Method for continuous production of N-methyldiethanolamine

A technology of methyldiethanolamine and monomethylamine, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve the problems of low product yield, low product purity, increased material consumption, etc. The product quality is stable, the separation effect is improved, and the production capacity is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

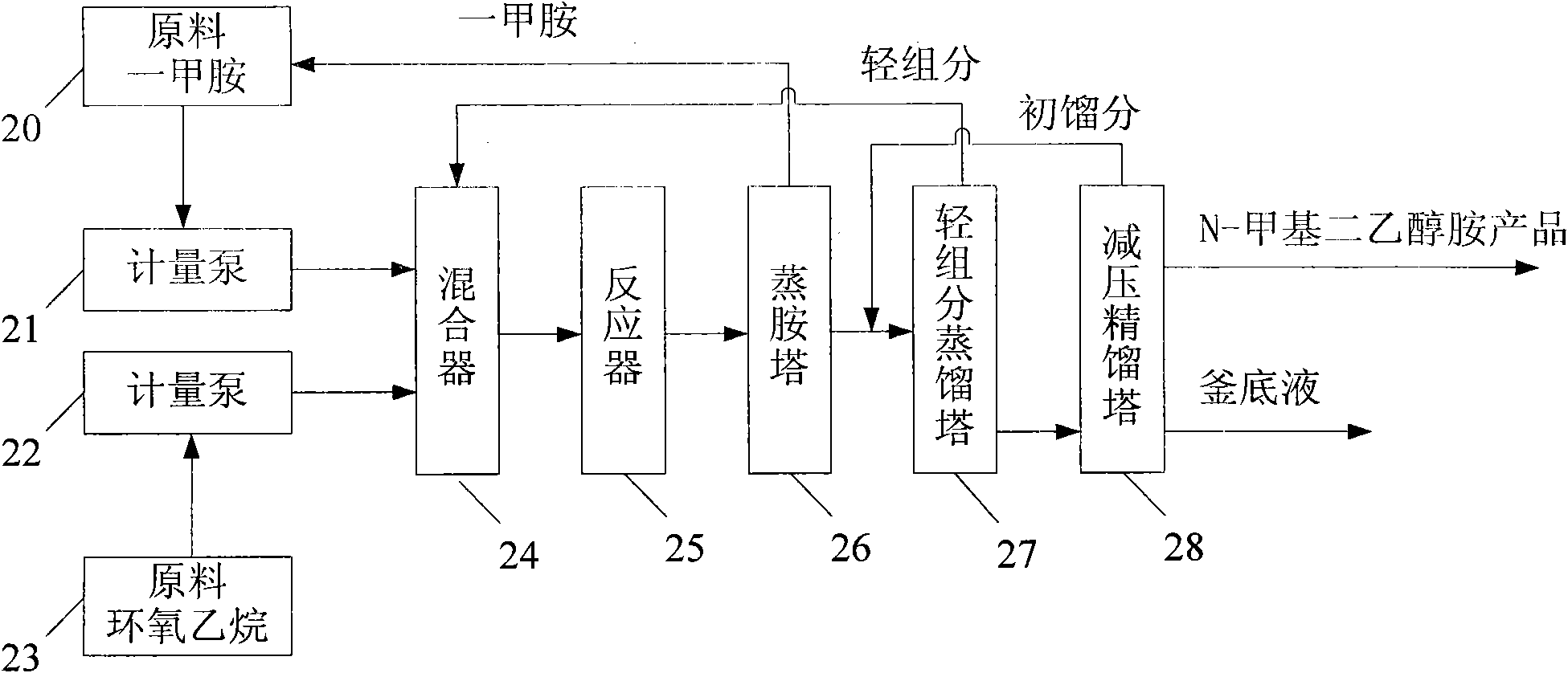

[0036] A kind of embodiment of the method for continuous production of N-methyldiethanolamine of the present invention is as figure 2 shown, including the following steps:

[0037] (1) After the raw material ethylene oxide 23 and the raw material monomethylamine 20 are pumped into the mixer 24 through the metering pumps 21 and 22 for mixing, the mixed raw materials enter the reactor 25, and are mixed in the reactor 25. The pressure inside is 3Mpa-6Mpa, and the temperature is controlled at 100°C-150°C for reaction to generate a mixture containing N-methyldiethanolamine. The raw materials are sent into the mixer 24 through the pipeline for mixing by means of pump pressure, and the raw materials are sent into the mixer 24 for mixing first, which is beneficial to improve the yield of the product, and its conversion rate and selectivity are high.

[0038] The ratio of the raw material ethylene oxide to the raw material monomethylamine is 1:1.2-1.5.

[0039] (2) The mixture conta...

Embodiment 2

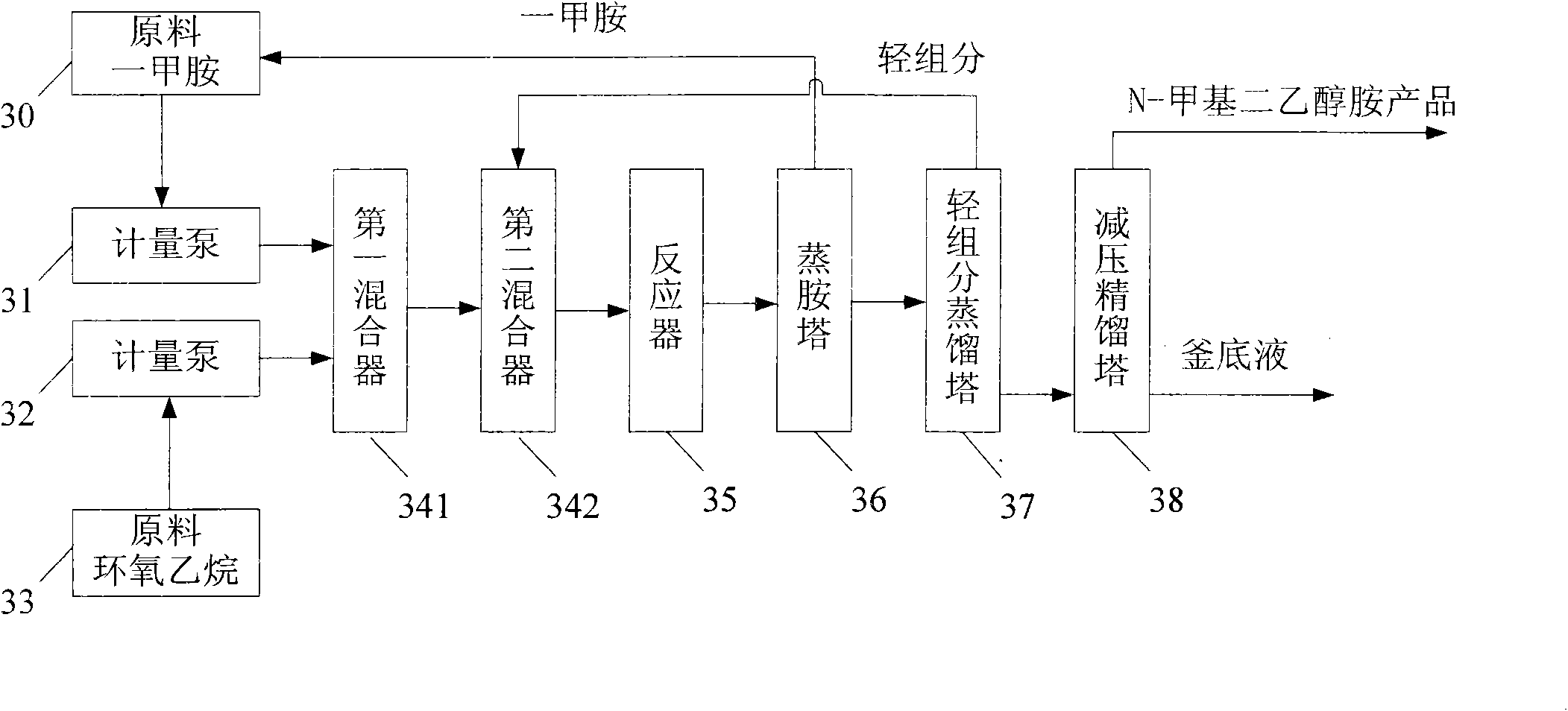

[0065] Another embodiment of a method for continuously producing N-methyldiethanolamine of the present invention is as image 3 shown, including the following steps:

[0066] (1) The raw material ethylene oxide 33 and the raw material monomethylamine 30 are pumped into the first mixer 341 through the metering pumps 31 and 32 for preliminary mixing, and then the raw materials after the preliminary mixing are sent into the second mixer 342 for further mixing. After further mixing, it enters into the reactor 35 and reacts under the condition that the pressure in the reactor 35 is 3Mpa-6Mpa and the temperature is controlled at 100°C-150°C to generate a mixture containing N-methyldiethanolamine. The raw materials are sent to the first mixer 341 through pipelines by pump pressure for preliminary mixing, and then sent to the second mixer 342 for further mixing, which is conducive to improving the yield of the product, and its conversion rate and selectivity are also high.

[0067] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com