Device and method for testing mechanical parameters of bumping diffusion process of bridge asphalt pavement

A technology of diffusion process and mechanical parameters, which is applied in the direction of measuring device, using repeated force/pulsation force to test material strength, preparation of test samples, etc., can solve the problem of affecting the service life of bridge deck pavement structure and the integrity of bridge deck pavement and flatness, accelerated bridge corrosion or corrosion, loss of bridge deck adhesion, etc., to overcome single-point deformation measurement, large loading range, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

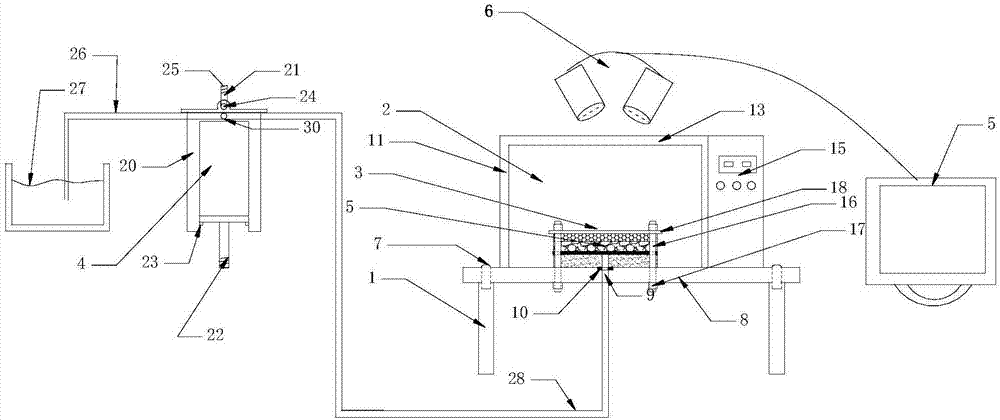

[0049] see figure 1 , The device of the present invention mainly includes: a support frame 1, an environmental chamber 2, a specimen fixing frame 3, a pressurized oil cylinder 4, an MTI-3D structural deformation measurement system 5 and other components.

[0050] The supporting frame 1 is placed on a flat ground, and its function is to support the upper assembly of the whole device. The upper assembly includes the environmental chamber 2 and the specimen fixing frame 3 . The support frame 1 is composed of four rigid cylinders, and the top of the cylinder is provided with a thread groove. The support frame 1 is fixed to the bottom plate 8 of the environmental chamber 2 through the connection between the support frame bolt 7 and the thread groove, and then the support frame is connected to the upper assembly. supporting role.

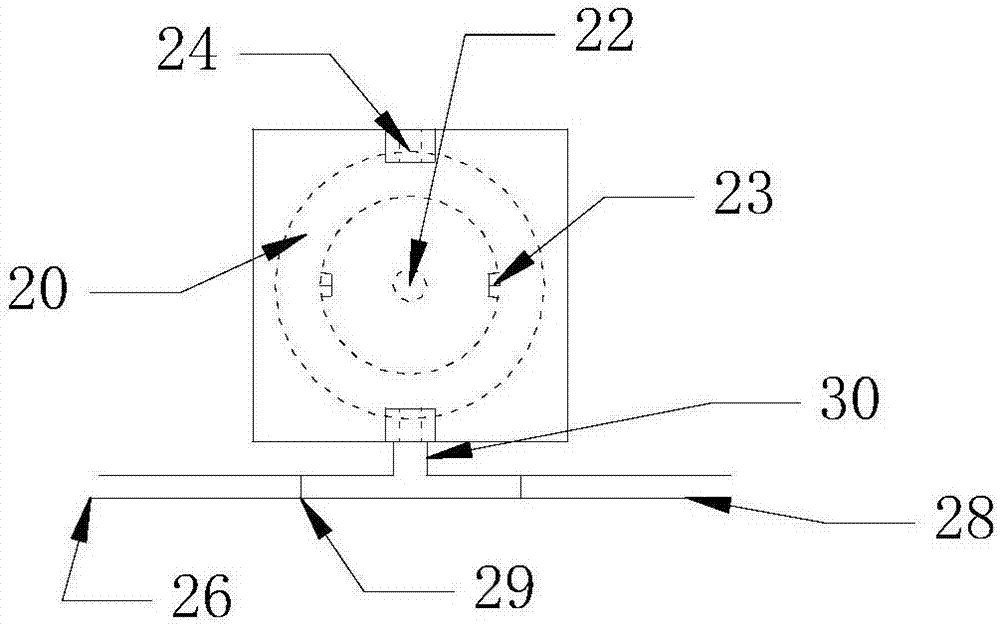

[0051] see image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com