Foul flue gas treatment method and device

A technology for flue gas treatment and odor, which is applied in the field of environmental science, can solve the problems of strong odor and odor, and cannot achieve effective breakthroughs in treatment technology, and achieve the effects of low equipment cost, minimum operating cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

[0042] In the glutamic acid fermentation industry, the fermentation effluent formed after extraction of the product is rich in high SO 4 2- , high NH 3 -N, high COD. At present, organic-inorganic compound fertilizers are produced by spraying and granulating the fermentation waste liquid at 550°C after being concentrated, so that the fermentation waste liquid can be recycled. However, under high temperature conditions, the organic matter in the fermentation waste liquid is cracked The formation of organic aerosol substances, VOCs, SVOCs, and water vapor together form the spray granulation malodorous smoke. In this example, 100,000 m 3 / h Malodorous flue gas treatment equipment as an example:

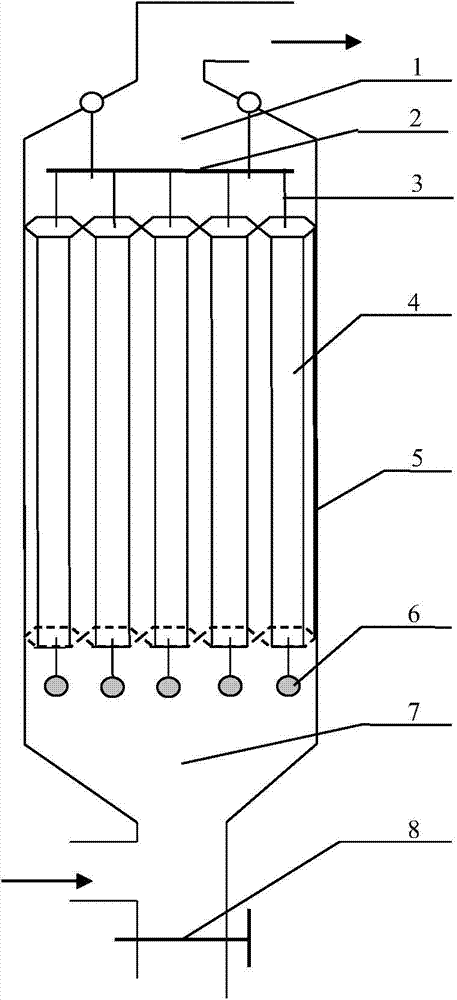

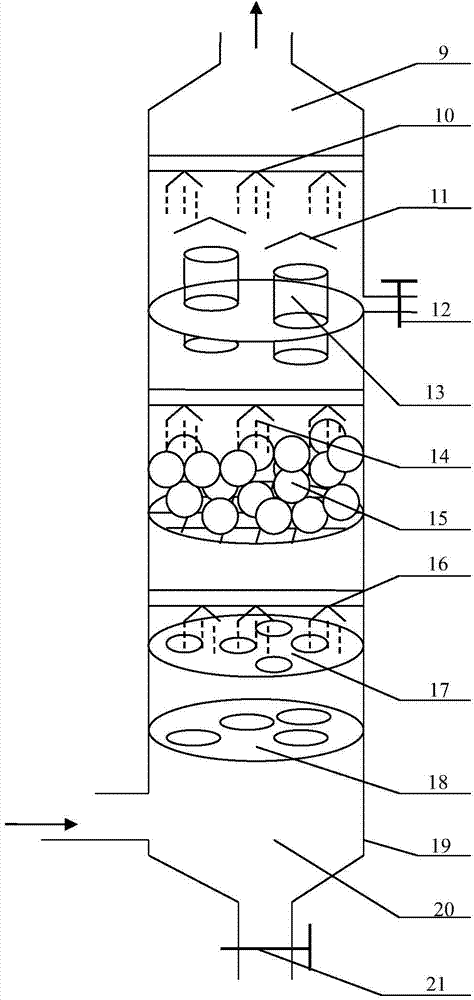

[0043] A malodorous flue gas treatment device is composed of two parts: an organic aerosol particle pollutant separation part, and a VOCs and SVOCs molecular decomposition part.

[0044] The structure of the organic aerosol particle pollutant separation part is as follows: it includes...

Embodiment 2

[0056] Other is with embodiment 1, and difference is:

[0057]The conductive anode tube group is composed of a number of anode tubes arranged in parallel, and the shape is a round tube honeycomb type, and the diameter of the round tube honeycomb type is 300-400mm;

[0058] The hydrogen peroxide reaction liquid sprayer is a primary spray, and the spray liquid is hydrogen peroxide (H 2 o 2 ); the acidic reaction liquid sprayer is a secondary spray, and the spray liquid is a hydrochloric acid reaction liquid with a pH value of 4; the alkaline solution sprayer is a three-stage spray, and the spray liquid is calcium hydroxide with a pH value of 10 solution.

[0059] The gas velocity of the pores of the secondary reaction layer sieve plate is 15m / s; the gas velocity of the pores of the primary reaction layer sieve plate is 18m / s.

[0060] The iron-carbon filler is made of iron-carbon micro-electrolytic material, and the components of the iron-carbon micro-electrolytic material ar...

Embodiment 3

[0062] Other is with embodiment 1, and difference is:

[0063] The hydrogen peroxide reaction liquid sprayer is a primary spray, and the spray liquid is hydrogen peroxide (H 2 o 2 ); the acidic reaction liquid sprayer is a secondary spray, and the spray liquid is a nitric acid reaction liquid with a pH value of 5; the alkaline solution sprayer is a three-stage spray, and the spray liquid is an ammonia solution with a pH value of 8.

[0064] The gas velocity of the pores of the secondary reaction layer sieve plate is 20m / s; the gas velocity of the pores of the primary reaction layer sieve plate is 22m / s.

[0065] The iron-carbon filler is made of iron-carbon micro-electrolytic material, and the components of the iron-carbon micro-electrolytic material are: iron filings: activated carbon: rare earth metal: clay=85%: 13.8%: 0.2%: 1%, all % by mass; the diameter of the iron-carbon micro-electrolytic filler is 3.0 cm. The rare earth metal includes Pr, and the rare earth metal is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com