Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Liquiritoside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn process of licoflavone from licorice and licorice slag

InactiveCN1810796ASimple processHigh yieldSugar derivativesSugar derivatives preparationLicorice acidOrganic solvent

The present invention discloses preparation process of licoflavone from licorice and licorice slag, and features licoflavone is extracted from crushed licorice or licorice slag after extracting glycyrrhetic acid through adding organic solvent for soaking, filtering, and concentrating the filtrate; and that the prepared licoflavone contains licochalcone, isoliquiritigenin, glabidin, liquiritin, liquiritigenin and other components. The preparation process is simple, high in yield and suitable for industrial production.

Owner:车庆明

Synergistic clean extraction method of effective components in licorice root

A synergistic clean extraction method of effective components in licorice root adopts a solvent to synchronously extract the effective components in licorice root in order to obtain a total extract product, and the total extract product is separated one by one according to physical and chemical properties of all the components. The method comprises the following steps: 1, preparing the total extract product of the licorice root; 2, separating water-soluble and fat-soluble components; 3, separating glycyrrhizic acid from licorice pigments, licorice glucose and licorice polysaccharides in the water-soluble components; 4, separating the licorice pigments from the licorice glucose and the licorice polysaccharides; 5, separating the licorice glucose from the licorice polysaccharides; 6, separating and purifying glabridin in the fat-soluble components; 7, separating and purifying liquiritin and isoliquiritin in the fat-soluble components; 8, separating and purifying isoliquiritigenin and liquiritigenin in the fat-soluble components; 9, separating and purifying licochalcone A in the fat-soluble components; 10, separating and purifying licorice lignin in the fat-soluble components; and 11, separating and purifying licorice cellulose in the fat-soluble components.

Owner:李玉山

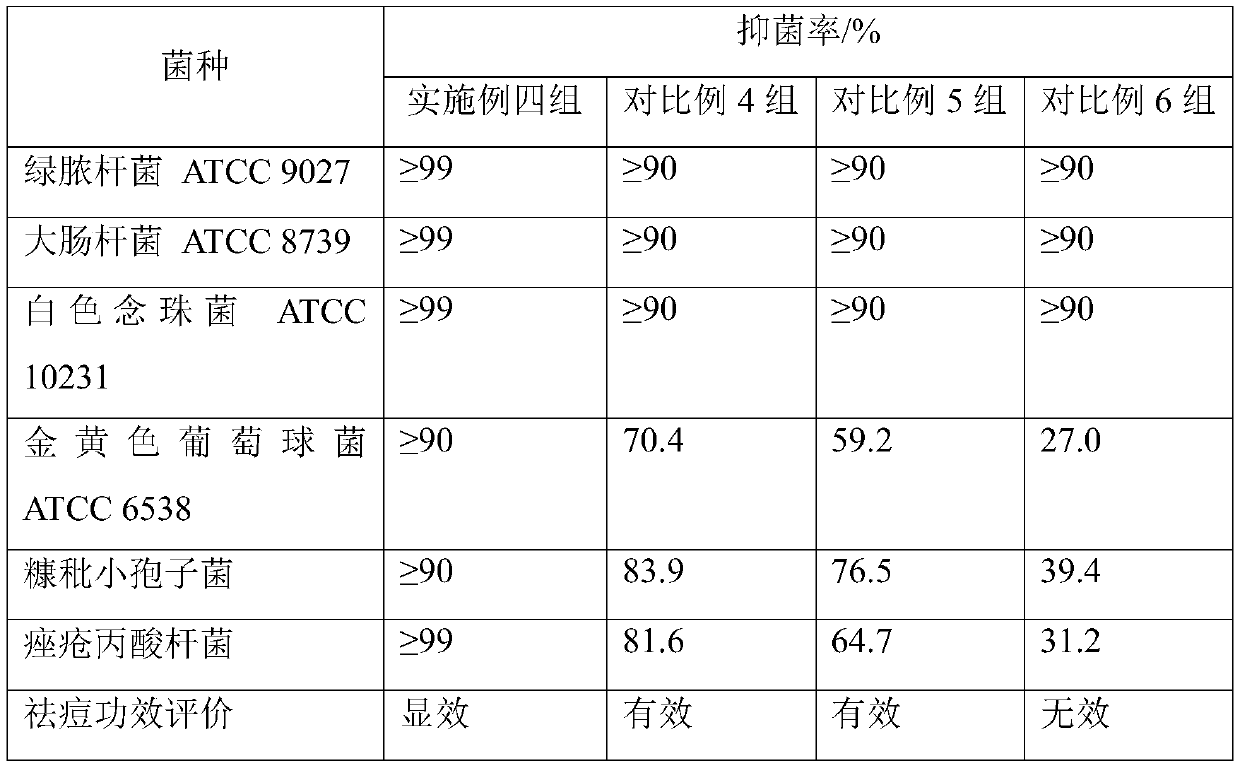

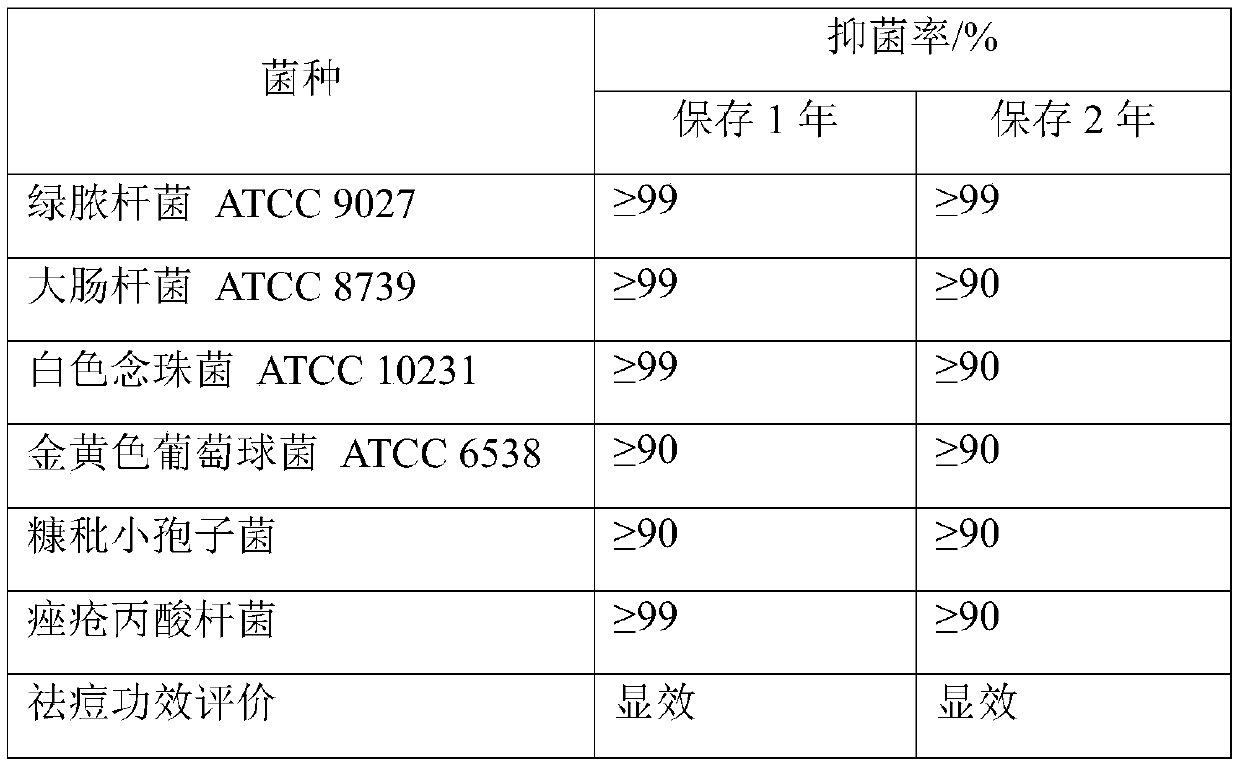

Acne-removing composition containing antibacterial peptide and acne-removing cream

ActiveCN106473944AGood securityUse low concentrationCosmetic preparationsToilet preparationsChemistryTreatment effect

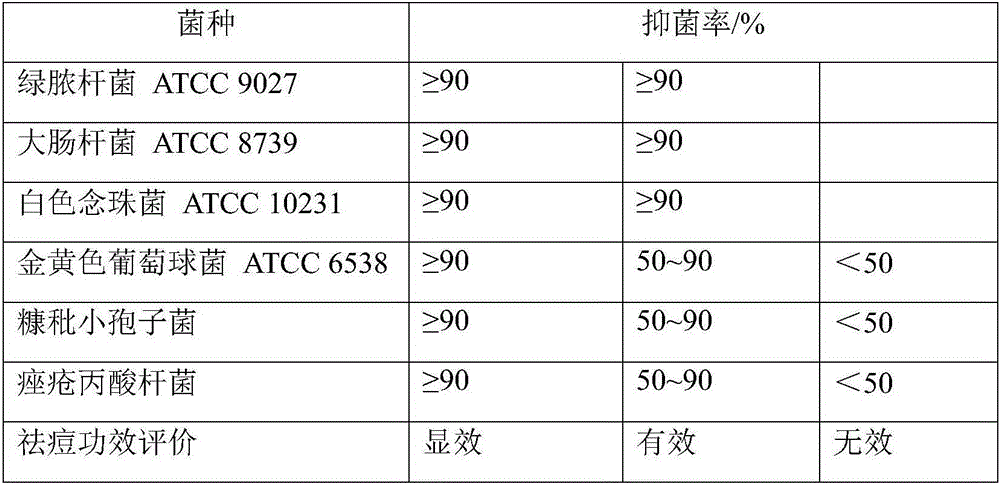

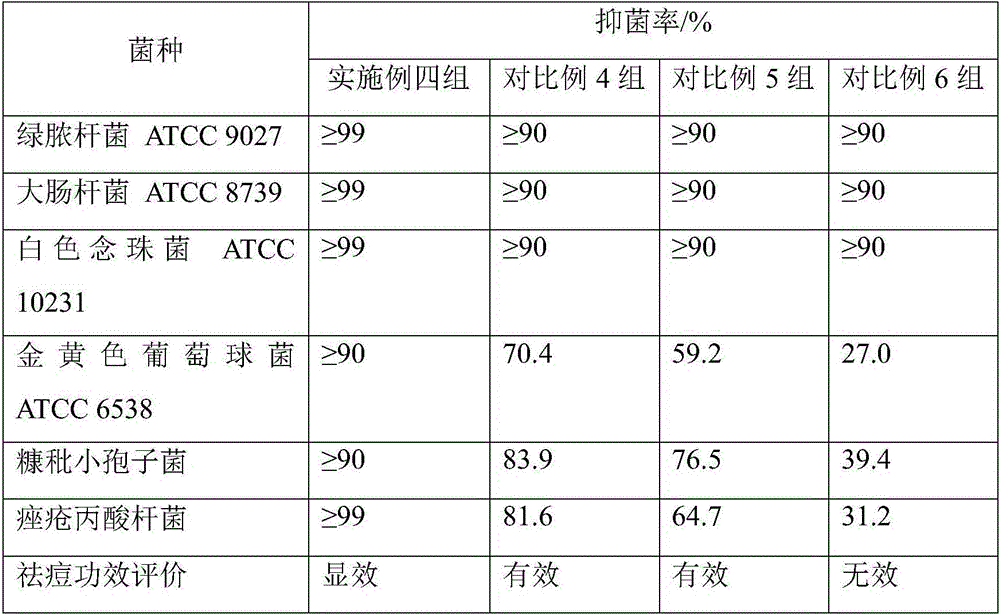

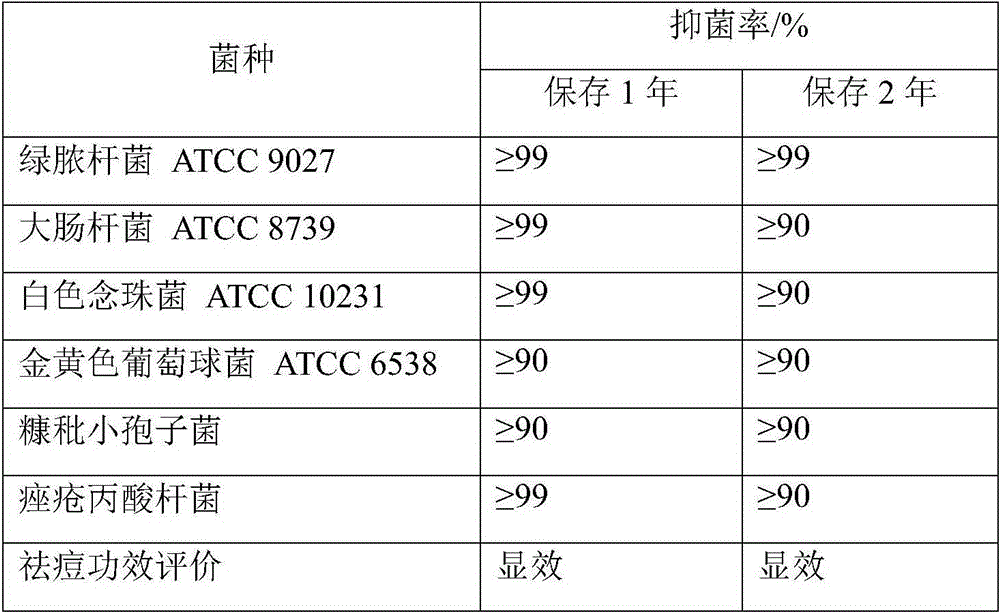

The invention provides an acne-removing composition containing antibacterial peptide. The acne-removing composition is prepared from the following components in parts by mass: 5 to 20 parts of herba centellae extract, 1 to 10 parts of liquiritin and 0.5 to 3 parts of the antibacterial peptide. The acne-removing composition containing the antibacterial peptide belongs to the technical field of cosmetics; by using the acne-removing composition provided by the invention, the synergistic interaction can be realized through compounding the antibacterial peptide, the herba centellae extract and the liquiritin according to a certain proportion; the antibacterial rates to cultures relevant to acne are all reach 90 percent or above; the acne-removing composition has obvious prevention and treatment effects on the acne, and is good in safety; the using concentration of the antibacterial peptide is decreased.

Owner:GUANGDONG COOWAY BIOTECH CO LTD

Detection method for fingerprint spectrum of medicinal preparation treating hepatitis

InactiveCN105181825AImprove securityImprove stabilityComponent separationDigestive systemChlorogenic acidMedicine

The invention relates to a detection method for a fingerprint spectrum of a medicinal preparation treating hepatitis. In the detection method, through optimization selection of a No.11 peak of baicalin as an internal reference peak of a fingerprint spectrum, retention time of characteristic common peaks: a No.3 peak of chlorogenic acid, a No.4 peak of gentiopicroside, a No.5 peak of paeoniflorin, a No.6 peak of liquiritin, a No.8 peak of ferulic acid and the like of a yindan pinggan capsule is determined, the yindan pinggan capsule can be detected comprehensively and rapidly, which facilitates comprehensive quality detection and whole quality control, and therefore safety and stability of medicine usage is raised.

Owner:ZHANGZHOU PIEN TZE HUANG PHARM

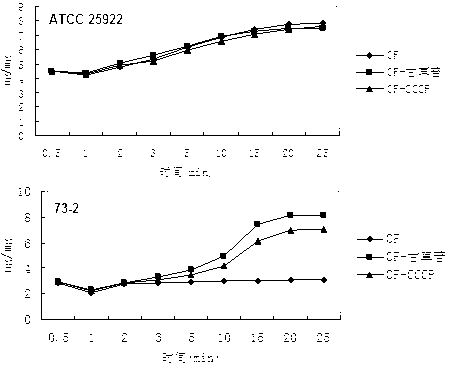

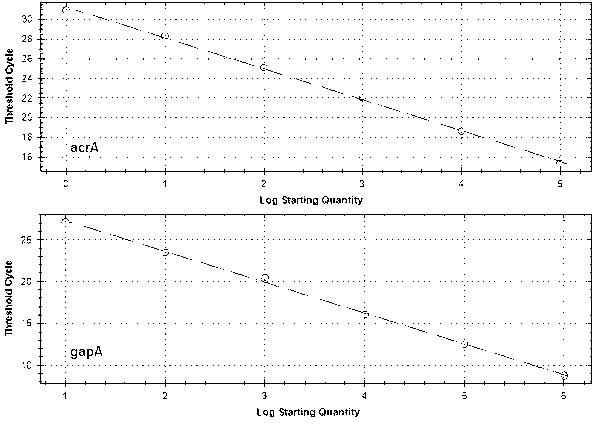

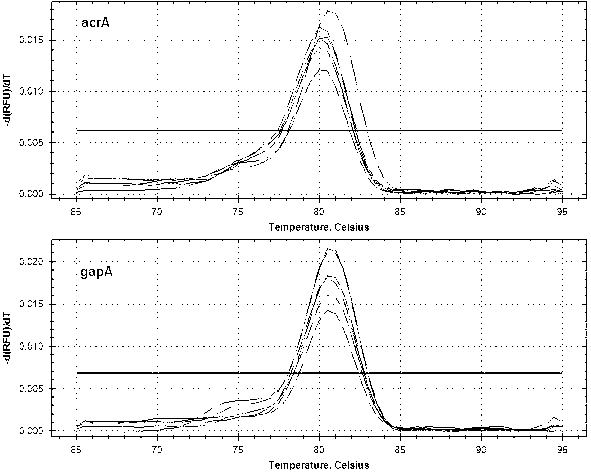

Application of liquiritin in preparing escherichia coli fluoroquinolone efflux pump inhibitor

ActiveCN102988400AHigh market valueMIC lowerAntibacterial agentsOrganic active ingredientsBiotechnologyEscherichia coli

The invention discloses an application of liquiritin in preparing an escherichia coli fluoroquinolone efflux pump inhibitor. Research results indicate that, the liquiritin can obviously reduce the minimal inhibitory concentration of fluoroquinolone of drug-resistant escherichia coli (fluoroquinolone active efflux phenotype and acrA gene high expression strain), obviously increase drug accumulation concentration in a thallus, and obviously reduce expression quantity of an efflux pump gene acrA, so that susceptibility of the drug-resistant escherichia coli to the fluoroquinolone is increased, usage amounts of drugs are reduced, treatment cost is reduced, and food safety problems such as drug residues are decreased. Simultaneously, the liquiritin is a natural compound existing in plants, has no side effects such as teratogenesis and carcinogenesis, and is safe and nontoxic. The invention not only broadens application fields of the liquiritin and improves market value of the liquiritin, but also provides an efficient and safe bacteria efflux pump inhibitor for anti-infective therapy.

Owner:SOUTHWEST UNIVERSITY

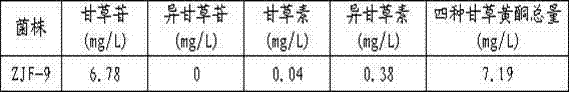

Endophytic fungi for producing flavones and application thereof

InactiveCN102757903AAnti agingEliminate inflammationFungiMicroorganism based processesBiotechnologyBacterial strain

The invention discloses an endophytic bacterial strain Penicillium commune CGMC CNO.6113 and an application in the flavone production. Compared with coordinative bacterial strains, the Penicillium commune CGMC CNO.6113 bacterial strain is apparent in the flavone production in mycology. When the bacterial strain is fermented, main ingredients of glycyrrhiza flavonoids of liquiritin, glycyrrhizin, isoliquiritigenin and the like can be produced, and the bacterial strain can be applied in antioxidation, senescence delaying, inflammation elimination and the like as a prevention and treatment method, accordingly, the endophytic fungi for producing flavones and the application thereof provide a novel approach for the development and application of glycyrrhiza flavonoids and have wide applicationvalues.

Owner:TARIM UNIV

Application of liquiritin in preparing medicine for treating cardiovascular and cerebrovascular diseases

InactiveCN102125576APrevent or improve damageNo adverse reactionOrganic active ingredientsCardiovascular disorderDiseaseMedication dose

The invention belongs to the technical field of medicament, particularly relates to an application of liquiritin in preparing medicament for treating cardiovascular and cerebrovascular diseases, more specifically relates to an application of liquiritin in preparing medicine for treating cerebrovascular diseases. Pharmacological experiments reveal that liquiritin has distinct effects in resisting thrombosis, resisting cerebral ischemia, resisting cerebral anoxia and improving memory. The medicine with liquiritin as active ingredient has low medication dose and high safety, and has wide application prospect.

Owner:北京联合大学应用文理学院

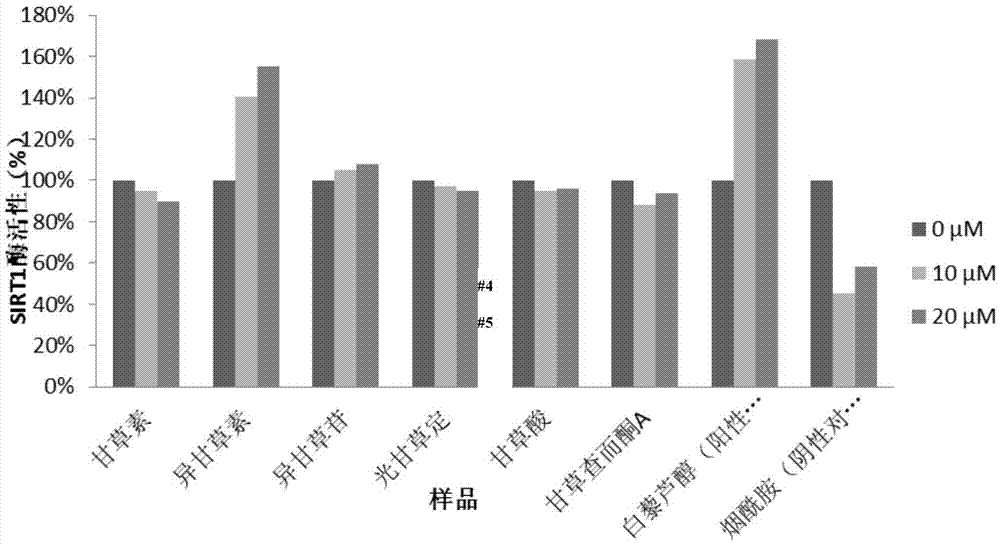

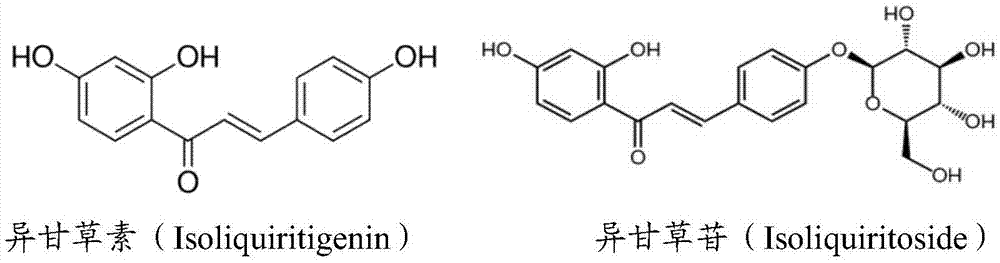

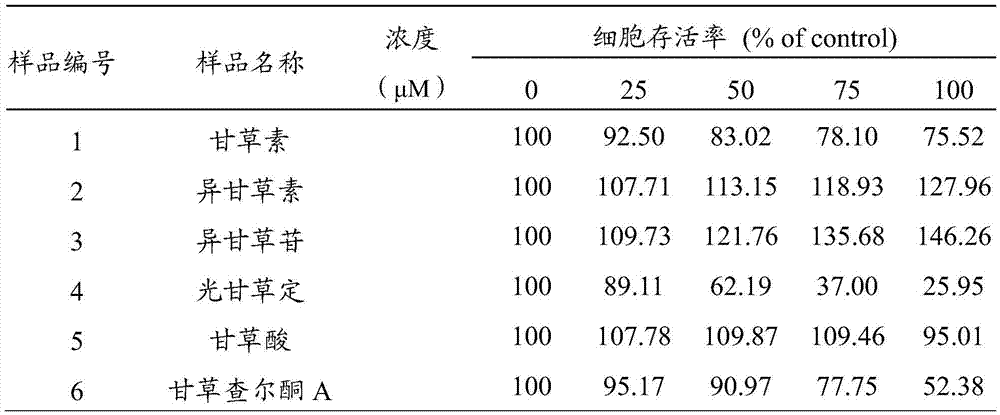

Application of isoliquiritigenin or isoliquiritoside to preparation of anti-aging cosmetic products with high safety performance

ActiveCN107028782AInhibit apoptosisReduced expression levelCosmetic preparationsToilet preparationsProcollagen iApoptosis

The invention discloses application of isoliquiritigenin or isoliquiritoside to preparation of anti-aging cosmetic products with high safety performance. Researches prove that isoliquiritigenin or isoliquiritoside can improve the expression level of the procollagen I alpha 1 chain (Col1A1) in human skin fibroblasts, reduce the expression level of matrix metalloproteinase 1 (MMP1), and promote the expression level of the silent information regulator 1 (Sirt1); therefore, isoliquiritigenin or isoliquiritoside can inhibit human skin fibroblast apoptosis and promote synthesis of collagen in human skin fibroblasts, so as to resist aging. Furthermore, isoliquiritigenin or isoliquiritoside has low toxicity to human skin fibroblasts. Researches show that isoliquiritigenin or isoliquiritoside is of great application value in preparation of anti-aging cosmetic products with high safety performance.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Drug composition

InactiveCN104721207ANo change in weightThere is no change in appearanceOrganic active ingredientsPharmaceutical non-active ingredientsCarmellose SodiumCellulose

The invention provides a drug composition and relates to a preparation composition containing liquiritin monohydrate, belonging to the technical field of drugs. Applications of liquiritin to drugs for resisting myocardial ischemia and reperfusion arrhythmia and resisting myocardial ischemia caused by isoprenaline are disclosed in Chinese patents 200610016770.0 and 200610016771 respectively. Due to technical problems, safe and effective liquiritin preparations suitable for human to take orally have not come out. The invention provides a safe and effective liquiritin oral preparation. The liquiritin composition contains 45-71.1% of liquiritin monohydrate, and when the mass percentage of croscarmellose sodium is 3-9.2%, the mass percentage of water soluble auxiliary materials is 6-35%.

Owner:迪嘉药业集团股份有限公司 +2

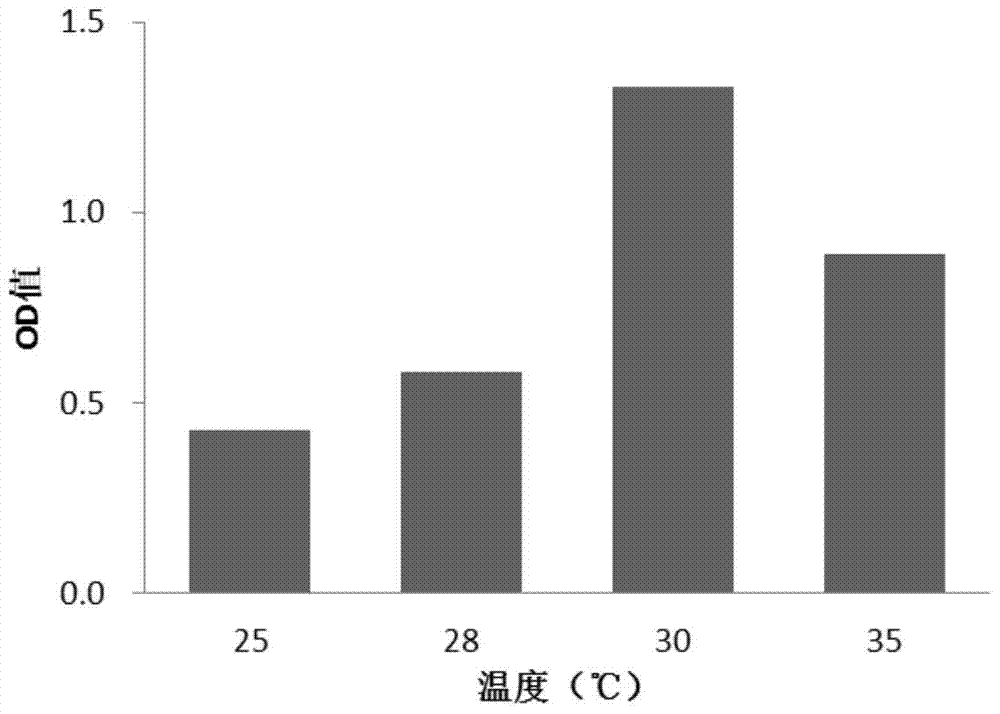

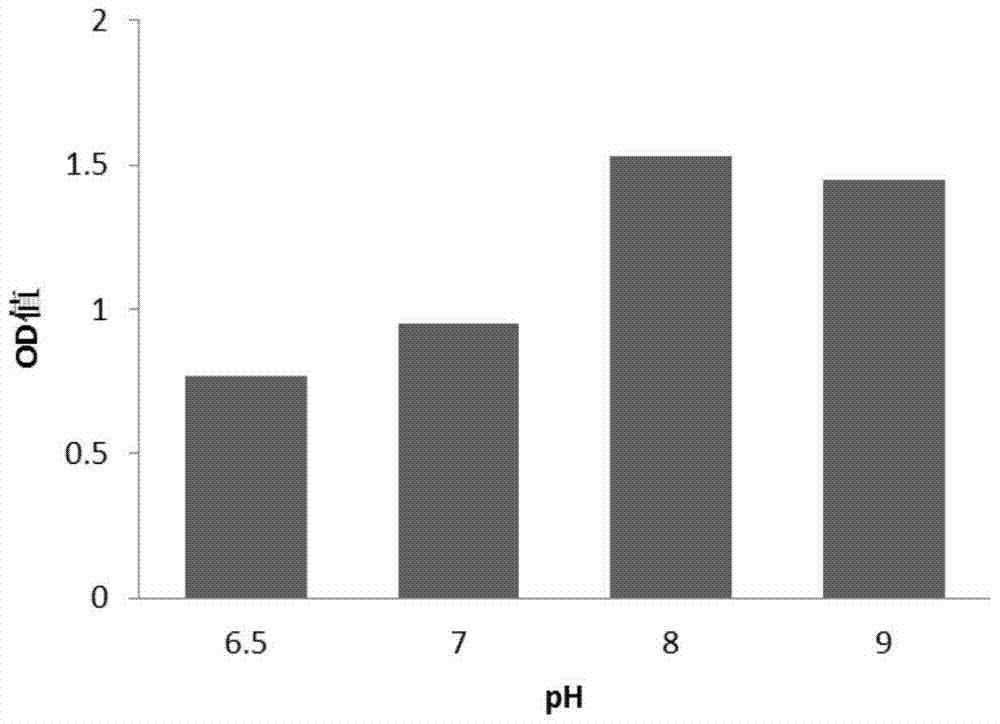

Microbial fermentation method for preparing licorice root fermentation liquor with high safety performance and whitening and anti-aging effects and product

The invention discloses a microbial fermentation method for preparing licorice root fermentation liquor with high safety performance and whitening and anti-aging effects and a product. The method comprises the steps of inoculating an unfermented licorice root solution with activated yeast strains, and conducting fermentation for 35-45 h at the temperature of 25-35 DEG C, the pH value of 6.5-9.0 and the rotating speed of 80-160 r / min, so as to obtain the licorice root fermentation liquor. Researches find that by the adoption of the method, the content of glabridin and licochalcone A in the licorice root fermentation liquor can be reduced remarkably, and the content of the active ingredients isoliquiritigenin and isoliquiritoside which have MMPs inhibition and collagen stimulation effects is increased remarkably. Therefore, the licorice root fermentation liquor prepared with the method has broad application prospects in preparation of cosmetic products, especially cosmetic products with high safety performance and whitening and anti-aging effects.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Pharmaceutical composition for alleviating vomiting reaction caused by oxytetracycline as well as preparation and detection method of formula granules and application thereof

InactiveCN108272813AImprove treatmentEfficacy in reducing vomitingOrganic active ingredientsComponent separationAdditive ingredientRutin

The invention provides a pharmaceutical composition for alleviating vomiting reaction caused by oxytetracycline as well as a preparation and detection method of formula granules and application thereof and belongs to the field of medicines. The pharmaceutical composition comprises uridine, glycyrrhizic acid, rutin, liquiritin and the like. The preparation method comprises the following steps: extracting, filtering, concentrating and drying licorice decoction pieces so as to obtain the composition, mixing, pelletizing, finishing, total blending and packaging the composition with ingredients, thereby obtaining formula granules. The formula granules are excellent in stability and high in quality controllability, and the vomiting reaction caused by oxytetracycline can be obviously alleviated.

Owner:ZHEJIANG HUISONG PHARMA

Chinese herbal medicine preparation pesticide and production method thereof

InactiveCN111789117AImprove immunityWith bactericidal functionBiocidePlant growth regulatorsBiotechnologySophocarpidine

The invention provides a Chinese herbal medicine preparation pesticide and a production method thereof. The pesticide comprises a solvent and a solute, and the solute comprises brassinolide, sophocarpidine, berberine, potassium fulvate, quercitrin, chlorogenic acid, ophiopogonin, arginine, echinacoside, liquiritin and daidzin. Solute components are extracted from plants containing the solute components through multiple times of water decoction by a traditional Chinese medicine decoction method, an aqueous solution is formed after concentration, and then a surfactant and an auxiliary agent areadded or filtration is performed to obtain the Chinese herbal medicine preparation pesticide. The pesticide is used for plantation of Chinese herbs, fruits and vegetables, diseases can be prevented, and planting quality can be improved.

Owner:潍坊久泽农生态农业科技研发有限公司

Application for liquiritin and derivatives of liquiritin in preparation of drugs for treating and/or preventing novel coronaviruses

The invention provides an application for liquiritin and geometric isomers, derivatives or pharmaceutically-acceptable salts and / or solvates and / or hydrates of the liquiritin in preparation of drugs for treating and / or preventing novel coronaviruses. According to the invention, the liquiritin is found to be able to effectively inhibit the novel coronaviruses SARS-CoV-2 at a cellular level, whereinEC50 is 2.39 [mu]M. The liquiritin is indicated to have positive effects on treatment and / or prevention of the novel coronaviruses SARS-CoV-2.

Owner:PEKING UNIV +1

Extract containing liquiritin and preparation method of extract

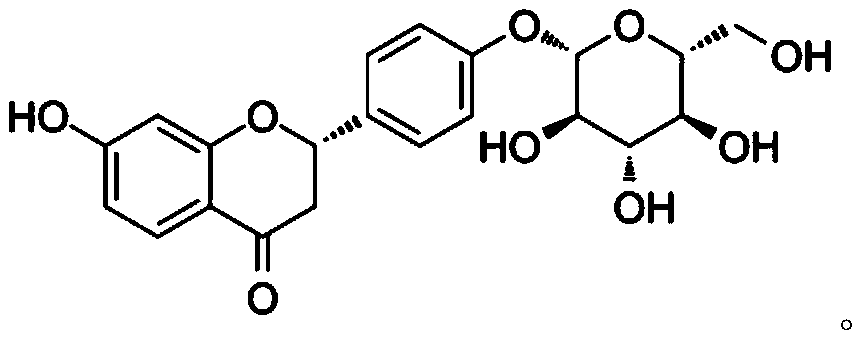

ActiveCN112094306AStructure is not destroyedAvoid heavy useSugar derivativesSugar derivatives preparationAlcohol ethylLiquiritoside

The invention discloses a preparation method of an extract containing liquiritin. The preparation method comprises the following steps: taking a mixed solution of ethanol, isopropanol and acetone as an extraction solvent, controlling the volume ratio of ethanol to the isopropanol to the acetone to be (85-95): (4-10): (1-5), and further comprehensively extracting the extract containing liquiritin twice under different conditions, so as to obtain the extract containing liquiritin. The content rate of the liquiritin in the extract containing Liquiritin is 35.82% or above. Besides, a gradient heating mode is adopted in the first ultrasonic treatment process, so that the content of the liquiritin in the extract is further increased. Furthermore, the invention also discloses the extract containing the Liquiritin, obtained by the preparation method.

Owner:大湾汉唯(广州)医药科技集团有限公司

Production process for jointly separating high-purity liquiritin, bitterness-removed glycyrrhizin and glycyrrhiza uralensis fisch total flavonoids from mono-ammonium glycyrrhizinate mother liquor paste

The invention discloses a production process for jointly separating high-purity liquiritin, bitterness-removed glycyrrhizin and glycyrrhiza uralensis fisch total flavonoids from mono-ammonium glycyrrhizinate mother liquor paste. The production process comprises the following steps that (1) the mono-ammonium glycyrrhizinate mother liquor paste is taken, water is added to adjust the pH value, the mono-ammonium glycyrrhizinate mother liquor paste is dissolved and passes through a resin column 1# to be subjected to chromatography, water elution is carried out to obtain eluent for later use, a resin column 2# is subjected to elution through gradient dilute ethanol, and after the eluent is concentrated and dried under reduced pressure, a liquiritin crude product is obtained; ethanol with the concentration of 95% is added into the crude product, and recrystallization, filtration and drying are carried out to obtain the high-purity liquiritin; (2) the eluent for later use is taken, flows through a resin column 3# and is subjected to water elution, and the eluent is concentrated and dried to obtain the bitterness-removed glycyrrhizin; and (3) the resin columns 1#, 2# and 3# are regeneratedby using the ethanol with the concentration of 95%, eluent is collected and combined, and concentration and drying are carried out to obtain the glycyrrhiza uralensis fisch total flavonoids. Accordingto the production process for jointly separating the high-purity liquiritin, the bitterness-removed glycyrrhizin and the glycyrrhiza uralensis fisch total flavonoids from the mono-ammonium glycyrrhizinate mother liquor paste, the mother liquor paste after production of mono-ammonium glycyrrhizinate is adopted as a raw material, and the three products are separated and purified in a combined mode,so that the comprehensive utilization degree of the raw material is improved, the product value is high, cost is low, reproducibility is good, and the production process is suitable for industrial large-scale production.

Owner:高颖

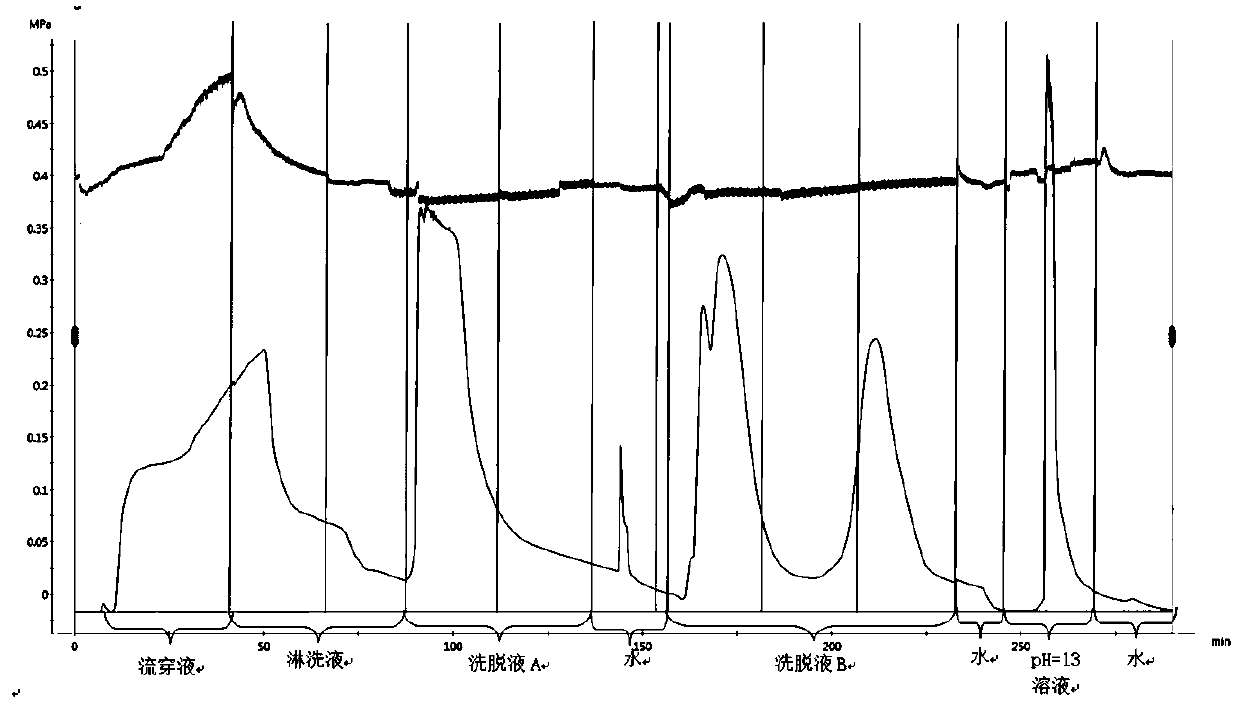

Method for capturing and separating effective components in liquorice by utilizing mixed-mode agarose gel medium

ActiveCN111001189AExtend engagement and criticalityWide operating conditionsIon-exchange process apparatusIon-exchanger regenerationNatural productIon exchange

The invention relates to a method for capturing and separating effective components in liquorice by utilizing a mixed-mode agarose gel medium. The method is characterized in that the mixed-mode agarose gel medium with ion exchange and hydrophobic ligands is used for capturing and separating acidic saponin substances and flavonoid substances in liquorice; the two substances are effectively adsorbedin the agarose gel medium in an adsorption mode, and effective separation of the acidic saponin substances and the flavonoid substances is realized by changing the pH value of an eluent. According tothe method for capturing and separating liquiritin and glycyrrhizic acid substances in liquorice, the result can approximately reach that the purity of the liquiritin substances is 65%-95%, and the yield is 80%-98% (calculated by taking the liquiritin as a standard substance); the purity of glycyrrhizic acid substances is 60-95%, the yield is 75-95% (calculated by taking ammonium glycyrrhizinateas a standard substance), the purity and the yield are relatively high, and the method has important significance for a component separation process of natural products and a traditional Chinese medicine extraction and purification process.

Owner:TAIZHOU GUOKEHUAWU BIOMEDICAL TECH CO LTD

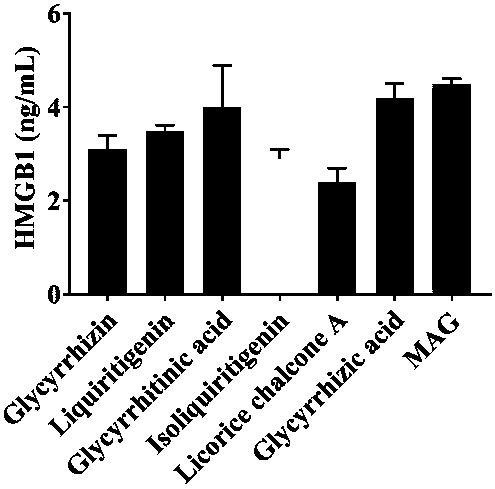

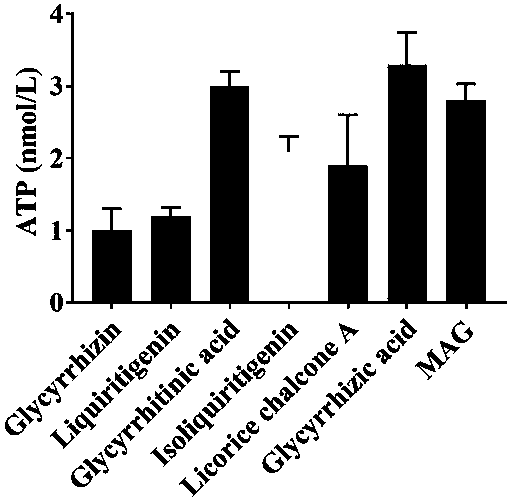

New medicinal application of effective components and derivatives thereof in Glycyrrhiza uralensis

InactiveCN110812384ADefinite curative effectWide variety of sourcesKetone active ingredientsAntineoplastic agentsMedicinal herbsSide effect

The invention discloses a new medicinal application of effective components and derivatives in Glycyrrhiza uralensis. The effective components and derivatives in Glycyrrhiza uralensis include liquiritin, glycyrrhizin, glycyrrhetinic acid, isoliquiritigenin, licochalcone A, glycyrrhizic acid and its derivative glycyrrhizic acid monoammonium salt, and the effective components and derivatives in Glycyrrhiza uralensis are used for preparing anticancer drugs. As that effective component in Glycyrrhiza uralensis and its derivative can induce tumor cells to produce immunogenic cell death. The invention provides a tumor treatment drug with definite curative effect, safety, convenience and wide sources, which can be combined with one or more pharmaceutically acceptable carriers or excipients to prepare pharmaceutical compositions or preparations of active components in licorice and derivatives thereof, it provides new drugs for tumor immunotherapy and is of great significance for improving tumor therapeutic effect and quality of life of patients. The effective components come from fruits, vegetables and medicinal materials, with small side effects, low cost and convenient popularization anduse.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Method for establishing a fingerprint spectrum of traditional Chinese medicine oral preparation and fingerprint spectrum thereof

The invention relates to the technical field of medicine detection, in particular to a method for establishing a fingerprint spectrum of a traditional Chinese medicine oral preparation and the fingerprint spectrum thereof, and the method comprises the following steps: S1, preparing a test solution: selecting different batches of dryness-clearing lung-rescuing decoction particle samples, precisely weighing, placing in a container, precisely adding water, ultrasonically dissolving, cooling, filtering, extracting filtrate by using ethyl acetate, mixing the ethyl acetate, evaporating to dryness, adding a methanol solution into residues, transferring into a measuring flask, adding methanol to dilute to a scale, shaking uniformly, filtering, and taking a subsequent filtrate to obtain a finished product. and S2, preparation of a reference substance solution: taking liquiritin, caffeic acid, iso-dendrobiin and isoliquiritin, adding methanol to dissolve, and preparing a solution containing 50 [mu]g of reference substances per 1ml as the reference substance solution. The fingerprint spectrum established by adopting the establishment method of the fingerprint spectrum can comprehensively characterize information of five medicinal materials including mulberry leaves, liquorice, ginseng, fried black sesame and honey loquat leaves in a prescription, and more comprehensively reflect the medicine quality.

Owner:SHANGHAI KAIBAO PHARMA

Ephedra decoction standard substance and preparation method and quality detection method thereof

ActiveCN113390985APrevent volatilizationPromote reductionComponent separationAgainst vector-borne diseasesPseudoephedrine HydrochlorideLiquiritoside

The invention belongs to the field of Chinese herbal medicine quality control, and particularly relates to an ephedrae decoction standard substance and a preparation method and a quality detection method thereof. According to the preparation method of the ephedra decoction standard substance, freeze-dried powder preparation is changed into standard decoction preparation, operations such as concentration and drying are not needed, and volatilization of some important components (such as cinnamaldehyde) is avoided. Based on the ephedra decoction standard substance prepared by the method, the original taste and flavor of the 'one bowl' of ancient prescription ephedra decoction can be restored. The method can be used for guiding actual industrial production. According to the ephedra decoction standard substance quality detection method, quantitative determination of ephedrine hydrochloride, pseudoephedrine hydrochloride and amygdalin and qualitative analysis of liquiritin, cinnamic acid, cinnamaldehyde and glycyrrhizic acid are fused, meanwhile, new chromatographic conditions are developed, the separation degree is better, the stability is better, the detection time is short, and the efficiency is high.

Owner:盛实百草药业有限公司 +1

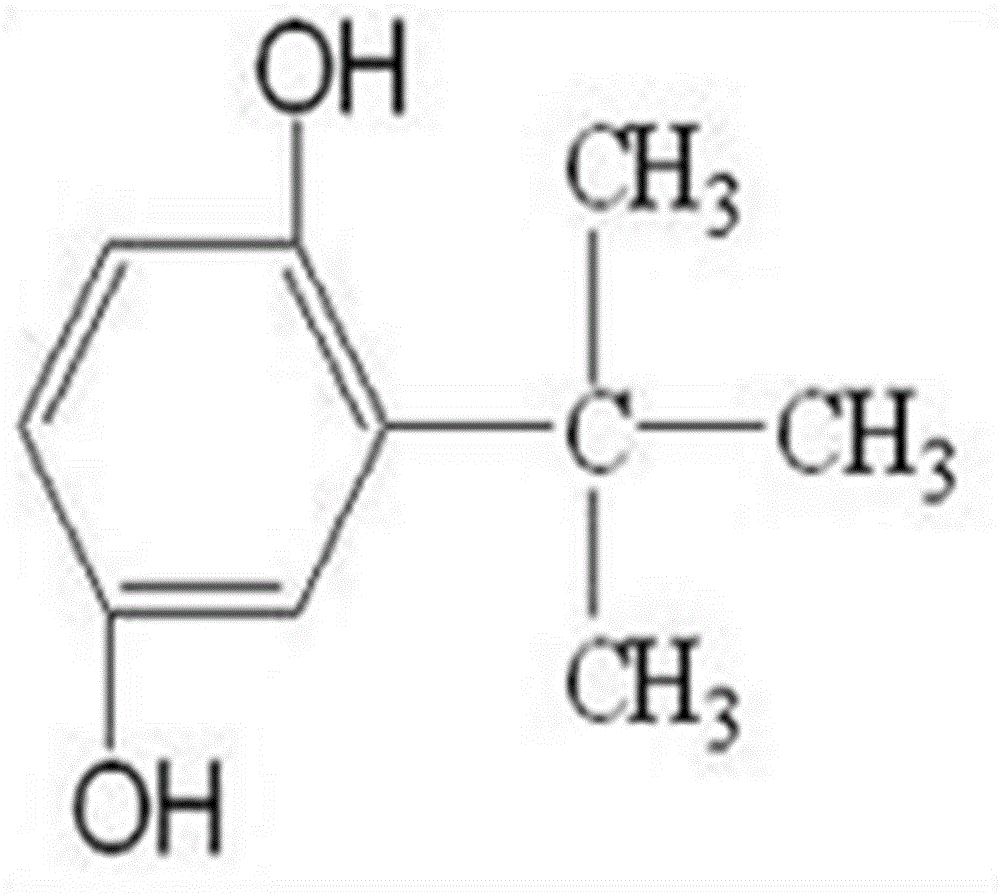

Palm oil using liquiritoside as an antioxidant

InactiveCN105265611AExtended shelf lifeImprove qualityFatty substance preservation using additivesEdible oils/fatsBiotechnologyLiquiritoside

The present invention discloses a palm oil using liquiritoside as an antioxidant. The palm oil is characterized by being prepared by adding the liquiritoside into palm oil. The advantages of the palm oil are that the natural food sweetener liquiritoside is applied into the palm oil. The test proves that the antioxidant effects of the liquiritoside are the same as the antioxidant effects of chemically synthesized antioxidant tertiary butyl hydroquinone (TBHQ), and the liquiritoside can extend the storage period of palm oil, are free of harms to human body, and can also improve the quality of palm oil.

Owner:郝再彬 +2

Fruit component composition for improving memory and application of fruit component composition

The invention discloses a fruit component composition for improving memory. The composition comprises liquiritin, Chinese wolfberry fruit polysaccharide and arbitrarily-chosen oleuropein, wherein theChinese wolfberry fruit polysaccharide is extracted according to the following steps of sequentially performing organic solvent reflow degreasing, performing complex enzyme aqueous extraction and performing micro filtration film filtration. According to the invention, the composition also comprises naringin and mangiferin. The components of the composition are fruit components, and the compositionis mild in properties. Besides, the components are in synergism to be used for improving memory.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

Traditional Chinese medicine effective chemical component composition for treating primary dysmenorrhea and application thereof

PendingCN112755016AGood curative effectRelieve painOrganic active ingredientsAntipyreticPseudoephedrinePrimary dysmenorrhoea

The invention discloses a traditional Chinese medicine effective chemical component composition for treating primary dysmenorrhea and application thereof, and relates to the field of natural medicine components and medicine health care. Chemical components (puerarin, daidzin, daidzein, ephedrine, pseudoephedrine, paeoniflorin, albiflorin, liquiritin and liquiritigenin) in traditional Chinese medicine compound radix puerariae decoction are screened by virtue of a modern analysis technology and network pharmacology analysis; based on the hypothesis that effect substances contained in traditional Chinese medicines should enter blood or reach target organs to achieve the treatment effect, the blood-entering components of the radix puerariae decoction are detected by applying the modern analysis technology; furthermore, main active components and action targets are screened through network pharmacology; several or more compounds with the best combined drug effect are selected for composition; and the effects of definite components, definite drug effect, measurable mechanism and controllable quality are achieved.

Owner:CHINA PHARM UNIV

Animal semen diluting powder and application thereof

InactiveCN111657263AEasy to storeConducive to preservationDead animal preservationAnimal scienceArginine

The invention relates to an animal semen diluting powder and application thereof, and belongs to the technical field of animal reproduction. The animal semen diluting powder is dissolved in a PBS buffer solution to prepare a pig semen diluting solution; the semen diluting solution comprises 0.1-0.3 g / L of liquiritin, 1-3 g of sodium glutamate, 0.5-1.0 g of L-arginine, 0.1-0.3 g of N-acetylcysteine, 1-3 g of fructose, 10-15 g of glucose, 2-4 g of potassium citrate, 0.5-1 g of potassium chloride, 1-2 g of EDTA, 1-2 g of sodium carbonate and 0.1-0.3 g of origanum oil. The liquiritin can also be replaced with glycyrrhetinic acid. The animal semen diluting powder does not adopt any antibiotics, and various components have a synergistic effect, so that the time and the motility rate of preservedsperms can be obviously improved, the integrity rate of acrosomes can be improved, and the pregnancy rate of artificial insemination after dilution can be increased.

Owner:洛宁农本畜牧科技开发有限公司

Liquiritin and glycyrrhizic acid components enriched in liquorice extract and preparation method of liquiritin and glycyrrhizic acid components

PendingCN111072736AHigh purityIncrease contentSugar derivativesSteroidsMedicinal herbsGLYCYRRHIZA EXTRACT

The invention relates to liquiritin and glycyrrhizic acid components enriched in a liquorice extract and a preparation method of the liquiritin and glycyrrhizic acid components, in particular to the processes of water extraction, clarification and filtration, preparative chromatography enrichment and concentration and drying. The method comprises the following steps: preparing a liquorice extractsolution from a liquorice medicinal material as a raw material through water extraction, concentration drying and powder dissolution, clarifying a crude extract by adopting a membrane filtration technology, and carrying out enrichment and purification by utilizing a high-pressure preparation system through reversed-phase preparative chromatography. The contents of liquiritin and glycyrrhizic acidcomponents in a sample prepared by purification are high, the production process is simple to operate and high in efficiency, and the process is easy to amplify. The components enriched and prepared by the method disclosed by the invention can be widely applied to the industries of medicines, health products and the like, and have wide market prospects and good economic benefits.

Owner:TAIZHOU GUOKEHUAWU BIOMEDICAL TECH CO LTD

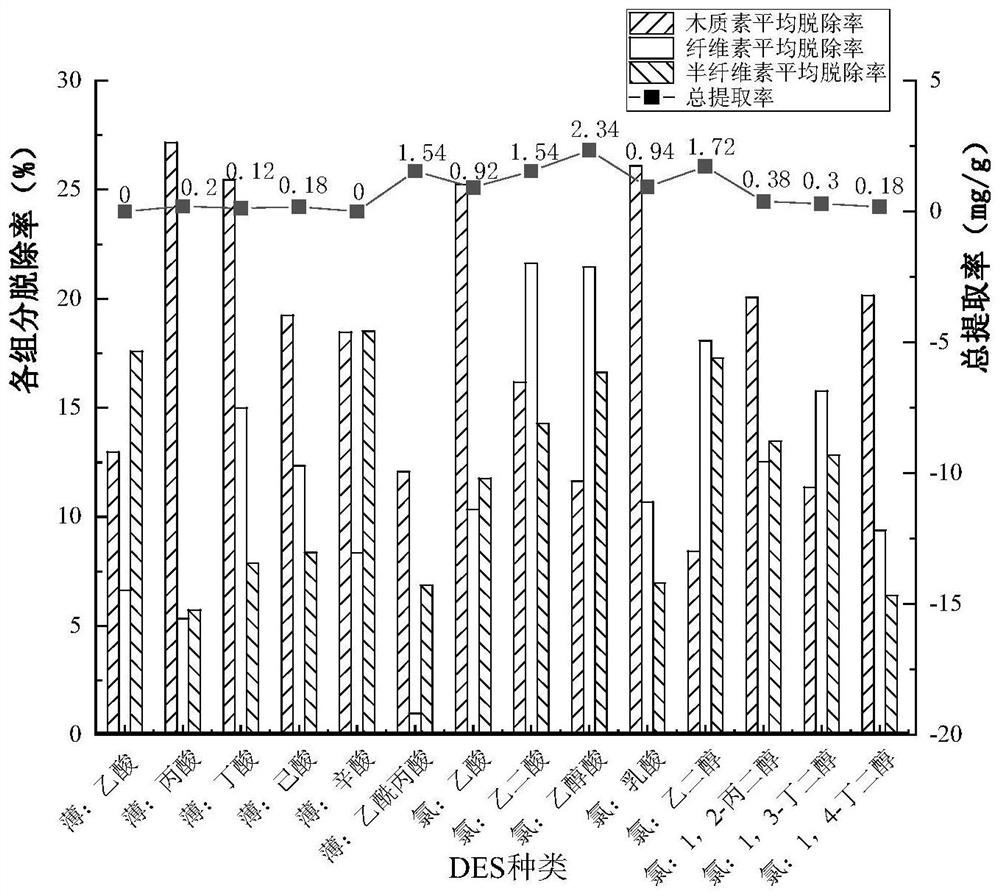

Method for selectively and efficiently extracting flavones from licorice herb residues and co-producing biomethane

PendingCN113480580AImplement selective extractionSimplify separation and purification stepsSugar derivativesWaste based fuelBiotechnologyDigestion

The invention discloses a method for selectively and efficiently extracting flavones from licorice herb residues and co-producing biological methane. The method comprises the following steps: firstly, mixing choline chloride and glycollic acid to obtain a deep eutectic solvent, then adding the licorice herb residues to carry out extraction reaction under the reaction conditions of extraction at 30-50 DEG C for 30-120 minutes or extraction at 70-90 DEG C for 30-120 minutes, and respectively preparing liquiritin and isoliquiritin and / or liquiritigenin and isoliquiritigenin; and carrying out solid-liquid separation on an extracted mixed system to obtain solid-phase residues, and directly inoculating anaerobic fermentation strains to carry out biological fermentation to obtain the biological methane. According to the method, by constructing a temperature-sensitive deep eutectic solvent system, selective extraction of different types of flavonoids in the licorice herb residues is achieved, meanwhile, a lignin-cellulose-hemicellulose compact structure of the licorice herb residues is damaged, contact digestion of microorganisms and cellulose is facilitated, and the anaerobic fermentation starting speed and the gas production rate are greatly increased.

Owner:SOUTH CHINA AGRI UNIV

Method for extracting and separating liquiritin and glycyrrhizic acid

ActiveCN113603737AChange temperatureAchieve separationSugar derivativesSteroidsLiquiritosideIonic liquid

The invention discloses a method for extracting and separating liquiritin and glycyrrhizic acid, which comprises the following steps: S1, mixing ionic liquid with licorice powder, and extracting the liquiritin and the glycyrrhizic acid; S2, after extraction is completed, carrying out solid-liquid separation, taking supernate, adding a NaOH solution, then increasing the temperature to 65-80 DEG C, obtaining an ionic liquid phase containing the liquiritin and a water phase containing the glycyrrhizic acid, and separating the water phase and the ionic liquid phase; wherein the ionic liquid is temperature response type ionic liquid. According to the method, the temperature response type ionic liquid is used as the extracting agent, the system temperature is changed after extraction is completed, the liquiritin and the glycyrrhizic acid can be separated, the method is simple, and the used ionic liquid can be recycled and reused, which is environmentally friendly.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Rapeseed oil using liquiritoside as antioxidant

InactiveCN105265610AExtended shelf lifeImprove qualityFatty substance preservation using additivesEdible oils/fatsBiotechnologyHydroquinone Compound

The present invention discloses a rapeseed oil using liquiritoside as an antioxidant. The rapeseed oil is characterized by being prepared by adding the liquiritoside into rapeseed oil. The advantages of the rapeseed oil are that the natural food sweetener liquiritoside is applied into the rapeseed oil. The test proves that the antioxidant effects of the liquiritoside are the same as the antioxidant effects of chemically synthesized antioxidant tertiary butyl hydroquinone (TBHQ), and the liquiritoside can extend the storage period of rapeseed oil, are free of harms to human body, and can also improve the quality of rapeseed oil.

Owner:郝再彬 +2

Production process for combined separation of various licorice active components

PendingCN113666977AImprove resource utilizationImprove product added valueSugar derivativesSteroidsActivated carbonLiquiritoside

The invention relates to a production process for combined separation of a plurality of licorice active components, which comprises the following steps: (1) stirring and extracting mother liquor powder and a solvent after production of mono-ammonium glycyrrhizinate at room temperature to obtain an extracting solution and a solvent insoluble part; (2) filtering, recovering, dissolving, drying and crushing the extracting solution to obtain a product A; adding purified water into the product A, heating, stirring and extracting to obtain supernate and a product B; concentrating the supernate under reduced pressure, adding 95% ethanol, and heating to dissolve the supernate; and sequentially adding activated carbon for decoloration, filtering, standing for crystallization, separating and recrystallizing to obtain liquiritin with the content of more than 90%, (3) performing vacuum drying and normal-pressure heating on the insoluble part of the solvent to obtain a product C, and drying and crushing the product C to obtain the debittered glycyrrhizin with the glycyrrhizic acid content of more than 10%; and (4) carrying out vacuum drying and crushing on the product B to obtain crude liquiritigenin and isoliquiritigenin with the content of 8-15%. The method is simple in process, low in cost, high in safety and suitable for industrial large-scale production.

Owner:GANSU YALAN PHARMA

Coconut oil using liquiritoside as antioxidant

The present invention discloses a coconut oil using liquiritoside as an antioxidant. The coconut oil is characterized by being prepared by adding the liquiritoside into coconut oil. The advantages of the coconut oil are that the natural food sweetener liquiritoside is applied into the coconut oil. The test proves that the antioxidant effects of the liquiritoside are the same as the antioxidant effects of chemically synthesized antioxidant tertiary butyl hydroquinone (TBHQ), and the liquiritoside can extend the storage period of coconut oil, are free of harms to human body, and can also improve the quality of coconut oil.

Owner:郝再彬 +2

Acne-removing composition and acne-removing cream containing antibacterial peptide

ActiveCN106473944BUse low concentrationLow fat contentCosmetic preparationsToilet preparationsBiotechnologyCentella asiatica extract

The invention provides an acne-removing composition containing antibacterial peptide. The acne-removing composition is prepared from the following components in parts by mass: 5 to 20 parts of herba centellae extract, 1 to 10 parts of liquiritin and 0.5 to 3 parts of the antibacterial peptide. The acne-removing composition containing the antibacterial peptide belongs to the technical field of cosmetics; by using the acne-removing composition provided by the invention, the synergistic interaction can be realized through compounding the antibacterial peptide, the herba centellae extract and the liquiritin according to a certain proportion; the antibacterial rates to cultures relevant to acne are all reach 90 percent or above; the acne-removing composition has obvious prevention and treatment effects on the acne, and is good in safety; the using concentration of the antibacterial peptide is decreased.

Owner:广东省华桑丽皙生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com