Characterization and control method for bonding strength of precision glass mould pressing interface

A technology of interface bonding and control method, which is applied in measuring devices, instruments, and mechanical devices, etc., and can solve problems such as forming errors, affinity fusion and adhesion, and molecular diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will now be described in conjunction with the corresponding drawings. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. These embodiments are provided only so that the present invention will be thorough and complete so that those skilled in the art can fully describe the scope of the present invention. Wording used in the detailed description of the embodiments illustrated in the drawings should not limit the invention.

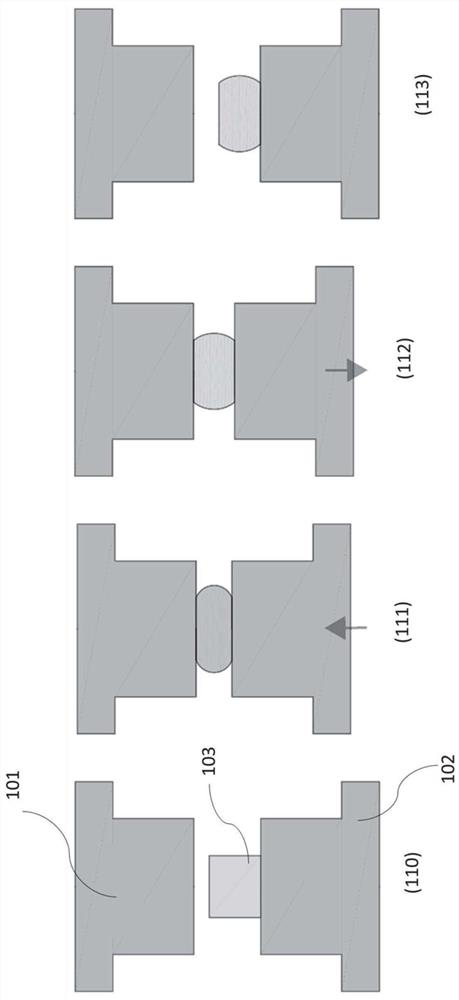

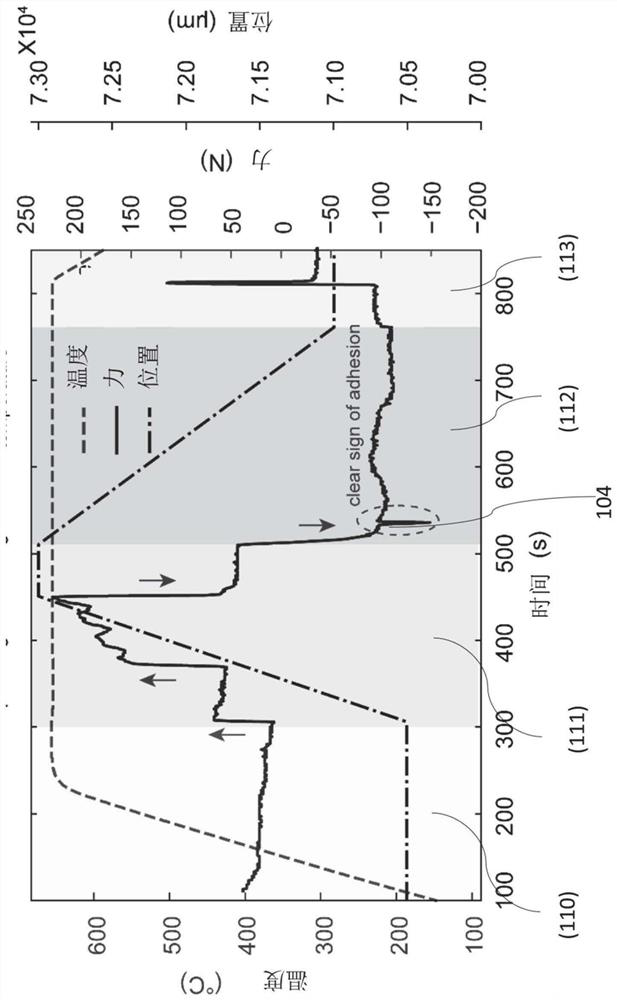

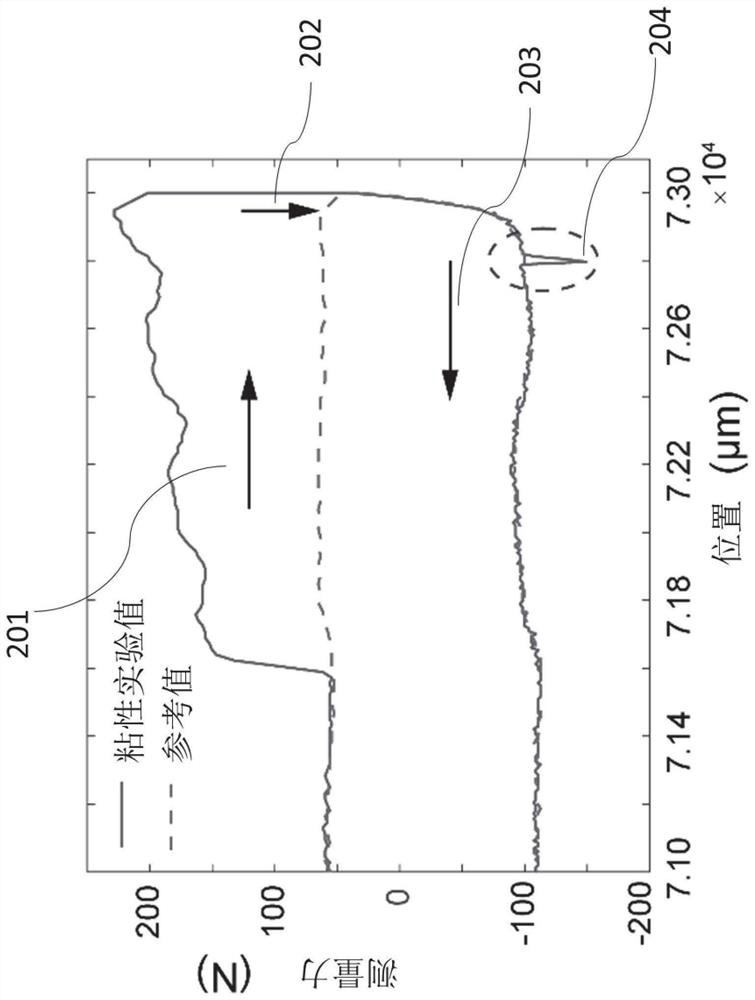

[0027] In the glass precision forming process, the result of adhesion is produced during the separation process between the glass and the mold. This invention provides a new glass molding method by studying the debonding behaviors of the typical glass molding interface. method, using the peak bond strength σ max and debonding power W deb relationship to characterize the debonding behavior.

[0028] The adhesion or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com