Method and device for continuously producing sartan biphenyl

A technology of sartan biphenyl and a special device, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of many reaction by-products, difficult recovery, low catalyst utilization rate, etc., and achieve yield and Effects of efficiency improvement, reduction of reaction by-products, and improvement of catalyst utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

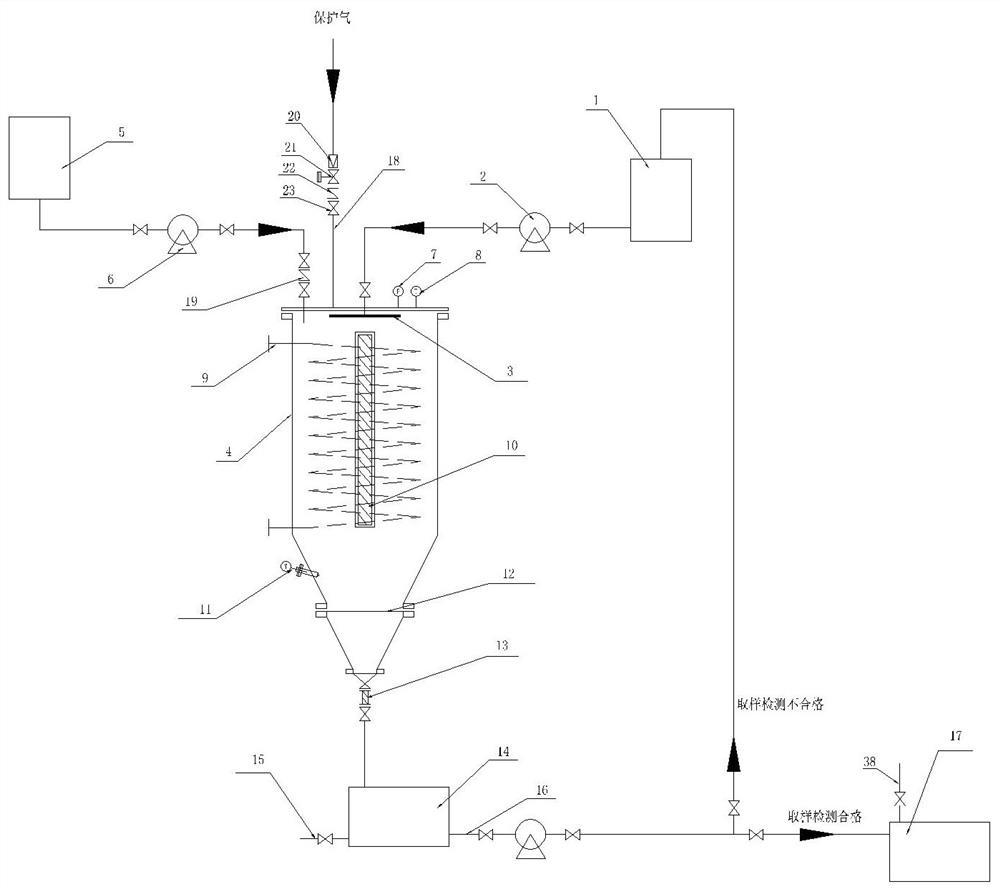

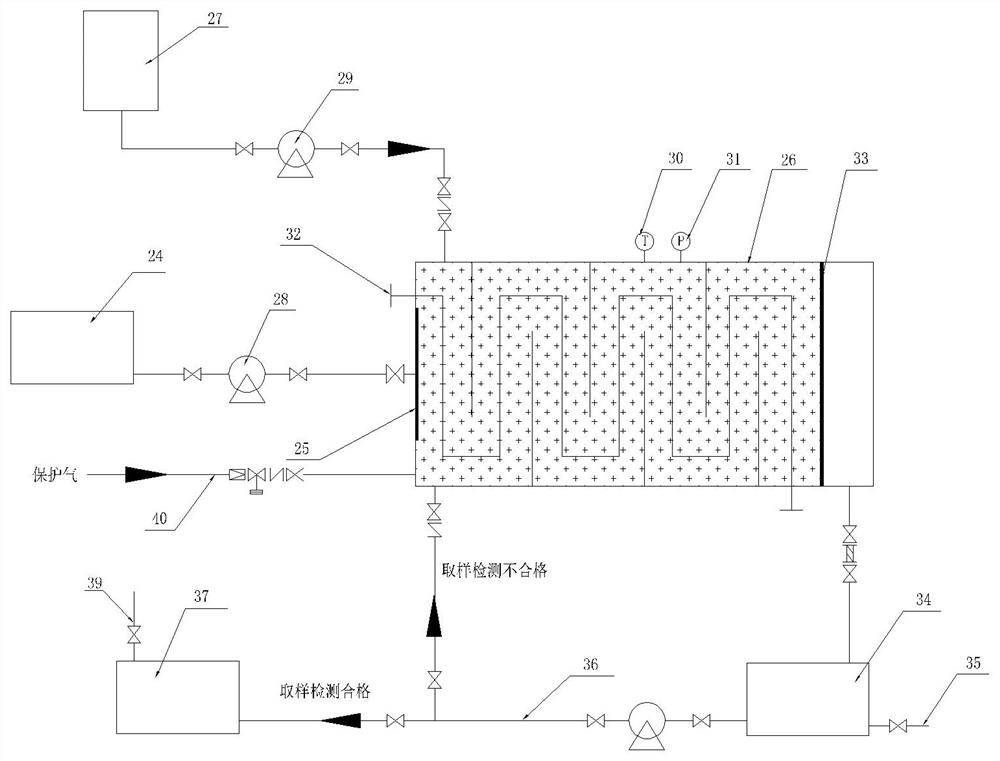

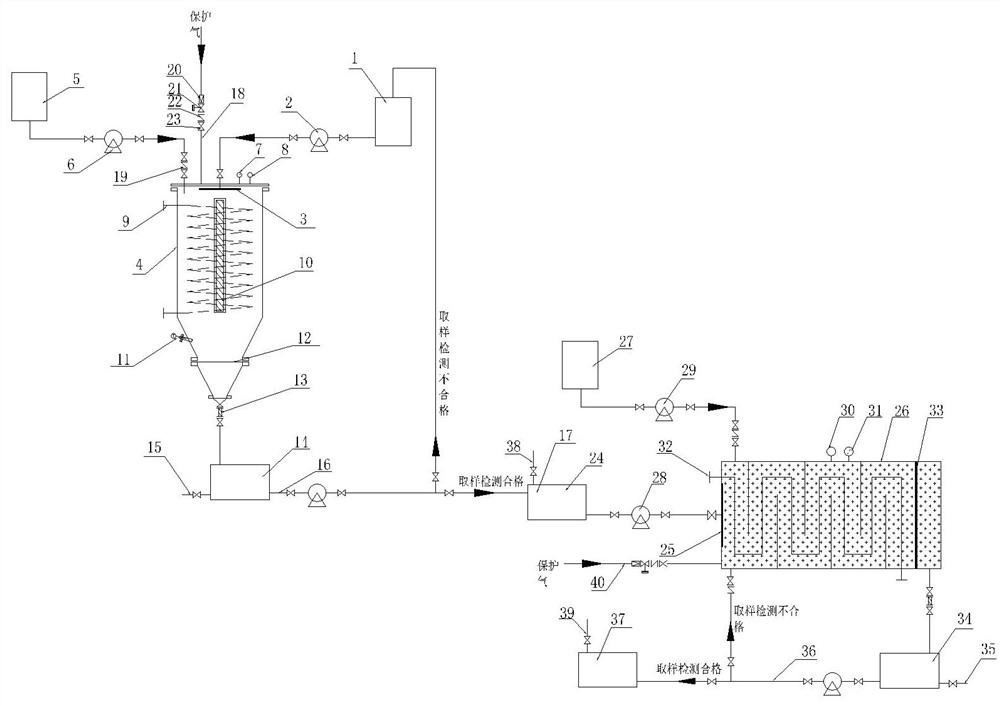

[0027] A method for continuous production of sartan biphenyl, using a fixed-bed reactor to carry out the continuous Grignard reaction of p-bromotoluene or p-chlorotoluene, and then using the obtained Grignard reagent in a fixed-bed reactor with a solid-loaded catalyst Carry out continuous coupling reaction with o-chlorobenzonitrile, and finally prepare sartan biphenyl, and the materials are added and output in a continuous manner during the reaction process after the whole production is started. The solid-supported catalyst spherical silica gel-supported unit Atomic Mn(0) and Zn(0) catalysts, wherein the coupling reaction is p-bromotoluene or p-chlorotoluene Grignard reagent and o-chlorobenzonitrile are pumped into the fixed bed to realize continuous reaction on the fixed reaction bed, p-bromotoluene Or p-chlorotoluene Grignard solution reacts with o-chlorobenzonitrile under the action of catalyst in the process of flowing on the reaction bed, by adjusting parameters such as fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com