Special reactor for oriented synthesis of p-chlorotoluene

A technique for directional synthesis of p-chlorotoluene, applied in chemical/physical/physical chemical nozzle reactors, chemical instruments and methods, organic chemistry, etc., to achieve high mass transfer efficiency, large reactant contact area, and reduced gas phase resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

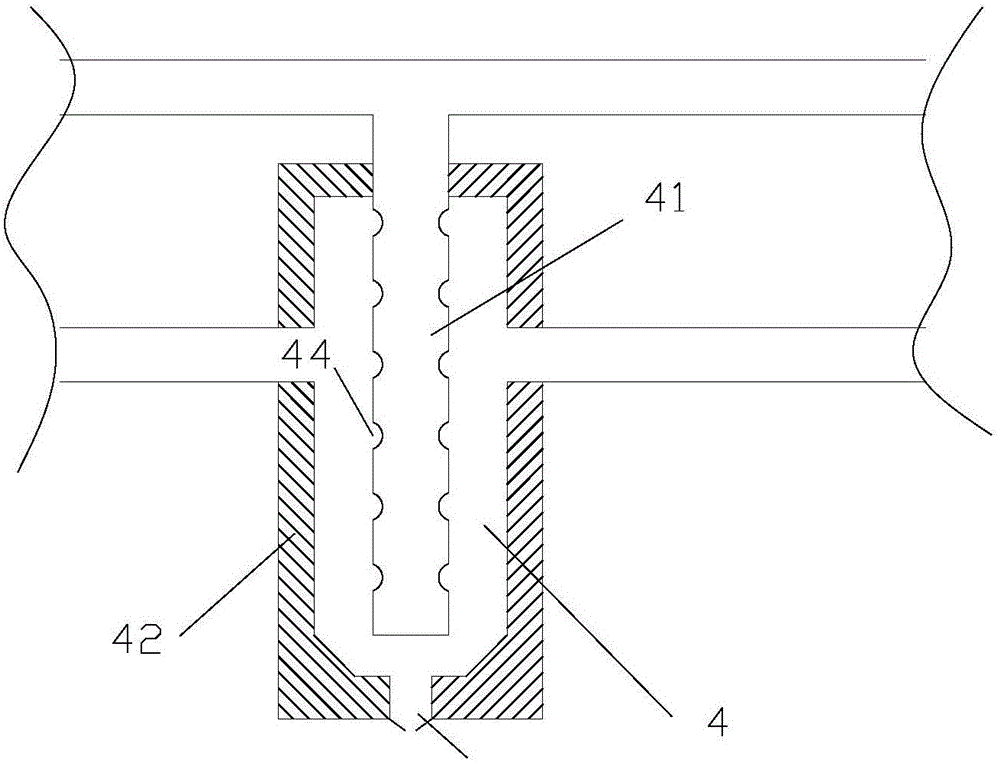

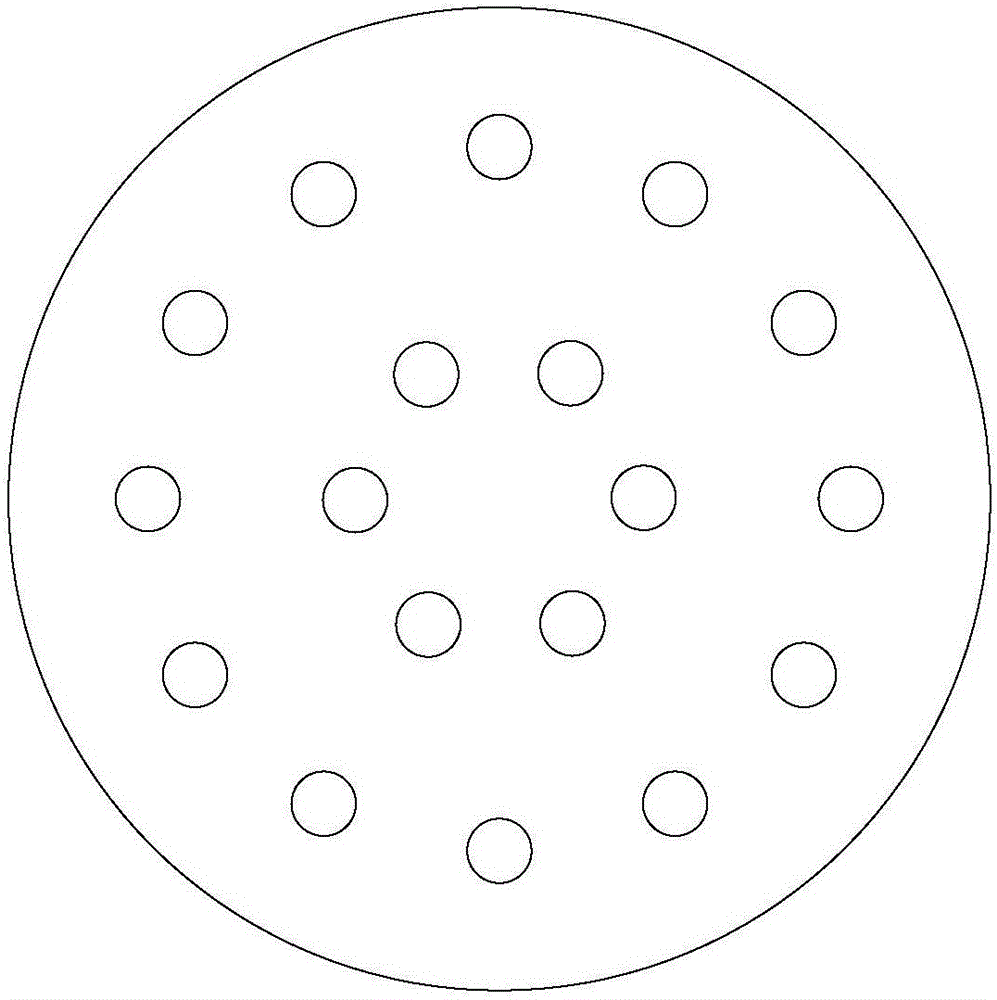

[0019] like figure 1 As shown, the special reactor for the directional synthesis of p-chlorotoluene of the present invention includes a reactor body 1, and the upper part of the reactor body 1 is provided with a first hollow inlet plate 2, a hollow liquid inlet plate 3, and a first hollow inlet plate 3. There are several nozzles 4 on the gas plate, such as figure 2 As shown, it consists of an inner tube 41, an outer shell 42 and a nozzle 43. The inner tube is connected to the first hollow inlet plate 1, and the outer shell is connected to the hollow liquid inlet plate 2; the inner space of the inner tube is connected to the first hollow inlet plate 2. The air inlet space of the air plate; the inner space of the shell is connected to the liquid inlet space of the hollow liquid inlet plate; the lowermost end of the inner pipe is closed. There are several small holes all over the inner tube, the diameter of the small holes is less than 5mm, and the distribution of the small hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com