Method for testing fracture toughness of sleeve-cement interface

A technology of fracture toughness and testing method, which is applied in the direction of using stable tension/pressure to test material strength, measuring device, strength characteristics, etc. cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

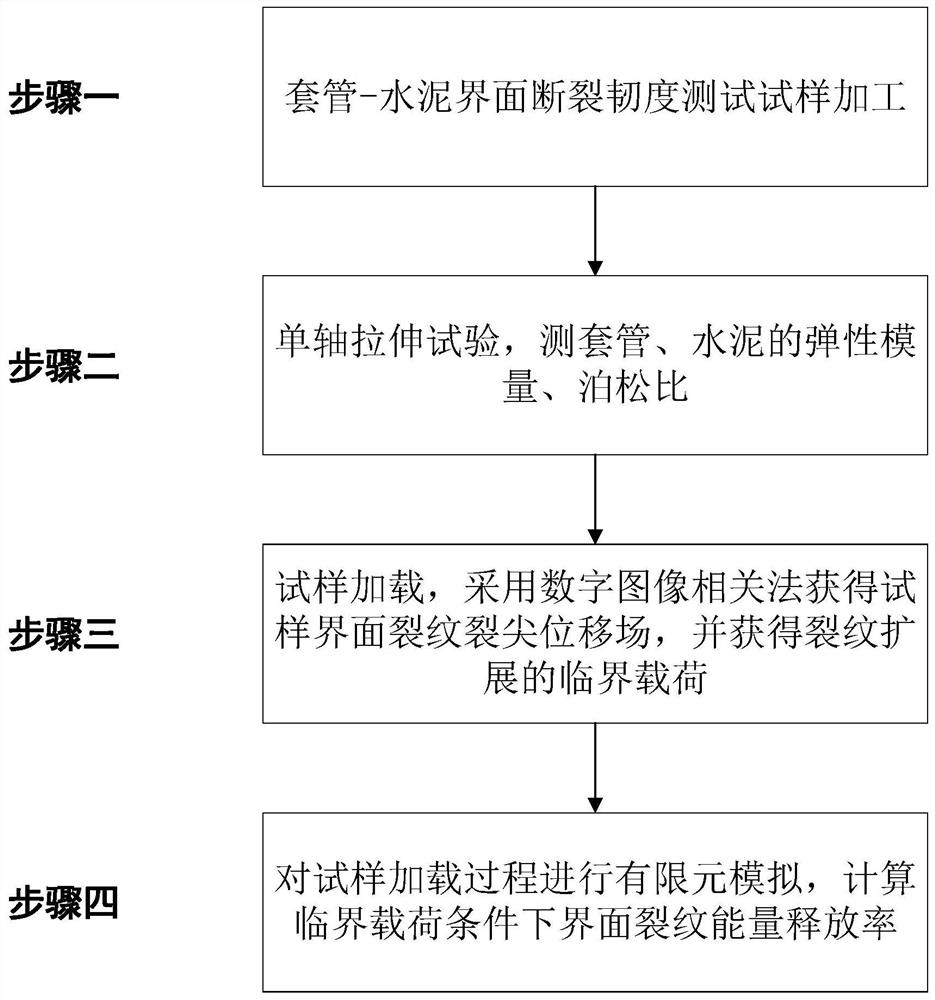

[0019] Such as figure 1 As shown, the embodiment of the present invention provides a kind of casing-cement interface fracture toughness testing method, comprises the following steps:

[0020] Step 1, processing casing-cement interface fracture toughness test sample;

[0021] Step 2. Obtain the elastic modulus and Poisson's ratio of the casing and cement stone in the casing-cement interface fracture toughness test sample;

[0022] Step 3, applying a symmetrical compressive load to the casing-cement interface fracture toughness test sample, and obtaining the critical load of the interface crack propagation of the casing-cement interface fracture toughness test sample;

[0023] Step 4. Calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com