High-temperature environmental thermal barrier coating surface and interface fracture toughness three-point bending detection method

A technology of thermal barrier coating and detection method, which is applied in the direction of testing the strength of materials, measuring devices, and strength characteristics by applying a stable bending force, which can solve the problems of time-consuming, complicated and cumbersome, etc., to improve detection efficiency and save costs , The effect of reducing the loss of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

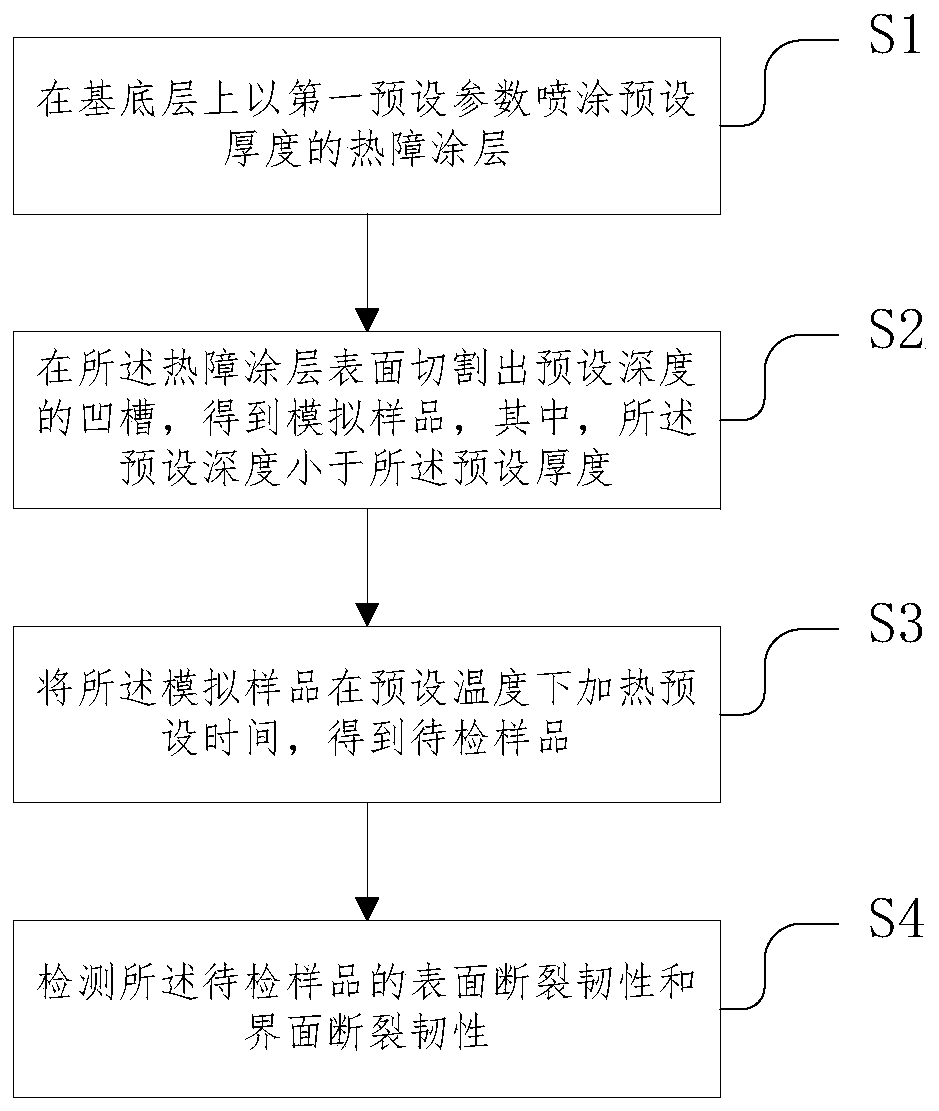

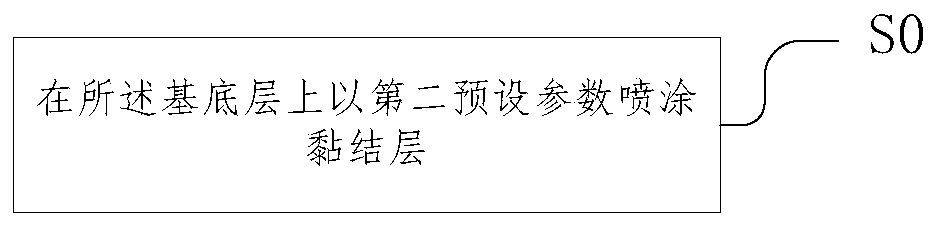

Method used

Image

Examples

specific Embodiment 1

[0062] Measurement results of surface fracture toughness and interface fracture toughness at room temperature:

[0063] Experimental temperature heating time Testing machine loading rate Ceramic layer thickness crack groove depth room temperature 0min 0.4mm / min 1mm 0.25mm

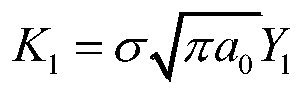

[0064] According to the pure bending model of three-point bending, the strain at the crack tip can be calculated, and the critical fracture stress can be obtained from the product of the strain and the elastic modulus of the ceramic layer and the residual stress at room temperature, so as to calculate the surface fracture toughness. The formula for calculating surface fracture toughness is:

[0065]

[0066] K 1 : stress intensity factor; ρ: critical stress; a 0 : pre-crack length; Y 1 :Correction factor.

[0067] The appearance of interfacial cracks was observed by DIC, and as the deflection of the sample increased, the interfacial cracks gradually became longer. Ac...

specific Embodiment 2

[0074] Measurement results of surface fracture toughness and interface fracture toughness at 650°C:

[0075] Experimental temperature heating time Testing machine loading rate Ceramic layer thickness crack groove depth 650℃ 17min 0.4mm / min 1.0mm 0.5mm

[0076] According to the pure bending model of three-point bending, the strain at the crack tip can be calculated, and the critical fracture stress can be obtained from the product of the strain and the elastic modulus of the ceramic layer and the residual stress at room temperature, so as to calculate the surface fracture toughness. The formula for calculating surface fracture toughness is:

[0077]

[0078] K 1 : stress intensity factor; ρ: critical stress; a 0 : pre-crack length; Y 1 :Correction factor. The appearance of interfacial cracks was observed by DIC, and as the deflection of the sample increased, the interfacial cracks gradually became longer. According to the data of DIC and ...

specific Embodiment 3

[0085] Measurement results of surface fracture toughness and interface fracture toughness at 1200°C:

[0086] Experimental temperature heating time Testing machine loading rate Ceramic layer thickness crack groove depth 1200℃ 20min 0.4mm / min 1.0mm 0.5mm

[0087] According to the pure bending model of three-point bending, the strain at the crack tip can be calculated, and the critical fracture stress can be obtained from the product of the strain and the elastic modulus of the ceramic layer and the residual stress at room temperature, so as to calculate the surface fracture toughness. The formula for calculating surface fracture toughness is:

[0088]

[0089] K 1 : stress intensity factor; ρ: critical stress; a 0 : pre-crack length; Y 1 :Correction factor.

[0090] The appearance of interfacial cracks was observed by DIC, and as the deflection of the sample increased, the interfacial cracks gradually became longer. According to the data ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com