Method for preparing N-methyldiethanolamine

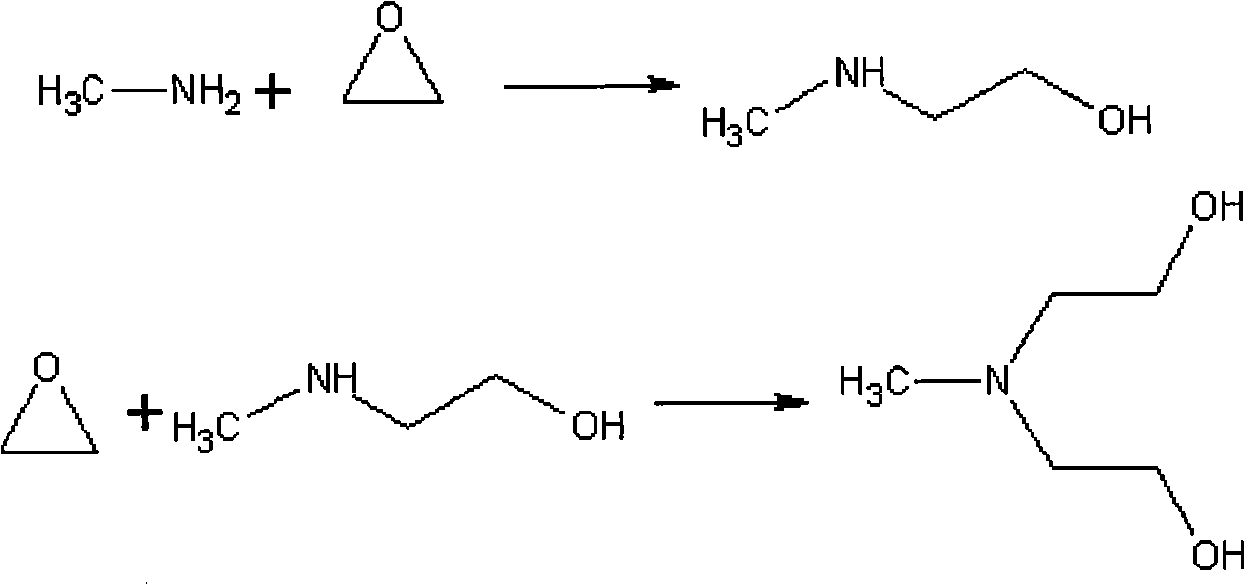

A technology of methyldiethanolamine and methylamine, which is applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, chemical instruments and methods, etc., can solve problems such as multi-environmental protection and cost, raw material consumption, etc., so as to reduce cost consumption, The effect of reducing the consumption of raw materials and reducing the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

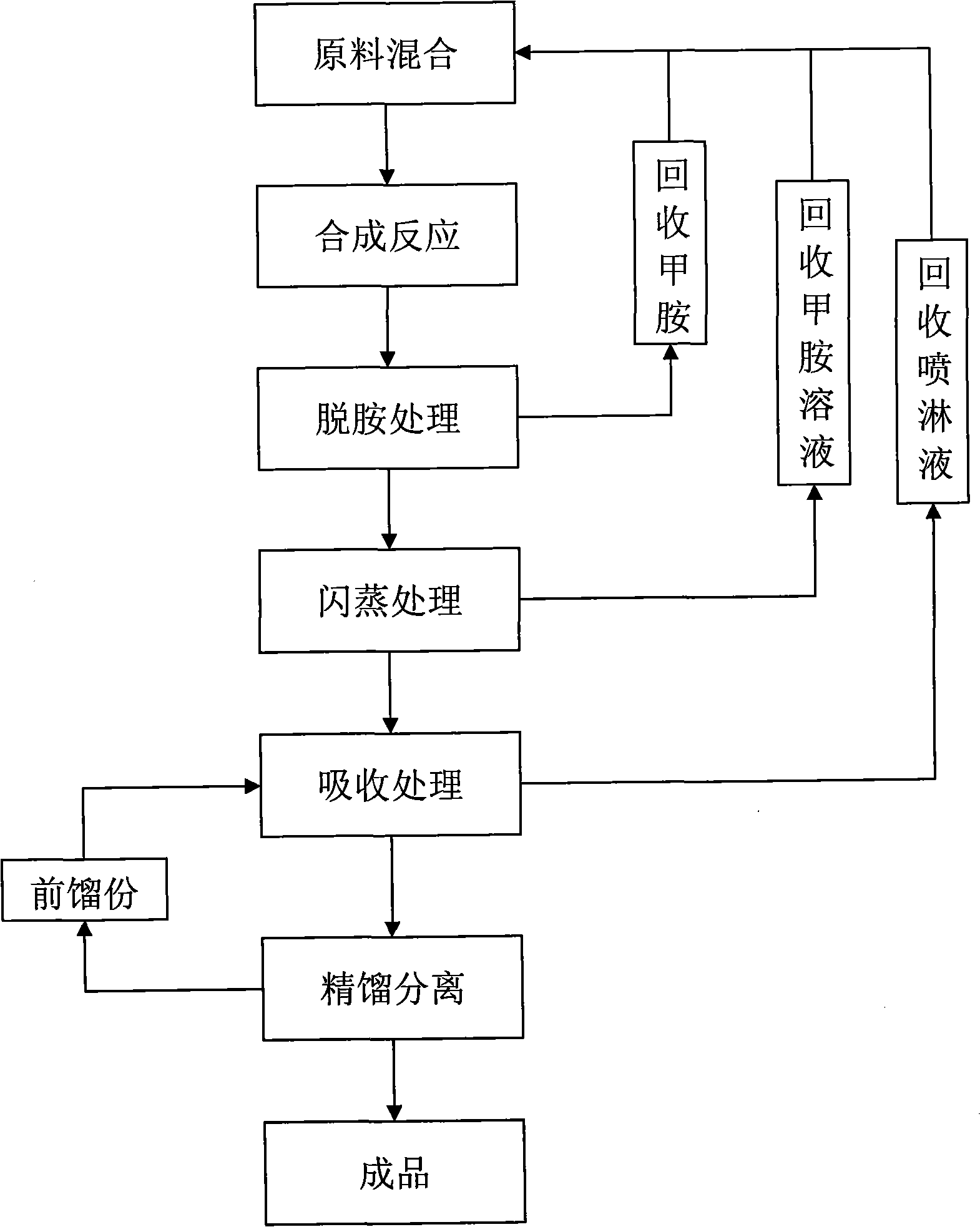

[0027] according to figure 1 Shown process flow sheet prepares N-methyldiethanolamine,

[0028] a. Mixing of raw materials: raw materials ethylene oxide, methylamine and circulating fluid are mixed in a mixer, wherein the ratio of ethylene oxide to the total amount of methylamine is 1:2;

[0029] b. Synthesis reaction: transfer the mixed raw materials into the reactor, the internal pressure of the reactor is increased to 6MPa, the temperature is controlled at 135°C, and a mixture containing N-methyldiethanolamine is obtained by the end of the reaction;

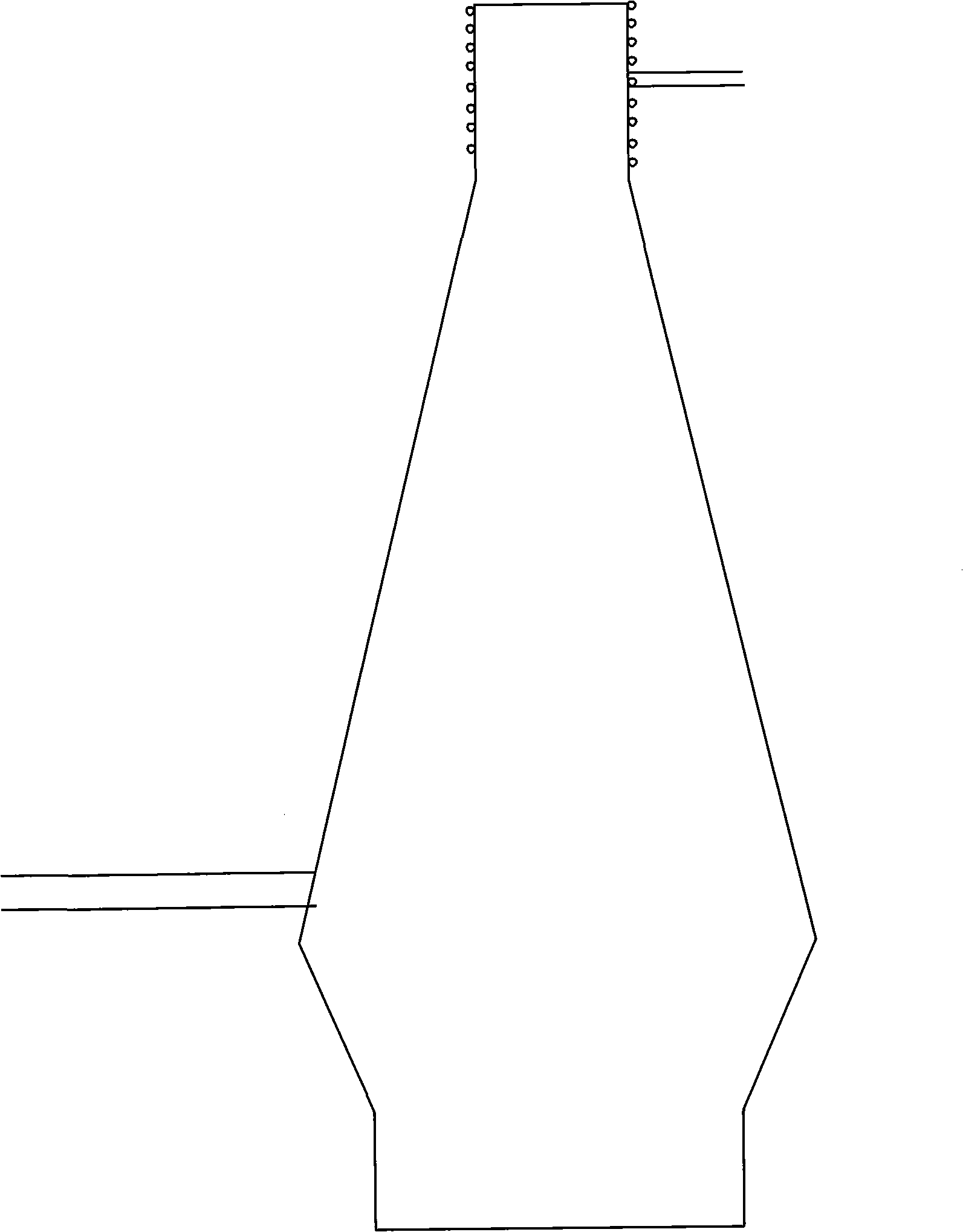

[0030] c. Deamination treatment: the pressure will be reduced to 1MPa by the mixture containing N-methyldiethanolamine through the first decompression valve, and the deamination tower used is such as figure 2 The tower body, tower kettle and condenser are shown in the figure. The tower kettle is installed at the lower end of the tower body, through the transition of the conical shell with folded edges. Condenser, the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com