Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Ortho-chlorotoluene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing CLT acid (6-chloro-3-aminotoluene-4-sulfoacid) by utilizing o-chlorotoluene direct nitrification method

InactiveCN101906057AReduce pollutionLow equipment requirementsSulfonic acid preparationO-chlorotolueneRaw material

The invention relates to a method for preparing 6-chloro-3-aminotoluene-4-sulfoacid (hereinafter referred to as CLT acid) in a direct nitrification way by taking o-chlorotoluene as a raw material. The method comprises the following steps of: obtaining o-chlorotoluene nitrate by taking acidic Beta zeolite as a catalyst and acetyl nitrate as a nitrifying agent; reducing the o-chlorotoluene nitrate by utilizing iron powder; recrystallizing the reduced product and separating out 6-chloro-3-aminotoluene crystal and 6-chloro-4-aminotoluene containing little 6-chloro-3-aminotoluene by adopting an acid extraction method; adding dichlorobenzene and sulfuric acid in the 6-chloro-3-aminotoluene crystal, and carrying out sulfonation at 170-190 DEG C to obtain the CHLOROT acid; and carrying out sulfonation on the 6-chloro-4-aminotoluene containing little 6-chloro-3-aminotoluene to obtain 2B acid containing little CLT acid. The invention has the characteristics of low pollution, high yield, simple process, low device requirements, and the like.

Owner:YANBIAN UNIV

Preparation method of orthocresol

ActiveCN103254039AHigh selectivityHigh purityOrganic chemistryOrganic compound preparationOrtho-chlorotolueneReaction temperature

The invention provides a preparation method of orthocresol, which comprises the steps of mixing ortho-chlorotoluene, an alkaline compound, water and a catalyst for reaction to obtain orthocresol, wherein the catalyst is selected from cuprum and / or a mixture of a cuprum-bearing compound with chloride, hydroxide, oxide, acetate or sulfate of M; and the M is selected from Fe, Mn, Zn, Ni or Ti. According to the method, orthocresol is prepared by taking cuprum, the cuprum-bearing compound and other metal salt as the composite catalyst and adopting a chloro-toluene hydrolysis method; the reaction can have higher activity at lower reaction temperature; raw materials are higher in conversion rate; the method has higher selectivity for orthocresol; and prepared orthocresol has higher purity.

Owner:济南尚博生物科技有限公司

Production method of ortho-chlorotoluene

InactiveCN102603469ASimple methodEasy to operateHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsOrtho-chlorotolueneToluene

The invention discloses a production method of ortho-chlorotoluene. The production method comprises toluene chlorinating, toluene removing and chorine mixed toluene rectifying steps. The method comprises the following steps of: during toluene chlorinating, putting toluene into a chlorinating kettle, and adding a catalyst; introducing chorine gas at the temperature of 40-60 DEG C for undergoing a chlorinating reaction; mixing the catalyst used in the reaction by using aluminum oxide and trichloride antimony; mixing with silica sol; and treating at the temperature of 80-120 DEG C for 4-6 hours. The method is simple and convenient, and is easy to operate; and in the total amount of parachlorotoluene and ortho-chlorotoluene in a final product, the ortho-chlorotoluene is over 44 percent. After rectification, the content of the product is over 99.5 percent.

Owner:江苏优普生物化学科技股份有限公司

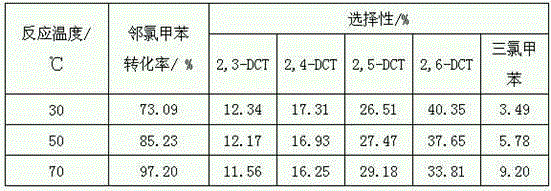

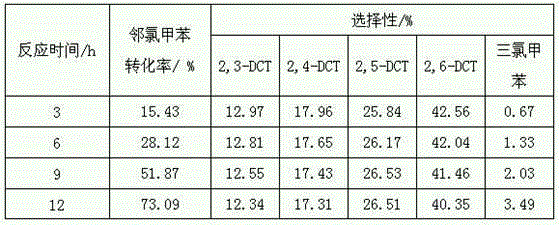

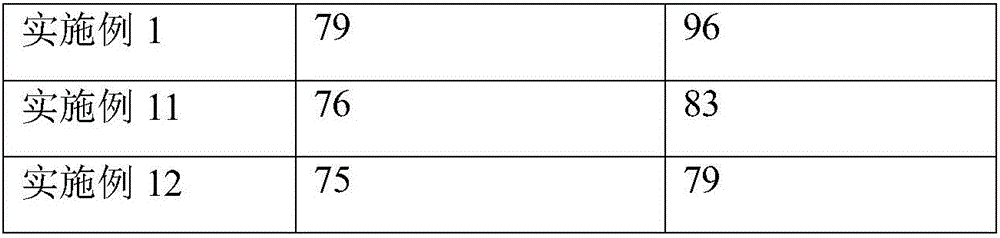

Method for preparing 2,6-dichlorotoluene by catalyzing o-chlorotoluene with ionic liquid

InactiveCN104803827AImprove conversion rateHigh catalytic activityHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method for preparing 2,6-dichlorotoluene by catalyzing o-chlorotoluene with an ionic liquid. According to the method for preparing 2,6-dichlorotoluene, Cl2 is taken as a chlorinating agent, under the action of a catalyst, namely, an aluminium chlorate ionic liquid, a raw material, namely, o-chlorotoluene, is directionally chlorinated, and the 2,6-dichlorotoluene is prepared; an intermediate of the aluminium chlorate ionic liquid is [BMIM]Cl, the molar ratio of AlCl3 to [BMIM]Cl is 1:3, and the usage amount of the aluminium chlorate ionic liquid accounts for 0.1%-1% of the mass of o-chlorotoluene; the method for preparing 2,6-dichlorotoluene by selectively chlorinating the o-chlorotoluene is simple in technology and mild in reaction condition, the used aluminium chlorate ionic liquid is good in catalytic activity and good in stability, can be separated from a product easily and can significantly improve the selectivity of 2,6-dichlorotoluene, and the method has the very high industrial application value.

Owner:NANJING ZHONGTENG CHEM +1

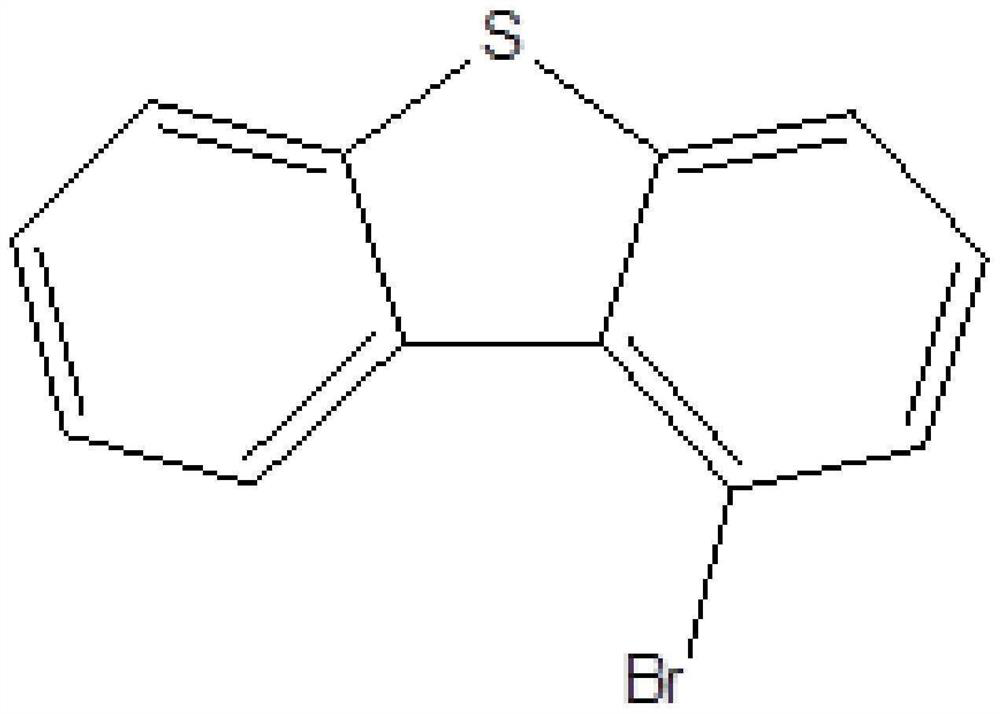

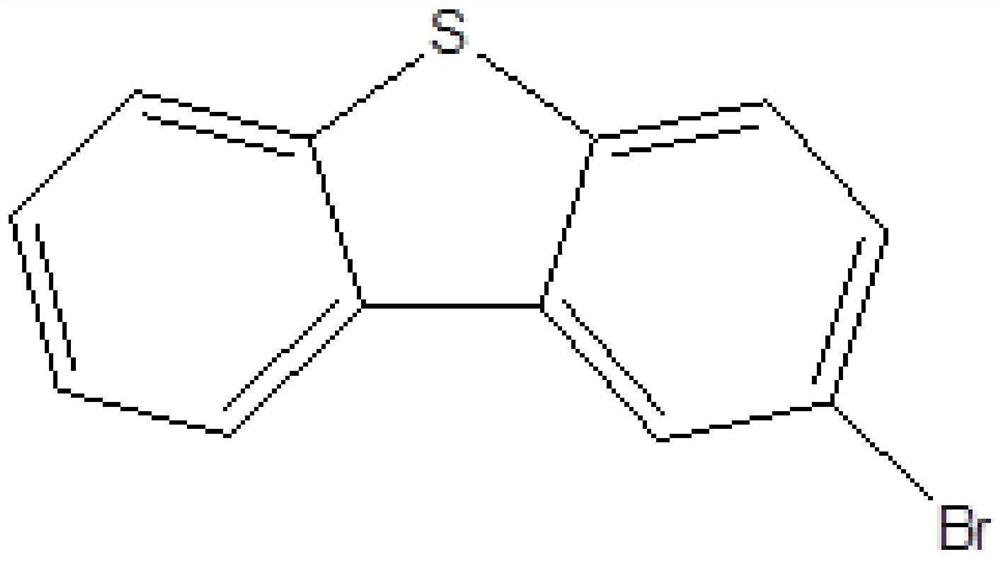

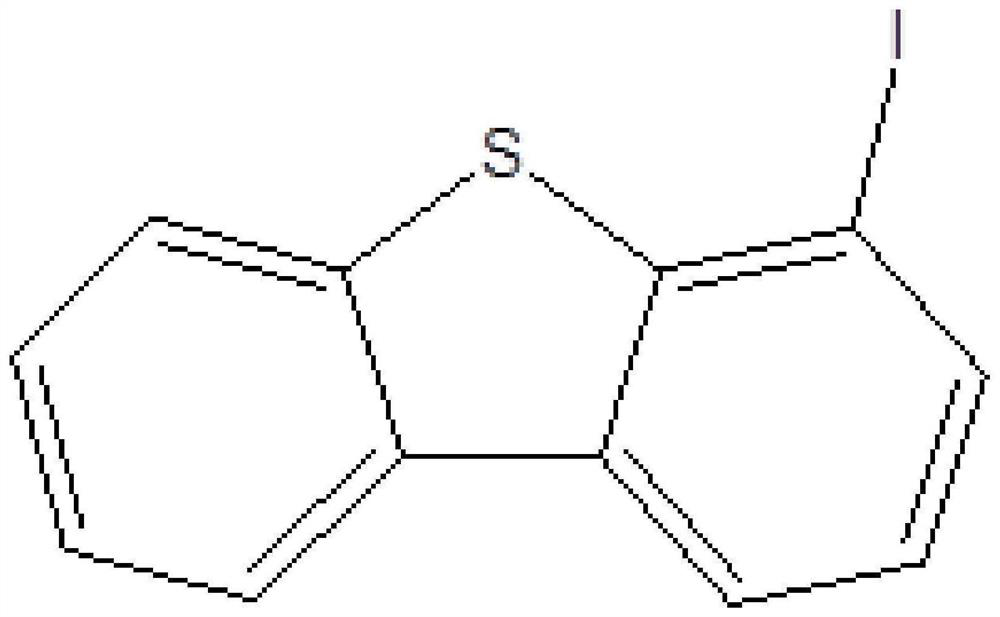

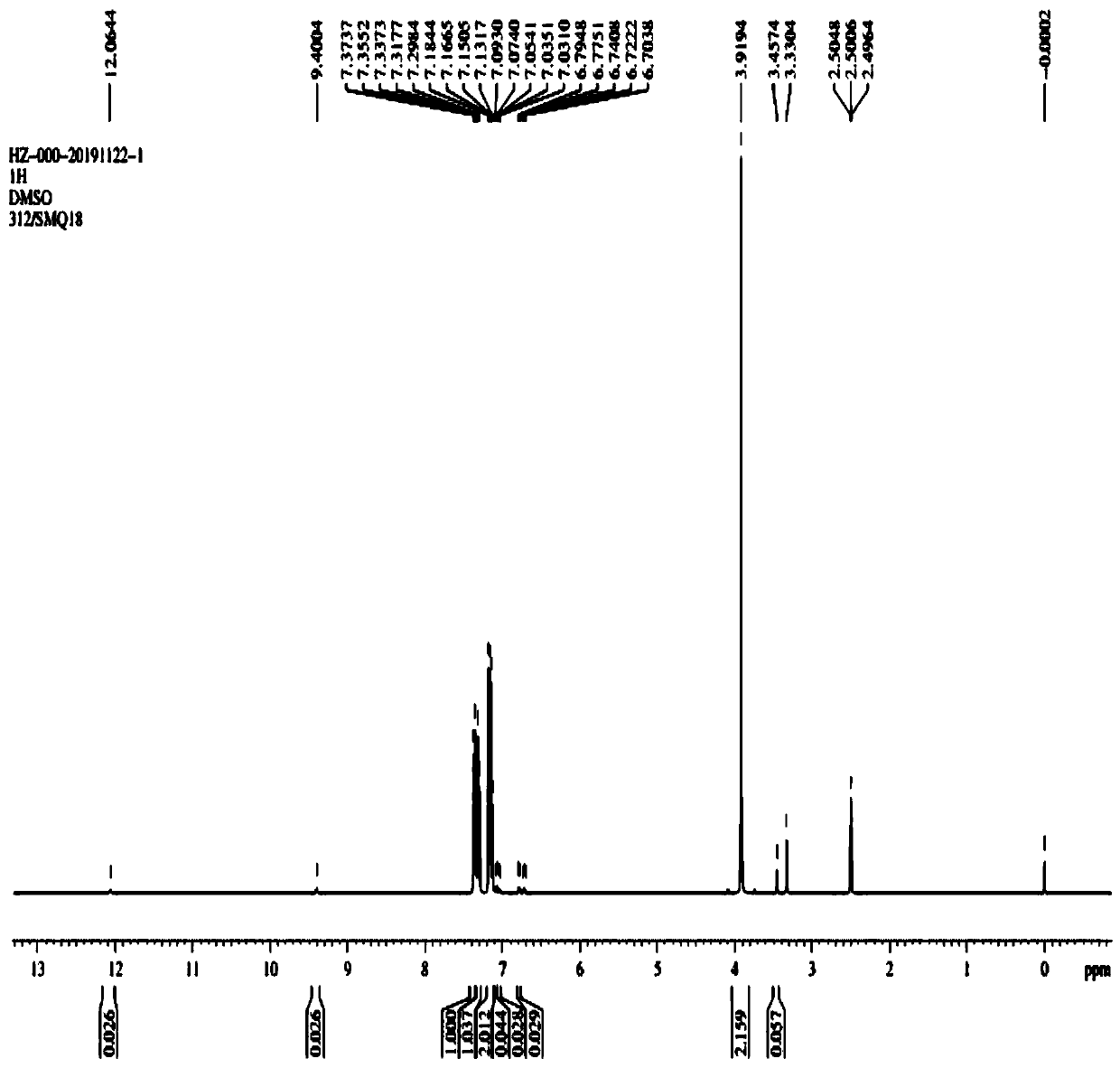

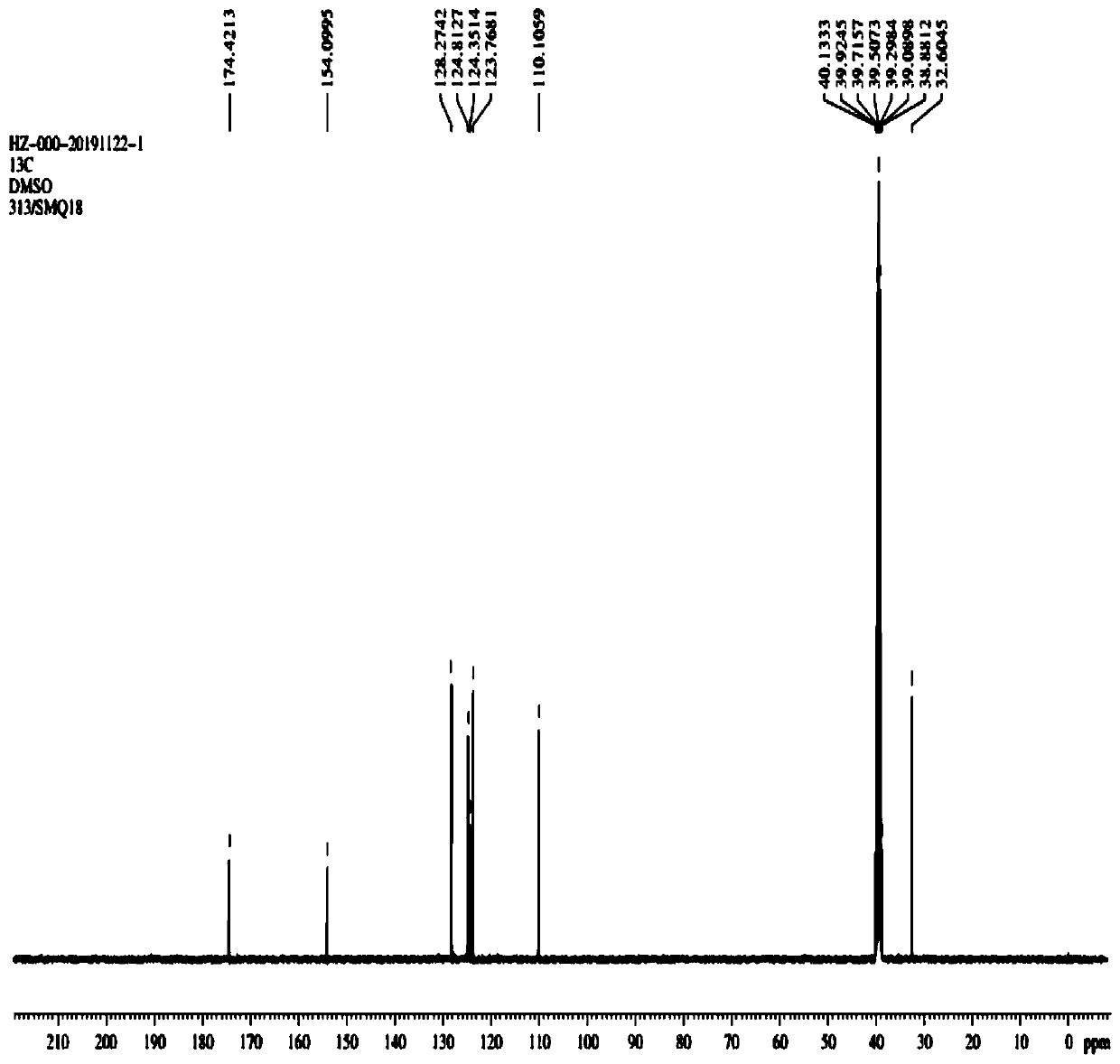

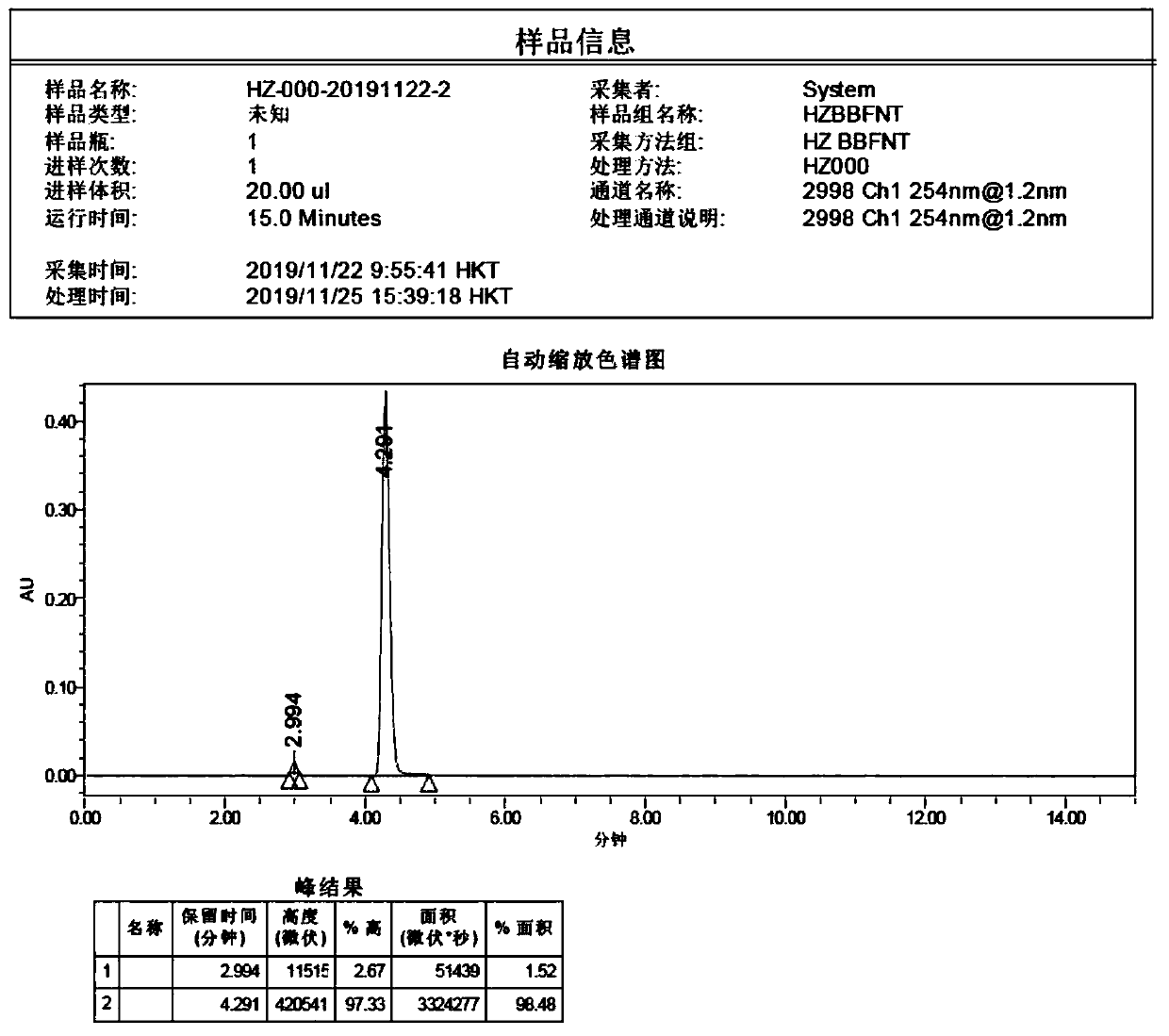

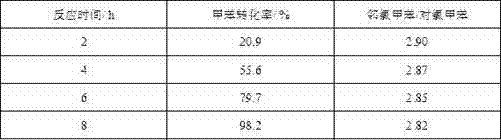

Method for selectively preparing o-chlorotoluene

ActiveCN113896612AHigh selectivityHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method for selectively preparing o-chlorotoluene, which is characterized in that a mixture of iron powder and a dibenzothiophene compound is used as a combined catalyst, and chlorine is introduced into toluene under a dark condition to obtain o-chlorotoluene. The temperature in the chlorination process is controlled to be 30-50 DEG C, and the conversion rate of toluene is 98-100% by controlling the chlorine introduction amount. The chlorination liquid obtained after the catalyst is applied to toluene chlorination takes o-chlorotoluene as a main product, the percentage content of o-chlorotoluene is effectively increased, the highest content of o-chlorotoluene reaches 68.50%, the content of m-chlorotoluene is smaller than 0.15%, the content of total dichlorotoluene is smaller than 2.21%, and the mass ratio of o-chlorotoluene to p-chlorotoluene reaches 2.28.

Owner:常州新东化工发展有限公司

Method for synthesizing benzofuranone by taking o-chlorotoluene as raw material

ActiveCN111170971ALow priceThe production process is environmentally friendly and pollution-freeOrganic chemistryChemical recyclingOrtho-chlorotolueneProcess engineering

The invention provides a method for synthesizing benzofuranone by taking o-chlorotoluene as a raw material. According to the method, the target product benzofuranone is prepared by taking the easily-available o-chlorotoluene as the initial raw material, and the whole preparation process is mild in condition, high in yield and suitable for large-scale industrial production.

Owner:安徽中羰碳一工业技术有限责任公司

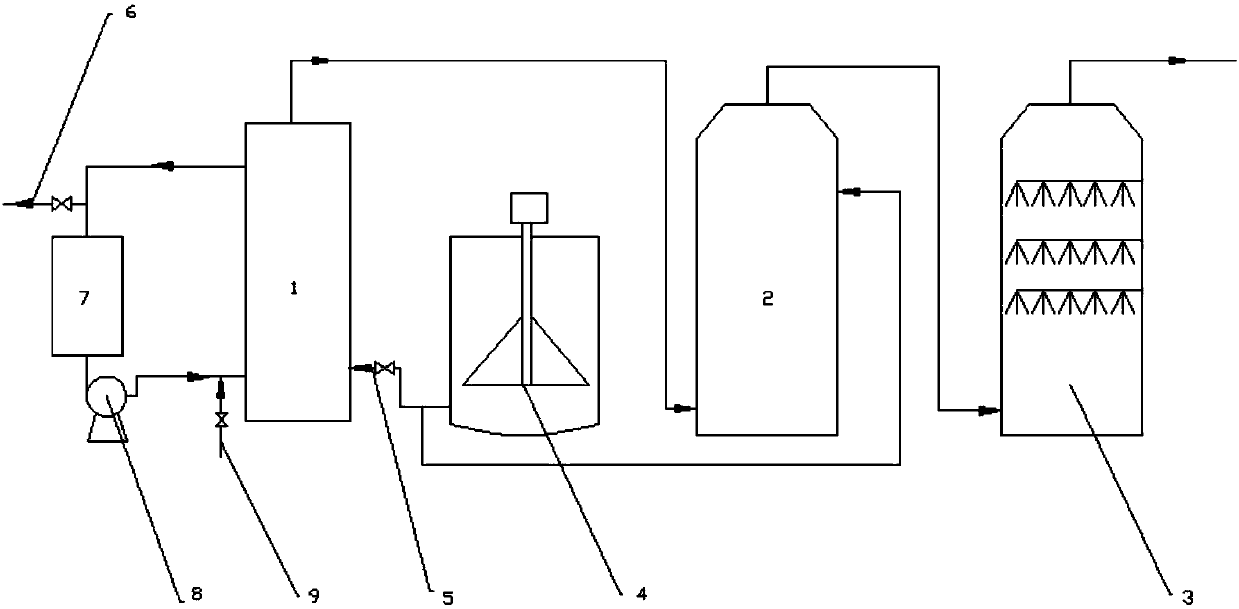

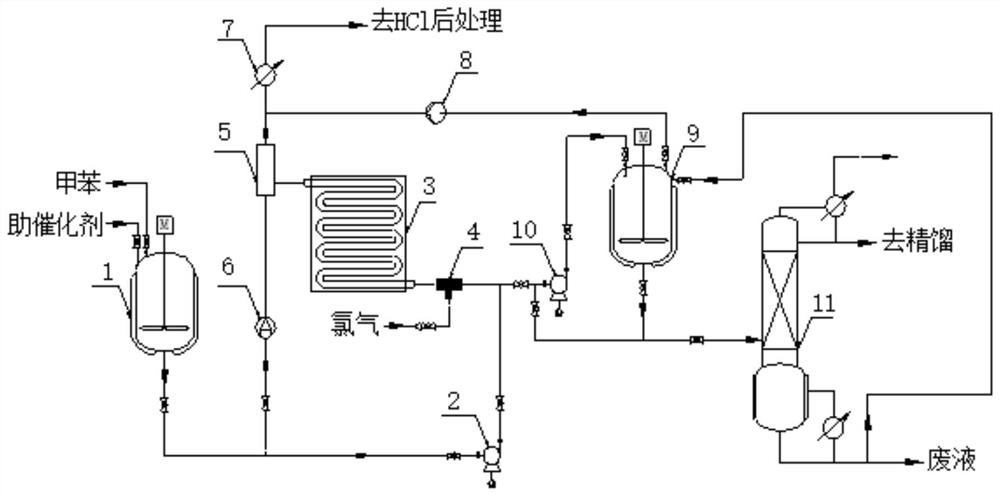

Method and device for producing dichlorotoluene by tower-type continuous chlorination

PendingCN107827703AIncrease profitEmission complianceHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method and a device for producing dichlorotoluene by tower-type continuous chlorination. The method comprises the following steps of: uniformly stirring a raw material namelyo-chlorotoluene and a solid powder catalyst to form a configuration liquid, feeding the configuration liquid into a tower-type reactor from the bottom of the tower-type reactor, continuously introducing chlorine gas into the tower-type reactor from the bottom of the tower-type reactor for chlorination reaction, and cooling the obtained chlorination liquid by an external circulation heat exchanger, and controlling the reaction temperature to be 25-40 DEG C; and when the conversion rate of the raw material namely o-chlorotoluene in the chlorination liquid reaches 45-75% and the selectivity of the 2,6-dichlorotoluene reaches 25% or more, discharging the chlorination liquid continuously, continuously introducing the configuration liquid at the same time, wherein the quantity of the introducedconfiguration liquid is ensured to be slightly smaller than the discharge quantity. The process is reasonable, the yield is high, the productivity is large, the device is simple, and the investment cost is low.

Owner:NANJING ZHONGTENG CHEM

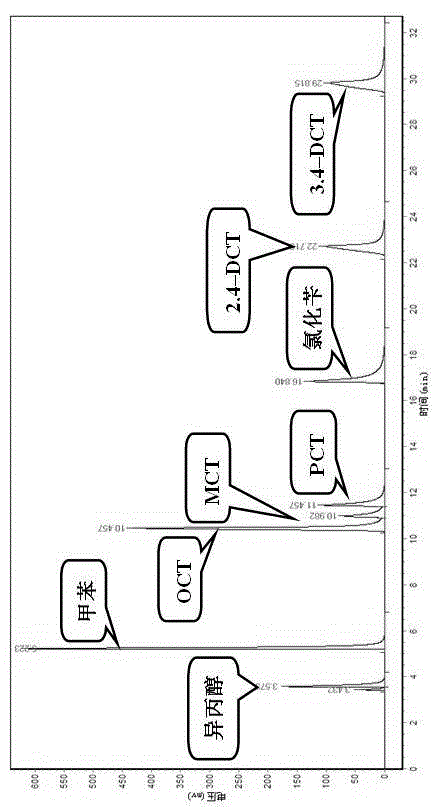

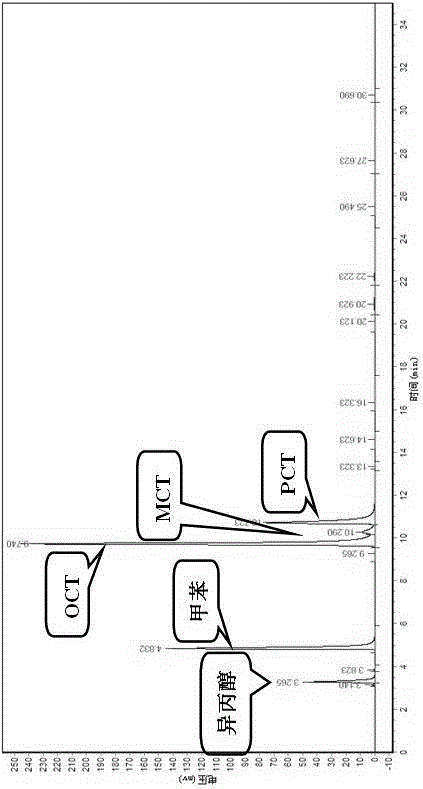

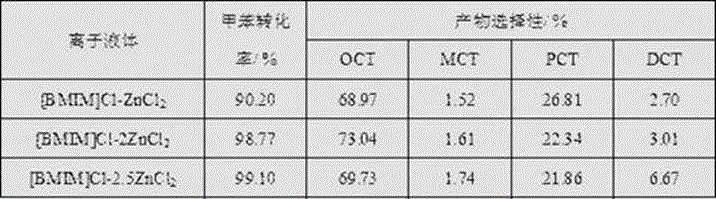

Preparation method of o-chlorotoluene

InactiveCN104817426AWide variety of sourcesLow costChemical recyclingHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention relates to a preparation method of o-chlorotoluene. Particularly, methylbenzene is used as a raw material, Cl2 is used as a chlorine source, and [BMIM]Cl-nZnCl2(n is equal to 1, 2, 2.5, and n is a molar ratio of ZnCl2 to [BMIM]Cl) acidic ionic liquid is used as a catalyst to catalyze the methylbenzene to prepare the o-chlorotoluene; the [BMIM]Cl-nZnCl2(n is equal to 1, 2 or 2.5) acidic ionic liquid is used as a chlorinated catalyst, and the Cl2 is used as the chlorine source to perform selective chlorination on the methylbenzene. According to the method, the selectivity of the o-chlorotoluene in the product can be improved, the [BMIM]Cl-nZnCl2 ionic liquid catalyst separated from the product can also be repeatedly used, so the production cost is reduced, and the method is an important method for contributing to industrial production of the o-chlorotoluene.

Owner:JIANGSU UNIV

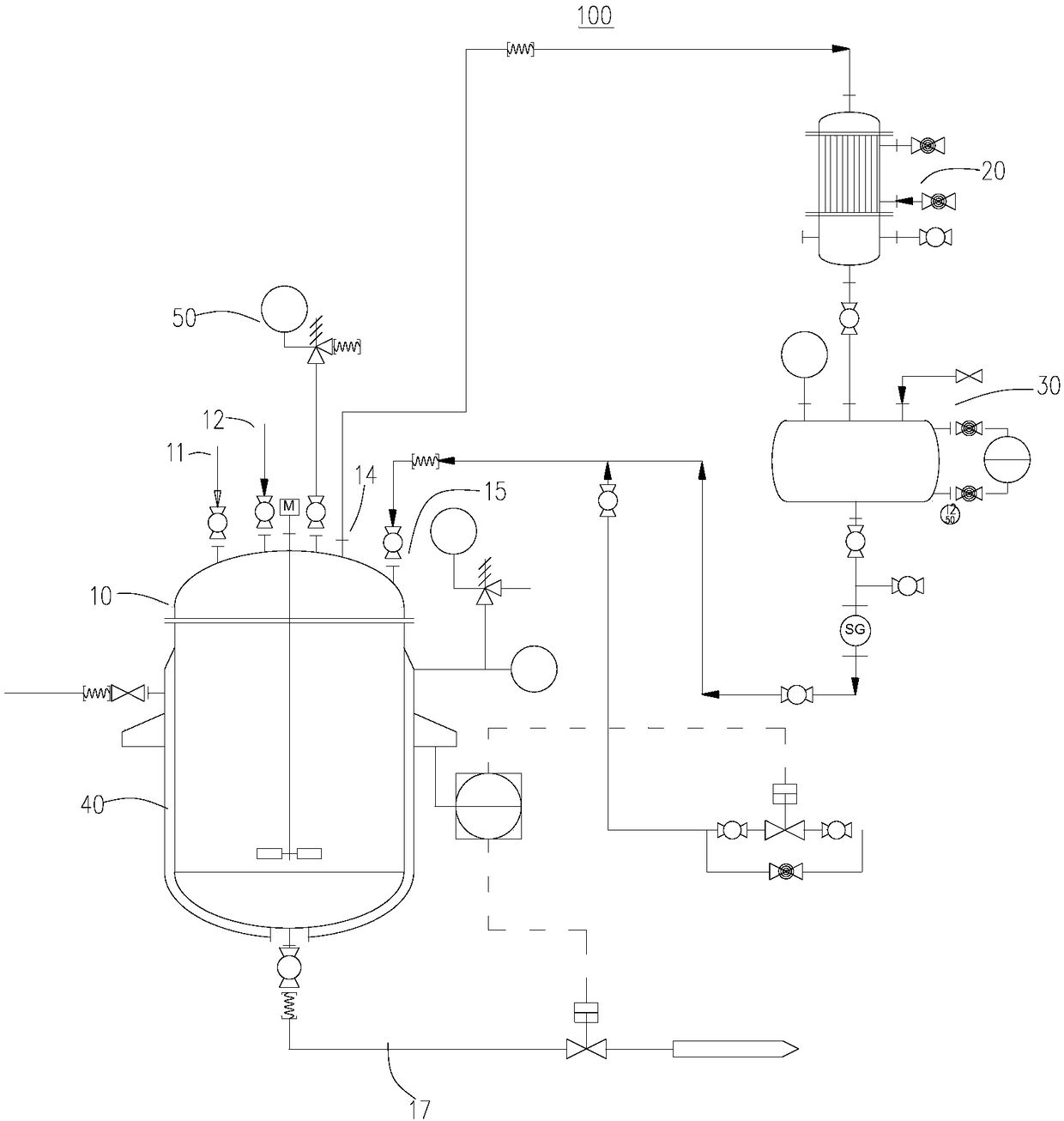

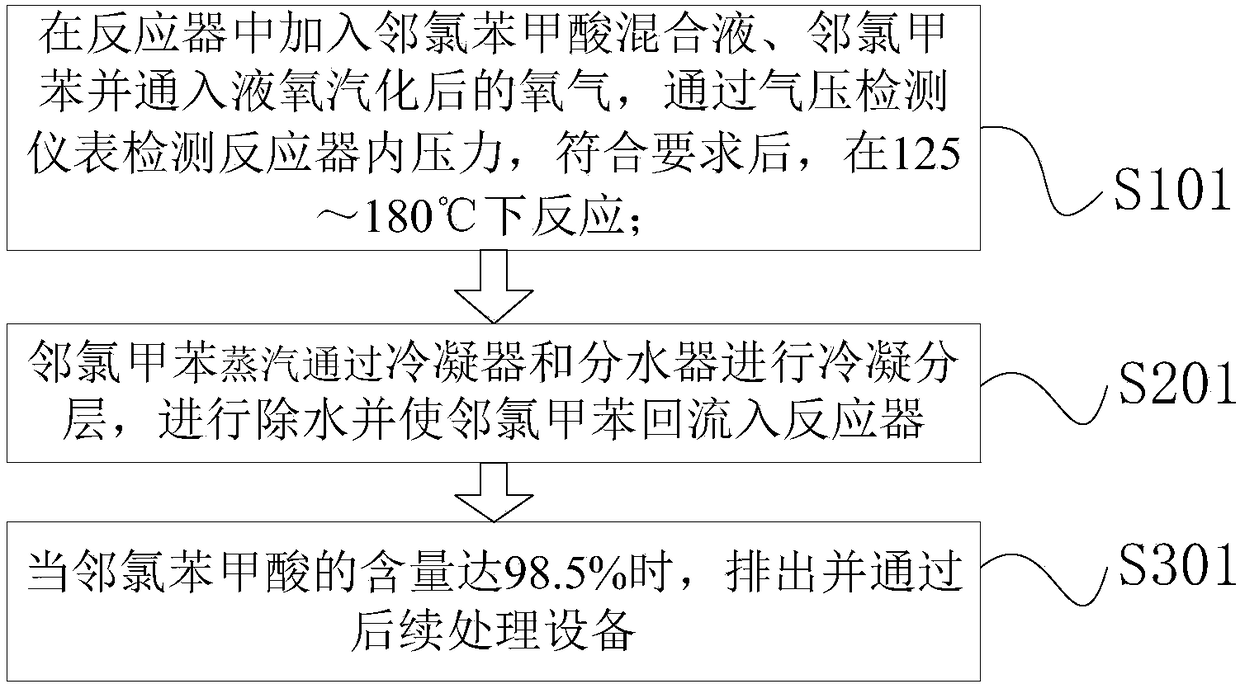

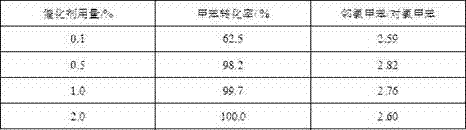

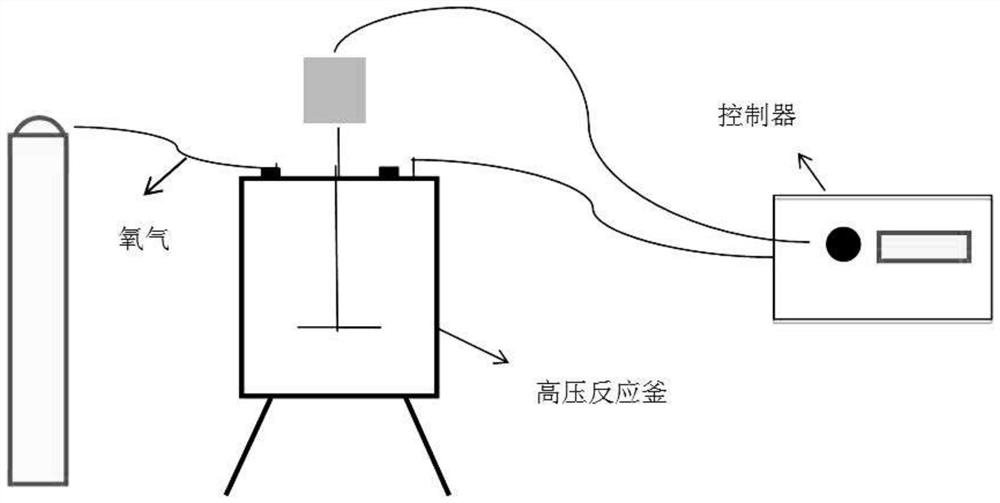

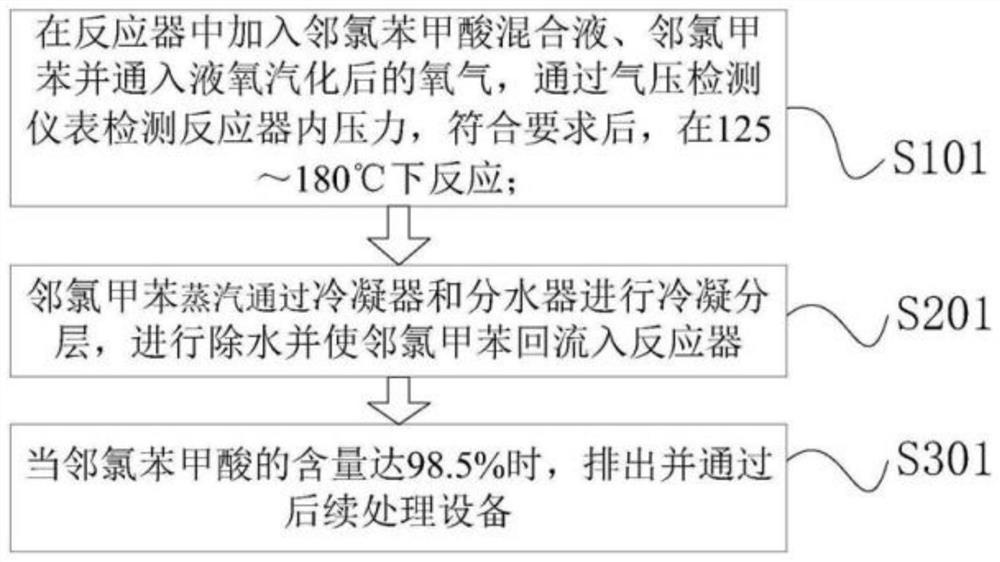

Production equipment and synthesis method of o-chlorobenzoic acid

PendingCN108558637AThe reaction process is shortNo dischargeOrganic compound preparationCarboxylic compound preparationSynthesis methodsWastewater

The invention discloses a synthesis method of o-chlorobenzoic acid. The synthesis method comprises the following steps: adding a mixed o-chlorobenzoic acid solution and o-chlorotoluene and inflating oxygen obtained by vaporizing liquid oxygen into a reactor, detecting the pressure in the reactor by using a gas pressure detecting instrument, reacting at a temperature of 125-180 DEG C after a requirement is met, condensing and stratifying o-chlorotoluene vapor by using a condenser and a water segregator, removing water, reflowing the o-chlorotoluene into the reactor, and when the content of theo-chlorobenzoic acid reaches 98.5%, discharging and passing through subsequent treatment equipment. By the synthesis method, a technological process is short, the yield is high, the cost is low, the environment pollution is low, pure oxygen replaces air, the reaction speed is high, and basically no waste gas is discharged; a solvent is not required during the reaction, a large amount of wastewaterin a diazotization method and a chlorination hydrolysis method is avoided, and an oxidation technology is greatly improved, the reaction conversion rate is high, the selectivity is good, and the crude product content is high.

Owner:ZHEJIANG ALPHARM CHEM TECH

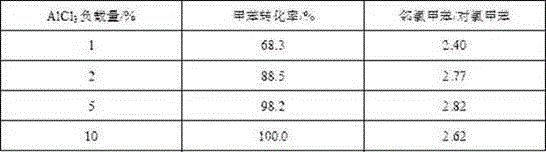

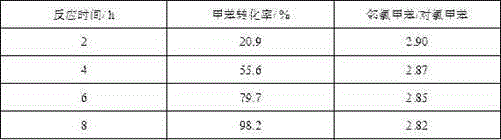

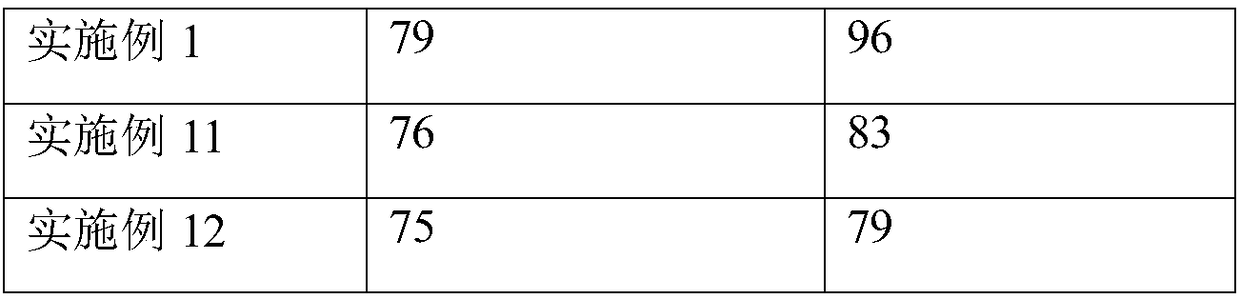

Method for catalyzing methylbenzene to compound orthochlorotoluene through supported molecular sieves

InactiveCN104945223AEase of industrial productionSolve the shortcomings of three wastes and moreMolecular sieve catalystsHalogenated hydrocarbon preparationOrtho-chlorotolueneMolecular sieve

The invention relates to the preparation technical field of orthochlorotoluene, in particular to a method for catalyzing methylbenzene to compound orthochlorotoluene through aluminum chloride (AlCl3) supported HZSM-5 molecular sieves, which belongs to the technical field of methylbenzene directional chlorination. The method for catalyzing the methylbenzene to compound the orthochlorotoluene through the AlCl3 supported HZSM-5 molecular sieves uses the AlCl3 supported HZSM-5 molecular sieves as catalysts, uses Cl2 as chlorinating agents, and selectively chloridizes the methylbenzene by adopting a liquid phase chlorination process. The method for selectively chloridizing to prepare the orthochlorotoluene is simple in synthetic process, mild in reaction condition, excellent in catalytic activity of the used AlCl3 supported HZSM-5 molecular sieves, easy to separate from products, small in environment pollution and small in corrosivity, and has extremely high industrial application value.

Owner:JIANGSU UNIV

Method for co-producing o-chlorobenzyl chloride, o-chlorobenzyl dichloride and o-chlorobenzyl trichloride through chlorination of o-chlorotoluene

PendingCN113105302APrevent impurity peaksInhibitory responseHalogenated hydrocarbon preparationOrtho-chlorotolueneBenzoyl peroxide

The invention relates to the technical field of chemical production, in particular to a method for co-producing o-chlorobenzyl chloride, o-chlorobenzyl dichloride and o-chlorobenzyl trichloride by chlorination of o-chlorotoluene, which comprises the following steps of: performing chlorination reaction on o-chlorotoluene serving as a raw material and chlorine, sampling, analyzing and controlling the content of components in the reaction material, rectifying and co-producing to obtain o-chlorobenzyl chloride, o-chlorobenzyl dichloride and o-chlorobenzyl trichloride. According to the method, benzoyl peroxide is taken as an initiator, and a metal ion masking agent is added into the raw material before chlorination reaction, so that metal ions in the raw material can be removed, side reaction can be inhibited, and the catalytic efficiency of the initiator is improved. The method is low in reaction temperature, mild in reaction, easy to control, high in reaction conversion rate, few in by-product and high in product purity.

Owner:老河口华辰化学有限公司

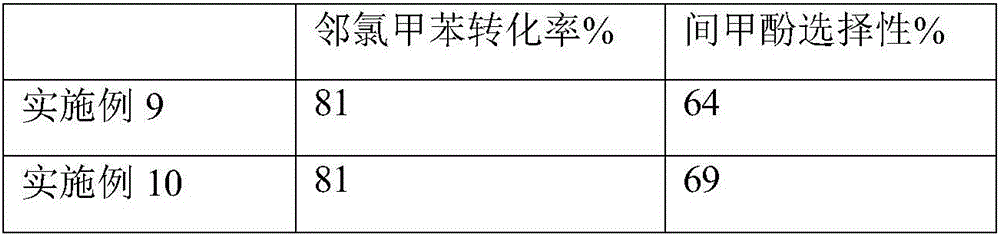

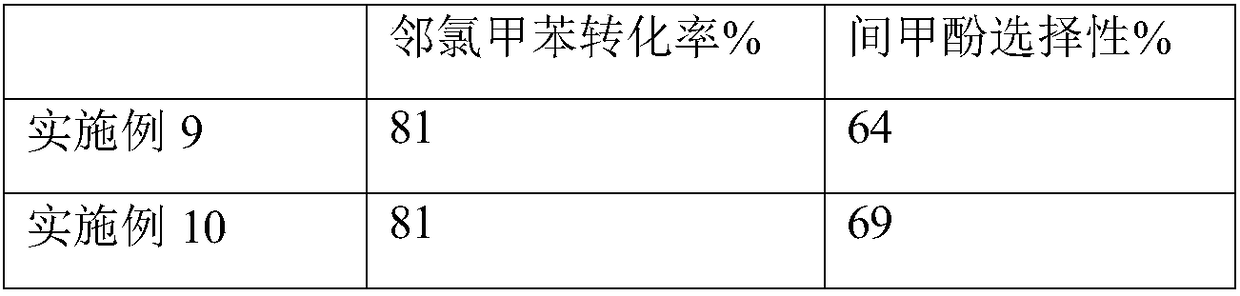

New green process for preparing high-purity m-cresol

ActiveCN106008170AThe conversion rate is not lowHigh purityOrganic chemistryMolecular sieve catalystsOrtho-chlorotolueneReaction temperature

The invention discloses a new green process for preparing high-purity m-cresol. Particularly, the preparation method of m-cresol comprises the following steps: by using ortho-chlorotoluene as a raw material, adding sodium hydroxide (the mole ratio of the sodium hydroxide to the ortho-chlorotoluene is (2-3):1), a catalyst and 18-crown ether-6, carrying out reaction at 250-270 DEG C under the pressure of 1-1.6 MPa for 1-6 hours, stopping reaction, dropping to normal temperature and pressure, adding hydrochloric acid until the pH value is 5 or so, stratifying, adding an extractant into the water layer, carrying out extraction, and carrying out rectification under vacuum to obtain the m-cresol.

Owner:菏泽智慧新材料科技有限公司

Preparation method of orthocresol

ActiveCN103254039BHigh selectivityHigh purityOrganic chemistryOrganic compound preparationOrtho-chlorotolueneReaction temperature

The invention provides a preparation method of orthocresol, which comprises the steps of mixing ortho-chlorotoluene, an alkaline compound, water and a catalyst for reaction to obtain orthocresol, wherein the catalyst is selected from cuprum and / or a mixture of a cuprum-bearing compound with chloride, hydroxide, oxide, acetate or sulfate of M; and the M is selected from Fe, Mn, Zn, Ni or Ti. According to the method, orthocresol is prepared by taking cuprum, the cuprum-bearing compound and other metal salt as the composite catalyst and adopting a chloro-toluene hydrolysis method; the reaction can have higher activity at lower reaction temperature; raw materials are higher in conversion rate; the method has higher selectivity for orthocresol; and prepared orthocresol has higher purity.

Owner:济南尚博医药股份有限公司

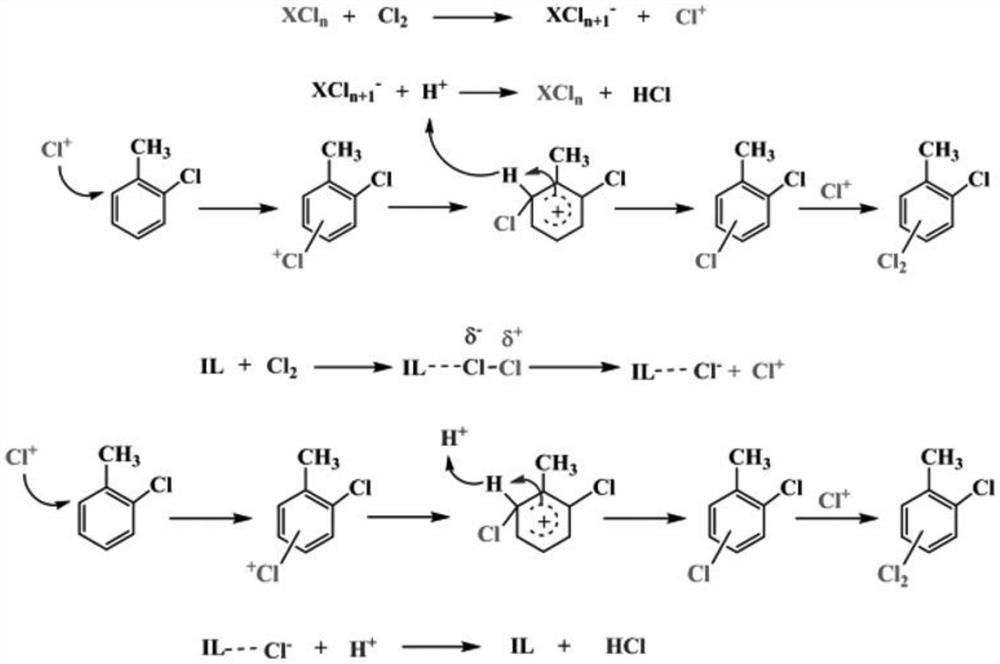

Method for synthesizing 2, 6-dichlorotoluene by directionally chlorinating o-chlorotoluene with novel composite catalyst

PendingCN114773145AHigh selectivityHigh yieldHalogenated hydrocarbon preparationOrtho-chlorotolueneChemical synthesis

The invention relates to a method for synthesizing 2, 6-dichlorotoluene by directionally chlorinating o-chlorotoluene with a novel composite catalyst, and belongs to the technical field of chemical synthesis. The method comprises the following steps: mixing aluminum trichloride and triethylamine salt according to a certain proportion under the protection of inert gas, adding the mixture into o-chlorotoluene, and stirring and reacting for 6-6.5 hours under the condition of introducing chlorine; after the reaction is finished, the raw material conversion rate is 60-65%, and the selectivity of the target product 2, 6-dichlorotoluene is stabilized at 34.5-35.7%. According to the method, the selectivity of 2, 6-dichlorotoluene is greatly improved, the yield of byproducts is relatively low, and compared with other methods for synthesizing 2, 6-dichlorotoluene, the amount of three wastes is low, the reaction steps are simple, the yield is high, the equipment investment is low, and the method has great significance on industrial production of 2, 6-dichlorotoluene.

Owner:NANJING UNIV OF TECH +1

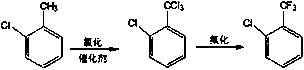

Novel synthesis method of chlorobenzotrifluoride

InactiveCN110655449AFewer chlorination side reactionsHigh purityPreparation by halogen replacementOrtho-chlorotolueneP-chlorobenzotrifluoride

The invention discloses a novel synthesis method of chlorobenzotrifluoride, wherein o-chlorotoluene is used as a raw material, copper chloride or cuprous chloride is used as a catalyst, and o-chlorobenzotrifluoride is synthesized through two steps of chlorination and fluorination. Compared with the method in the prior art, the method of the invention has the following characteristics that raw materials are subjected to heating dehydration treatment in the dehydration kettle, so that the chlorination side reactions are few, the product purity is high, the graded chlorination device does not need to be additionally arranged, the technological process is simple, and the operation is convenient. According to the chlorination process of the invention, the catalyst is added in batches to increase the efficiency of the catalyst, so that the by-product generated by thechlorination reaction and the emission of waste gas in the production are greatly reduced, and the emission of pollutants in the production process is reduced.

Owner:JIANGSU FENGHUA CHEM IND

Novel chlorination process of o-chlorobenzotrichloride

InactiveCN110655442AWide variety of sourcesLow priceHalogenated hydrocarbon preparationBenzeneOrtho-chlorotoluene

The invention discloses a novel chlorination process of o-chlorobenzotrichloride, wherein o-chlorotoluene is used as a raw material, and side chain chlorination, pressure reducing rectification, neutralization, filtration and other steps are performed to obtain the target compound o-chlorobenzotrichloride. Compared with the process in the prior art, the process of the invention has the following characteristics that the step-by-step catalytic process is adopted, the reaction conditions are mild, no special equipment is added in the production process, the side chain trichlorination selectivityis high, the generation of monochlorides, dichlorocompounds, side chains and benzene ring chlorination byproducts is greatly reduced, the separation and purification process is simplified, the emission of three organic wastes is reduced, and the yield is about 99% and is about 10% higher than the yield of the common chlorination process.

Owner:JIANGSU FENGHUA CHEM IND

A new green process for preparing high-purity m-cresol

ActiveCN106008170BThe conversion rate is not lowHigh purityOrganic chemistryMolecular sieve catalystsOrtho-chlorotolueneReaction temperature

The invention discloses a new green process for preparing high-purity m-cresol. Particularly, the preparation method of m-cresol comprises the following steps: by using ortho-chlorotoluene as a raw material, adding sodium hydroxide (the mole ratio of the sodium hydroxide to the ortho-chlorotoluene is (2-3):1), a catalyst and 18-crown ether-6, carrying out reaction at 250-270 DEG C under the pressure of 1-1.6 MPa for 1-6 hours, stopping reaction, dropping to normal temperature and pressure, adding hydrochloric acid until the pH value is 5 or so, stratifying, adding an extractant into the water layer, carrying out extraction, and carrying out rectification under vacuum to obtain the m-cresol.

Owner:菏泽智慧新材料科技有限公司

A kind of method that loaded molecular sieve catalyzes toluene to synthesize o-chlorotoluene

InactiveCN104945223BEase of industrial productionSolve the shortcomings of three wastes and moreMolecular sieve catalystsHalogenated hydrocarbon preparationOrtho-chlorotolueneMolecular sieve

The invention relates to the technical field of preparation of o-chlorotoluene, in particular to a method for catalyzing toluene to synthesize o-chlorotoluene with an AlCl3 loaded HZSM‑5 molecular sieve, and belongs to the technical field of toluene directional chlorination. The method adopts AlCl3 loaded HZSM-5 molecular sieve as a catalyst, Cl2 as a chlorination agent, and adopts a liquid phase chlorination method to carry out selective chlorination of toluene. The selective chlorination of toluene to produce ortho-chlorotoluene has simple synthesis process and mild reaction conditions, and the AlCl3-loaded HZSM-5 molecular sieve used has good catalytic activity, is easy to separate from the product, has little environmental pollution, and has low equipment corrosion. High industrial application value.

Owner:JIANGSU UNIV

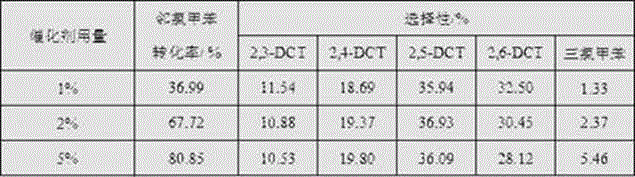

A kind of method that the catalytic oxidation of chlorotoluene prepares chlorobenzaldehyde

ActiveCN112110802BSimple processFew synthetic stepsMolecular sieve catalystsOrganic compound preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method for preparing chlorobenzaldehyde by catalytic oxidation of chlorotoluene. The method adopts a high-pressure reactor as a reactor, and uses M / Al-MCM-41 (M=Co, Mn) supported metal oxide as a A catalyst, wherein Al-MCM-41 molecular sieve is used as a carrier, Co and Mn are used as active components, oxygen is used as an oxidant, KBr is used as a co-catalyst, and acetic acid is used as a solvent. The optimal reaction conditions are: reaction temperature 120°C, reaction time 10h, catalyst dosage 2.5%, active component loading 13%, Co / Mn=1 / 2, co-catalyst dosage 0.5%, and the reaction pressure controlled by oxygen flow does not exceed 0.2MPa, the solvent dosage is 30%, the conversion rate of o-chlorotoluene is up to 90%, and the selectivity of chlorobenzaldehyde is up to 92%. The catalyst of the invention has the advantages of good stability, low catalyst cost, environmental friendliness, simple reaction process and the like, and has good industrial application prospect.

Owner:CHINA SALT CHANGZHOU CHEM

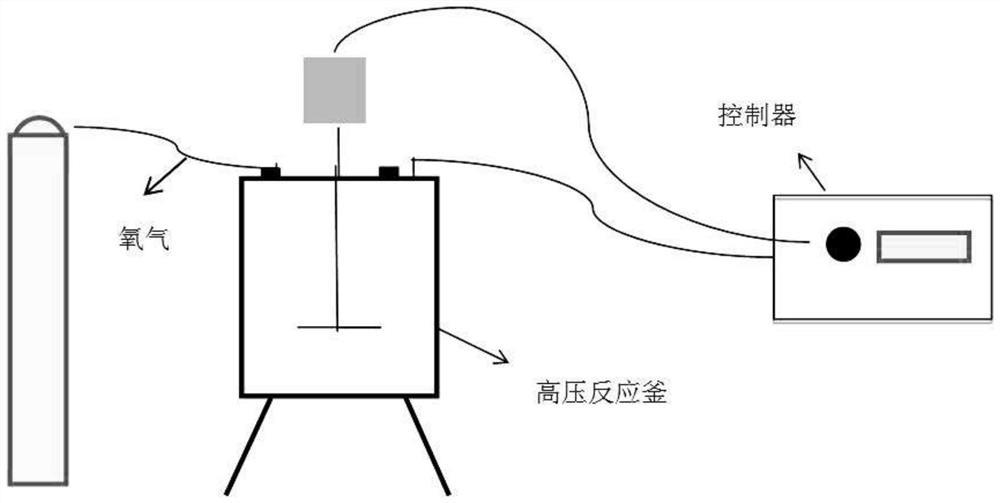

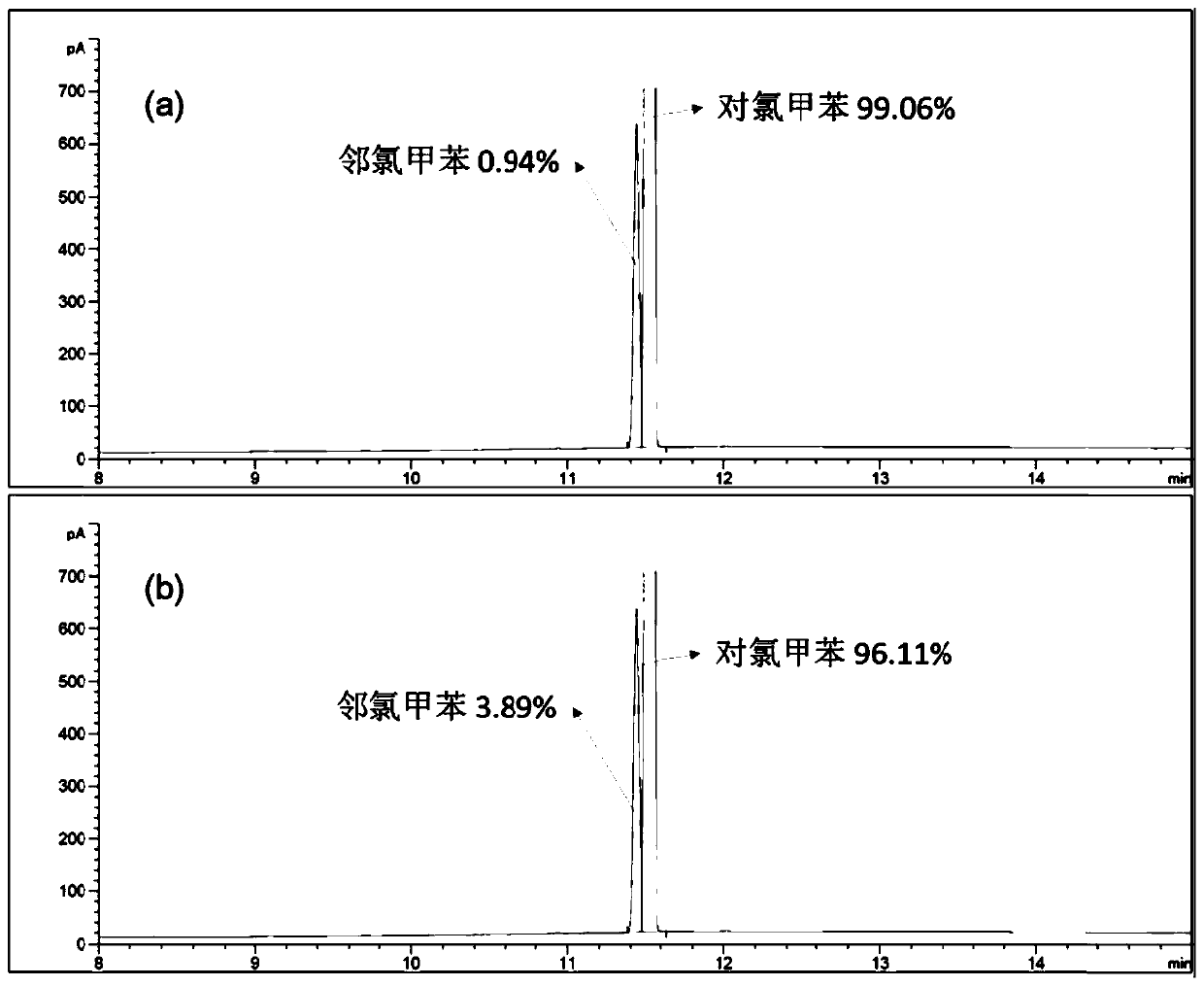

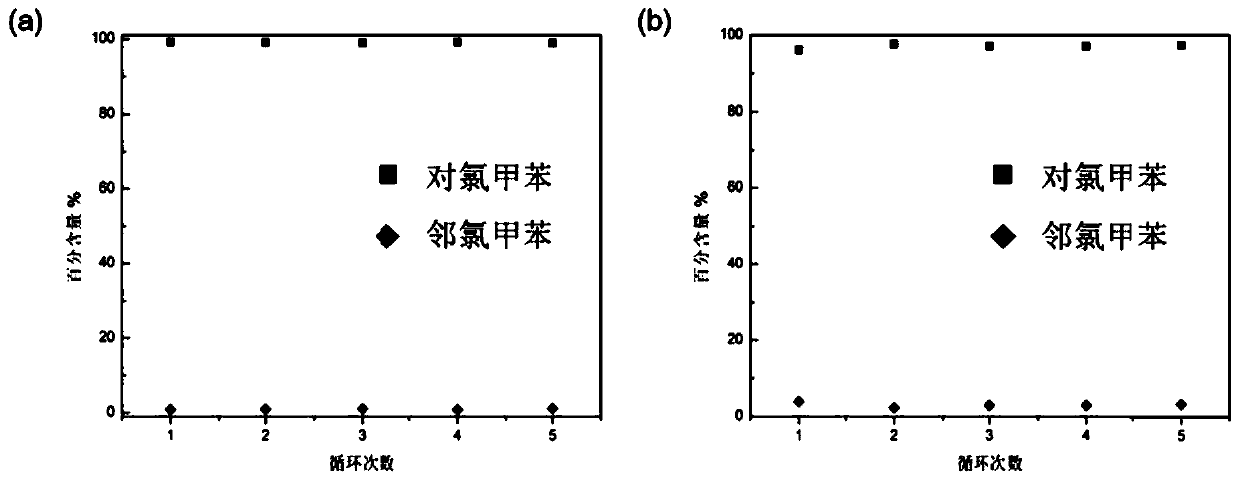

A kind of separation method of p-chlorotoluene and o-chlorotoluene

ActiveCN110092706BReduce manufacturing costImprove stabilityHalogenated hydrocarbon preparationOrtho-chlorotolueneChemical structure

The invention discloses a separation method of p-chlorotoluene and o-chlorotoluene. A bis-diethoxy column [n] arene crystal material is utilized to adsorb and separate a p-chlorotoluene and o-chlorotoluene mixture, and the chemical structural formula of the bis-diethoxy column [n] arene crystal material is as shown in the specification, wherein n is 5 or 6. The separation method has simple separation process operation and low equipment requirement. No rectification operation is required in the separation process, the energy consumption is low, the energy is saved, and the production cost of the p-chlorotoluene is reduced. The crystal material used has high stability, and can be recycled, and the separation effect cannot be reduced.

Owner:ZHEJIANG UNIV

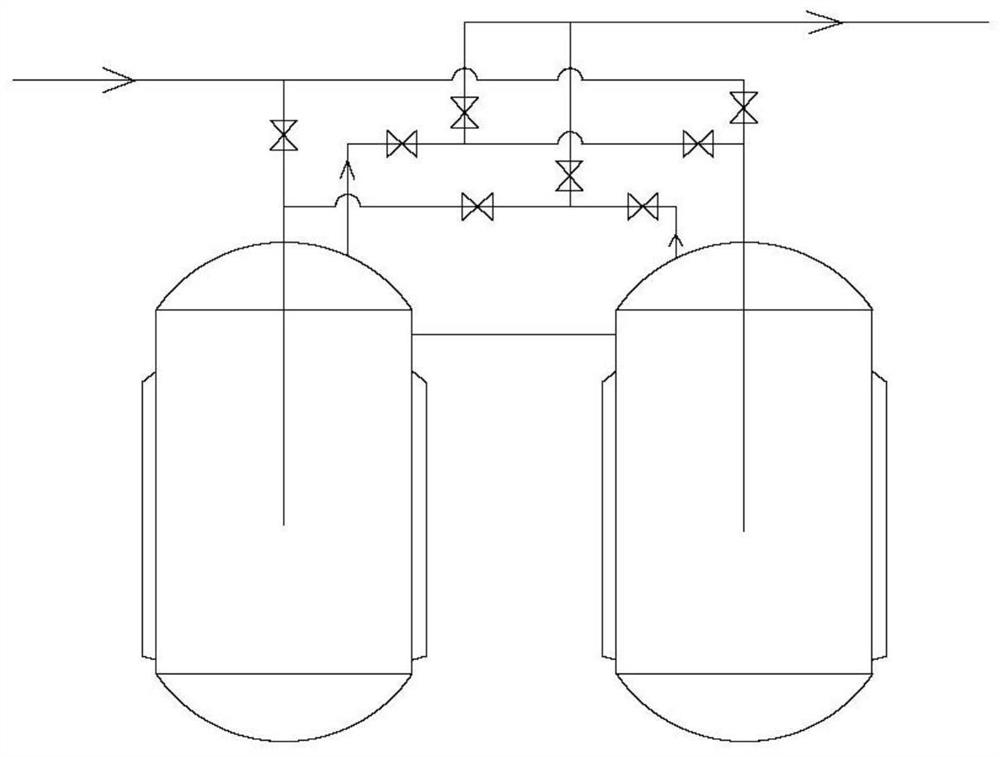

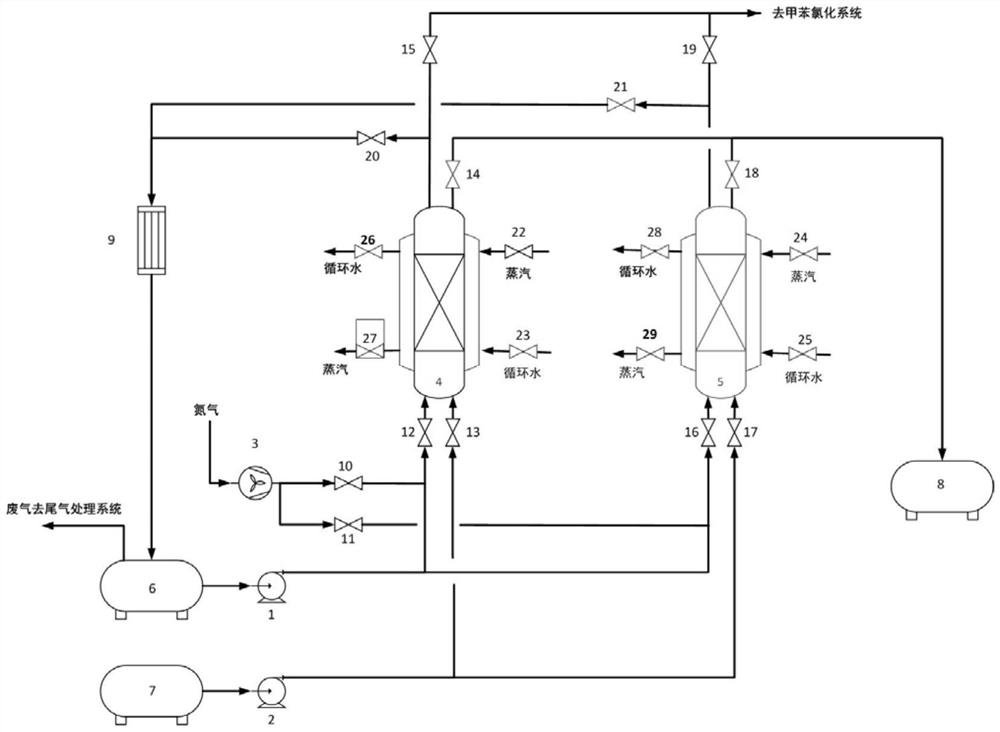

Production method of double-kettle-switching continuous chlorination

PendingCN113072418AReduce chlorine contentReduce entrainmentHalogenated hydrocarbon preparationOrtho-chlorotolueneWater chlorination

The invention relates to the technical field of chemical production, in particular to a production method of double-kettle-switching continuous chlorination. According to the invention, two reaction kettles are connected in series, and the double reaction kettles are alternately switched to serve as a main reaction kettle and an auxiliary reaction kettle for a chlorination reaction; after a solution in the kettle serving as the main reaction kettle is sampled and detected to meet requirements, the reaction of the main reaction kettle is finished, introduction of chlorine into the main reaction kettle and the auxiliary reaction kettle is stopped, the main reaction kettle enters a discharging procedure, and the auxiliary reaction kettle is allowed to enter a heat preservation state; as materials are further fed into the main reaction kettle, chlorine is continuously introduced into the main reaction kettle for a reaction, and the main reaction kettle and the auxiliary reaction kettle are switched when the main reaction kettle does not contain or contains a small amount of o-chlorotoluene; and the original auxiliary reaction kettle serves as the main reaction kettle for a reaction, introduction of chlorine is stopped and the reaction is stopped until the solution in the original auxiliary reaction kettle is sampled and detected to be qualified, then cooling and discharging are conducted, and the original main reaction kettle is used as the auxiliary reaction kettle to maintain a reaction temperature in the kettle. According to the invention, the continuous production of the chlorination reaction can be realized, a chlorine content in tail gas is reduced, and the raw material entrainment in the tail gas is reduced.

Owner:老河口华辰化学有限公司

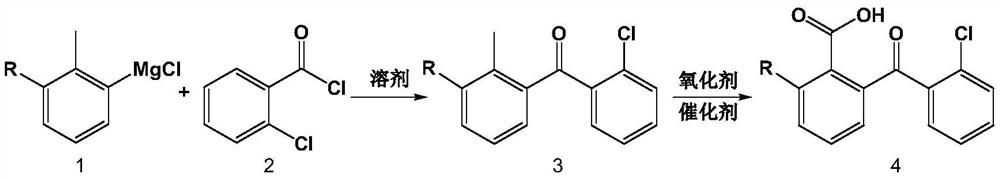

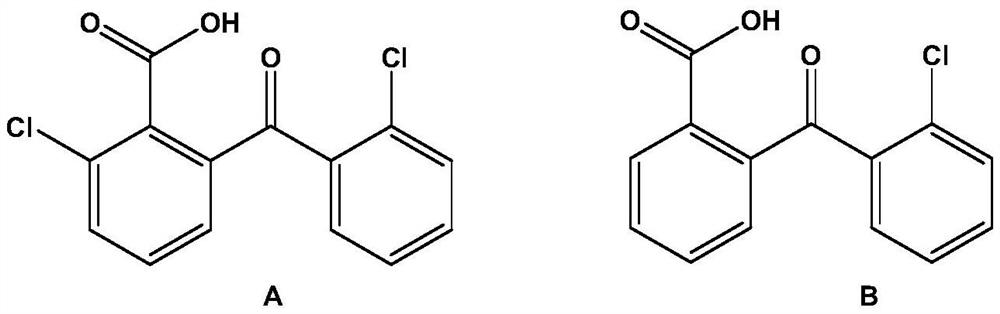

A kind of preparation method of high-purity chlorinated 2-carboxybenzophenone

ActiveCN108530293BThe synthesis steps are simpleLow costOrganic compound preparationCarbonyl compound preparation by condensationOrtho-chlorotolueneChlorobenzene

The invention discloses a preparation method of high-purity chloro-2-carboxybenzophenone. The preparation method comprises the following steps: preparing chlorine-substituted or non-substituted o-chlorotoluene into a Grignard reagent, and then, enabling the Grignard reagent to react with o-chlorobenzoyl chloride to obtain chloro-2-methylbenzophenone; and enabling chloro-2-methylbenzophenone to besubjected to oxidation reaction in the presence of a catalyst and an oxidizing agent to obtain the chloro-2-carboxybenzophenone. The preparation method disclosed by the invention has the advantages that the synthetic steps are simple, the cost is low, the process is environmentally friendly, and the obtained product has high purity and can be directly applied to the fields of micro-electronics andthe like.

Owner:王华平

Method for preparing chlorobenzaldehyde through catalytic oxidation of chlorotoluene

ActiveCN112110802ASimple processFew synthetic stepsMolecular sieve catalystsOrganic compound preparationOrtho-chlorotolueneMolecular sieve

The invention discloses a method for preparing chlorobenzaldehyde through catalytic oxidation of chlorotoluene. According to the method, a high-pressure reaction kettle is adopted as a reactor, M / Al-MCM-41 (M=Co, Mn) loaded metal oxide is adopted as a catalyst, an Al-MCM-41 molecular sieve is adopted as a carrier, Co and Mn are adopted as active components, oxygen is adopted as an oxidizing agent,KBr is adopted as a cocatalyst, and acetic acid is adopted as a solvent. The optimal reaction conditions are as follows: the reaction temperature is 120 DEG C, the reaction time is 10 hours, the catalyst dosage is 2.5%, the active component loading capacity is 13%, the Co / Mn ratio is 1 / 2, the cocatalyst dosage is 0.5%, the oxygen introduction control reaction pressure is not more than 0.2 MPa, the solvent dosage is 30%, the highest o-chlorotoluene conversion rate can reach 90%, and the highest chlorobenzaldehyde selectivity is 92%. The catalyst provided by the invention has the characteristics of good stability, low catalyst cost, environmental friendliness, simple reaction process and the like, and has a good industrial application prospect.

Owner:CHINA SALT CHANGZHOU CHEM

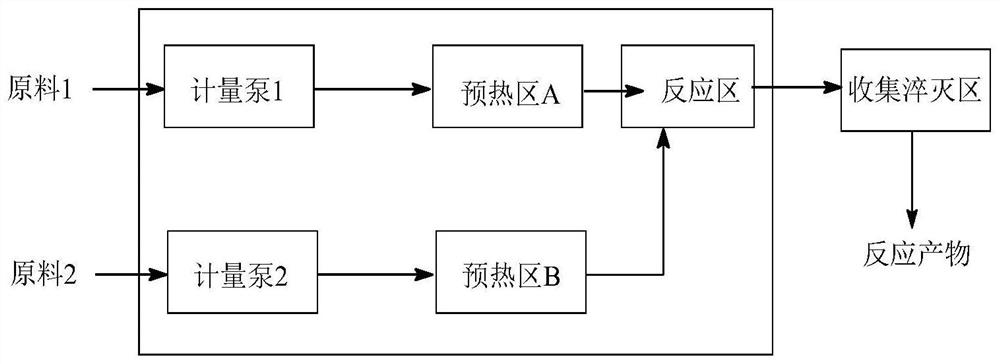

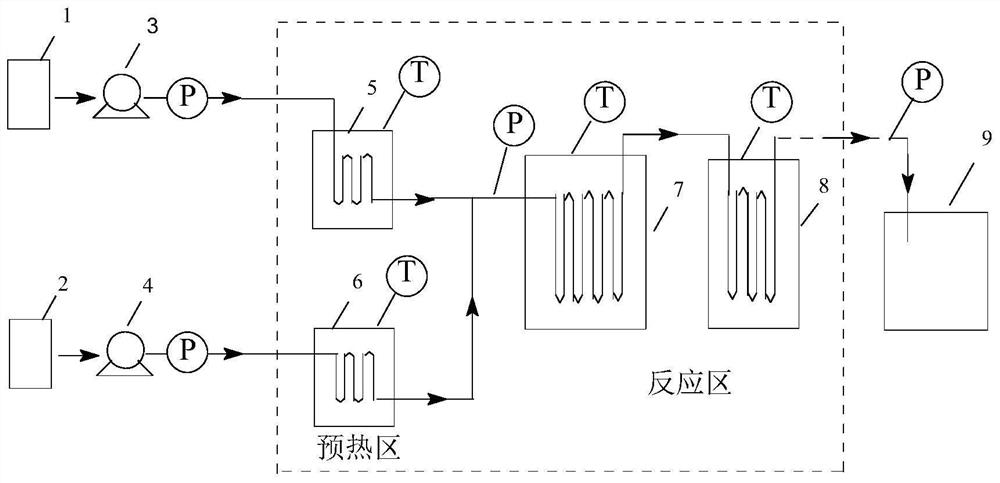

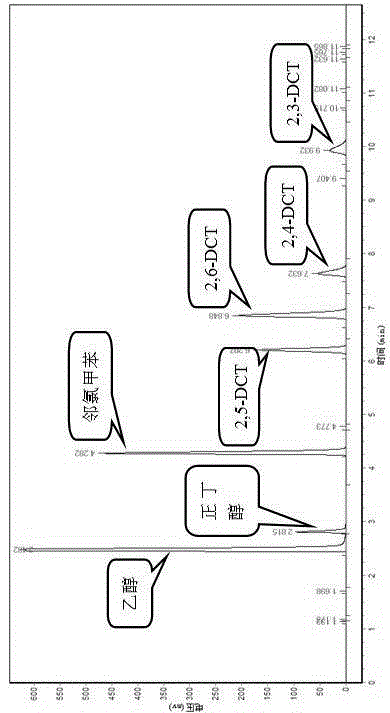

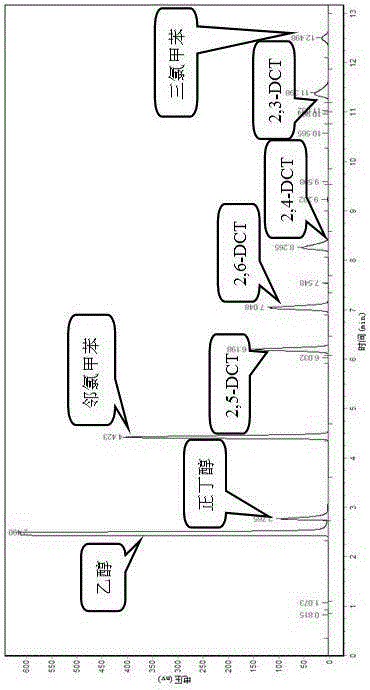

A kind of method for preparing o-chlorobenzaldehyde by continuous oxidation of o-chlorotoluene

ActiveCN108794311BShort reaction timeMild reaction conditionsProcess control/regulationCarbonyl compound preparation by oxidationOrtho-chlorotolueneChlorobenzene

Owner:CHANGZHOU UNIV

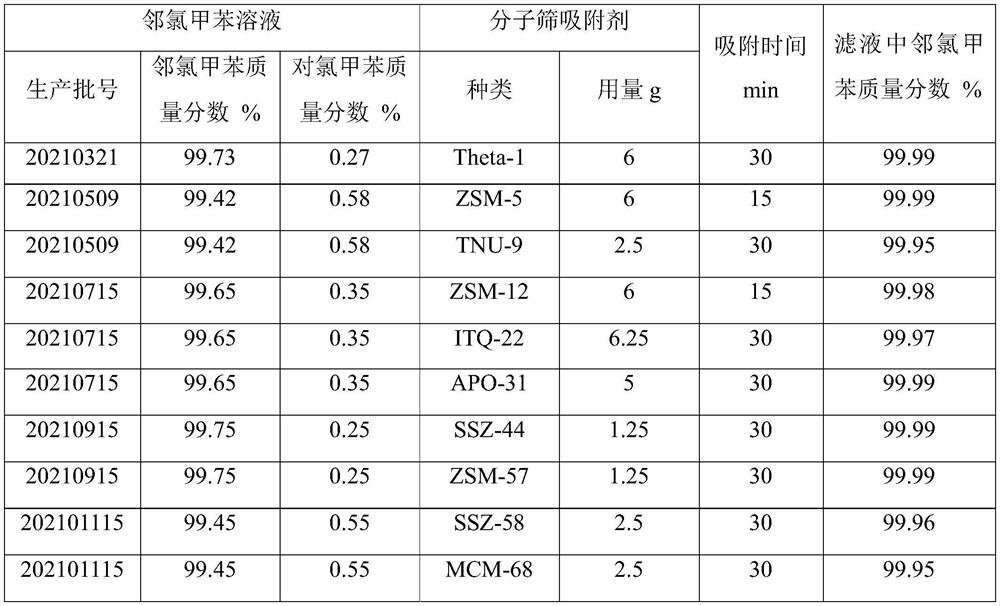

Method for producing high-purity o-chlorotoluene by adsorption separation method

PendingCN114436766AHigh purityAvoid the recycling stepHalogenated hydrocarbon preparationChemical recyclingOrtho-chlorotolueneSorbent

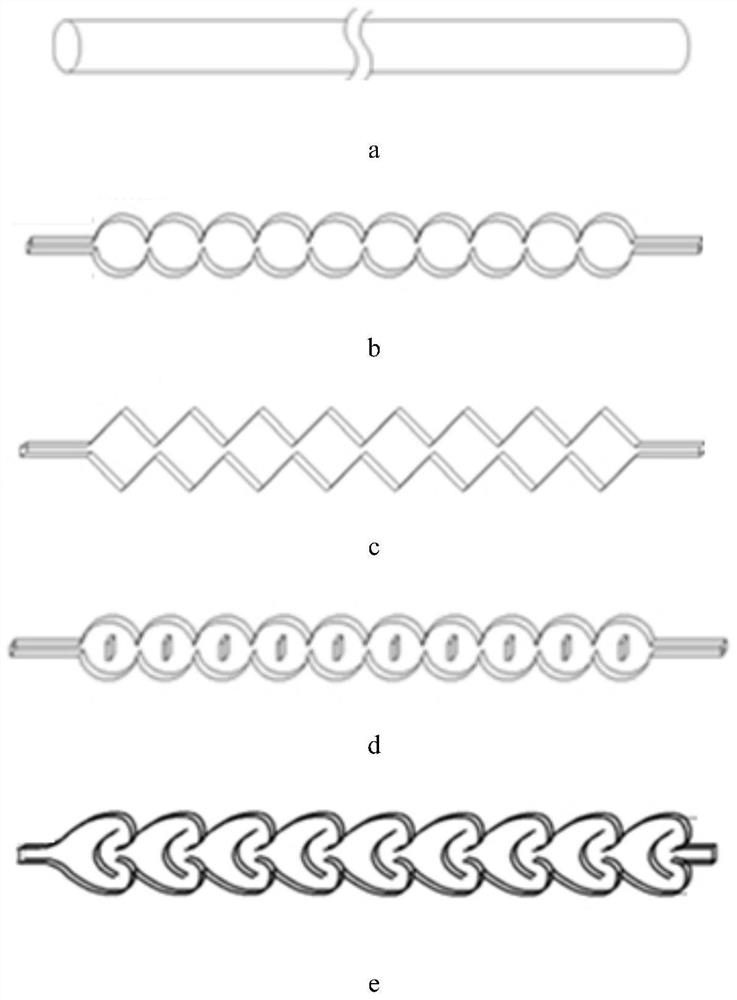

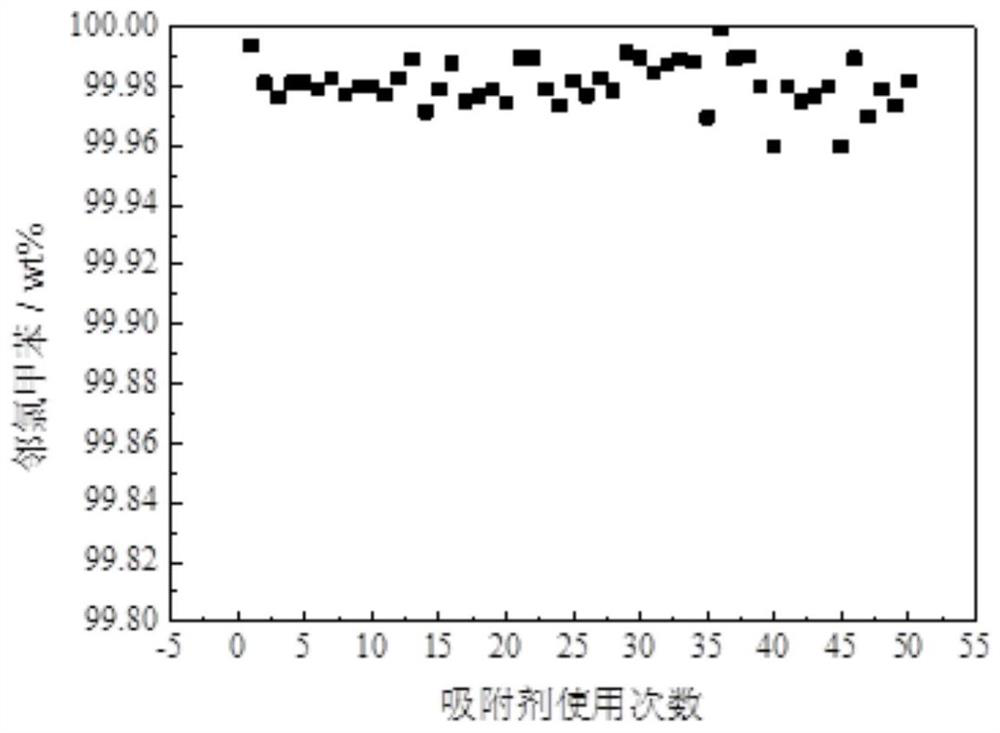

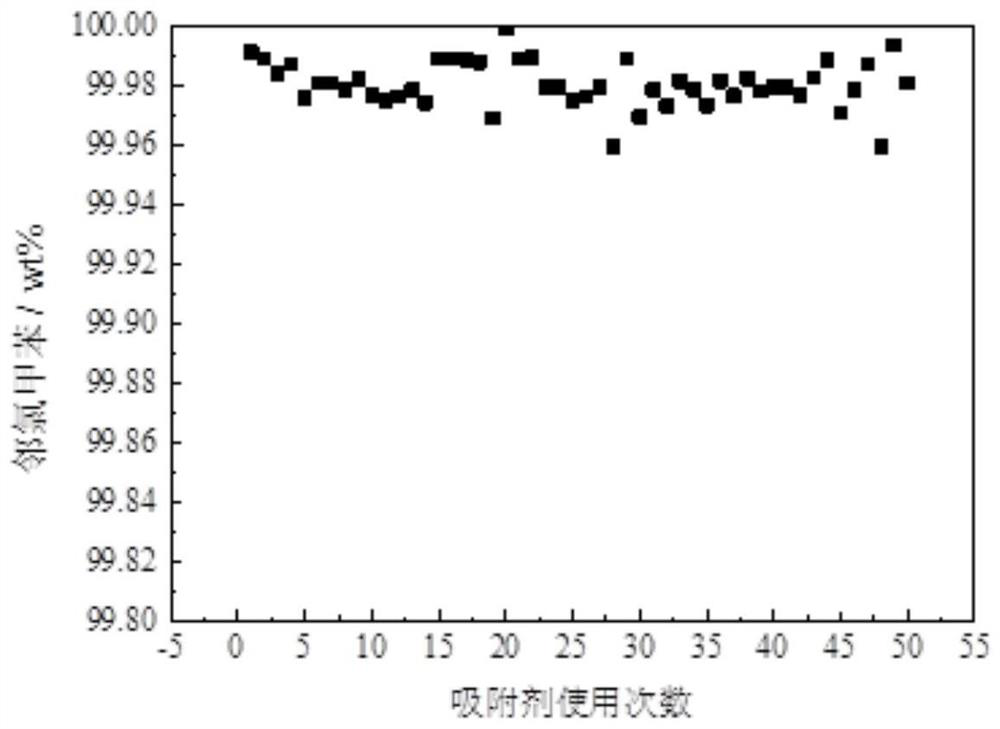

The invention relates to a method for producing high-purity o-chlorotoluene by an adsorption separation method, and belongs to the technical field of chemical raw material preparation. According to the method for selectively adsorbing the parachlorotoluene contained in the o-chlorotoluene to produce the high-purity o-chlorotoluene, the mass fraction of the parachlorotoluene in the o-chlorotoluene can be reduced to 0.05 wt% or below, after adsorption saturation of the adsorbent, the adsorbent can be recycled through toluene washing, filtering and normal-pressure drying, and the method is suitable for industrial production. The used adsorbent can be recycled for more than 50 times, the regenerant toluene is a raw material for producing ortho / parachlorotoluene, and ortho / parachlorotoluene-containing liquid washed by toluene can be continuously used as a reaction raw material, so that a new regenerant does not need to be purchased, meanwhile, the recycling procedure of the regenerant is omitted, the process route is simplified, and the treatment cost is reduced; the method has the advantages that the operation is simple, the purity of the produced o-chlorotoluene is high, the energy consumption is low, and the like.

Owner:常州新东化工发展有限公司 +1

Preparation method of chlorotoluene

PendingCN114797710AReduce generationReduce corrosionProcess control/regulationChemical/physical/physico-chemical stationary reactorsOrtho-chlorotoluenePtru catalyst

The invention relates to a preparation method of chlorotoluene, and belongs to the technical field of chemical material preparation. The method comprises the following steps: mixing toluene with a cocatalyst, then carrying out forced circulation reaction on the obtained mixture and chlorine in a plug flow reactor to obtain a mixed chlorotoluene crude product, carrying out dechlorination, deacidification and catalyst removal, and carrying out rectification separation to obtain o-chlorotoluene and p-chlorotoluene. The chlorotoluene preparation method provided by the invention has the advantages that the process is simple, the reaction process is easy to control, 75-95% of catalyst-containing high-boiling substances in a catalyst removal tower kettle can be recycled, the catalyst utilization rate is high, the discharge amount of wastes and tail gas is small, and the prepared target product has high purity.

Owner:常州新东化工发展有限公司

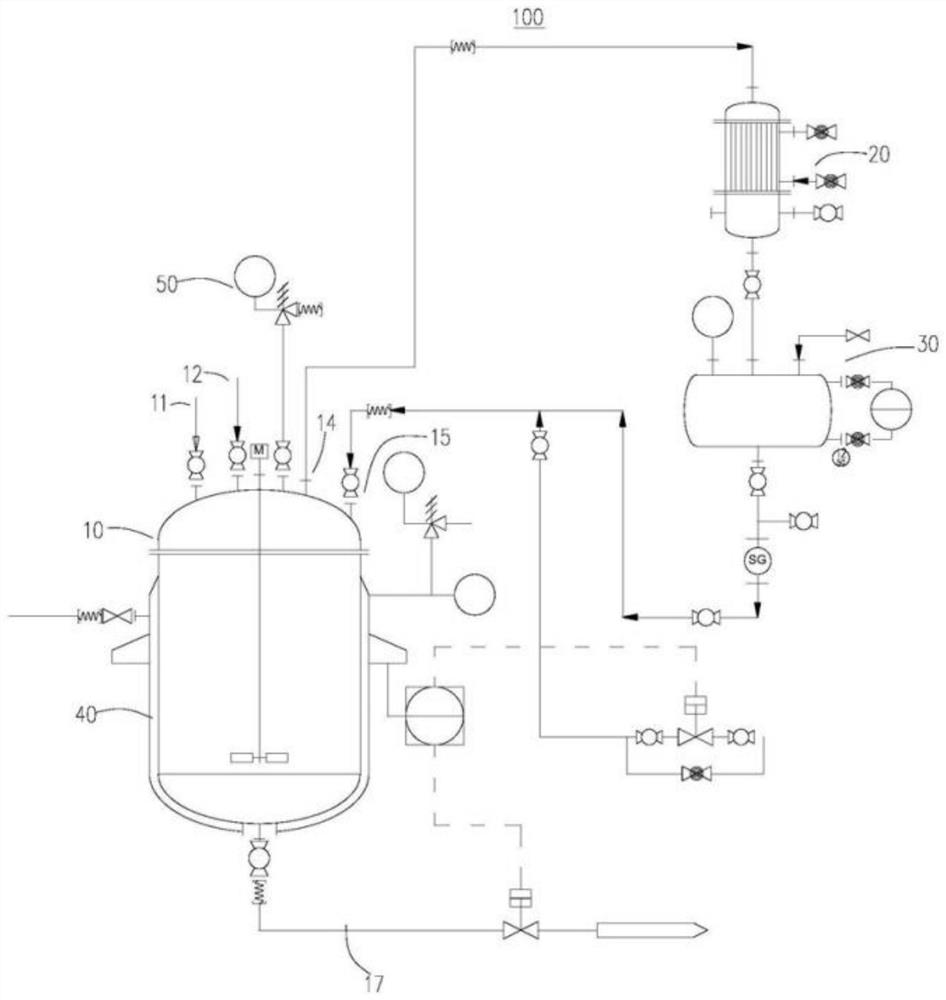

O-chlorobenzoic acid production equipment and synthesis method

PendingCN113563174AThe reaction process is shortNo dischargeOrganic compound preparationCarboxylic compound preparationOrtho-chlorotolueneBenzoic acid

The invention discloses an o-chlorobenzoic acid synthesis method which comprises the following steps: adding an o-chlorobenzoic acid mixed solution and o-chlorotoluene into a reactor, introducing oxygen after liquid oxygen vaporization, detecting the pressure in the reactor through an air pressure detection instrument, reacting at 125-180 DEG C after the pressure in the reactor meets the requirement, condensing and layering o-chlorotoluene steam through a condenser and a water separator, removing water, and refluxing the o-chlorotoluene into the reactor, and discharging and passing through subsequent treatment equipment when the content of the o-chlorobenzoic acid reaches 98.5 percent, wherein the process flow is short, the yield is high, the cost is low, the environmental pollution is small, pure oxygen replaces air, the reaction speed is high, and no waste gas is discharged basically; and the reaction does not need a solvent, a large amount of wastewater generated by a diazotization method and a chlorination hydrolysis method is avoided, the oxidation process is greatly improved, the reaction conversion rate is high, the selectivity is good, and the crude product content is high.

Owner:ZHEJIANG ALPHARM CHEM TECH

Method for continuously producing high-purity o-chlorotoluene by adsorption separation method

PendingCN114874068ARealize continuous productionEasy to operateChemical recyclingHalogenated hydrocarbon preparationOrtho-chlorotolueneMolecular sieve

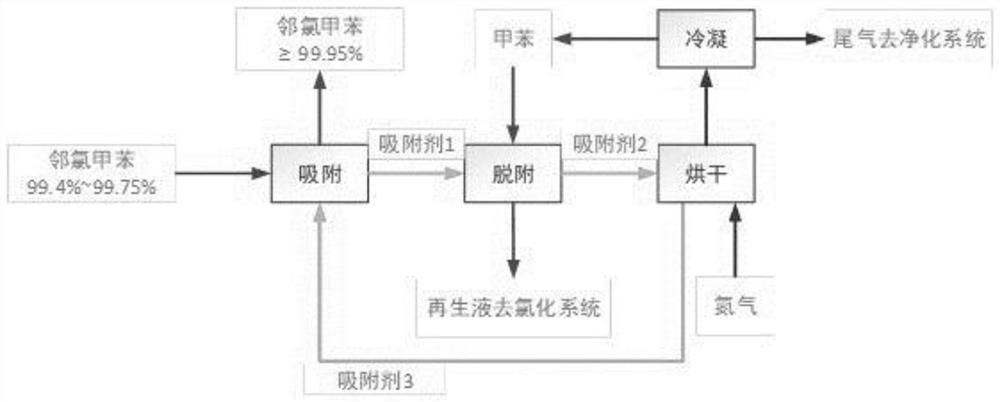

The invention discloses a method for producing high-purity o-chlorotoluene, which comprises the following steps: filling a molecular sieve adsorbent in a tube pass of a tubular adsorption tower, introducing circulating cooling water into a shell pass of the tubular adsorption tower, and introducing an o-chlorotoluene raw material to be purified into the tube pass to be in full contact with the molecular sieve adsorbent to obtain o-chlorotoluene with the mass fraction greater than or equal to 99.95%, and carrying out desorption treatment on the molecular sieve adsorbent saturated by adsorption: heating for desorption, purging with nitrogen, and cooling. The method is easy to operate, continuous production of high-purity o-chlorotoluene can be achieved, and the high-purity o-chlorotoluene product with the mass fraction of 99.95% or above is obtained; according to the method disclosed by the invention, the raw material toluene for producing the o / p-chlorotoluene system is used as the regeneration solvent of the molecular sieve adsorbent, and the regenerated solution can be directly returned to the o / p-chlorotoluene production system, so that the recycling step of the regeneration solvent is avoided, the process route is simplified, and the treatment cost is reduced.

Owner:NANJING UNIV OF TECH +2

Method for preparing 2,6-dichlorotoluene employing Hbeta molecular sieve and catalytic o-chlorotoluene

InactiveCN104876790AWide variety of sourcesLow costHalogenated hydrocarbon preparationOrtho-chlorotolueneMolecular sieve

The invention relates to the technical field of 2,6-dichlorotoluene preparation, in particular to a method for preparing 2,6-dichlorotoluene employing selective chlorination of an Hbeta molecular sieve and catalytic o-chlorotoluene. With cheap o-chlorotoluene as a raw material, a chlorine gas as a chlorinating agent and the Hbeta molecular sieve as a catalyst, the 2,6-dichlorotoluene is prepared by selective chlorination of the catalytic o-chlorotoluene employing a one-step chlorination method. The method is easy to operate, simple in steps, relatively low in production cost and easy to industrialize.

Owner:NANJING ZHONGTENG CHEM

Method for adsorbing and purifying impurities by using high-purity benzyl chloride

ActiveCN113896615ASimple processHigh purityChemical industryHalogenated hydrocarbon preparationOrtho-chlorotolueneBenzaldehyde

The invention relates to a method for adsorbing and purifying impurities through high-purity benzyl chloride, and belongs to the technical field of compound purification and impurity removal. According to the method, after an adsorbent is pretreated and activated under a high-temperature condition, o-chlorotoluene, parachlorotoluene, toluene, benzaldehyde and other impurities in a raw material benzyl chloride are removed by a dynamic adsorption method. The method can greatly reduce the content of o-chlorotoluene, p-chlorotoluene, toluene, benzaldehyde and other impurities in benzyl chloride, especially reduce the content of o-chlorotoluene / p-chlorotoluene, improve the purity of benzyl chloride, and is convenient and safe in process operation, and suitable for large-scale production.

Owner:常州新东化工发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com