Method for measuring interface fracture toughness of APS thermal barrier coating based on double-layer material model

A technology of thermal barrier coating and fracture toughness, which is applied in the field of measurement to achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used for further description of the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Those skilled in the art can Further non-essential improvements and adjustments are made according to the above content of the invention.

[0034] The method for measuring the radius of curvature of the APS coating residual stress test piece based on the parabolic model provided by the present embodiment includes the following steps carried out in order:

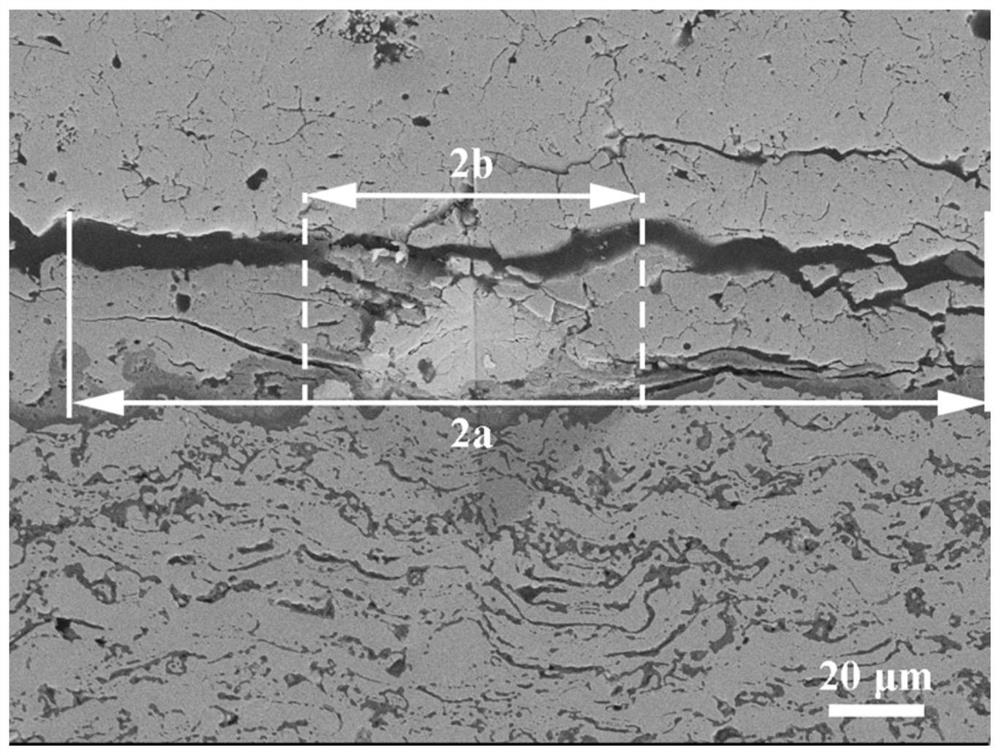

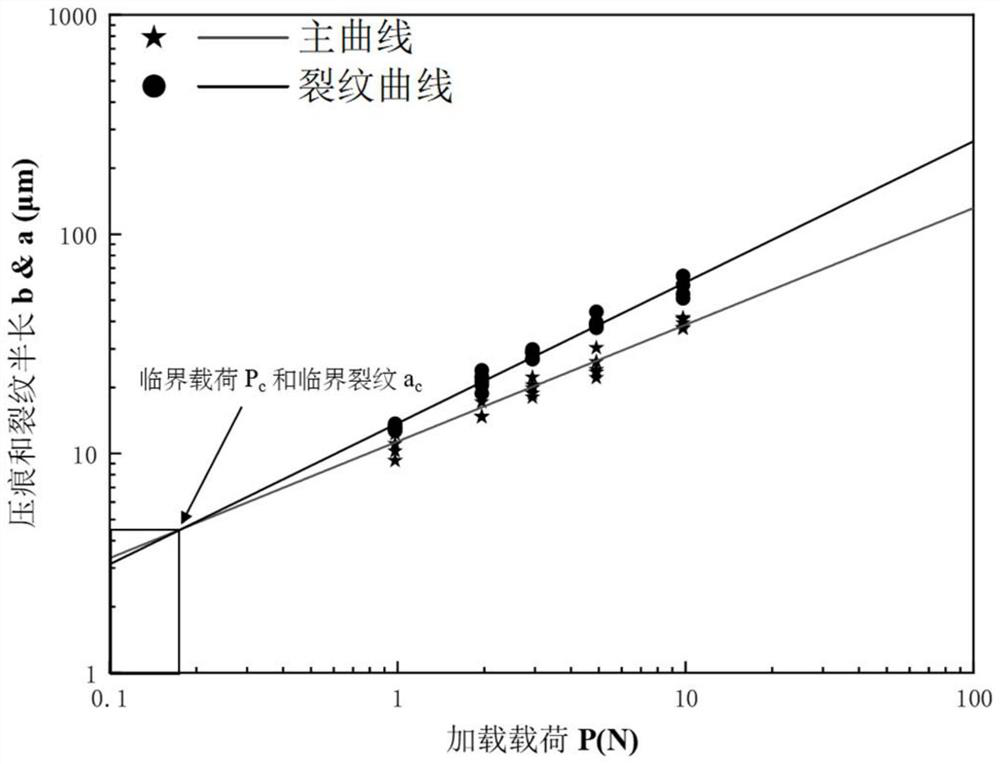

[0035] 1) Preparation of APS thermal barrier coating samples: Select Hastelloy X with a flat and smooth surface as the substrate, with a size of 25mm×6mm, perform sandblasting and roughening treatment, and then perform atmospheric plasma spraying on the sandblasted side of the substrate in turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com