Production method of double-kettle-switching continuous chlorination

A production method and chlorination reaction technology, applied in the production field of continuous chlorination with double-tank switching, can solve the problems of discontinuous production, tail gas pollution, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

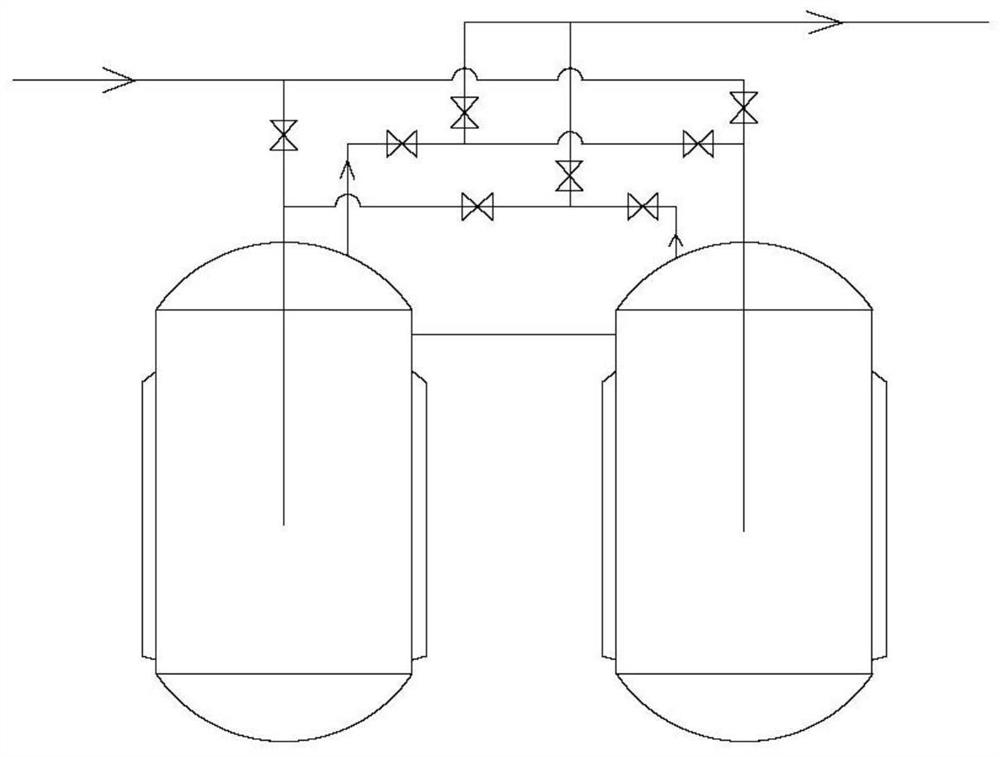

[0020] Such as figure 1 Shown, the present invention is a kind of production method of double kettle switching continuous chlorination, two reactors are connected in series, adopt double reactor to switch alternately as main and secondary reactor to carry out chlorination reaction, one reactor feeds chlorine, one reactor The chlorine-containing tail gas enters another reactor to be absorbed and then discharged; as the solution in the reactor of the main reactor is sampled and tested to meet the requirements, the reaction in the main reactor is completed, the main and auxiliary reactors stop feeding chlorine gas, and the main reactor is released. The auxiliary reactor maintains the reaction temperature in the kettle; after the main reactor continues feeding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com