Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211 results about "N-methyldiethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-methyldiethanolamine: PubChem CID. 7767; RTECS number: KL7525000 UNII: ... Methyl diethanolamine, also known as N-methyl diethanolamine and more commonly as MDEA, is the organic compound with the formula CH 3 N(C 2 H 4 OH) 2. It is a, colorless liquid with an ammonia odor.

Process for the purification of gases

InactiveUS6277345B1Improve efficiencyIncreased gas throughputHydrogenOrganic chemistryPoly(ethylene glycol) dimethyl etherHydrogen

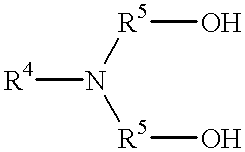

The present invention relates to the use of an absorption liquid for purifying a gas by removal of gaseous, acidic impurities. The gas to be purified can be any gas, such as synthesis gas or natural gas, which contains gaseous, acidic impurities such as CO2, H2S, SO2, CS2, HCN, COS or mercaptans. The absorption liquid comprises:A) from 0.01 to 4% by weight of at least one compound of the formulaB) from 0.001 to 8.0% by weight of water, andC) at least one polyalkylene glycol alkyl ether of the formulato 100% by weight,whereR1 is C1-C4-alkyl,R2 is ethylene or 2-methylethylene,R3 is hydrogen or C1-C4-alkyl,R4 is hydrogen or C1-C4-alkyl,R5 is C1-C4-alkylene andX is an integer from 1 to 10. The amine may be N-methyldiethanolamine and the ether may be polyethylene glycol dimethyl ether.

Owner:CLARIANT PROD DEUT GMBH

Preparation and use of cation aqueous polyurethane emulsion

InactiveCN101440152ASave energyEasy to processWater-repelling agents additionPulp material addition processesPolyesterPolyethylene glycol

The invention relates to a method for preparing cationic waterborne polyurethane surface sizing agent capable of being used as paper and paperboard surface sizing agent. Toluene di-isocyanate (TDI), polyester dibastic alcohol, polyethylene glycol, 1,4-butanediol and N-methyldiethanolamine as a hydrophilic chain extender are selected to synthesize a cationic waterborne polyurethane emulsion by an internal emulsification method. The prepared polyurethane emulsion can be well used in cooperation with aluminum sulfate, poly aluminum and other aluminum salts. When the prepared polyurethane emulsion is used in cooperation with starch, aluminum salts and the like for the surface sizing of paper and paperboards, good sizing effects can be obtained, and the correlation of the paper and the paperboards can be greatly improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

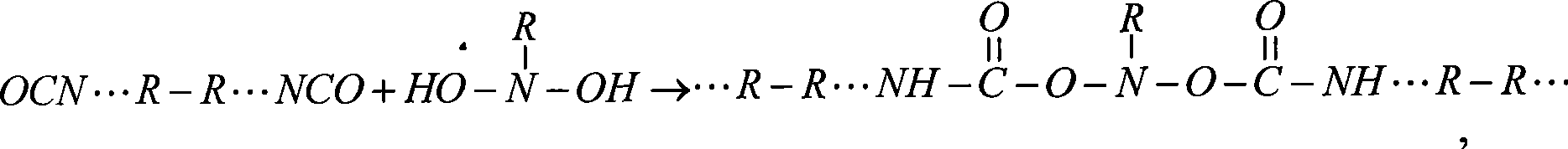

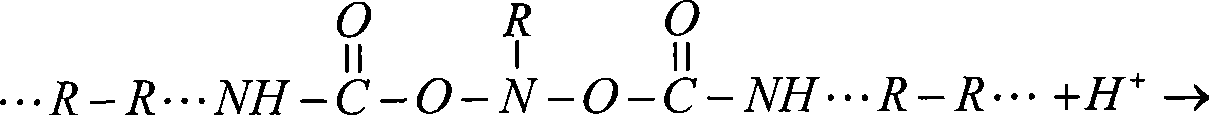

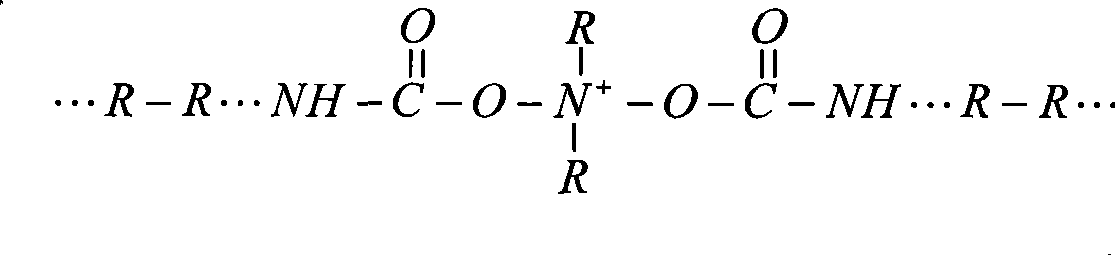

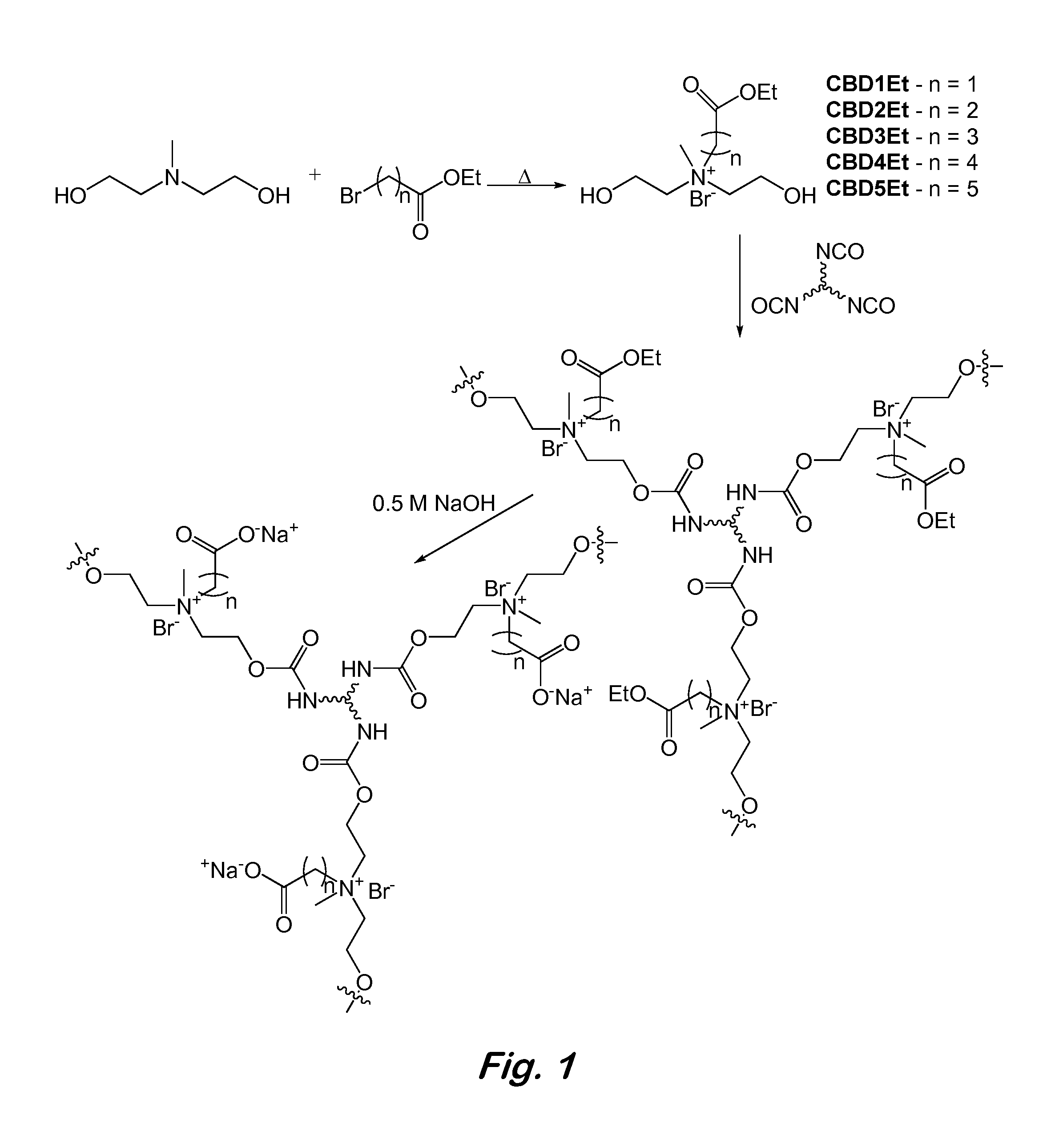

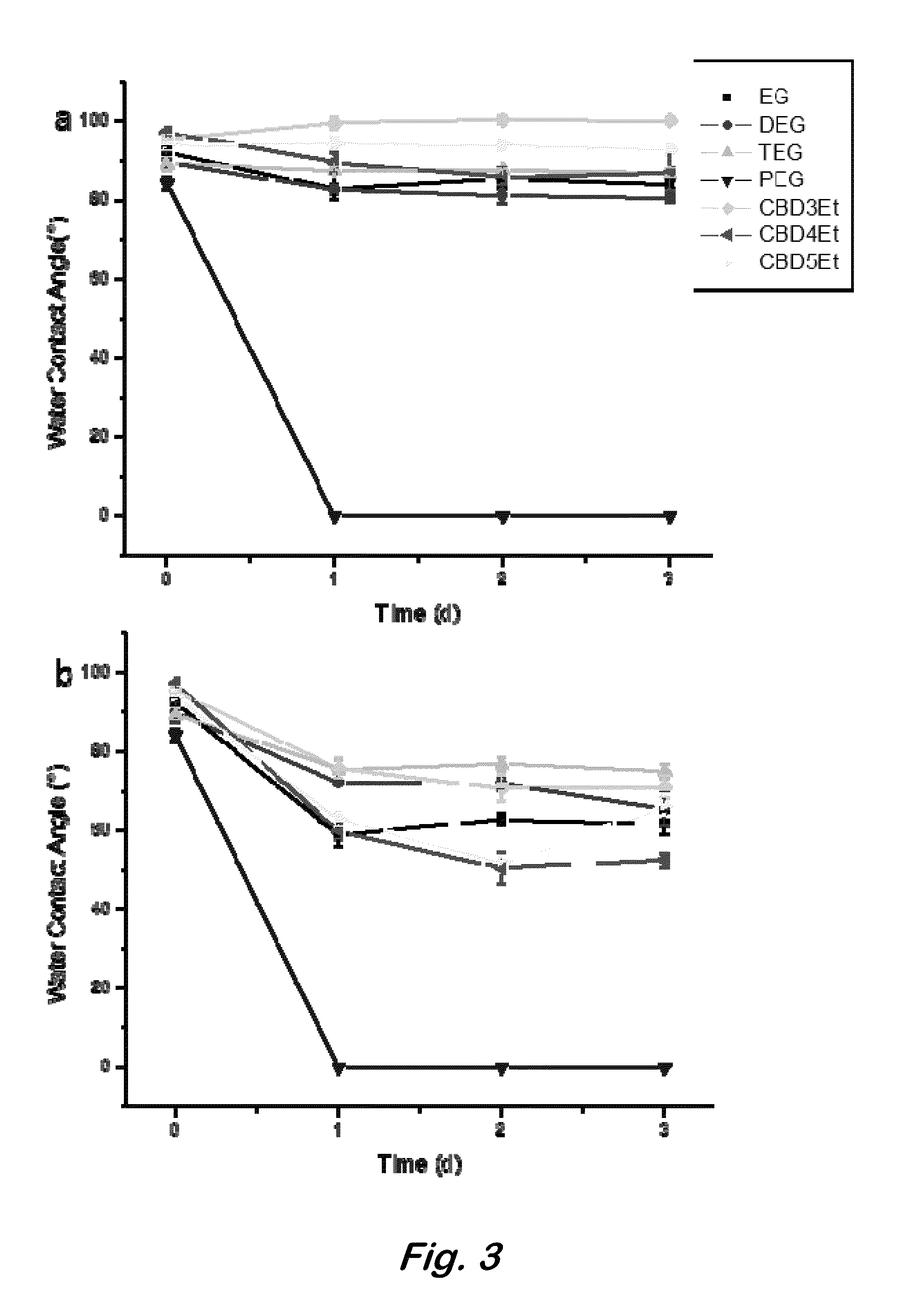

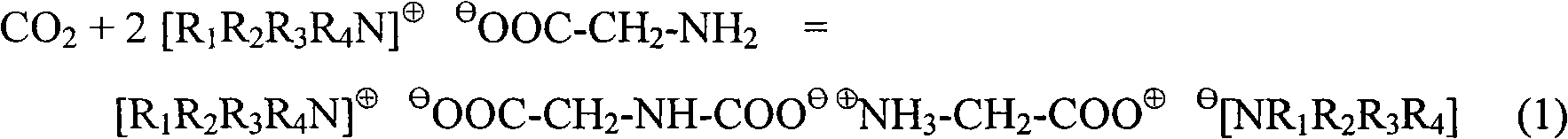

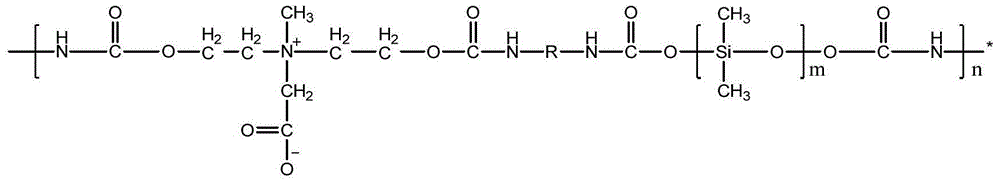

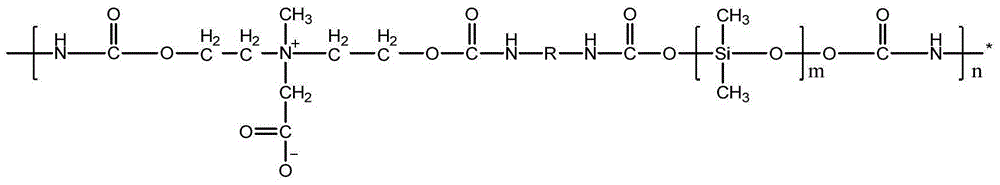

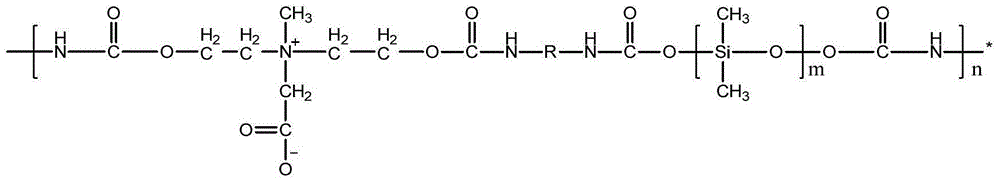

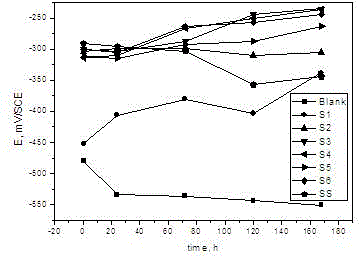

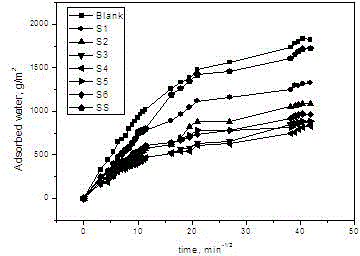

Carboxybetaine-functionalized diols and zwitterionic polyurethane hydrogels derived therefrom

A compound having the formula: X−N+(CH3)(CH2CH2OH)2[(CH2)n—COO—R1] and a polymer having the repeat unit: X−{—OCH2CH2—N+(CH3)[(CH2)n—CO—Y]—CH2CH2O—CO—NH—R2—NH—CO—}. R1 is an ester protecting group, R2 is an organic group, X is a halide, and n is a positive integer. Each Y is O−Z+ or O—R1, where Z+ is a cation from an aqueous base. A method of reacting N-methyldiethanolamine with an ω-halo-n-alkanoate ester to form the above compound.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

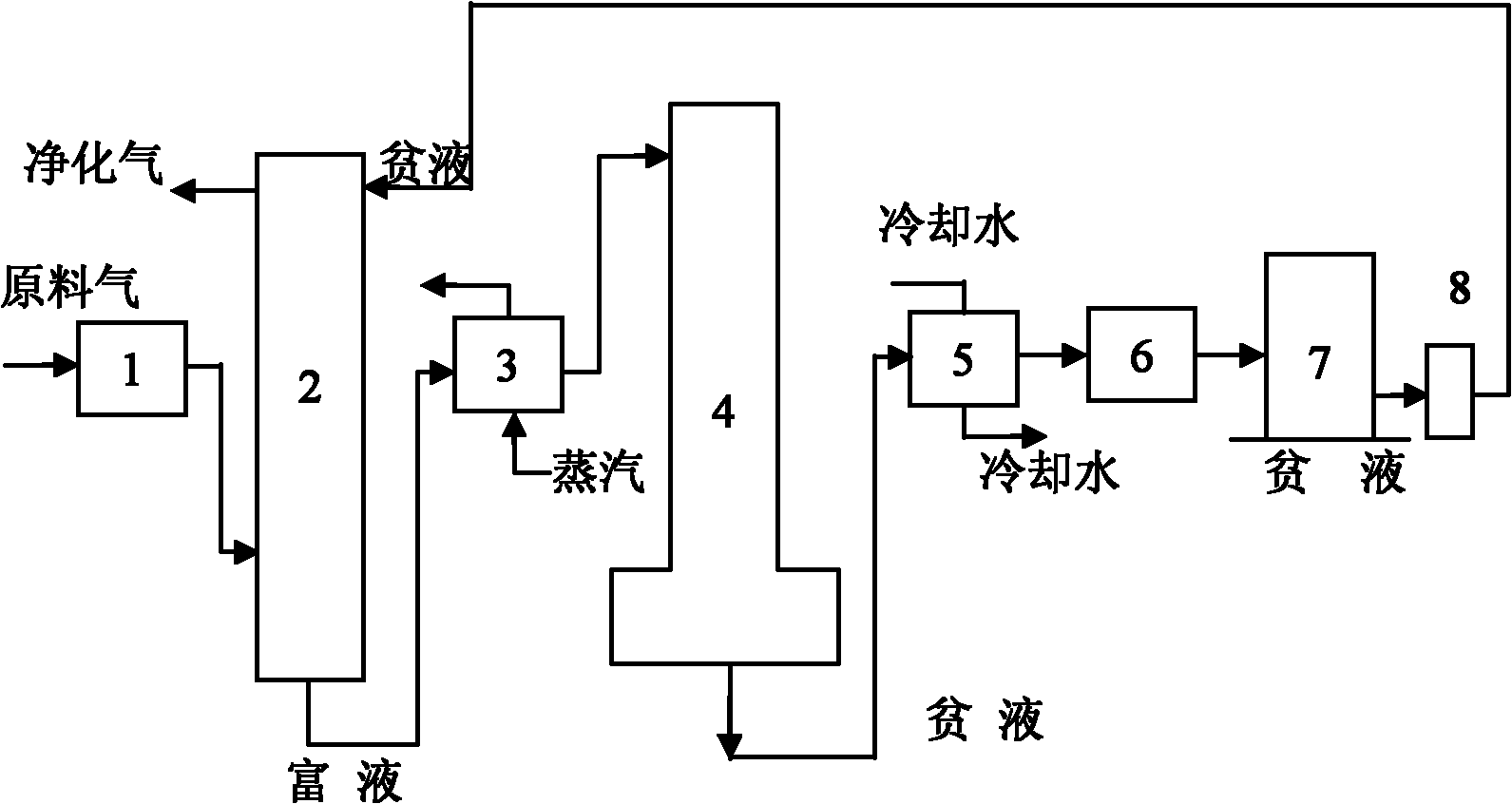

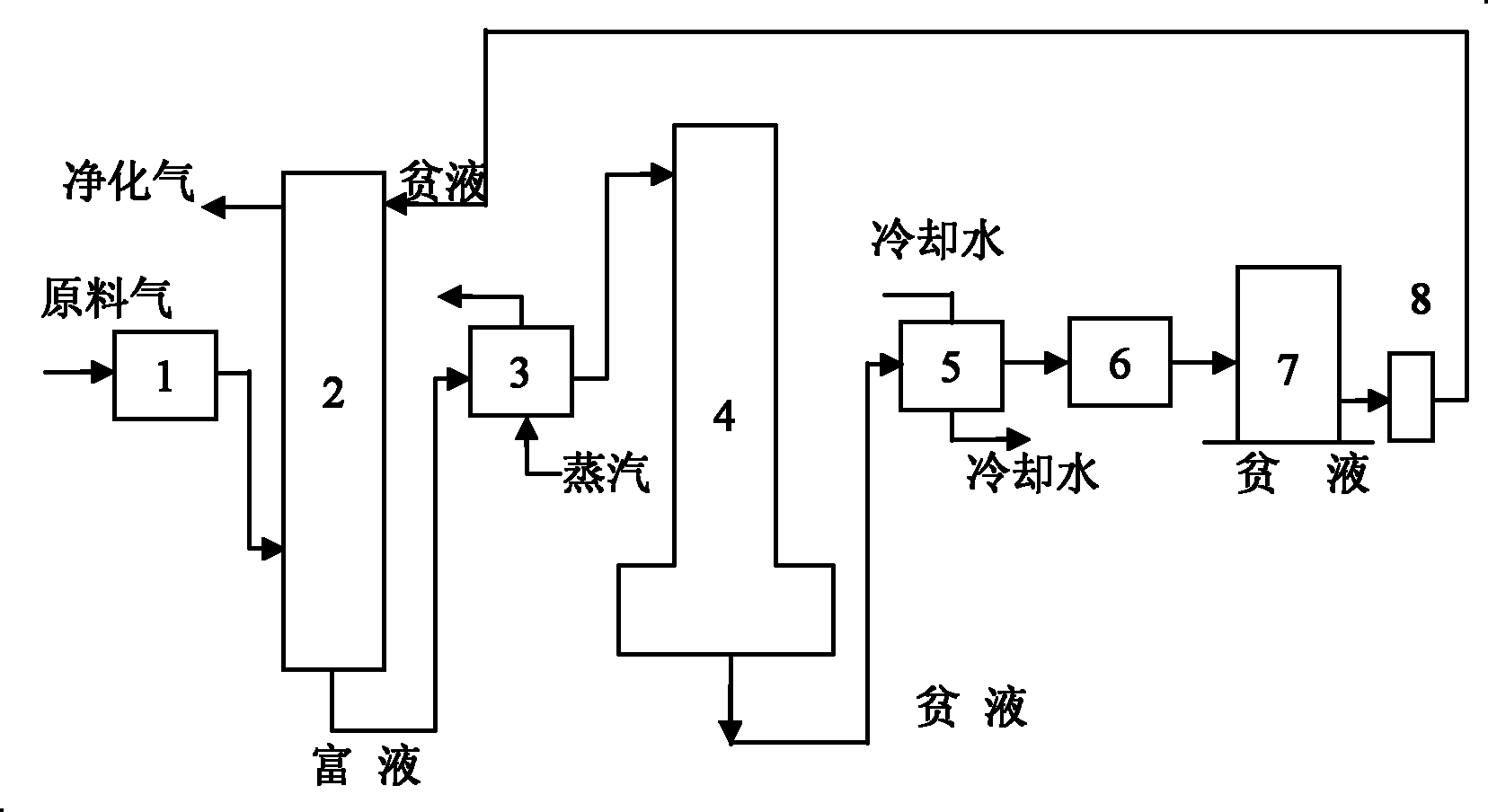

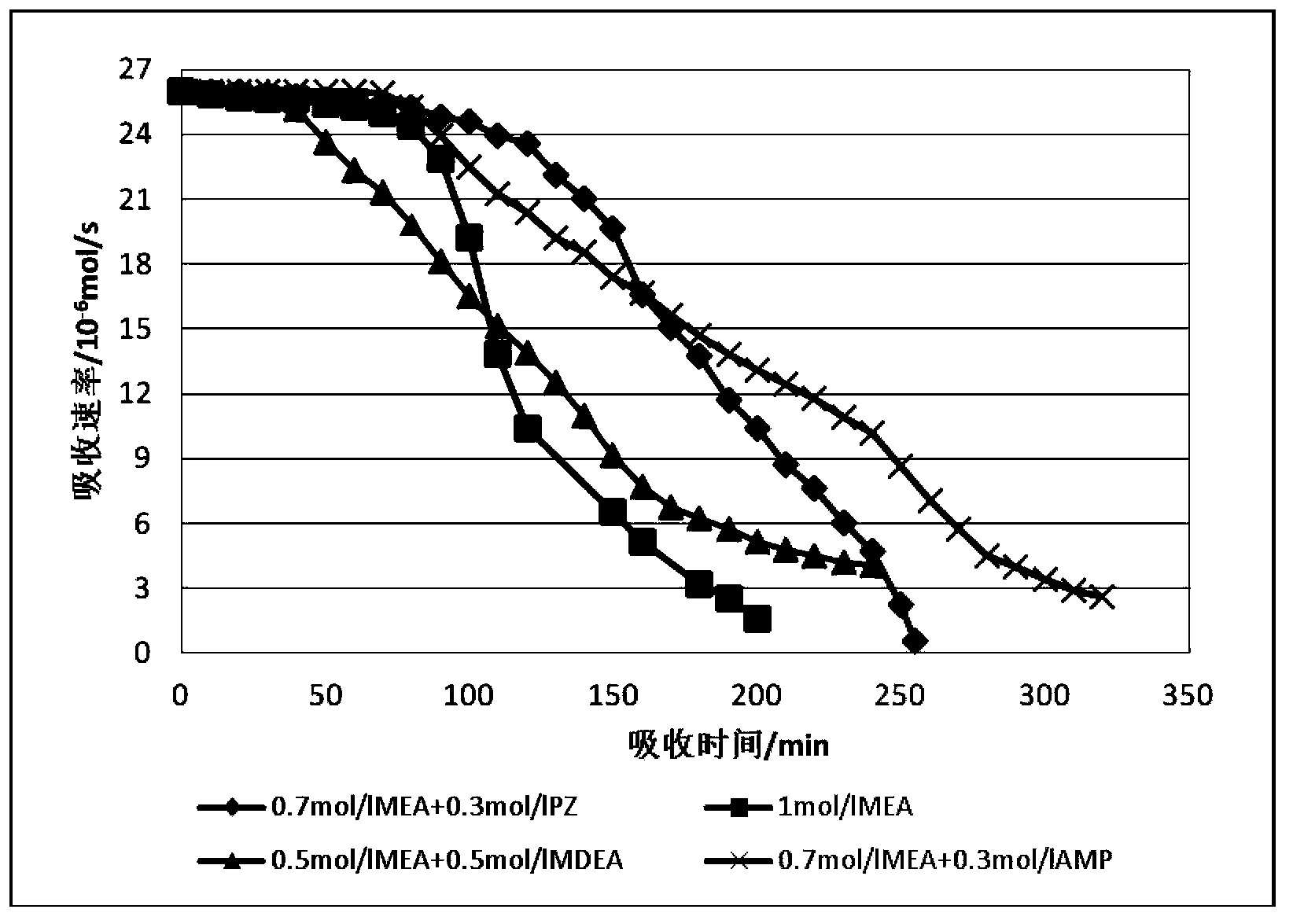

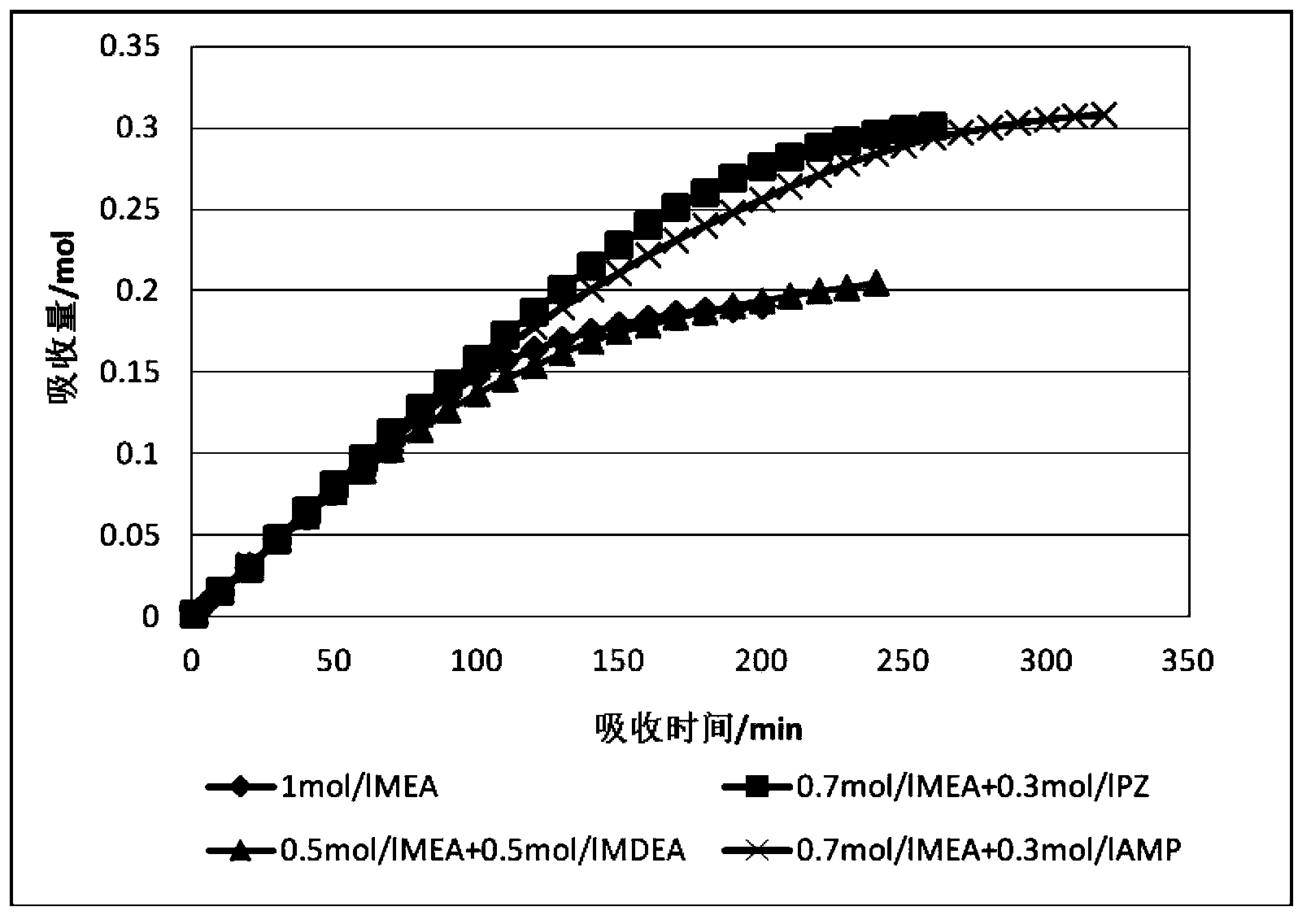

Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

InactiveCN101804292AReduce lossOvercome the disadvantage of high energy consumptionDispersed particle separationBy chemical separationSulfolanePoly(ethylene glycol) dimethyl ether

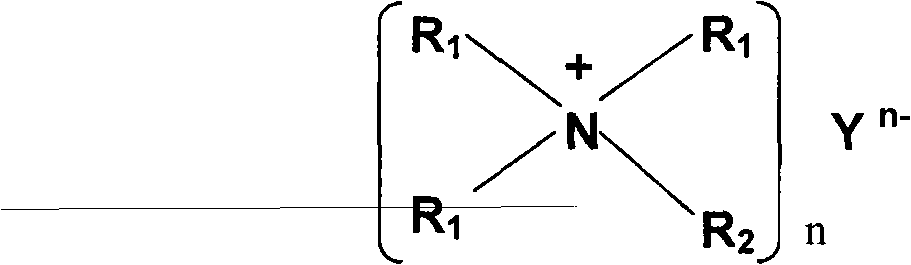

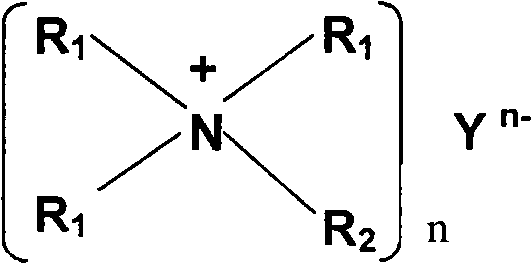

The invention relates to a special N-methyldiethanolamine formula solution activated by ion liquid for CO2 gas absorption separation, which consists of the following ingredients in mass percent: 35 to 50 percent of N-methyldiethanolamine, 5 to 20 percent of low-viscosity kalescent functional ion liquid, 15 to 30 percent of dimethyl ether of polyethlene glycol and / or sulfolane and 15 to 30 percent of water, wherein cations of the low-viscosity kalescent functional ion liquid are tetraalkylammonium ions, and anions of the low-viscosity kalescent functional ion liquid are amino acid radicals or organic carboxylate anions. The formula solution of the invention has the advantages that the high mass transfer performance of the absorption-desorption process is improved, the material consumption in the use process is low, the defect of high energy consumption because a large amount of water vapor is brought away during the absorbing agent regeneration, and the invention belongs to an energy-saving formula with high green degree. The regeneration temperature of the solution is lower than that of the traditional absorbing liquid, the grade of a heat source required to be provided in the regeneration process is reduced, energy sources can be saved, the stability of the absorbing agent solution in the operation is high, the consumption of each absorption-desorption circulation is low, and in addition, the cost is low.

Owner:NANJING UNIV

High-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas

InactiveCN101844035AHigh mercaptan removalHigh acid gas loadDispersed particle separationSulfolaneTert-Butylamine

The invention discloses a high-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas, which comprises serotonin, wherein the serotonin consists of N-methyl diethanolamine and ethoxy ethanol tert-butylamine, and also comprises sulfolane and N-Hydroxyethyl piperidine. The weight ratio of the serotonin in the desulfurizing agent is 70 to 85 percent; the weight ratio of the sulfolane in the desulfurizing agent is 5 to 10 percent; and the weight ratio of the N-Hydroxyethyl piperidine in the desulfurizing agent is 10 to 20 percent. By mixing physical and chemical solvent and abstracting the advantages of the physical and chemical solvent, so on the premise that the removal effect of H2S is ensured, the organic sulfur can be removed high efficiently; and the desulfurizing agent has large acid gas load, strengthens the reaction speed between the H2S and MDEA and TBEE, so the consumption of the desulfurizing agent is small during the gas purification process, and the regeneration energy consumption of the solvent is low.

Owner:四川省精细化工研究设计院

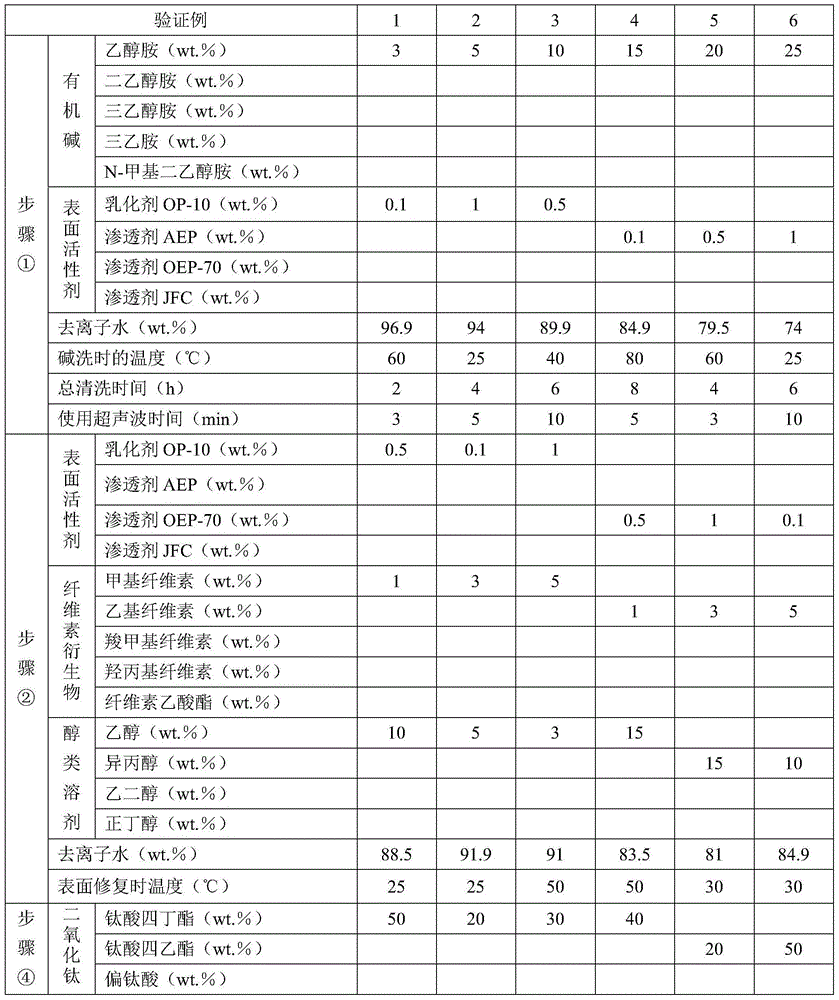

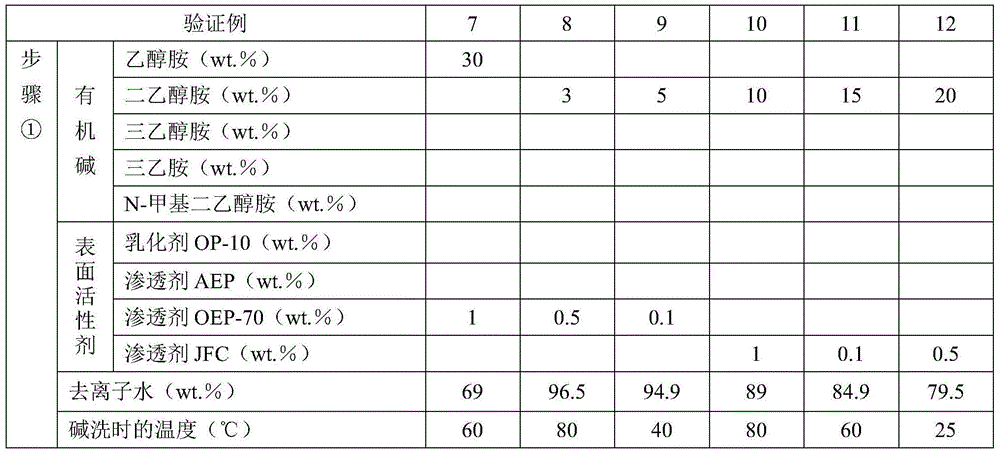

Alkali washing liquid for regenerating SCR denitration catalysts and application thereof

InactiveCN104826669AImprove denitrification rateDispersed particle separationCatalyst regeneration/reactivationBULK ACTIVE INGREDIENTCalcination

An alkali washing liquid for regenerating SCR denitration catalysts and an application thereof are provided. The alkali washing liquid is composed of an organic alkali, a surfactant and deionized water, wherein the organic alkali is a mixture of one or two of ethanol amine, diethanol amine, triethanolamine, triethylamine and N-methyl diethanol amine. In the method for regenerating the SCR denitration catalysts, firstly, to-be-regenerated SCR denitration catalysts are subjected to air purging and cutting, then immersed in the alkali washing liquid, and subjected to ultrasonic alkali washing. Compared with the prior art, the method has surface repairing and surface reconstruction processes aiming at the to-be-regenerated SCR denitration catalysts increased, and finally, after active ingredient supplementing and calcination processes, the specific surface area and the denitration rate of the obtained regenerated SCR denitration catalysts are both relatively greatly improved compared with those of the conventional washing and regeneration technology. The alkali washing liquid is suitable for regeneration treatment of the honeycomb type, corrugated type and plate type SCR denitration catalysts.

Owner:CHONGQING UNIV

Amphipathic polyurethane with anti-bacterial and anti-protein function as well as preparation method and application of amphipathic polyurethane

ActiveCN105199070AImprove stain resistanceGood biological stabilityAntifouling/underwater paintsPaints with biocidesCross-linkHydrolysis

The invention discloses amphipathic polyurethane resin based on polysiloxane and a preparation method of the amphipathic polyurethane resin, as well as an anti-bacterial anti-protein performance of the amphipathic polyurethane resin. The preparation method comprises the following steps: carrying out a reaction between tert-Butyl bromoacetate and N-methyldiethanolamine under a certain condition to obtain a quaternary ammonium diol; carrying out cross-link between the quaternary ammonium diol and hydroxymethyl-terminated polydimethylsiloxane; carrying out hydrolysis to obtain the amphipathic polyurethane of which a molecular chain segment has not only a hydrophilic ingredient but also a hydrophobic ingredient. The amphipathic polyurethane has all of the relatively high hydrophilicity of zwitter ions, the low surface energy and dirt discharging superiority of polysiloxane, and the stability of polyurethane, thereby having an excellent practical application value in the anti-bacterial and anti-protein field.

Owner:ZHEJIANG UNIV +1

Organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas

ActiveCN103394277AImprove protectionSolving Corrosion ProblemsDispersed particle separationBy chemical separationSulfolaneAbsorption capacity

The invention discloses an organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas; the organic amine compound absorbent comprises the following components: by mass, 10%-45% of a main absorbent component, 0-10% of an assistant absorbent component, 0.01%-6% of a corrosion inhibitor, 0.01-3% of an antioxidant, 0-5% of a defoaming agent and the balance of water; wherein the main absorbent component comprises the following components: account for the total mass percentage of the organic amine composite absorbent, 3%-20% of monoethanolamine MEA, 0-12% of 2-amino-2-methyl-1-propanol AMP, 1%-15% of sun of piperazine PZ and N-aminoethyl piperazine AEP and 1%-12% of sum of aminoethyl ethanolamine AEEA and N-methyl monoethanolamine MMEA; and the assistant absorbent comprises one or a plurality of component selected from the group comprising diethanol amine DEA, diethylenetriamine DETA, triethylene tetramine TETA, N-methyldiethanolamine MDEA, sulfolane and tertbutylaminoethoxyethanol TBEE. The organic amine compound absorbent has the advantages of good stability, large absorption capacity, high purification degree, low regeneration energy consumption, good desorption effect, great reduction of degradation loss of the compound absorbent in the process of using, and the like.

Owner:STATE GRID CORP OF CHINA +1

Heavy grease stain environment-friendly type water base cleaning compound

InactiveCN103834487AGood decontamination effectGood compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsWater basedTriclosan

The invention discloses a heavy grease stain environment-friendly type water base cleaning compound comprising 10-15% of surfactant, 1-3% of additive, 1-5% of antiseptic, 3-5% of organic amine and remaining tap water; the ingredient of the surfactant comprises 4-5% of aliphatic acid methyl esters ethoxylate, 2-3.5% of APG, 1-3% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.5-1% of straight chain sodium alkyl benzene sulfonate (LAS) and 0.5-2% of aliphatic acid methyl esters ethoxylate; the additive is one or more from a group formed by sodium citrate, citric acid, lactic acid and DL-malic acid; the organic amine is one or more from a group formed by triethanolamine, n-butylamine, diethanolamine and N-methyl diethanolamine; the antiseptic at least is triclosan or tetrachloro isophthalonitrile; through the said method, the heavy grease stain environment-friendly type water base cleaning compound has anti bacterium, heavy grease stain cleaning and environmental protection performances.

Owner:SUZHOU LOTTE CHEM TECH

Compound desulfurizer and preparation method thereof

The invention discloses a compound desulfurizer. The compound desulfurizer comprises the following components in percentage by weight: 30-40% of N-methyldiethanolamine, 40-50% of steric hindered amine, 10-29% of physical absorption solvent and 0.5-1% of defoaming agent. Meanwhile, the invention further discloses a preparation method of the compound desulfurizer. The compound desulfurizer has the advantages that sulfide in mixed gas can be effectively removed, the selectivity is good, the absorption rate of carbon dioxide is low, the handling capacity of subsequent processes is lowered, the sulfur capacity is high, the foaming is difficult, the use concentration is high, and the circulation volume is low; and meanwhile, no extra desulfurizers are need, the integral energy consumption of a desulfurizing system can be reduced by above 20%.

Owner:宜兴汉光高新石化有限公司

Composite decarbonization solvent for eliminating carbon dioxide in natural gases

ActiveCN101822932AIncrease reaction rateReduce concentrationGaseous fuelsDispersed particle separationDecreased energyAntioxidant

The invention discloses a composite decarbonization solvent for eliminating carbon dioxide in natural gases, consisting of the following components in percentage by weight: 91.00%-96.45% of N-methyldiethanolamine solvent, 3.4%-8% of activator, 0.05%-0.4% of foam inhibiting agent, 0.05%-0.3% of corrosion inhibitor and 0.05%-0.3% of antioxidant. The invention has the advantages that the composite decarbonization solvent improves reaction rate of the composite decarbonization solvent and the carbon dioxide, increasing adsorption amounts; reduces circulation quantity of a decarbonization solution, decreasing energy consumption of solution circulation; reduces the degradation of the decarbonization solvent, lowering consumption of the decarbonization solvent; and at the same time, the composite decarbonization solvent improves corrosion resistance, oxidation resistance and foaming resistance of the decarbonization solution.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cationic waterborne polyurethane and preparation method thereof

The invention discloses cationic waterborne polyurethane and a preparation method thereof. The waterborne polyurethane is prepared from the following raw materials in parts by weight: 140-160 parts of polyether N220, 90-110 parts of toluene diisocynate, 5-7 parts of trimethylolpropane, 22-30 parts of 1,4-butanediol, 8-16 parts of N-methyldiethanolamine, 4-5 parts of acetone, 5-8 parts of acetic acid and 690-700 parts of deionized water. By adopting the woodware sealing primer prepared from the waterborne polyurethane resin of the invention, the bleeding phenomenon can be efficiently solved during the coating of the waterborne woodware paint; and the sealing primer is safe, environmentally friendly, nonpoisonous and tasteless and can meet the requirements of full hydration and environmental protection in the coating process of the woodware paint.

Owner:安徽好思家涂料股份有限公司

Highly selective desulfurization solvent and preparation method thereof

The invention relates to a highly selective desulfurization solvent. The highly selective desulfurization solvent is at least prepared from the raw materials: an organic amine component which is taken as a main component and consists of triethanolamine in a monoamine type, N-methyl-diethanolamine and N-hydroxyethyl piperazine in a diamines type as well as a mixed additive component consisting of a desulfurization accelerator and a defoamer, so that as the desulfurization solvent contains the organic amine component consisting of the triethanolamine, the N-methyl-diethanolamine and the N-hydroxyethyl piperazine, supplemented by the mixed additive component consisting of the desulfurization accelerator and the defoamer, by virtue of the synergistic effect among the components, when being used for treating a mixed raw gas with high carbon-sulfur ratio, the desulfurization solvent is relatively high in the selectivity for removing sulfuretted hydrogen and can be used for effectively lowering the energy consumption of a desulfurization system.

Owner:PANJIN XINANYUAN CHEM IND

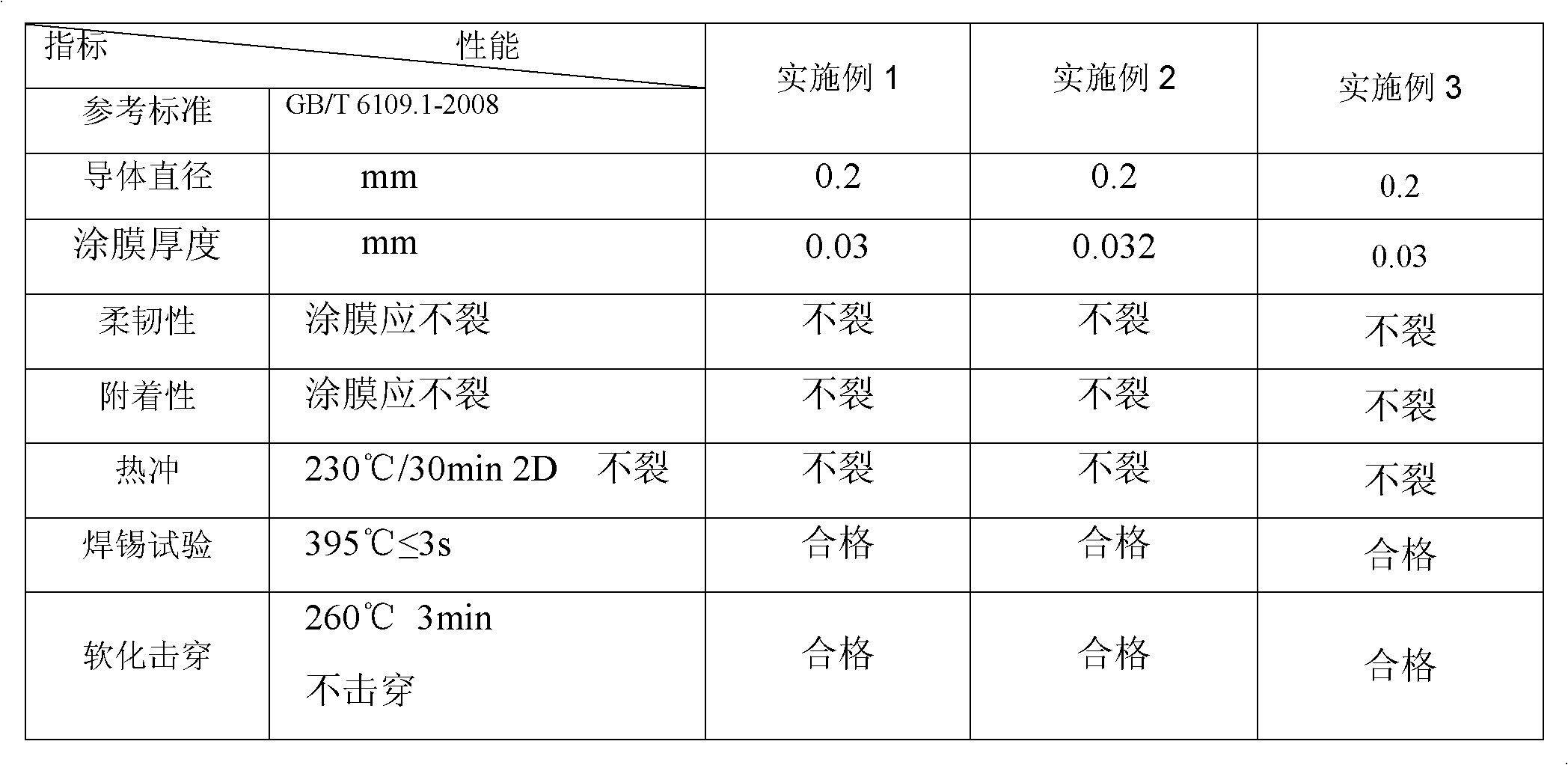

Method for synthesizing C-level polyurethane wire enamel

ActiveCN102618160ANo pollution in the processSimple processPolyurea/polyurethane coatingsPolyesterPhysical performance

The invention discloses a method for synthesizing C-level polyurethane wire enamel. The C-level polyurethane wire enamel prepared by the method has high heat-resistant performance and solderability and physical performance, and the heat-resistant level reaches a C level. The method for synthesizing the C-level polyurethane wire enamel mainly comprises the following steps of: synthesizing polyester polyol, synthesizing a diphenylmethane diisocyanate (MDI) tripolymer and preparing polyurethane paint, wherein the polyester polyol is prepared by reacting dimethyl terephthalate, tri-(2-ethoxy) isocyanurate and dihydric alcohol which serve as raw materials under the action of a catalyst; and the dihydric alcohol is N-methyldiethanolamine, and part of dimethyl terephthalate is replaced by addingtetracarboxylic dianhydride for reaction.

Owner:江苏四达特材科技有限公司 +1

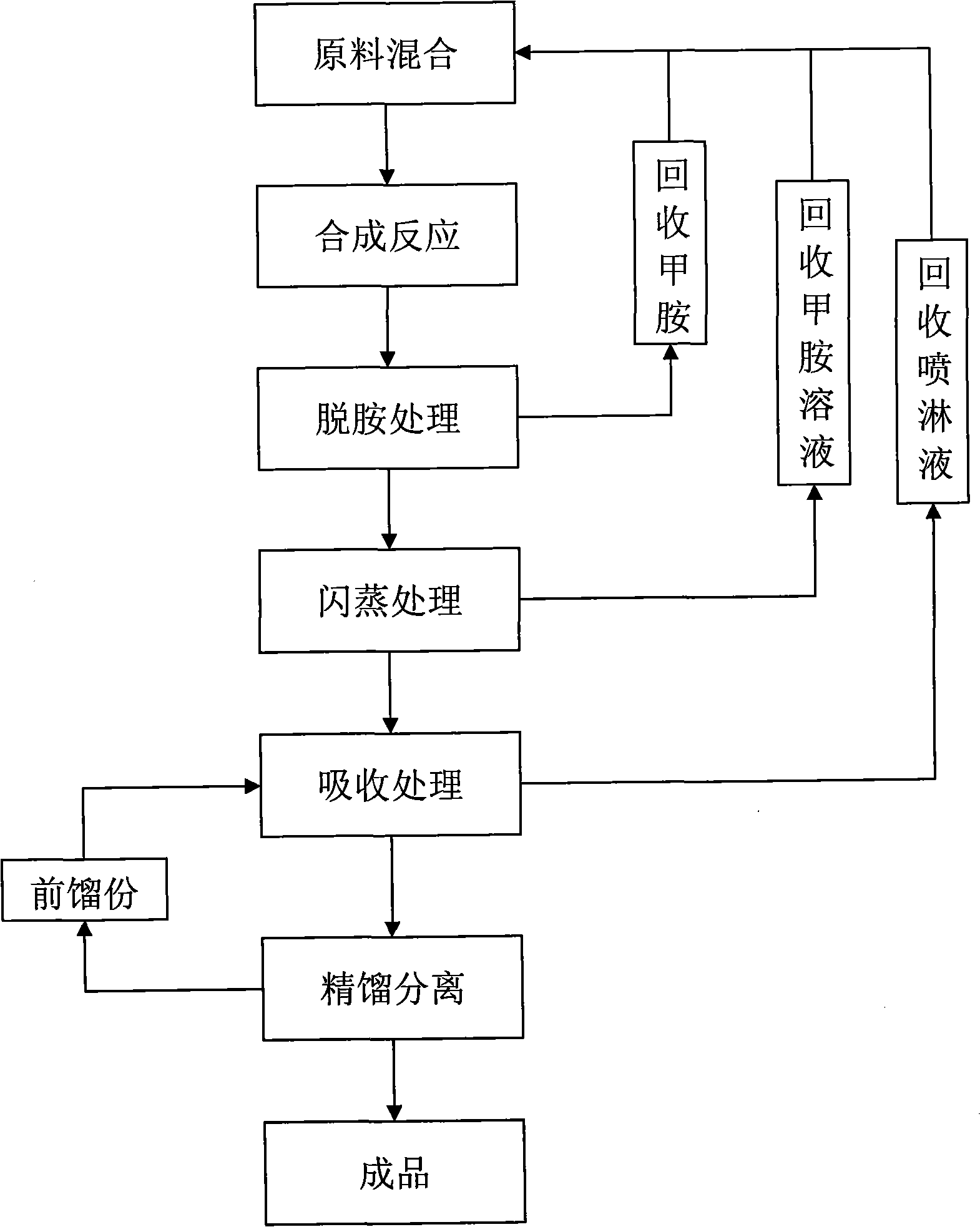

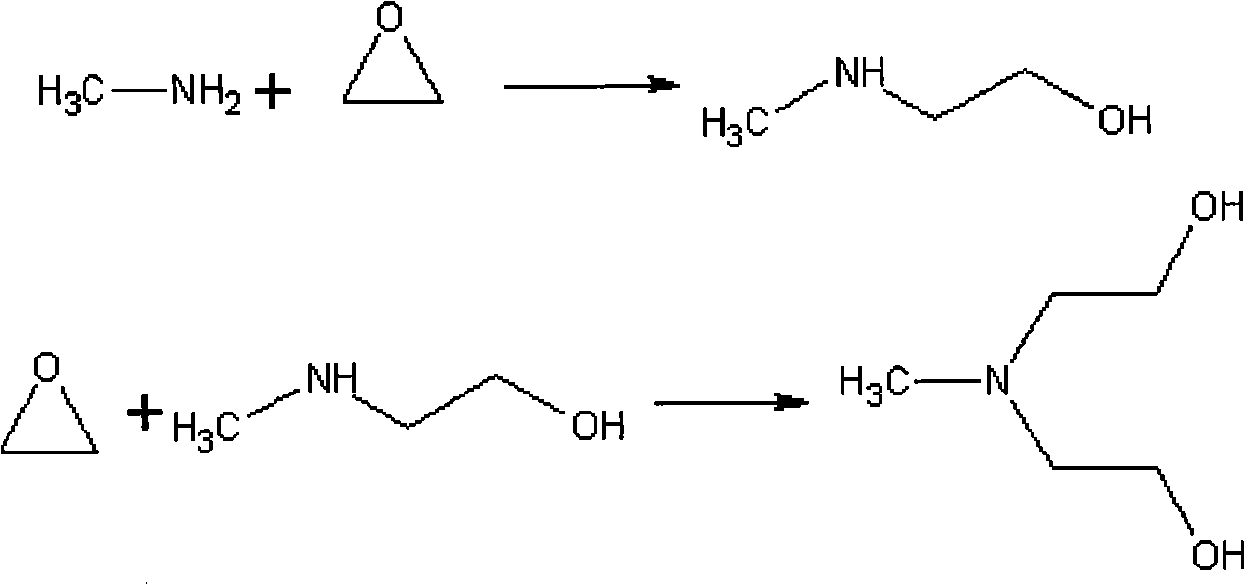

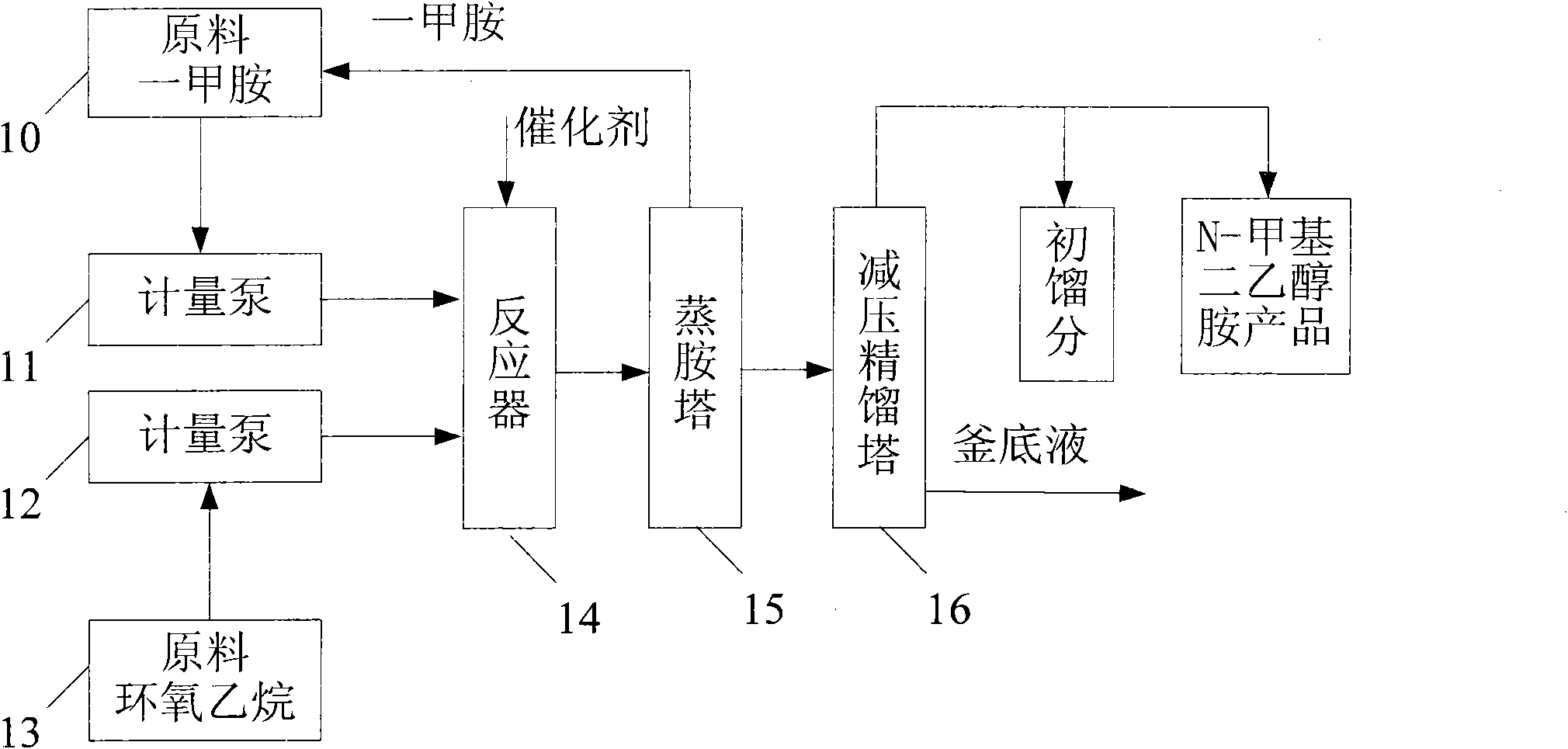

Method for preparing N-methyldiethanolamine

ActiveCN101265195AReduce consumptionConsumption quota reductionOrganic compound preparationAmino-hyroxy compound preparationEpoxyEthylene oxide

The invention relates to the technology field of the synthesis of chemical products, in particular to a method of preparing N-methyl diethano lamine. The preparation comprises the following steps that are a. the mixing of raw material; b. synthetic reaction; c. de-amine processing; d. flash evaporation processing; e. absorption treatment; and f. rectification processing, so that N-methyl diethano lamine products are separated. The method solves the technical problems that the raw material consumption is large, the environment protection performance is bad and the cost is high in the production process of the N-methyl diethano lamine at present. The method adopts anhydrous methylamine instead of monomethyl amine water solution so as to lead the MDEA content in the products to be raised from 95 percent to more than 99 percent, the raw material consumption is reduced in a ration way, the unit consumption of epoxy ethane is reduced to reach 0.84 to 0.87 from the original unit consumption that is 0.95 to 1.0, the unit consumption of methylamine is reduced to reach 0.30 to 0.35 from the original unit consumption that is 0.4 to 0.45, and the consumption of the raw material is greatly reduced; all other matters except the products in the technical process of the method are used as raw material for reusing, thereby lowering the cost consumption, and also avoiding the environmental pollution.

Owner:JIANGSU TAIHU CHEM +1

Desulfurization solvent

The invention relates to a normal temperature high efficiency hydrogen sulfide remover and preparation method, in particular to a complex formulation type high efficiency desulphurization solvent and preparation method, which comprises n-methyldiethanolamine, defoamer, corrosion inhibitor, antioxidant, and strengthening agent; wherein, the content of the n-methyldiethanolamine is 93.5 to 96wt% in the desulphurization solvent; the preparation method of the desulfurizing agent is that 93.5 to 96 portion (the portion below is mass portion) of n-methyldiethanolamine, 0.05 to 0.2 portion of defoamer, 0.02 to 0.05 portion of corrosion inhibitor, 0.05 to 0.2 portion of antioxidant and 3 to 6 portion of strengthening agent are stirred in the stirred tank, and the even solution is acquired, which is desulphurization solvent. The normal temperature high efficiency hydrogen sulfide remover has an advantage of resolving the prior MDEA desulphurization solvent drawback of inferior performance of desulfurization caused by reaction with CO2.

Owner:顾泽元

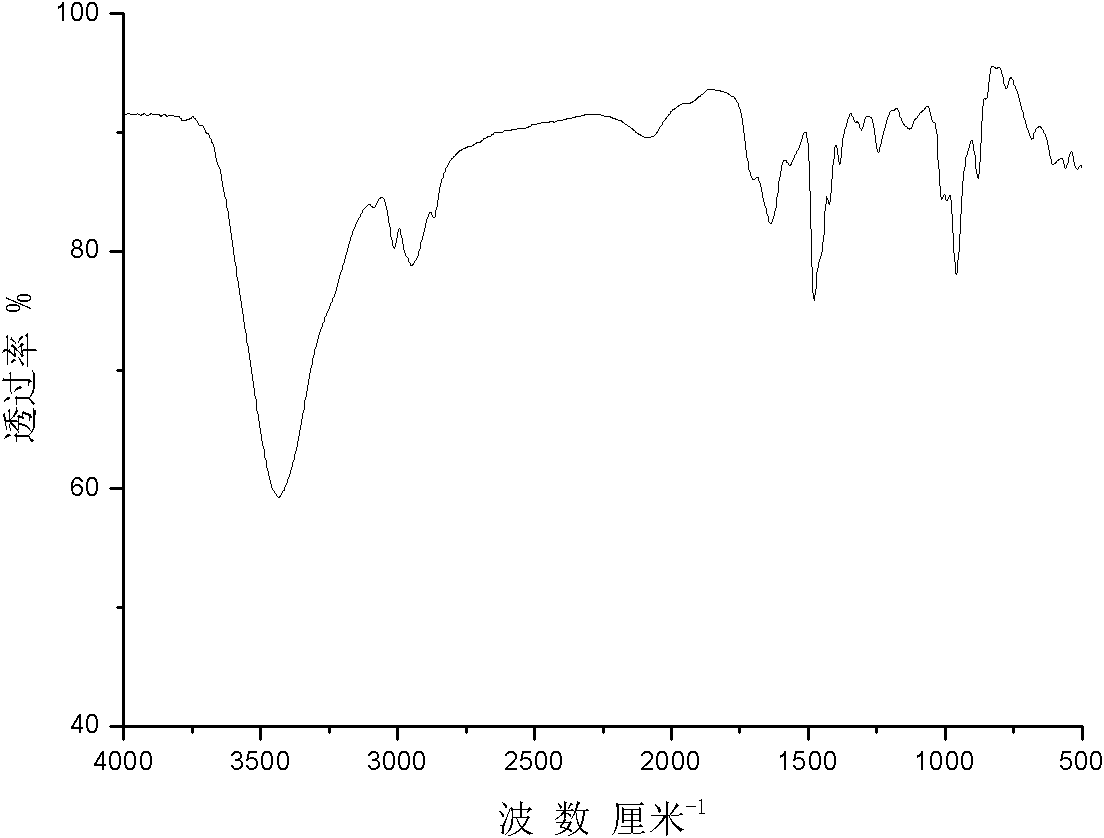

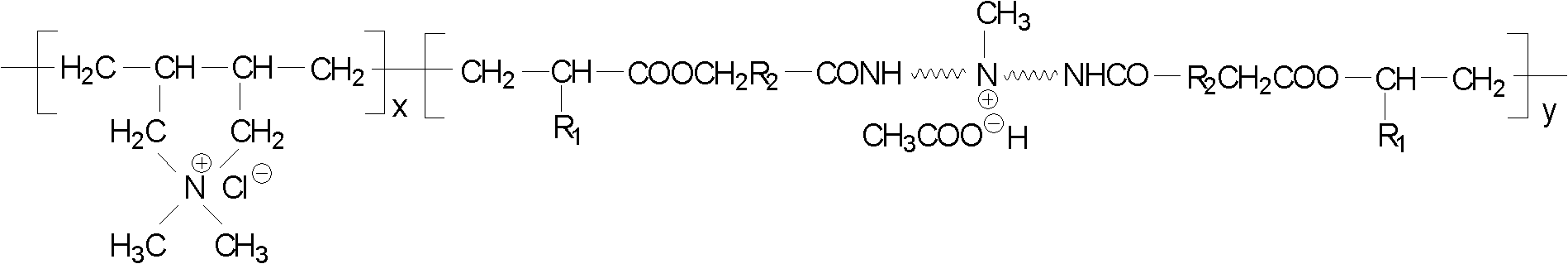

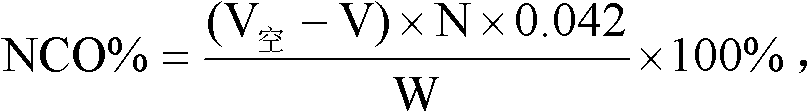

Method for preparing cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent

The invention discloses a method for preparing a cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent, which comprises: synthesizing vinyl terminated cationic polyurethane prepolymer by using isocyanate, polyol, N-methyldiethanolamine and acrylate functional monomers as polymerization monomers; hydrating and dispersing the vinyl terminated cationic polyurethane prepolymer, and performing reversed emulsion polymerization of the vinyl terminated cationic polyurethane prepolymer and dimethyl diallyl ammonium chloride in a water soluble initiator to obtain the formaldehyde-free poly(urethane-dimethyldiallylammonium chloride) color fixing agent. The cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent contains no formaldehyde, retains the property of a polyurethane material, realizes the organic combination of the high performance of the two kinds of resins due to the high positive charge density of a poly(dimethyl diallyl ammonium chloride) chain segment and can effectively improve the color fastness of the dyed fabrics. When the color fixing agent is used, the color fastness of the fabrics dyed with direct dye and active dye is as follows: the dry friction fastness is grade 5, the wet friction fastness is grade 3 to 4, and the brushing fastness is 4 to 5.

Owner:ANHUI UNIVERSITY

Improved N-methyldiethanolamine decarbonizing solution

InactiveCN1608712ALarge absorption capacityImprove the degree of purificationDispersed particle separationAir quality improvementAbsorption capacityMorpholine

The present invention relates to one kind of N-methyldiethanolamine decarbonizing solution comprising N-methyldiethanolamine aqua and activating agent, and features that the activating agent comprises morpholine and piperazine or diethanolamine. The decarbonizing solution of the present invention may be used in eliminating CO2 from synthetic gas, city gas, natural gas and other mixed gas, and the sulfide may be also eliminated simultaneously. The decarbonizing solution has the advantages of great absorption capacity, high purifying degree, low regeneration power consumption, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

Total sulfides removing solvent and preparation thereof

The invention discloses a desulfurizing total sulfur solvent, which comprises n-methyldiethanolamine (MDEA), defoamer and activator; wherein, the content of the n-methyldiethanolamine is 30 to 95wt% in the decarburization solvent; the content of the defoamer is 0.1 to 0.5wt% in the decarburization solvent; the content of the activator is 5 to 69.5wt% in the decarburization solvent. The desulfurizing total sulfur solvent has the advantages of resolving the prior desulfurizing total sulfur solvent drawback that hydrogen sulfide can not be removed and alkaline solution is required to remove hydrogen sulfide in the subsequent handling, low material and energy consumption, and no environmental pollution and easy process of waste alkaline residue.

Owner:王胜利

Novel high-efficient compound decarbonization solvent

ActiveCN101816878AHigh boiling pointReduce volatilityProductsCarbon compoundsAbsorption capacityCo2 absorption

The invention discloses a novel high-efficient compound decarbonization solvent which comprises N-methyldiethanolamine and an active agent. The active agent is a mixture which consists of at least two of N-hydroxyethyl morpholine, 2-amino-2-methyl-1-propanol and piperazine, wherein the weight ratio of the N-hydroxyethyl morpholine is 80 to 90 percent; the weight ratio of the active agent is 10 to 20 percent and a defoaming agent is also added into the compound decarbonization solvent. The novel high-efficient compound decarbonization solvent has the advantages of high carbon dioxide absorption capacity, high purification degree, low regeneration energy consumption, and no foams after long-term use of the decarbonization solvent.

Owner:四川精事达科技有限公司

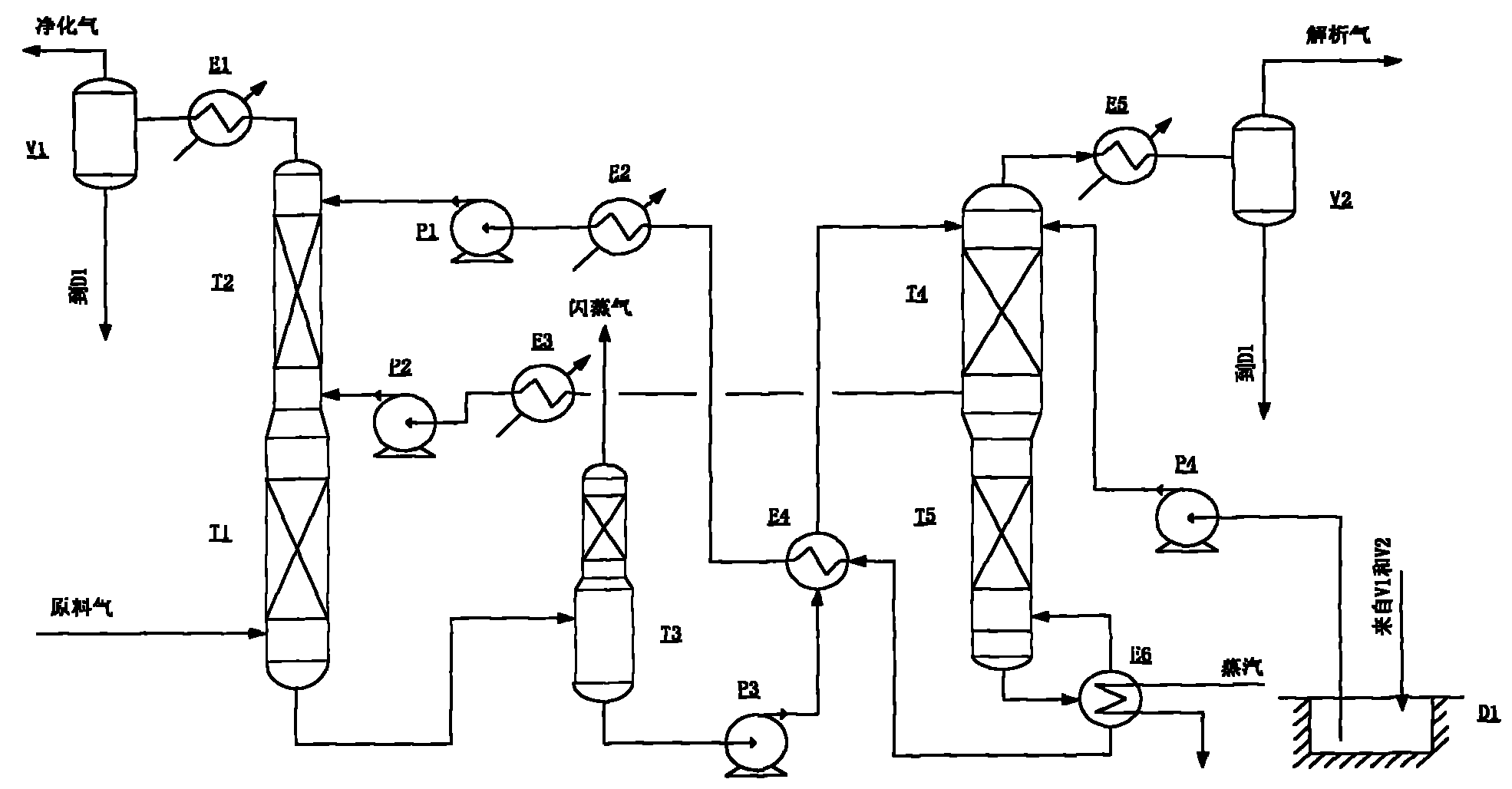

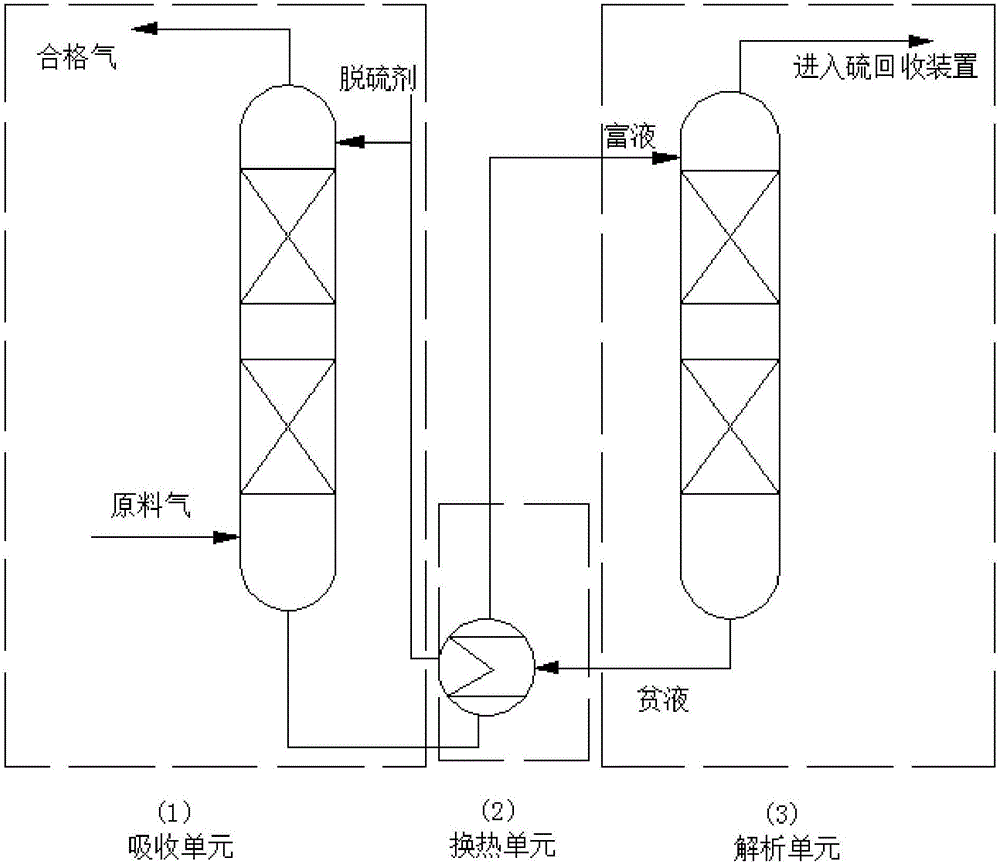

High-selectivity desulfurization system and compounding method of desulfurization agent of high-selectivity desulfurization system

InactiveCN106823744AImprove the degree of purificationLarge absorption capacityGas treatmentDispersed particle separationChemical industryAbsorption capacity

The present invention provides a high-selectivity eutectic compounding desulfurization agent, and relates to high selectivity removal of sulfides from acid gases during chemical industry production. The system comprises an absorption unit, a rich and poor liquid heat exchange unit and a desorption unit. The desulfurization absorber is a high-selectivity desulfurization compounding solvent, and is formed by compounding 40-50 wt% of N-methyldiethanolamine (MDEA), 1-5 wt% of an eutectic solvent (DES), and 45-59 wt% of water. According to the present invention, the eutectic solvent is firstly used for the removal of industrial gas H2S, wherein the H2S content after desulfurization is less than 10 ppm (the H2S recovery rate of the sulfur recovery apparatus is more than 80% and the CO2 content is less than 20 ppm); the desulfurization system has advantages of high purification degree, large absorption capacity, low regenerative energy consumption, and the like; and the eutectic desulfurization agent is non-toxic, green, and environmentally friendly, and high economic and social benefits are provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for organic silicon modified polyester type polyurethane emulsion leather finishing agent

InactiveCN103073987AImprove antibacterial propertiesImprove bindingFibre treatmentPolyurea/polyurethane coatingsPolyesterDissolution

The invention relates to a preparation method for an organic silicon modified polyester type polyurethane emulsion leather finishing agent. The conventional finishing agent is poor in comprehensive performance. The preparation method comprises the steps as follows: preparing an organic silicon modified cationic polyester type polyurethane emulsion and a finishing agent solution respectively at first and then uniformly mixing by a machine according to the weight ratio of 100:(5-10). The organic silicon modified cationic polyester type polyurethane emulsion is prepared by adding toluene diisocynate and a catalyst into dehydrated polyester polyol, reacting, adding N-methyldiethanolamine for continuing to react, and adding acetone and de-ionized water. The finishing agent solution is prepared by adding hydroxyethyl cellulose into a sodium hydroxide solution, adding epoxypropyl trimethyl ammonium chloride for reaction, washing and drying a solid product, and adding the solid product and polyvinylpyrrolidone into the de-ionized water for dissolution. The preparation method is simpler in process, and the prepared leather finishing agent is excellent in comprehensive performance and good in antibacterial properties.

Owner:HANGZHOU DIANZI UNIV

Multifunctional organic rust inhibitor and preparation method thereof

The invention relates to a multifunctional organic rust inhibitor prepared by reaction of an organic acid and a hydroxyl compound, the molar ratio of organic acid to hydroxyl compound is 1:1-1:2.5; the organic acid is an arbitrary proportion mixture of one or more than two substance of lauric acid, palmitic acid, stearic acid, benzoic acid, p-tert-butyl benzoic acid, lauroyl sarcosine and oleoyl sarcosine, the hydroxyl compound is an arbitrary proportion mixture of one or more than two substance of n-butyl alcohol, lauryl alcohol, ethanolamine, diethanolamine, triethanolamine, N-methyldiethanolamine, N, N-dimethylethanolamine, and 2-amino-2-methyl-1 - propanol. The multifunctional organic rust inhibitor can protect steel bar and concrete from erosion of chloride and sulfate and other corrosion mediums, plays a dual role of concrete self protection and steel bar corrosion protection, greatly improves the service life of a reinforced concrete structure, and is simple in synthesis process and easy to implement.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

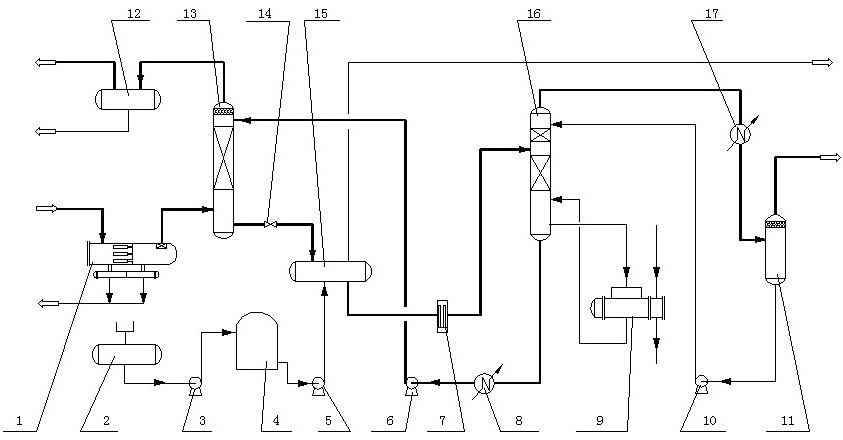

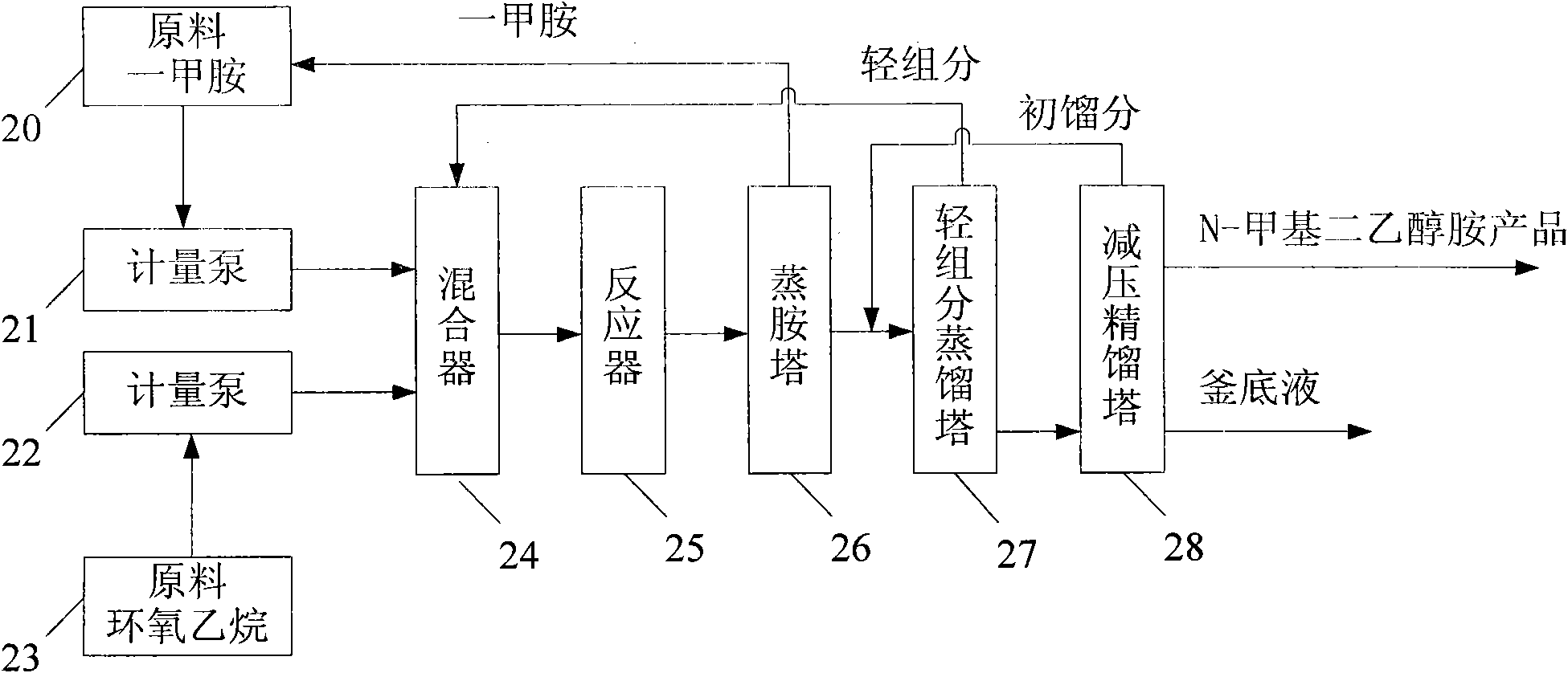

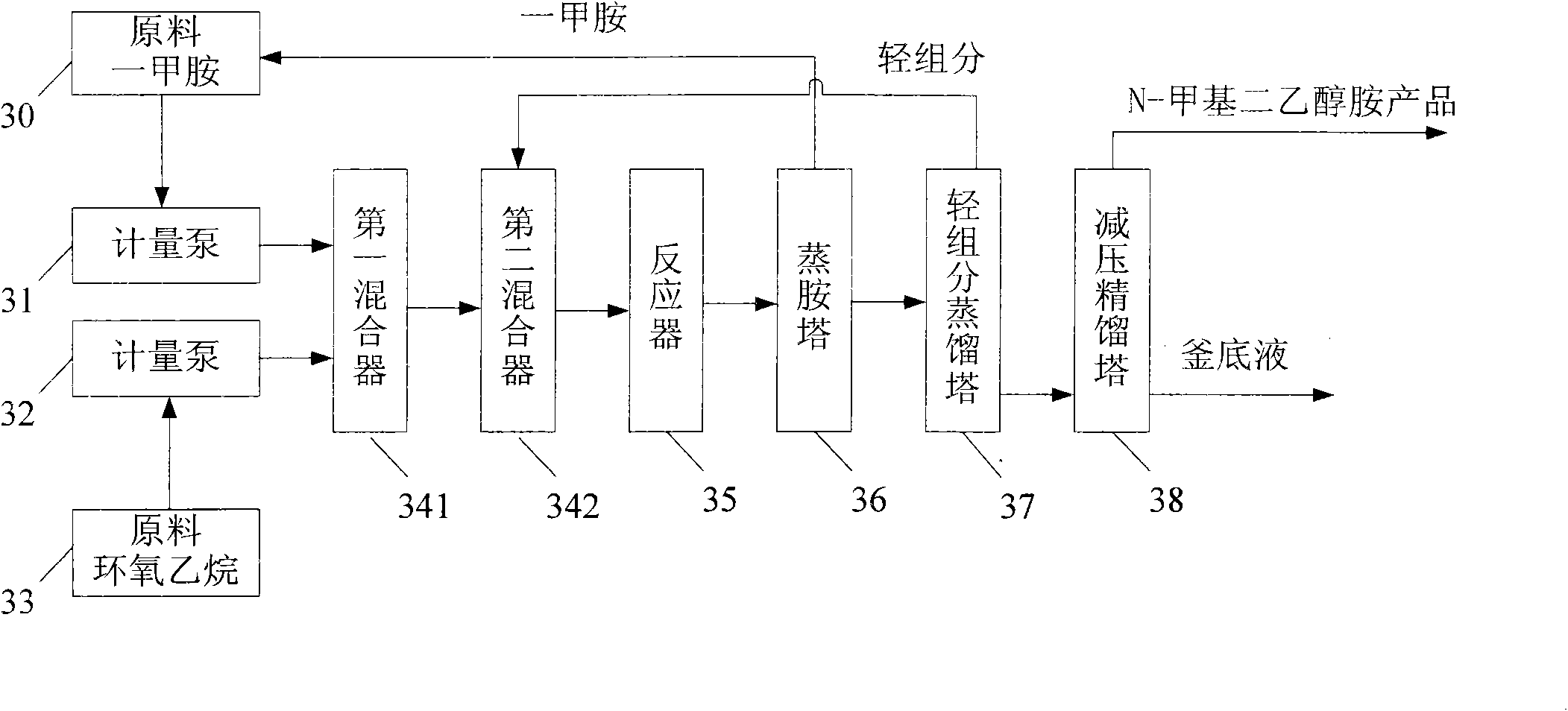

Method for continuous production of N-methyldiethanolamine

ActiveCN101781219AReduce labor intensityContinuous and stable productionOrganic compound preparationAmino-hyroxy compound preparationEpoxyChemistry

The invention relates to a method for continuous production of N-methyldiethanolamine, which comprises the following steps: (1) pumping raw materials of epoxy ethane and monomethyl amine into a mixer through a metering pump respectively for mixing, wherein the amount-to-substance ratio of the epoxy ethane to the monomethyl amine is 1:1.2-1.5; then sending the mixed raw materials into a reactor, reacting under the pressure of 3Mpa-6Mpa and the temperature of 100 DEG C-150 DEG C within the reactor, thus obtaining a mixture containing N-methyldiethanolamine; (2) sending the mixture containing N-methyldiethanolamine into an ammonia vaporizing tower, distilling and separating the crude products of monomethyl amine and N-methyldiethanolamine; and (3) sending the N-methyldiethanolamine crude product into a light component distillation tower and a vacuum distillation tower which are connected in series, distilling and separating the N-methyldiethanolamine product continuously, and recovering the N-methyldiethanolamine product from the vacuum distillation tower, wherein efficient ripple packing is arranged in the light component distillation tower and / or the vacuum distillation tower. The invention has the characteristics of continuous and steady production process, stable product quality, low material consumption and energy consumption, lowered labor intensity for operators, and easy-industrializing popularization and application.

Owner:MAOMING YUNLONG IND DEV

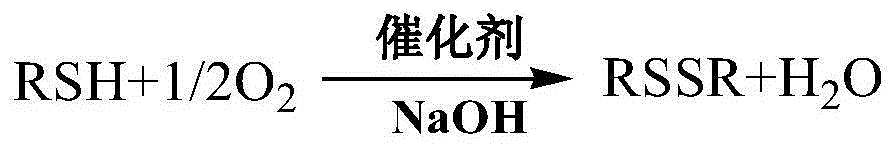

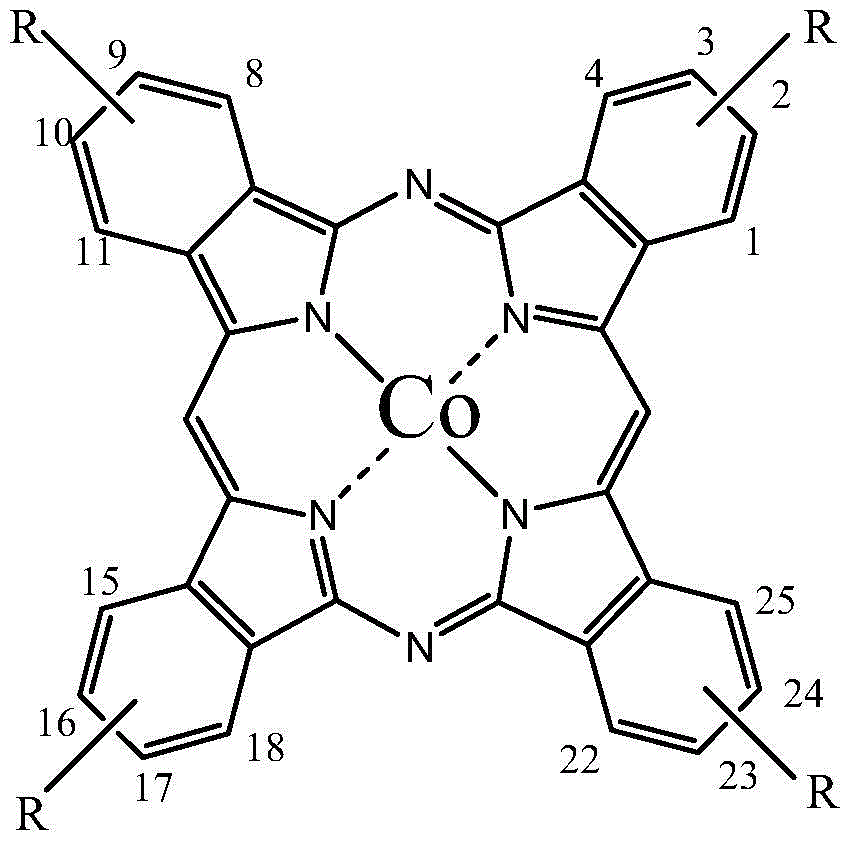

Liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal

ActiveCN104785296AImprove solubilityGood water solubilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPhthalocyanineCobalt

The invention discloses a liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal; the liquid catalyst is composed of an active component tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt, a stabilizer propylene glycol dimethyl ether, one or a combination of N-methyl diethanolamine or triethanolamine, an emulsifier octadecyl dimethyl benzyl ammonium chloride and an NaOH solution. The invention also discloses a tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt structure designed for the first time, and a catalytic conversion effect of the liquid catalyst on liquefied gas mercaptan. The catalyst active component tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt has extremely good solubility in water and alkali liquids, and has higher mercaptan removal activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of epoxy resin-modified polyurethane emulsion leather finishing agent

InactiveCN103073988AImprove antibacterial propertiesImprove bindingAntifouling/underwater paintsPaints with biocidesEpoxyHydroxyethyl cellulose

The invention relates to a preparation method of an epoxy resin-modified polyurethane emulsion leather finishing agent and aims to solve the problem of insufficient comprehensive performance of the existing finishing agent. The preparation method comprises the following steps: firstly preparing epoxy resin-modified cationic polyether type polyurethane emulsion and finishing agent solution; and then uniformly mixing in a mechanical manner according to the weight ratio of 100:5-10. A preparation method of the epoxy resin-modified cationic polyether type polyurethane emulsion comprises the following steps: adding toluene diisocynate and a catalyst into dehydrated polyoxyethylene glycol, then adding N-methyldiethanolamine for continuous reaction, regulating the pH value to 5-7 and finally adding acetone and deionized water. A preparation method of the finishing agent solution comprises the following steps: adding hydroxyethyl cellulose into sodium hydroxide solution, then adding epoxypropyl trimethyl ammonium chloride for reaction, washing and drying a solid product and dissolving into deionized water with polyvinylpyrrolidone. The preparation method has the benefits that the process is simpler; and the prepared leather finishing agent not only has high film strength and excellent comprehensive performance, but also has good antibacterial performance.

Owner:HANGZHOU DIANZI UNIV

Environmentally-friendly weak alkaline low-temperature deburring softening solution, and preparation method and use method thereof

ActiveCN102808190ALower operating temperatureImprove softening effectNo productionCryogenic deflashing

The invention discloses a preparation method and a use method of environmentally-friendly weak alkaline low-temperature deburring softening solution. The environmentally-friendly weak alkaline low-temperature deburring softening solution comprises the components with weight percentages as follows: 10 to 35 percent of tetrahydrofuran, 10 to 35 percent of propylene glycol, 1 to 5 percent of alkyl phenol polyoxyethylene ether, 5 to 20 percent of ethanolamine, 1 to 10 percent of N-methyldiethanolamine and the balance of water. The environment-friendly weak alkaline low-temperature deburring softening solution provided by the invention has the advantages of low use temperature, good softening and flashing effect, no production of poisons and harmful gases, excellent deoiling effect, safety, environmental friendliness, adoption of formula substances completely satisfying of an environmentally-friendly requirement, product stability, simple process, energy conservation and high efficiency, and is convenient to use.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

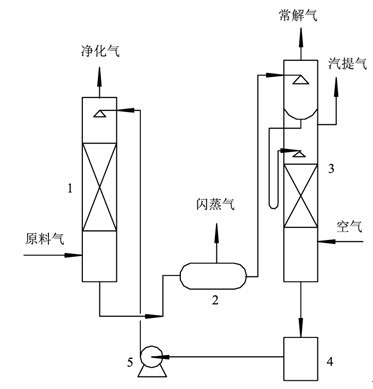

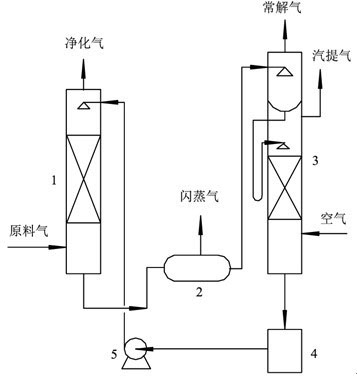

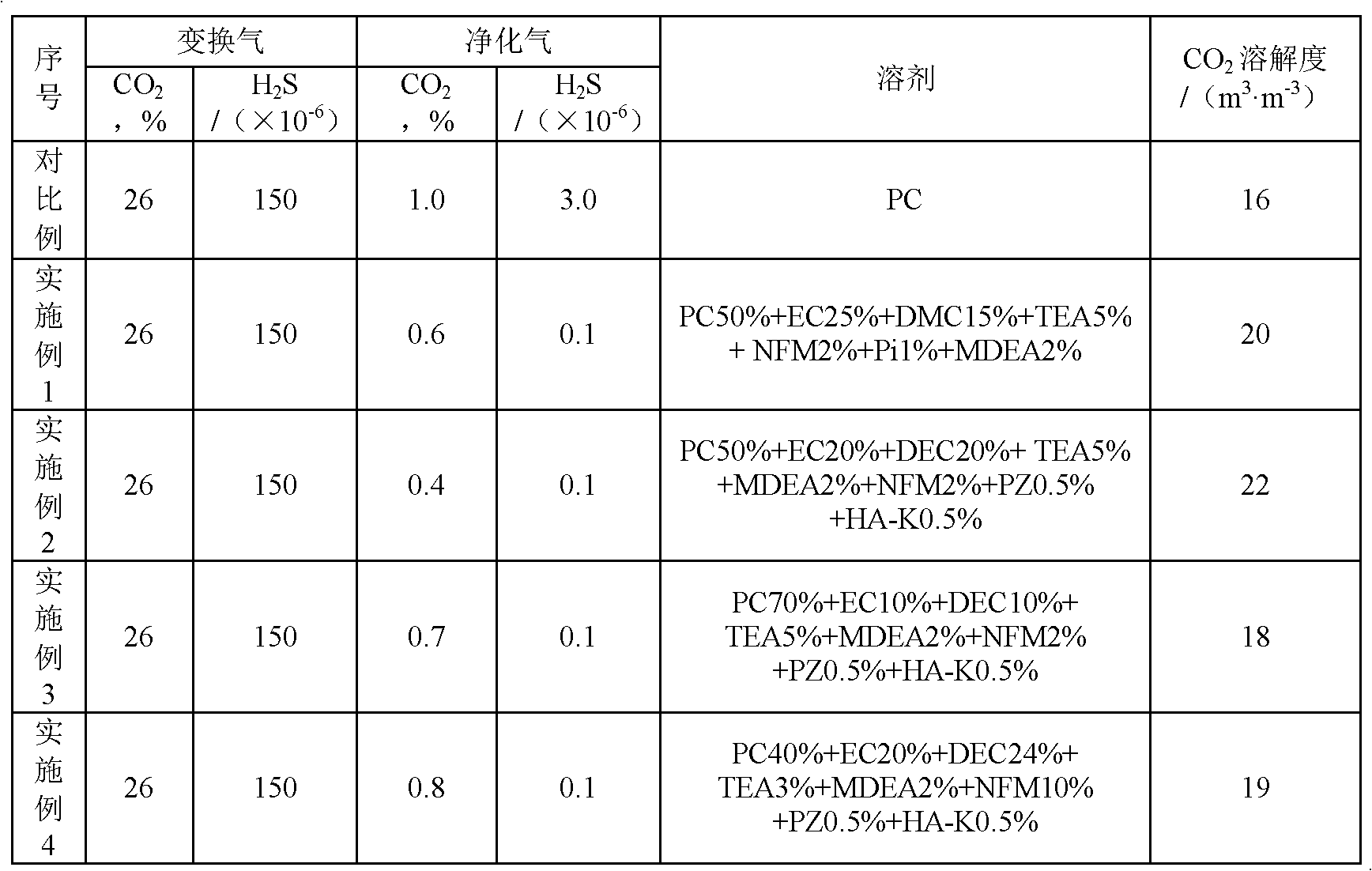

Mixed solvent for removing acid gas

InactiveCN102657998AFlexibleOptimized formulaDispersed particle separationAbsorption capacityMethyl carbonate

The invention discloses a mixed solvent for removing acid gas, which belongs to the technical field of gas separation and is characterized by being composed of two or more than two of main absorption components, assisting absorption components and active components in mixing mode, wherein the main absorption components comprise propylene carbonate (PC), ethylene carbonate (EC), dimethyl carbonate (DMC), diethyl carbonate (DEC) and N-methyl-2-pyrrolidone (NMP), the assisting absorption components comprise N-methyldiethanolamine (MDEA), triethanolamine (TEA), diglycolamine (DGA) and dimethylethanolamine (DMEA), and the active components comprise phosphoric acid (Pi), piperazine (PZ), urotropin (HA-K), N-Formylmorpholine formylmorpholine (NFM), 2-amino-2methyl-1-propyl alcohol (AMP) and morpholine by-products. By means of the mixed solvent for removing acid gas, on one hand, absorption capacity and purification of CO2 are improved, and on the other hand, desulfuration accuracy is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

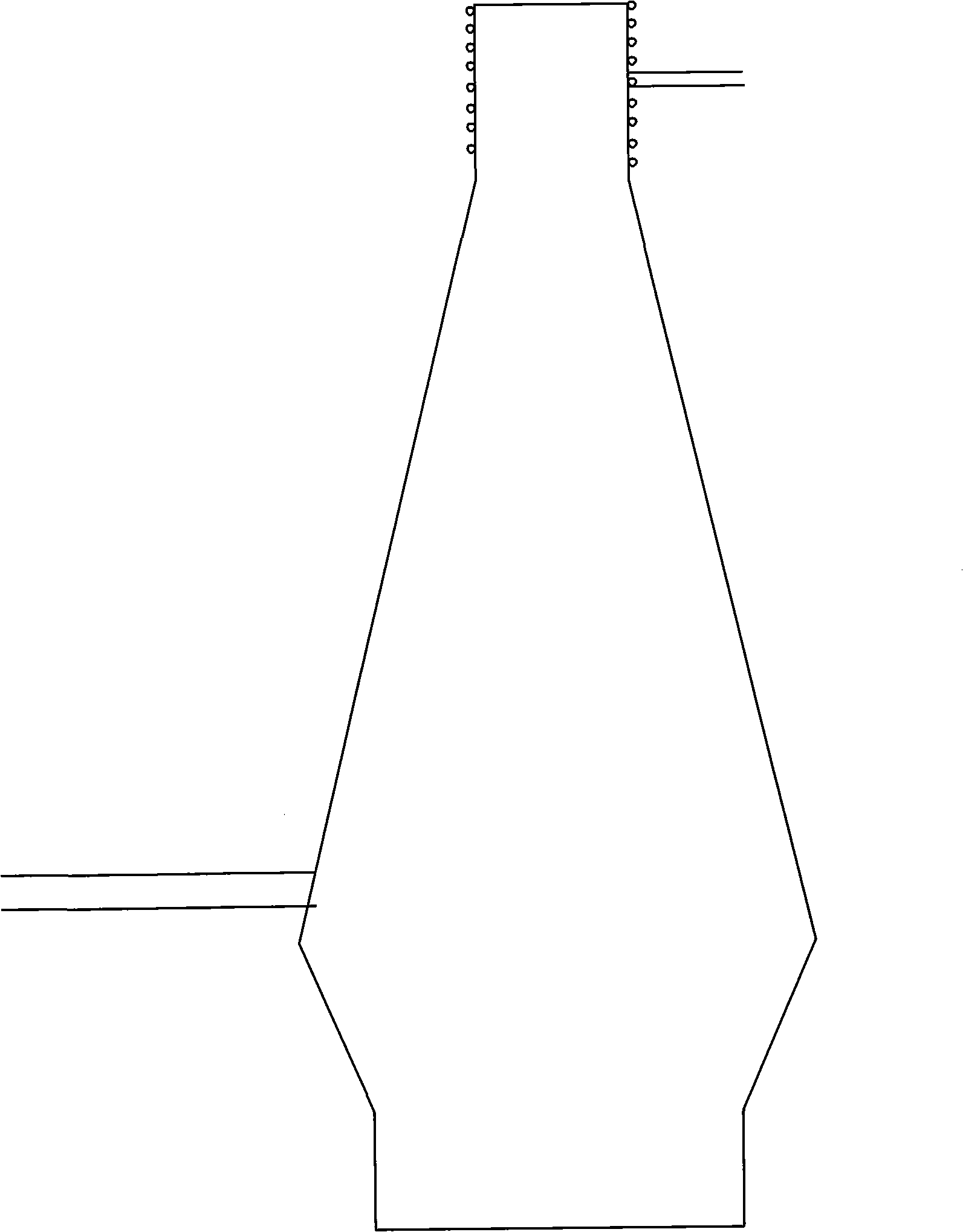

Method and device for selectively removing hydrogen sulfide from gas by utilizing amine droplets

The invention relates to a method and a device for selectively removing hydrogen sulfide from gas by utilizing amine droplets, and provides the method for selectively removing hydrogen sulfide from gas by utilizing amine droplets. The method comprises the steps of (1) atomizing N-methyldiethanolamine solution into droplets with particle size of not larger than 50 micrometer; (2) uniformly mixing the droplets with hydrogen sulfide-containing mixed gas, and introducing into a micro-swirler; (3) allowing thorough contact and reaction between N-methyldiethanolamine droplets and hydrogen sulfide in the micro-swirler to transfer hydrogen sulfide into the droplets, and meanwhile separating the hydrogen sulfide-absorbed droplets from gas; and (4) enriching the hydrogen sulfide-absorbed droplets, recycling, regenerating, and circulating to the step (2). The invention also provides the device for selectively removing hydrogen sulfide from gas by utilizing amine droplets.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

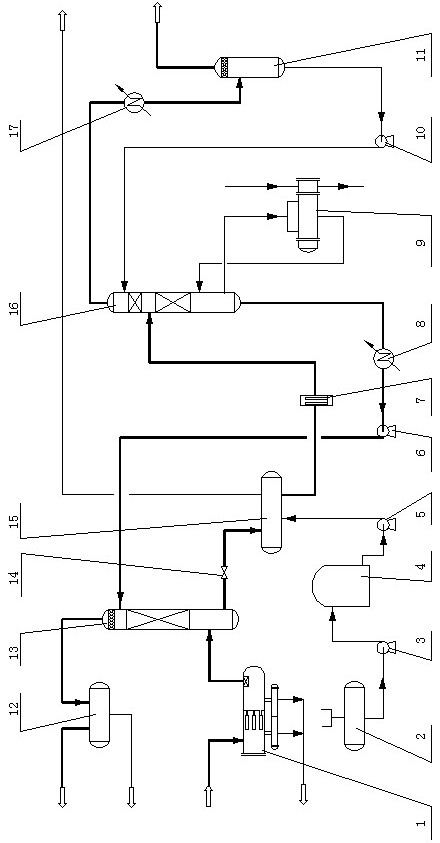

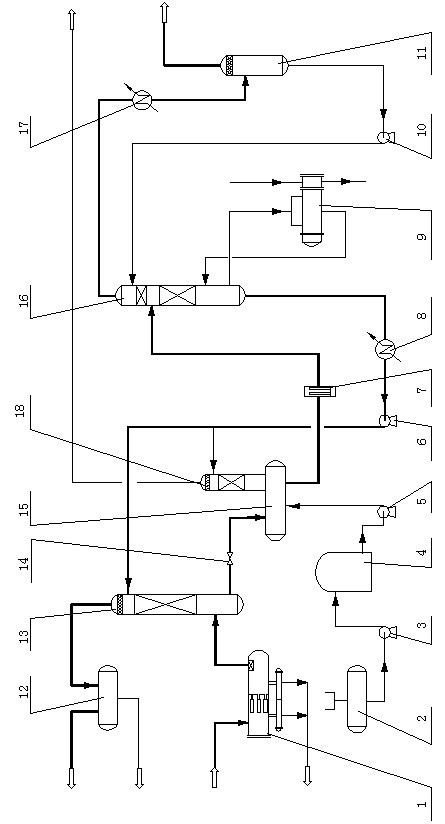

System and technology for trapping CO2 in smoke

The invention discloses an absorbent for trapping CO2 in smoke and a trapping regeneration technology, and belongs to the technical field of smoke purification. The CO2 trapping technology includes the absorbent, a CO2 absorbing system and a regeneration system. The absorbent is an aqueous solution of N-methyldiethanolamine (MDEA) and piperazine (PZ), the concentration of the PZ is 10wt.% to 20wt.%, and the concentration of the MDEA is 30wt.% to 40wt.%. The absorbing system comprises an absorbing tower and an intermediate cooling system, and rapid and high-capacity absorption can be achieved; the distributed rich liquor feeding technology is adopted for the regeneration system, a poor-rich-liquor heat exchange unit is designed in the middle of a desorption tower, high integration of system energy is achieved, the energy consumed in the regeneration process of the absorbent is greatly reduced, and the energy efficiency of the whole process is effectively improved. The absorbent and the trapping regeneration technology are suitable for flue gas of coal-fired power plants and the like and the fields in which the requirements for decarburization efficiency are not high in the chemical industry.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com