Method for improving performance of medium manganese steel resistance spot welding joint

A welding head, manganese steel technology, applied in resistance welding equipment, welding power source, welding medium, etc., can solve the problems of difference in bearing performance of spot welding joints, low bearing capacity of joints, complete interface fracture, etc., to achieve significant bearing capacity, bearing capacity The effect of ability improvement and nugget plasticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment is used as an effect comparison example, and the technology of the present invention is not adopted. The material to be welded is 7Mn steel with a plate thickness of 1.4 mm, and its chemical composition is shown in Table 1. The adopted spot welding process parameters are common specifications, as shown in Table 2.

[0050] Table 1 Chemical composition of 7Mn steel (wt.%)

[0051] C Si Mn S P 0.13 0.22 7 0.0011 0.006

[0052] Table 2 Spot welding process parameters

[0053]

[0054] Under the welding process parameters, the electron microscope microstructure photos of the nugget are as follows: Figure 7 As shown, it is coarse martensite, the maximum cross tensile force (CTS) that the welded joint can bear is 1.71kN, and the tensile curve is as follows Figure 9 As shown in the 1# curve in the middle, the fracture mode of the welded joint is complete interfacial fracture (FIF).

Embodiment 2

[0056] This embodiment adopts the technology of the present invention. The material to be welded is 7Mn steel with a plate thickness of 1.4 mm, and its composition is shown in Table 1. The spot welding process parameters are shown in Table 3.

[0057] Table 3 Spot welding process parameters

[0058]

[0059] Using the welding process parameters in Table 3, the maximum cross tensile force (CTS) that the medium manganese steel welded joint can withstand is 3.12kN (the tensile curve is as follows: Figure 9 shown in the 2# curve), which is the comparative ratio ( Figure 9 1# curve), the fracture mode of welded joint is partial interface fracture (PIF).

Embodiment 3

[0061] This embodiment adopts the technology of the present invention. The material to be welded is 7Mn steel with a plate thickness of 1.4 mm, and its composition is shown in Table 1. The spot welding process parameters are shown in Table 4.

[0062] Table 4 Spot welding process parameters

[0063]

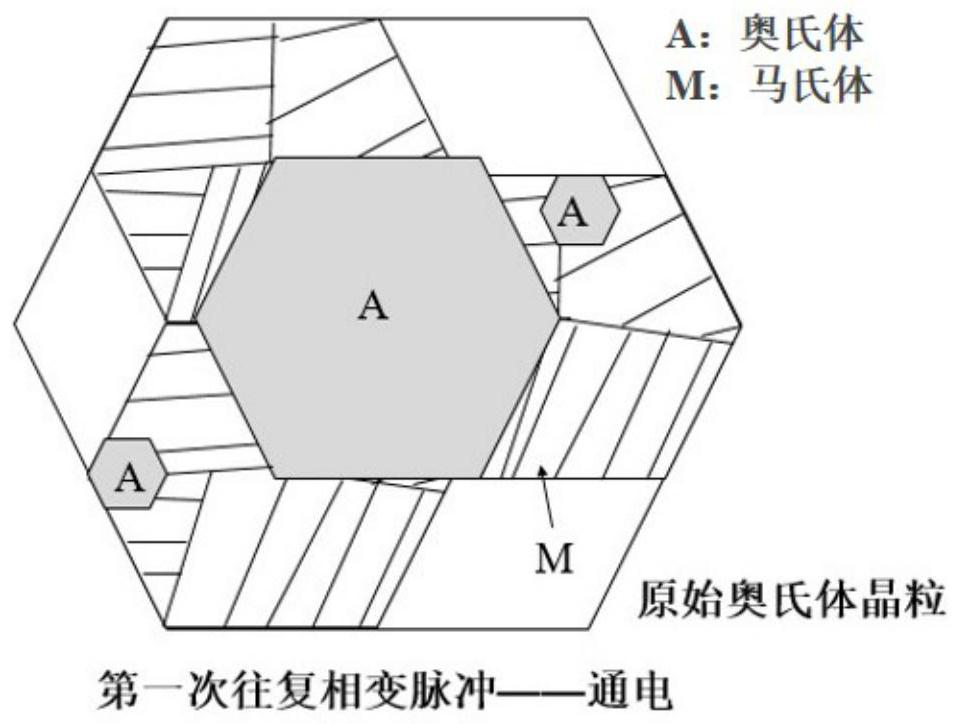

[0064] Using the welding process parameters in Table 4, the photo of the nugget electron microscope structure is as follows Figure 8 As shown, it is fine martensite and austenite, and the maximum cross tensile force (CTS) that the welded joint can bear is 4.62kN (the tensile curve is as shown in Figure 9 shown in the 3# curve), which is the comparative ratio ( Figure 9 270% of the 1# curve), the fracture mode of the welded joint is the button fracture (B). It can be seen that, by the method of the present invention, the joint bearing capacity and plasticity of the medium manganese steel are significantly improved.

[0065] In this embodiment, fine martensite and fine a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com