A core-shell structure nanosphere photocatalytic material and its preparation method and application

A technology of photocatalytic materials and core-shell structure, which is applied in the field of core-shell structure nanosphere photocatalytic materials and its preparation, can solve the problems of limiting energy utilization and catalytic efficiency, and achieve improved catalytic efficiency and stability, low cost, The effect of rapid infiltration and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

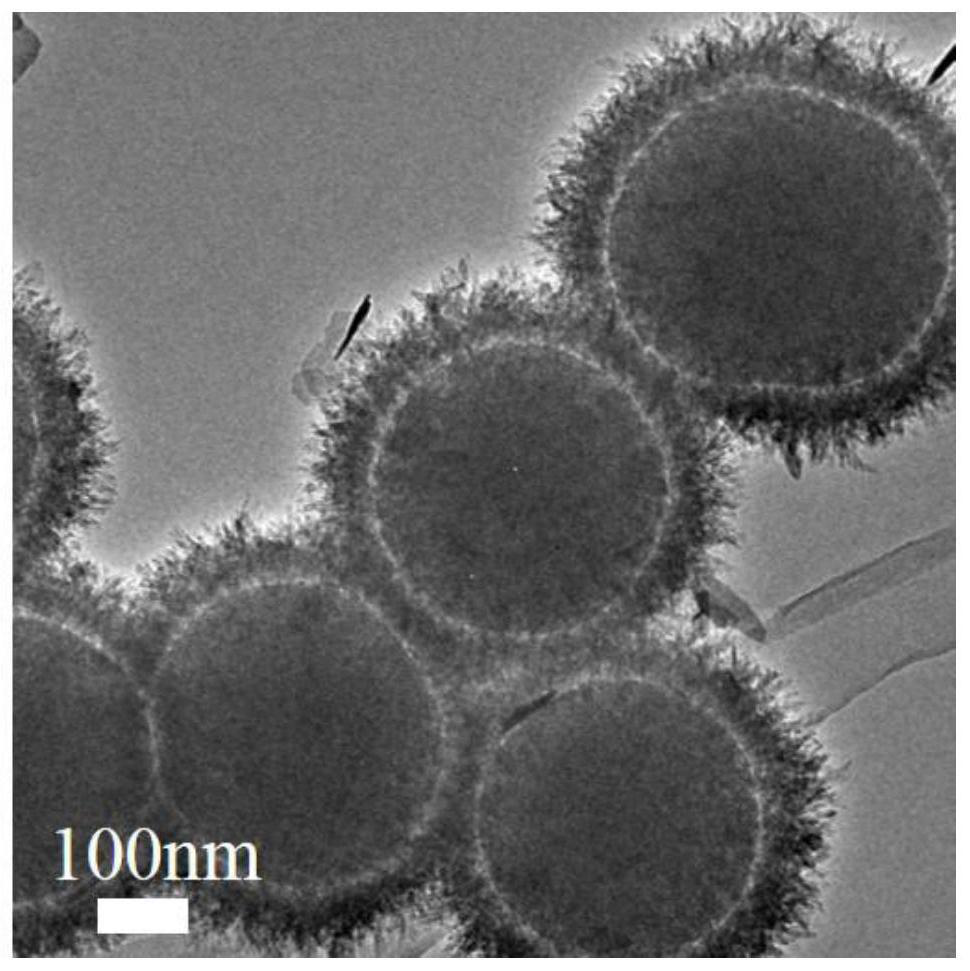

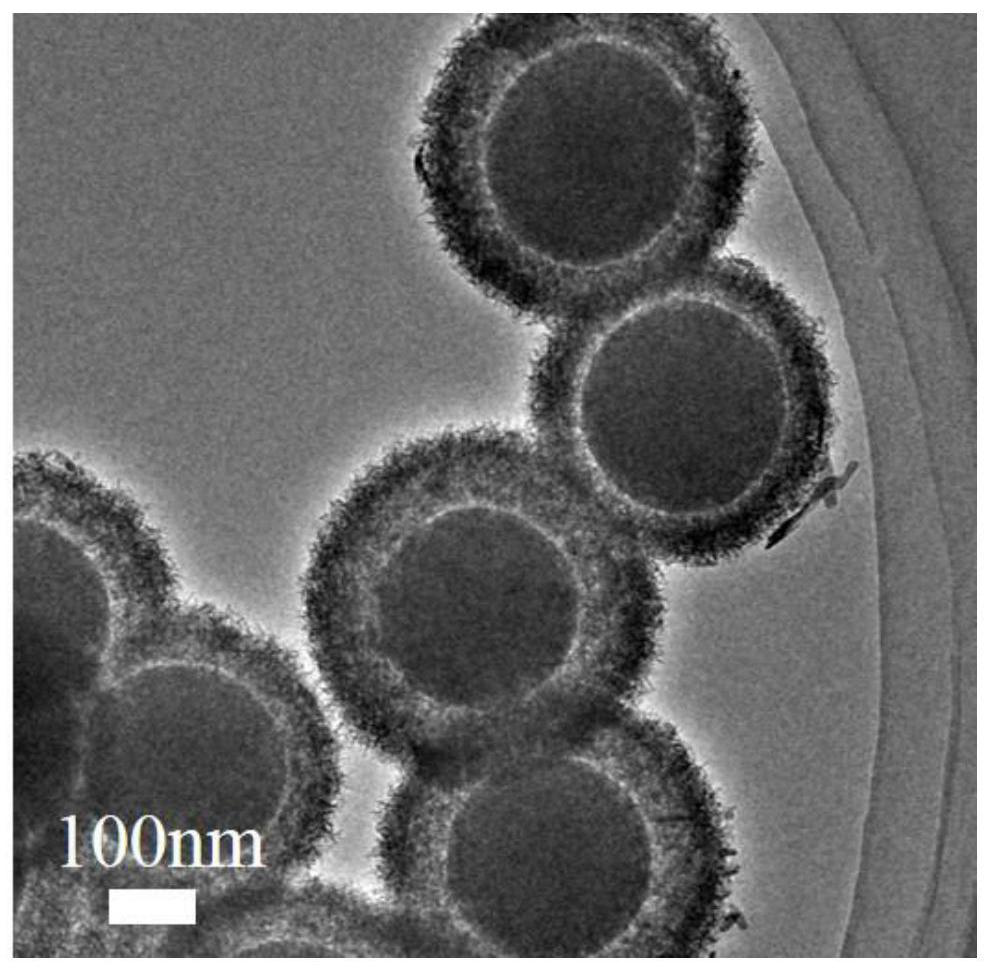

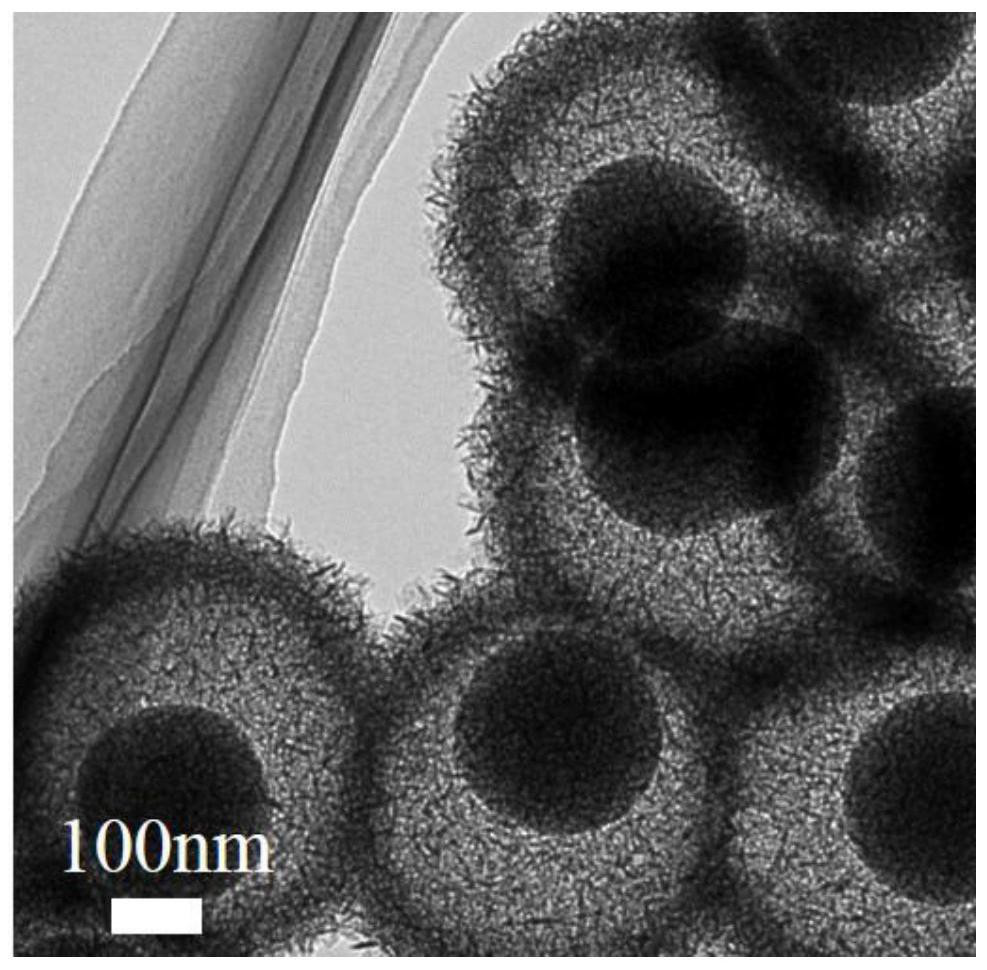

[0032] The core-shell structure nanosphere photocatalytic material of the present embodiment, the core-shell structure nanosphere photocatalyst material is made of SiO 2 Nanospheres as the core, with ZnS / CuS x The nanosheet-like structure is the shell; the SiO 2 The diameter of the nanosphere is 300nm-350nm; the diameter of the core-shell nanosphere photocatalytic material is 500nm-600nm; the ZnS / CuS x The molar ratio of Zn element and Cu element is 0.2:1.

[0033] This embodiment also provides a method for preparing the above-mentioned core-shell structure nanosphere photocatalytic material, the method is:

[0034] S1. At room temperature, add 4.2 mL of tetraethyl orthosilicate and 24 mL of ammonia water with a mass fraction of 17% to 80 mL of ethanol, stir and mix for 5 h at a speed of 300 r / min to obtain SiO 2 nanospheres;

[0035] The SiO formed can be adjusted by controlling the amount of ammonia water and tetraethyl orthosilicate, stirring speed and stirring time. 2...

Embodiment 2

[0045] The core-shell structure nanosphere photocatalytic material of the present embodiment, the core-shell structure nanosphere photocatalyst material is made of SiO 2 Nanospheres as the core, with ZnS / CuS x The nanosheet-like structure is the shell; the SiO 2 The diameter of the nanosphere is 200nm-300nm; the diameter of the core-shell nanosphere photocatalytic material is 500nm-600nm; the ZnS / CuS x The molar ratio of Zn element and Cu element is 0.2:1.

[0046] This embodiment also provides a method for preparing the above-mentioned core-shell structure nanosphere photocatalytic material, the method is:

[0047] S1. At room temperature, add 4.2 mL of tetraethyl orthosilicate and 24 mL of ammonia water with a mass fraction of 17% to 80 mL of ethanol, stir and mix for 1 h at a speed of 600 r / min to obtain SiO 2 nanospheres;

[0048] S2, SiO obtained from 30mg of S1 2 Nanospheres were dispersed in 30mL of deionized water, and then 0.8g of urea, 0.5mL of 0.1mol / L copper n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com