P-benzyldiethoxymethylsilane and preparation method thereof

A technology of benzyldiethoxymethylsilane and methyltriethoxysilane, which is applied in the field of silicon-containing compound p-benzyldiethoxymethylsilane and its synthesis, and can solve solvent recovery Utilization, solvent environmental pollution and other problems, to achieve the effect of saving operating costs, simple separation and purification, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

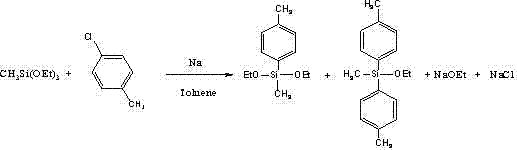

Image

Examples

Embodiment 1

[0024] In a dry 250mL four-neck flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 82g (0.4599 moles) of methyltriethoxysilane, and add 10.54g (0.4585 moles) of freshly chopped The sodium flakes were heated up to 110°C, and the sodium flakes were beaten into sodium sand; within 2 hours, 29.2g (0.2307 moles) of p-chlorotoluene was added dropwise to the reaction system through a constant pressure dropping funnel, and the reaction temperature was controlled between 108 ~112°C, continue to react for 2 hours after the dropwise addition, after cooling to 25°C, slowly add 1.5g (0.0326 moles) of absolute ethanol within 0.5h to neutralize the excess metal sodium, and then wait for 25 Maintain at ℃ for 1 h; then add 9.4 mL (0.0805 mol) of methyltrichlorosilane dropwise to the mixture within 1 h to neutralize the generated sodium alkoxide; after the addition is complete, continue the reaction at this temperature for 3 h. Then the reaction m...

Embodiment 2

[0027] In a dry 250mL four-necked flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 122.4g (0.6865 moles) of methyltriethoxysilane, and add 10.9g (0.4741 moles) of new Cut the sodium flakes, raise the temperature to 110°C, and beat the sodium flakes into sodium sand; within 1 hour, add 29.2g (0.2307 moles) of p-chlorotoluene into the reaction system dropwise through a constant pressure dropping funnel, and control the reaction temperature between 108~112°C, continue to react for 4 hours after the dropwise addition, after cooling to 30°C, slowly add 3.1g (0.0673 moles) of absolute ethanol within 1.0h to neutralize the excess metal sodium, and then add Maintain at 30°C for 1.5h; then add 9.4mL (0.0805mol) methyltrichlorosilane dropwise to the mixture within 2h to neutralize the generated sodium alkoxide; after the dropwise addition, continue the reaction at this temperature for 4h . Then the reaction mixture was suction-filtered ...

Embodiment 3

[0030] In a dry 250mL four-necked flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 163.2g (0.9153 moles) of methyltriethoxysilane, and add 10.8g (0.4698 moles) of new Cut the sodium flakes, raise the temperature to 95°C, and beat the sodium flakes into sodium sand; within 2 hours, add 29.2g (0.2307 moles) of p-chlorotoluene into the reaction system dropwise through a constant pressure dropping funnel, and control the reaction temperature between 95~98°C, continue to react for 5 hours after the dropwise addition, after cooling to 20°C, slowly add 5.0g (0.1085 moles) of absolute ethanol within 1.0h to neutralize the excess metal sodium, and then add Maintain at 20°C for 1.5h; then add 16.0mL (0.1327mol) dimethyldichlorosilane dropwise to the mixture within 1.5h to neutralize the generated sodium alkoxide; after the addition is complete, continue at this temperature Reaction 2h. Then the reaction mixture was filtered under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com