Method for measuring fracture mechanical properties of rock-SCC interface and composite test piece

A Fracture Mechanics, -SCC Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

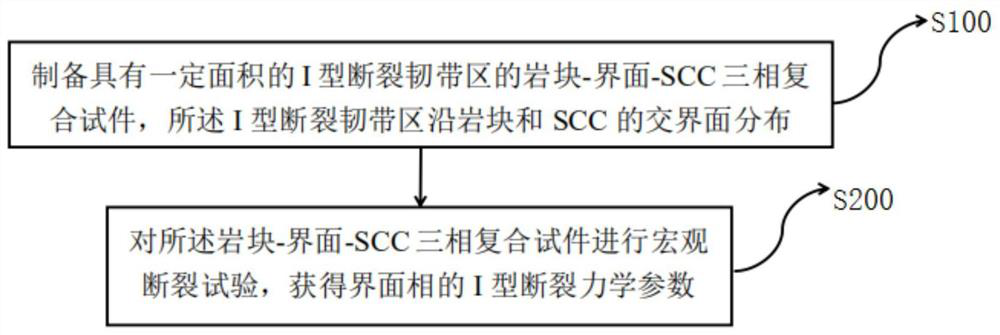

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

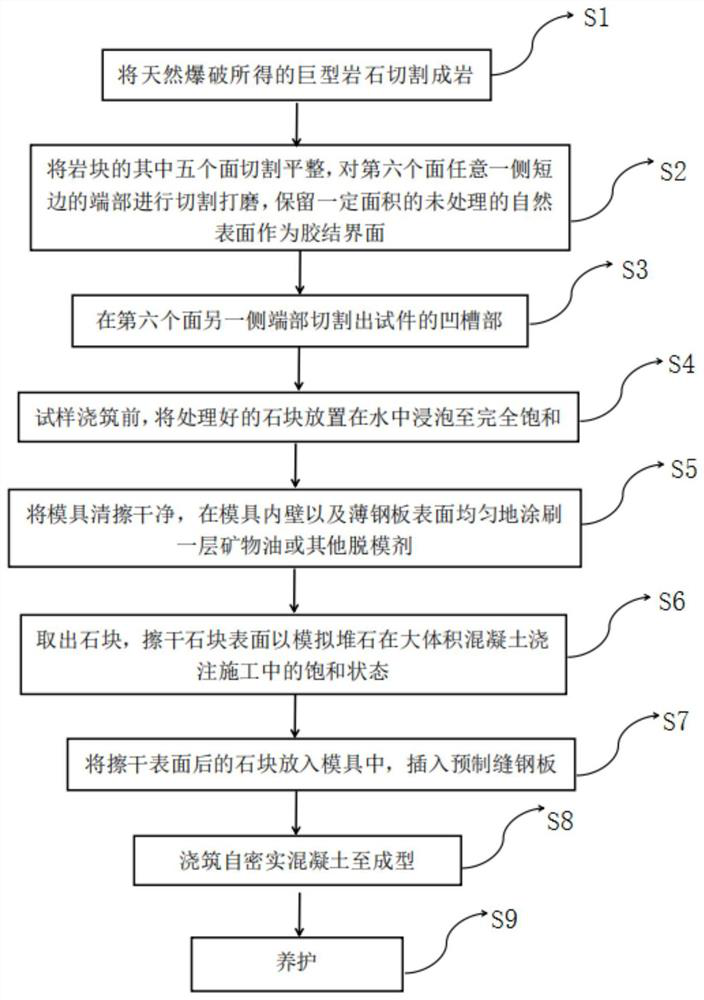

[0050] In some embodiments of the present invention, the rock block-interface-SCC three-phase composite specimen is cast by the above rock block and self-compacting concrete, refer to figure 2 , the specific preparation methods include:

[0051] S1: Cut the huge rock obtained by natural blasting into rock blocks.

[0052] S2: Cut five faces of the rock block flat, cut and polish the end of the short side on any side of the sixth face, and reserve a certain area of untreated natural surface as the cement interface.

[0053] In this step, the two short side faces, two long side faces and any one thickness face of the rock block are cut flat, and the end of the short side on any side of the sixth face is cut and polished, and 200mm×(120 ~200) mm untreated natural surface as the cement interface.

[0054] S3: Cut out the groove part of the test piece at the end on the other side of the sixth surface.

[0055] S4: Before pouring the sample, soak the treated stone in water unt...

Embodiment 1

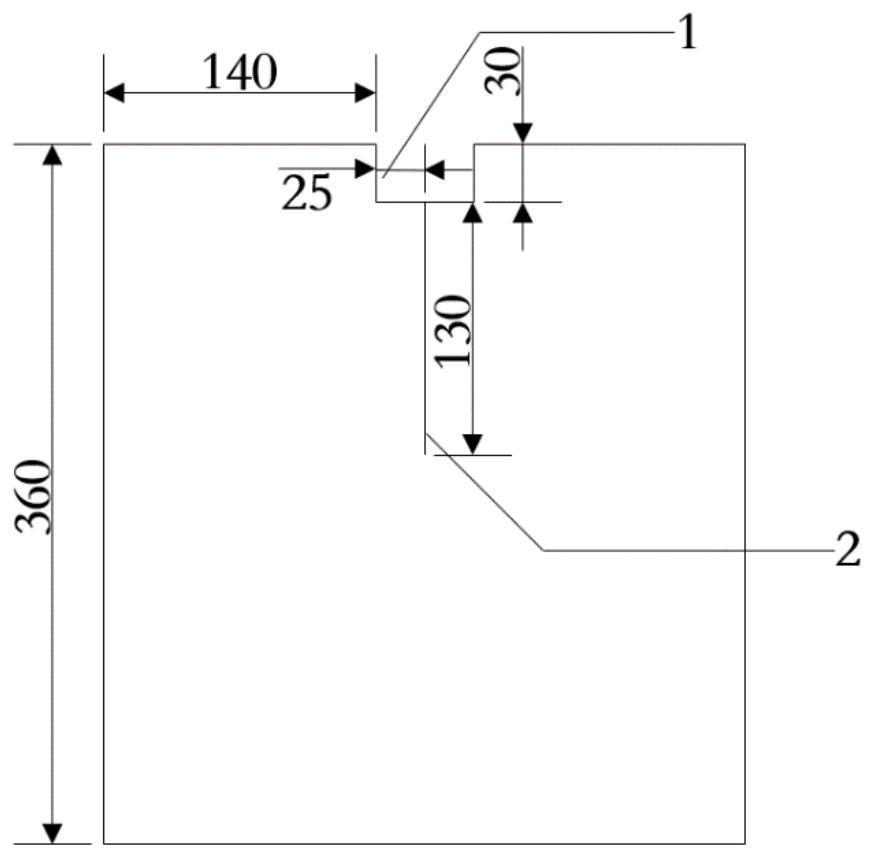

[0075] In this example, the fracture height ratio of the rock block-interface-SCC three-phase composite specimen is 0.4, and the area of the fracture ligament is guaranteed to be H×B=200mm×200mm, and the size of the specimen is estimated to be L×B×D=360mm ×330mm×200mm.

[0076] The preparation method of the above rock block-interface-SCC three-phase composite specimen is as follows:

[0077] S1: Cut the huge rock obtained by natural blasting into rock blocks.

[0078] S2: Cut the two short sides, two long sides and any thickness side of the rock block flat, cut and polish the end of the short side on any side of the sixth side, and keep the 200mm×200mm untreated natural The surface acts as a cemented interface.

[0079] S3: Cut out the groove part of the test piece at the end on the other side of the sixth surface.

[0080] S4: Before pouring the sample, soak the treated stones in water for 12 hours to simulate the wet environment of the stones in the rockfill concrete. ...

Embodiment 2

[0091] In this example, the wedge splitting test is used to study the fracture performance of the rock block-self-compacting concrete interface. The specific test steps are as follows:

[0092] 1. Prepare in advance:

[0093] ①Before the test starts, the knife-edge thin steel plates are symmetrically pasted on both sides of the prefabricated cracks of the specimen for subsequent clamp-type extensometer fixation;

[0094] ②Place the specimen on the support before loading, and adjust the position of the specimen so that the support-specimen-loading indenter are on the same central axis;

[0095] ③Apply a layer of lubricating oil evenly on the surface of the loading plate rollers, then install the two loading plates to the bayonet of the test piece, insert the loading frame between the two loading plates, and ensure that the wedge-shaped plate of the loading frame is stuck between the two loading plate rollers, And it is on the same central axis as the loading head;

[0096] ④...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com