Method for producing high-purity o-chlorotoluene by adsorption separation method

An o-chlorotoluene, adsorption separation technology, applied in chemical instruments and methods, organic chemistry, halogenated hydrocarbon preparation, etc., can solve problems such as the inability to obtain high-purity o-chlorotoluene, affecting downstream high-end pharmaceutical applications and development, etc., to avoid The recycling steps and processes are simplified and easy to implement, and the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

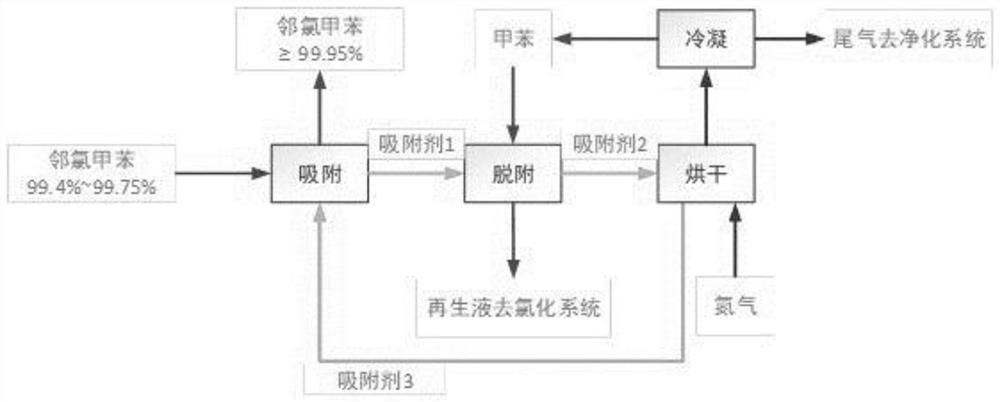

Method used

Image

Examples

Embodiment 1

[0045] Take 50 g of o-chlorotoluene solutions of different production batches, add different kinds of adsorbents, filter after stirring for a certain period of time, analyze the mass fraction of o-chlorotoluene in the filtrate, and compare the adsorption effects of different adsorbents. The results are shown in Table 2.

[0046] Table 2 Adsorption effect of different adsorbents

[0047]

Embodiment 2

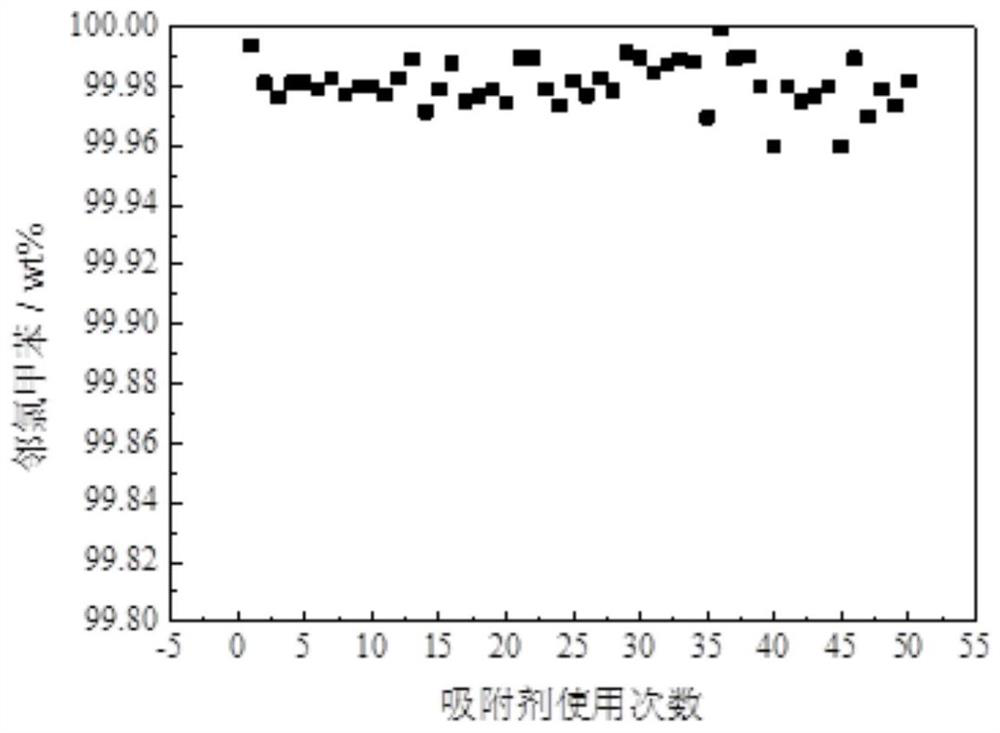

[0049] Take 50 g of o-chlorotoluene with production batch number 20210321 and put it into a 250 mL three-necked flask, add 5 g of IM-5 molecular sieve, stir for 30 minutes and then filter to obtain o-chlorotoluene solution. IM-5 adsorbent uses 30 g of toluene as a desorbent to desorb it Washing, the adsorbent IM-5 obtained after washing remains in the three-necked flask, put the three-necked flask into a bowl-shaped electric furnace, feed 0.83L / min nitrogen, control the temperature of the electric furnace to 180°C, and regenerate at this temperature for 3h Then, cool to room temperature. After cooling down to room temperature, the adsorbent is used again, and the cycle is applied in this way, and the result is as follows: figure 1 As shown, the adsorption regeneration of the adsorbent is recycled 50 times, and the mass fraction of o-chlorotoluene is above 99.95%.

Embodiment 3

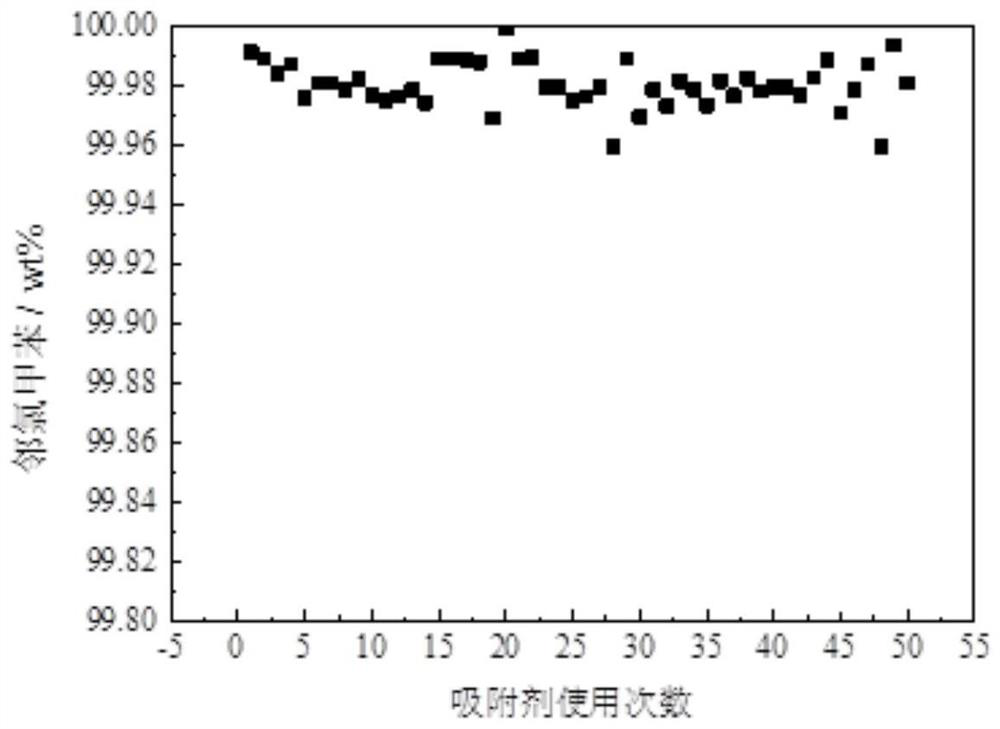

[0051] Take 50 g of o-chlorotoluene with the production batch number of 20210915 and add it to a 250 mL three-neck flask, add 6.25 g of ZSM-5 molecular sieve, stir for 30 minutes, and then filter to obtain an o-chlorotoluene solution. ZSM-5 adsorbent uses 35 g of toluene as a desorbent to desorb it. After washing, the adsorbent ZSM-5 obtained after washing remains in the three-necked flask. Put the three-necked flask into a bowl-shaped electric furnace, feed 0.11L / min nitrogen, control the temperature of the electric furnace to 180°C, and regenerate at this temperature After 4h, cool to room temperature. After cooling down to room temperature, the adsorbent is used again, and the cycle is applied in this way, and the result is as follows: figure 2 As shown, the adsorption regeneration of the adsorbent is recycled 50 times, and the mass fraction of o-chlorotoluene is above 99.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com