Method for obtaining I-type fracture toughness of three-dimensional woven composite material interface

A fracture toughness and composite material technology, applied in the direction of analyzing materials, testing material strength using stable tension/pressure, sampling, etc. Simple internal structure, single failure mode effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

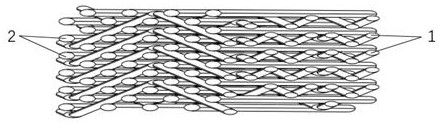

[0027] The research object of the present invention is a typical three-dimensional woven composite material internal yarn weaving structure, and its structure is as follows: figure 1 As shown, warp yarn 1 and weft yarn 2 are included, and there is spatial interlocking between the two yarns. Among them, the warp yarn 1 fluctuates greatly, while the weft yarn 2 is relatively straight.

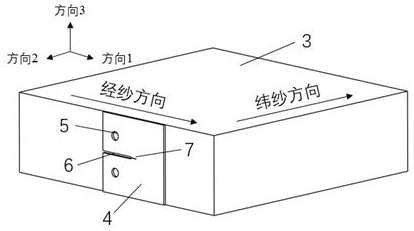

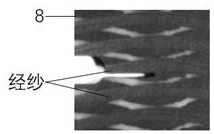

[0028] figure 2 is the cutting position of the specimen, image 3 is the incision position of the crack tip. For the convenience of expression, the warp direction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com