Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Interfacial fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

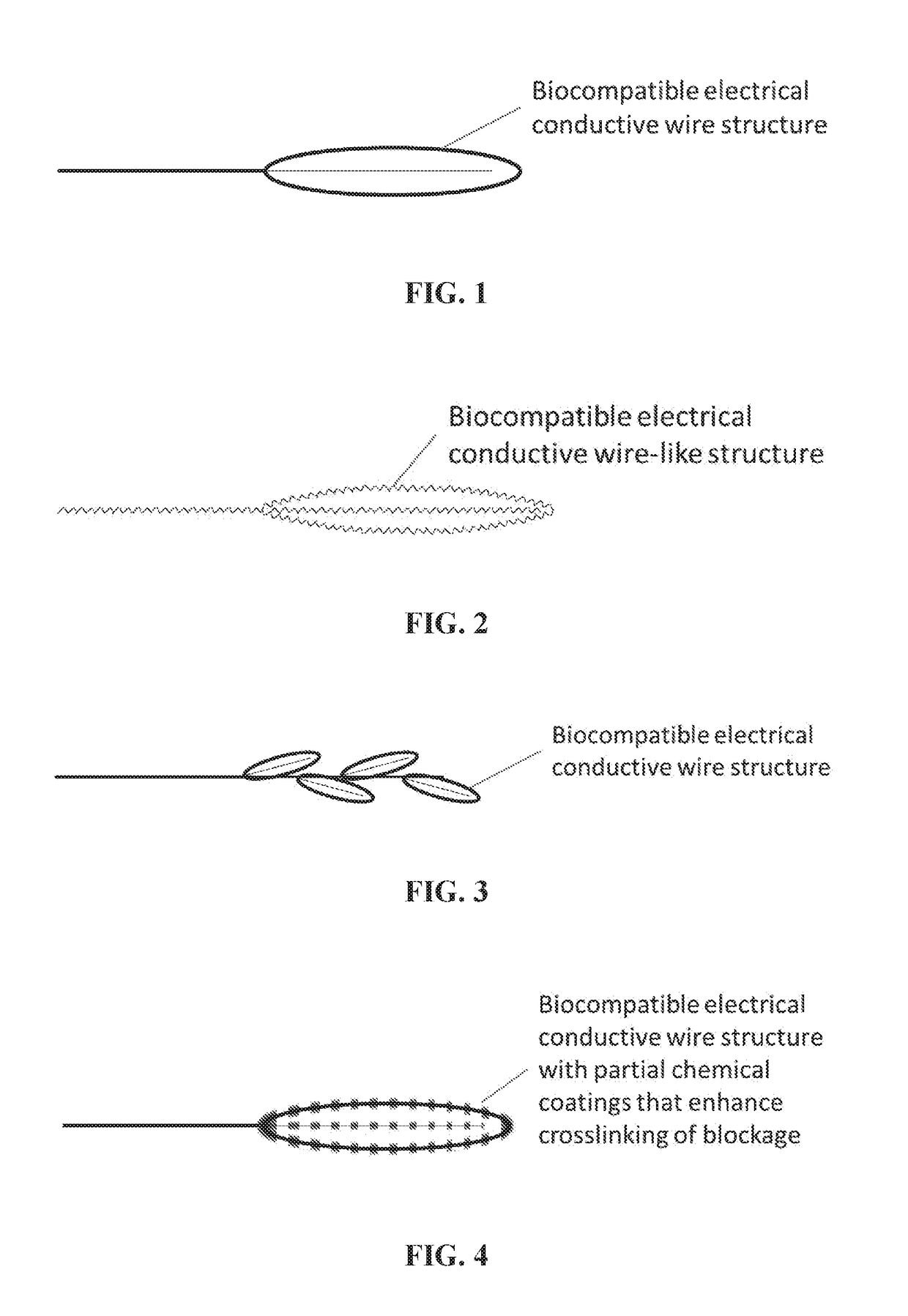

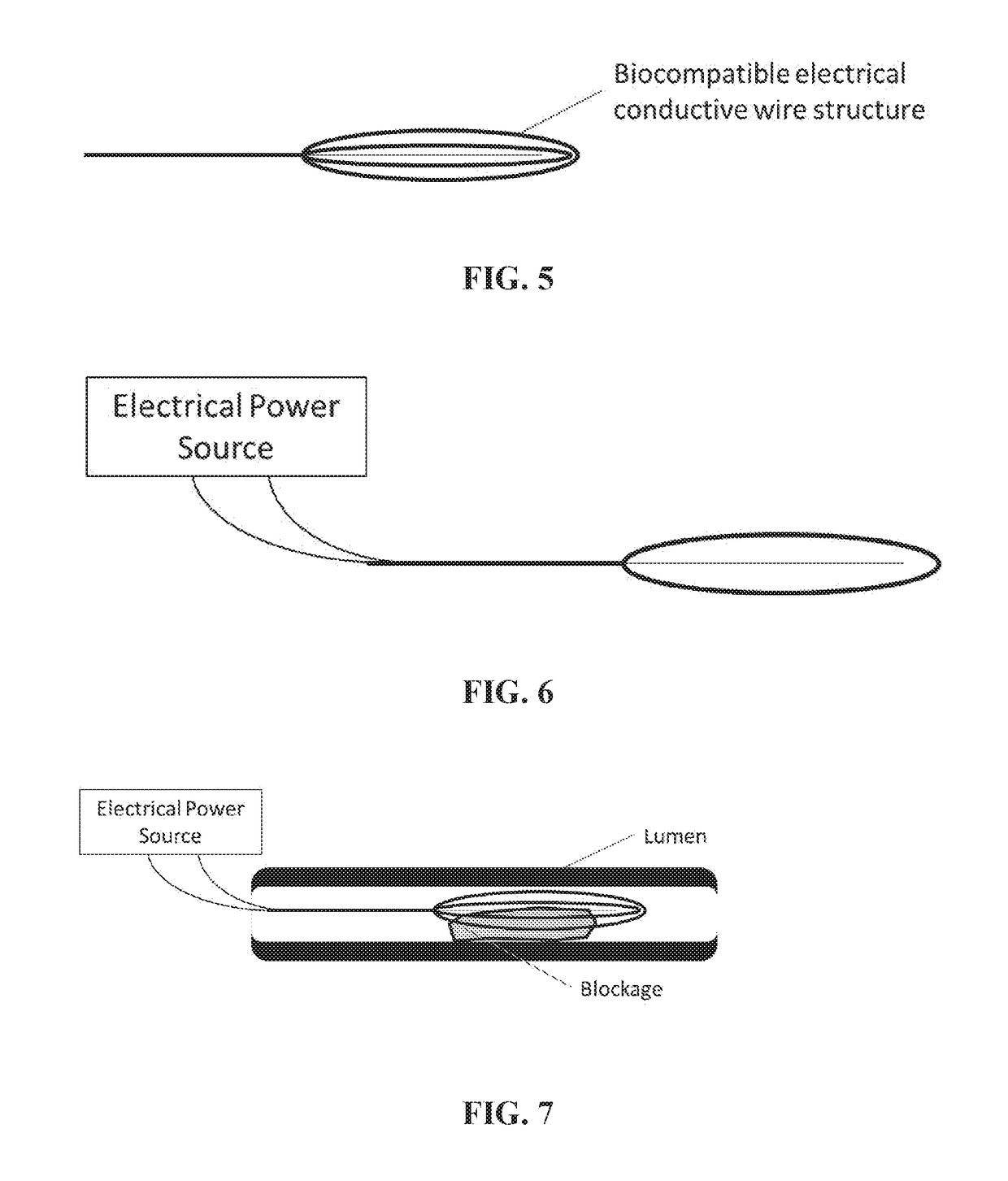

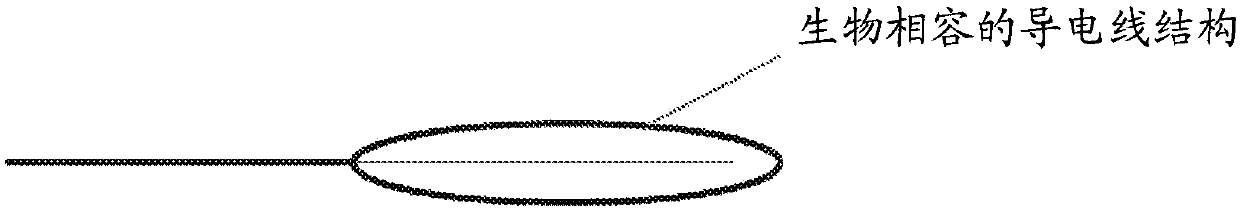

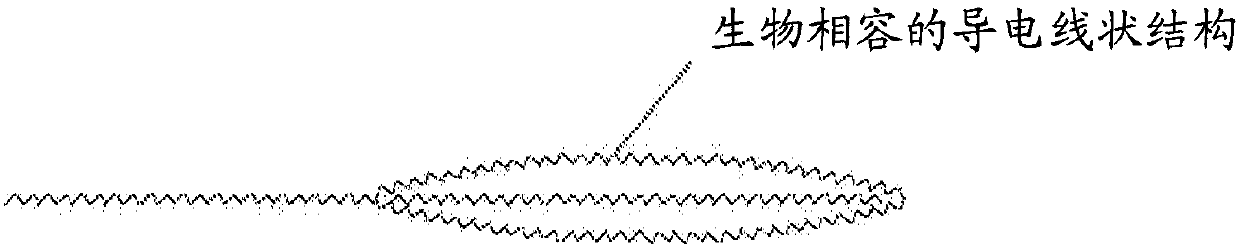

Radio frequency electro-thrombectomy device

ActiveUS20180140354A1Reduce riskImprove adhesionSurgical instruments for heatingCross-linkPower flow

A device is designed to remove blockages in a lumen such as a thrombus, blood clot, or embolus. The device comprises a manipulating wire and a structure that can conduct electrical current to a lumen blockage. The electrical current is preferably in radio frequency (RF). The RF electric current in the blockage can excite the contents such as proteins of the blockage, so that cross-linking density and interfacial adsorption of the entire blockage is enhanced. The enhanced cross-linking density can result in increased fracture resistance of the blockage such that fracture of the blockage during the removal process is unlikely. The enhanced interfacial adsorption results in increased interfacial fracture resistance between the device and blockage so that the blockage can be securely captured during the removal process without using radially applied force.

Owner:THE HONG KONG UNIV OF SCI & TECH

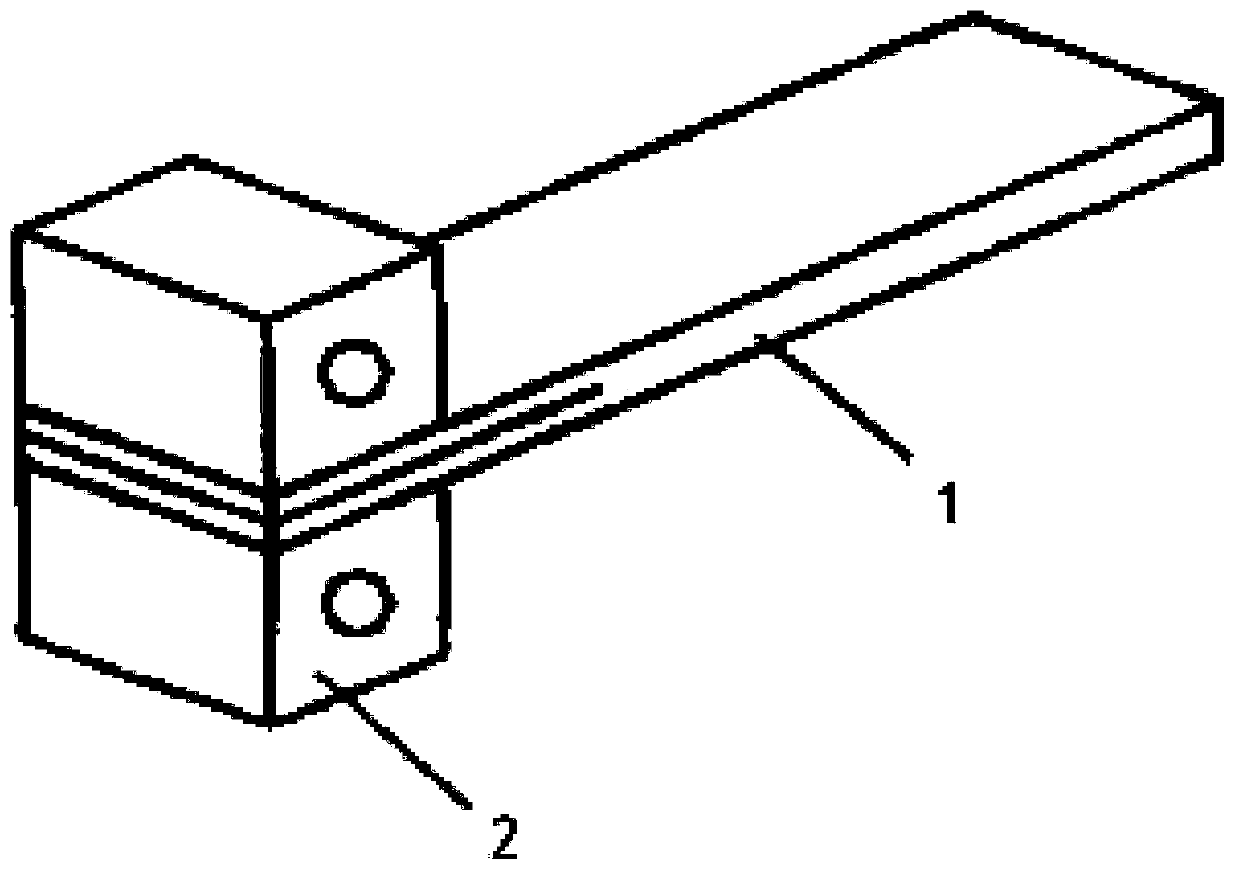

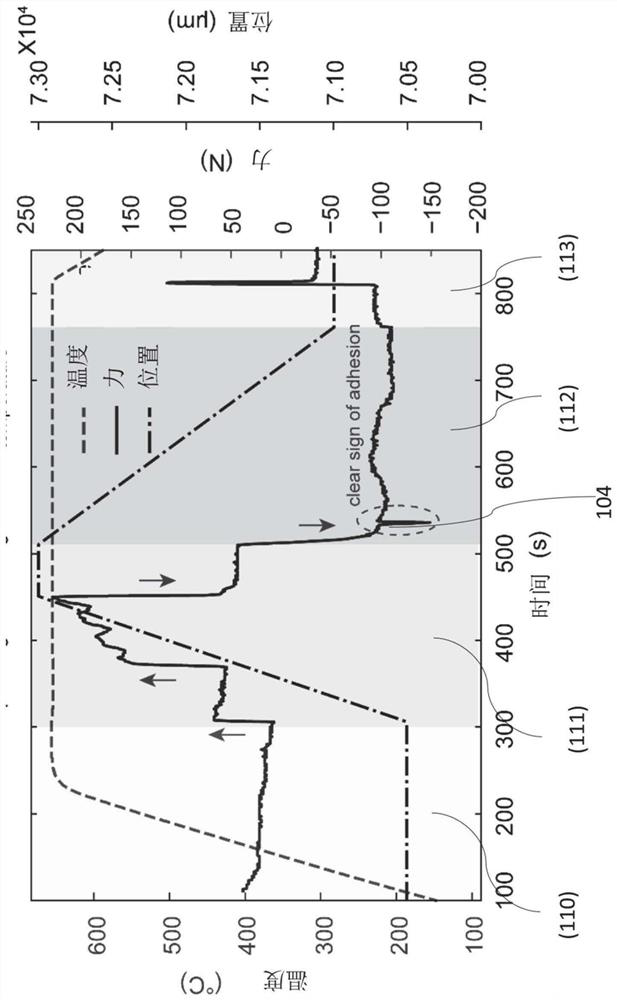

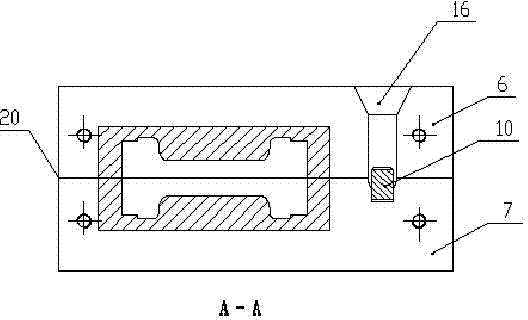

Method for testing mechanical property of braze welding connector

InactiveCN104181052AAvoid human errorEfficient testingMaterial strength using tensile/compressive forcesEngineeringMechanical property

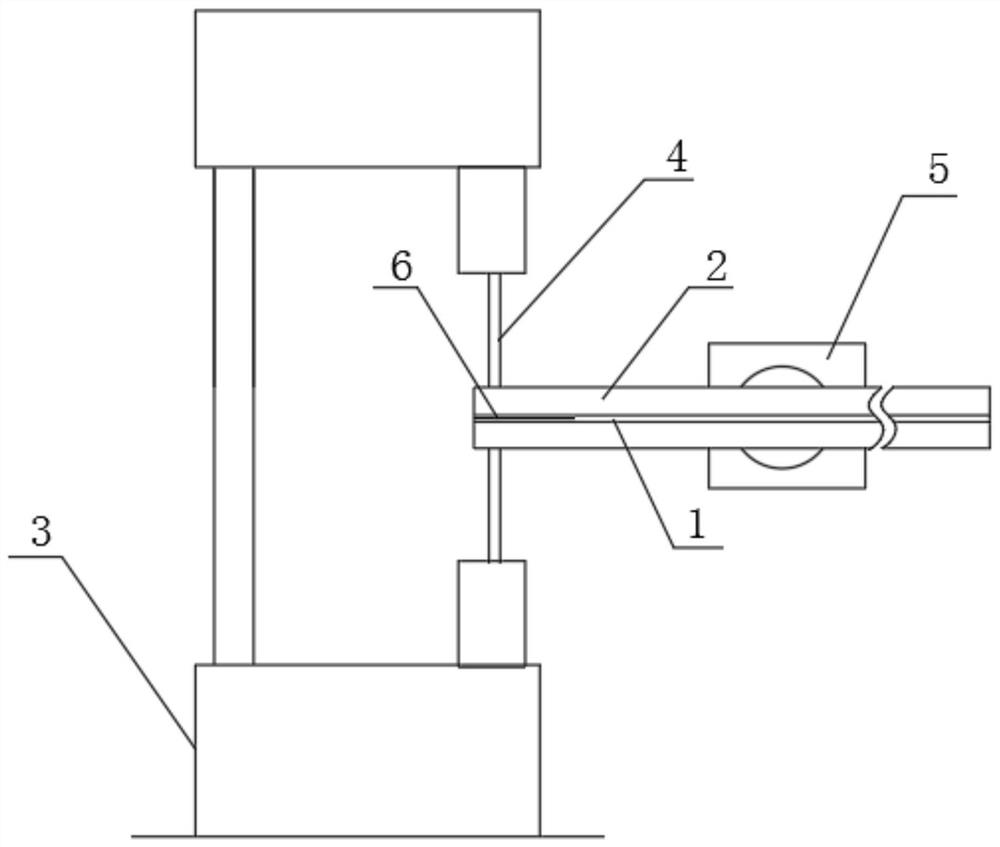

The invention relates to a method for testing a mechanical property of a braze welding connector. The method comprises the following steps: (1) preparing a T-shaped tensile sample; (2) preparing test equipment including an electronic universal testing machine, a clamp, a heating furnace, a temperature control system and a control system; (3) installing the T-shaped tensile sample; (4) testing the mechanical property of a T-shaped tensile sample connector in an environment of the room temperature; (5) testing the mechanical property of the T-shaped tensile sample connector in a high-temperature environment; (6) representing the mechanical property of the connector: integrating a load-displacement curve, dividing the area of a fractured surface to obtain fracture total energy, calculating interface fracture energy (refer to the specification) and a maximal load (refer to the specification) when in fracturing, wherein the interface fracture energy and the maximal load are main parameters representing the mechanical property of the tensile sample. The T-shaped connector sample conforming to the real structure stress situation is provided; the problem that the method for testing the mechanical property of the braze soldering plate-fin structure is in lack and the rest result is incorrect can be solved; the test method is simple, data can be automatically acquired, error in manual operation can be avoided, more efficiency in test can be achieved, and the test result is more accurate.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for the interlayer interface fracture toughness of ballastless track

InactiveCN111189694AOvercome limitationsPreparing sample for investigationMaterial strength using tensile/compressive forcesMeasuring instrumentTrackway

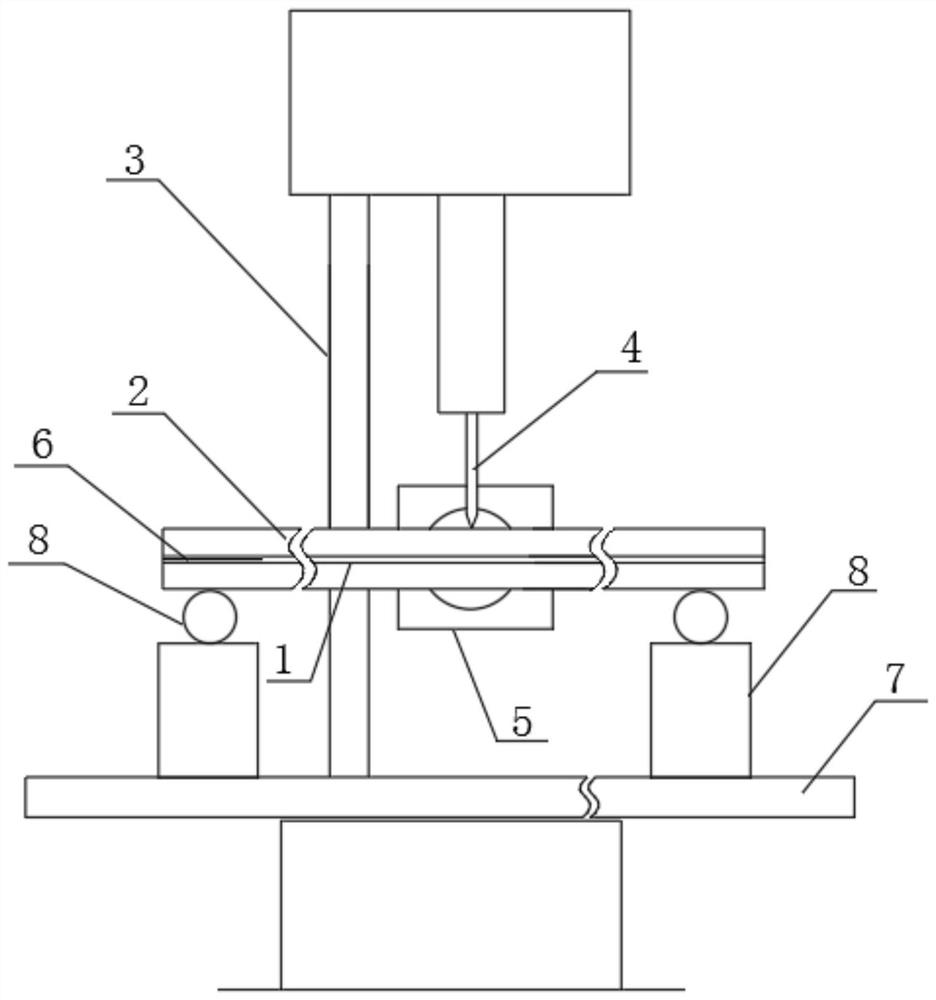

The invention relates to a method for testing the interlayer interface fracture toughness of a ballastless track. The method comprises the following steps: (1) manufacturing a concrete test block of adouble-layer concrete layer structure containing interlayer cracks; (2) mounting the concrete test block on a testing machine, and mounting at least one of a displacement sensor, a strain gauge and the like, pre-pulling the concrete test block, and the pre-pulling load being a failure load with the value range of (0-20%); (3) adjusting a measuring instrument, carrying out formal testing, controlling the load speed to be 0.1-1mm / min until the test piece is damaged, and recording the damage load and the fracture position; and (4) processing a test result, and solving the fracture toughness. Thetest result is processed according to a formula, and the toughness of the concrete interlayer crack is calculated and is accurate to 0.1 J / mm < 2 >. According to the method, the fracture toughness ofthe interlayer interface of the ballastless track is measured based on an energy method, the method is suitable for elastoplasticity and different material combinations, and a judgment basis can be provided for the interlayer hydraulic splitting opportunity of the CRTS I-type double-block ballastless track in a tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

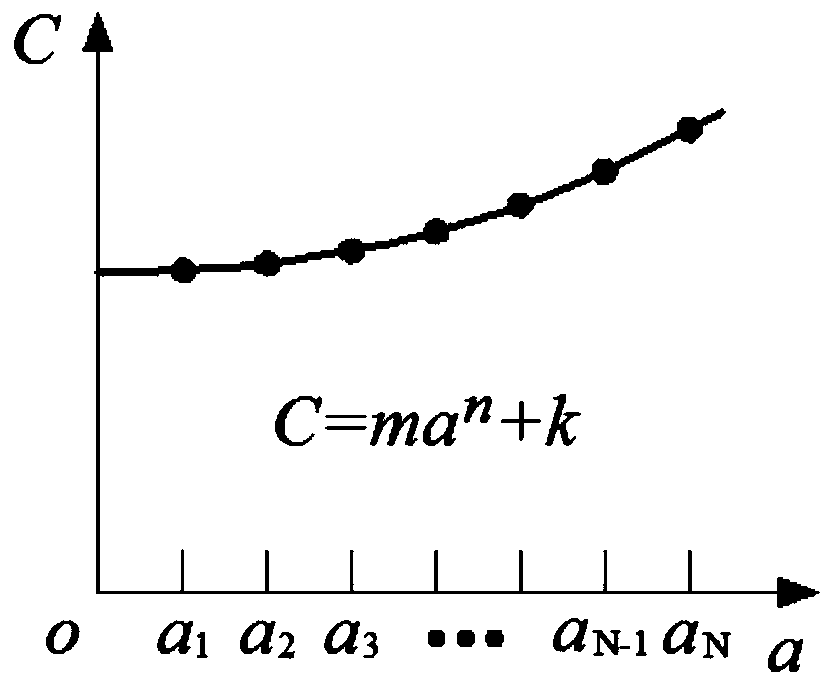

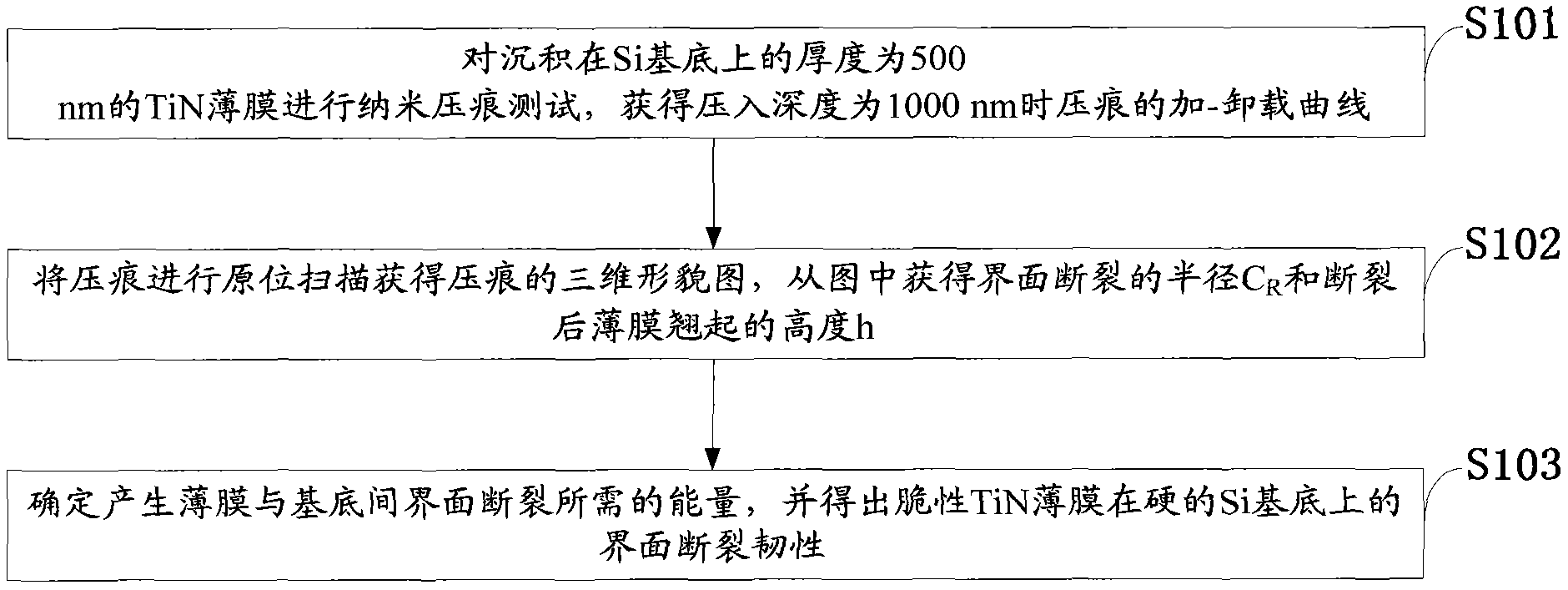

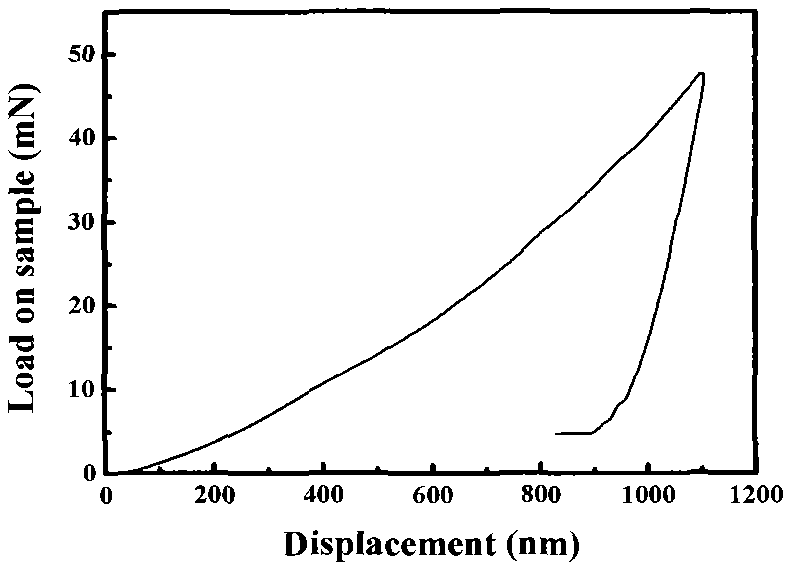

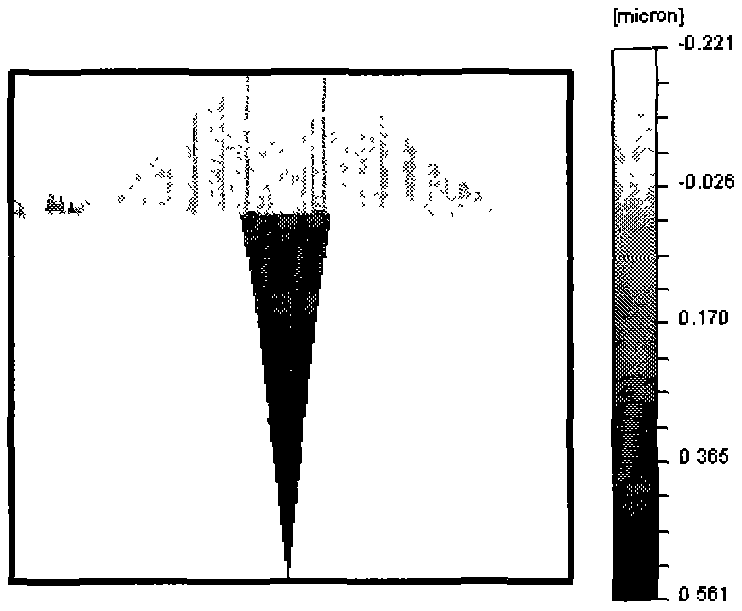

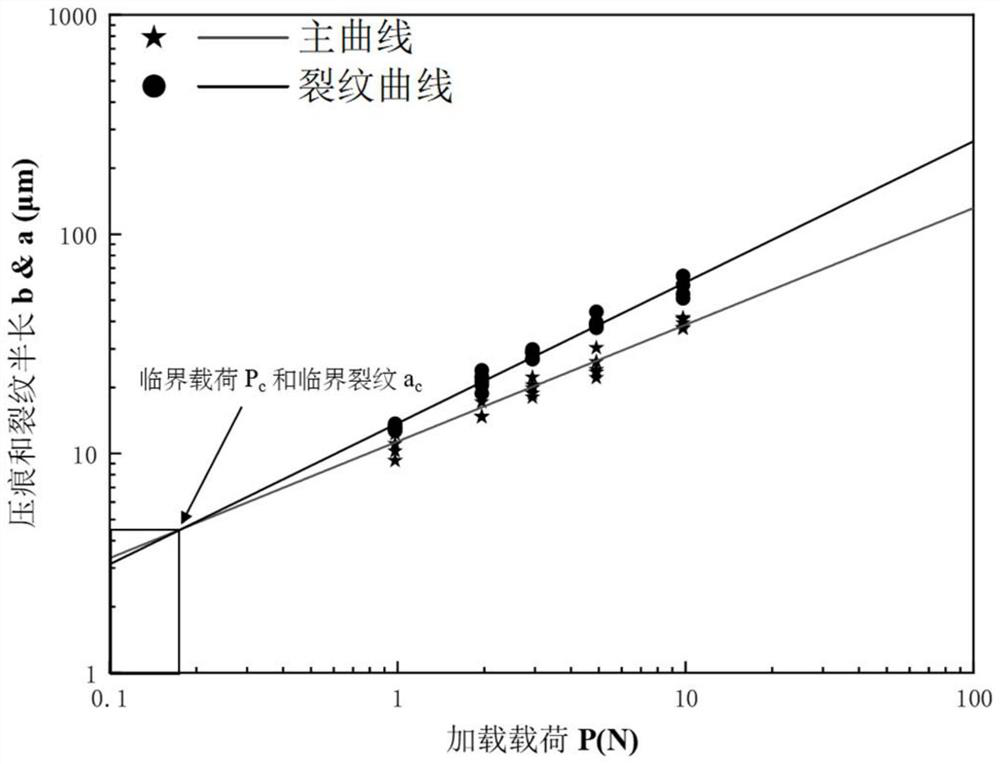

Method for observing and measuring interfacial fracture toughness of fragile film on hard substrate

InactiveCN103592188ADetermine energyDetermining the size of the interfacial breakInvestigating material ductilityTitanium nitrideThin membrane

The invention discloses a method for observing and measuring the interfacial fracture toughness of a fragile film on a hard substrate. The method for observing and measuring the interfacial fracture toughness of the fragile film on the hard substrate includes the following steps: carrying out a nanoindentation test on a 500nm-thick TiN (titanium nitride) film deposited on a Si (silicon) substrate, and obtaining a loading-unloading curve of an indentation at an indentation depth of 1,000nm; carrying out in-situ indentation scanning to obtain a three-dimensional topography of the indentation, and acquiring from the topography the interfacial fracture radius CR and the film tilting height H after the fracture; determining the energy U necessary for the interfacial fracture between the film and the substrate, and obtaining the interfacial fracture toughness of the fragile TiN film on the hard Si substrate. The method provided by the invention has the advantage that through the integration of the indentation loading-unloading curve and the in-situ three-dimensional topography, energy released by the interfacial fracture of the film and the interfacial fracture size can be accurately determined, so that the interfacial fracture toughness of the film can be accurately obtained.

Owner:CHANGCHUN UNIV

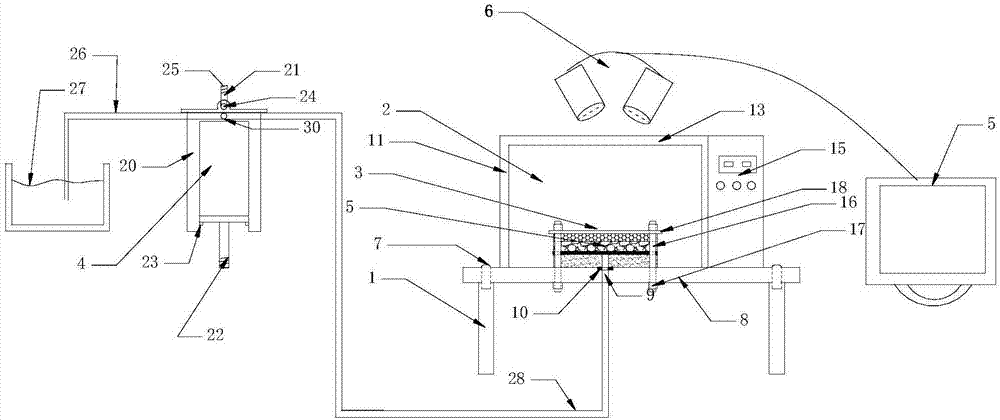

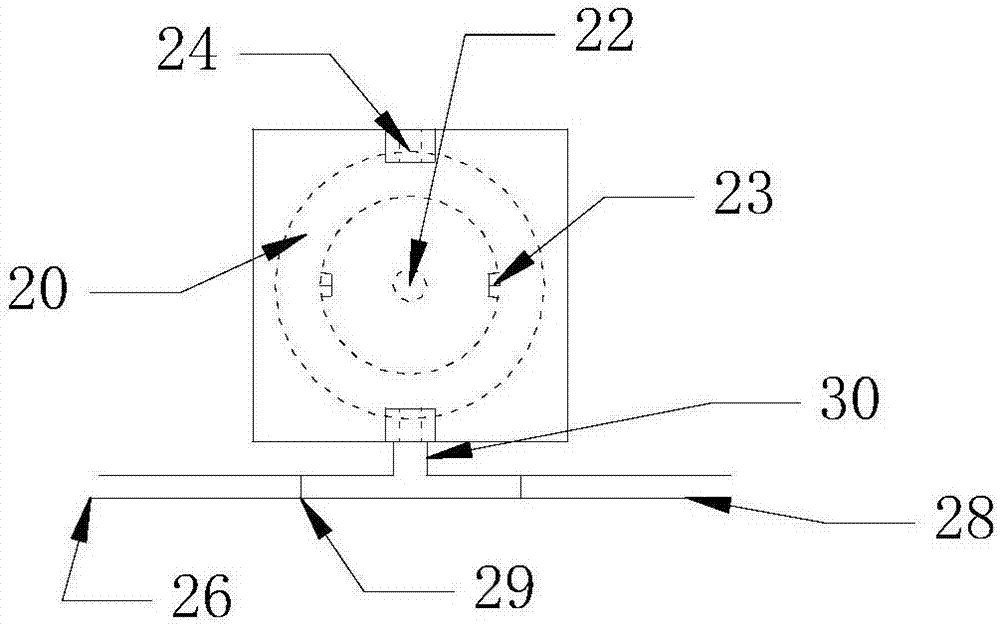

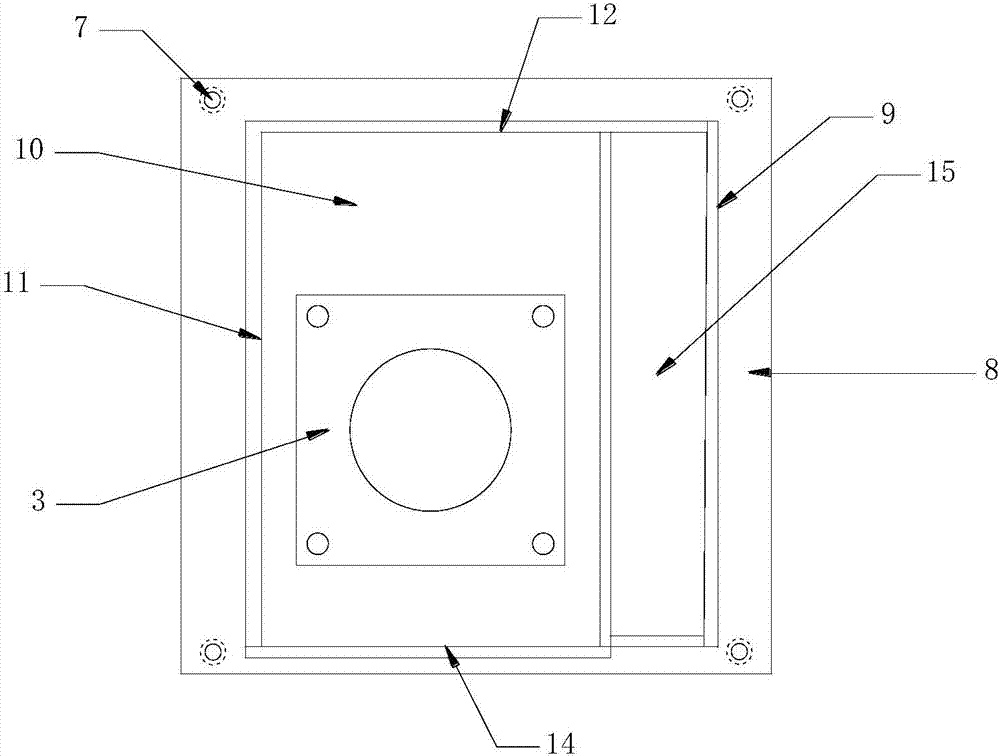

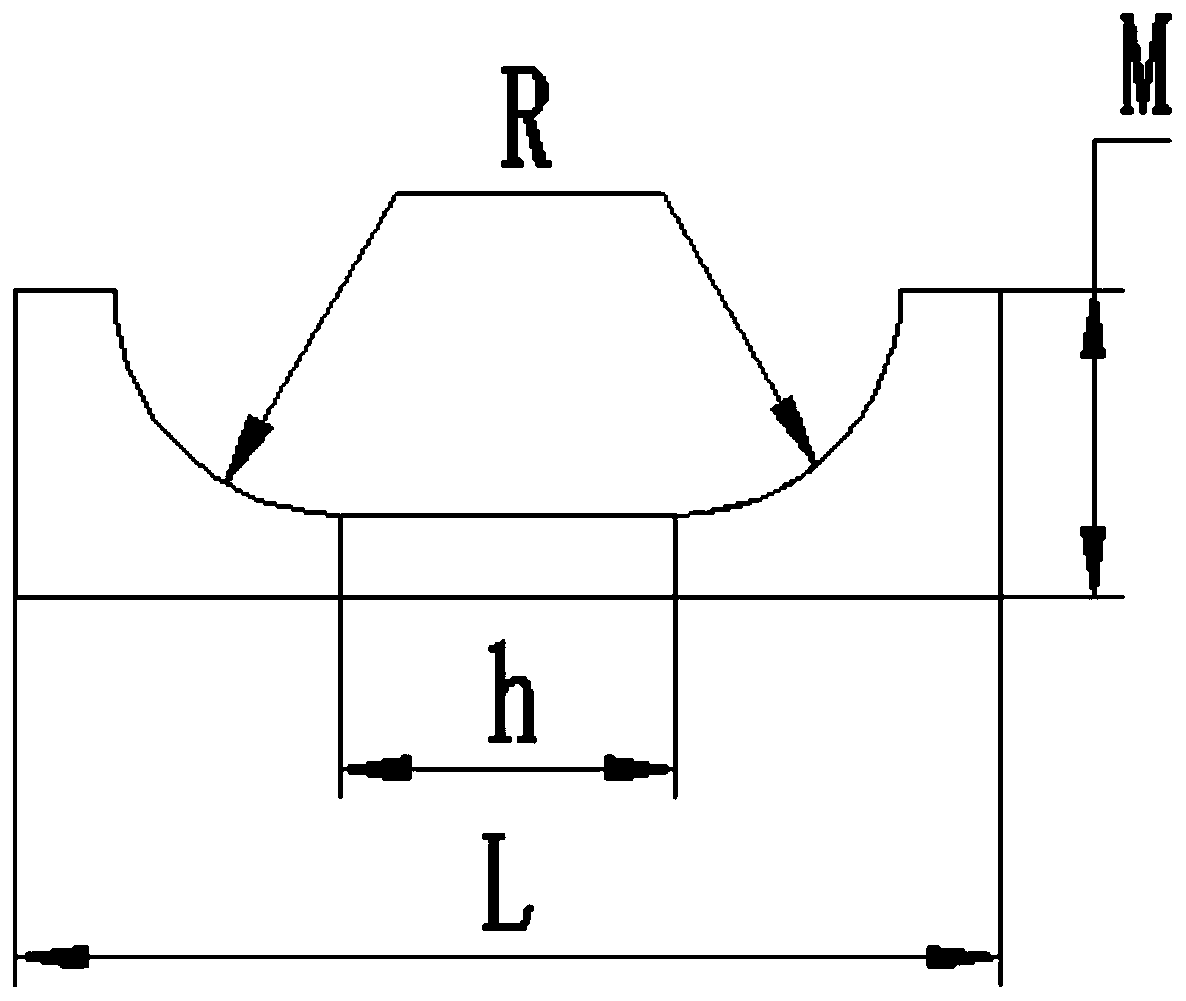

Device and method for testing mechanical parameters of bumping diffusion process of bridge asphalt pavement

ActiveCN107328669ALarge loading rangeOvercoming distractionsPreparing sample for investigationMaterial strength using repeated/pulsating forcesStructural deformationEngineering

The invention discloses a device and a method for testing mechanical parameters of bumping diffusion process of a bridge asphalt pavement, aiming at precisely testing the relationship of bumping deformation characteristic parameters of bridge pavement material and applied load, and calculating the interfacial fracture performance and destructive strain of bumps of different pavement systems. According to the technical scheme, the device comprises an environment box arranged on a support frame, wherein a test piece fixing mount is arranged in the environment box, and is connected to a pressurized oil cylinder through an output oil pipe, the pressurized oil cylinder is connected with an MTS fatigue testing machine and can press hydraulic oil into a test piece to generate load action; and a temperature and humidity sensor and a temperature and humidity generation controller are arranged in the environment box, and a camera capable of photographing the surface bumping deformation of the test piece is arranged at the top of the environment box, and is connected to an MTI-3D structural deformation measurement system capable of processing and analyzing the surface bumping deformation of the test piece.

Owner:CHANGAN UNIV

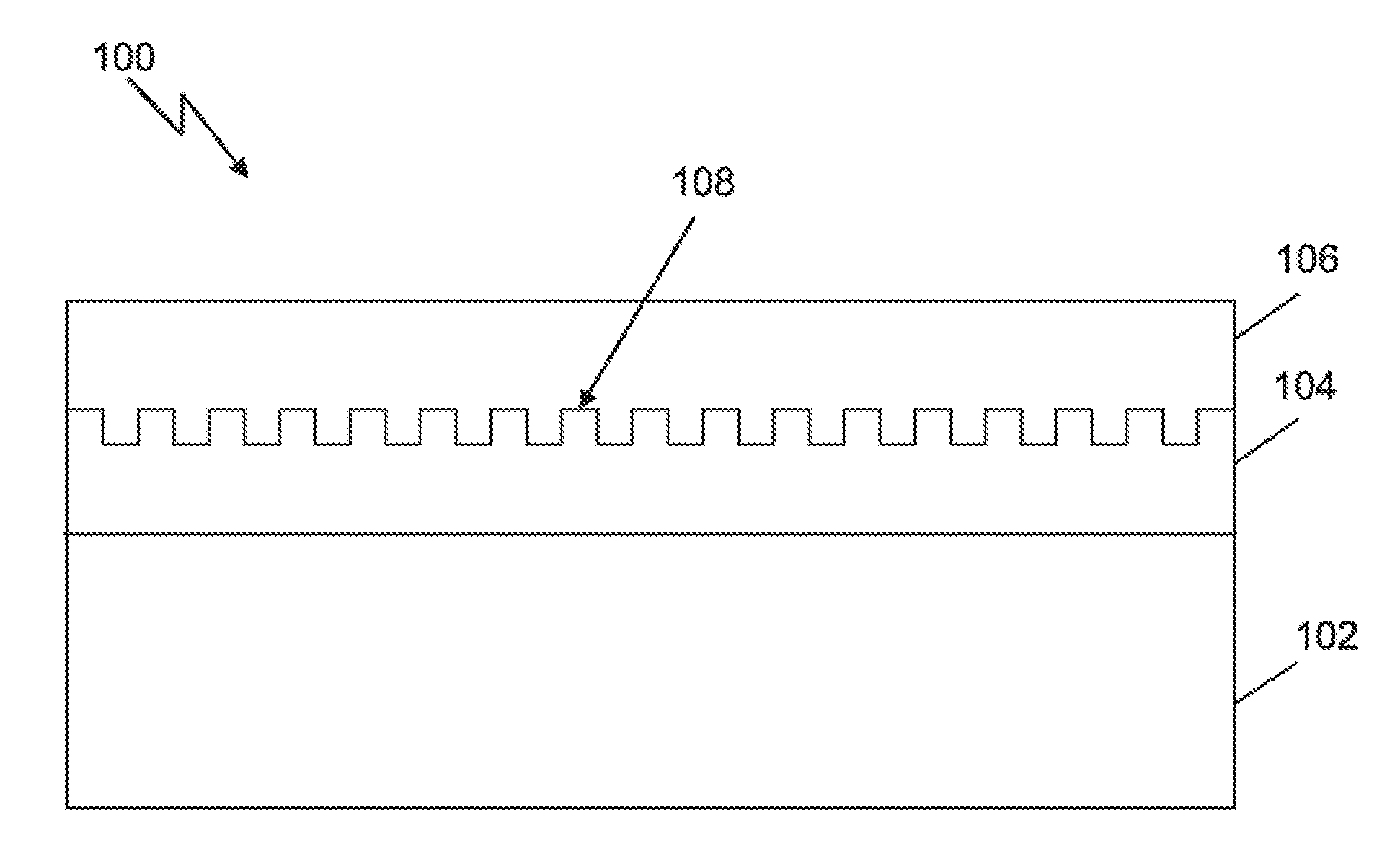

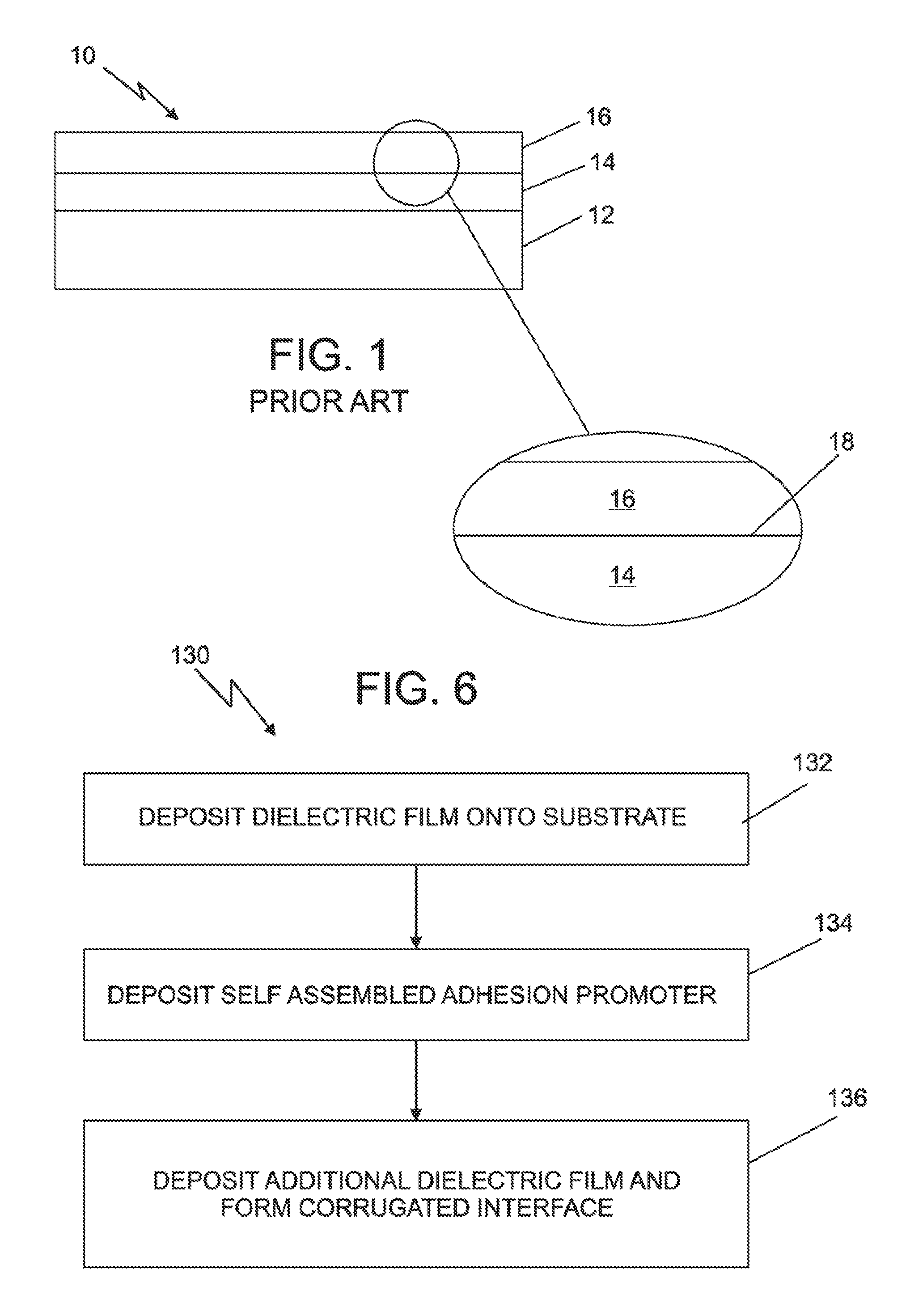

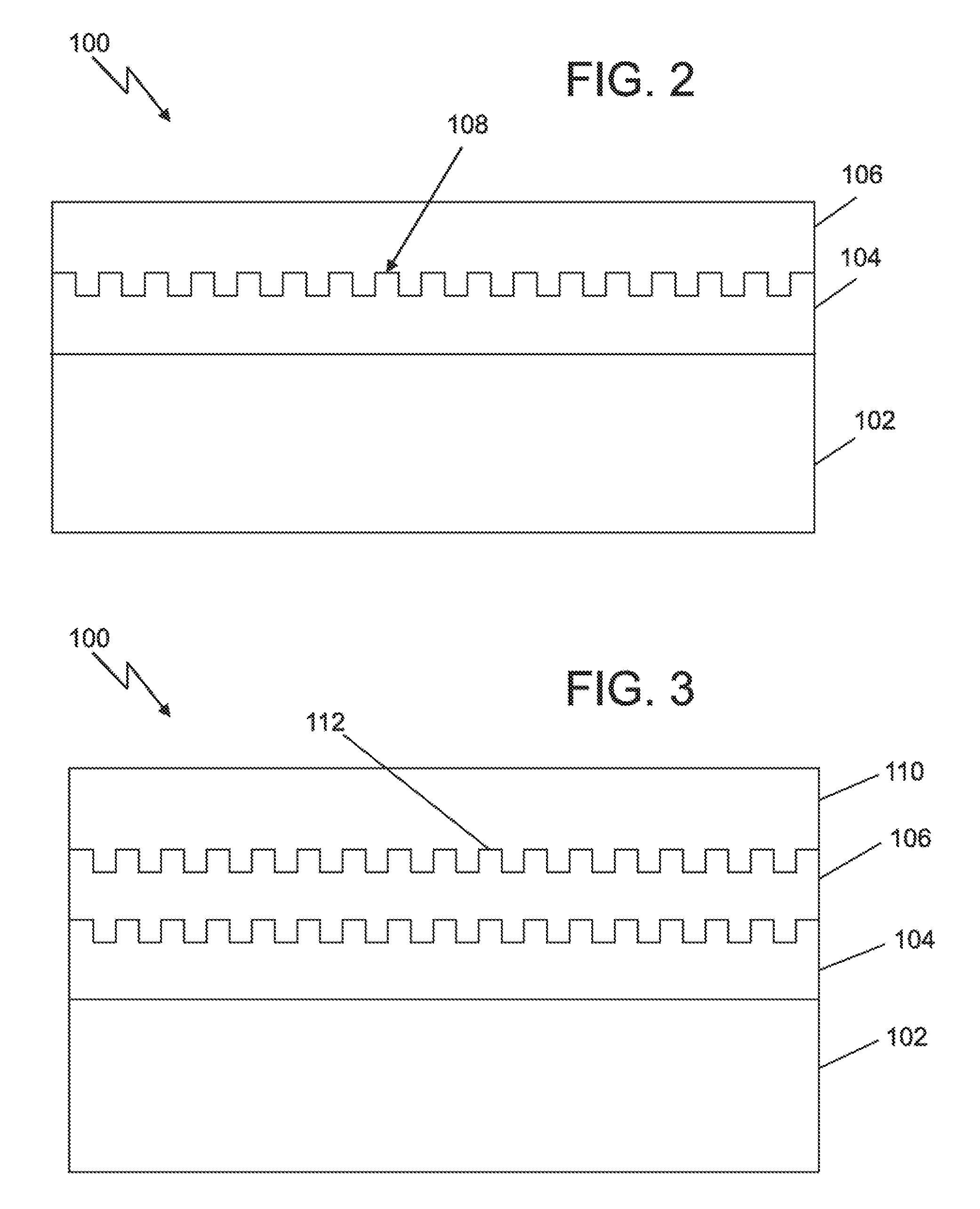

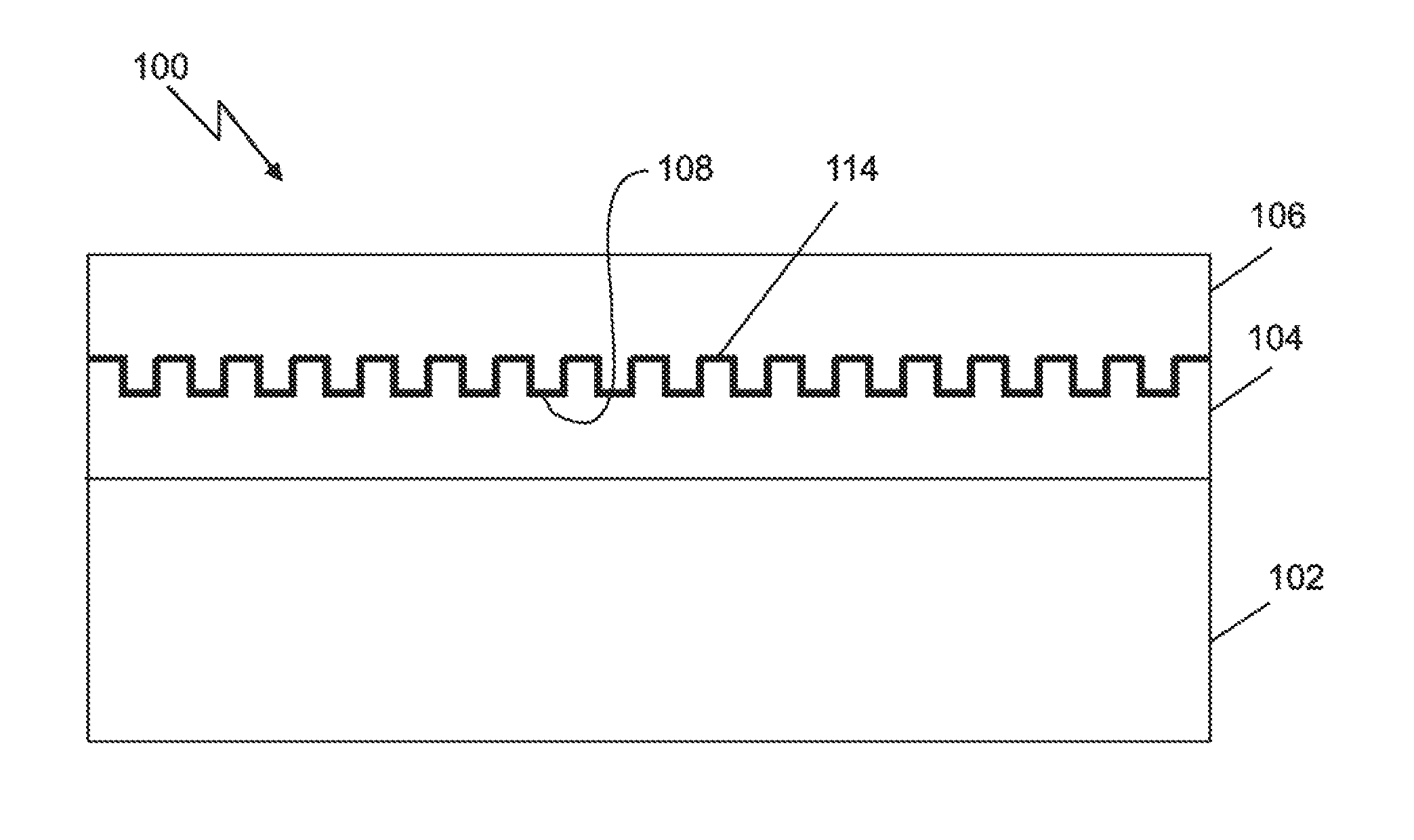

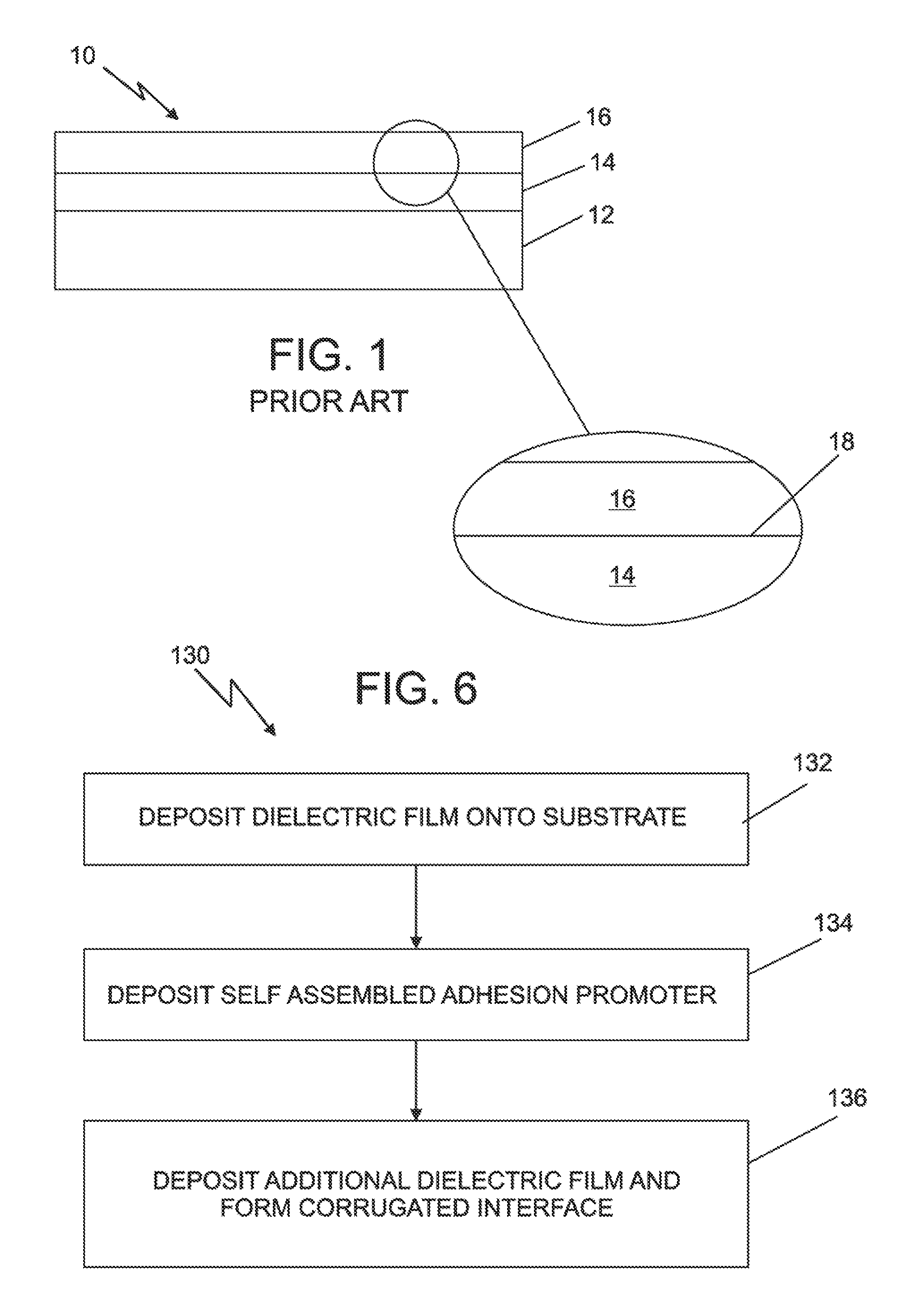

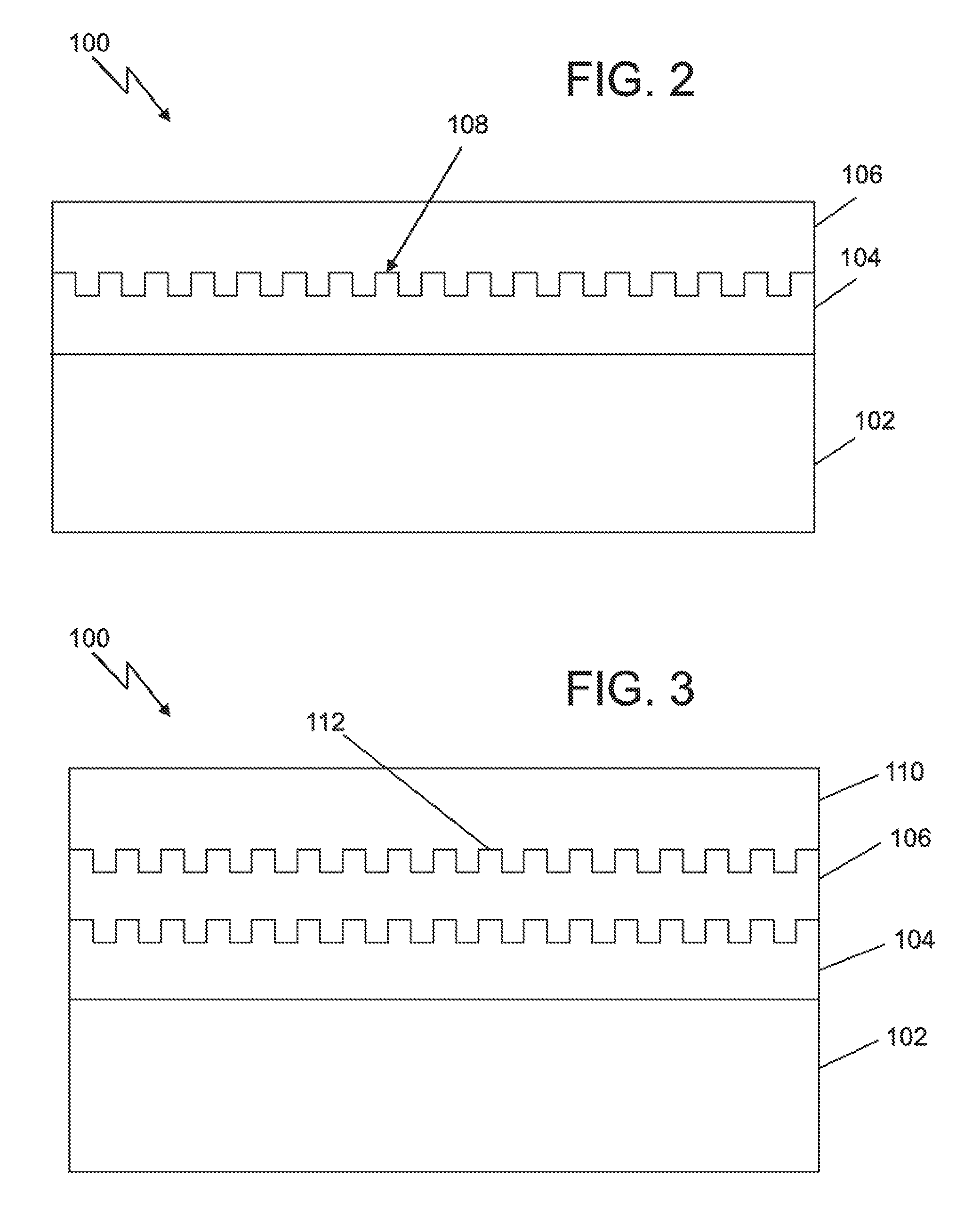

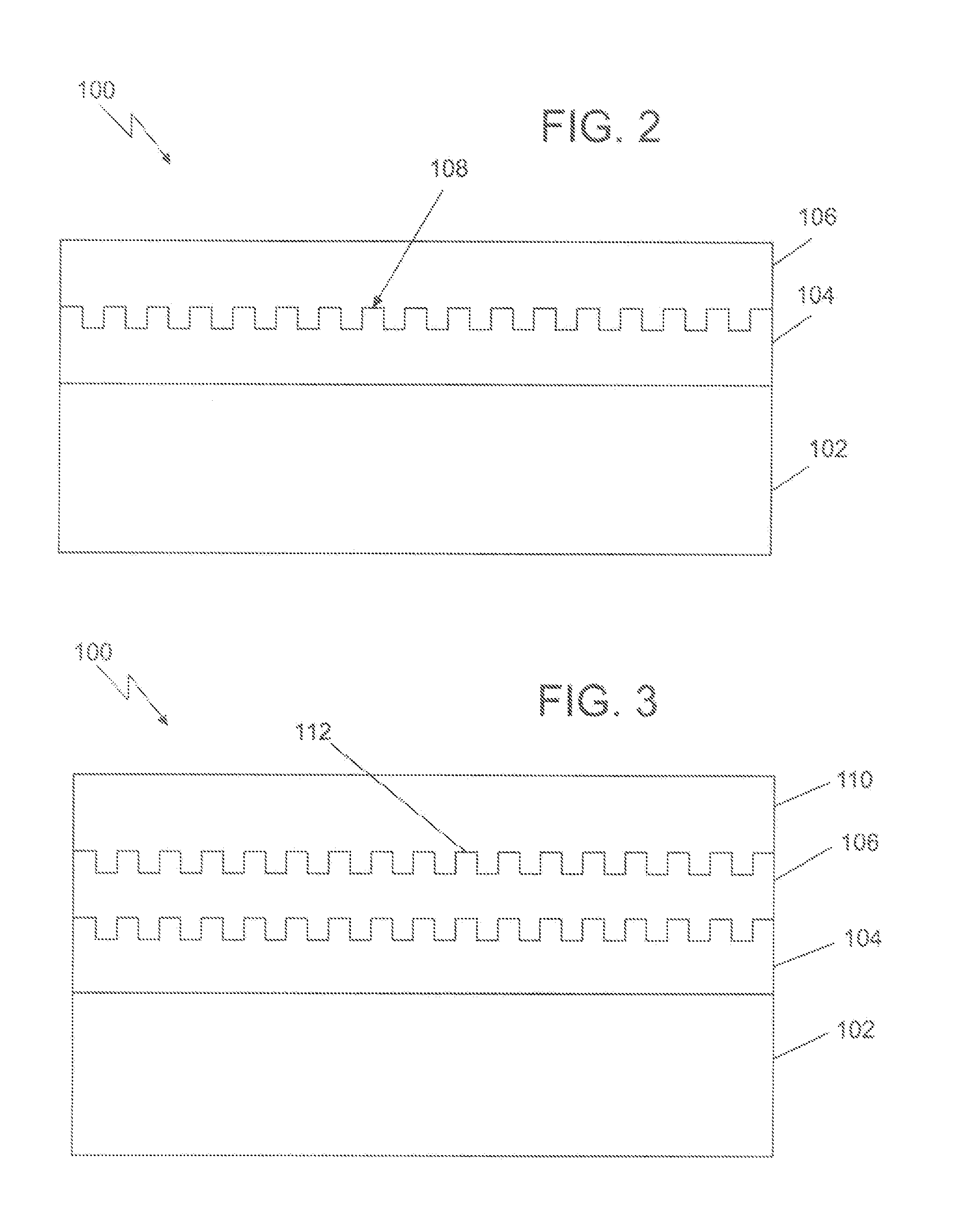

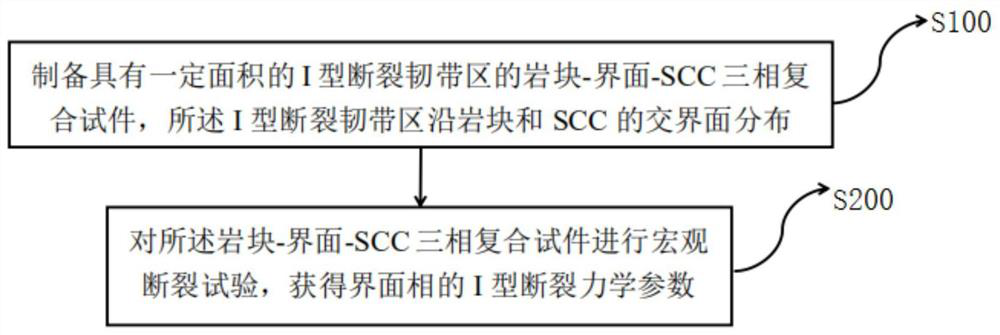

Corrugated interfaces for multilayered interconnects

ActiveUS20090041989A1Layered productsSemiconductor/solid-state device detailsInterfacial adhesionAdhesion strength

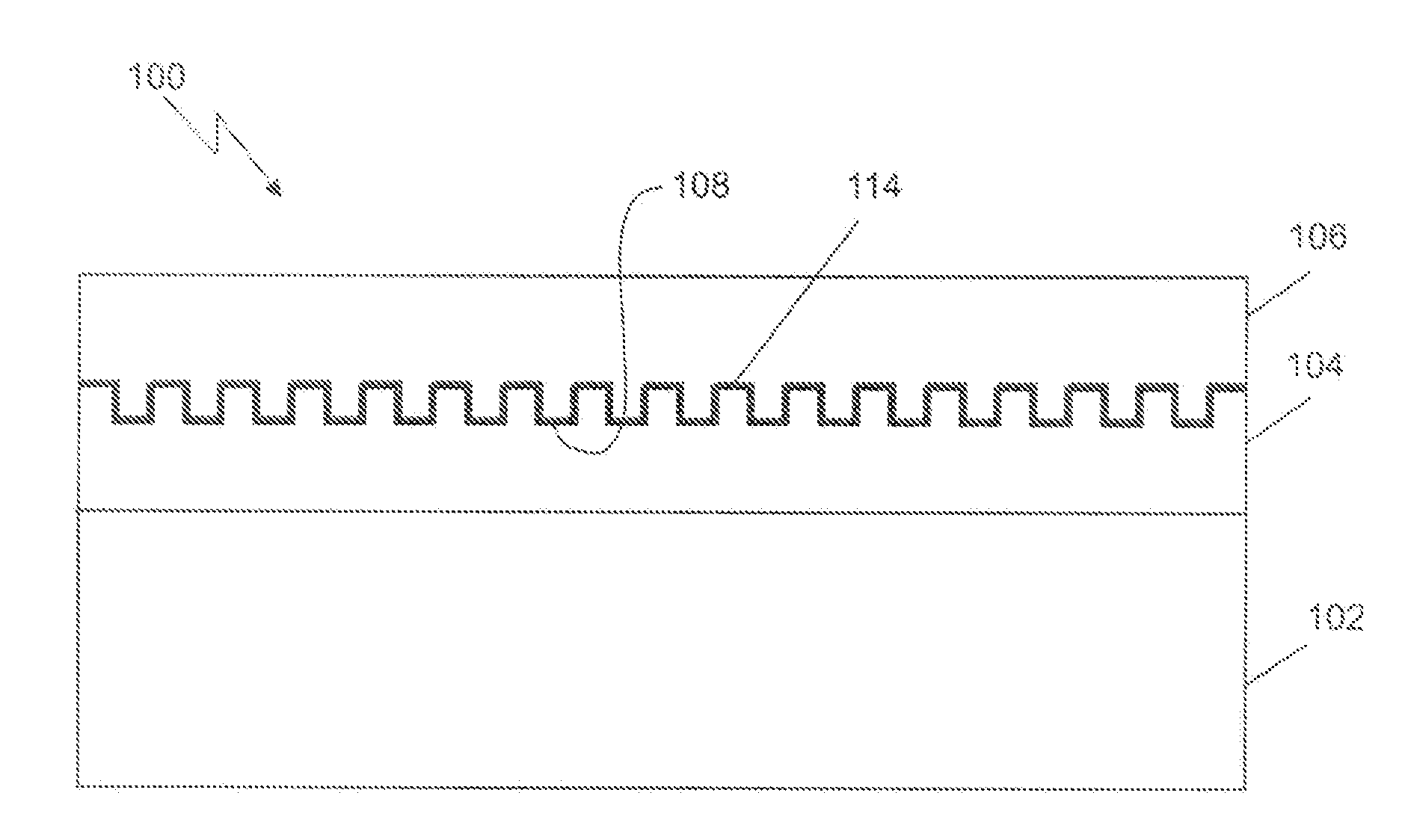

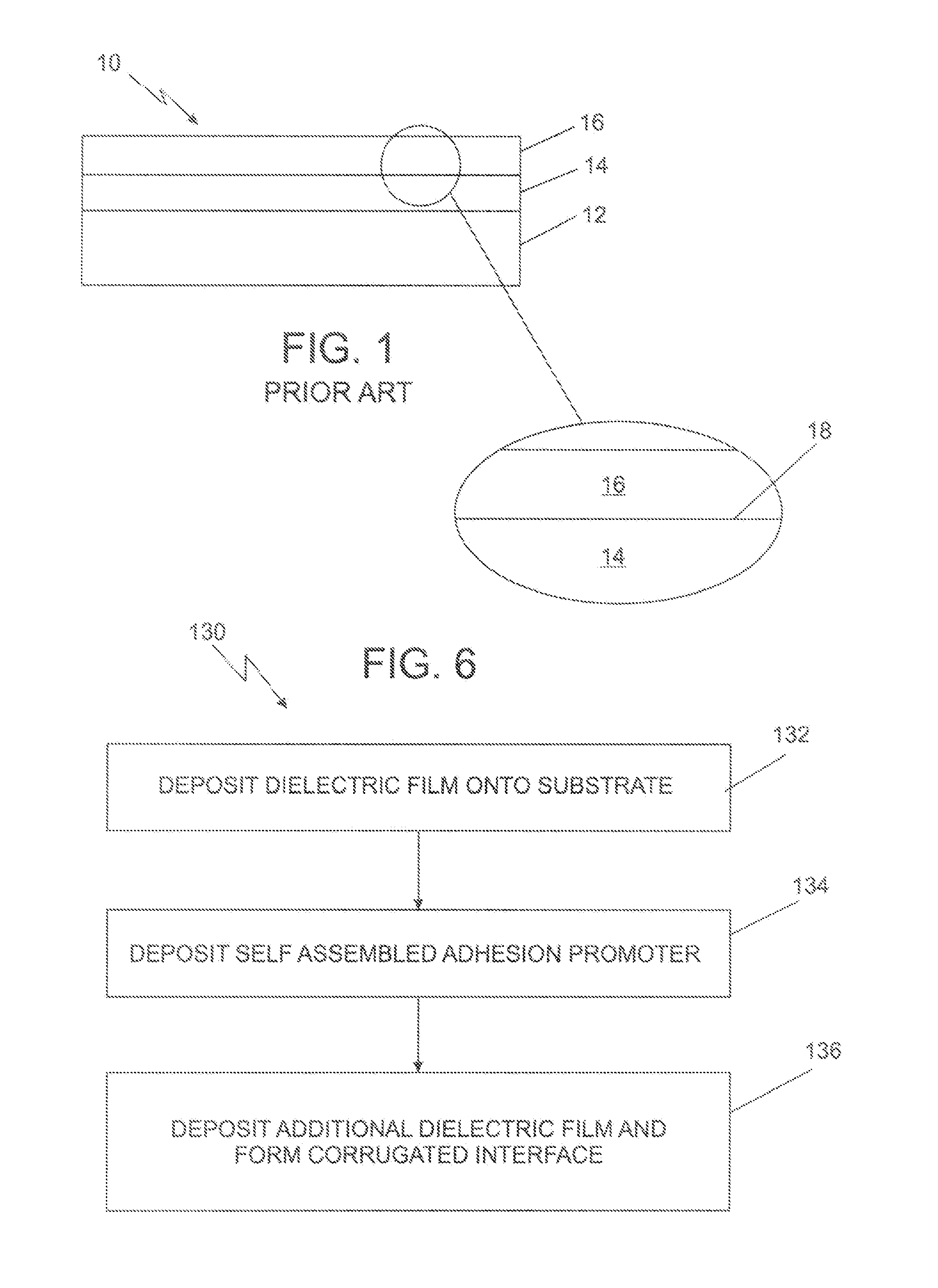

Dielectric composite structures comprising interfaces possessing nanometer scale corrugated interfaces in interconnect stack provide enhances adhesion strength and interfacial fracture toughness. Composite structures further comprising corrugated adhesion promoter layers to further increase intrinsic interfacial adhesion are also described. Methods to form the nanometer scale corrugated interfaces for enabling these structures using self assembling polymer systems and pattern transfer process are also described.

Owner:TAIWAN SEMICON MFG CO LTD

Corrugated interfaces for multilayered interconnects

ActiveUS8512849B2Layered productsSemiconductor/solid-state device detailsInterfacial adhesionAdhesion strength

Dielectric composite structures comprising interfaces possessing nanometer scale corrugated interfaces in interconnect stack provide enhances adhesion strength and interfacial fracture toughness. Composite structures further comprising corrugated adhesion promoter layers to further increase intrinsic interfacial adhesion are also described. Methods to form the nanometer scale corrugated interfaces for enabling these structures using self assembling polymer systems and pattern transfer process are also described.

Owner:TAIWAN SEMICON MFG CO LTD

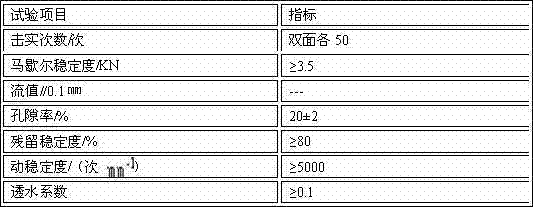

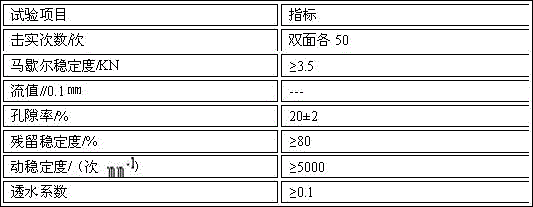

Anti-rut agent for cool mixing and cool spreading of asphalt road

The invention discloses an anti-rut agent for cool mixing and cool spreading of an asphalt road. The anti-rut agent mainly comprises a high-rigidity normal-temperature asphalt blend and a concentrated curing agent, wherein the curing agent and the normal-temperature asphalt blend are cured to form reinforced fibers, and a polymer and the curing agent have chemical bonding, thus the interfacial binding is also strengthened, and the interfacial fracture energy can be improved, therefore, the overall toughened, high-strength and consistent gel structure can be formed by modifying the normal-temperature asphalt. In addition, the different amounts of the curing agents have certain impact on demulsification of the asphalt blend. The usage amounts of the curing agent and the emulsifier can be selected according to the construction requirements, and the demulsification time can be controlled so as to guarantee the successful running of the construction.

Owner:南通福伦利新材料有限公司

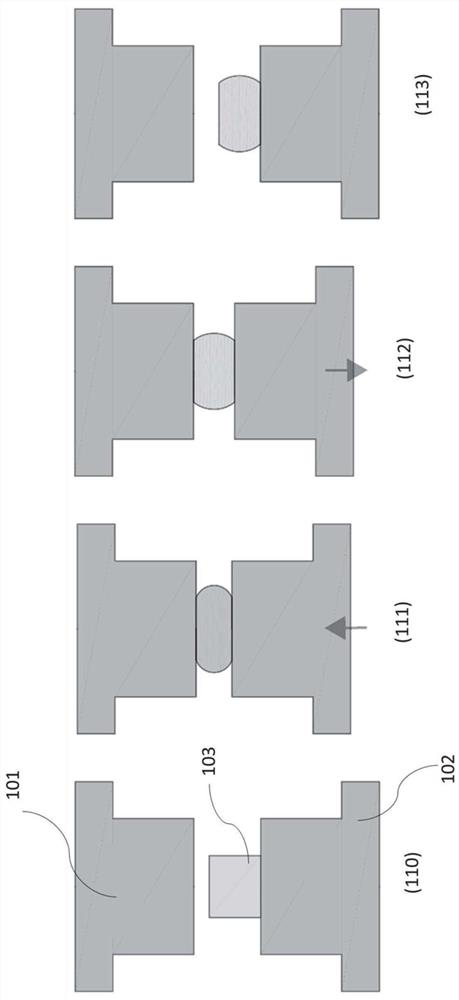

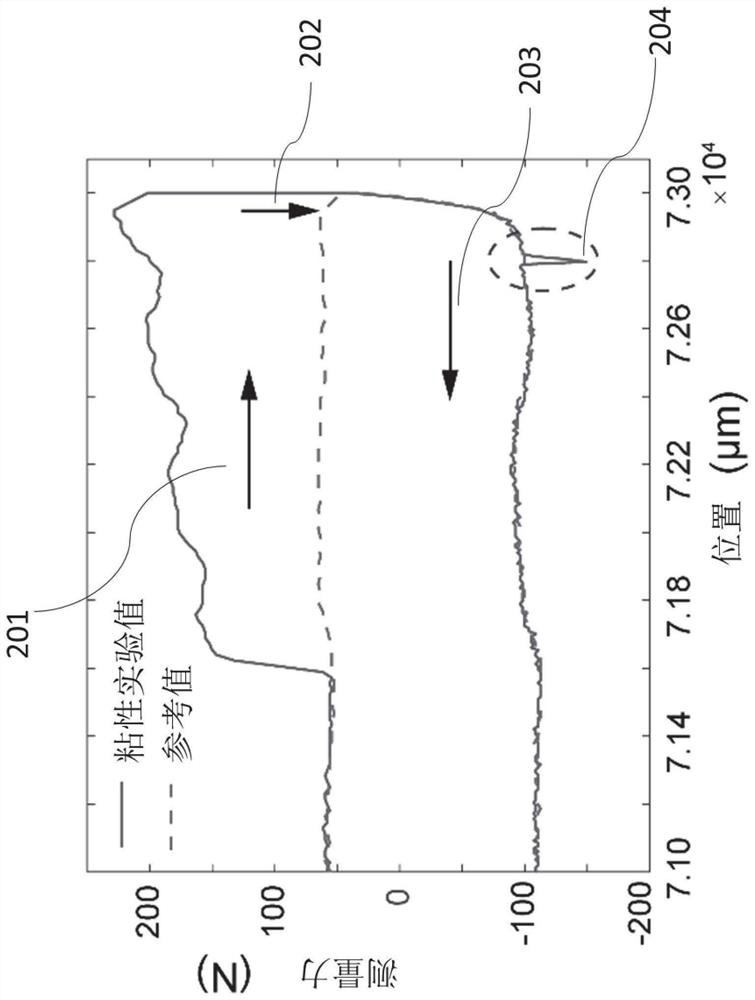

Characterization and control method for bonding strength of precision glass mould pressing interface

The invention relates to a characterization and control method for bonding strength of a precision glass mould pressing interface. Specifically, the method comprises the following steps: heating and soaking a top plane mold (101), a bottom plane mold (102) and a glass sample (103); performing pressing and holding operations; performing debonding operation; and performing a cooling and releasing operation; wherein the debonding operation comprises maintaining a certain forming temperature; enabling the bottom plane mold (102) and the glass sample (103) to move downward at a certain debonding speed until a preset debonding distance is reached; meanwhile, adjusting different forming temperatures, so that the glass sample (103) is in a cohesive state, a bonding interface transition state and an interface fracture state respectively. The optical element obtained through the method is high in forming quality, and the service life of a precious mold is prolonged.

Owner:SHENZHEN TECH UNIV

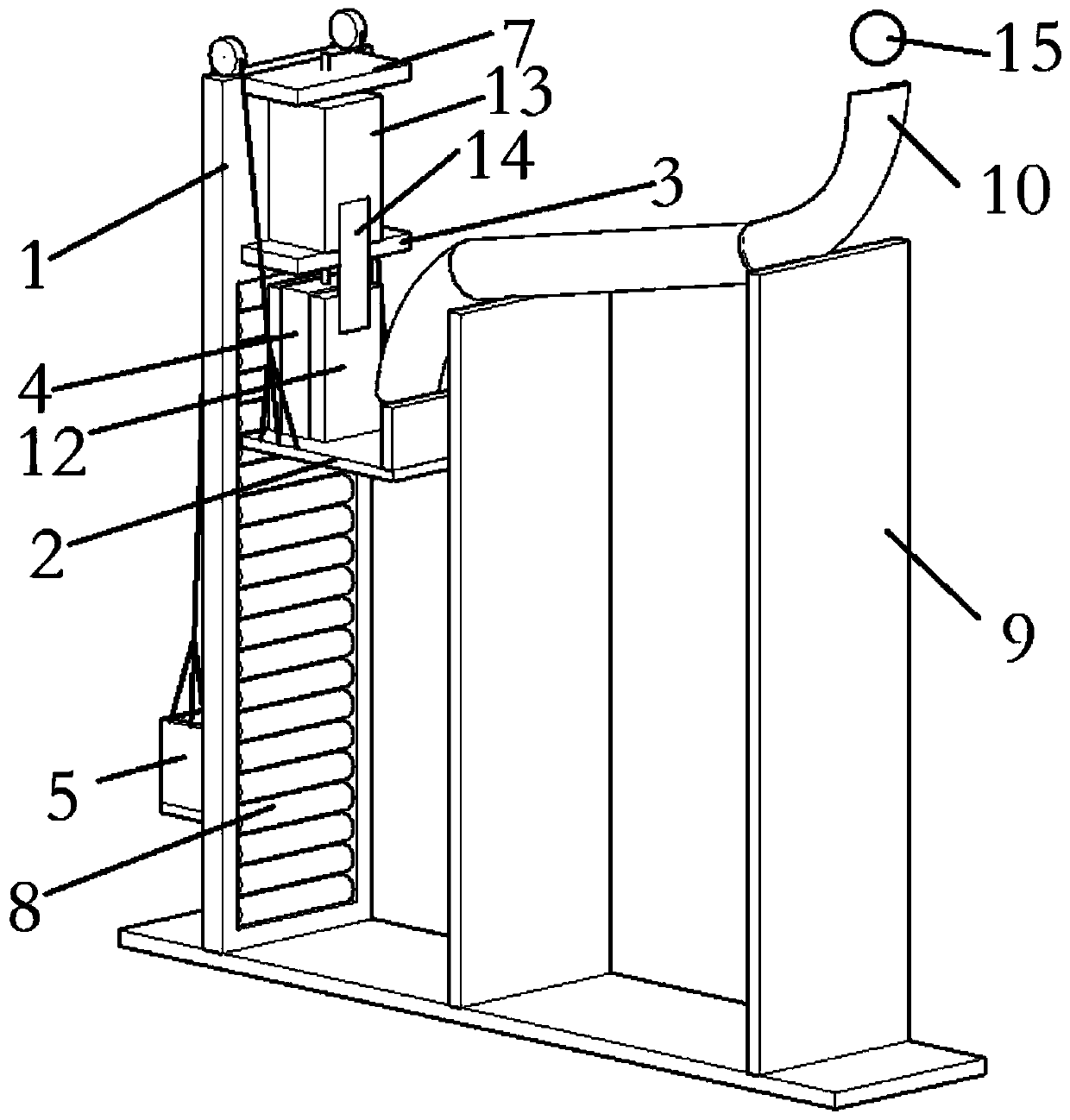

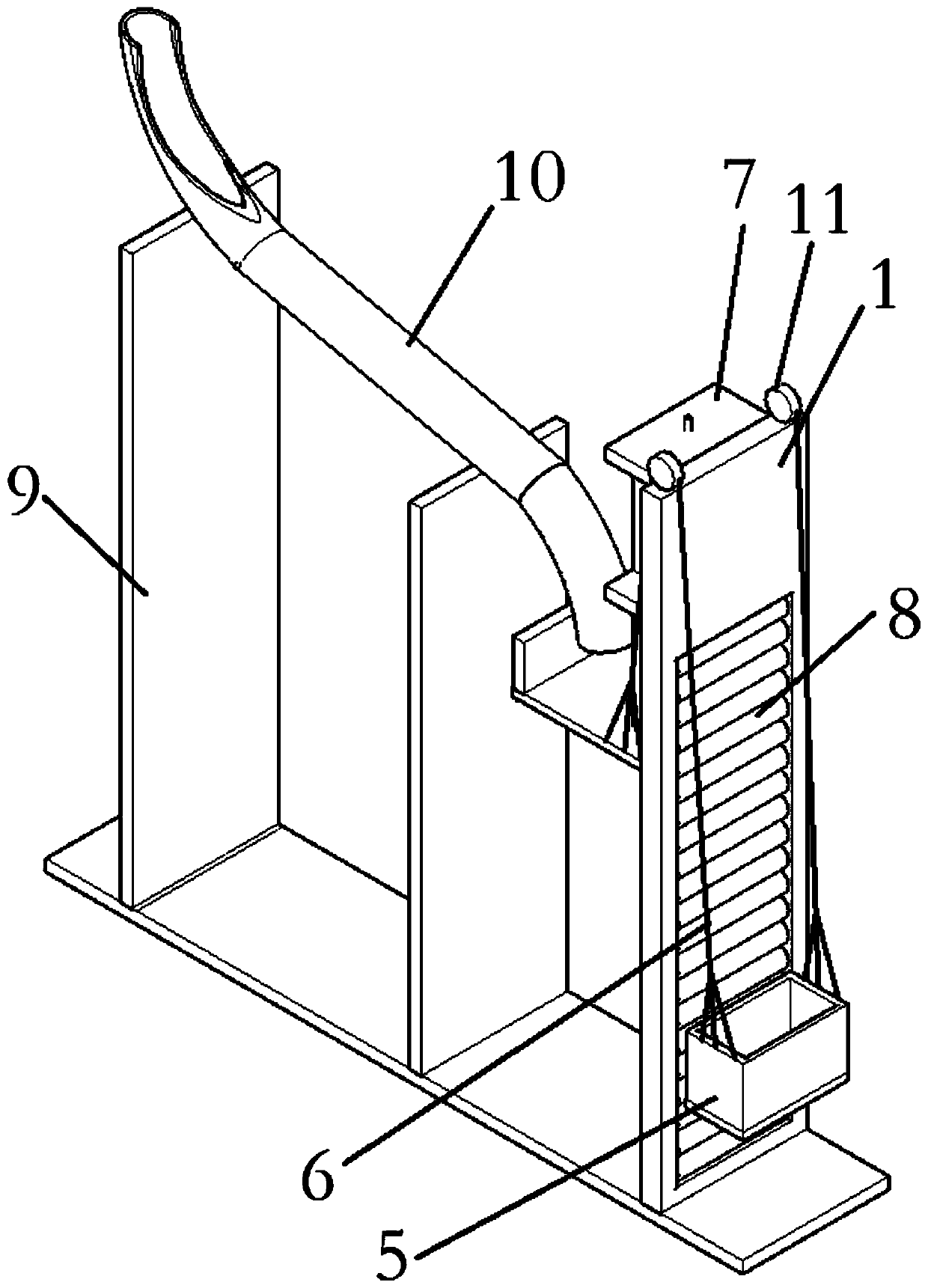

Device and method for testing adhesive property of fiber reinforced composite reinforced concrete

ActiveCN111257221AAvoid displacementGuaranteed accuracyUsing mechanical meansStrength propertiesReinforced concreteConstruction engineering

The invention relates to the technical field of mechanical property test devices, in particular to a device and a method for testing the adhesive property of fiber reinforced composite reinforced concrete. The device comprises an installation support and a balance box, a movable platform and a fixed platform are sequentially installed on the installation support from bottom to top, the movable platform extends outwards to form an impact part, and a first storage space used for storing a first test block and a second storage space used for storing a second test block are formed in the movable platform and the fixed platform respectively; the balance box is connected with the movable platform through a connecting piece, a balance weight is arranged in the balance box, and the connecting piece bypasses the top of the installation support, so that the balance box and the movable platform are located on the two sides of the installation support. Accurate energy consumed by fracture of a fiber reinforced composite material sheet can be obtained by measuring the difference between the energy of an impact piece impacting the movable platform and the energy of the movable platform, the first test block and the impact piece after the connection interface is fractured.

Owner:济南景明建材有限公司

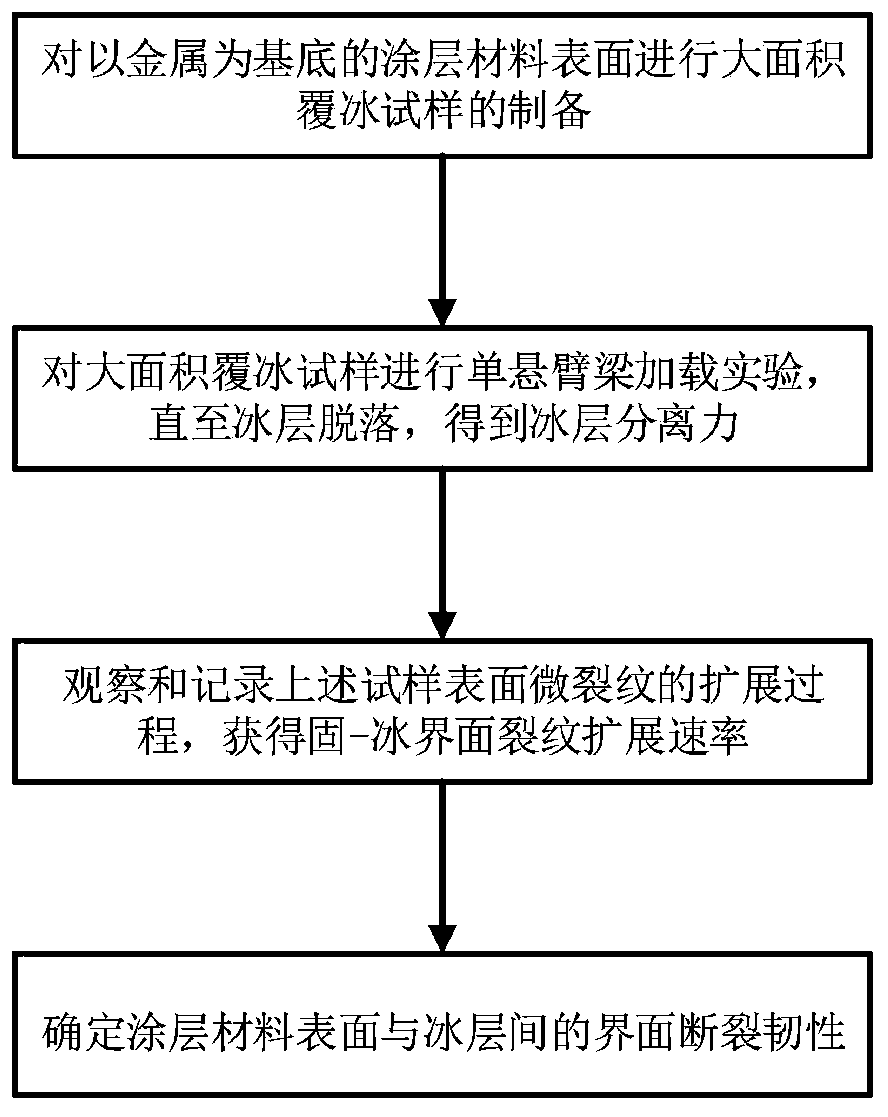

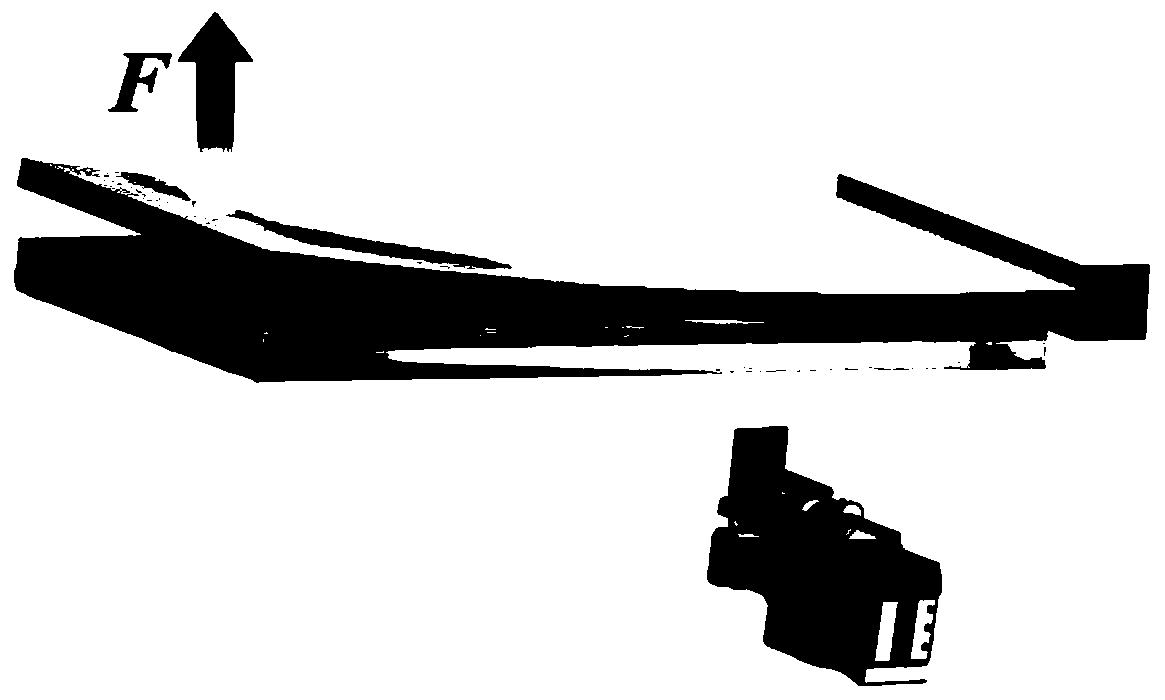

Device and method for testing fracture toughness of solid-ice interface of coating layer material surface under large-area icing condition

ActiveCN111537436AAccurately evaluate anti-icing performanceEvaluate anti-icing performanceUsing mechanical meansStrength propertiesCantilevered beamCrazing

The invention provides a device and a method for testing fracture toughness of a solid-ice interface of a coating layer material surface under a large-area icing condition. The testing method adopts asingle cantilever beam loading principle, utilizes bending stress of a metal substrate to induce initiation and expansion of microcracks at a solid-ice interface, and aims to observe an interface fracture behavior between the surface of a coating layer material taking a metal as a substrate and an ice layer so as to obtain the interface fracture toughness between the ice layer and the surface ofthe substrate. The method has the advantages that the anti-icing performance of a large-area component coating layer material can be accurately evaluated, operation is easy and convenient, the purposeof objectively evaluating the fracture toughness of a solid-ice interface under a large-area icing condition is achieved, and important significance is achieved for industrial application and development of the anti-icing surface; and the testing device is simple in structure, ingenious in design and easy to operate, and has a good using effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Radio frequency electro-thrombectomy device

ActiveCN107847239ADamage minimizationImprove chip resistanceSurgical instrument detailsCross-linkPower flow

A device is designed to remove blockages in a lumen such as a thrombus, blood clot, or embolus. The device comprises a manipulating wire and a structure that can conduct electrical current to a lumenblockage. The electrical current is preferably in radio frequency (RF). The RF electric current in the blockage can excite the contents such as proteins of the blockage, so that cross-linking densityand interfacial adsorption of the entire blockage is enhanced. The enhanced cross-linking density can result in increased fracture resistance of the blockage such that fracture of the blockage duringthe removal process is unlikely. The enhanced interfacial adsorption results in increased interfacial fracture resistance between the device and blockage so that the blockage can be securely capturedduring the removal process without using radially applied force.

Owner:THE HONG KONG UNIV OF SCI & TECH

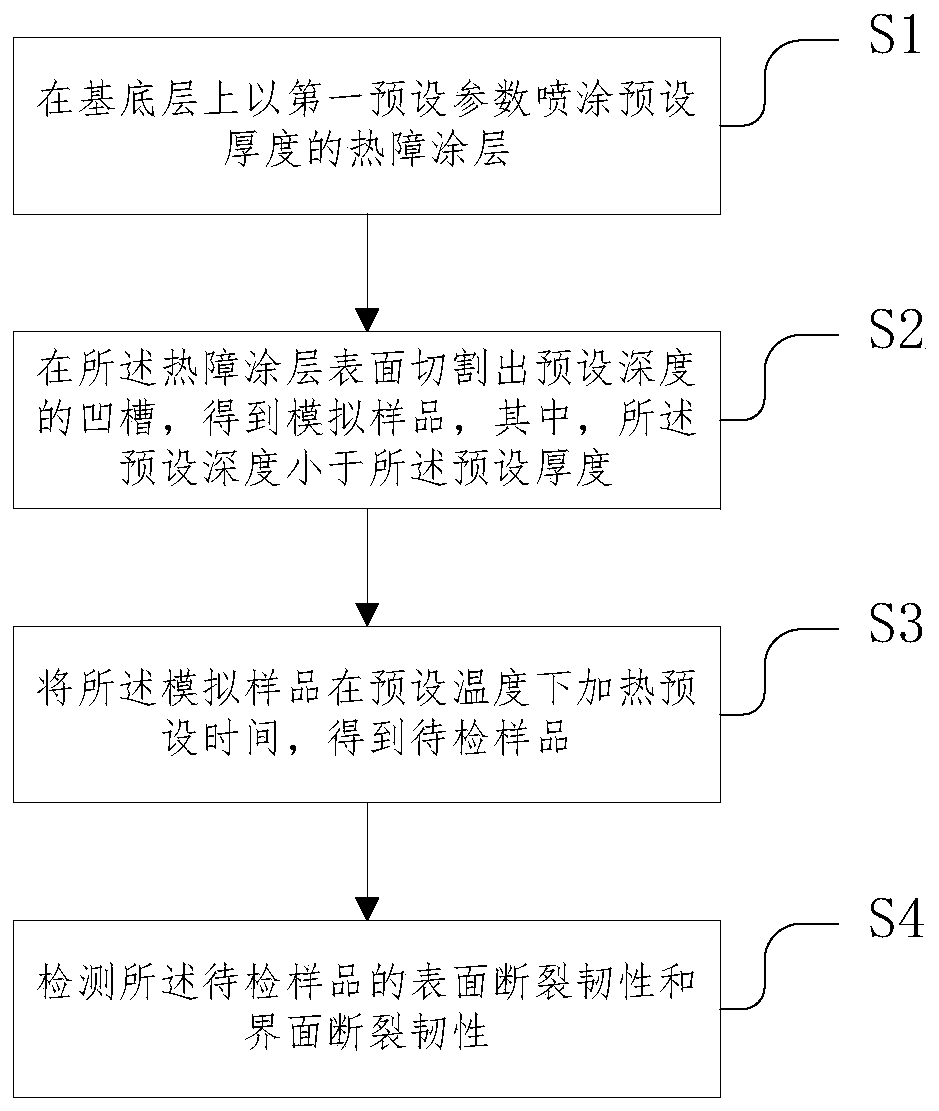

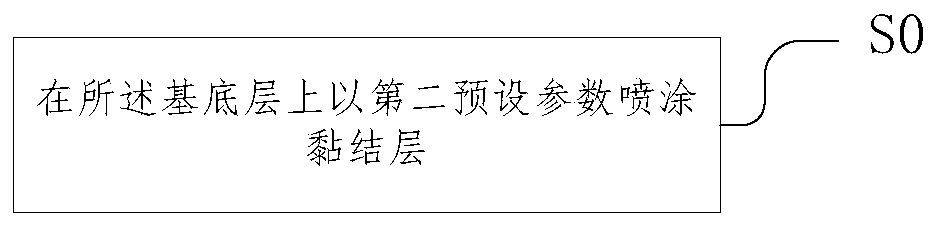

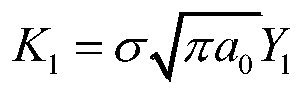

High-temperature environmental thermal barrier coating surface and interface fracture toughness three-point bending detection method

ActiveCN110823714ARealize a DIC observationReduce lossMaterial strength using steady bending forcesThermal barrier coatingInterfacial fracture

The invention discloses a high-temperature environmental thermal barrier coating surface and interface fracture toughness three-point bending detection method. The method comprises the steps that a thermal barrier coating with a preset thickness is sprayed on a substrate layer according to first preset parameters; a groove with a preset depth is cut in the surface of the thermal barrier coating, and a simulation sample is obtained, wherein the preset depth is smaller than the preset thickness; and the simulation sample is heated for a preset time under a preset temperature, and a to-be-detected sample is obtained; and the surface fracture toughness and interface fracture toughness of the to-be-detected sample are detected. Through the method, one-time DIC (digital image correlation) observation of the thermal barrier coating is realized, the surface fracture toughness and interface fracture toughness of the thermal barrier coating can be detected, and the problems that surface fracturetoughness detection and interface fracture toughness detection of an existing thermal barrier coating need to be performed respectively, and repeated operation of DIC observation is complicated and tedious and consumes a long time are solved. Therefore, the detection efficiency of the surface fracture toughness and interface fracture toughness of the thermal barrier coating is improved, materialloss is reduced, and cost is saved.

Owner:XIANGTAN UNIV

Method for surface modification of carbon fibers by sizing agent containing carbon nanomaterials

InactiveCN110004707AGood mechanical propertiesImprove mechanical propertiesCarbon fibresFiberCarbon fiber reinforced composite

The invention discloses a method for surface modification of carbon fibers by a sizing agent containing carbon nanomaterials. Graphene and carbon nanotubes are adopted as materials of the sizing agentfor surface modification of carbon fibers. The method includes steps of carbon fiber surface treatment, GnP-CNTs sizing agent preparation and GnP-CNTs sizing agent surface modified carbon fiber preparation. The nanomaterials including the carbon nanotubes and graphene with excellent mechanical properties and large specific surface areas are added into the sizing agent, and graphene and the carbonnanotubes are uniformly deposited on the carbon fiber surface. After surface modification, the mechanical properties of the carbon fibers are evidently improved after surface modification, and aftersizing time reaches 30s, monofilament tensile strength of CF subjected to surface modification is improved by 20.7% as compared with that of desized CF, so that problems of poor interfacial fracture toughness and low interfacial strength of a carbon fiber reinforced composite material can be solved.

Owner:NANCHANG HANGKONG UNIVERSITY

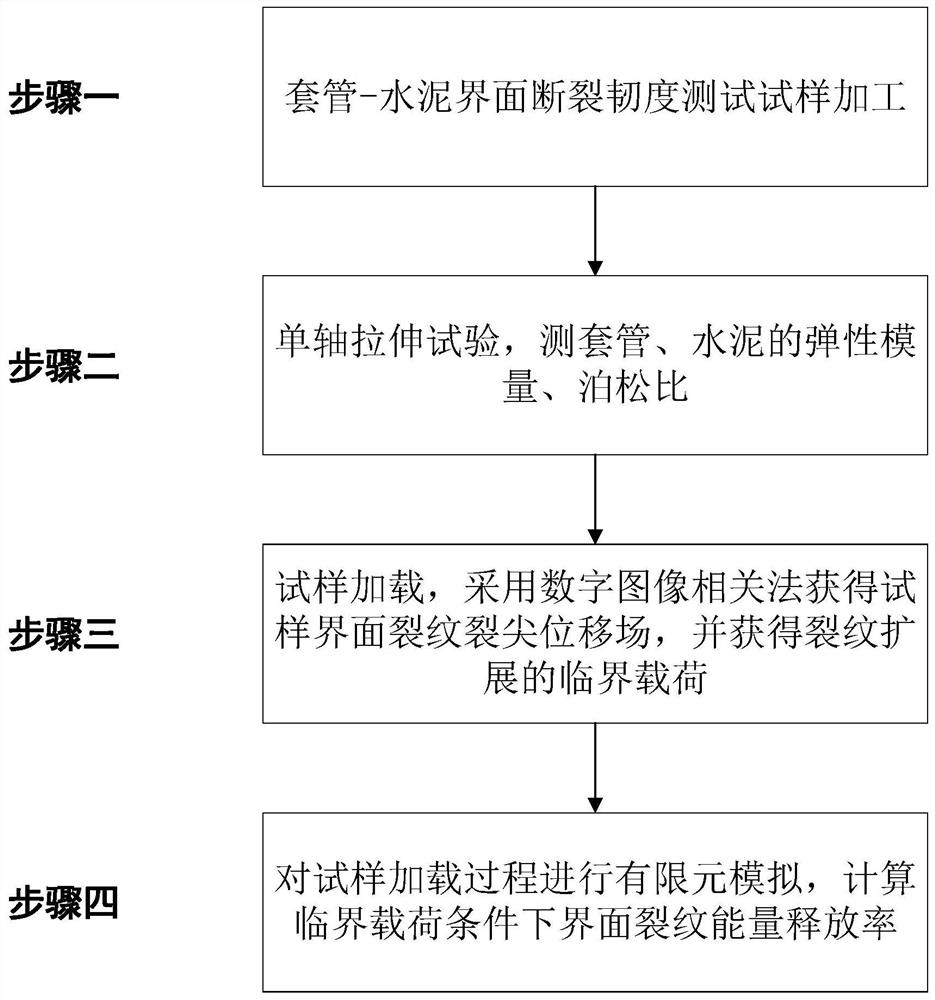

Method for testing fracture toughness of sleeve-cement interface

PendingCN113155615AEffective fracture toughnessValid testMaterial strength using tensile/compressive forcesCritical loadTest sample

The invention provides a method for testing the fracture toughness of a sleeve-cement interface. The method comprises the following steps: step 1, processing a test sample for testing the fracture toughness of the sleeve-cement interface; step 2, acquiring the elastic modulus and Poisson ratio of the casing and set cement in the casing-cement interface fracture toughness test sample; step 3, applying a symmetric compression load to the casing-cement interface fracture toughness test sample, and obtaining a critical load of interface crack propagation of the casing-cement interface fracture toughness test sample; and step 4, calculating the interface energy release rate of the casing-cement interface fracture toughness test sample under the critical load condition, and comparing the interface energy release rate with the interface fracture toughness value of the casing-cement interface fracture toughness test sample to evaluate the crack propagation trend of the casing-cement interface fracture toughness test sample. According to the invention, the fracture toughness of the casing-cement interface can be effectively tested, and whether the casing-cement sheath connection interface has the risk of interface failure and fracture can be evaluated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

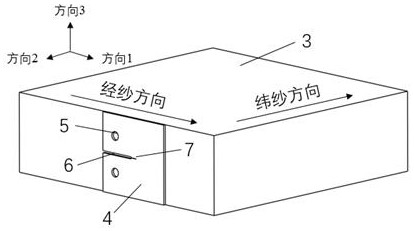

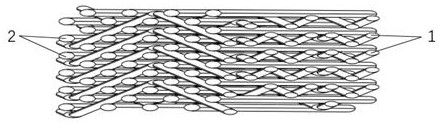

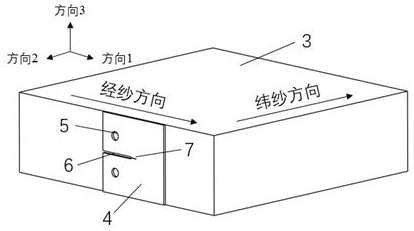

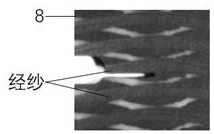

A Method for Obtaining the I-Mode Fracture Toughness of the Interface of Three-dimensional Woven Composites

ActiveCN113654894BRemove the Fracture Toughness Calculation ProcessSimple internal structurePreparing sample for investigationMaterial strength using tensile/compressive forcesType fractureFiber bundle

Owner:HARBIN INST OF TECH

Method for measuring interface fracture toughness of APS thermal barrier coating based on double-layer material model

ActiveCN113740233AMeet the requirements of precise measurementPermeability/surface area analysisInvestigating material hardnessPorosityBi layer

The invention discloses a method for measuring interface fracture toughness of an APS thermal barrier coating based on a double-layer material model. The method comprises the following steps: preparing a thermal barrier coating sample by adopting APS, and measuring the hardness and Young modulus values of different layers and different points of the sample; for the ceramic surface layer, considering the influence of porosity, and correcting the hardness and Young modulus of the ceramic surface layer by adopting a correction formula; substituting the obtained data into a double-layer model calculation formula to obtain the ratio of the overall Young modulus to the hardness; performing linear fitting on indentation data at the interface in Origin or Excel to calculate coordinates of an intersection point to obtain a critical load and a critical crack length at the interface; and substituting the data into a classical formula to obtain the interface fracture toughness. According to the method, the characteristic that the thermal barrier coating sprayed by the APS has certain porosity is considered, the hardness and the Young modulus of the ceramic surface layer are corrected, a quite accurate interface fracture toughness value is obtained, errors caused by pores are reduced, and the interface fracture toughness is closer to a true value.

Owner:CIVIL AVIATION UNIV OF CHINA

An anti-rutting agent for cold mixing and paving of asphalt roads

ActiveCN104496258BIncrease the interface fracture energyGuaranteed smoothnessFiberInterfacial binding

Owner:南通福伦利新材料有限公司

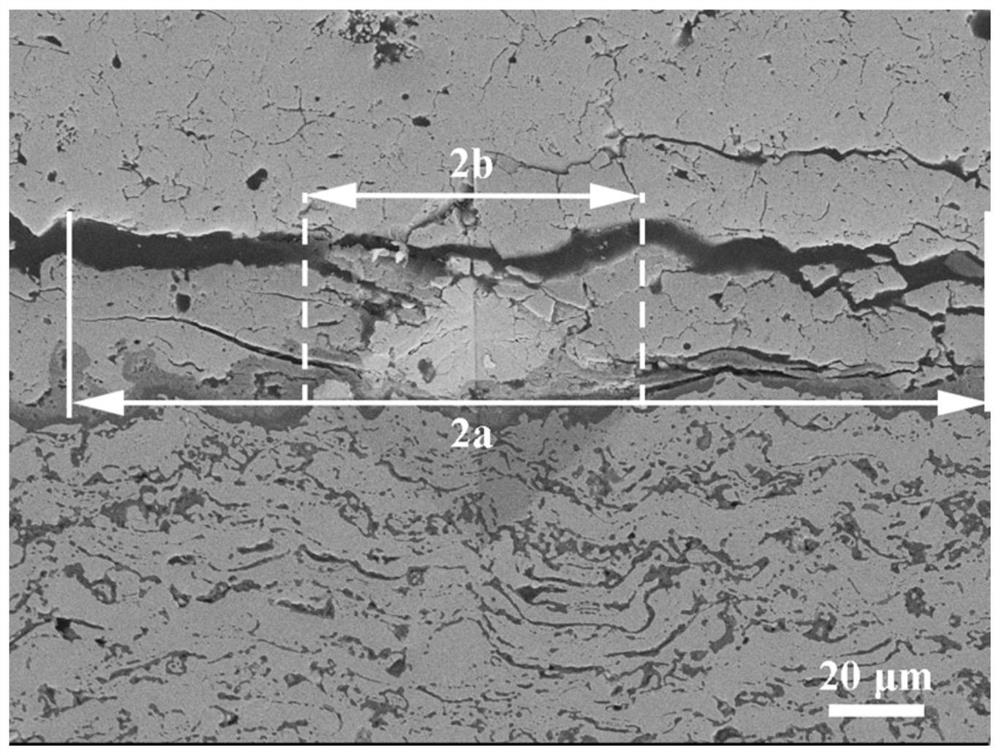

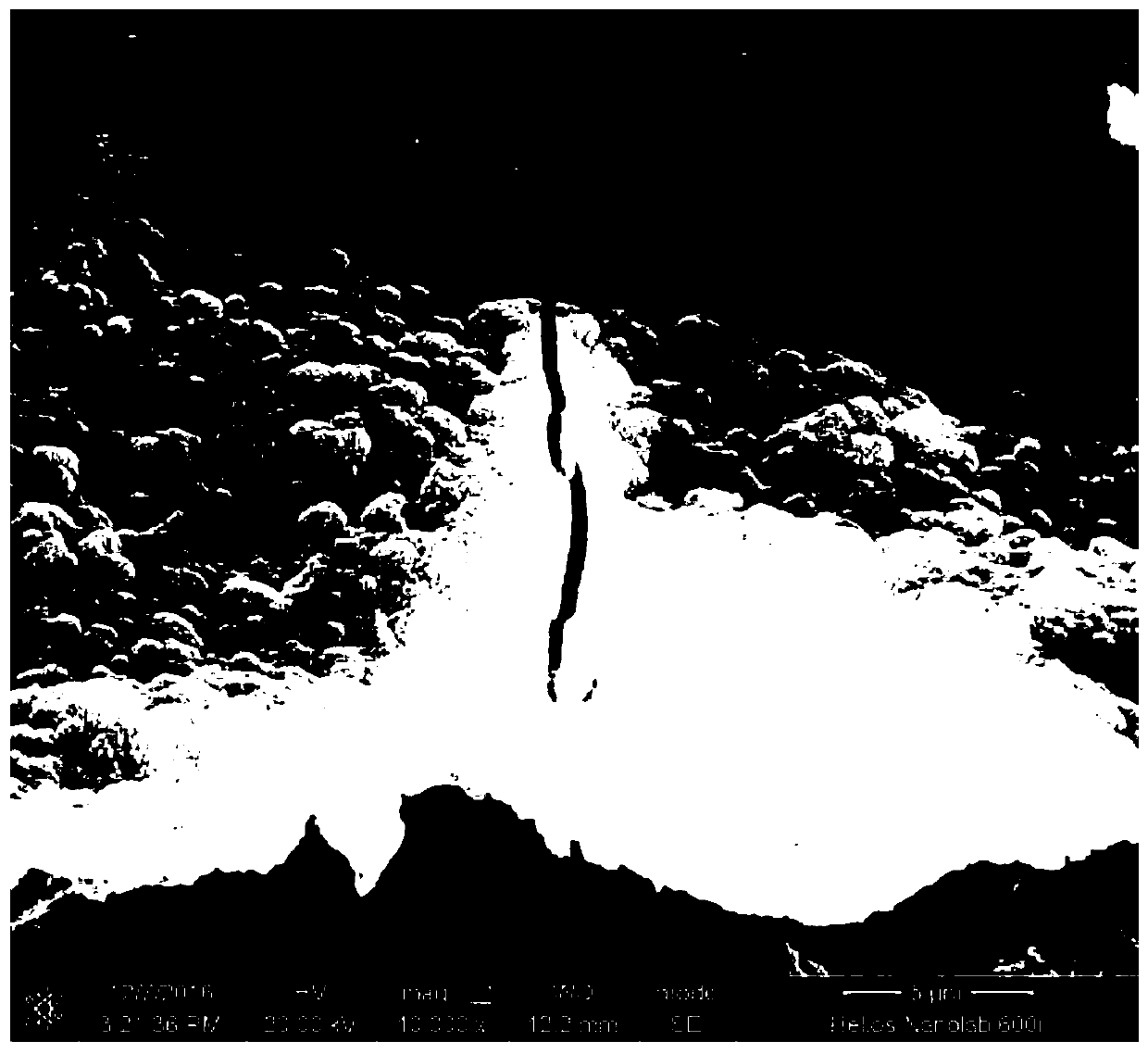

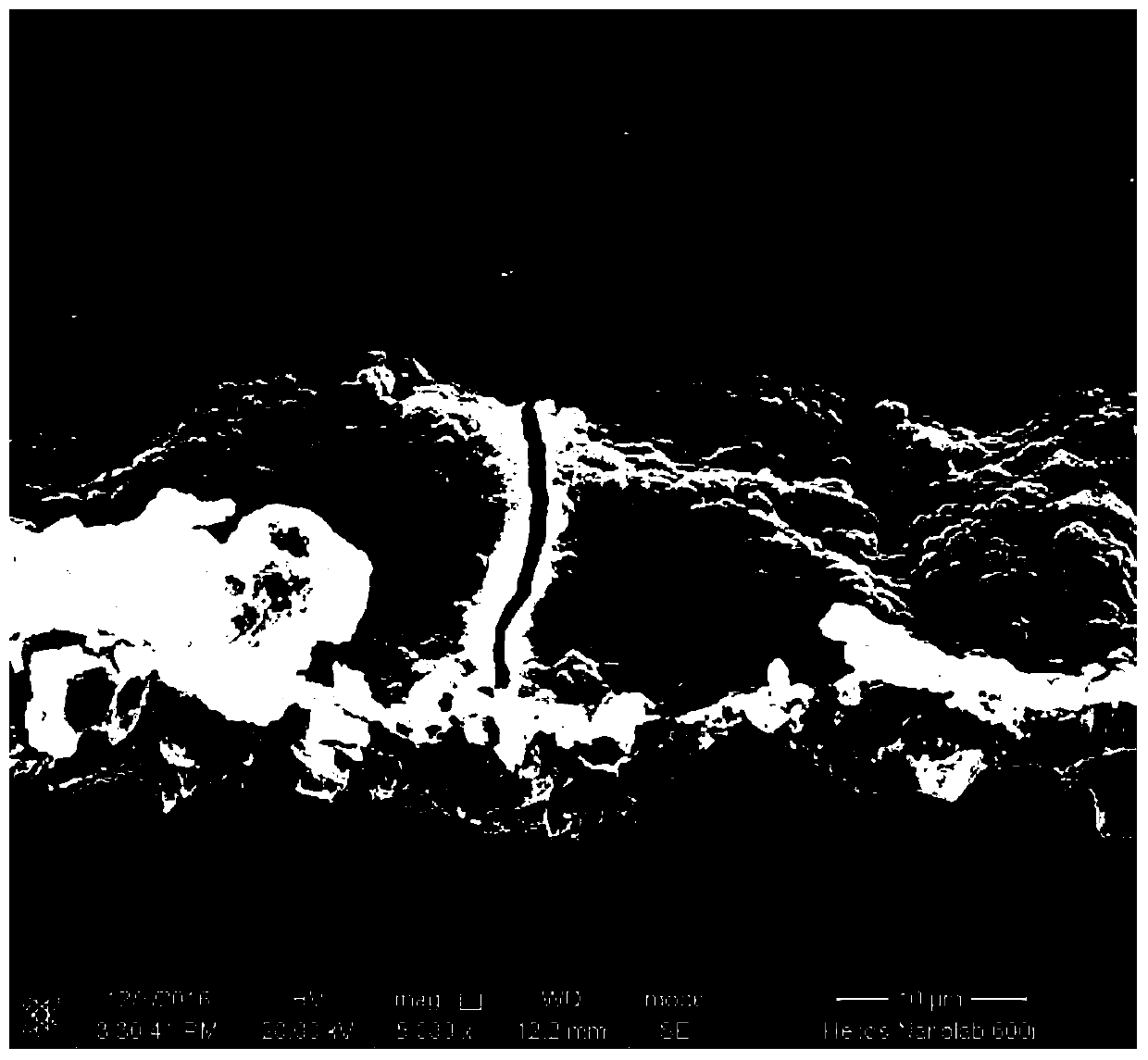

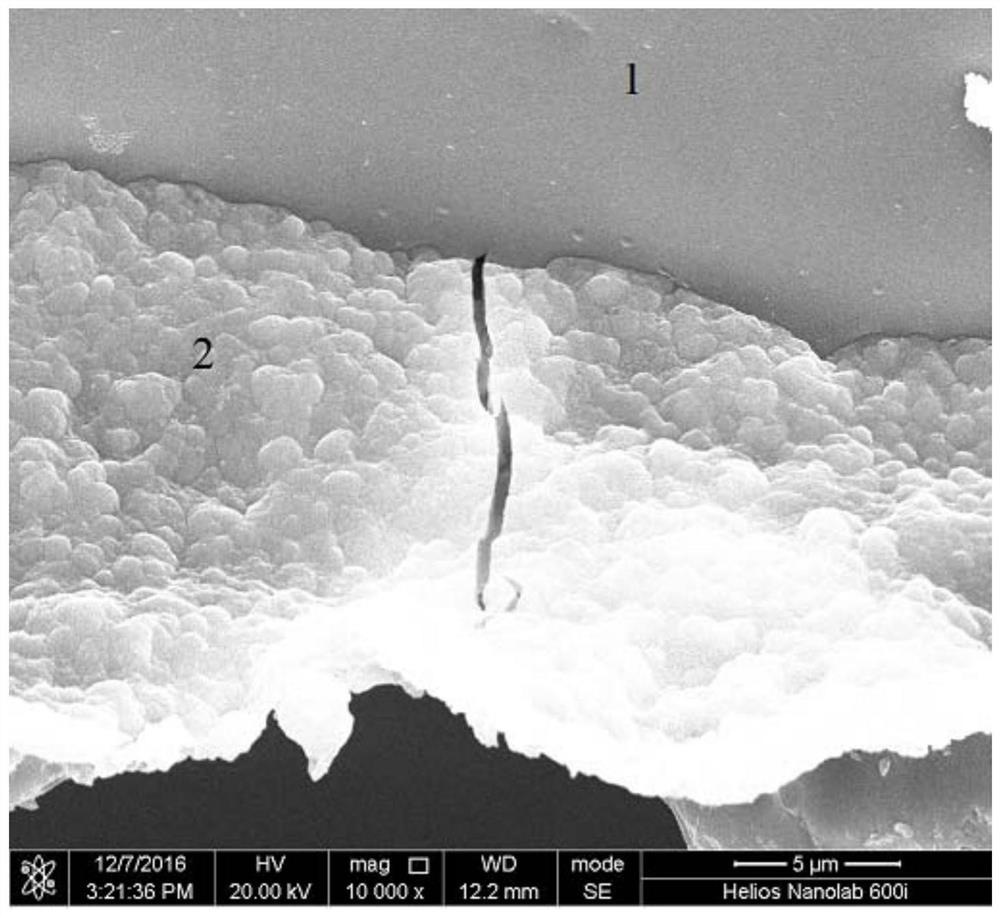

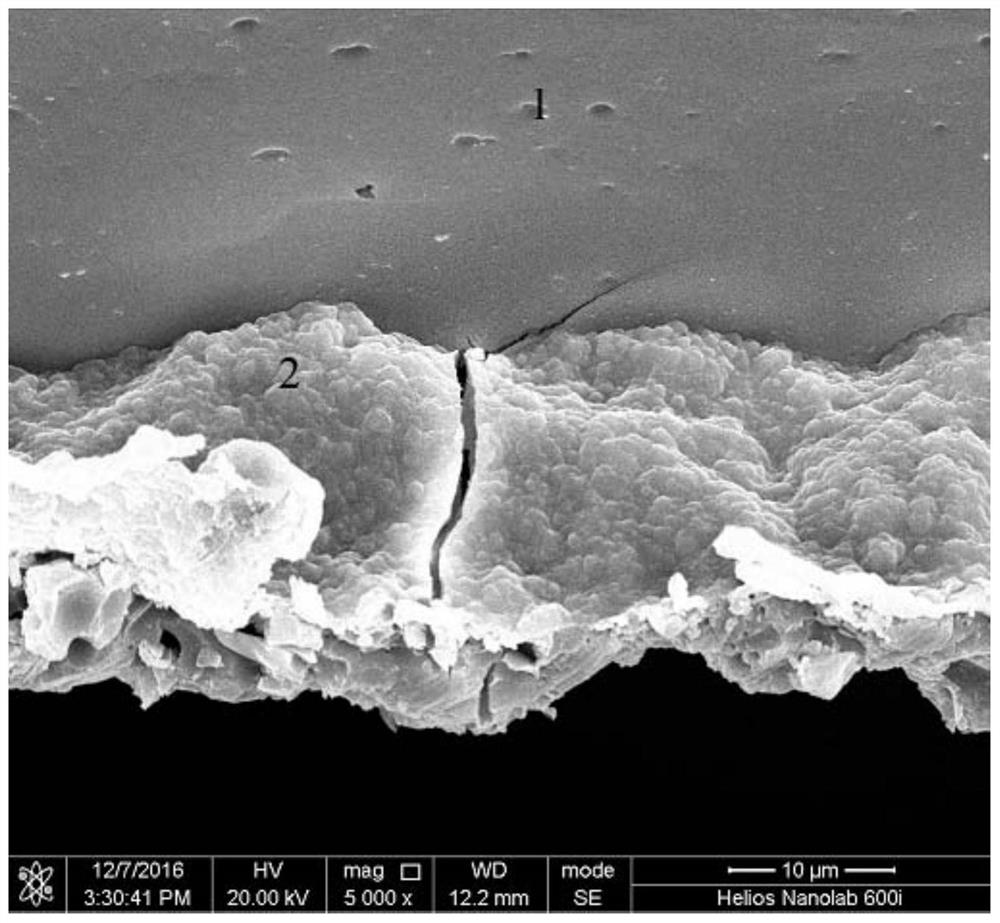

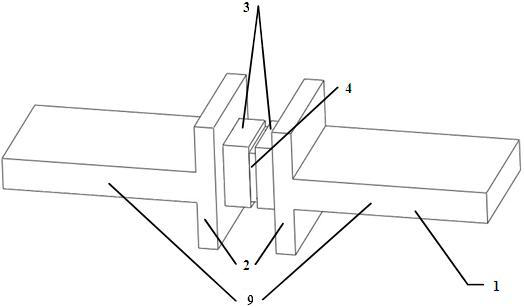

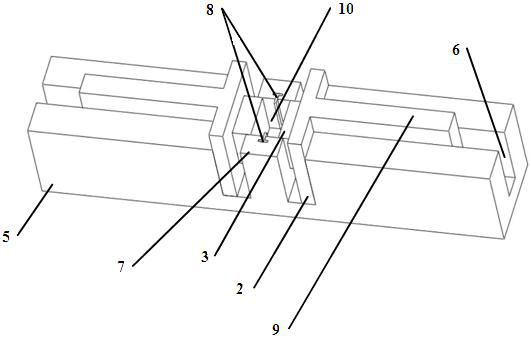

SEM in-situ tensile test method for researching interface fracture behavior of metal matrix and ceramic film layer

ActiveCN110967254AUnraveling the Mechanism of Fracture BehaviorWide applicabilityMaterial analysis using wave/particle radiationPreparing sample for investigationTensile testingCeramic membrane

The invention discloses an SEM in-situ tensile test method for researching an interface fracture behavior of a metal matrix and a ceramic film layer, and relates to an SEM in-situ tensile test method.The invention aims to solve the problem that an SEM in-situ tensile sample and a tensile test mode of an existing homogeneous material are not suitable for revealing the fracture process and mechanism analysis of a brittle film layer and a plastic matrix system. The method comprises the following steps: 1, preparation of an in-situ tensile sample; 2, sample treatment; and 3, recording of mechanical property parameters and microtopography in real time in the in-situ tensile process, so as to finish the SEM in-situ tensile test method for researching the interface fracture behavior of the metalmatrix and the ceramic film layer.

Owner:HARBIN INST OF TECH

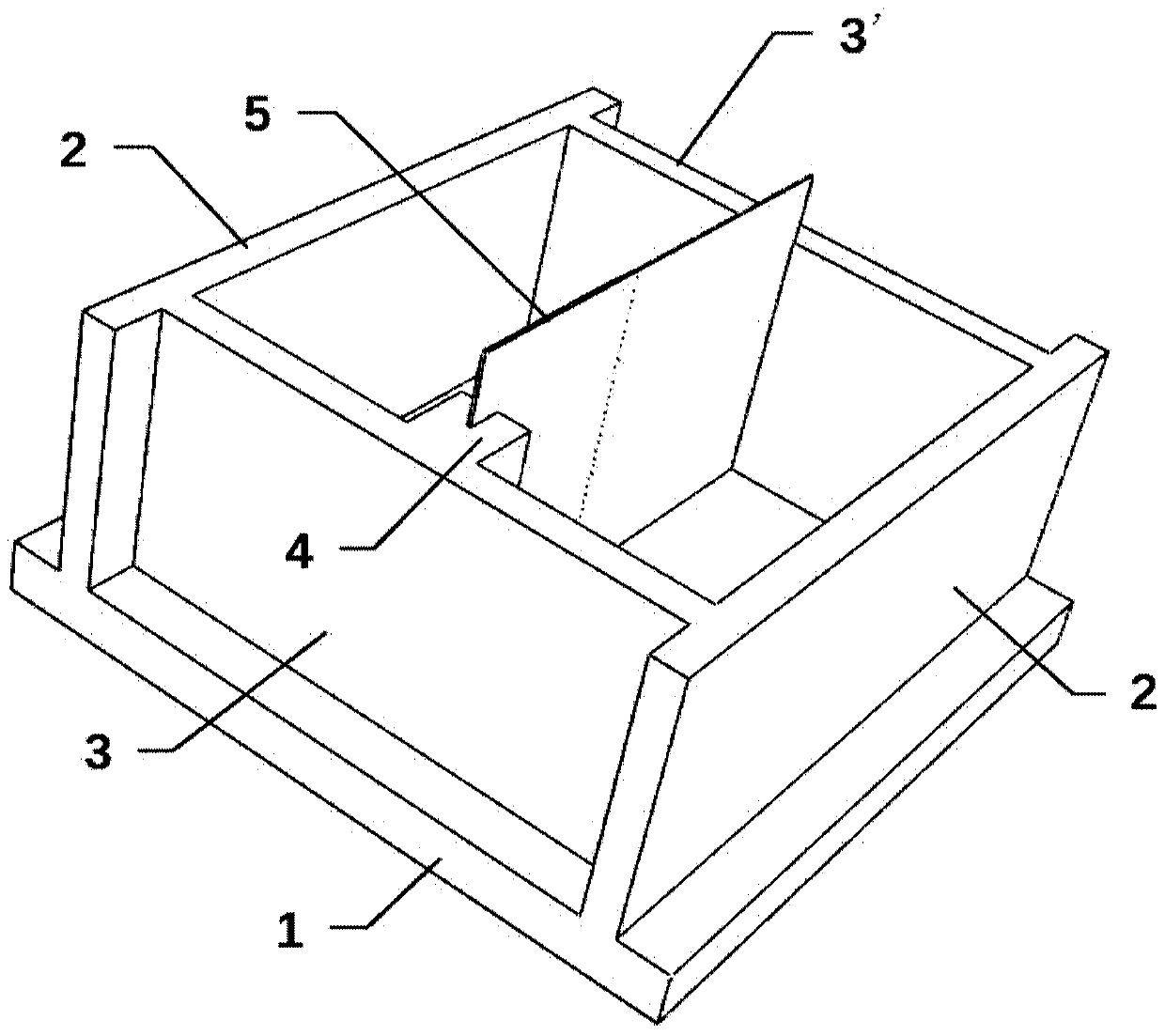

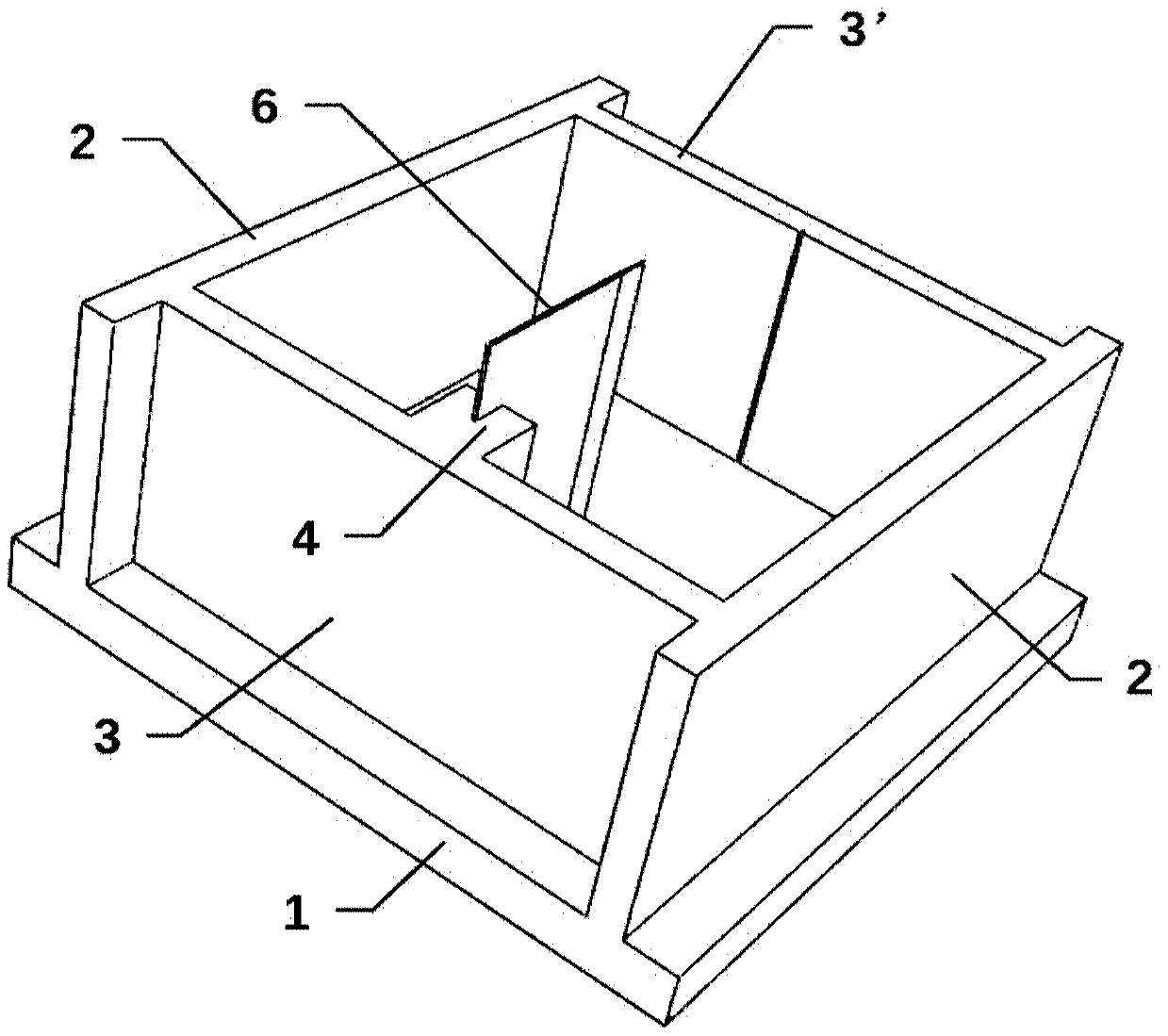

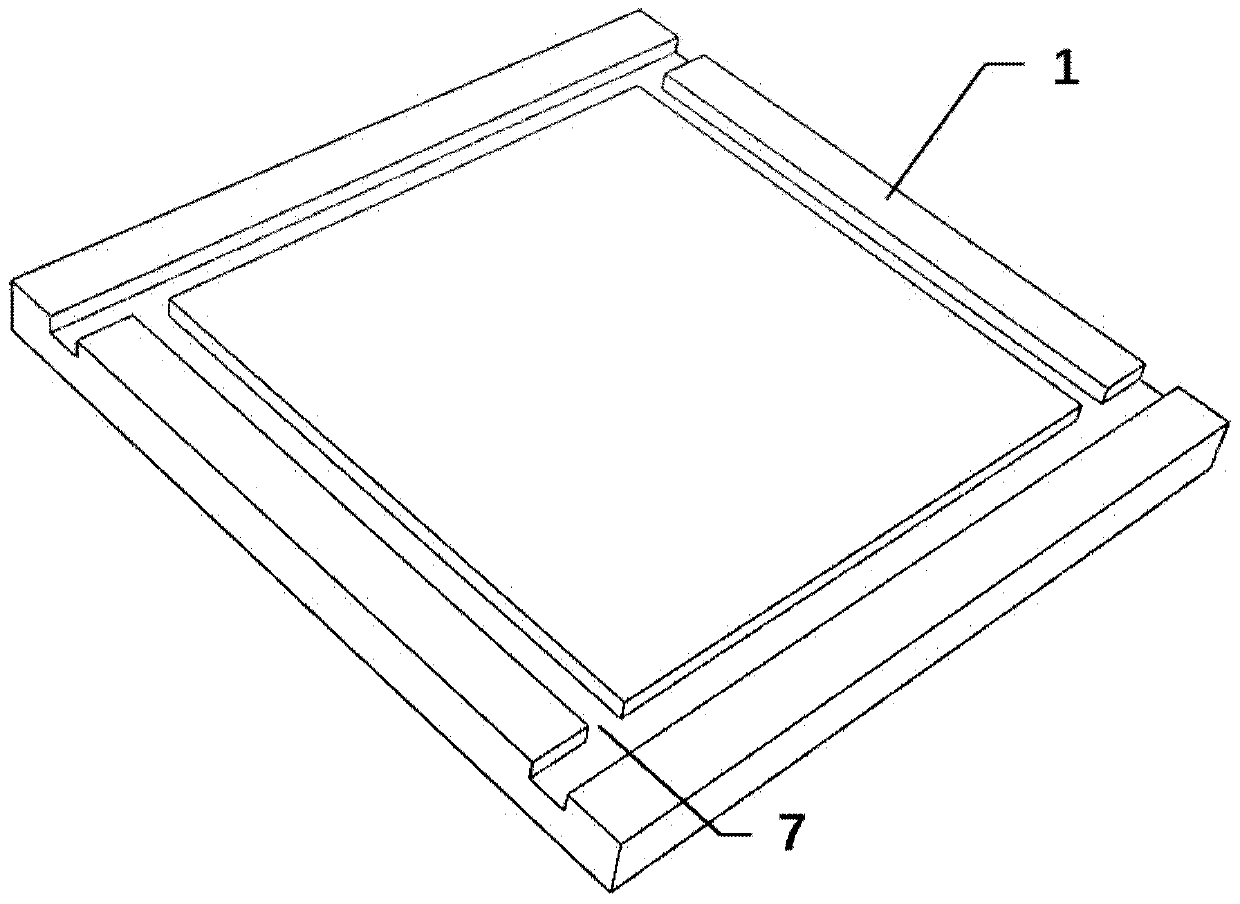

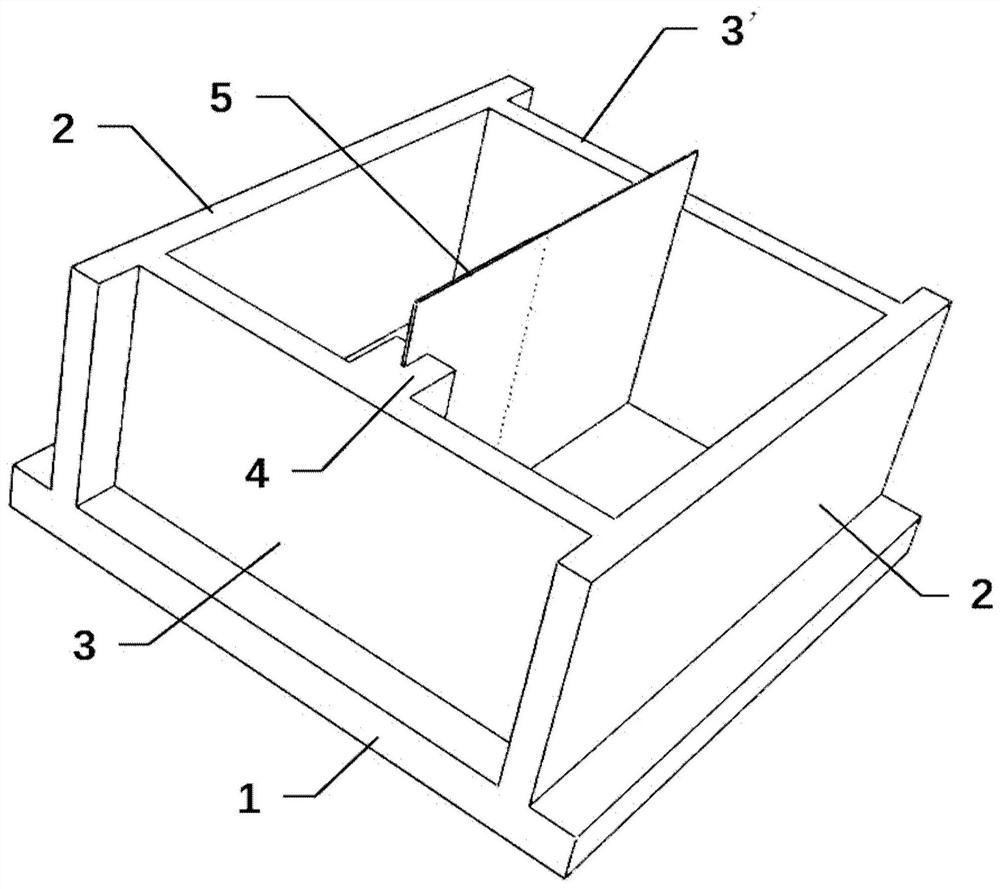

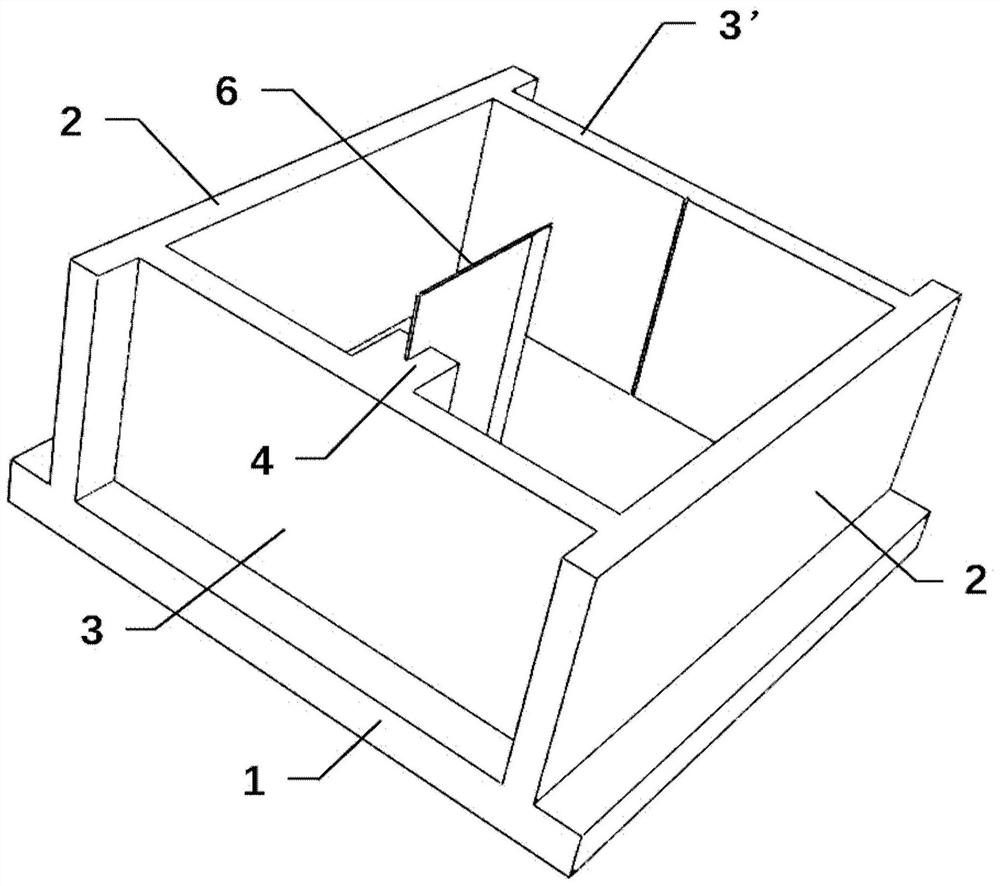

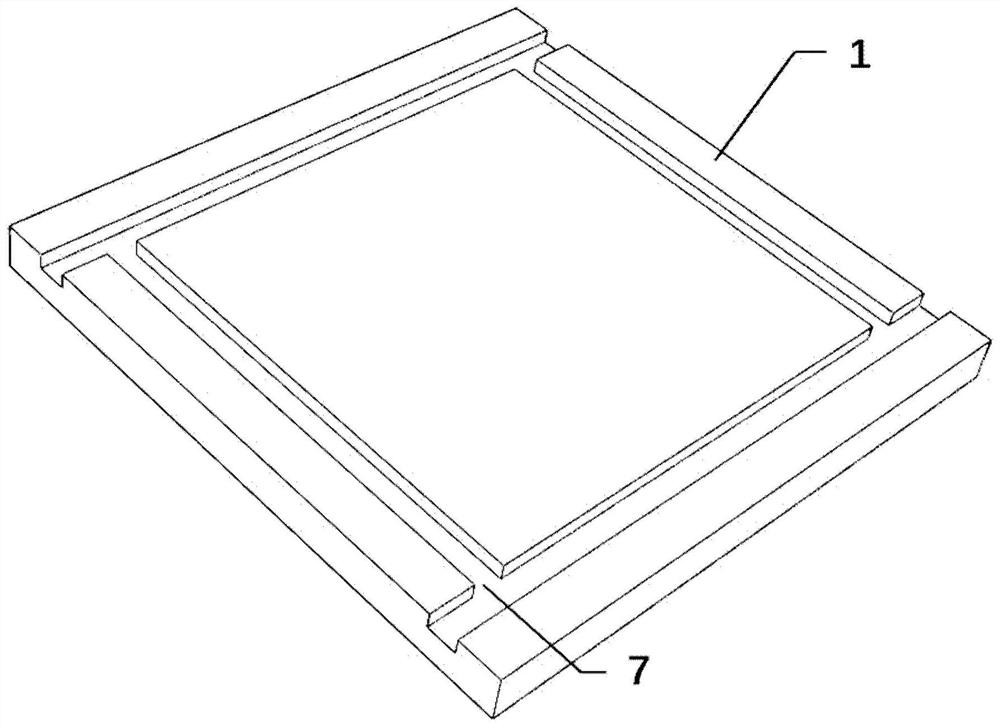

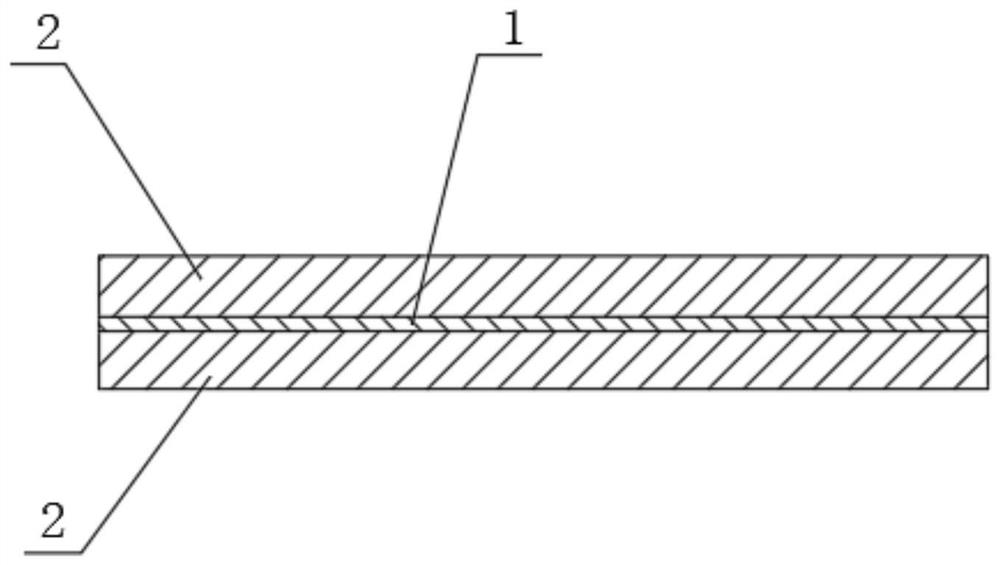

Forming die for testing interface fracture performance of heterogeneous concrete and preparation method

ActiveCN111595656AIntermixing phenomenon does not occurEasy to operateMouldsPreparing sample for investigationStructural engineeringMechanical engineering

The invention discloses a forming die for testing interface fracture performance of heterogeneous concrete and a preparation method. The forming die comprises a bottom plate, two front and rear baffles, two left and right baffles, an isolation baffle and an embedded plate, wherein the bottom plate, the front and rear baffles and the left and right baffles are perpendicularly fixed to one another to form a forming die cavity of a heterogeneous concrete composite test piece, and a cubic protrusion extending downwards from the top end to the bottom plate is arranged in the middle of one of the left and right baffles; the two side ends of the isolation baffle are fixed to the cubic protrusion and the opposite sides of the other of the left and right baffles respectively; and one side end of the embedded plate is fixed to the cubic protrusion, and the other opposite side end of the embedded plate is suspended. The invention further provides a method for preparing the heterogeneous concretecomposite test piece by using the forming die. The forming die has the advantages of being easy to operate, low in cost and reusable, and the interface position of the heterogeneous concrete is accurately controlled, thereby guaranteeing that material mutual doping does not occur at the interface position, revealing the rule of the interface fracture performance of the heterogeneous concrete, andproviding technical support for structural design of the heterogeneous concrete.

Owner:TIANJIN UNIV

Forming mold and preparation method for testing the interface fracture performance of heterogeneous concrete

ActiveCN111595656BIntermixing phenomenon does not occurEasy to operateMouldsPreparing sample for investigationStructural engineeringMechanical engineering

Owner:TIANJIN UNIV

A test method for interface fracture toughness of second-generation high-temperature superconducting strips

ActiveCN109738289BReduce measurement impactGuarantee the accuracy of the experimentPreparing sample for investigationMaterial strength using tensile/compressive forcesCrazingHigh temperature superconducting

The invention provides a second-generation high-temperature superconducting strip interface fracture toughness test method, which includes the following steps: (1) solidifying a reinforcing layer with a thickness much larger than that on both sides of the superconducting strip to form a composite beam structure and serve as a Test sample; (2) Coat the speckle on the narrow side of the sample length direction; (3) Cut the initial crack at one end of the sample superconducting strip, then load the sample on the tensile machine, and the CCD Aim the camera at the speckle-coated side of the sample; (4) Carry out Type I and Type II interlaminar fracture experiments respectively; (5) Use the digital image correlation method to calculate the Type I and Type II interlaminar fractures of the sample Toughness, the result is the type I and type II interlaminar fracture toughness of the superconducting tape. In the present invention, by adding a reinforcing layer with a thickness much larger than the superconducting strip on both sides of the superconducting strip, the fracture toughness of the superconducting strip can be measured by a conventional experimental method, and the experimental method is simple and has high accuracy.

Owner:LANZHOU UNIVERSITY

Corrugated interfaces for multilayered interconnects

ActiveUS20130273325A1Layered productsSemiconductor/solid-state device detailsInterfacial adhesionAdhesion strength

Dielectric composite structures comprising interfaces possessing nanometer scale corrugated interfaces in interconnect stack provide enhances adhesion strength and interfacial fracture toughness. Composite structures further comprising corrugated adhesion promoter layers to further increase intrinsic interfacial adhesion are also described. Methods to form the nanometer scale corrugated interfaces for enabling these structures using self assembling polymer systems and pattern transfer process are also described.

Owner:TAIWAN SEMICON MFG CO LTD

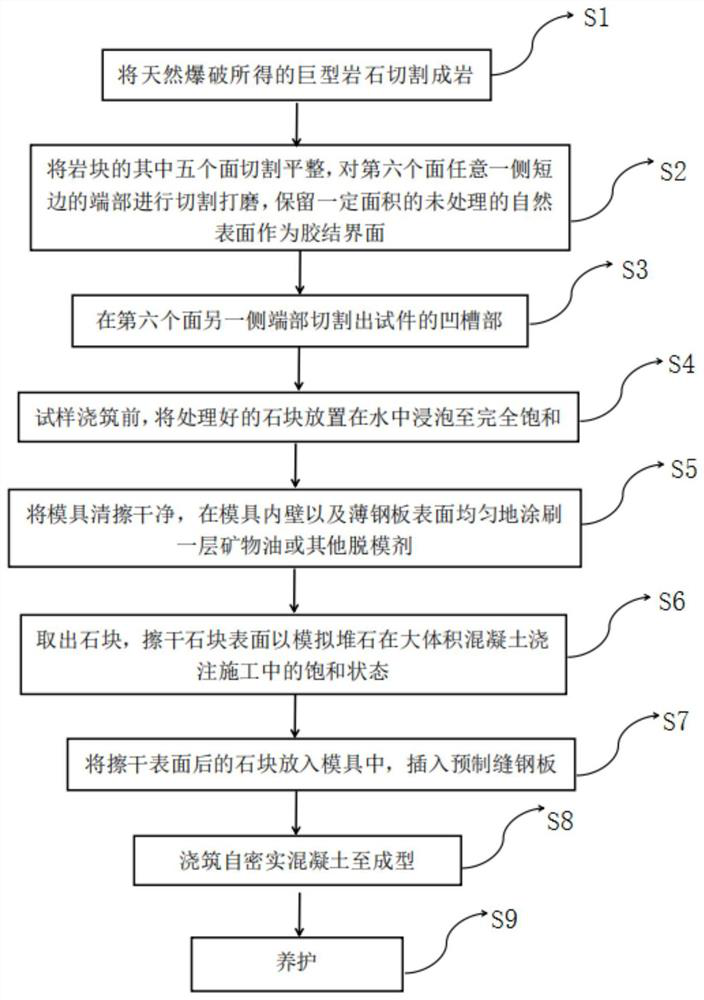

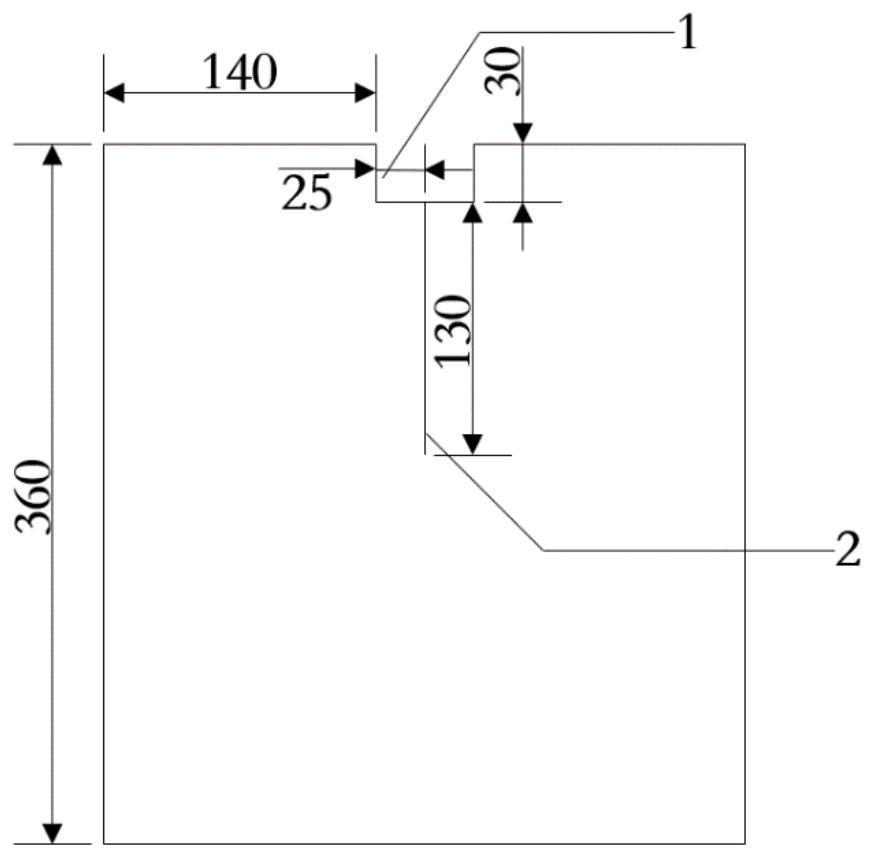

Method for measuring fracture mechanical properties of rock-SCC interface and composite test piece

InactiveCN111624102AIncrease awarenessGuaranteed areaPreparing sample for investigationMaterial strength using tensile/compressive forcesType fractureClassical mechanics

The invention discloses a method for measuring I-type fracture mechanical properties of a rock-self-compacting concrete interface and a rock-interface-SCC three-phase composite test piece. The methodcomprises the steps that a rock mass-interface-SCC three-phase composite test piece with a certain area of an I-type fracture ligament area is prepared, and the I-type fracture ligament area is distributed along the interface of a rock mass and SCC; and a macroscopic fracture test is performed on the rock mass-interface-SCC three-phase composite test piece to obtain I-type fracture mechanical parameters of the interface phase. According to the method, the area of the fractured ligament area with a certain area size can be guaranteed to represent the mechanical behavior of the engineering-scalerock-fill concrete, the fractured ligament area is distributed along the interface of the rock mass and the SCC, a subsequent macroscopic fracture experiment is carried out on the test piece, and related mechanical parameters of the interface phase are obtained.

Owner:TSINGHUA UNIV

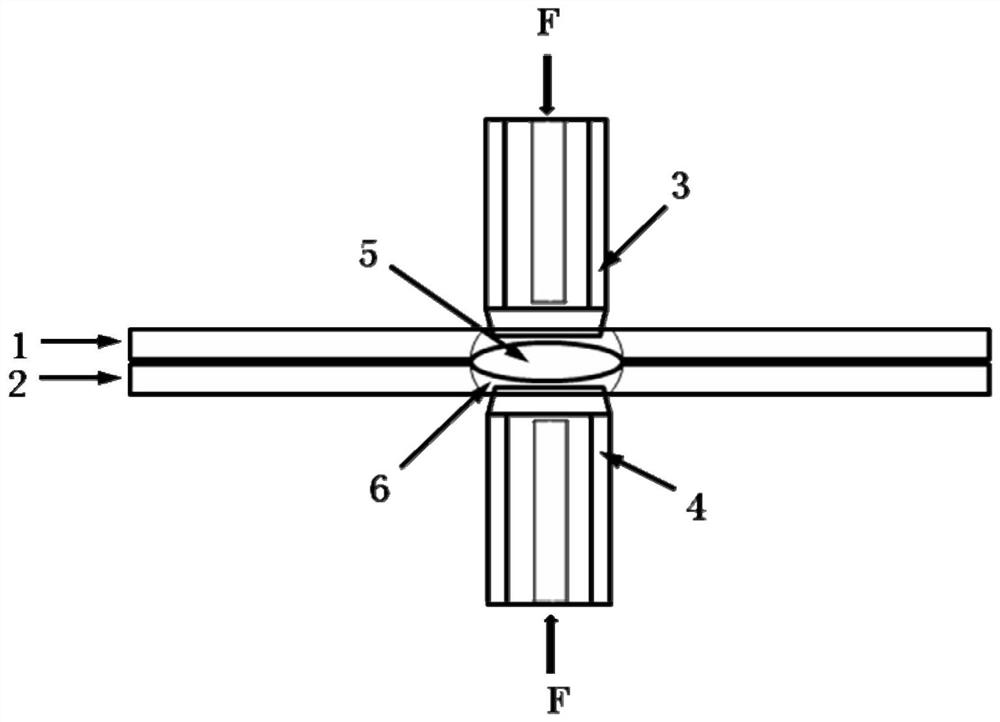

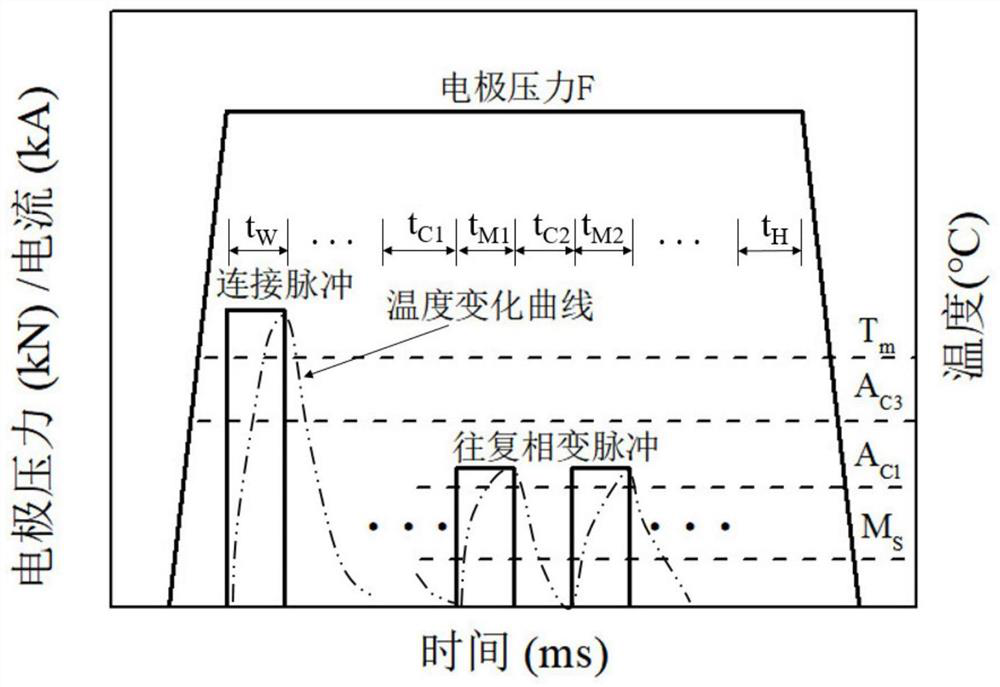

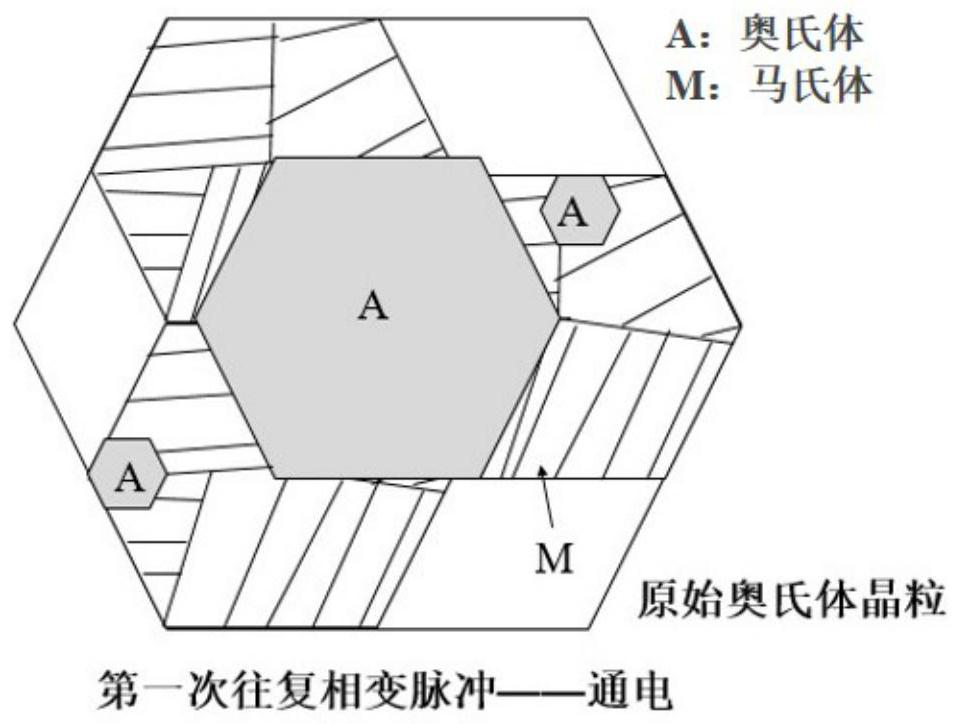

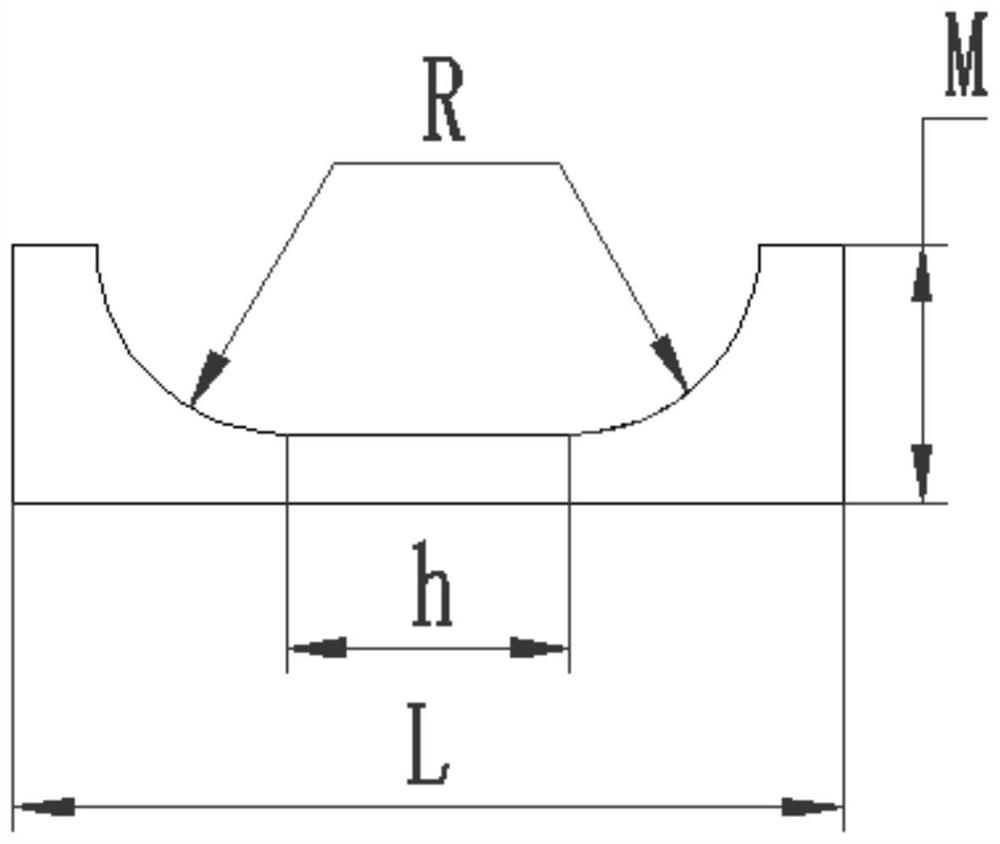

Method for improving performance of medium manganese steel resistance spot welding joint

ActiveCN111843151AHigh strengthImprove plasticityWelding electric supplyWelding/cutting media/materialsElectrical resistance and conductanceMartensite transformation

The invention relates to a method for improving the performance of a medium manganese steel resistance spot welding joint. The method comprises the following steps that 1) the austenitizing end temperature AC3, the austenitizing initial temperature AC1 and the martensite transformation starting temperature MS of a medium manganese steel plate to be welded are tested; 2) the medium manganese steelplate is placed between two electrodes of a resistance spot welding machine, and a constant electrode pressure of 2.0-8.0 kN is applied to clamp the medium manganese steel plate; 3) a connection pulseis applied for melting the medium manganese steel in the welding area to form a required nugget size; (4) reciprocating phase change pulses are applied, the reciprocating phase change pulses are twoor more pulses, the current value and the action time of each pulse are equal or unequal, each pulse current is 3-10 kA, the action time is 3-30 cyc, and the time interval between the pulses is 5-30 cyc; and after the reciprocating phase change pulse is finished, the nugget is cooled by 5-25 cyc under the action of electrode pressure. According to the method, the bearing capacity of the medium manganese steel spot welding joint can be improved by 3 times, and the joint fracture mode is changed from complete interface fracture to button fracture.

Owner:BAOSHAN IRON & STEEL CO LTD

A SEM in-situ tensile test method for studying the interface fracture behavior of metal substrate and ceramic film layer

ActiveCN110967254BUnraveling the Mechanism of Fracture BehaviorWide applicabilityMaterial analysis using wave/particle radiationPreparing sample for investigationTensile testingCeramic membrane

The invention discloses an SEM in-situ tensile test method for researching an interface fracture behavior of a metal matrix and a ceramic film layer, and relates to an SEM in-situ tensile test method.The invention aims to solve the problem that an SEM in-situ tensile sample and a tensile test mode of an existing homogeneous material are not suitable for revealing the fracture process and mechanism analysis of a brittle film layer and a plastic matrix system. The method comprises the following steps: 1, preparation of an in-situ tensile sample; 2, sample treatment; and 3, recording of mechanical property parameters and microtopography in real time in the in-situ tensile process, so as to finish the SEM in-situ tensile test method for researching the interface fracture behavior of the metalmatrix and the ceramic film layer.

Owner:HARBIN INST OF TECH

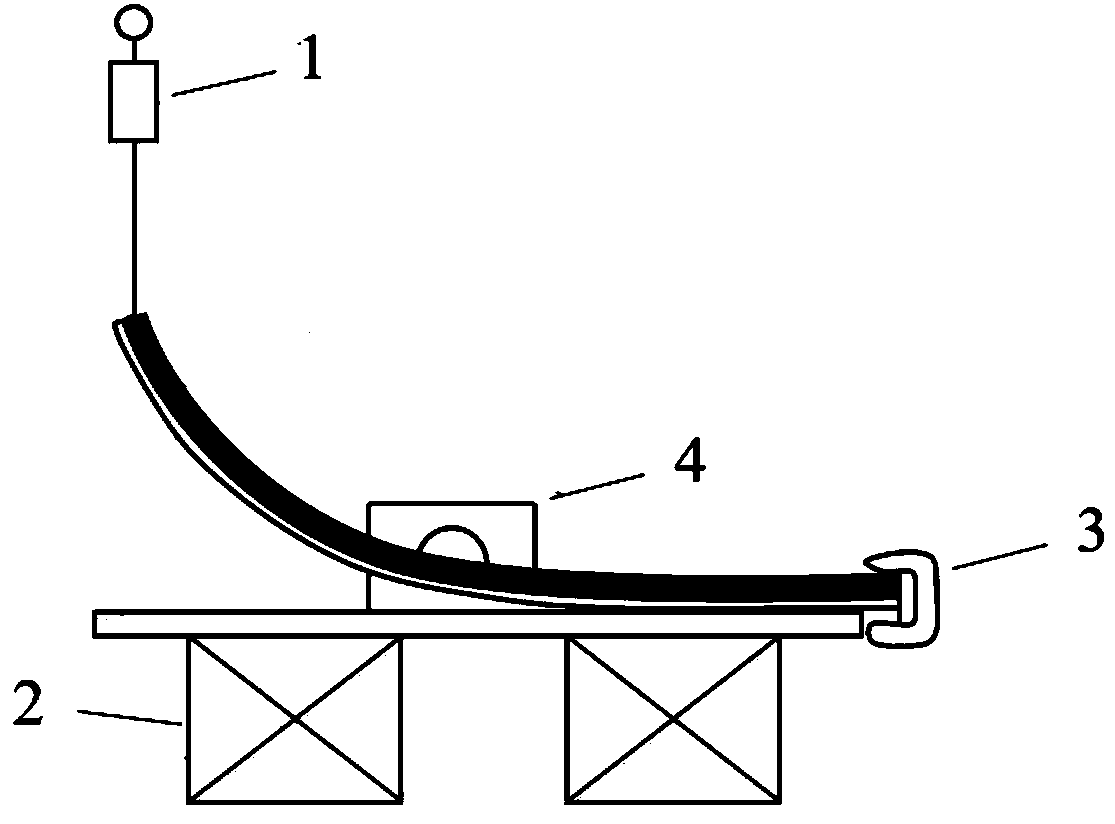

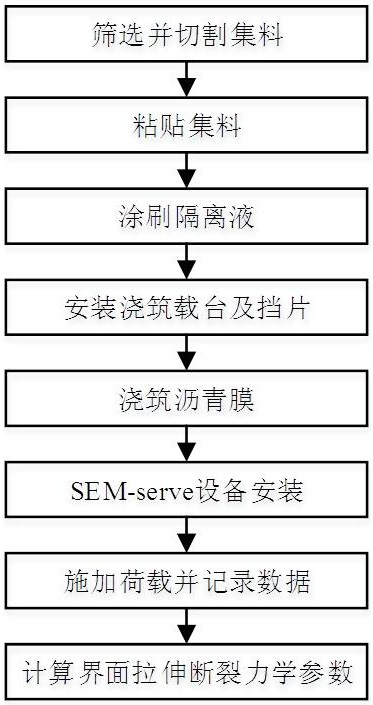

A test fixture and test method for obtaining fracture mechanics parameters of asphalt mortar and aggregate interface at the mesoscopic scale

ActiveCN109781517BQuantitative thickness controlMaterial strength using tensile/compressive forcesEpoxyInterfacial fracture

This application discloses a test fixture and its test method for obtaining fracture mechanics parameters of asphalt mortar and aggregate interface at the mesoscopic scale. The test fixture includes the following components: test fixture main body, specimen pouring platform and asphalt mortar film thickness Control flap; test method includes the following steps: screening aggregates, pouring epoxy hard glue, cutting aggregates, pouring asphalt membrane, pasting fixtures, installing end wedge fixtures, applying loads and recording data, and calculating interfacial tensile fracture mechanics parameters; this test method can realize the determination of the tensile fracture mechanics parameters of the asphalt mortar and aggregate interface at the mesoscale, and can eliminate the influence of factors such as size effects and boundary conditions in the macroscale test; this method can quantitatively control the asphalt mortar It is suitable for measuring the interface between different types of asphalt mortar and aggregates.

Owner:SOUTHEAST UNIV

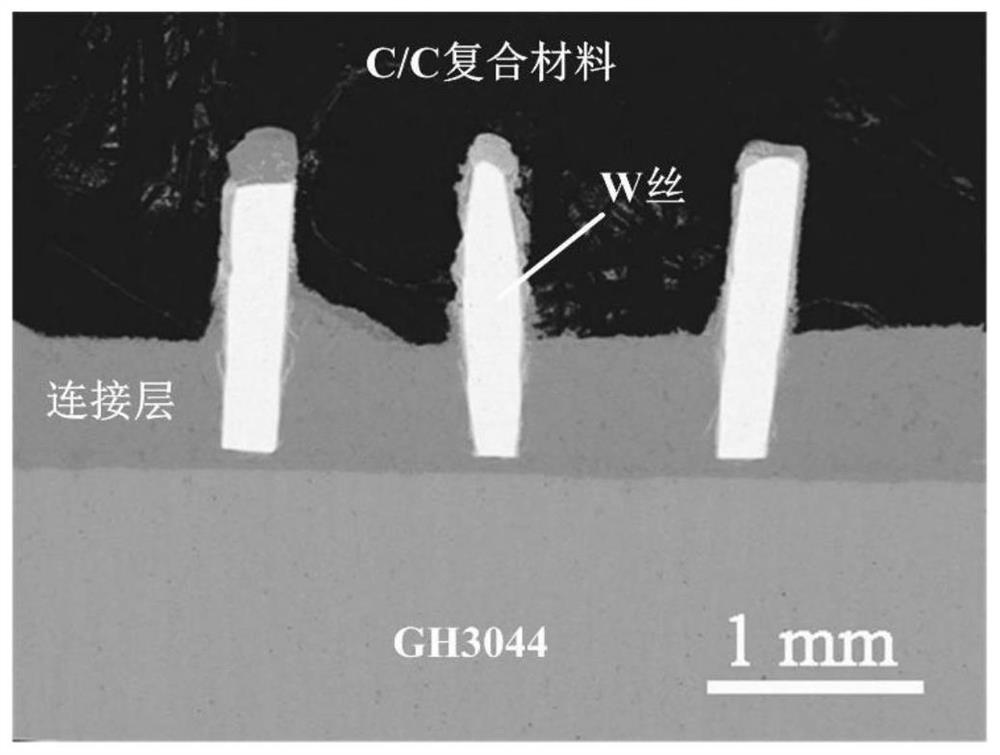

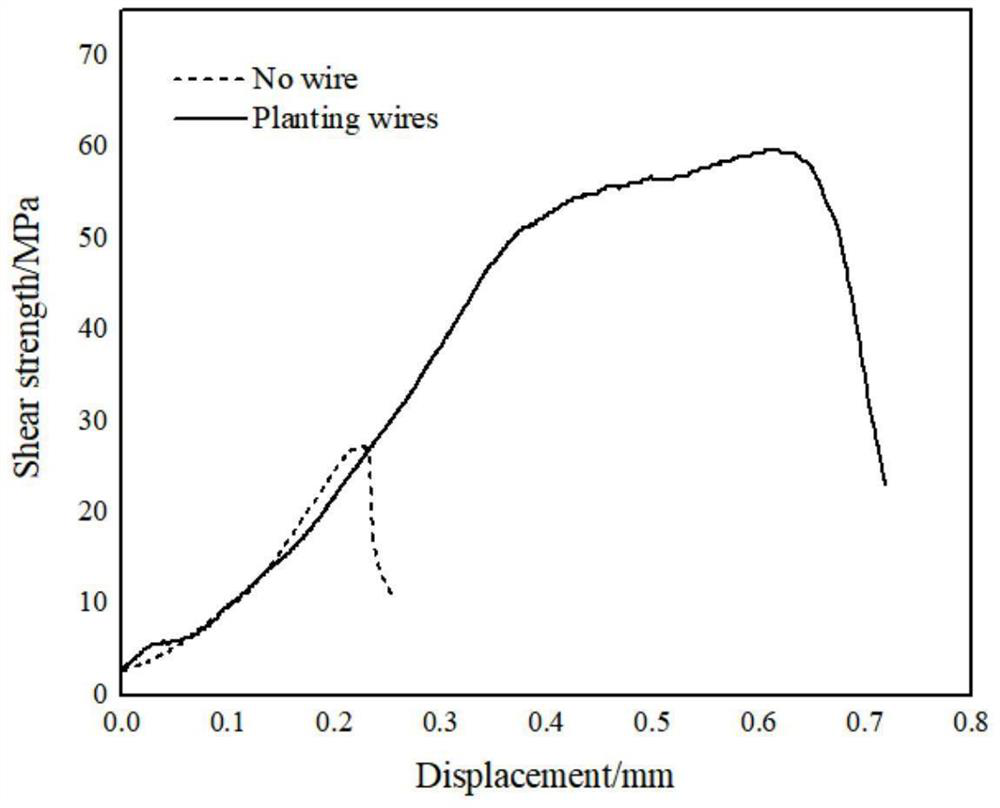

Wire planting reinforced brazing connection method for C/C and C/SiC composite materials and metal

Owner:UNIV OF SCI & TECH BEIJING

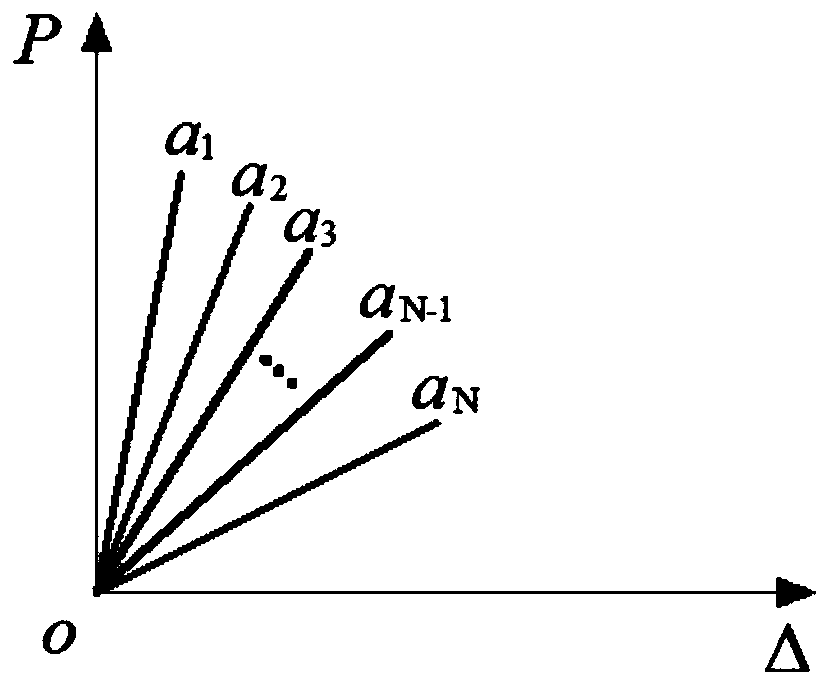

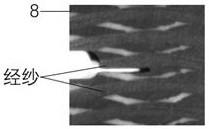

Method for obtaining I-type fracture toughness of three-dimensional woven composite material interface

ActiveCN113654894ARemove the Fracture Toughness Calculation ProcessSimple internal structurePreparing sample for investigationMaterial strength using tensile/compressive forcesType fractureFiber bundle

The invention discloses a method for obtaining the I-type fracture toughness of a three-dimensional woven composite material interface, which comprises the following steps: 1, observing the arrangement structure of three-dimensional woven composite material yarns, selecting a test piece processing surface, and aiming at the requirement of an interface fracture toughness test piece, selecting a compact stretching form, the device comprises two loading holes, a notch and a crack tip notch, the crack tip notch is machined between two parallel warp yarns or weft yarns, the cutting position is selected in the middle of a single row of fiber bundles, and it is guaranteed that only one row of warp yarns or only one row of weft yarns exist in a cut test piece; A pin or other forms are inserted into the loading hole, the interface fracture toughness test piece is connected with a mechanical testing machine, and the fracture toughness of the interface fracture toughness test piece is calculated by using the mechanical testing machine according to a load displacement curve output by the testing machine. The method for testing and obtaining the I-type fracture toughness of the three-dimensional woven composite material interface is provided for the first time, and the blank in the field is filled up.

Owner:HARBIN INST OF TECH

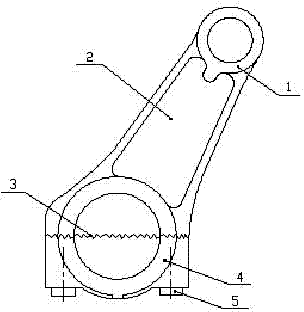

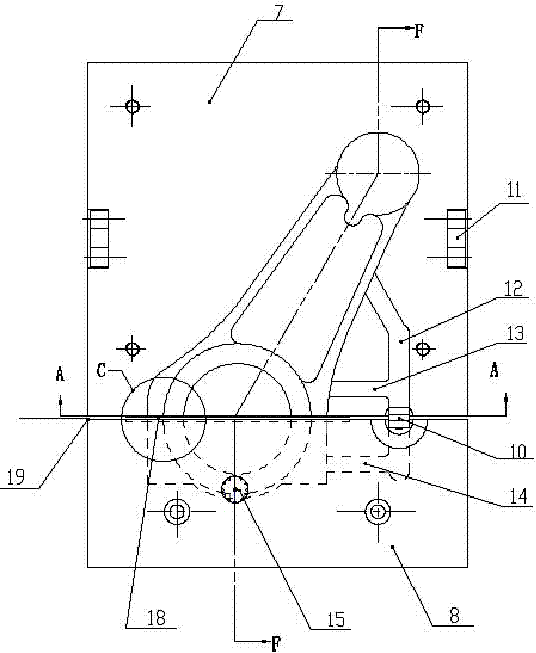

Manufacturing method of splitting-type connecting rod

ActiveCN102626770BBreak through the limitationsEasy to processFoundry mouldsFoundry coresSlagEngineering

The invention relates to the field of connecting rod manufacturing, in particular to a method for manufacturing a cracked connecting rod. The connecting rod is produced by casting or combined casting and forging process. During casting, a suitable material is placed at the interface (3) of the large head of the connecting rod cavity to interact with the molten metal and form a cracking interface after cooling. By applying a bursting load in the big hole of the connecting rod, the connecting rod body (2) and the connecting rod cover (4) are broken and split along the prefabricated cracking interface, and the intermeshed dog-tooth structure formed on the fracture surface makes the connecting rod body It has good meshing and repeat positioning characteristics with the connecting rod cover, and realizes the precise assembly of the two. This connecting rod manufacturing method can break through the limitations of cracking technology on connecting rod materials, and apply cracking technology to the manufacturing of connecting rods made of materials such as aluminum alloy, titanium alloy, and 40Cr steel; it can effectively improve the connecting rod existing in the actual cracking process Bulk tearing, cracking, slag falling, fracture surface deformation and other problems.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com