Method for synthesizing C-level polyurethane wire enamel

A technology of polyurethane paint and synthesis method, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of restricting the development of electrical insulation industry, poor heat resistance, influence of physical properties of products, etc., and achieve good solderability and physical properties, The effect of high heat resistance and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

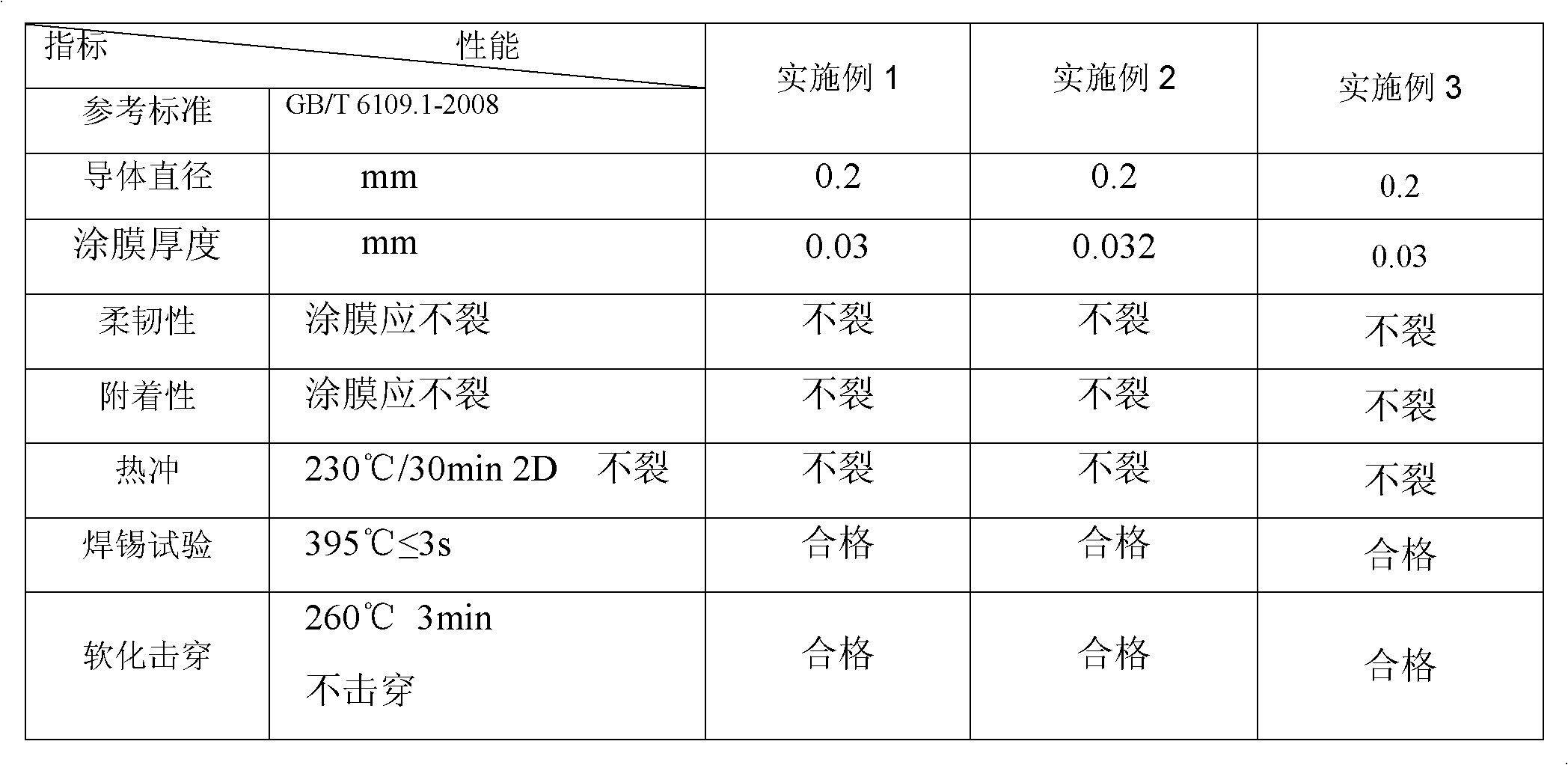

Examples

Embodiment 1

[0019] Add metered tris-(2-hydroxyethyl)isocyanurate (1.0mol), N-methyldiethanolamine (6.5mol), 3,3 ', 4,4'-biphenyltetracarboxylic dianhydride (0.8mol) and catalyst zinc acetate, heated to 100-120°C, then added dimethyl terephthalate (5.2mol), stirred and dissolved, heated to 150 Reaction at ℃ for 4 hours, program temperature rise to 220℃ for reaction, when the temperature of the distillation head is lower than 60℃, carry out vacuum operation, the pressure first decreases and then increases, first slow and then fast, until the viscosity is between 950-1300mPas (25℃), stop the vacuum Operation, taking samples to measure acid value 2.49, hydroxyl value 147.1, adding measured cresol to dissolve until clarification.

[0020] Add a certain amount of diphenylmethane diisocyanate into a three-necked reaction flask equipped with a reflux condenser, a thermometer and a stirrer, add the same amount of DMF and stir to dissolve, add the catalyst tris-(dimethylaminomethyl)phenol, and heat...

Embodiment 2

[0023] Add metered tris-(2-hydroxyethyl)isocyanurate (1.0mol), N-methyldiethanolamine (6.5mol), 3,3 ',4,4'-benzophenonetetraacid dianhydride (0.8mol) and catalyst zinc acetate, heated to 100-120°C, then added dimethyl terephthalate (5.2mol), stirred and dissolved, heated to 150 Reaction at ℃ for 4 hours, program temperature rise to 220℃ for reaction, when the temperature of the distillation head is lower than 60℃, carry out vacuum operation, the pressure first decreases and then increases, first slow and then fast, until the viscosity is between 950-1300mPas (25℃), stop the vacuum Operation, take a sample to measure acid value 2.71, hydroxyl value 198.2, add metered cresol to dissolve until clarification.

[0024] With 160.1g of the above-mentioned polyester polyol, 700.2g of MDI trimer in Example 1, 850.1g of cresol, 430.2g of xylene, 201.1g of DMF, 35.1g of zinc isooctanoate, heated and stirred and mixed uniformly, obtained yellow transparent Lacquer liquid, solid content 3...

Embodiment 3

[0026] Add metered tris-(2-hydroxyethyl)isocyanurate (1.0mol), N-methyldiethanolamine (6.5mol), pyromellitic Formic acid dianhydride (0.8mol) and catalyst zinc acetate, heated to 100-120°C, then added dimethyl terephthalate (5.2mol), stirred to dissolve, heated to 150°C for 4 hours, programmed temperature rise to 220°C for reaction, When the temperature of the distillation head is lower than 60°C, carry out vacuum operation, the pressure first decreases and then increases, first slow and then fast, until the viscosity is between 950-1300mPas (25°C), stop the vacuum operation, take a sample to measure the acid value 1.35, the hydroxyl value 210.4 , add metered cresol to dissolve until clarified.

[0027] 150.1g of the above-mentioned polyester polyol, 800.2g of MDI trimer in Example 1, 851.1g of cresol, 433.2g of xylene, 204.1g of DMF, and 34.1g of zinc isooctanoate were heated and stirred evenly to obtain a yellow transparent Lacquer solution, solid content 32% (180°C / 2g / 1h),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com