Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Molecular decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular decomposition process is an electrochemical grinding process that has been refined to enable: – The removal of increased amount of material while maintaining workpiece temperature to within 1ºF.

Gas reformulation system comprising means to optimize the effectiveness of gas conversion

InactiveUS20080277265A1Facilitate speedImprove efficiencyCombustible gas chemical modificationHydrogenHydrogenControl system

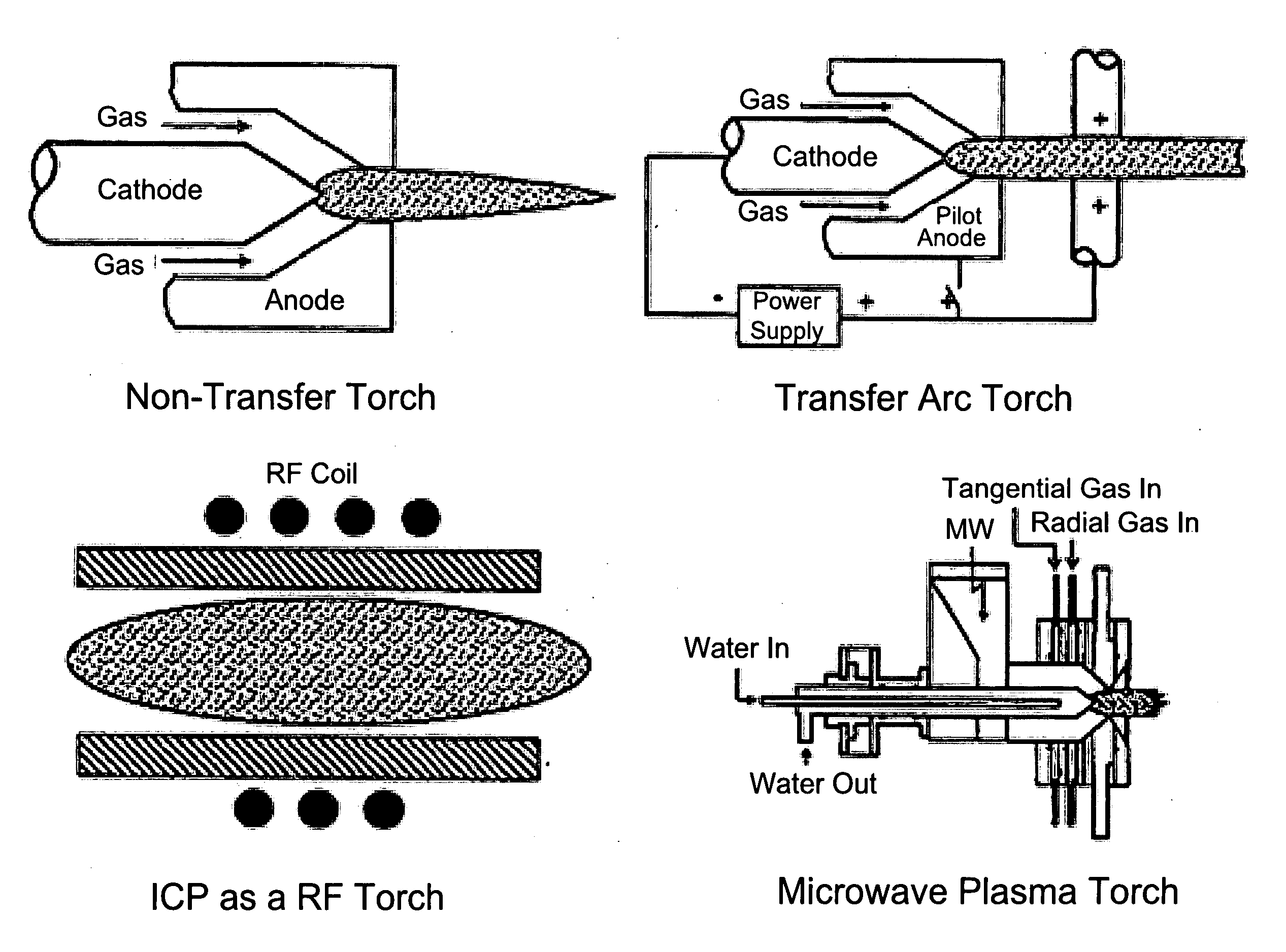

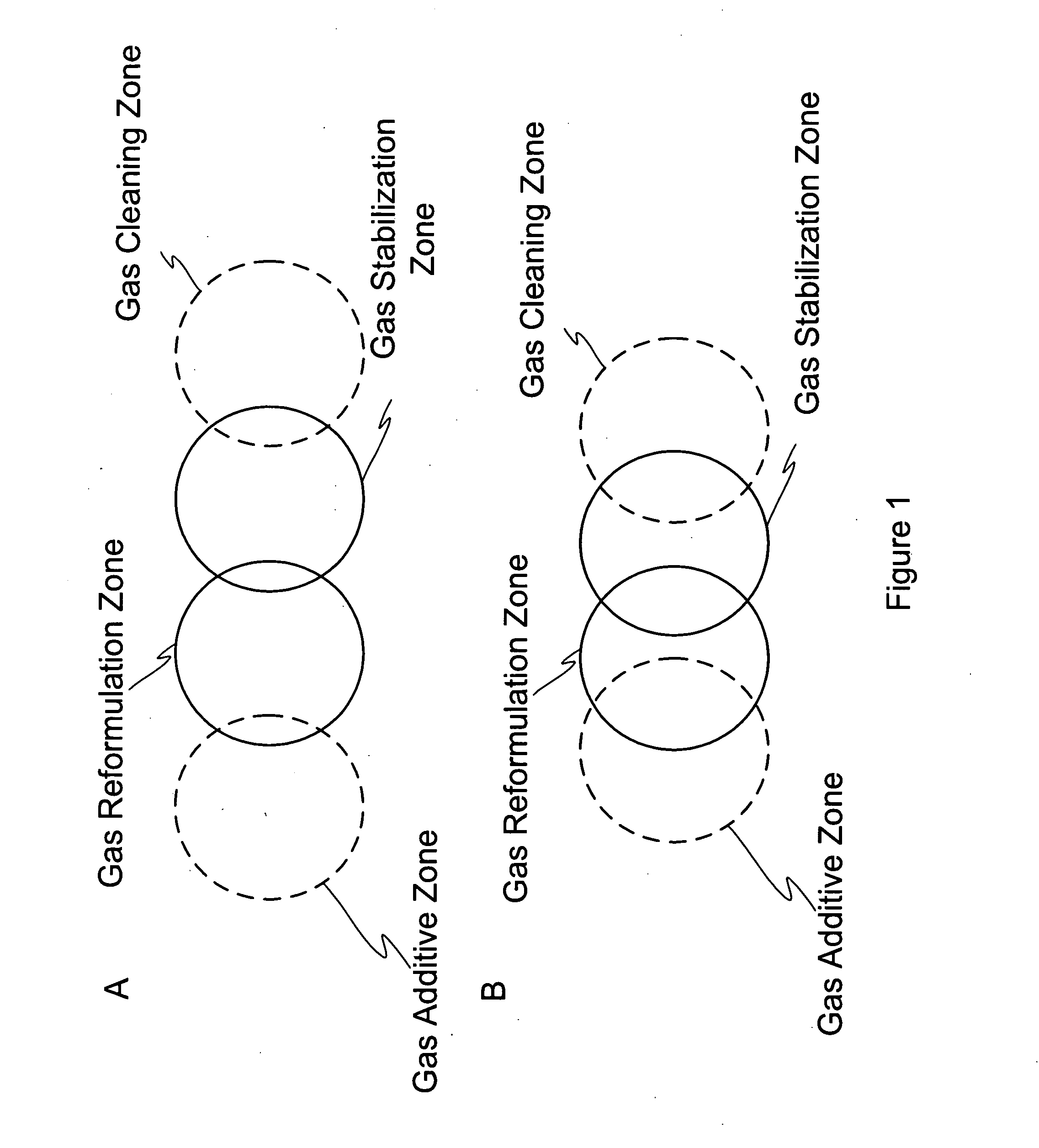

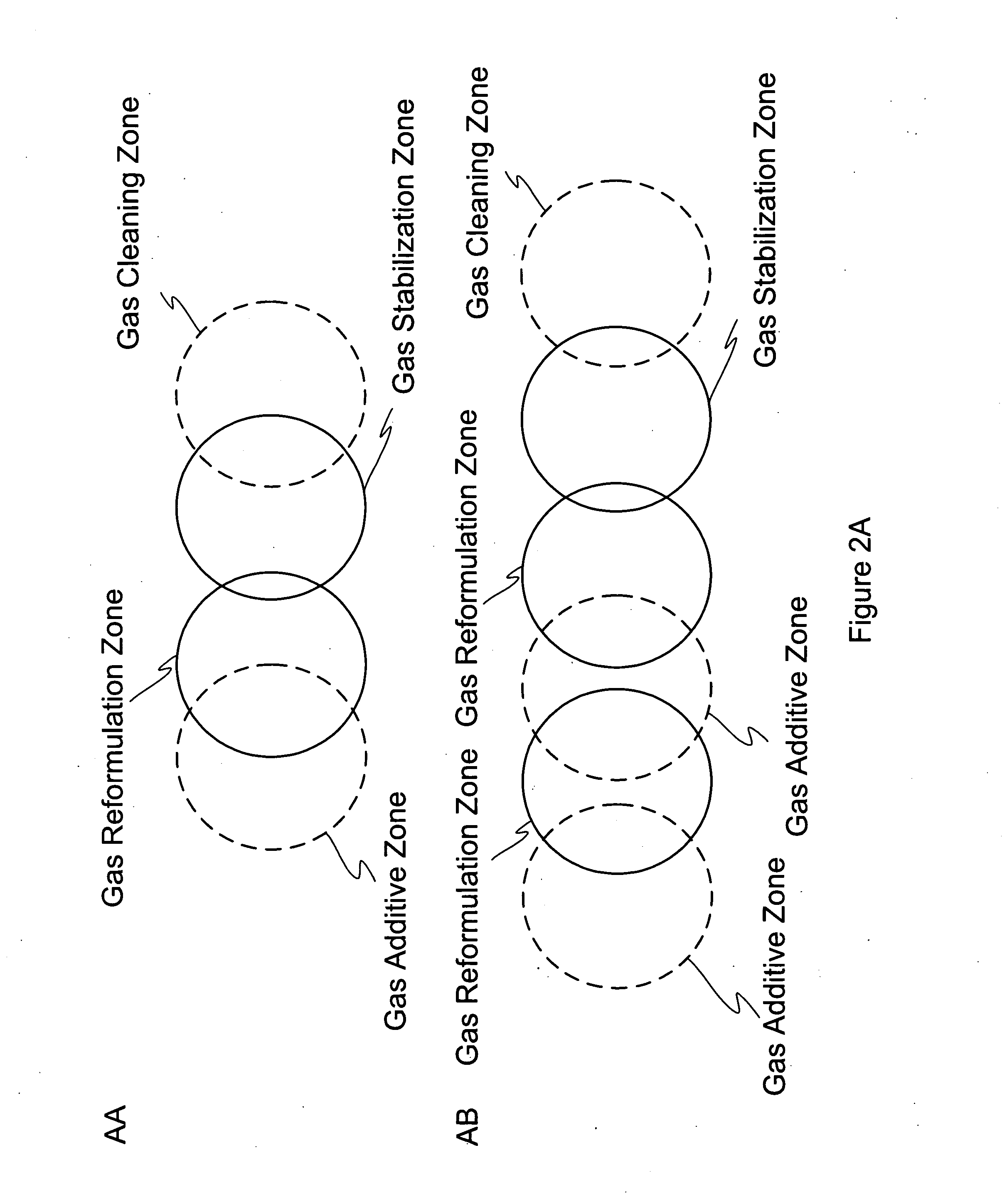

This invention provides a system and method for efficient reformulation of an initial gas with associated characteristics into an output gas with desired characteristic parameters, within a substantially sealed, contained, and controlled environment. The gas reformulating system uses a gas energizing field to disassociate the initial gas molecules and molecules of injected process additives of appropriate types and amounts, into their constituents that then recombine to form the output gas with the desired parameters. The gas reformulating system further comprises a control system that regulates the process and thereby enables the process to be optimized. The gas energizing field may be provided at least partly by hydrogen burners or plasma torches.

Owner:PLASCO ENERGY GROUP INC

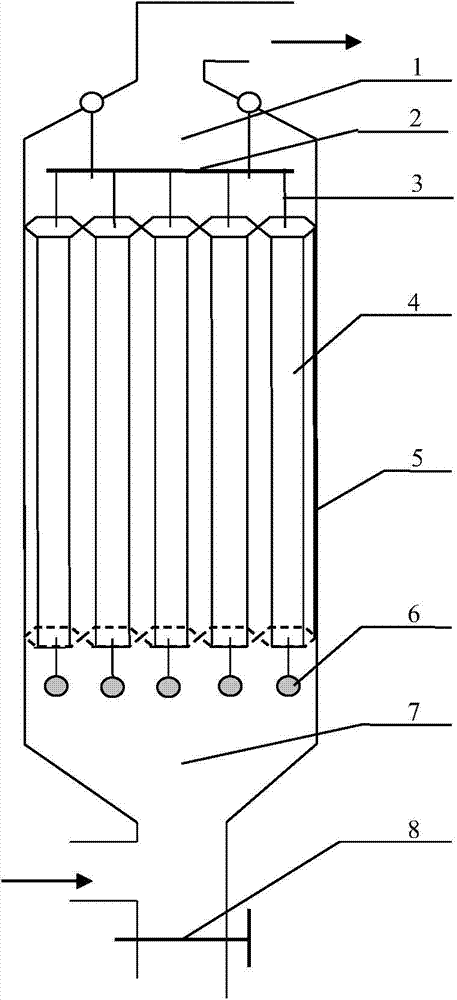

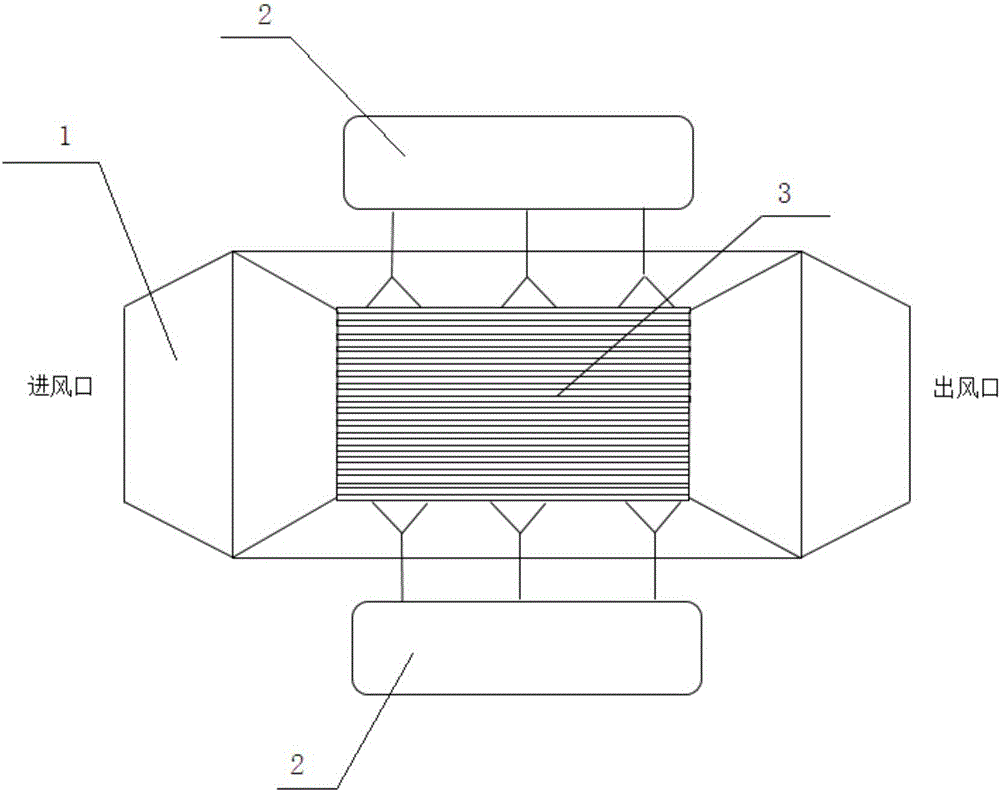

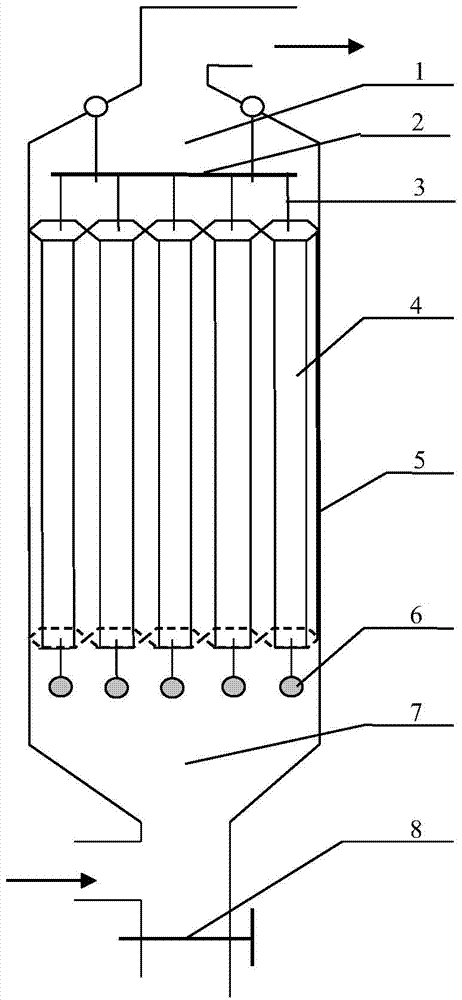

Filling type device for purifying VOCs (Volatile Organic Compounds) through low-temperature plasma synergistic adsorption and catalysis

InactiveCN105749744AReduce concentrationGuaranteed dwell timeGas treatmentDispersed particle separationEngineeringSmall footprint

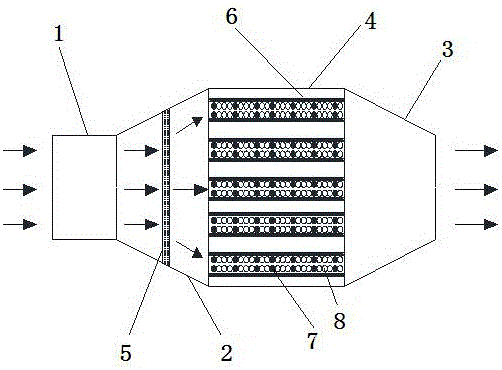

The invention discloses a filling type device for purifying VOCs (Volatile Organic Compounds) through low-temperature plasma synergistic adsorption and catalysis. The device comprises a pre-dedusting device and a shell, wherein the shell comprises an inlet horn with a small front part and a big rear part, a middle section and an outlet horn with a big front part and a small rear part; the pre-dedusting device, the inlet horn, the middle section and the outlet horn are communicated in sequence; a low-temperature plasma reactor is arranged in the middle section; the low-temperature plasma reactor is filled with a catalyst and activated carbon; the low-temperature plasma reactor is connected with a high-frequency and high-voltage power supply. The device integrates the low-temperature plasma technology and the adsorption and catalysis technology and improves the removal rate of the VOCs through mutual cooperation. The purifying device has the characteristics of being efficient in pollutant molecular decomposition and low in treatment energy consumption, adopts a one-section type structure and is small in floor area, so that a new idea is opened up for the treatment of the industrial VOCs.

Owner:ZHEJIANG ZHONGTAI ENVIRONMENTAL PROTECTION EQUIP CO LTD

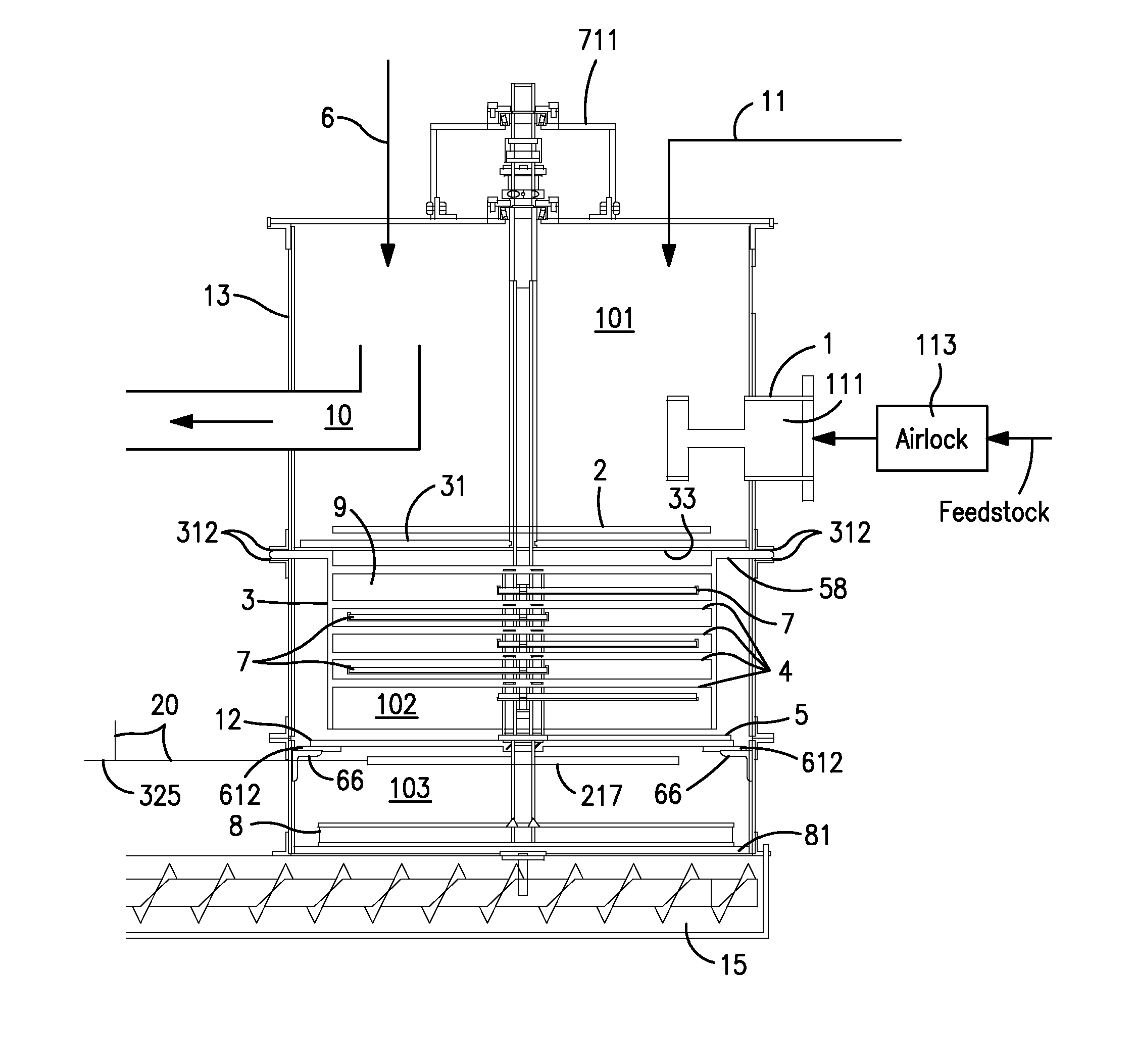

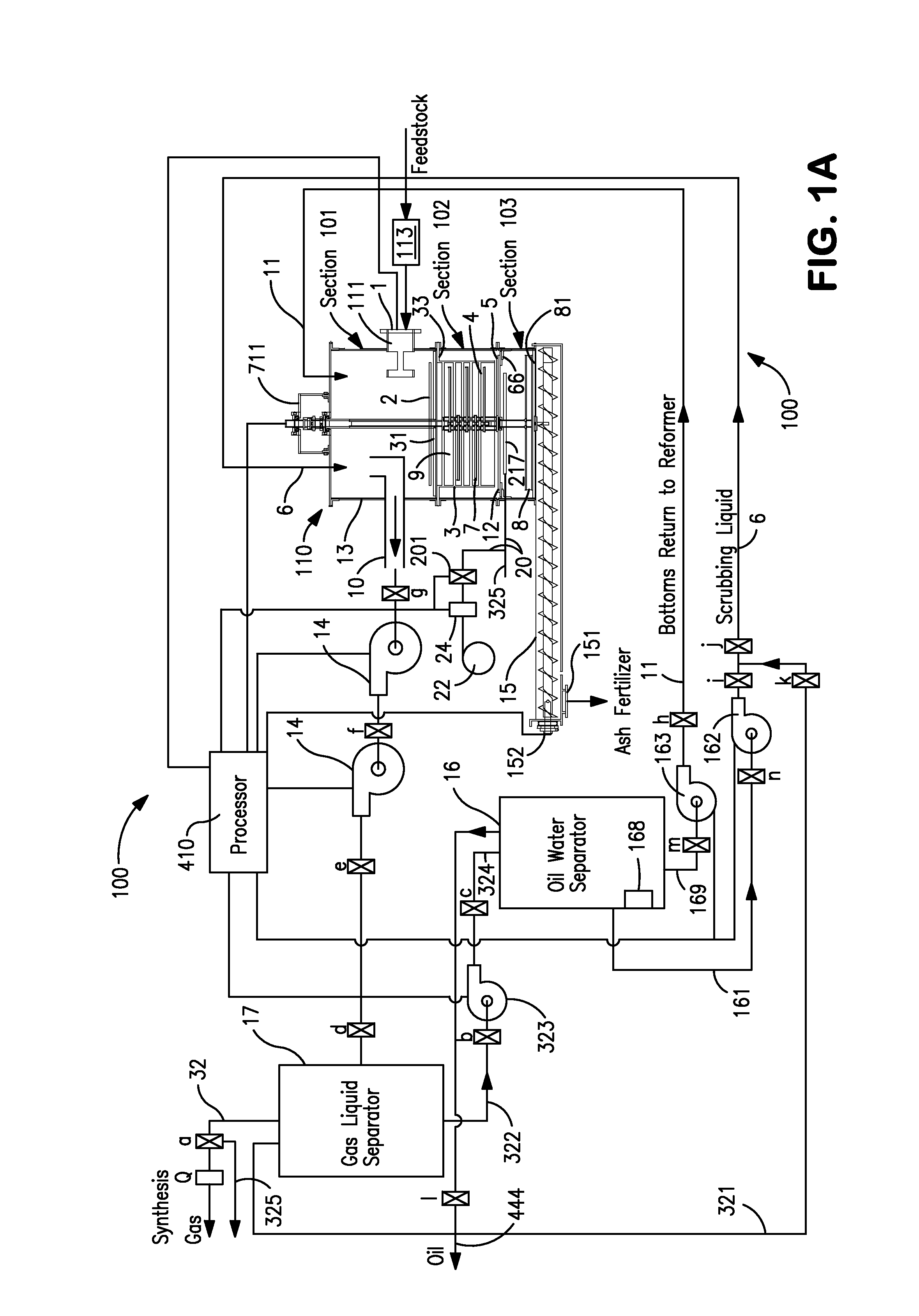

Apparatus and method for conversion of solid waste into synthetic oil, gas, and fertilizer

ActiveUS9005536B1Overcome problemsHigh energyExcrement fertilisersDirect heating destructive distillationChemistrySynthetic oil

Apparatus and method converting feedstock (e.g., chicken litter) into oil, gas, and ash fertilizer has a reformer unit with (i) a feedstock input, (ii) an outer wall, (iii) a reaction chamber with an inner wall, (iv) a combustion gas input, (v) a scrubbing liquid input, (vi) a feedstock stirrer, (vii) an ash stirrer, (viii) an ash plate below the reaction chamber, and (ix) a combined liquid / gas output. The ash plate is separated from the inner wall. Feedstock and scrubbing liquid are preferably reacted within the reaction chamber to release useful hydrocarbon liquids and gasses which migrate to the top of the reformer, while ash from the reaction falls onto the ash plate from where it is output. Liquid / gas pump structure sends the combined liquid / gas from the reformer to gas / liquid separator structure which provides a gas output and a liquid output. The gas output may be used, flamed off, and / or recirculated to the reaction chamber. Oil / water separator structure receives the liquid output and provides a (e.g., scrubbing) water output and an oil output. Processor structure controls the various motors, valves, etc., to control the inputs / outputs and the temperature of the reformer so as to cause an electric current to flow upward along the inner wall and inward toward the reaction product within the reaction chamber to cause arcing in the feedstock; which arcing disassociates molecules into atoms, thus releasing more energy. The oil is refinable, the gas is high in energy content, and the ash fertilizer is high in nitrogen.

Owner:RIOMAR ENERGY LLC

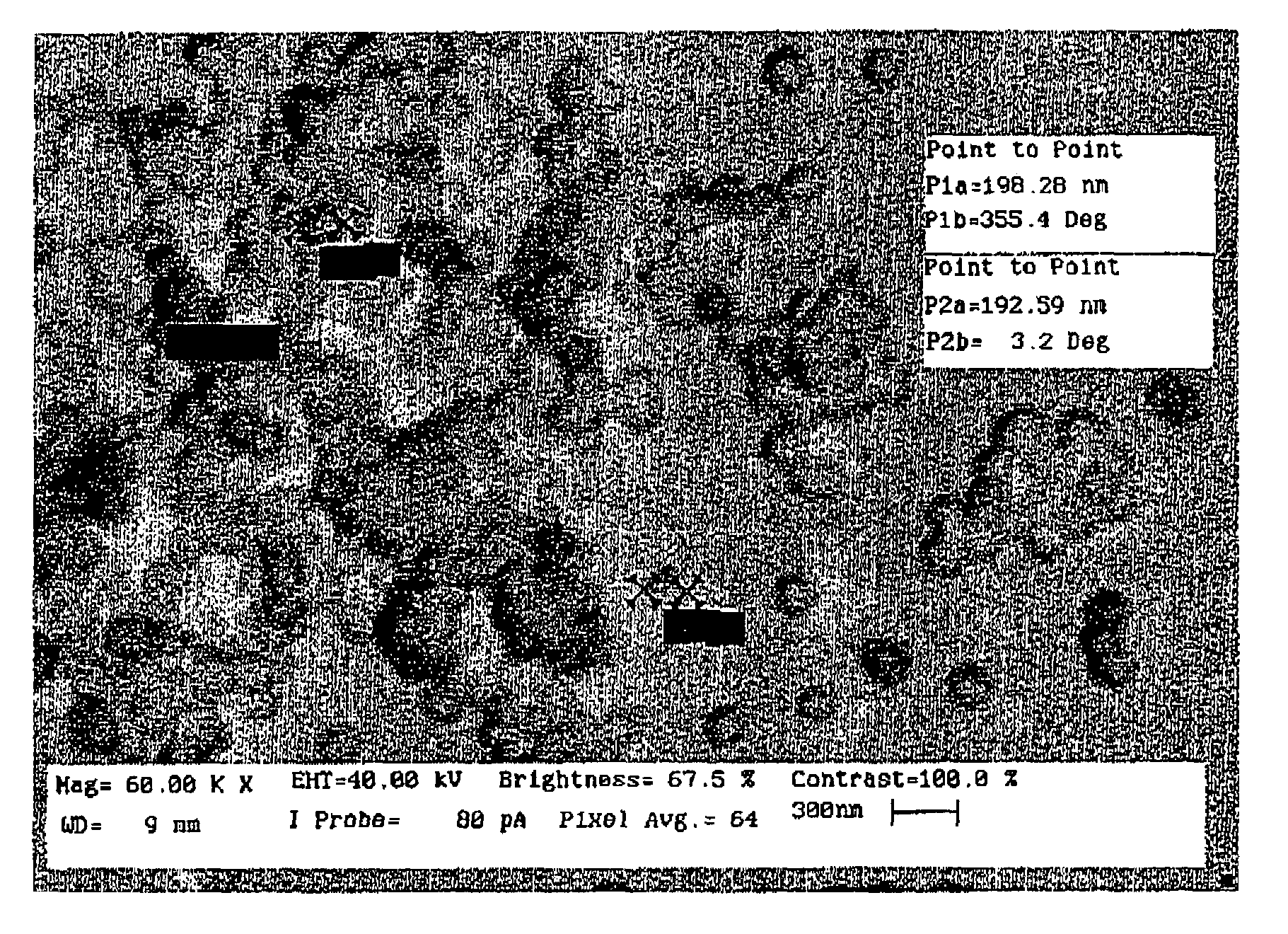

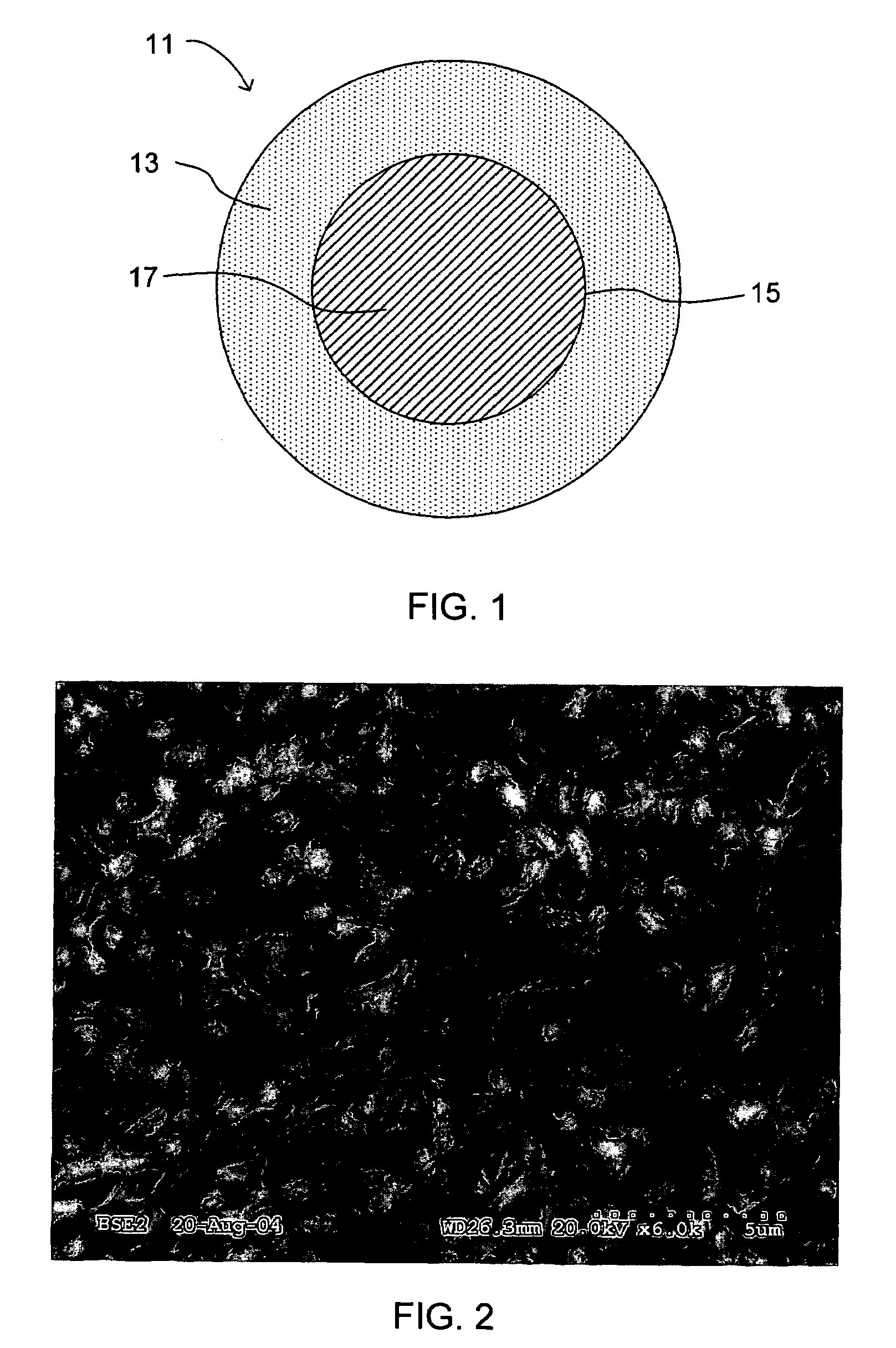

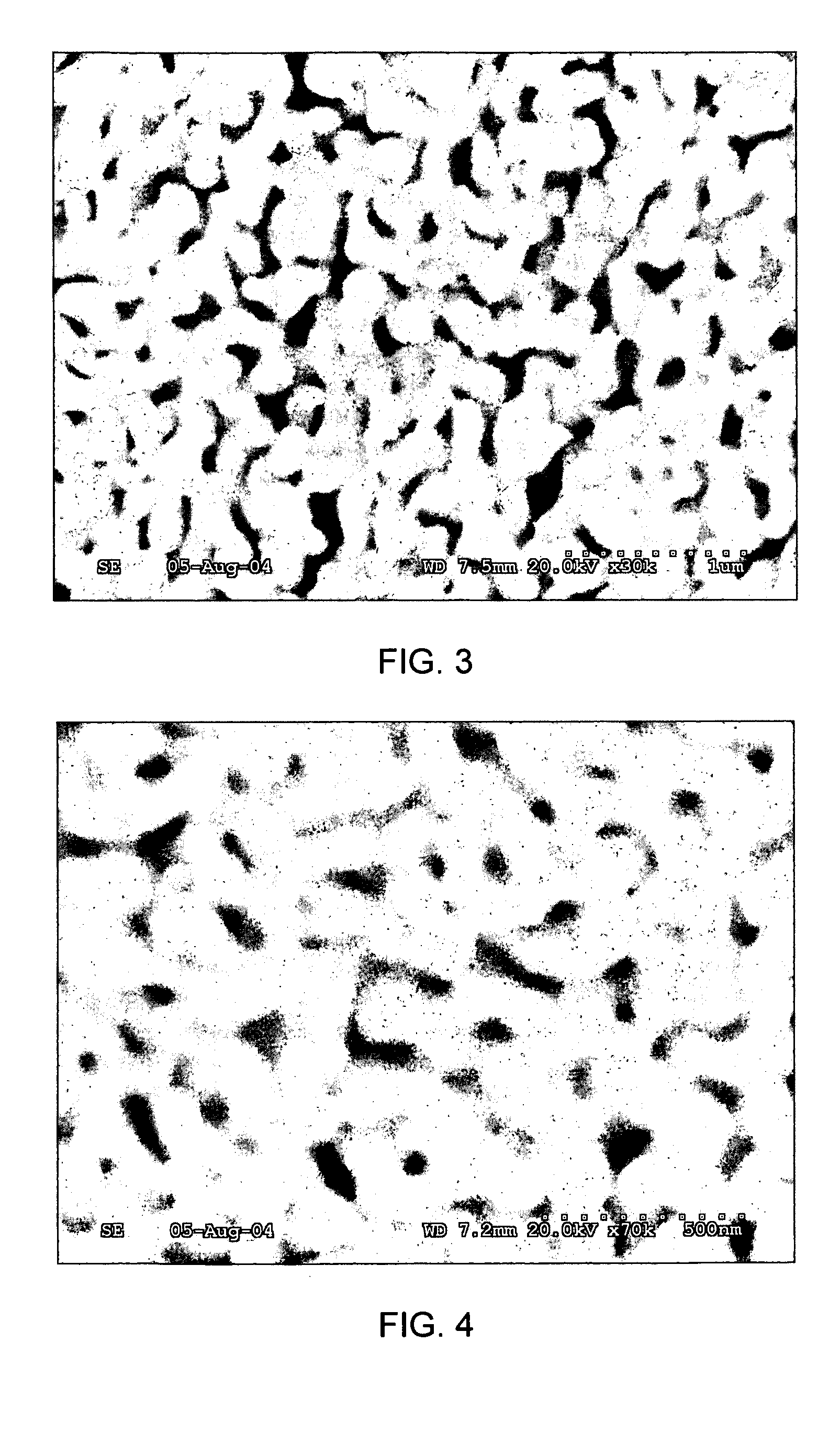

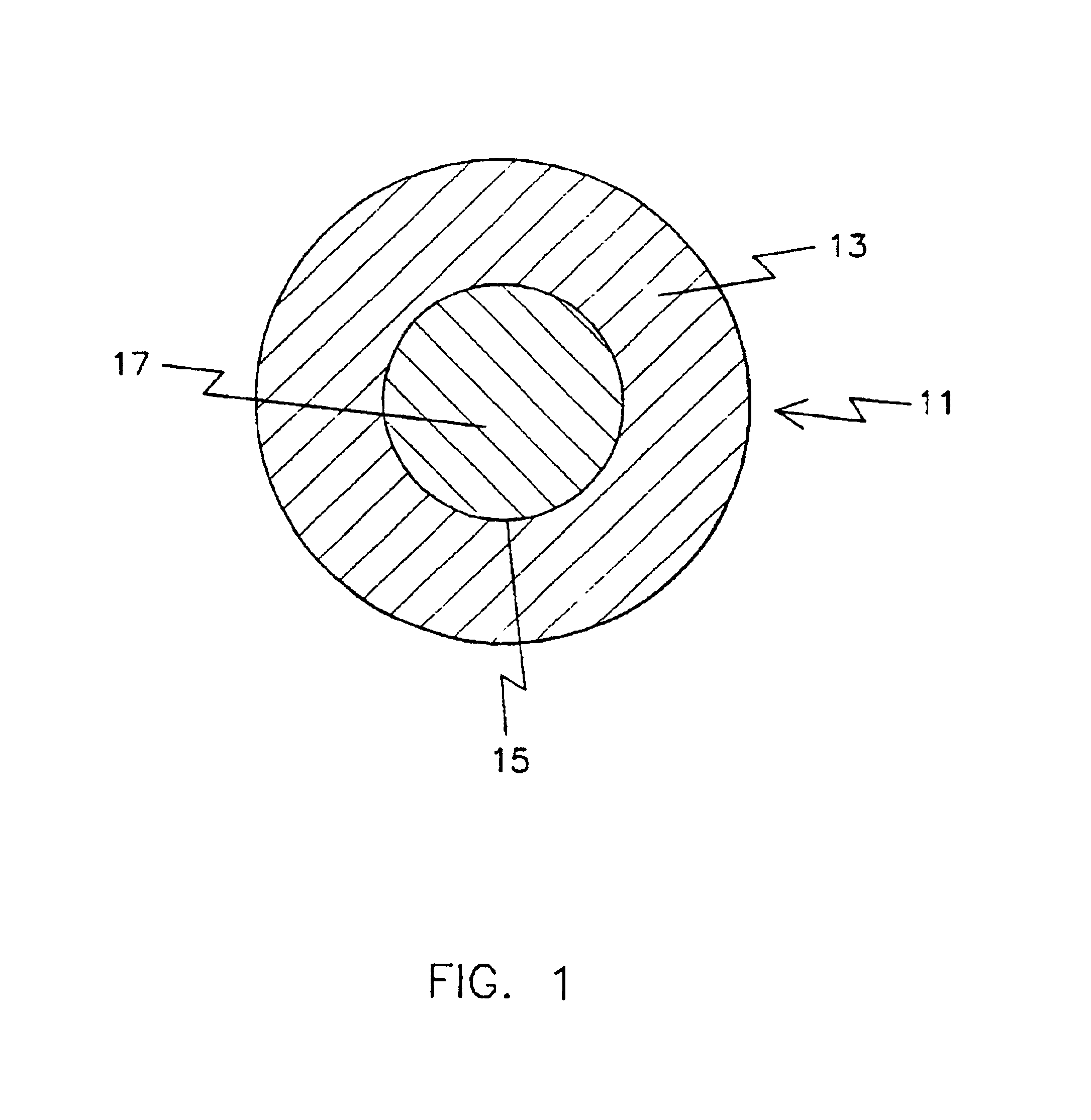

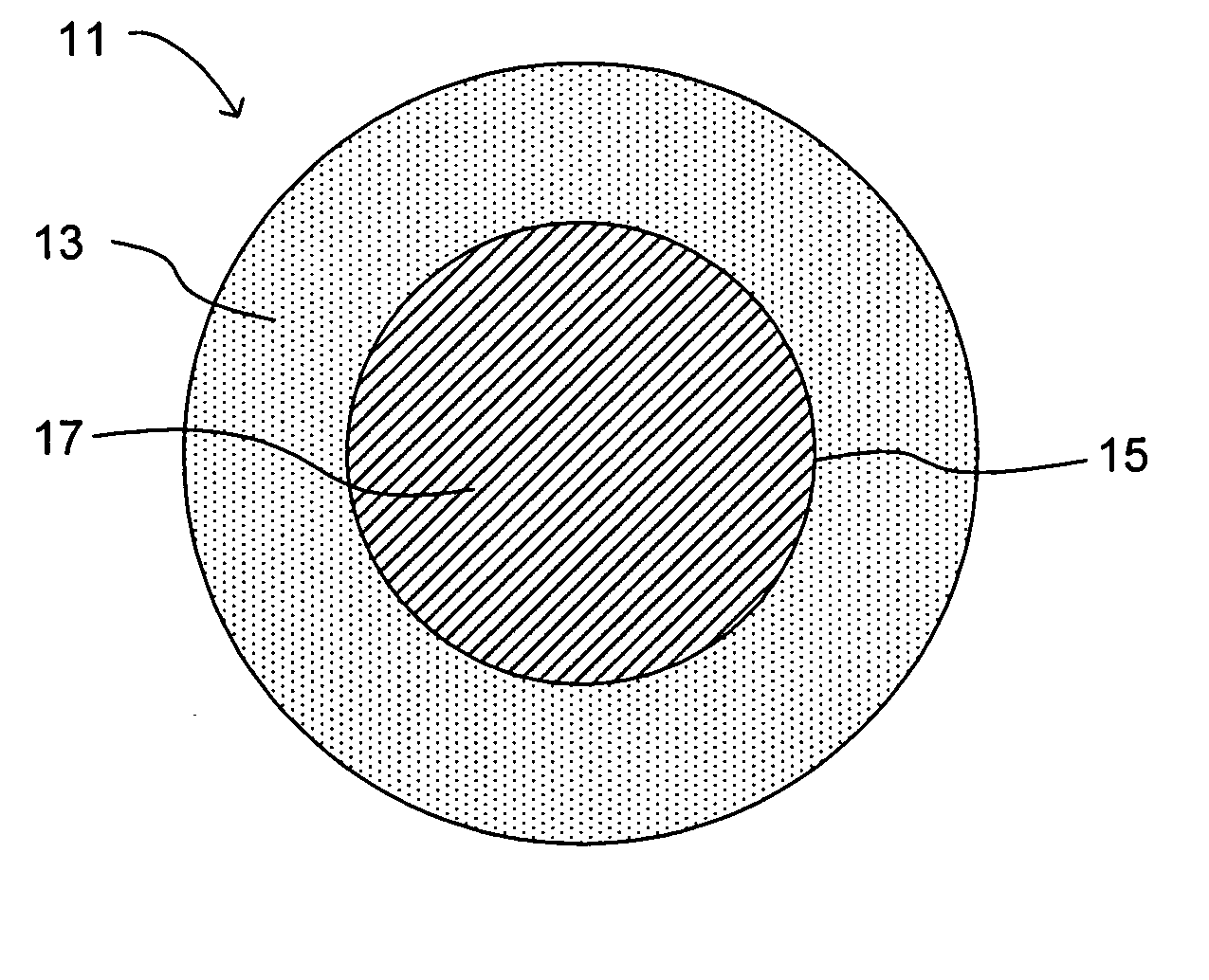

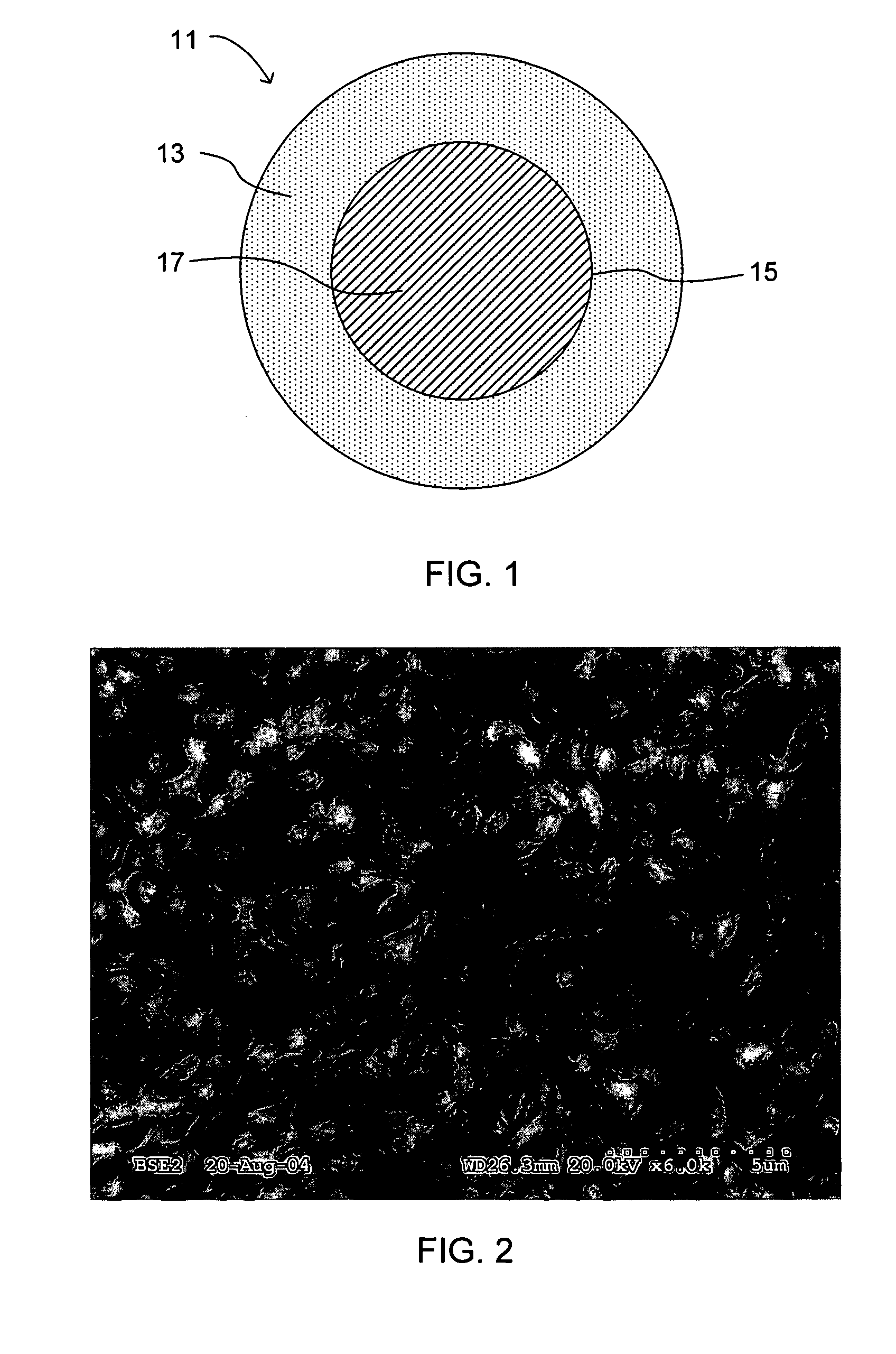

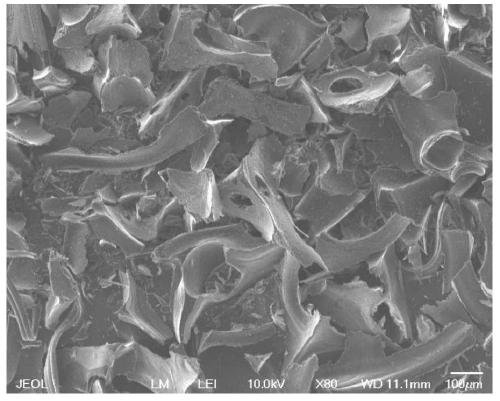

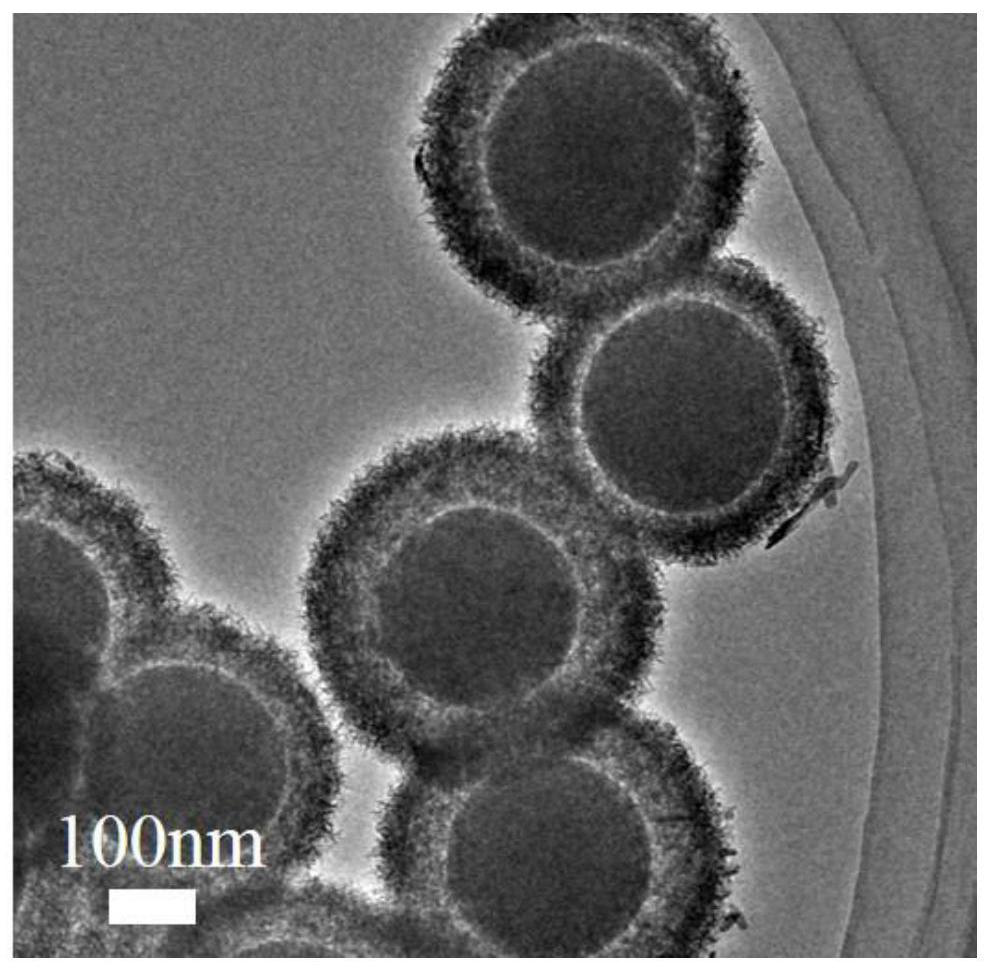

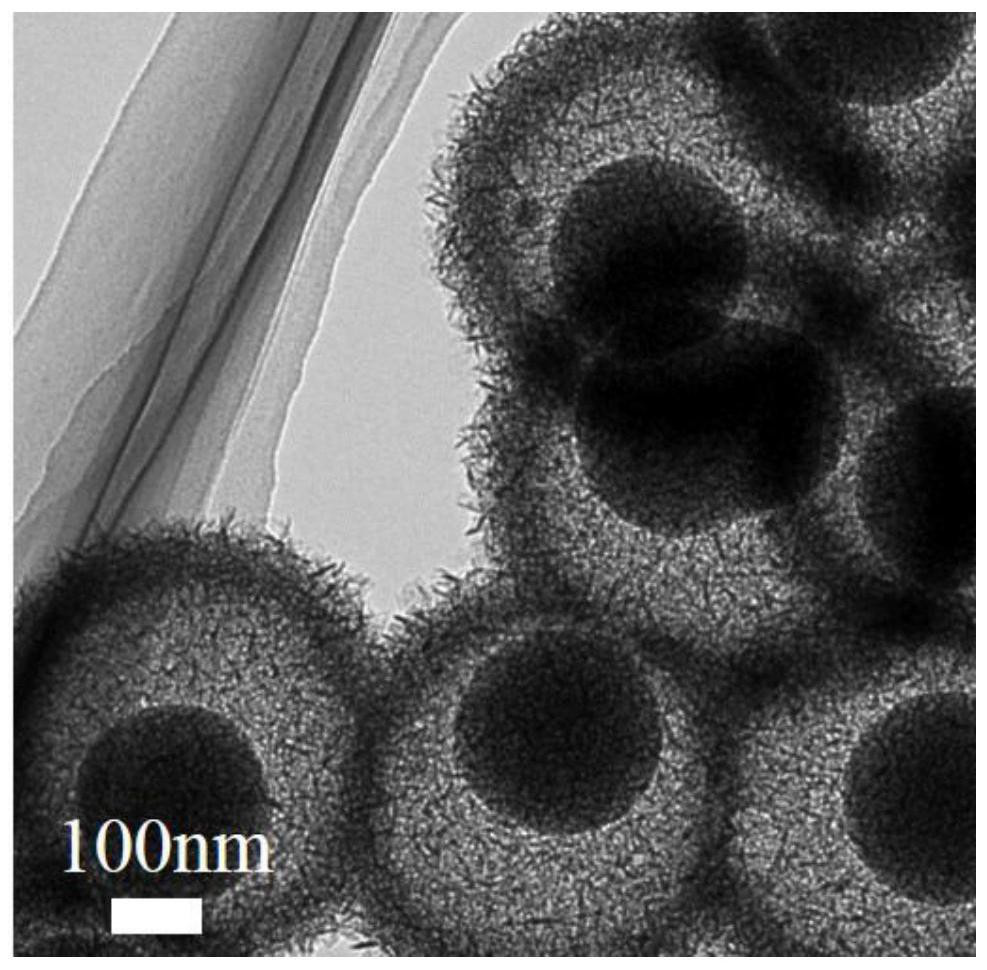

Molecular decomposition processes for the synthesis of nanosize metallic powders

InactiveUS7311754B2Improve solubilitySmall granularityMaterial nanotechnologyOxide/hydroxide preparationMetal alloySolvent

A method for synthesizing nanosize metallic powders can include providing a metallic precursor. The metallic precursor can include a metal alloy formed having a fugitive constituent and a target metal. The fugitive constituent and target metal are chosen such that the fugitive constituent can be selectively dissolved or removed by leaching with an appropriate solvent while leaving the target metal undissolved. The fugitive constituent can be leached from the metallic precursor to leave a metallic residue which is a mass of nanosize metallic particles made substantially of the target metal. The nanosize metallic particles can then be recovered from the metallic residue either merely by removing the solvent and / or breaking up the mass of nanosize metallic particles. The disclosed methods allow for a convenient avenue for production of nanosize particles from readily formed materials for use in a wide variety of potential industrial and commercial applications.

Owner:UNIV OF UTAH RES FOUND

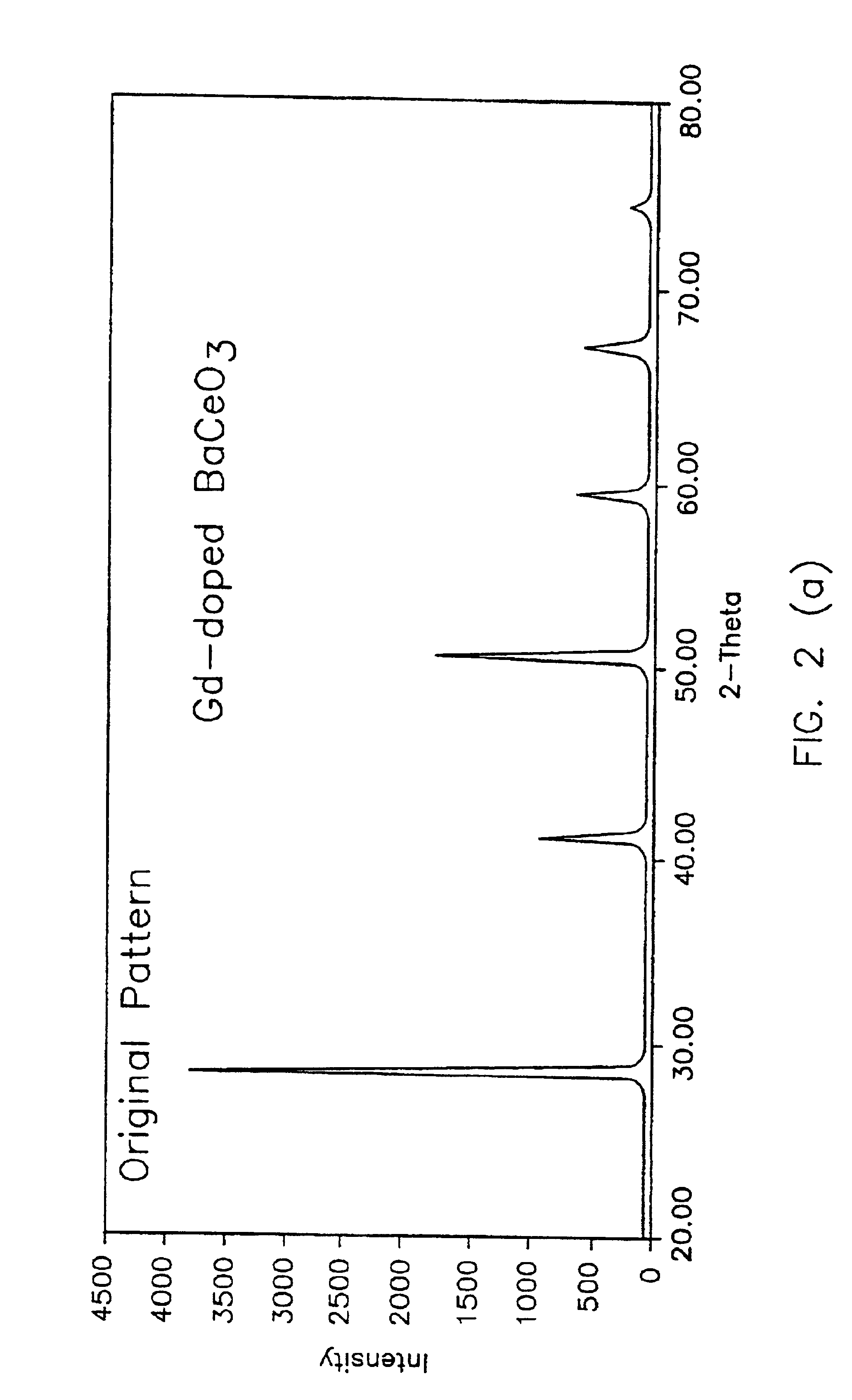

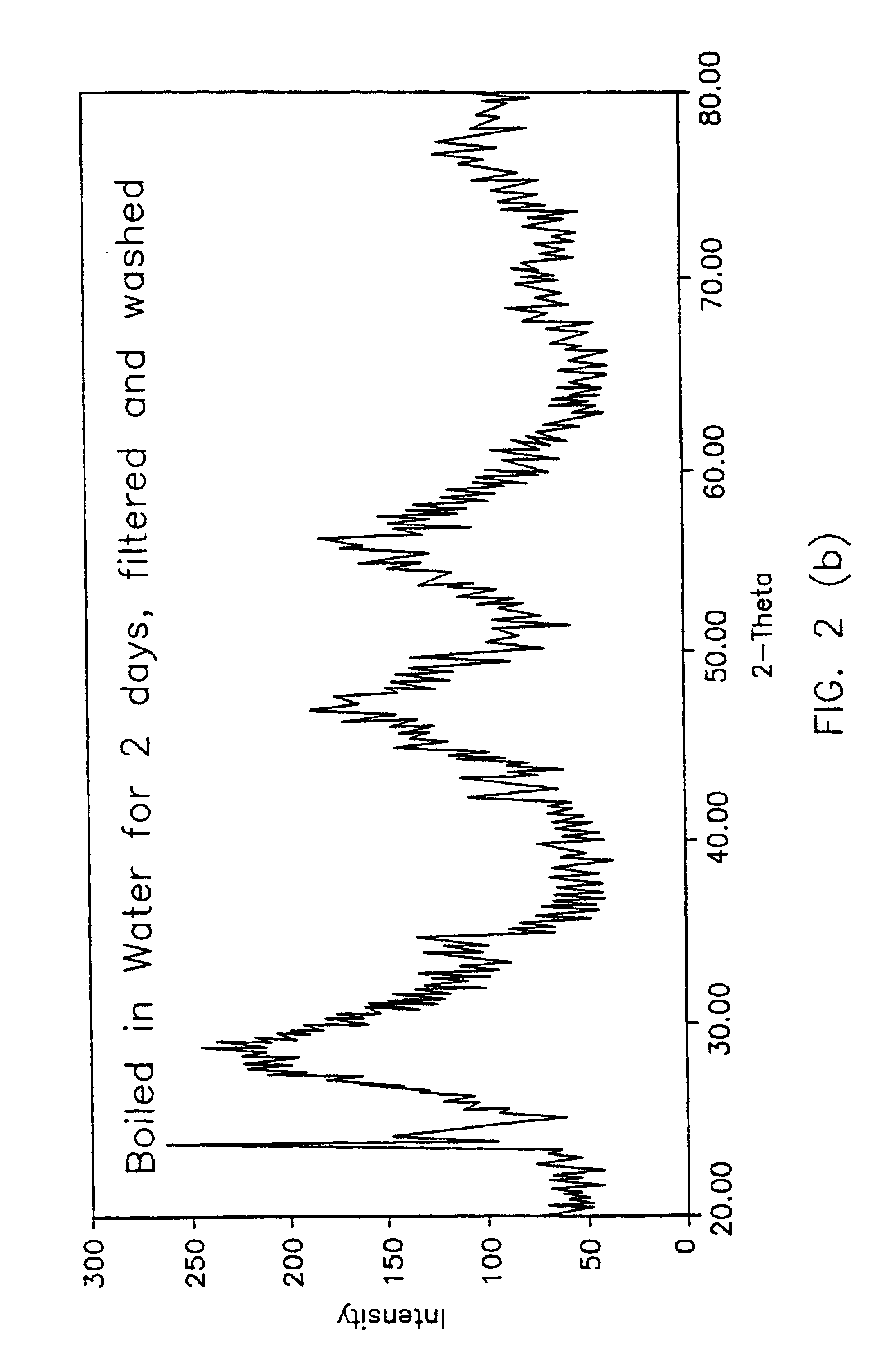

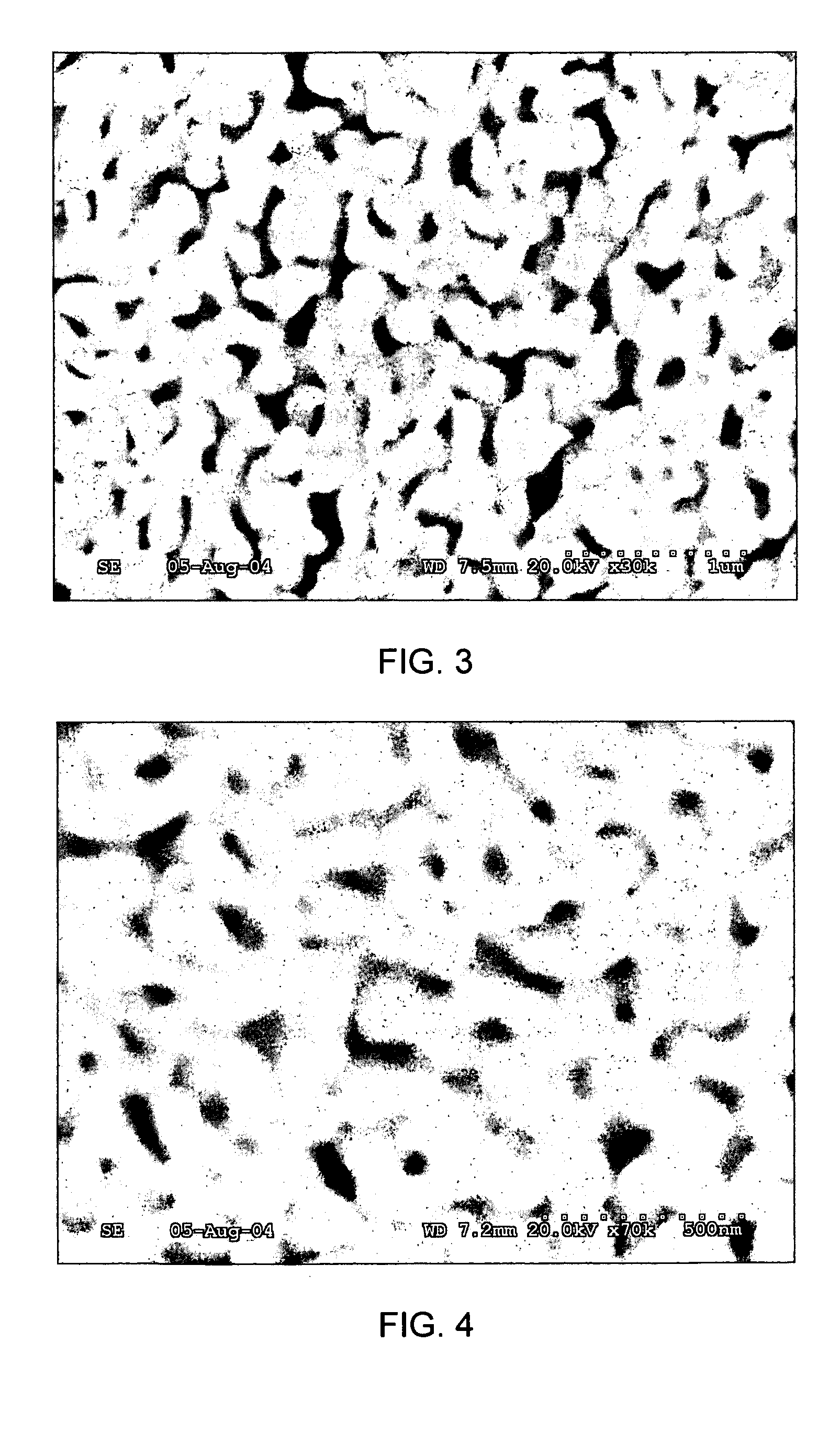

Molecular decomposition process for the synthesis of nanosize ceramic and metallic powders

InactiveUS6803027B1Easy to implementImprove scalabilityMaterial nanotechnologyTantalum compoundsSolventMetal powder

A process is disclosed for forming a nanosize ceramic powder. A precursor ceramic material is formed of a fugitive constituent and a non-soluble constituent in a single phase. The precursor is contacted with a selective solvent (water, acid, etc.) to form a solution of the fugitive constituent in the solvent and a residue of the non-soluble constituent. The precursor is sufficiently reactive with the solvent to form the solution of the fugitive constituent in the solvent and form the nondissolved residue of the non-soluble constituent. The precursor material and the non-soluble residue are sufficiently insoluble in the solvent such that there is insufficient precursor material and non-soluble residue in solution to deposit and precipitate upon the residue of the non-soluble-constituent. The fugitive constituent is sufficiently soluble in the solvent such that the precursor reacts with the solvent to form the solution of the fugitive constituent without precipitation and deposition of fugitive constituent upon the residue of the non-soluble constituent in the form of nanosize particles. After the fugitive constituent is dissolved the selective solvent containing the fugitive constituent is removed from the residue. The residue remains in the form of a nanosize powder of the non-soluble constituent.

Owner:UNIV OF UTAH RES FOUND

Molecular decomposition processes for the synthesis of nanosize metallic powders

InactiveUS20050115362A1Improve solubilityImprove microstructureMaterial nanotechnologyOxide/hydroxide preparationMetal alloySolvent

A method for synthesizing nanosize metallic powders can include providing a metallic precursor. The metallic precursor can include a metal alloy formed having a fugitive constituent and a target metal. The fugitive constituent and target metal are chosen such that the fugitive constituent can be selectively dissolved or removed by leaching with an appropriate solvent while leaving the target metal undissolved. The fugitive constituent can be leached from the metallic precursor to leave a metallic residue which is a mass of nanosize metallic particles made substantially of the target metal. The nanosize metallic particles can then be recovered from the metallic residue either merely by removing the solvent and / or breaking up the mass of nanosize metallic particles. The disclosed methods allow for a convenient avenue for production of nanosize particles from readily formed materials for use in a wide variety of potential industrial and commercial applications.

Owner:UNIV OF UTAH RES FOUND

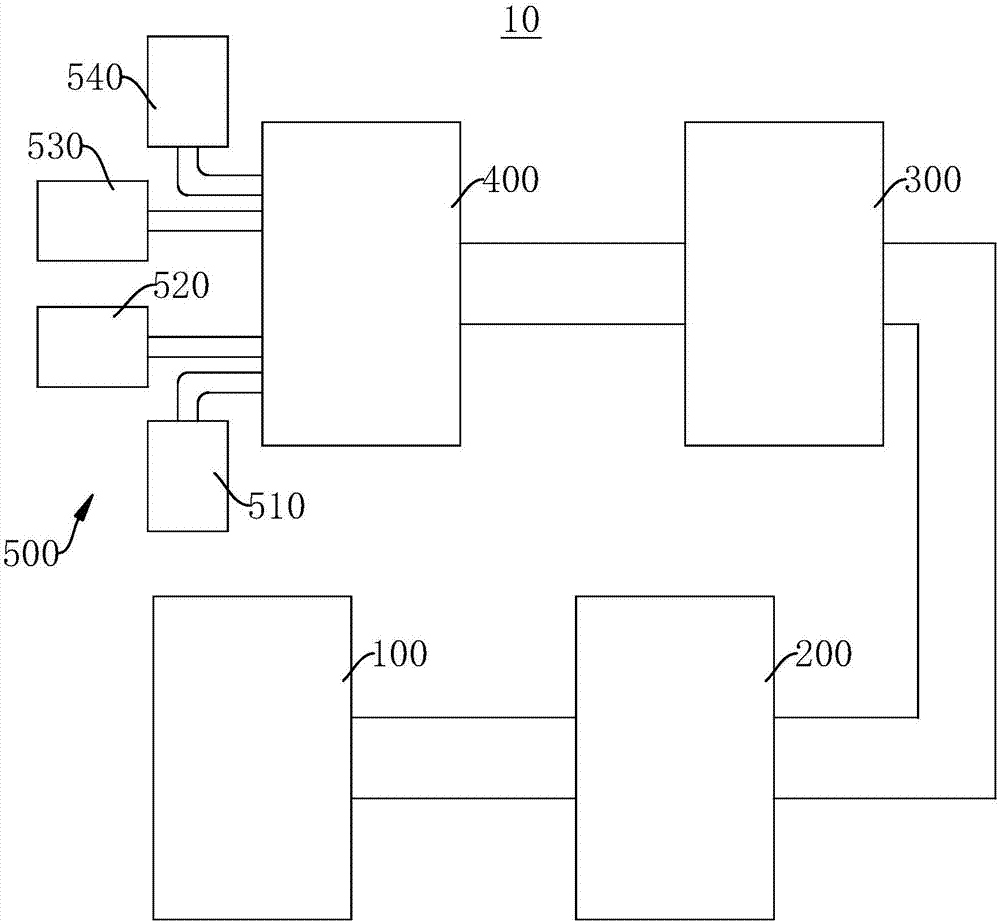

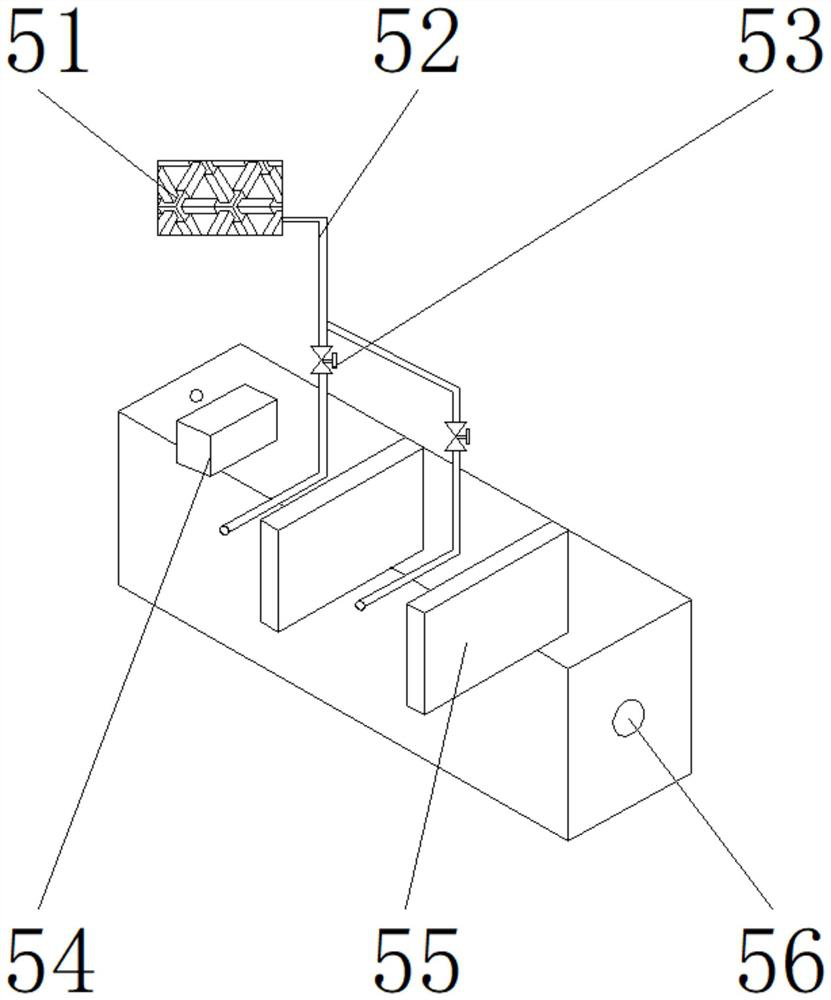

Automobile coating wastewater treatment process and automobile coating wastewater treatment system

PendingCN107265787ASmall footprintSimple structureSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesIndustrial waste waterProcess engineering

The invention discloses an automobile coating wastewater treatment process and an automobile coating wastewater treatment system and relates to the field of treatment of industrial wastewater. The automobile coating wastewater treatment process provided herein comprises the steps of pretreatment, coagulating reaction, precipitate removing, hydrolytic acidification, and molecular decomposition. The invention also provides the automobile coating wastewater treatment system employing the automobile coating wastewater treatment process. In addition, the automobile coating wastewater treatment process and the automobile coating wastewater treatment system have the advantages that floor area is small, investment and operation costs are low, operative management is convenient, and good social and economic benefits are created.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

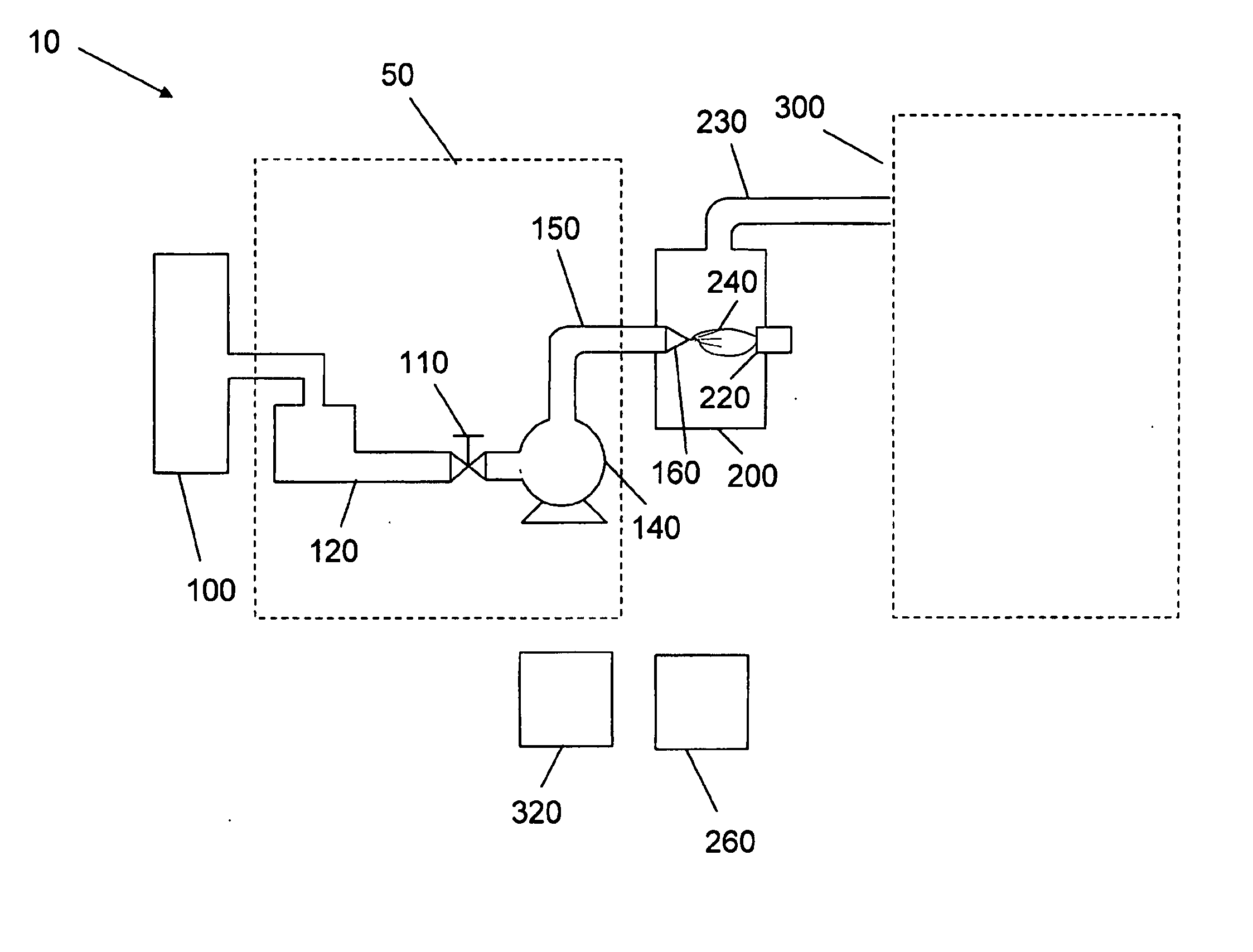

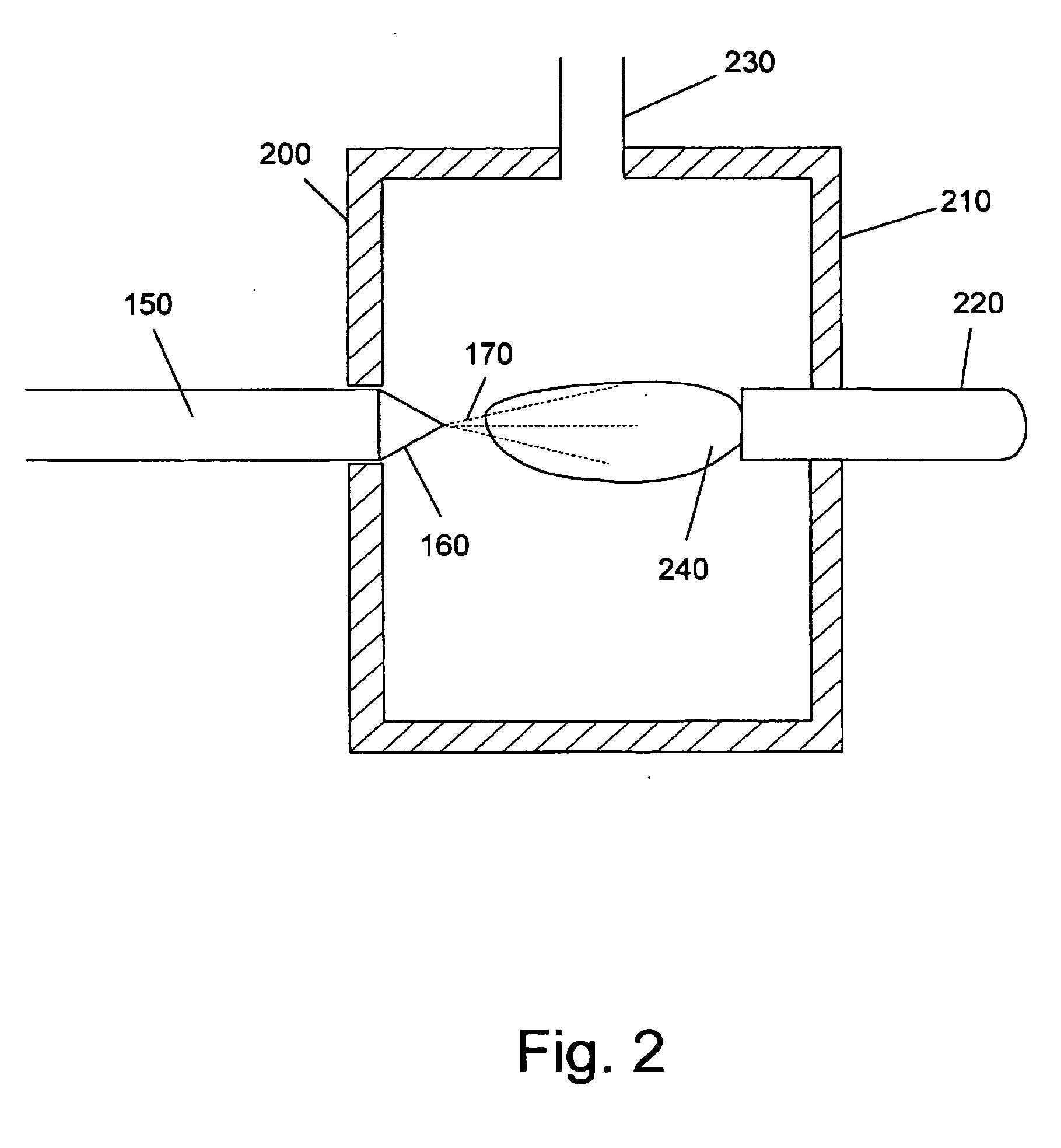

Method and system for treating chemical waste

InactiveUS20070114119A1Effective contactSafe releaseGas treatmentCombustible gas coke oven heatingLiquid wasteProduction line

The invention is a system and method for neutralizing fluid chemical waste products that result from a chemical production process and are collected from the production line. The invention comprises a pyrolysis / reaction chamber into which the fluid chemical waste is pumped through an atomizer. The jet of small droplets of liquid waste that is formed by the atomizer effectively contacts the plasma stream created by a plasma torch. When the droplets contact the plasma stream the molecules of the waste from which the droplets are composed are dissociated into atoms and / or ions. These atoms and ions move out of the immediate region of the plasma stream and recombine to form a mixture of product gases which exits the chamber. The product gases then enter a post-pyrolysis subsystem, which is designed to neutralize and / or collect the components comprising the mixture of product gases.

Owner:E S T ECOLOGICAL SYST

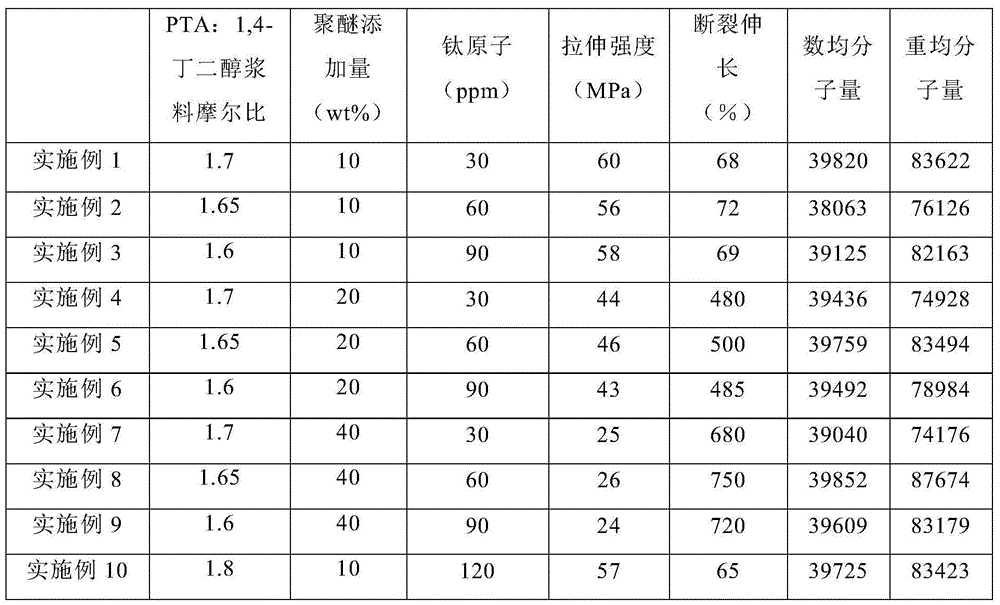

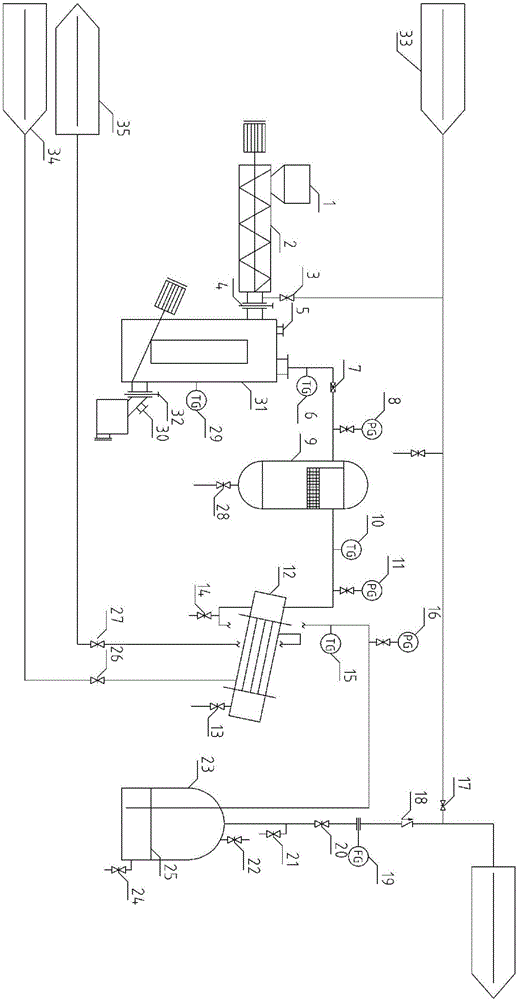

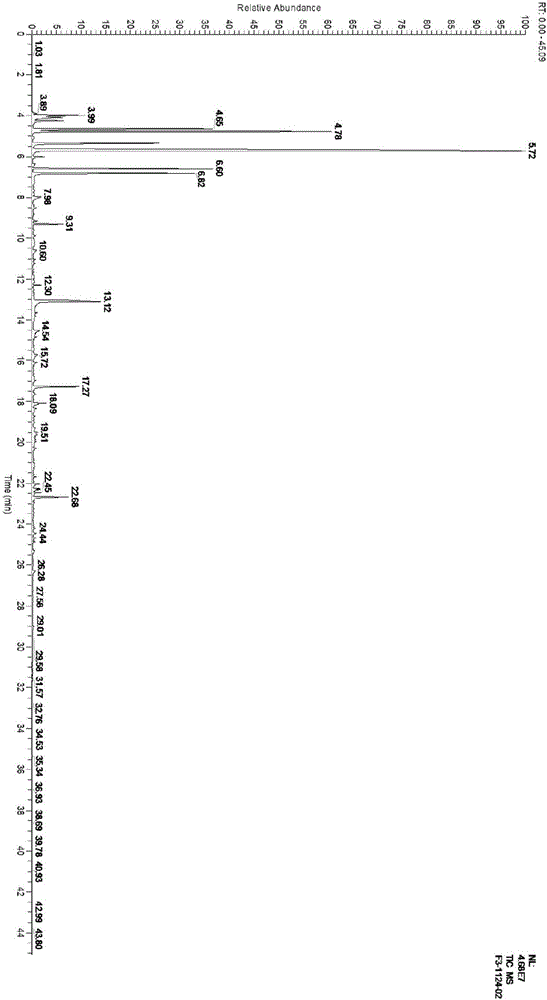

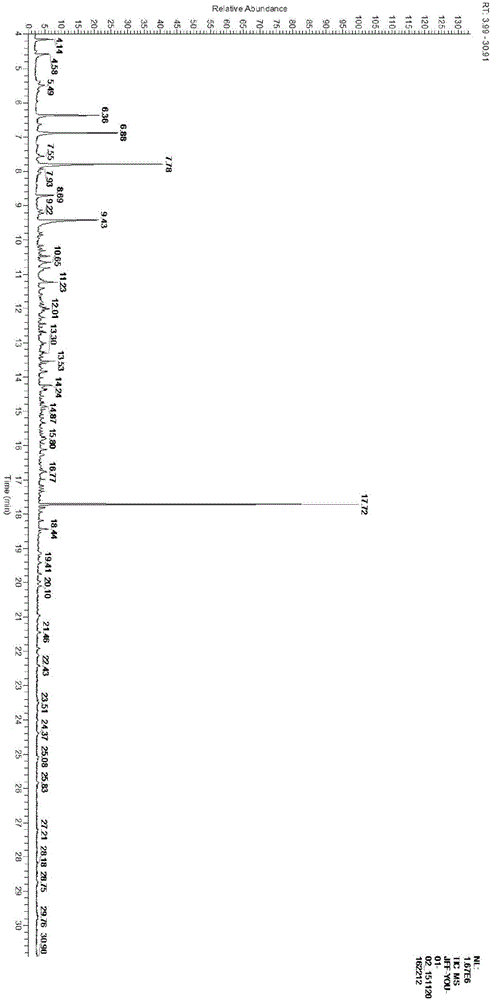

Continuous preparation method of elastic copolyester

The invention discloses a continuous preparation method of an elastic copolyester. The continuous preparation method comprises the following steps: firstly, mixing a butanediol solution of a titanium catalyst, terephthalic acid and butanediol so as to prepare slurry, and performing a primary esterification reaction; secondly, mixing a polyether butanediol solution with the obtained intermediate namely bishydroxybutyl terephthalate, and performing a secondary esterification reaction and a pre-polymerization reaction; and finally performing a condensation polymerization reaction, thereby obtaining the elastic copolyester. By adopting the continuous preparation method disclosed by the invention, the elastic copolyester which is excellent and stable in product ductility can be prepared, and the problems that polyether macromolecules can be easily subjected to thermal degradation in the reaction process, particularly under the conditions of high temperature and relatively long reaction time, the polyether macromolecules can be decomposed into chain segments of a low molecular weight, and furthermore the modification function of generated polyether can be degraded, can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid waste harmless and resourceful treatment method and treatment device

ActiveCN106475395AProductizationImprove liquidityTransportation and packagingSolid waste disposalLiquid productFuel oil

The invention discloses a solid waste harmless and resourceful treatment method and a treatment device. The method comprises the steps that firstly, a physical reselection method is adopted, and garbage is sorted into garbage screen overflow small in specific gravity and screen underflow large in specific gravity according to different specific gravities; then, the garbage screen overflow large in size and small in density is decomposed through a photocatalysis cracking furnace, organic solid macromolecules are decomposed into organic micromolecules, and oil gas and solid separation is formed after the organic micromolecules are evaporated out from the photocatalysis cracking furnace; and gas collection is formed by C1-C4 micromolecules in oil gas products, liquid collection is formed by organic matter of C4-C20, and solids are left in the cracking furnace to be discharged from the bottom. The organic macromolecules are decomposed into organic micromolecule compounds through breakage resonant C-C keys, and no influence is generated on inorganic matter; and separated-out gas products can be used for producing clean fuel, separated-out liquid products can be used for producing fuel oil and organic chemical materials, solid inorganic matter is subjected to concentration and refining, and inorganic mineral products can be formed in the manners of magnetic separation, reselection, flotation and the like.

Owner:河南光解环保科技有限公司 +1

High-performance environment-friendly modified PBT (polybutylene terephthalate)

The invention relates to the technical field of new materials, and particularly relates to high-performance environment-friendly modified PBT (polybutylene terephthalate) which is prepared from a component A and a component B, wherein the component A is a PBT raw material, and the PBT raw material is an original new material or is prepared by mixing a reclaimed material with a new material; and the component B is an auxiliary material, and the auxiliary material at least comprises halogen-free flame retardant, toughener, compatilizer and a glass fiber. In the preparation process, the high-performance environment-friendly modified PBT comprises the following specific components in percentage by weight: 15-20% of halogen-free flame retardant, 5-10% of toughener, 3-5% of compatilizer, 25-35% of glass fiber and the balance of PBT raw material; and the preparation process comprises the following steps: performing molecular decomposition, recombining, and granulating. According to the invention, the high-performance environment-friendly modified PBT is prepared by using PBT as a carrier and adding the halogen-free flame retardant, the toughener, the compatilizer, the glass fiber and other auxiliary materials; the invention can enhance the fire retardance degree and physical properties of the product, and ensures that the product meets the environmental requirements for no halogen and no phosphorus and conforms to industrial utilization; and the product is free of I and Br, thereby doing no harm to environment and health of people.

Owner:东莞市百思特塑胶有限公司

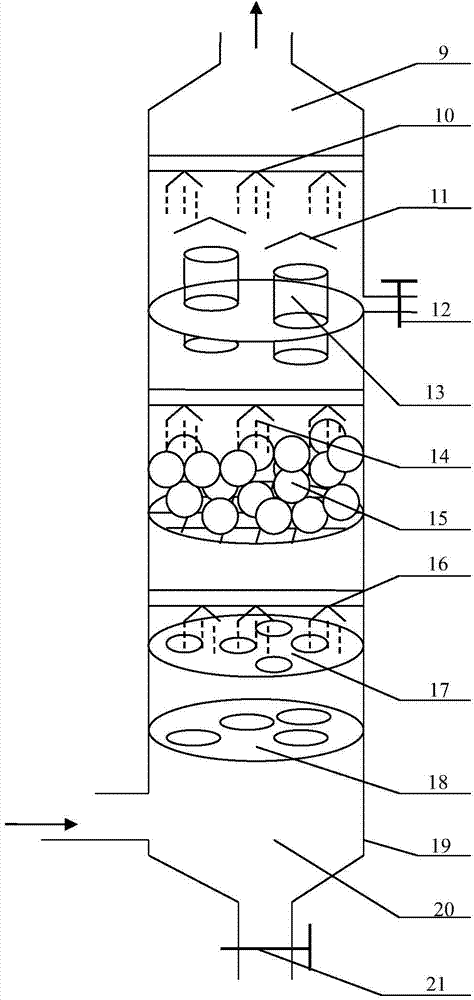

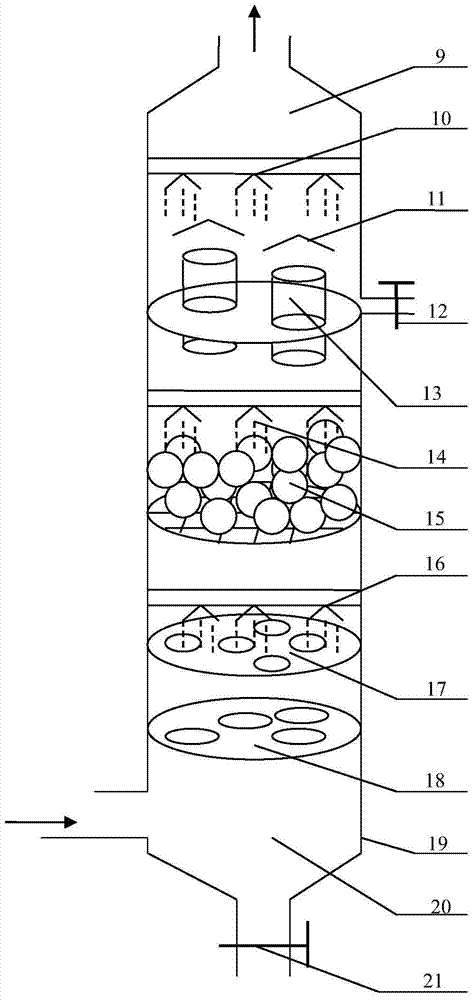

Foul flue gas treatment method and device

ActiveCN104707460ACorrosion resistanceExtended service lifeDispersed particle separationExternal electric electrostatic seperatorReaction layerElectrostatic separation

The invention discloses a foul flue gas treatment device which consists of two parts, namely an organic aerosol particle pollutant separation part and a VOCs and SVOCs molecular decomposition part, wherein the organic aerosol particle pollutant separation part structurally comprises a nonmetallic housing in which a lower electrostatic separation gas collection chamber, a gas distributor and an upper electrostatic separation gas collection chamber are sequentially arranged; the VOCs and SVOCs molecular decomposition part structurally comprises a housing in which a lower organic matter decomposition gas collection chamber, a secondary reaction layer sieve plate, a primary reaction layer sieve plate, a hydrogen peroxide reaction liquid sprayer, a filler reaction area, an acidic reaction liquid sprayer, a partition plate, an alkali liquor absorption area and an upper organic matter decomposition gas collection chamber are sequentially arranged. The invention further provides a foul flue gas treatment method. When the foul flue gas treatment device is used for treating foul flue gas, the treatment efficiency of organic pollutants reaches over 95 percent, VOCs and SVOCs can be completely decomposed, and undesirable odor can be completely eliminated.

Owner:QILU UNIV OF TECH

Process of composite material product

InactiveCN103507383AImprove production efficiencyImprove adhesionLaminationLamination apparatusHome improvementMedical treatment

The invention provides a process of a composite material product. A PC raw material or a PP raw material after high temperature decomposition is pressurized and attached with one of PU, leather fibers, a composite layer of the PU and microfiber cloth and a composite layer of the microfiber cloth and the leather fibers to prepare the product. The provided process of the composite material product utilizes a raw material molecular decomposition principle under a high temperature and a heavy pressure to bond the PP or the PC raw material with the PU, the leather fibers, the microfiber cloth and other different materials without any bonder, has the characteristics of colorlessness, odorlessness, environmental protection, low production cost, and high manufacturing efficiency; moreover, the process allows the bonding degree to be higher than a glued bonding degree, solves needs of manpower intensive type enterprises, and promotes sustainable economic development; and the product is applicable to 3C consumption electronic products and the peripheral accessory field, medical field, automotive filed, home decoration, furniture field, aerospace, sports devices, architecture field and other fields.

Owner:曾平安

Method for modifying silicon-carbon composite negative electrode by asphalt modification process derivative

ActiveCN111342035ALow light contentReduce escapeMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to the technical field of lithium battery materials. The invention particularly relates to a method for modifying a silicon-carbon composite negative electrode by an asphalt modification process derivative. The content of light components of the modified asphalt is low, the relative molecular mass is high, and the hydrocarbon ratio is greater than 1.5. The molecular decomposition polymerization reaction is gentle in the carbonization process, and volatile gas escape is greatly reduced, so that a higher coking value is achieved after carbonization, a compact asphalt nano-coated carbon layer with low pore defect degree is formed on the surfaces of nano-silicon and graphite, excessive active lithium ion consumption is avoided in the charging and discharging process of the modified asphalt coated silicon-carbon composite negative electrode material, and the first coulombic efficiency of the battery is remarkably improved. Besides, the compact asphalt nano-coated carbon layer with low pore defect degree can also play an effective role in buffering the volume expansion of the inner-layer silicon, so that the diving condition of the battery is obviously delayed, andthe coulombic efficiency and the cycle retention rate of the material are improved.

Owner:西安英纳吉科技有限公司

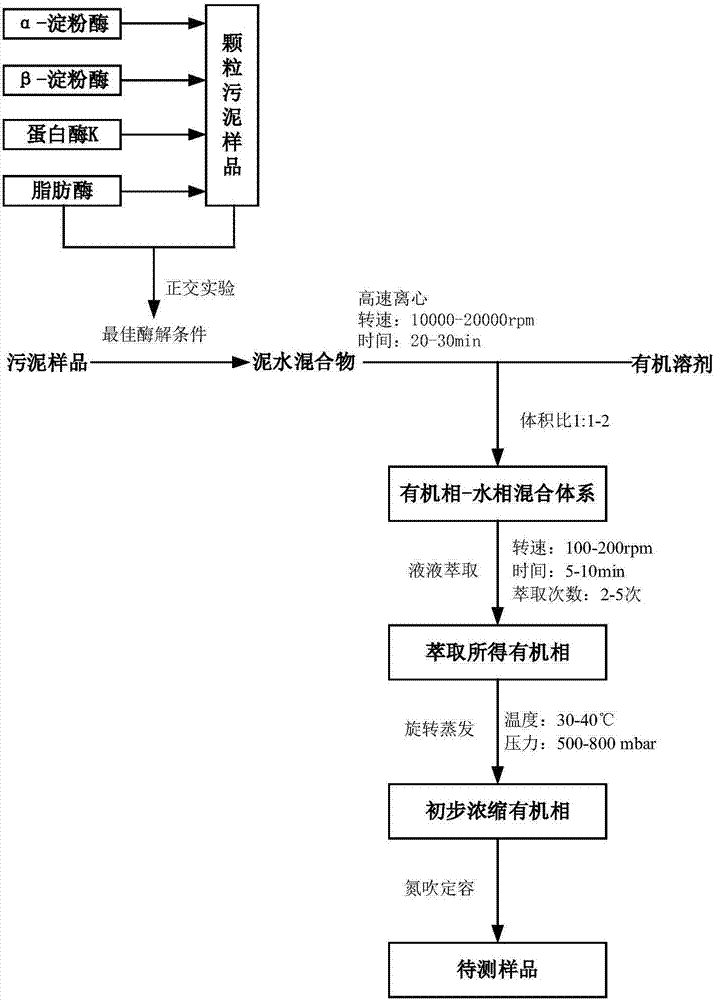

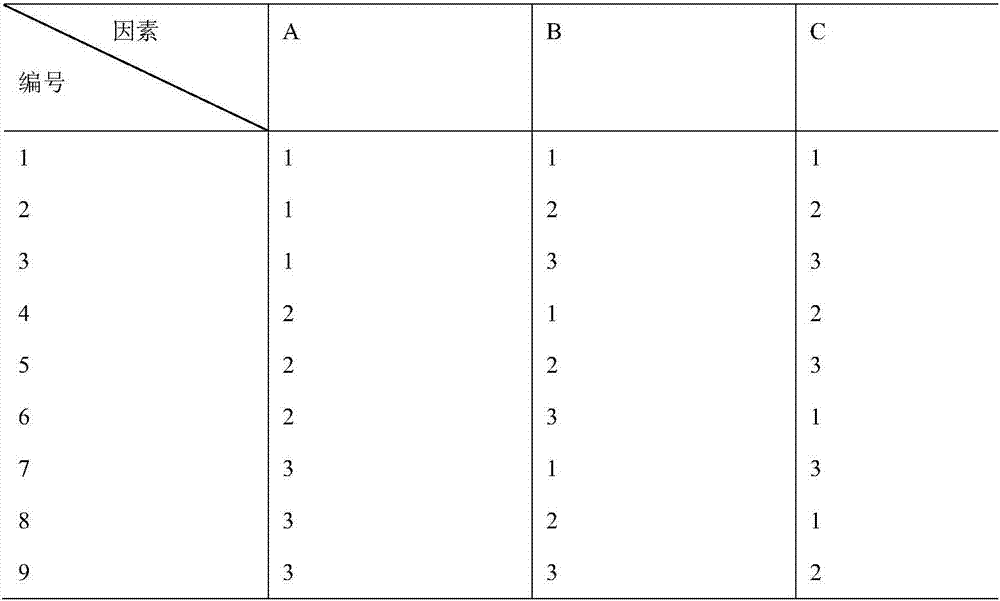

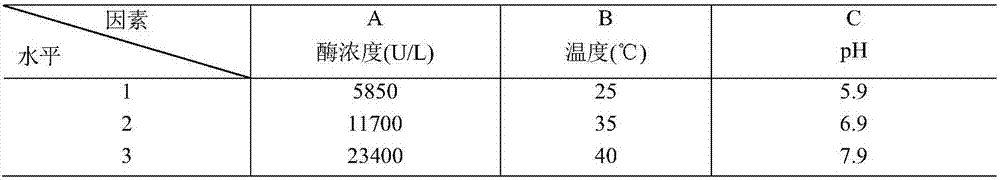

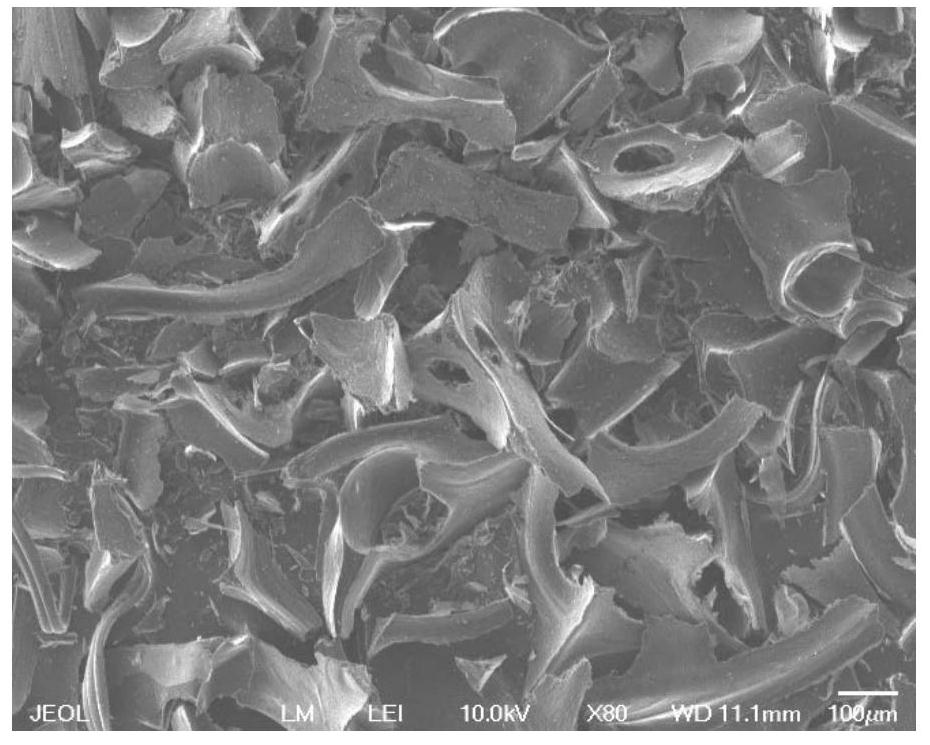

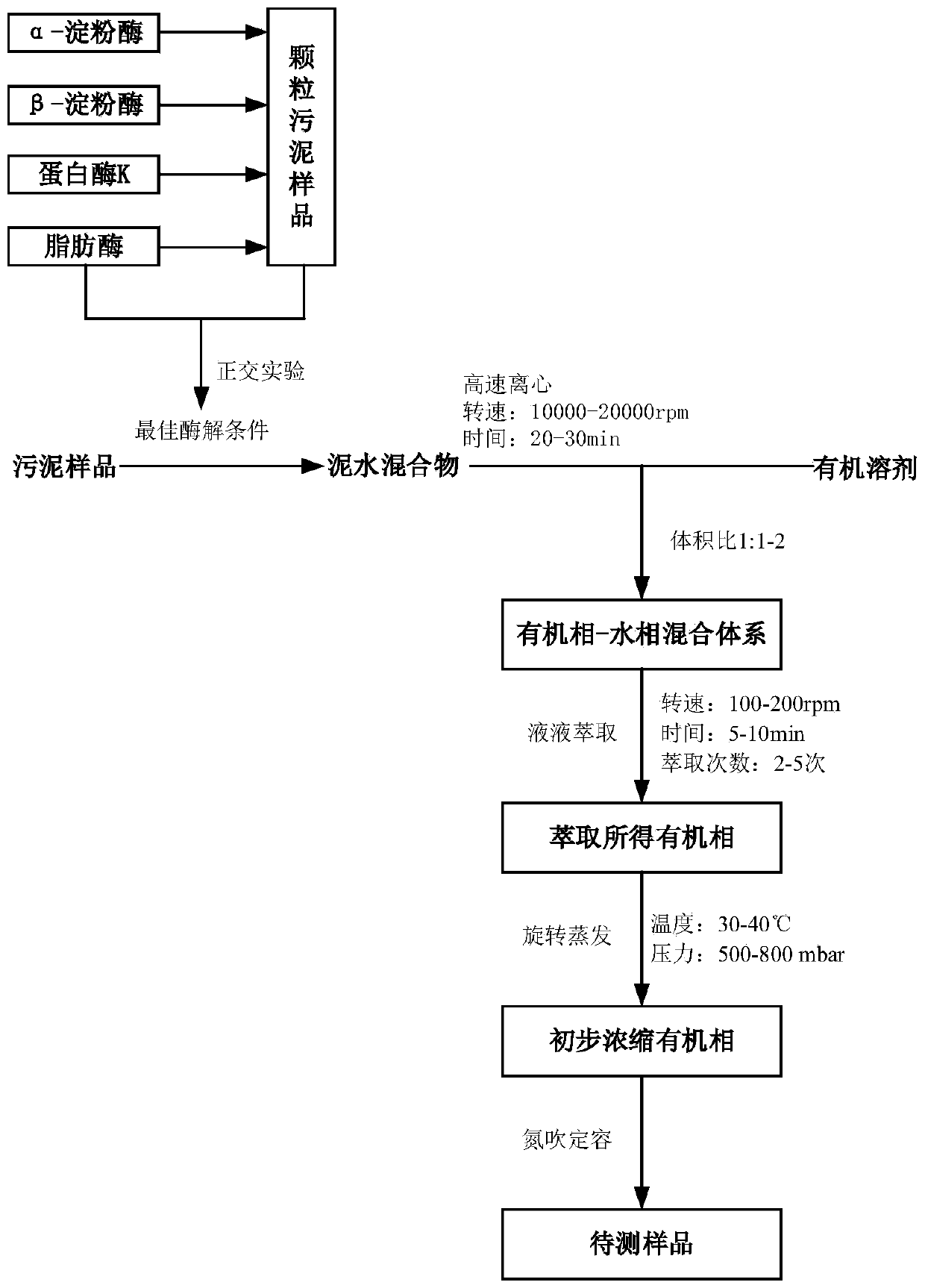

Method of efficiently extracting quorum sensing signal molecules from aerobic granular sludge

ActiveCN107515143AReduce the possibility of degradationEffectively study the regulation mechanism of quorum sensingPreparing sample for investigationSludgeSignalling molecules

The invention discloses a method of efficiently extracting quorum sensing signal molecules from aerobic granular sludge. The method can efficiently extract quorum sensing signal molecules from extracellular polymeric substances in aerobic granular sludge. The method comprises the following steps: (1) extracellular polymeric substance hydrolysis; (2) hydrolysis supernate collection; (3) liquid-liquid extraction; (4) vacuum concentration; and (5) nitrogen blowing and constant volume. The operation is convenient, and the reaction conditions are mild. The method can solve the problem of single molecular decomposition caused by release of intracellular organic matters during the process of extracting signal molecules from a granular sludge system and is an efficient and feasible signal molecule extraction method.

Owner:ZHEJIANG UNIV

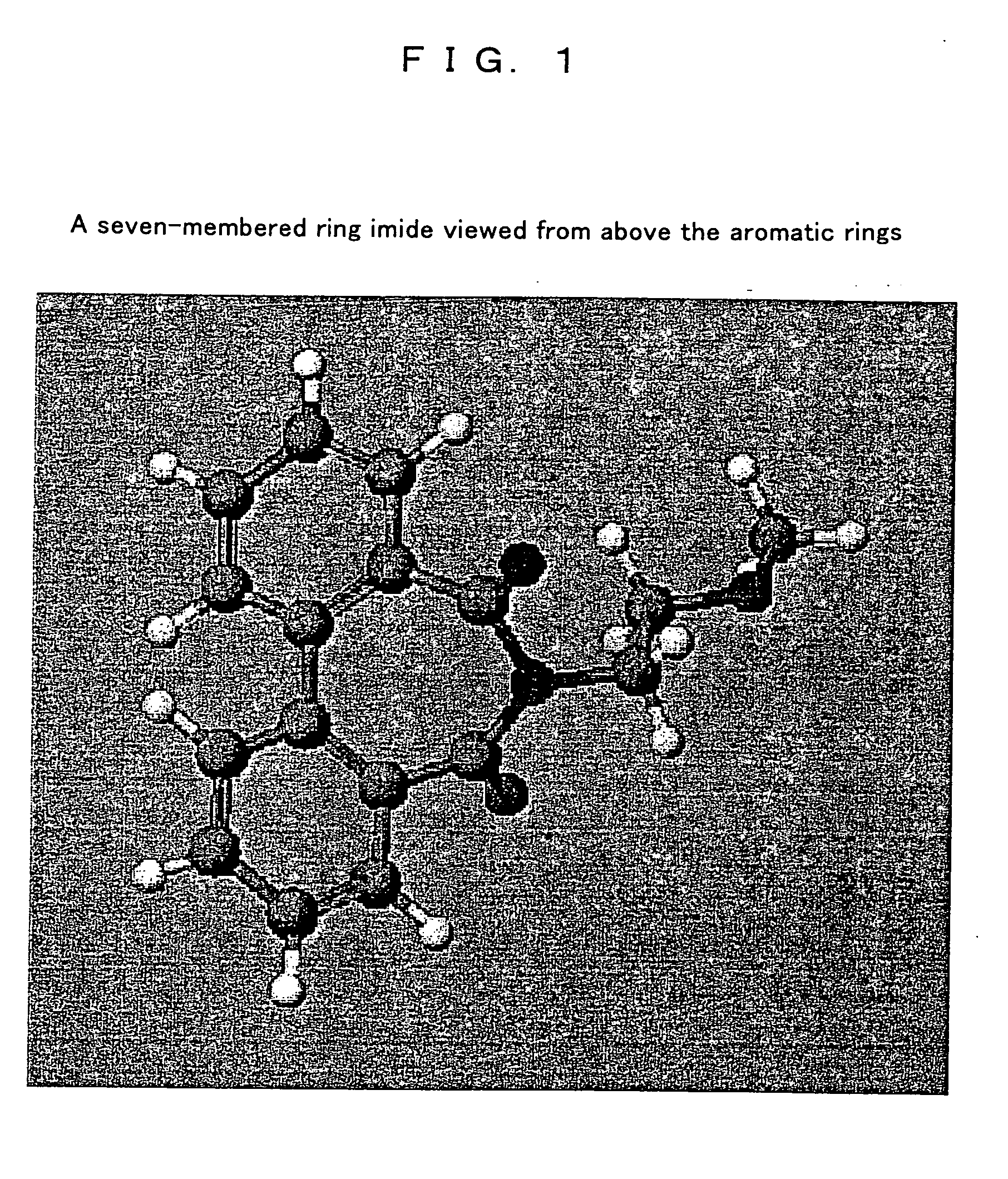

Photo radical generator, photo sensitive resin composition and article

ActiveUS20050119432A1Improve abilitiesIncrease resistanceSilicon organic compoundsPhotomechanical apparatusImideHydrogen atom

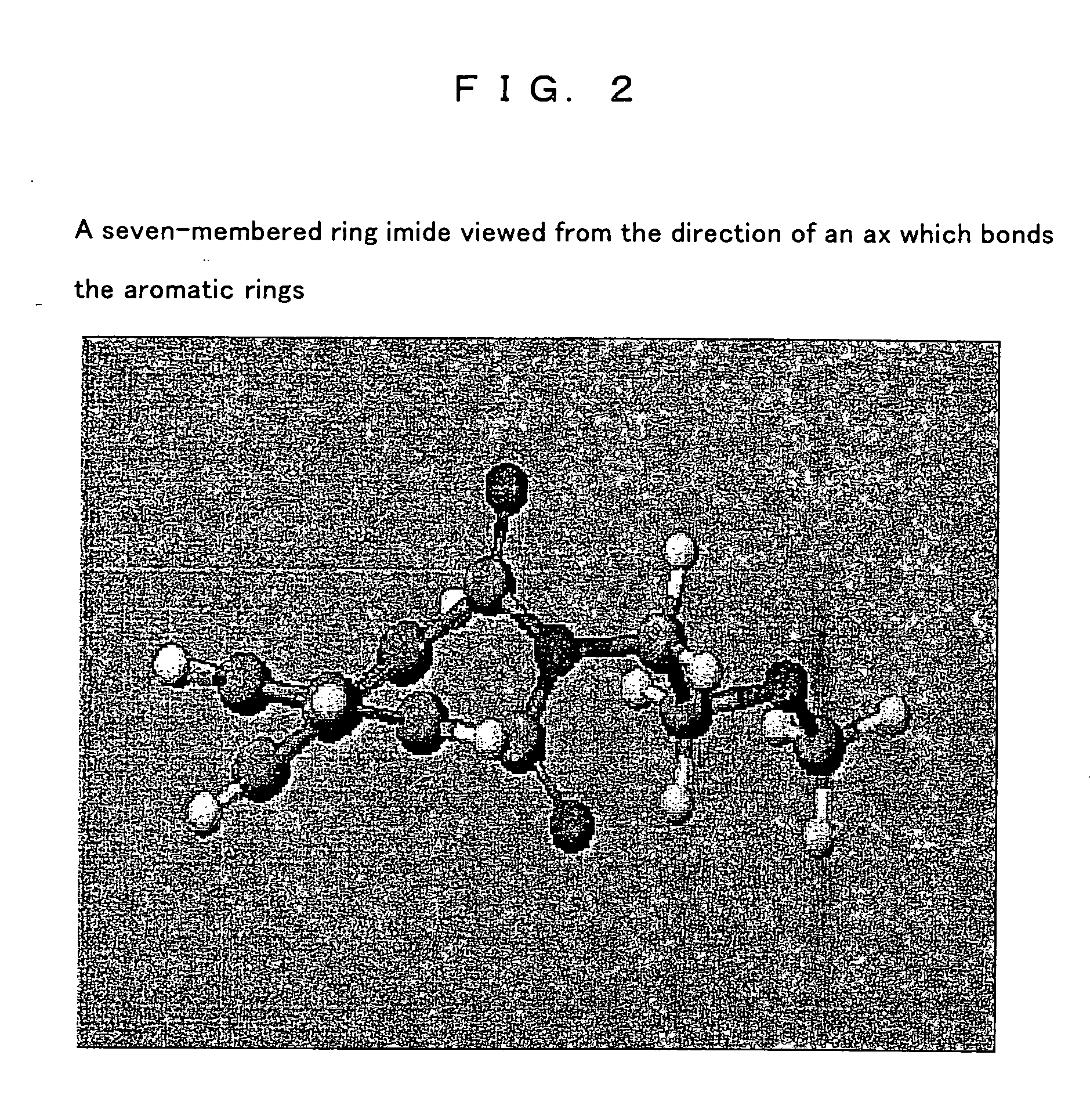

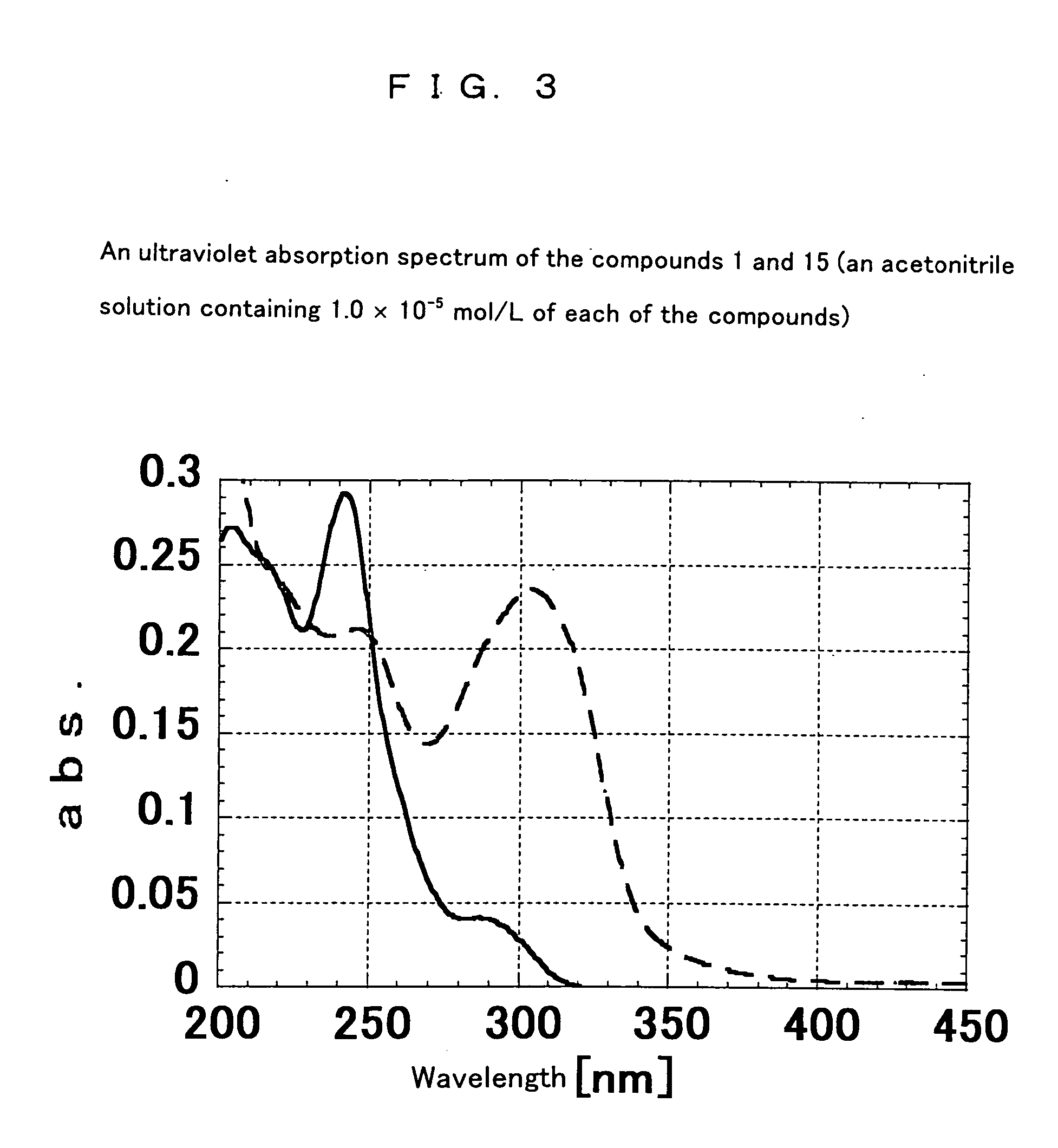

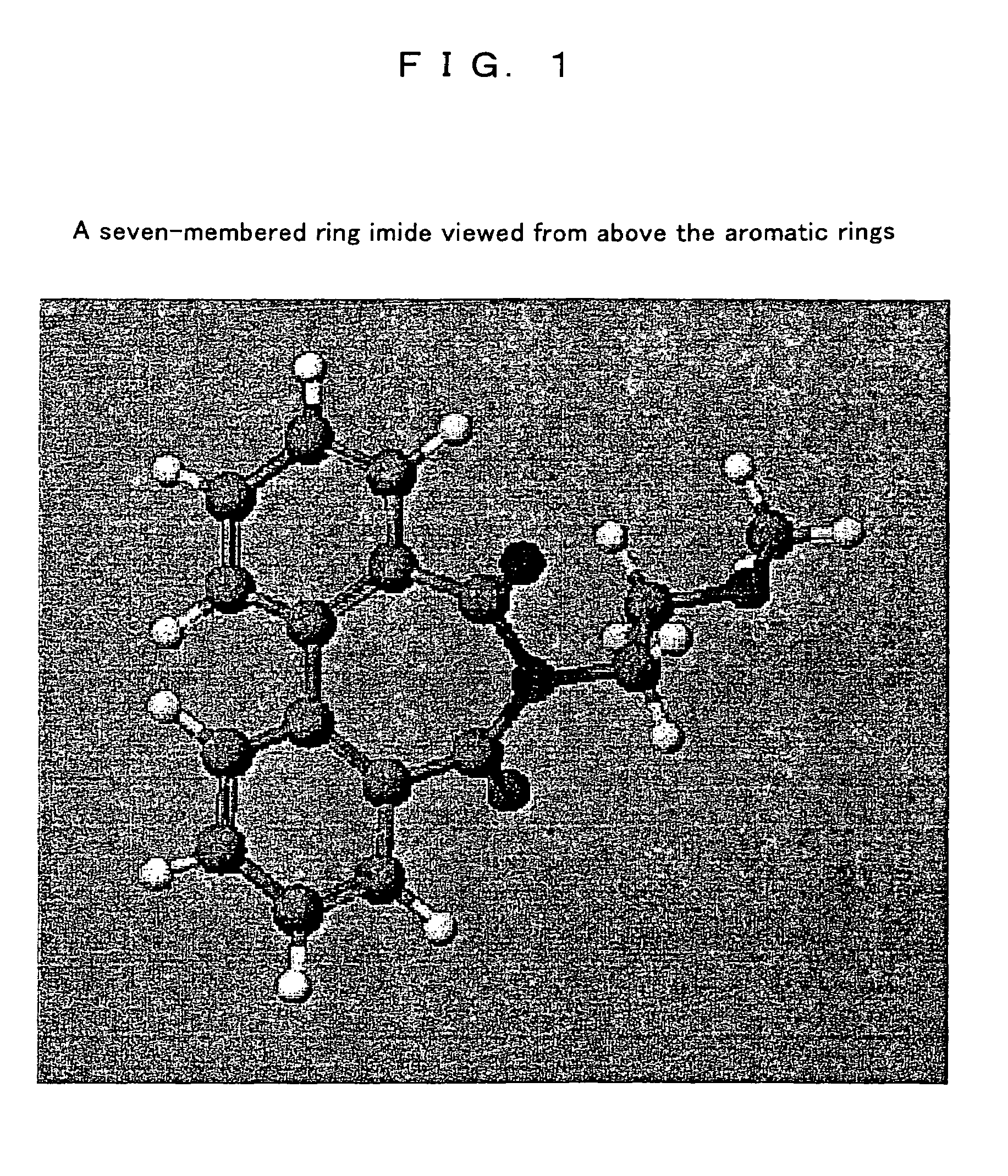

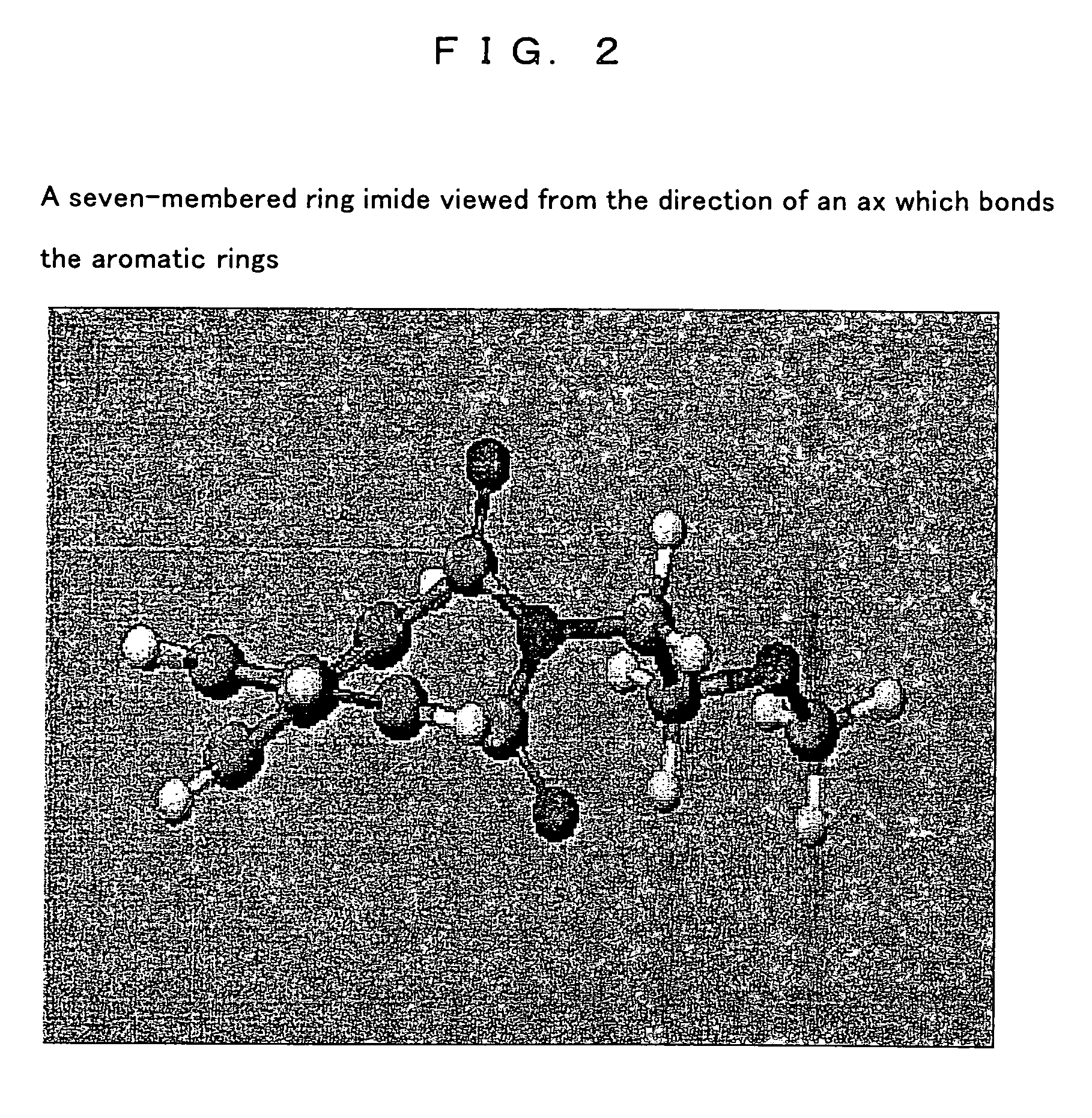

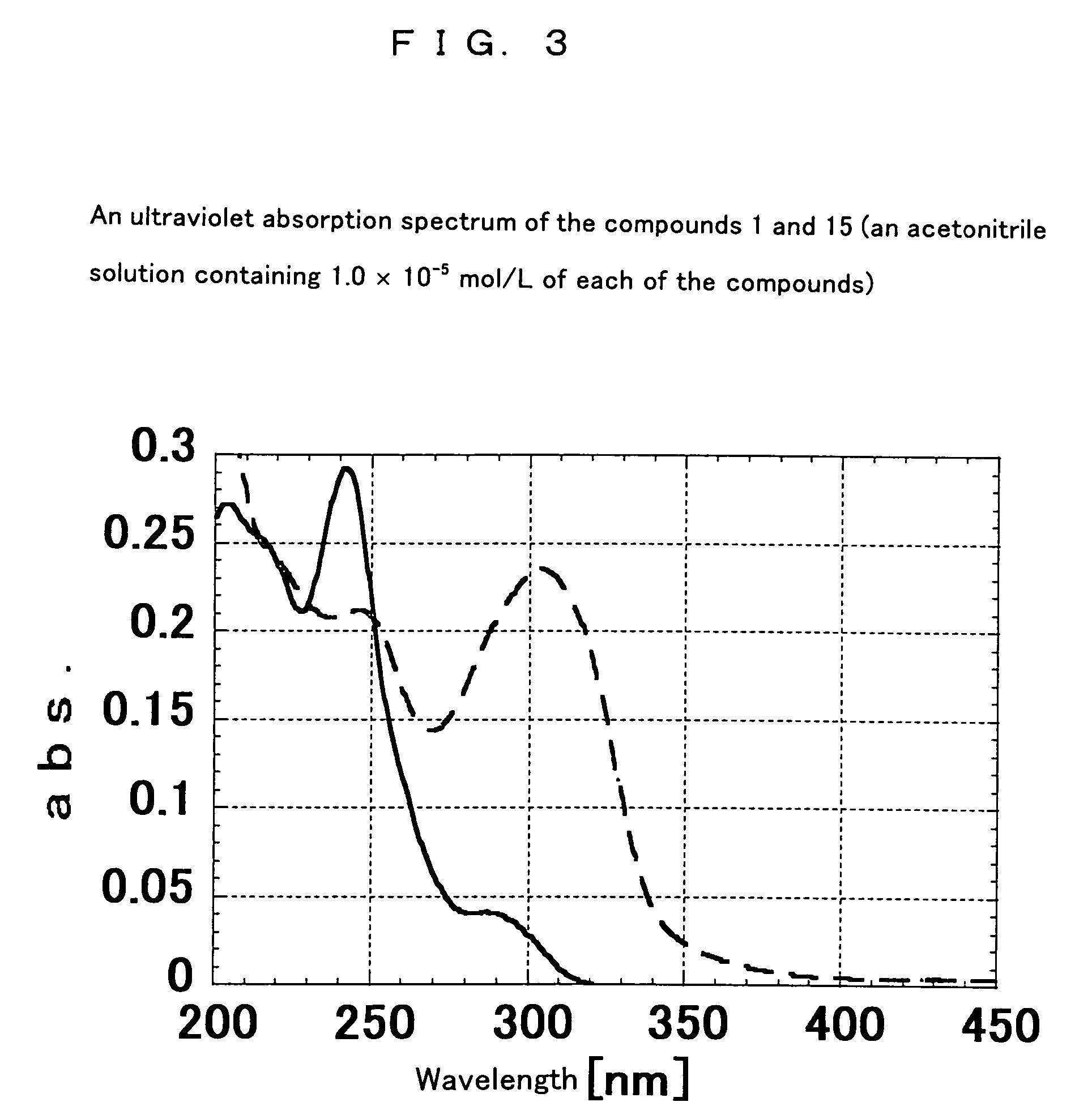

A photoradical generator which produces no low-molecular decomposition material but a radical during a photoradical generating process, does not generate a radical during a heating process, exists in a chemically stable state in a resulting product of a radical reaction such as a cured coating layer or the like, has high heat resistance, stability and preserving ability, and is excellent in compatibility or solubility is provided. The photoradical generator is comprised of a compound (a) having a seven-membered ring imide structure-containing group represented by the following formula (1), wherein, R1 to R8 respectively represent a hydrogen atom or a substituent and may be a cyclic structure in which they are bonded to each other.

Owner:DAI NIPPON PRINTING CO LTD

Electric leakage resistant PP material

The invention relates to the technical field of novel materials and particularly relates to an electric leakage resistant PP material. The electric leakage resistant PP material is prepared from the following raw material components in percentage by weight: 60-90% of PP resin, 1-5% of a phosphorus phenol flame retardant, 4-8% of a bromine flame retardant, 1-3% of a powder filler, 2-7% of a flexibilizer and 0.2-1% of a lubricating agent. The preparation method comprises the following steps: adopting the principle condensed phase flame retardance and auxiliary interrupted heat exchange, strictlycontrolling the component of metal components in the materials, taking the PP resin as a carrier, performing molecular decomposition and recombination by a twin-screw extruder, granulating, performing physical test and environmental inspection, and finally obtaining the high-PTI (Proof Tracking Index) low-cost PP material. The product is stable in quality and excellent in safety performance, thePTI value reaches 600V, the cost is greatly reduced relative to PBT (Poly Butylenes Terephthalate), the cost performance is high, and the requirements of the electronics and electric appliance industries on the product safety are met.

Owner:东莞市百思特塑胶有限公司

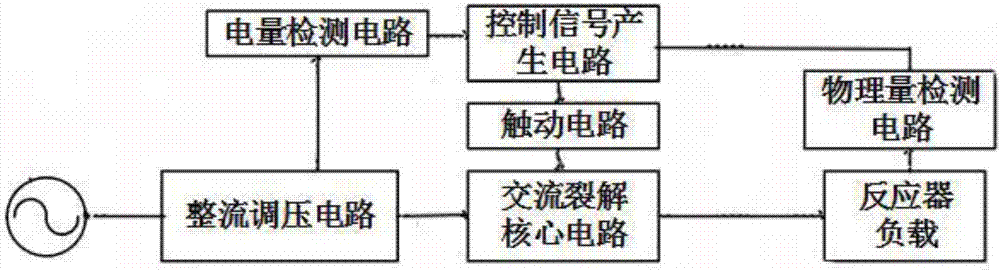

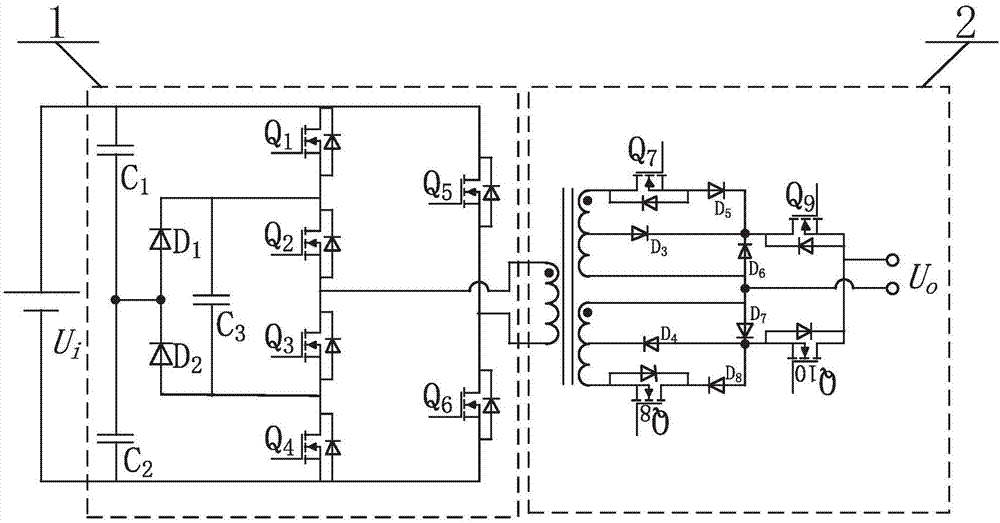

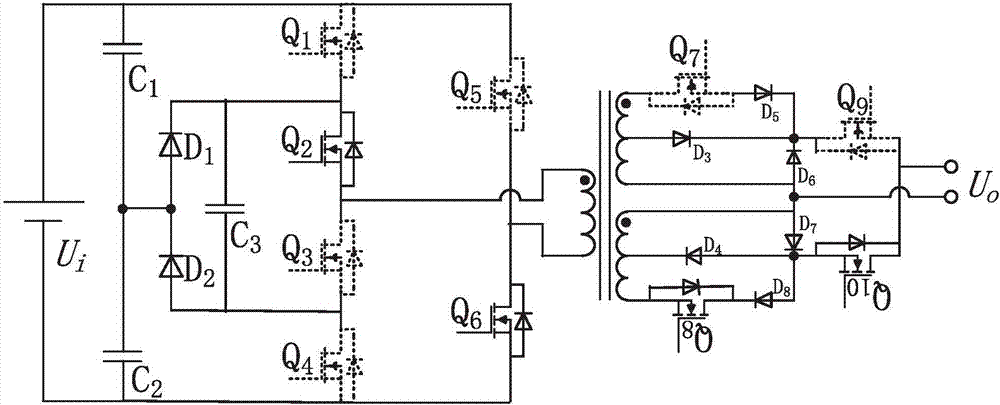

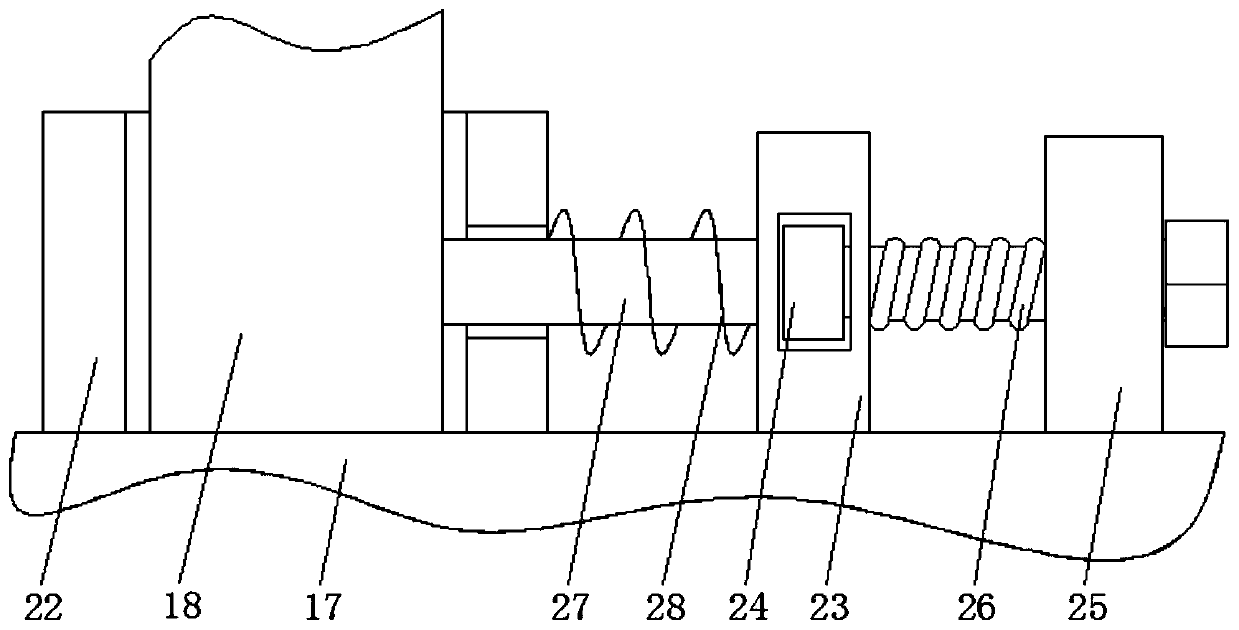

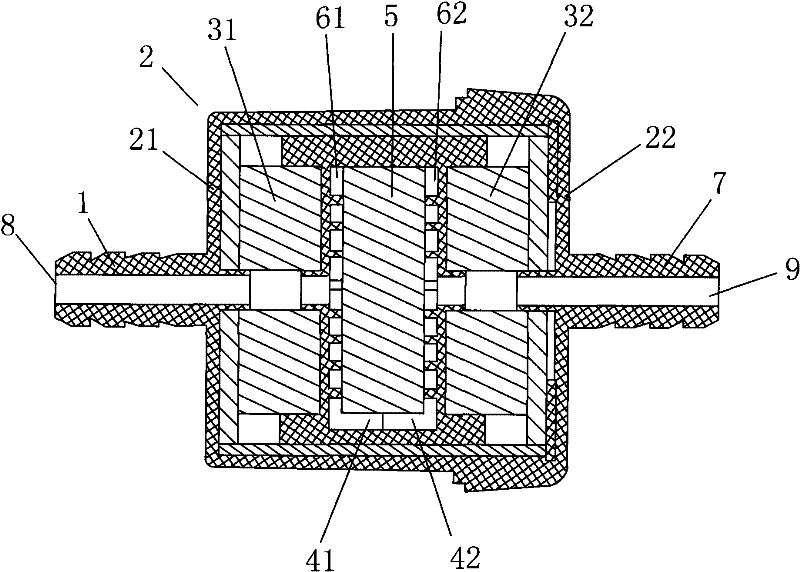

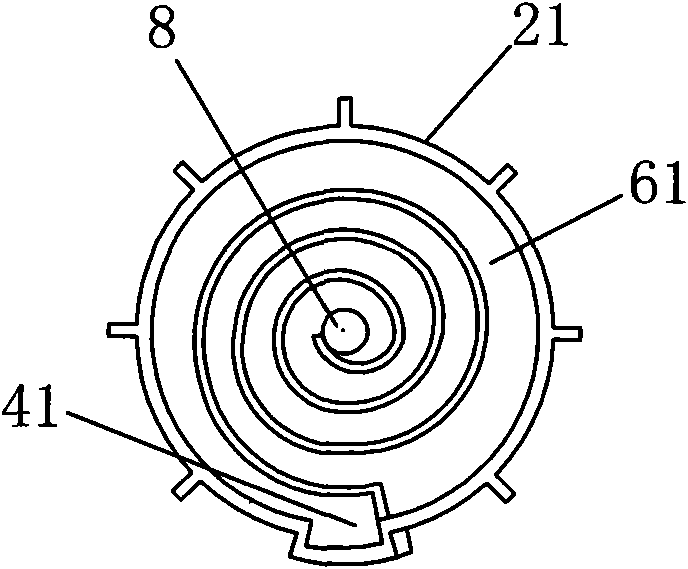

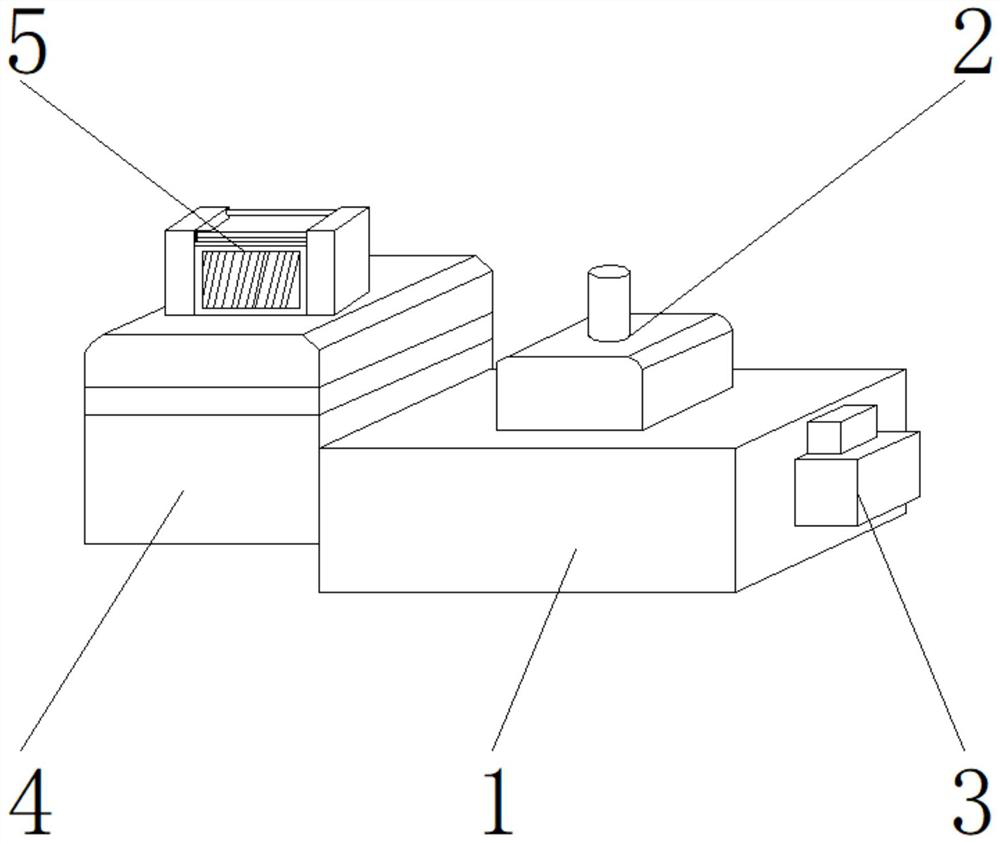

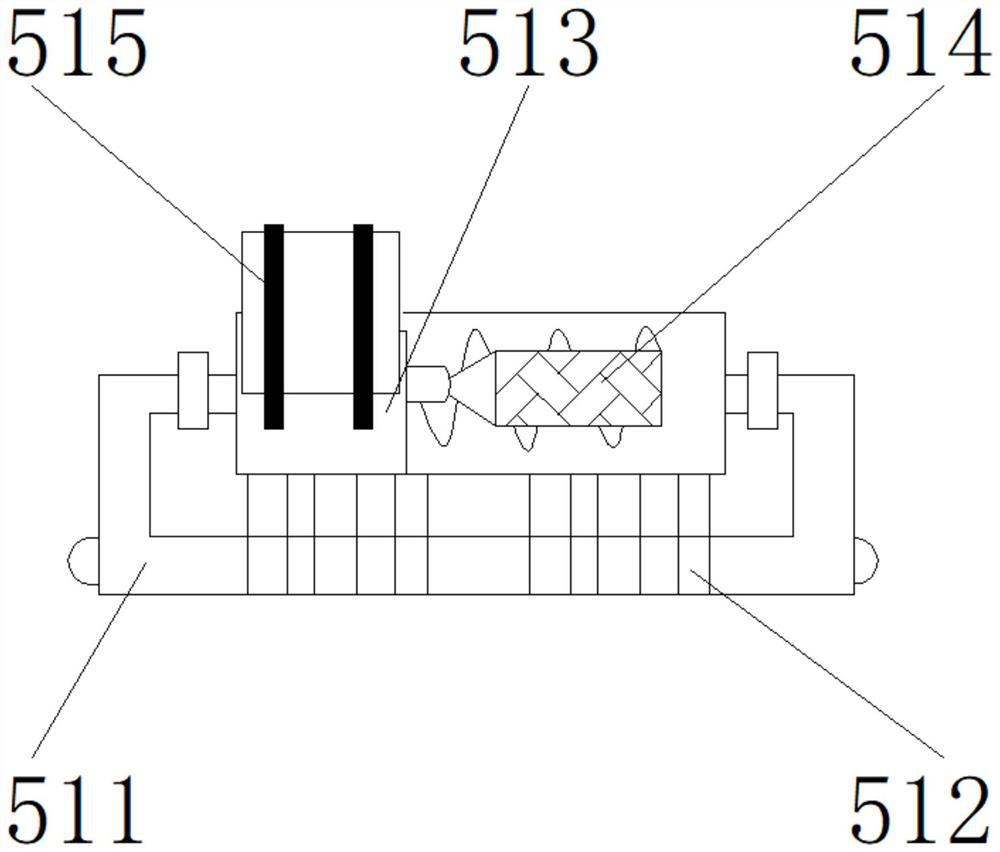

Molecular decomposition alternating-current driver

ActiveCN107070232AImprove conversion efficiencySave energyEfficient power electronics conversionDc-dc conversionResonanceTransformer

The invention discloses a molecular decomposition alternating-current driver comprising a rectifier voltage-regulating circuit, an alternating-current decomposition core circuit and a decomposition reactor. The alternating-current decomposition core circuit consists of an external power supply Ui, a compound level generation circuit, and a variable boost resonance circuit; the compound level generation circuit generates different levels and the variable boost resonance circuit realizes outputs of different drive energy levels. According to the molecular decomposition alternating-current driver, outputs at different energy levels is realized for different decomposition needs. Compared with the traditional fixed resonant output device, the driver enables the energy output form to be optimized, the energy utilization efficiency to be improved, the resonant transformer size to be reduced, the service life of the molecular decomposition driver to be prolonged. The control plan is simple and is easy to implement; and the reliability is high and the cost is low.

Owner:NJTECH ENVIRONMENT TECH CO LTD

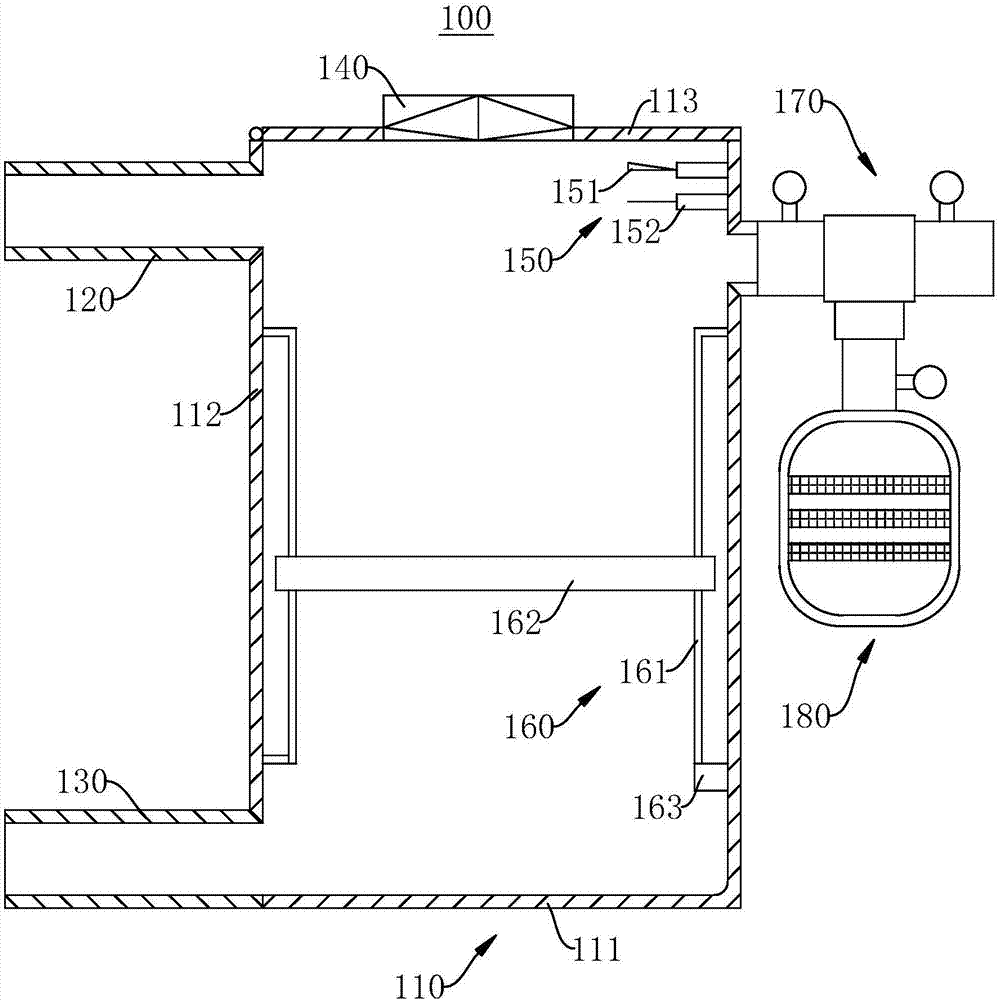

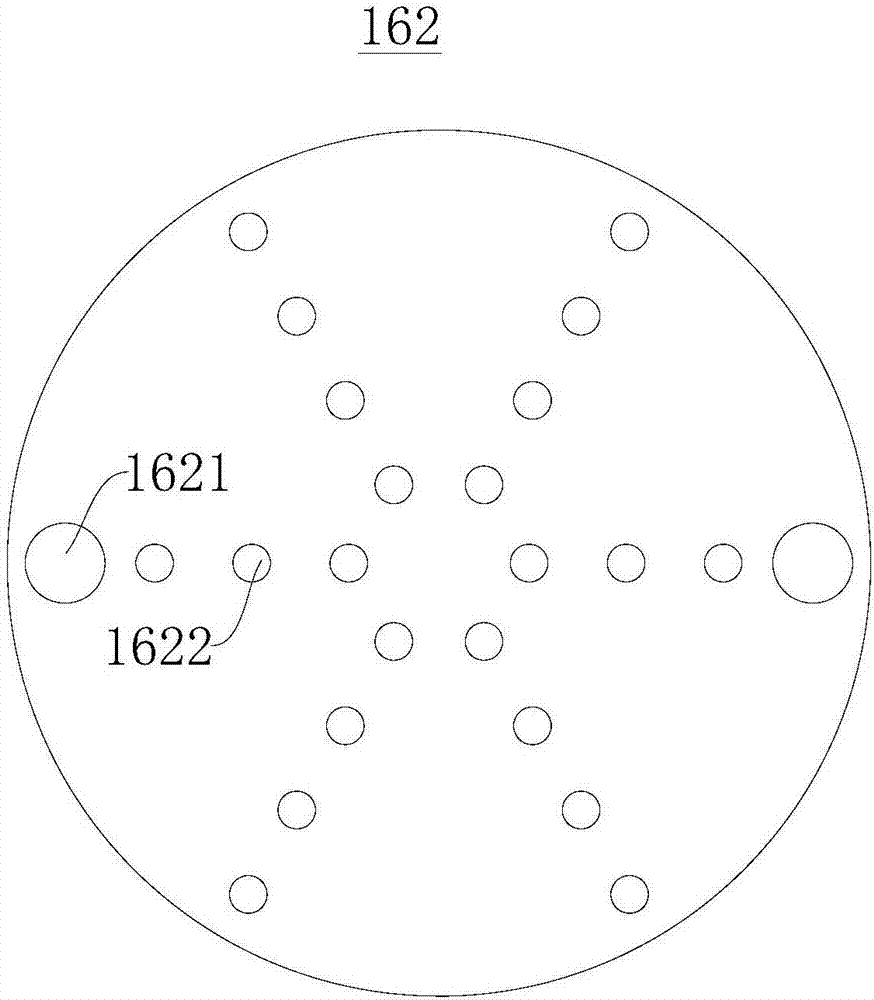

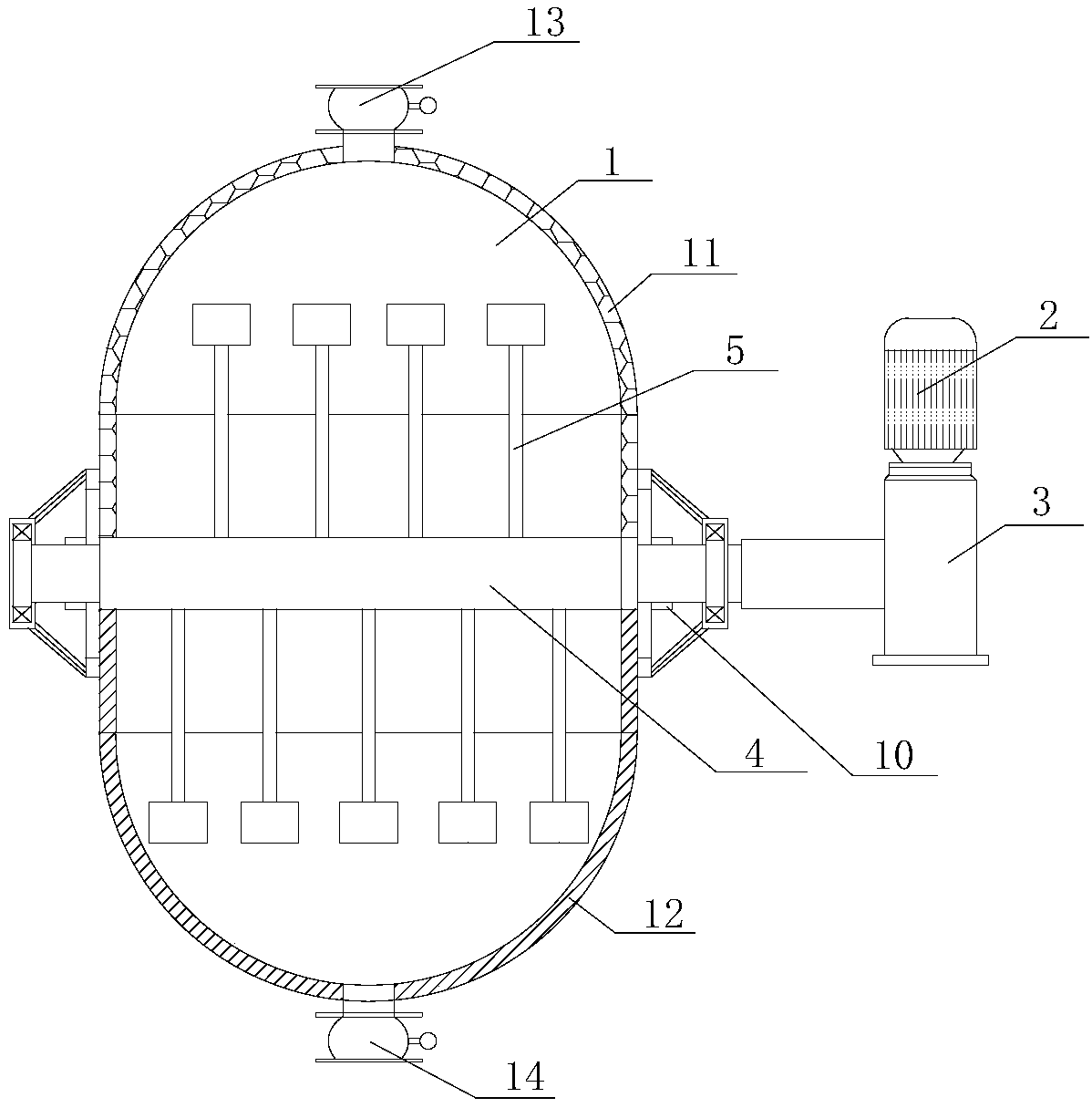

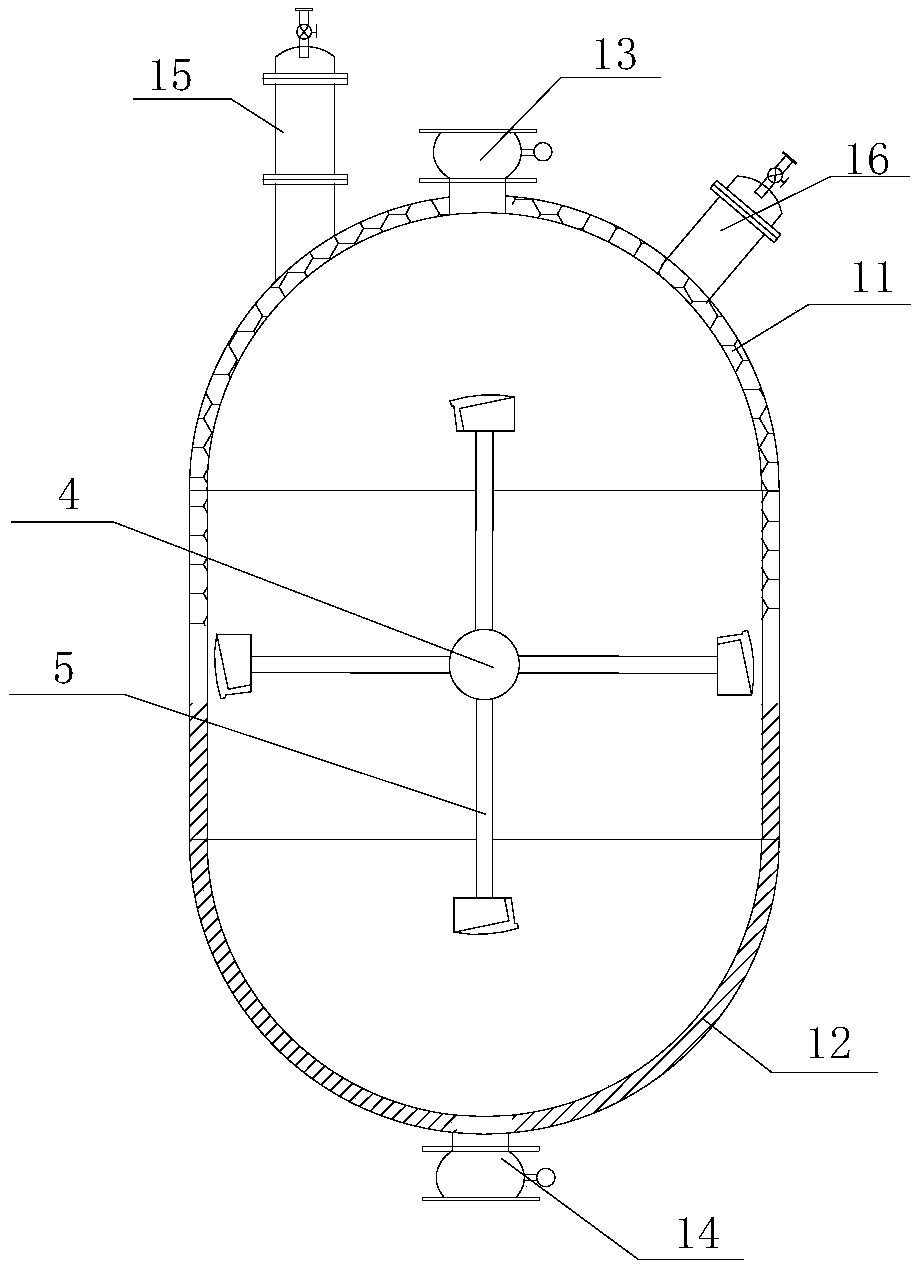

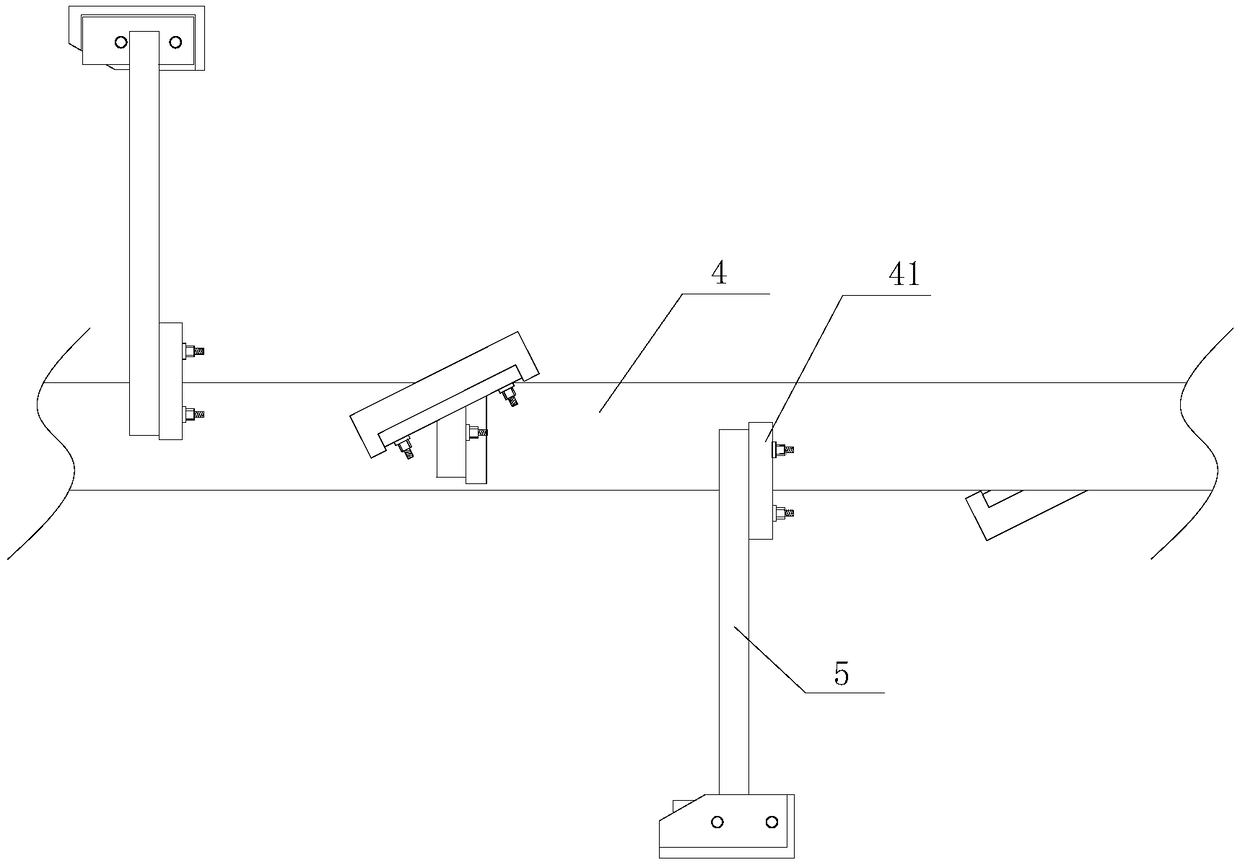

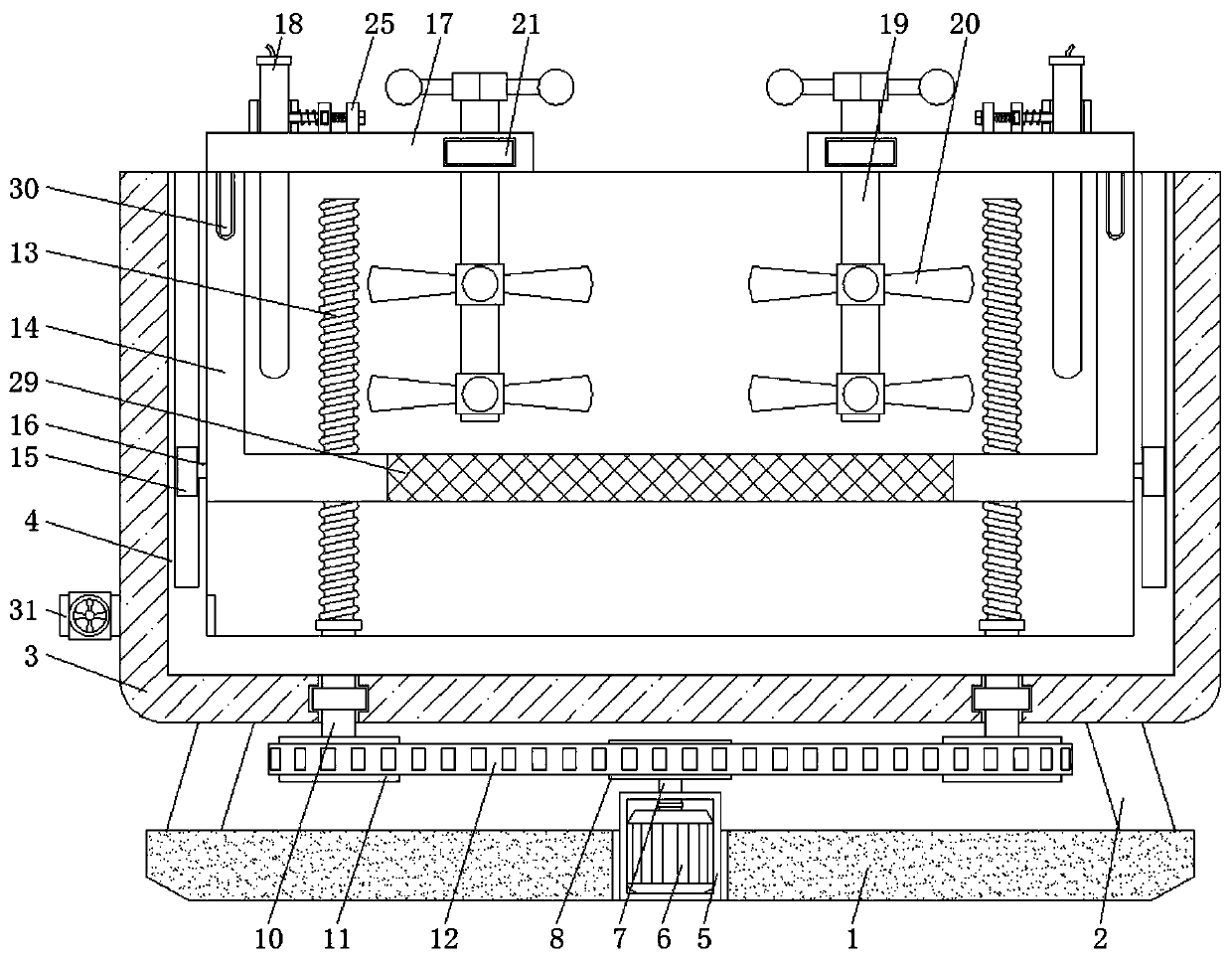

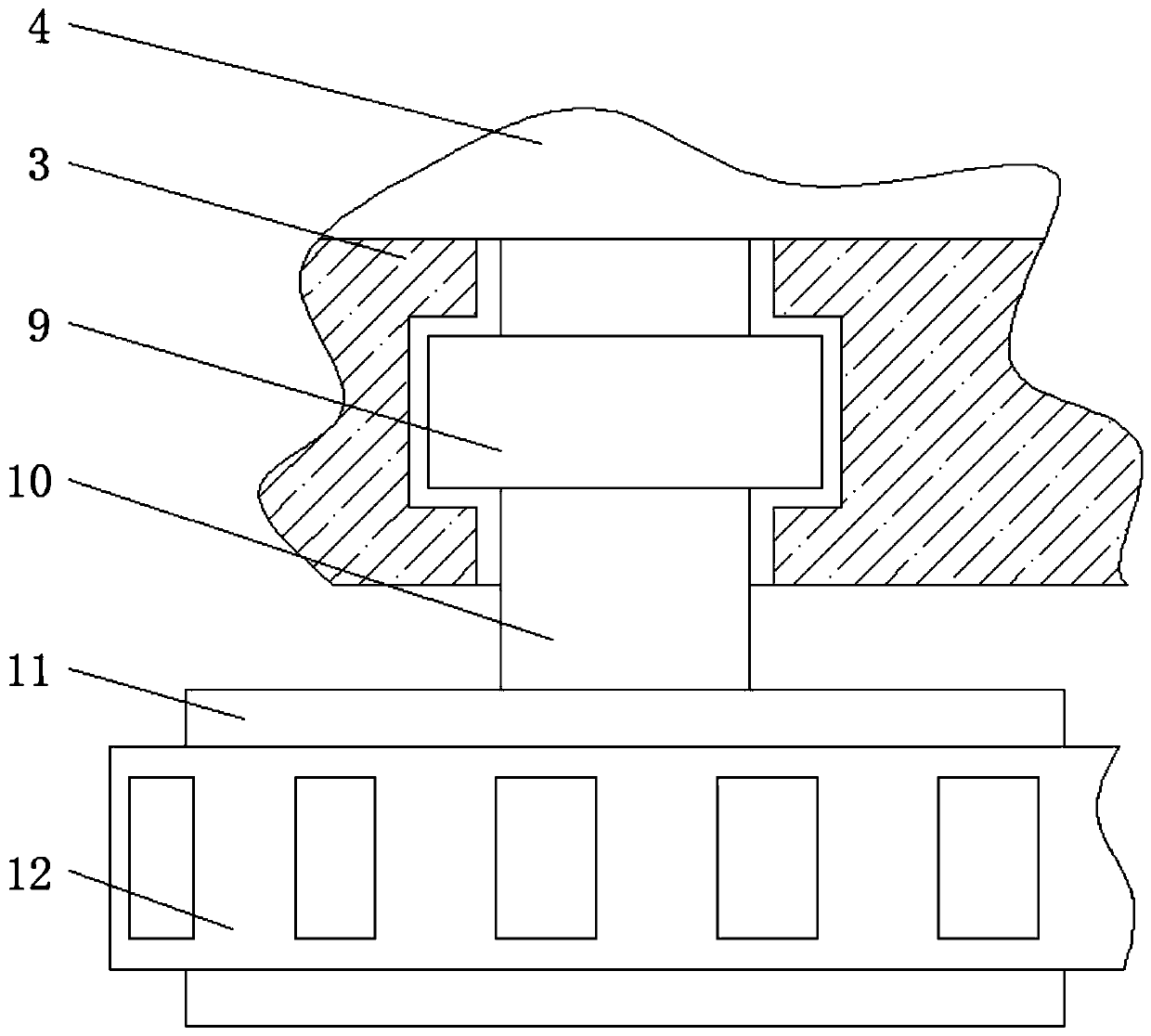

Domestic refuse treatment device

PendingCN109226187AReasonable structureImprove processing efficiencyTransportation and packagingSolid waste disposalTherapeutic effectEngineering

The invention discloses a domestic refuse treatment device comprising a tank body, a driving motor, a transmission mechanism, a stirring driving shaft and stirring mechanisms; the tank body is provided with an upper treatment tank body and a lower drying tank body; the middle of the tank body is provided with the stirring driving shaft; the driving motor controls the stirring driving shaft to rotate by virtue of the transmission mechanism; the plurality of stirring mechanisms are mounted in the circumferential direction of the stirring driving shaft and are staggered in an axis direction of the stirring driving shaft; the end parts of the stirring mechanisms are provided with stirring blades; steam in the tank body is decomposed into oxygen molecules and hydrogen molecules in vacuum, the oxygen molecules and the hydrogen molecules can be combined with carbon molecules decomposed by refuse at high temperature and in vacuum, and thus, the treatment effect is achieved by molecular decomposition; and materials are controlled to be stirred by the stirring mechanisms, so that that the materials are in suspended states in a refuse treatment process is ensured, and the refuse treatment efficiency is increased.

Owner:王姜明

Photo radical generator, photo sensitive resin composition and article

ActiveUS7528205B2Improve abilitiesIncrease resistanceSilicon organic compoundsPhotomechanical apparatusImideHydrogen atom

A photoradical generator which produces no low-molecular decomposition material but a radical during a photoradical generating process, does not generate a radical during a heating process, exists in a chemically stable state in a resulting product of a radical reaction such as a cured coating layer or the like, has high heat resistance, stability and preserving ability, and is excellent in compatibility or solubility is provided. The photoradical generator is comprised of a compound (a) having a seven-membered ring imide structure-containing group represented by the following formula (1), wherein, R1 to R8 respectively represent a hydrogen atom or a substituent and may be a cyclic structure in which they are bonded to each other.

Owner:DAI NIPPON PRINTING CO LTD

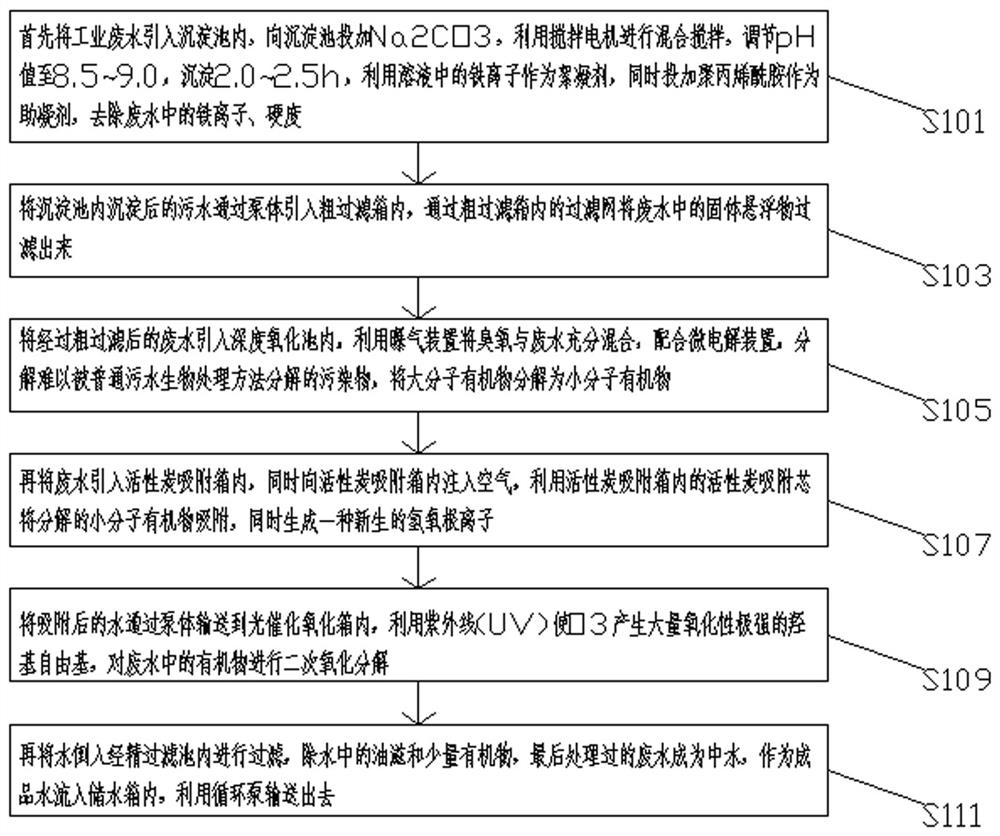

Advanced treatment and cyclic utilization method for industrial wastewater

PendingCN113429045AImprove purification effectSimple structureWater treatment parameter controlWater/sewage treatment by irradiationActivated carbonIndustrial waste water

The invention discloses an advanced treatment and cyclic utilization method for industrial wastewater, which comprises the steps of firstly, removing iron ions and hardness in wastewater in a sedimentation tank under the action of a flocculating agent and a coagulant aid, then introducing sewage precipitated in the sedimentation tank into a coarse filtration tank through a pump body, then introducing the sewage into an advanced oxidation tank, fully mixing ozone with the wastewater by using an aeration device, decomposing macromolecular organic matters into micromolecular organic matters for primary decomposition, adsorbing the decomposed micromolecular organic matters by using an activated carbon adsorption core in the activated carbon adsorption box, conveying the adsorbed water into the photocatalytic oxidation box through the pump body, carrying out secondary oxygenolysis on organic matters in the wastewater, finally filtering the wastewater in a fine filter tank, and conveying out by a circulating pump. The method has the beneficial effects that the device is simple in structure and convenient to operate, the wastewater can be subjected to double decomposition and filtration, the effect of decomposing macromolecules into micromolecules is greatly improved, the purification effect on the wastewater is improved, and cyclic utilization can be realized.

Owner:福建省环境保护设计院有限公司

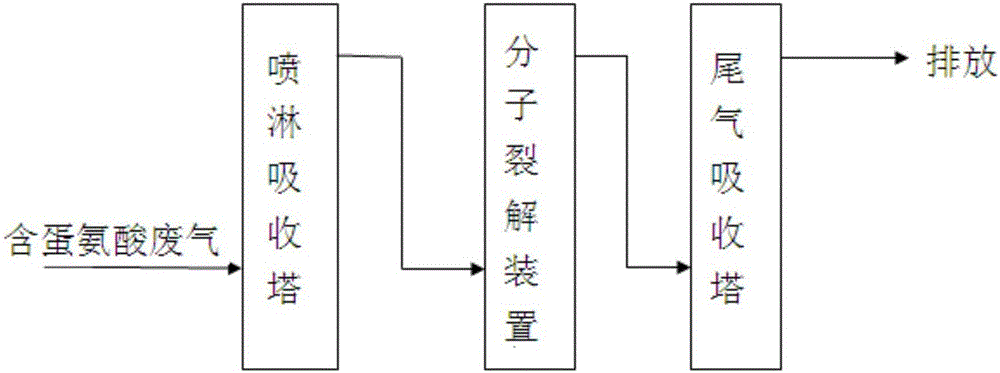

Method for treating methionine production technology waste gas

InactiveCN105771569ALow costReduce processing costsDispersed particle separationChemical LinkageReactor system

The invention belongs to the field of waste gas treatment and relates to a method for treating methionine production technology waste gas. The method includes enabling the methionine production technology waste gas to pass through a pretreatment absorption tower, a molecular decomposition system and a tail gas absorption tower sequentially, wherein the molecular decomposition system comprises an energy release system and a reactor system, and the energy release system generates a high-energy field in a reactor to enable chemical bonds of contaminants to break and degrade. The method for treating the methionine production technology waste gas has the advantages of simplicity in operation, low treatment cost, low device investment and the like.

Owner:NANJING UNIV OF TECH

A method for modifying silicon-carbon composite negative electrode with asphalt modified process derivatives

ActiveCN111342035BLow light contentReduce escapeMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

Owner:西安英纳吉科技有限公司

A method for efficient extraction of quorum-sensing signaling molecules from aerobic granular sludge

ActiveCN107515143BReduce the possibility of degradationEffectively study the regulation mechanism of quorum sensingPreparing sample for investigationSludgeSignalling molecules

The invention discloses a method of efficiently extracting quorum sensing signal molecules from aerobic granular sludge. The method can efficiently extract quorum sensing signal molecules from extracellular polymeric substances in aerobic granular sludge. The method comprises the following steps: (1) extracellular polymeric substance hydrolysis; (2) hydrolysis supernate collection; (3) liquid-liquid extraction; (4) vacuum concentration; and (5) nitrogen blowing and constant volume. The operation is convenient, and the reaction conditions are mild. The method can solve the problem of single molecular decomposition caused by release of intracellular organic matters during the process of extracting signal molecules from a granular sludge system and is an efficient and feasible signal molecule extraction method.

Owner:ZHEJIANG UNIV

Environment-friendly wastewater treatment device for printing plant

InactiveCN110563216AIncreased precipitation rateThorough treatmentTreatment involving filtrationMultistage water/sewage treatmentRedoxPulp and paper industry

The invention relates to the technical field of sewage treatment, and discloses an environment-friendly wastewater treatment device for a printing plant. The wastewater treatment device comprises a bottom plate; supporting rods are fixedly arranged at the top of the bottom plate, wherein the number of the supporting rods is two; an outer open tank is fixedly arranged at the top ends of the two supporting rods; an inner open tank is movably sleeved in the outer open tank; a box body is fixedly sleeved in the middle of the bottom plate; and a driving motor is fixedly arranged in the box body. According to the environment-friendly wastewater treatment device for a printing plant, printing plant wastewater is mixed with precipitation reagents through cooperation of stirring shafts, stirring blades and baffle rings, so that the precipitation rate is increased; two metal rods are matched and are respectively set to have different activity, so that metal ions in the printing plant wastewaterare separated out again through oxidation-reduction reactions; and meanwhile, macromolecules are decomposed into small molecules, so that the wastewater is subjected to secondary treatment, and the effect of thorough treatment is achieved.

Owner:FOSHAN SITECH CHEM TECH

molecular catalyst

InactiveCN101564670BGood effectMultiple pole changesEnergy based chemical/physical/physico-chemical processesFar infraredCooling fluid

Owner:沃吉安(厦门)电子科技有限公司

Method and device for treating malodorous flue gas

ActiveCN104707460BCorrosion resistanceExtended service lifeDispersed particle separationExternal electric electrostatic seperatorReaction layerElectrostatic separation

Owner:QILU UNIV OF TECH

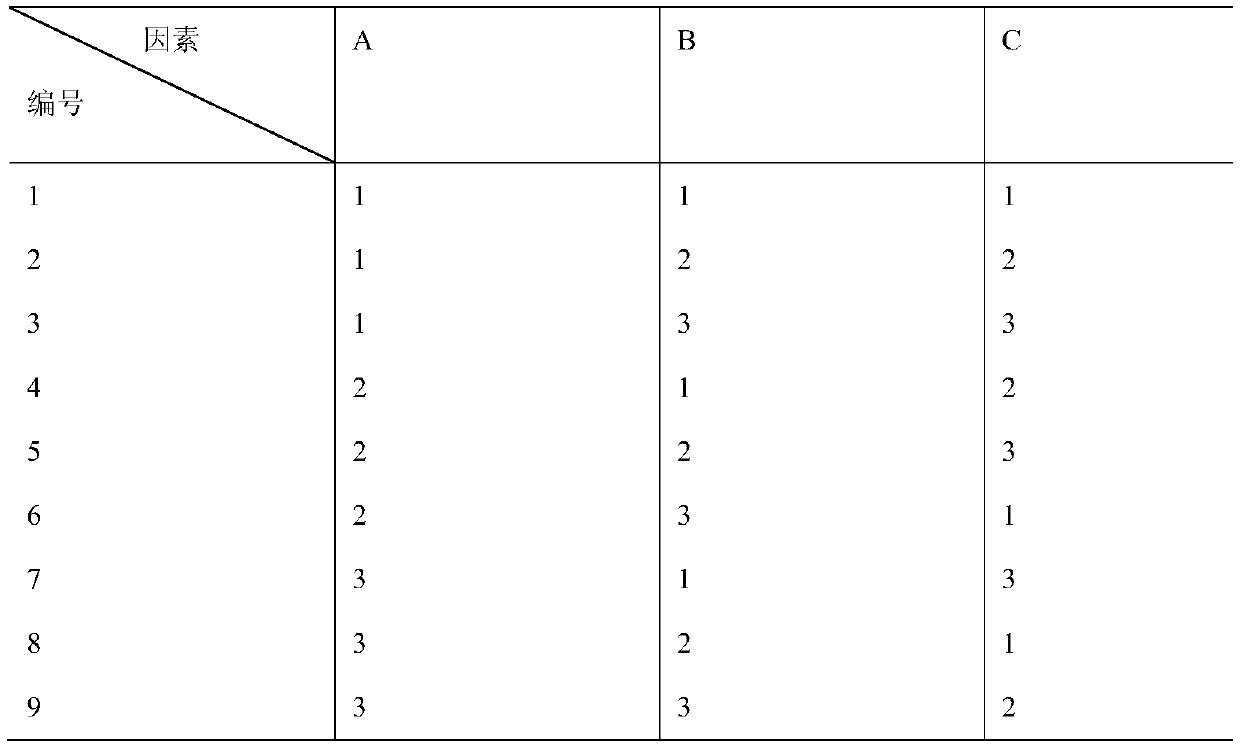

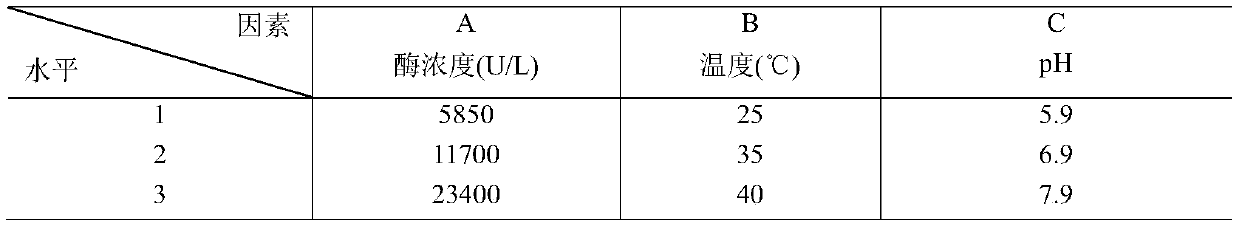

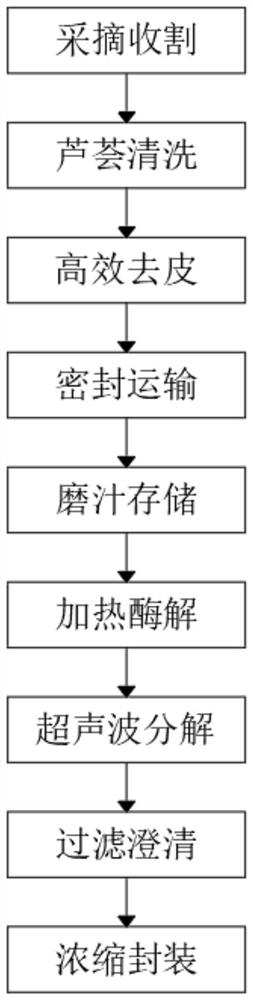

Aloe processing technology

PendingCN114794344AFully absorbedGuaranteed yieldJuice extractionVegetable peelingUltrasound deviceProcess engineering

The invention relates to the technical field of aloe processing, and discloses an aloe processing technology which comprises the following steps: picking, harvesting and beautifying leaves in an aloe planting base, then cleaning, peeling, sealing and transporting pulp, grinding into juice and storing, heating and carrying out enzymolysis, carrying out ultrasonic decomposition, filtering and clarifying, and finally concentrating and packaging. According to the aloe processing technology, the aloe normal juice is subjected to cyclic decomposition treatment in an ultrasonic high-frequency generator through a technology or a processing method for performing decomposition treatment on the aloe normal juice by adopting ultrasonic equipment, so that macromolecules are decomposed into tiny molecules on the premise of not damaging and not losing effective components such as aloe polysaccharide, and then the aloe normal juice is subjected to cyclic decomposition treatment in the ultrasonic high-frequency generator. Effective components of the product can be fully absorbed in the using process, the yield of the dry powder can be guaranteed, the processing efficiency and the processing quality are improved, and compared with a homogeneous enzymolysis process, the yield of the dry powder is improved.

Owner:海南荟研生物工程有限公司

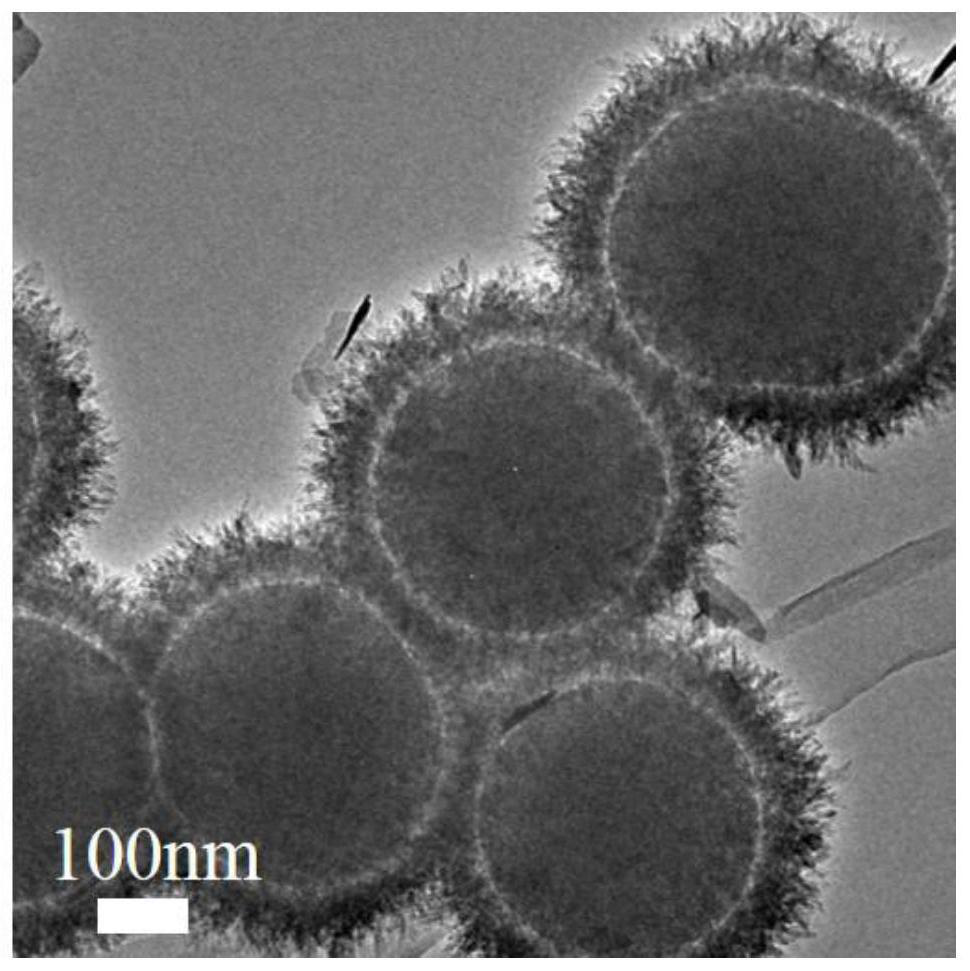

A core-shell structure nanosphere photocatalytic material and its preparation method and application

ActiveCN111468139BHigh catalytic efficiencyImprove catalytic stabilityPhysical/chemical process catalystsEnergy inputThioureaLight energy

The invention provides a nanosphere photocatalytic material with a core-shell structure, which is made of SiO 2 Nanospheres as the core, with ZnS / CuS x The nanosheet structure is the shell, and a preparation method is also provided, the method is: adding tetraethyl orthosilicate and ammonia water to ethanol, stirring and mixing to obtain SiO 2 Nanospheres are dispersed in deionized water, urea, copper nitrate aqueous solution and zinc nitrate aqueous solution are added, after hydrothermal reaction, centrifuged and dried to obtain the primary product of core-shell structure, thiourea is added, after hydrothermal reaction, centrifuged and dried, The core-shell structure nanosphere photocatalytic material was obtained. Also provided is the application of the core-shell structure nanosphere photocatalytic material for solar energy splitting water to produce hydrogen. The present invention passes photons in the core SiO 2 Nanosphere and Shell ZnS / CuS x Continuous reflection improves the light energy utilization rate, and can make full use of the light energy of visible light to catalyze the decomposition of water molecules to produce hydrogen gas, which can be precipitated quickly.

Owner:CENT SOUTH UNIV

Deodorizing kitchen waste treatment equipment

PendingCN114226404ANot easy to produce odorWill not corrodeSolid waste disposalTransportation and packagingOil and greaseGutter oil

The invention discloses deodorization kitchen waste treatment equipment, and relates to the technical field of kitchen waste treatment equipment, the deodorization kitchen waste treatment equipment comprises a main body, one side of the main body is provided with a sealing mechanism, the upper end of the main body is provided with a flushing device, the other side of the main body is provided with a material preparation box, and the upper end of the material preparation box is provided with a deodorization device. Under the combined action of a circulating water pump, a control valve, a water pipe, a flushing pipe and a protective sleeve, the equipment can have a cleaning function, kitchen waste is flushed, peculiar smells are not likely to be generated, and therefore the deodorization function is achieved; according to the invention, various forms of catering waste grease can be decomposed, secondary pollution is not generated, the grease is decomposed into hydrophilic molecules, the decomposition speed is high, the efficiency is high, the deodorization function of the equipment is obvious, and illegal cooking oil is fundamentally eliminated.

Owner:德清华得环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com