Mixed chlorotoluene MVR (mechanical vapor recompression) rectification system and method

A technology of mixed chlorotoluene and rectification system, which is applied in the field of mixed chlorotoluene MVR rectification system, which can solve the problems of no energy-saving improvement measures, high operating costs, and large steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

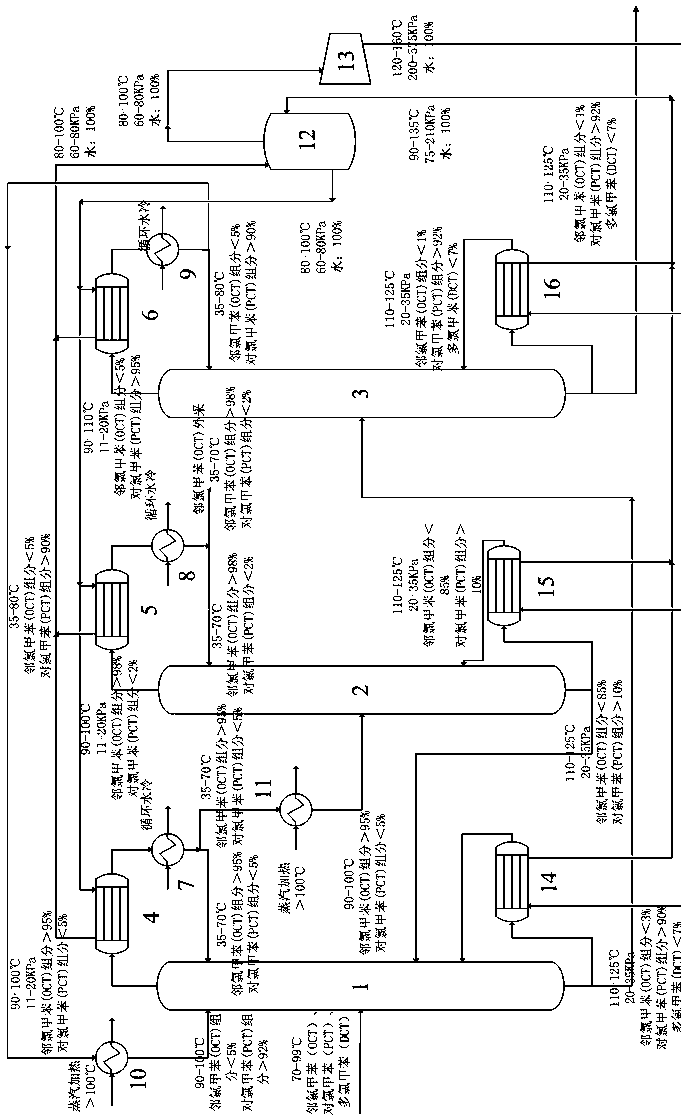

Method used

Image

Examples

Embodiment 1

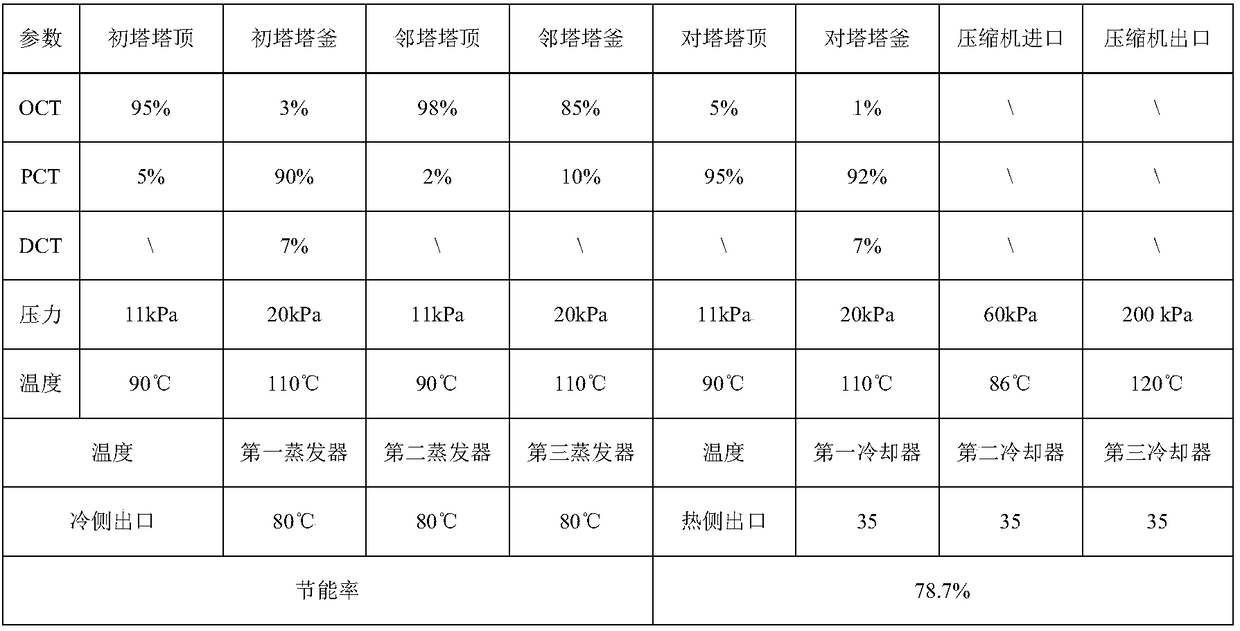

[0027]

[0028] Conclusion: The feed temperature of the initial column is 70 ℃, the operating pressure of the top of the three towers is 11kPa, the operating pressure of the tower kettle is 20kPa, the compression ratio of the compressor is 3.33, and the purity of 98% o-chlorotoluene (OCT) is obtained from the top of the adjacent tower. ), to the tower kettle to obtain p-chlorotoluene (PCT) with a purity of 92%, and the energy saving rate is 78.7%.

Embodiment 2

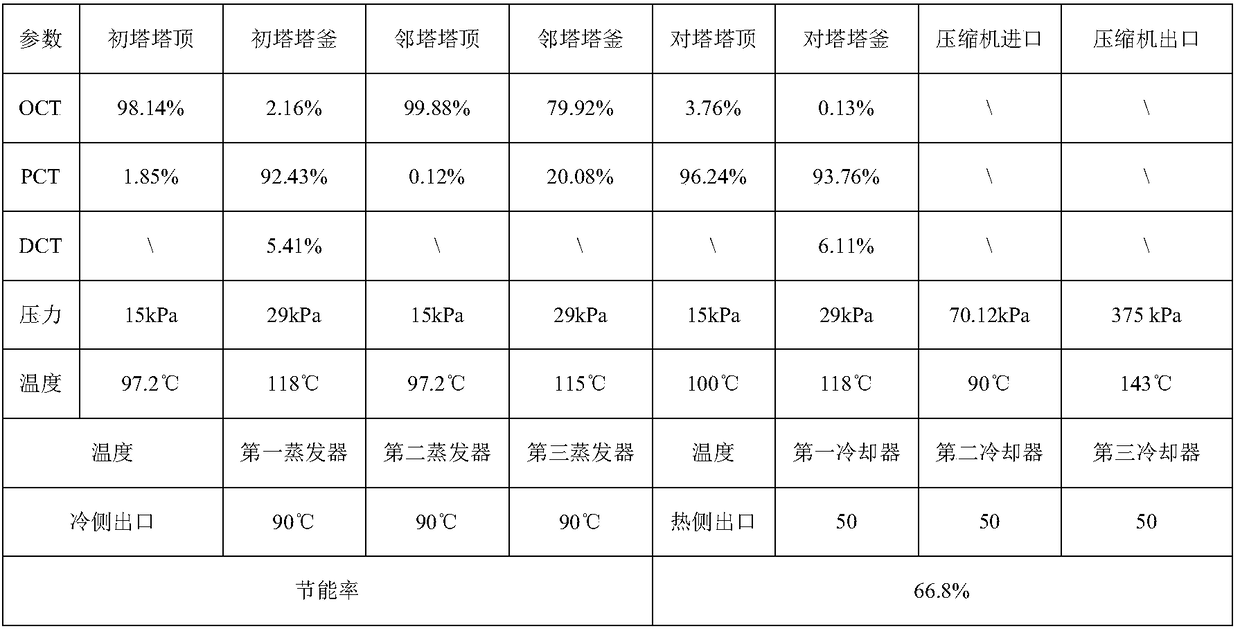

[0030]

[0031] Conclusion: The feed temperature of the initial tower is 90℃, the operating pressure of the top of the three towers is 15kPa, the operating pressure of the tower kettle is 29kPa, the compression ratio of the compressor is 5.35, and the ortho-chlorotoluene (OCT) with a purity of 99.88% is obtained from the top of the adjacent tower. ), to the tower kettle to obtain p-chlorotoluene (PCT) with a purity of 93.76%, and the energy saving rate is 66.8%.

Embodiment 3

[0033]

[0034] Conclusion: The feed temperature of the initial column is 99℃, the operating pressure of the top of the third tower is 20kPa, the operating pressure of the tower kettle is 35kPa, the compression ratio of the compressor is 6, and the ortho-chlorotoluene (OCT) with a purity of 99.9% is obtained from the top of the adjacent column. ), to the tower kettle to obtain p-chlorotoluene (PCT) with a purity of 94.13%, and the energy saving rate is 62.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com