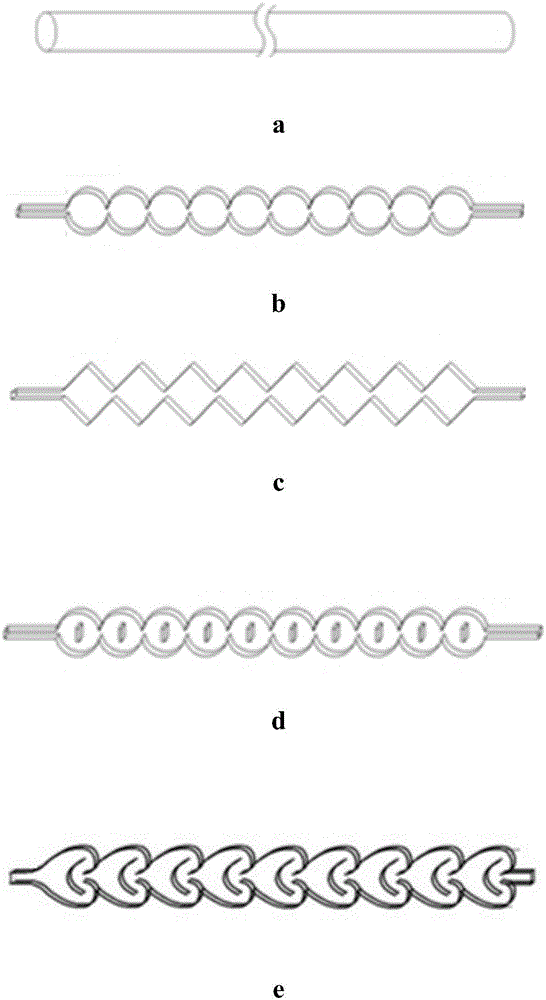

ActiveCN105749850AIncrease contact areaMeets requirementsChemical/physical/physico-chemical nozzle-type rreactorsHalogenated hydrocarbon preparationP-chlorotolueneEngineering

The invention discloses a special reactor for oriented synthesis of p-chlorotoluene. The special reactor comprises a reactor body 1, wherein a first hollow air inflow board 2 and a hollow liquid inflow board 3 are arranged at the upper part of the reactor body 1; a plurality of nozzles 4 are arranged on the first hollow air inflow board; each nozzle consists of an inner tube, a housing and a spray nozzle; the inner tubes are connected with the first hollow air inflow board 1; the housings are connected with the hollow liquid inflow board 2; a second hollow air inflow board 5 is arranged at the lower part of the reactor body; a plurality of injection orifices are formed in the second hollow air inflow board; the nozzles are arranged opposite to the jetting directions of the injection orifices.

Owner:JIANGSU LIYANG NEW MATERIALS CO LTD

Method for preparing o-chlorotoluene

InactiveCN105418358AHigh catalytic activityHigh activityPhysical/chemical process catalystsHalogenated hydrocarbon preparationO-chlorotolueneEthyl Chloride

The invention discloses a method for preparing o-chlorotoluene. The method comprises the following steps: adding a raw material toluene and a FeCl3-loaded macroporous metal silica gel catalyst into a reaction kettle; introducing chlorine into the reaction kettle for a liquid-phase ring chlorination reaction between the toluene and chlorine; after the reaction is complete, aerating to remove residual chlorine and hydrogen chloride gas in the reaction liquid; rectifying the reaction liquid to separate out unreacted toluene and a little dichlorotoluene to obtain mixed chlorotoluene; and then, separating high-purity p-chlorotoluene from the mixed chlorotoluene by using a melt crystallization process. According to the method disclosed by the invention, the FeCl3-loaded macroporous metal silica gel catalyst is adopted for catalyzing the selective chlorination of toluene, the reaction is fast, the catalytic activity is high, the o-chlorotoluene selectivity is good, the requirements for the technological conditions are low, the catalyst consumption is low, the catalyst has high activity and can be recycled, and the method has a good industrial prospect.

Owner:NANJING ZHONGTENG CHEM

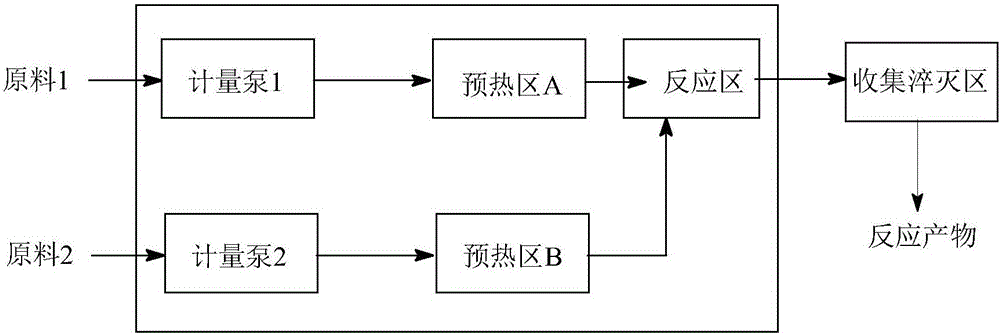

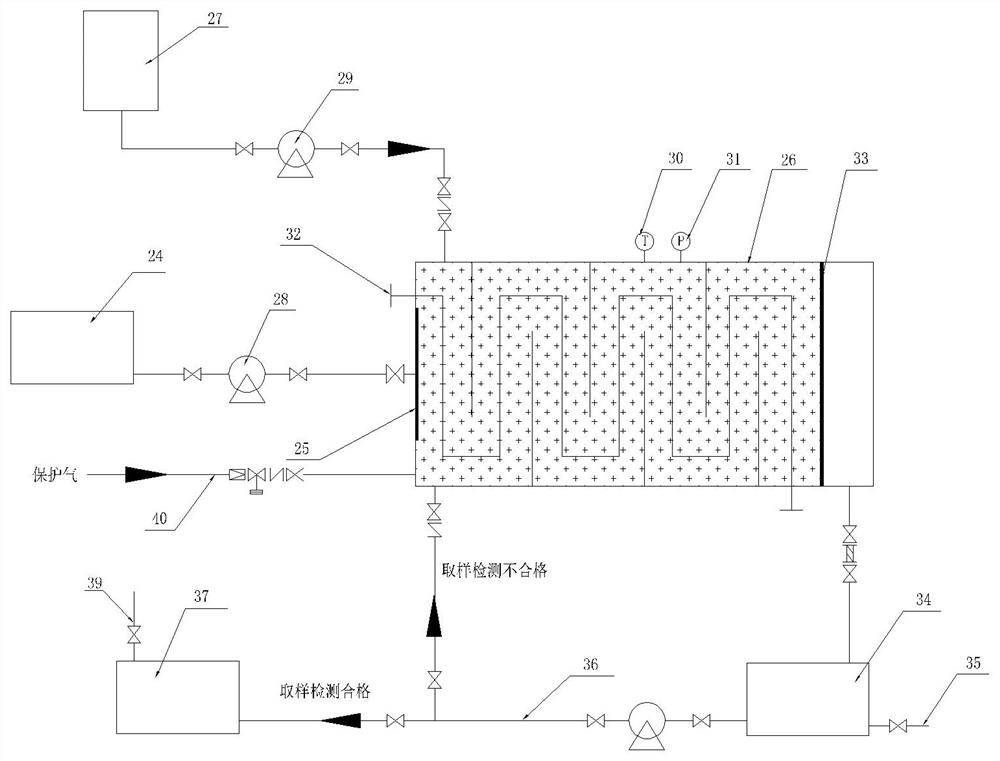

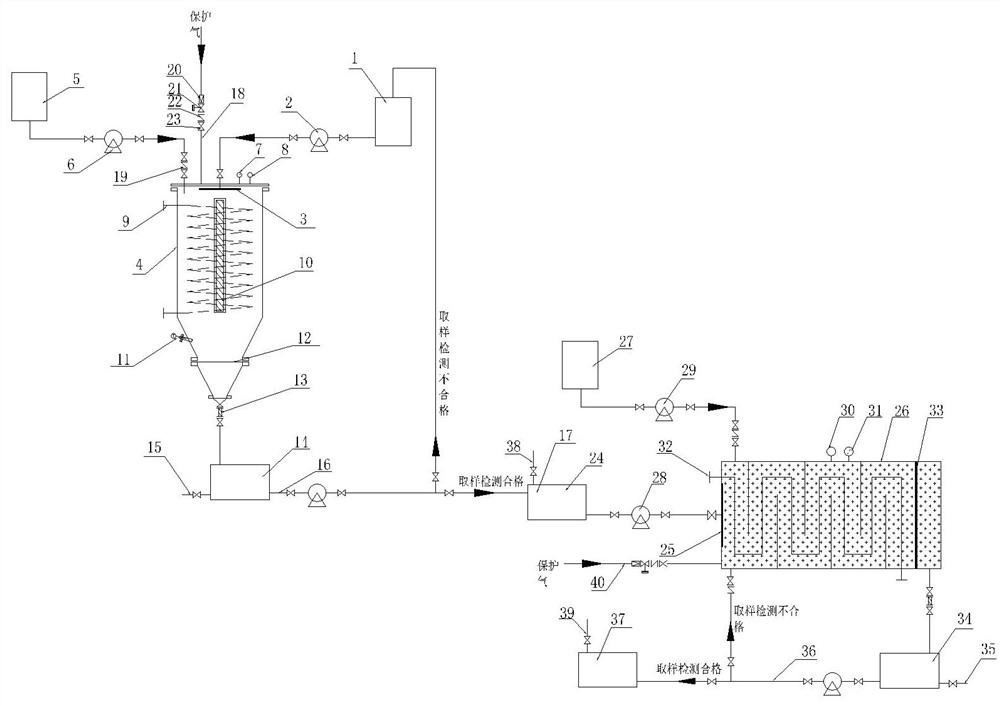

Method and device for continuously producing sartan biphenyl

ActiveCN111718279ANotable featuresSignificant positive effectCarboxylic acid nitrile preparationOrganic compound preparationChlorobenzenePtru catalyst

The invention discloses a method and a device for continuously producing sartan biphenyl. The method comprises the following steps: carrying out continuous Grignard reaction on p-bromotoluene or p-chlorotoluene by adopting a fixed bed reactor; carrying out continuous coupling reaction on the obtained Grignard reagent and o-chlorobenzonitrile in a fixed bed reactor with a solid supported catalyst;finally, preparing the sartan biphenyl. Materials are added and output in a continuous manner in the whole reaction process after the production is started; the solid supported catalyst is spherical silica gel supported monoatomic Mn (0) and Zn (0) catalyst. The invention has the characteristics of continuous and stable production, timely transmission of reaction heat, no temperature runaway and deflagration problems, high reaction safety, reduction of reaction byproducts, and high product yield and efficiency.

Owner:山东盛华电子新材料有限公司 +2

Method for catalyzing chlorination of alkylbenzene ring by using combined catalyst

ActiveCN102659505AEasy to separateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationPtru catalystHydroxamic acid

The invention discloses a method for catalyzing chlorination of alkylbenzene ring by using a combined catalyst. The method comprises the following steps: adding iron powder or Lewis acid which serves as a primary catalyst into a toluene liquid, adding a composition of an elementary substance sulfur and hydroxamic acid, which serves as a cocatalyst, introducing chorine under the condition of keeping out of the sun, controlling the temperature within 0-70DEG C in the whole chlorination process, and controlling the chlorine introducing amount to ensure that the conversion rate of toluene is over 97 percent. After the combined cocatalyst is applied to the chlorination of a benzene ring, the selectivity of a product, namely parachlorotoluene is effectively improved, the selectivity of the parachlorotoluene is over 50 percent and the catalyst is easy to separate.

Owner:SOUTHEAST UNIV

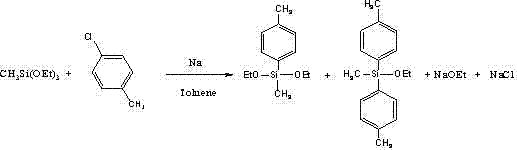

P-benzyldiethoxymethylsilane and preparation method thereof

ActiveCN102898455AMild reaction conditionsSimple processGroup 4/14 element organic compoundsTriethoxysilaneP-chlorotoluene

The invention relates to the field of organic chemistry and provides p-benzyldiethoxymethylsilane and a preparation method thereof. The preparation method solves the problem that in sodium condensation method-based synthesis of p-substituted benzyldiethoxymethylsilane, a large amount of a solvent is used so that environmental pollution is produced and solvent recycle is difficult. The preparation method comprises that the p-benzyldiethoxymethylsilane is synthesized from methyl triethoxysilane and p-chlorotoluene as raw materials by a sodium condensation method. The preparation method does not use a toluene solvent, allows mild reaction conditions, has simple processes and is suitable for large-scale industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of parachlorobenzoyl chloride

InactiveCN107382715AShort chlorination timeHigh yieldHalogenated hydrocarbon preparationCarboxylic acid halides preparationDistillationP-chlorotoluene

The invention discloses a preparation method of parachlorobenzoyl chloride. The method includes the steps of: (1) chlorination: adding the raw material p-chlorotoluene into a reaction kettle, performing stirring, adding triethanolamine into the reaction kettle, and conducting stirring for 30min, adding thionyl chloride, conducting stirring for 10min, then slowing raising the temperature, adding azodiisobutyronitrile, introducing chlorine gas for reaction to obtain 4-chlorobenzotrichloride; (2) hydrolysis: adding the4-chlorobenzotrichloride obtained in step (1) into a hydrolysis kettle, adding the catalyst ferric trichloride, adding water dropwise to obtain a parachlorobenzoyl chloride crude product; and (3) distillation: distilling the parachlorobenzoyl chloride crude product to obtain the product. Specifically, the p-chlorotoluene is 30000-40000 parts, and triethanolamine is 1-10 parts. P-chlorotoluene is adopted as the raw material for chlorination by chlorine gas to obtain 4-chlorobenzotrichloride, and then hydrolysis and distillation are carried out so as to obtain the product. Firstly triethanolamine is utilized to remove the influence of iron ions, then thionyl chloride is utilized to remove the moisture influence, the chlorination reaction time is short, the reaction by-product is few, and the yield is high.

Owner:山东福尔有限公司

A kind of preparation method of p-chlorobenzaldehyde

ActiveCN109651111BLower the temperature of the substitution reactionHigh selectivityCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationChlorobenzenePtru catalyst

The invention discloses a preparation method of p-chlorobenzaldehyde, which uses p-chlorotoluene as a raw material to undergo a substitution reaction with chlorine under the action of a catalyst to obtain a mixture of p-chlorobenzyl chloride and p-chlorobenzylidene dichloride. The mixture of p-chlorobenzyl chloride and p-chlorobenzylidene dichloride undergoes hydrolysis reaction and air catalytic oxidation reaction under the action of a catalyst to obtain p-chlorobenzaldehyde. The present invention reduces the reaction temperature of the substitution reaction through the action of the catalyst, improves the selectivity of the substitution reaction, adopts the combination of the hydrolysis reaction and the air catalytic oxidation reaction to improve the yield of p-chlorobenzaldehyde, and reduces the yield of p-chlorobenzaldehyde through the mechanical application of the catalyst. The amount of waste water from the hydrolysis reaction.

Owner:烟台舜康生物科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com