Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Increased fractures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

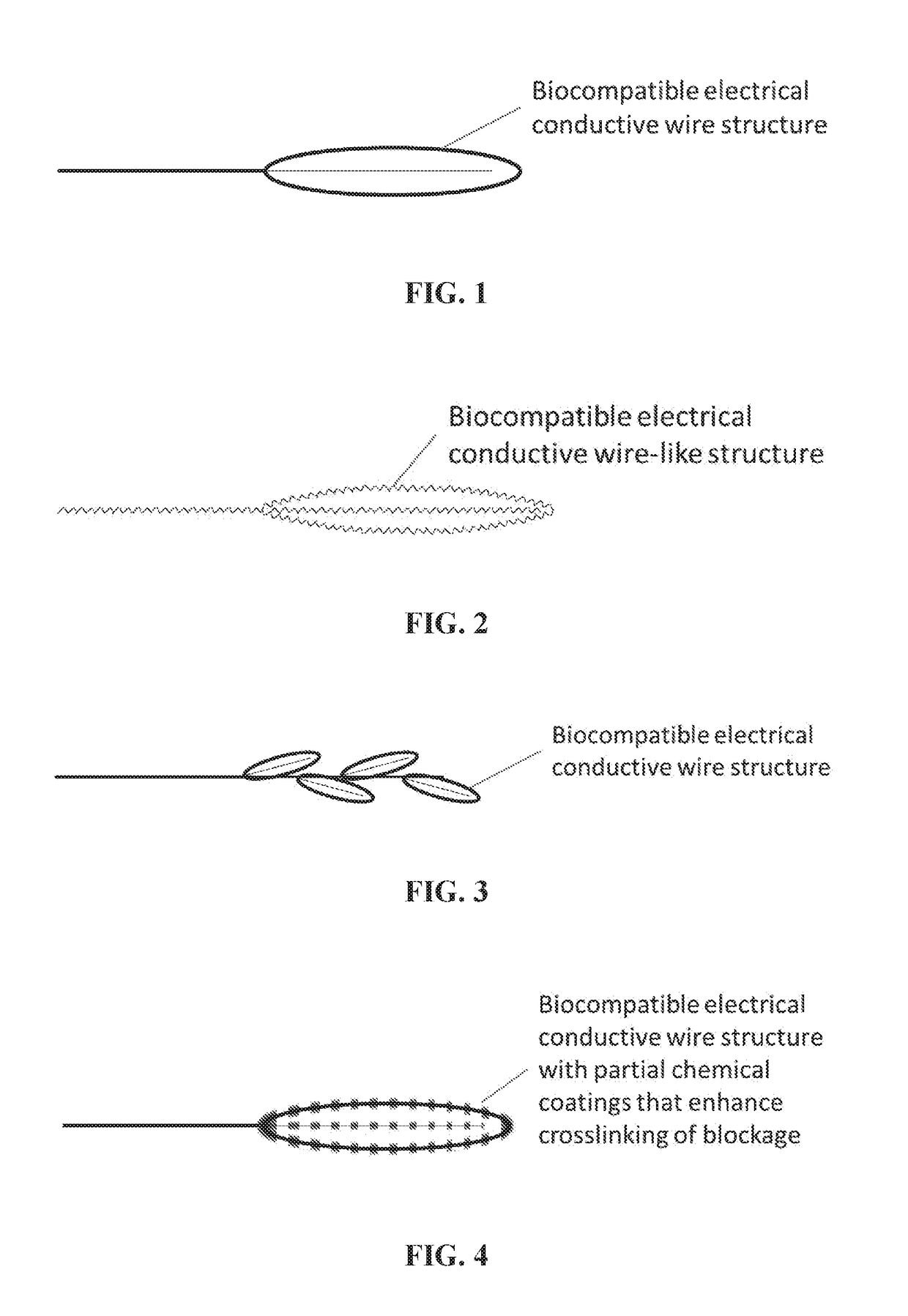

Radio frequency electro-thrombectomy device

ActiveUS20180140354A1Reduce riskImprove adhesionSurgical instruments for heatingCross-linkPower flow

A device is designed to remove blockages in a lumen such as a thrombus, blood clot, or embolus. The device comprises a manipulating wire and a structure that can conduct electrical current to a lumen blockage. The electrical current is preferably in radio frequency (RF). The RF electric current in the blockage can excite the contents such as proteins of the blockage, so that cross-linking density and interfacial adsorption of the entire blockage is enhanced. The enhanced cross-linking density can result in increased fracture resistance of the blockage such that fracture of the blockage during the removal process is unlikely. The enhanced interfacial adsorption results in increased interfacial fracture resistance between the device and blockage so that the blockage can be securely captured during the removal process without using radially applied force.

Owner:THE HONG KONG UNIV OF SCI & TECH

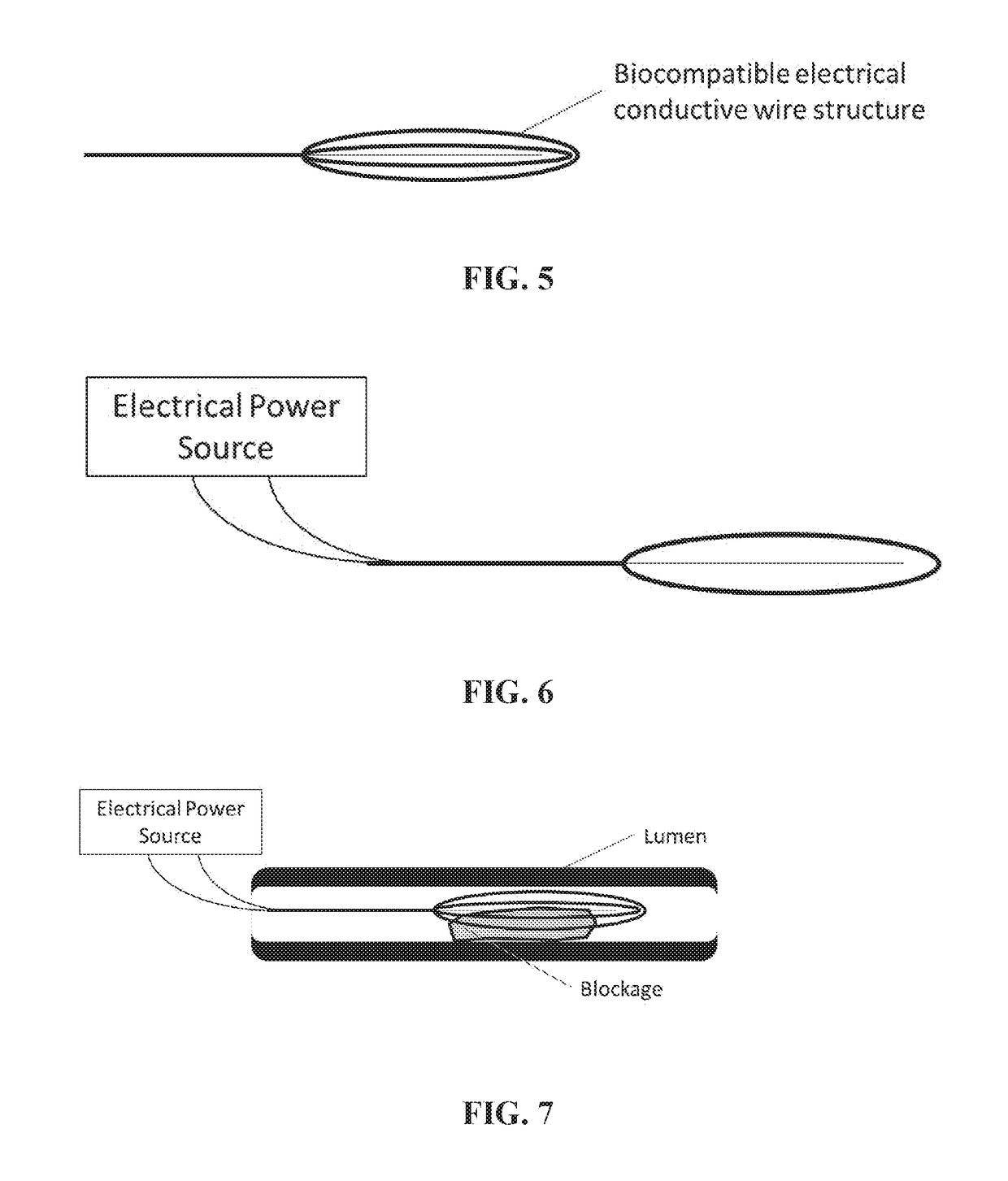

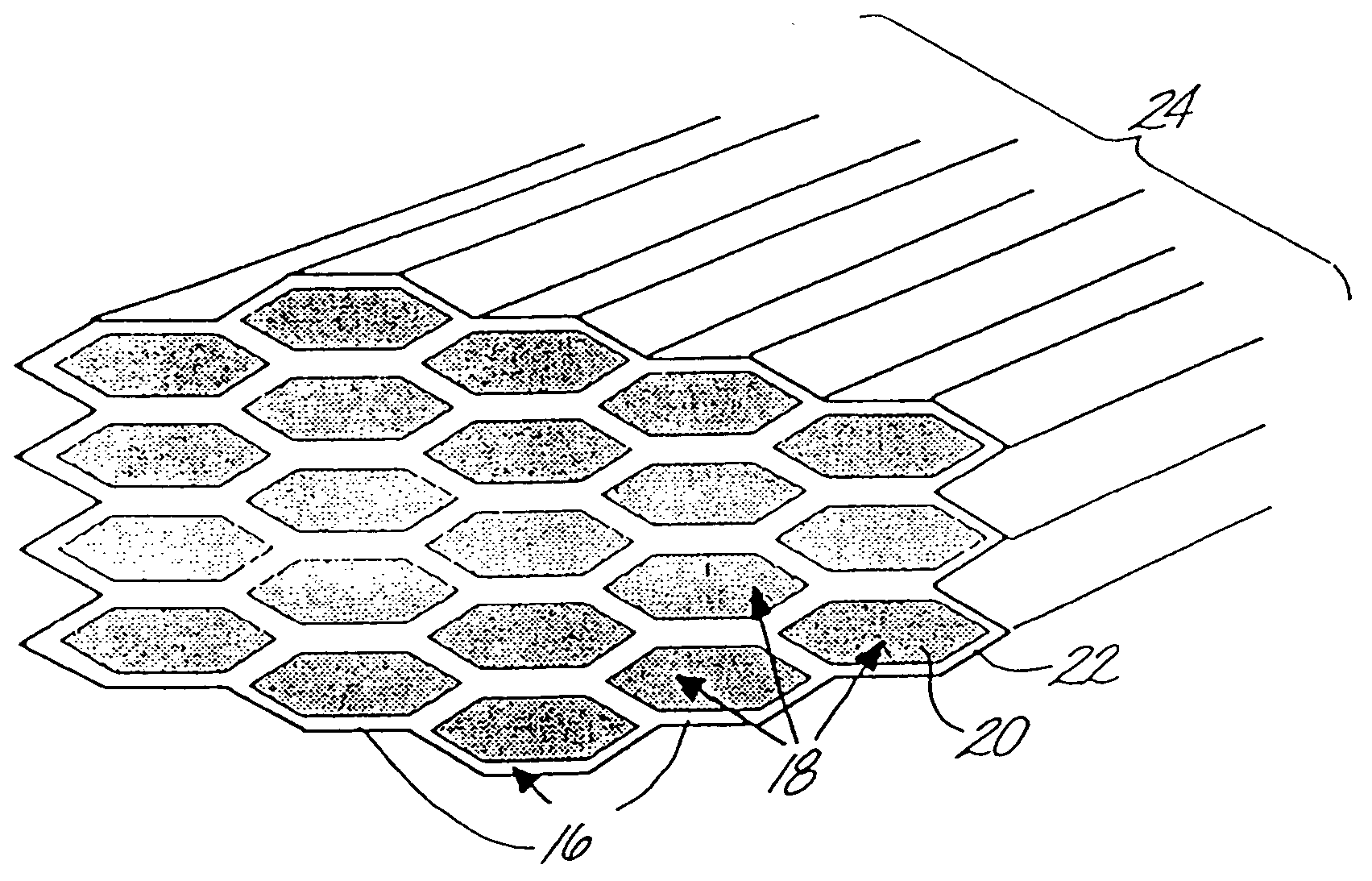

Well treating composite containing organic lightweight material and weight modifying agent

InactiveUS7772163B1Reduce conductivityImprove conductivityOther chemical processesFluid removalParticulatesWater production

Well treating composites are composed of an organic lightweight material and a weight modifying agent. The organic lightweight material preferably forms the continuous phase and the weight modifying agent forms the discontinuous phase. The apparent specific gravity (ASG) of the organic lightweight material is less than the ASG of the well treating composite. The composite of the invention is particularly useful in hydraulic fracturing fluids as lightweight proppants as well as in sand control methods, such as gravel packing and frac packing A subterranean formation may be treated by injecting the well treating composite into the formation in order to increase fracture conductivity, reduce the generation of fines, reduced unwanted water production and / or reduce particulate production.

Owner:BAKER HUGHES INC

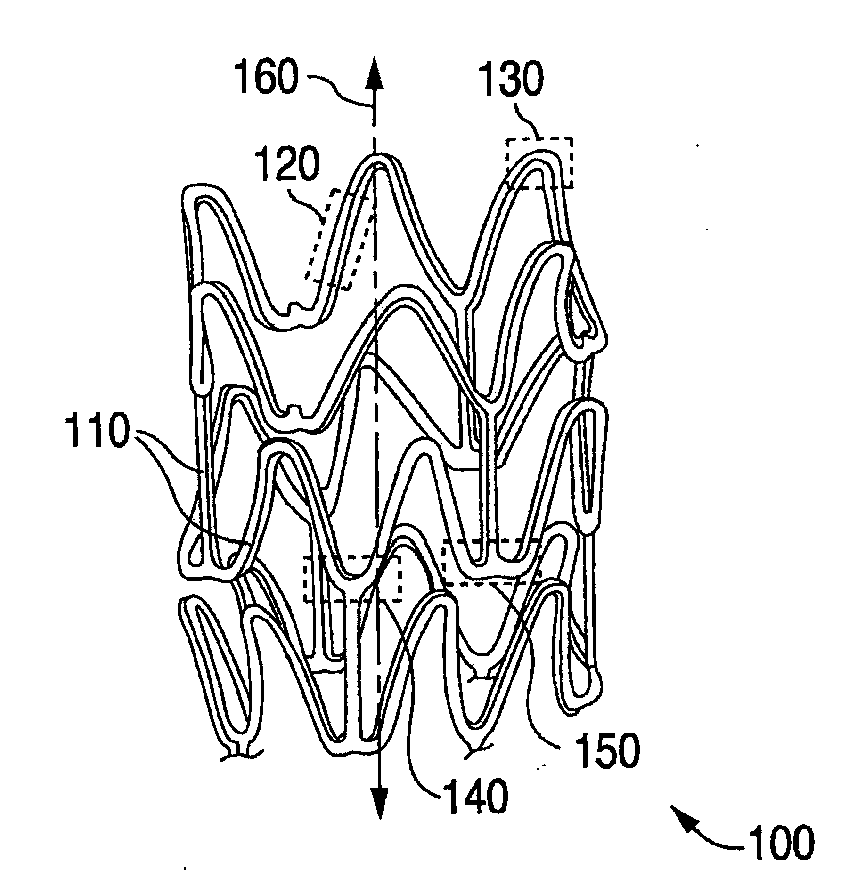

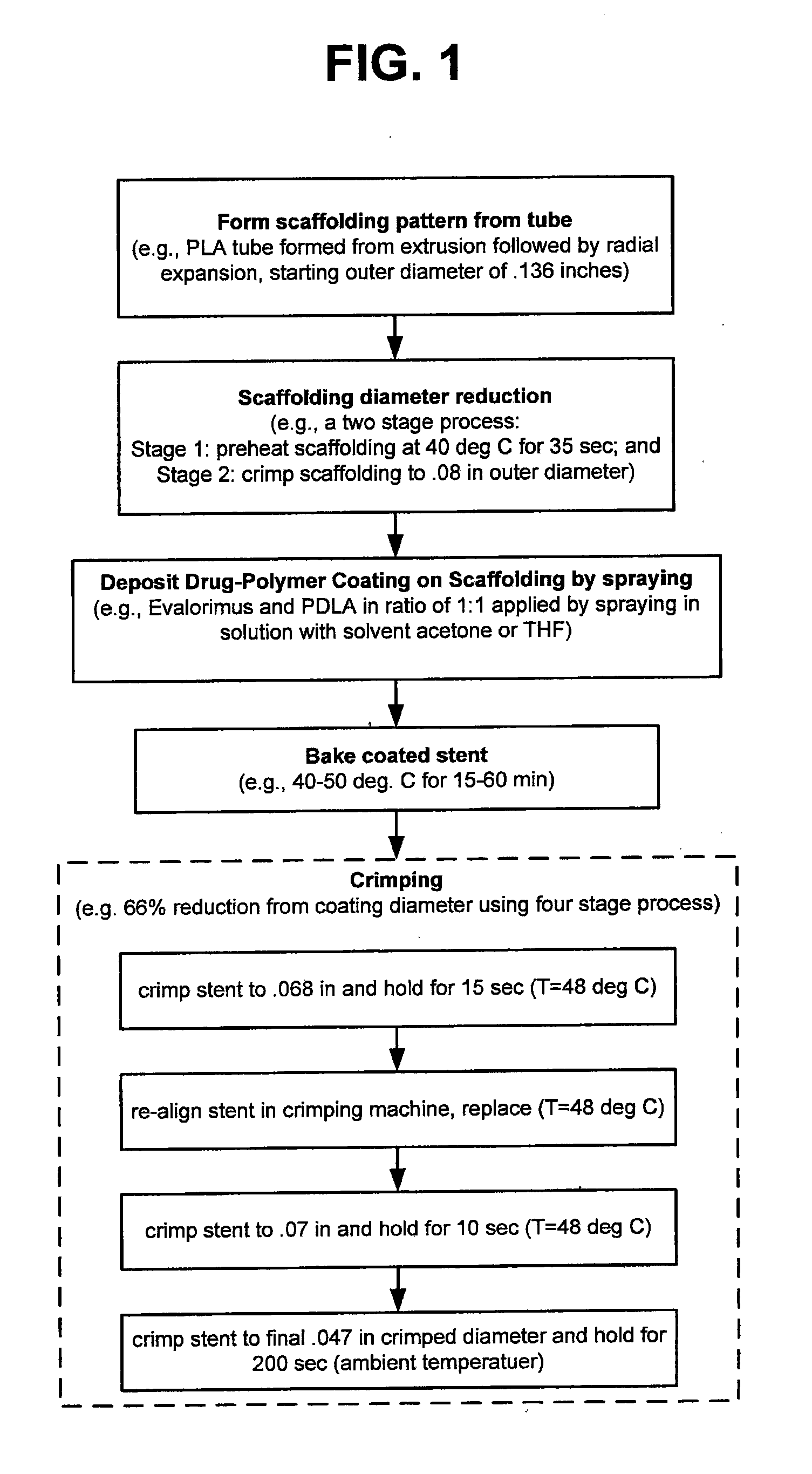

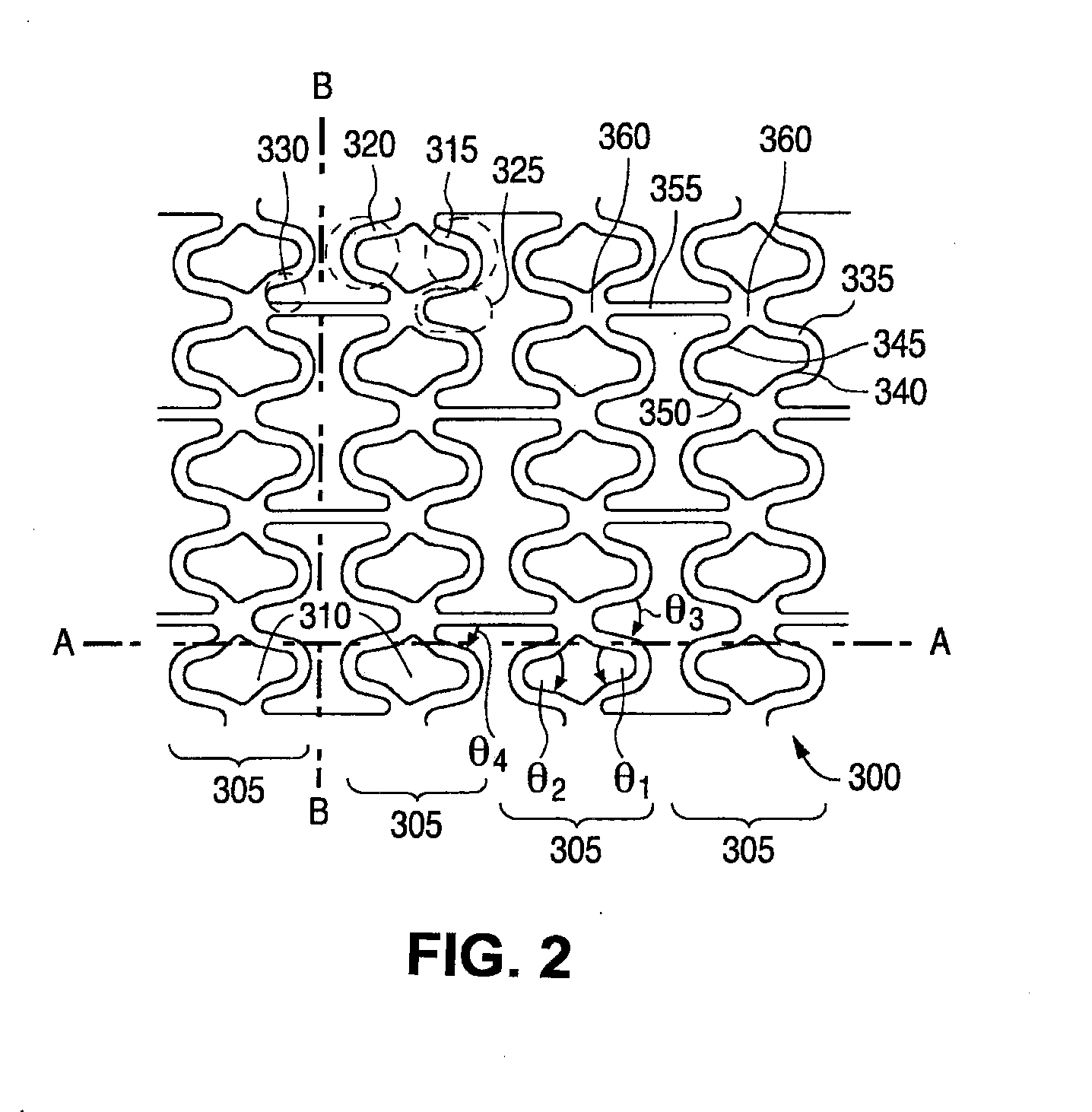

Methods To Increase Fracture Resistance Of A Drug-Eluting Medical Device

InactiveUS20100323091A1Improve fracture resistanceRelieve stress/strainStentsPharmaceutical containersPolymer coatingsMedical device

Owner:ABBOTT CARDIOVASCULAR

Silicon penetration device with increased fracture toughness and method of fabrication

InactiveUS6852365B2Improve fracture toughnessSkin reliablyDecorative surface effectsVacuum evaporation coatingSputteringOptoelectronics

A silicon penetration device with increased fracture toughness and method of fabrication thereof are provided. The method comprises strengthening silicon penetration devices by thermally growing a silicon oxide layer on the penetration device and then subsequently stripping the silicon oxide. The method also includes strengthening silicon penetration devices through the sputtering of thin film coatings on the silicon penetration devices.

Owner:KUMETRIX

Methods of increasing fracture resistance in low permeability formations

ActiveUS20100282470A1Low resistance goodIncreased formationFluid removalSealing/packingParticulatesCrack resistance

A method of increasing the fracture resistance of a low permeability formation that includes emplacing a wellbore fluid in a wellbore through the low permeability formation, the wellbore fluid comprising: a settable carrier fluid; and a solid particulate bridging material; increasing the pressure in the wellbore such that fractures are formed in the formation; allowing the settable carrier fluid to enter the fractures; bridging and sealing the mouths of the fractures to form a substantially impermeable bridge proximate the mouth of the fractures thereby strengthening the formation; and holding the increased pressure for an amount of time sufficient for setting of the carrier fluid in the fractures is disclosed.

Owner:BP CORP NORTH AMERICA INC +2

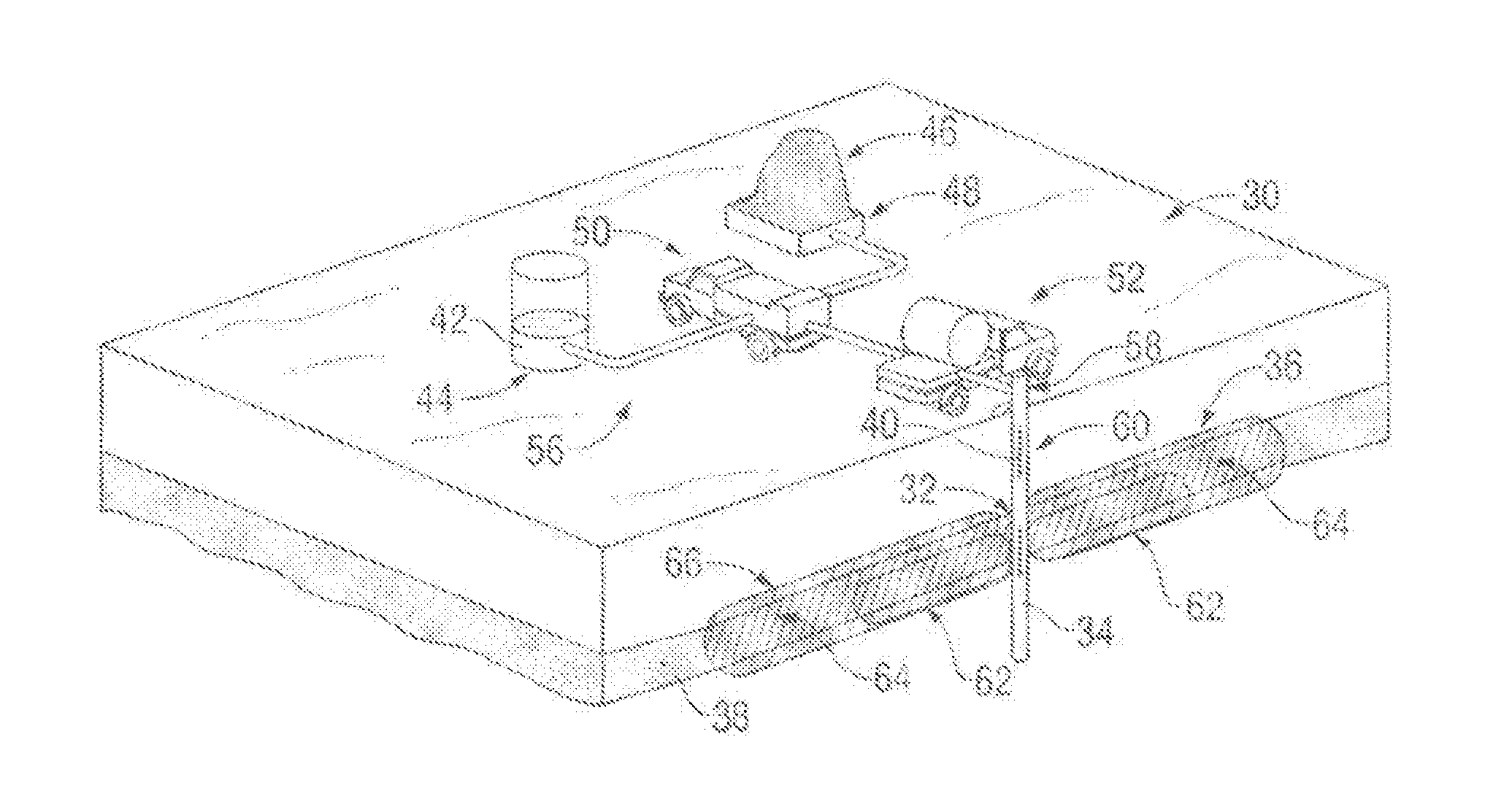

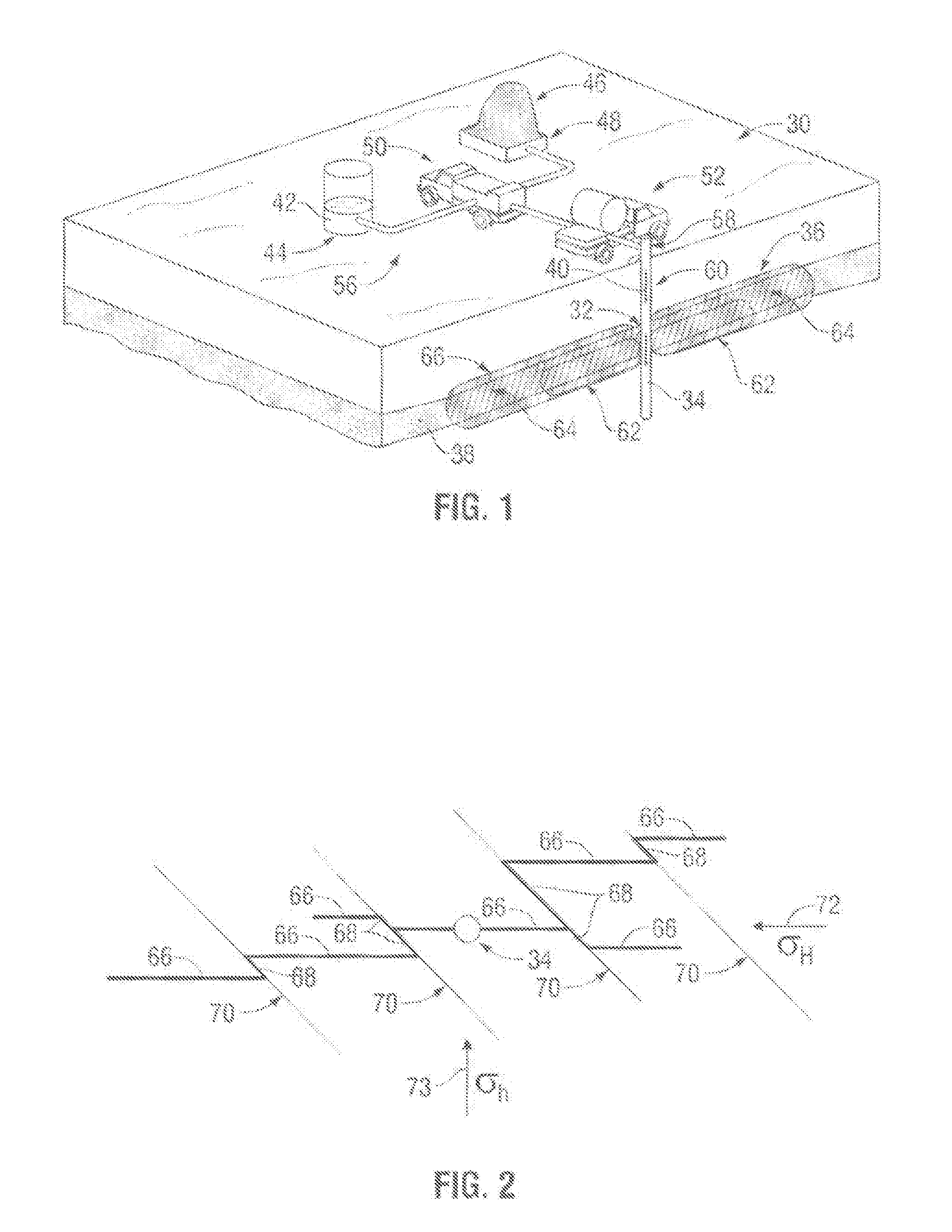

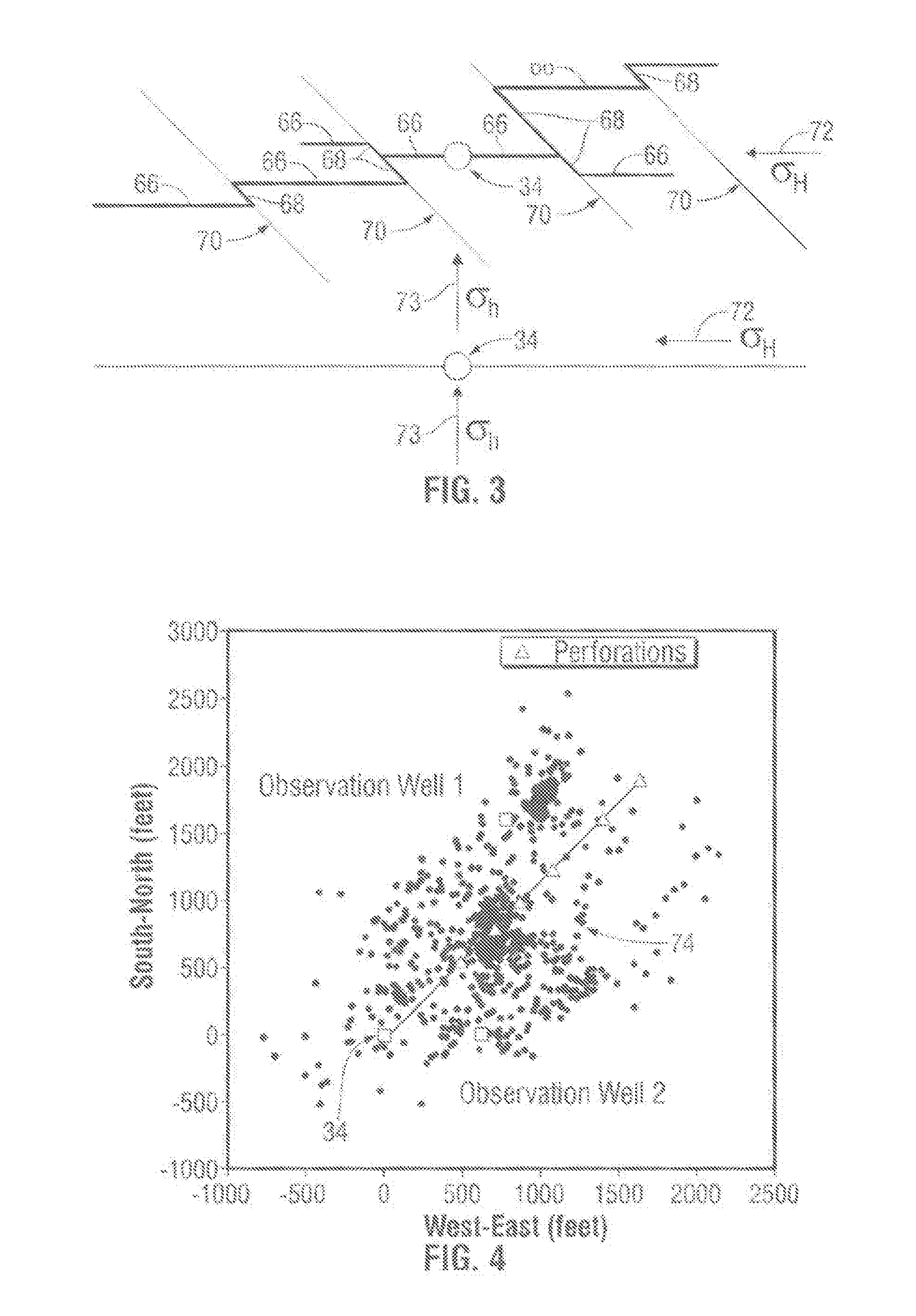

Method for increasing fracture area

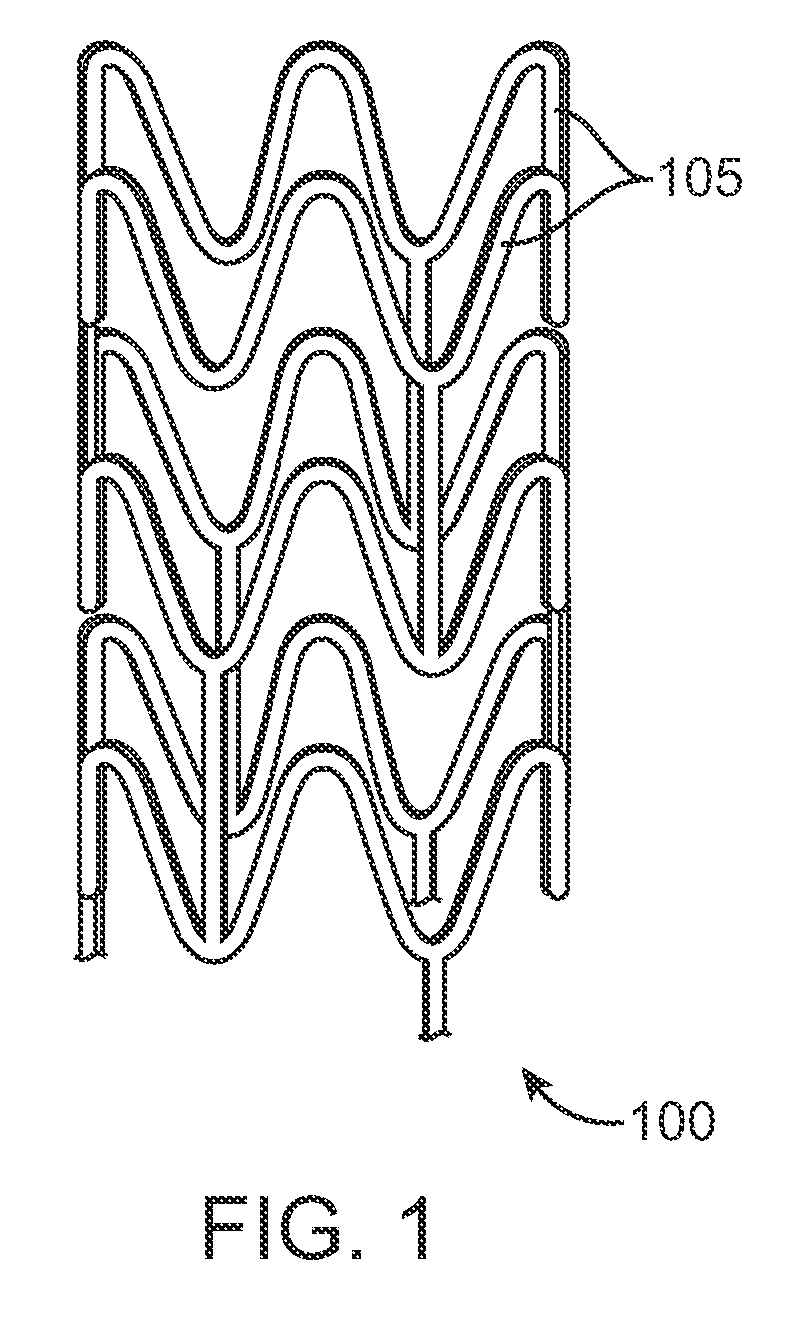

ActiveUS20130140020A1Convenient treatmentIncrease the lengthSurveyFluid removalMining engineeringHydraulic fracturing

A technique enables improvements in hydraulic fracturing treatments on heterogeneous reservoirs. Based on data obtained for a given reservoir, a fracturing treatment material is used to create complex fractures, which, while interacting with the interfaces and planes of weakness in the reservoir, develop fracture connectors, e.g. step-overs, which often grow for short distances along these planes of weakness. The technique further comprises closing or sealing at least one of the fracture connectors to enable reinitiation of fracturing from the truncated branches, and to subsequently develop additional connectors. As a result, the overall fracturing becomes more complex (more branches and more surface area per unit reservoir volume is created), which leads to an increase in the effective fracture area and improved fluid flow through the reservoir.

Owner:SCHLUMBERGER TECH CORP

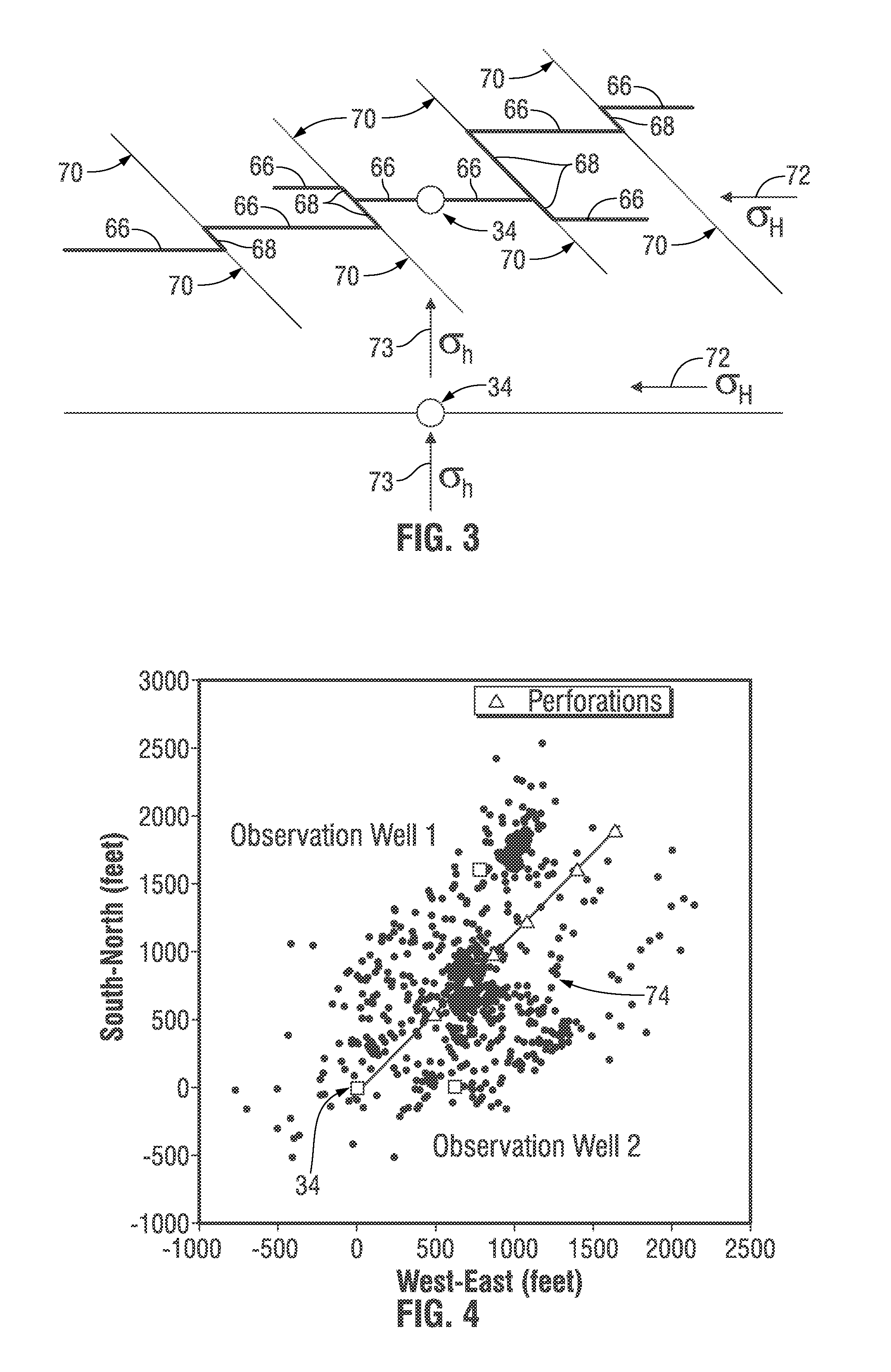

Method for increasing fracture stimulated reservoir volume of shale gas

ActiveCN106703778AIncrease the volume of the transformationImprove diversion capacityFluid removalHorizontal stressFracture testing

The invention provides a method for increasing the fracture stimulated reservoir volume of shale gas. The method includes the following steps that firstly, the brittleness index of shale is fine analyzed and evaluated; secondly, a proper number of shower holes are selected; thirdly, induced fracturing testing is conducted on each segment; fourthly, acid pretreatment is conducted; fifthly, the amplitude of shale original horizontal stress difference relative to major fracture net pressure is judged, and a fracture is further treated; sixthly, balls are thrown according to the cluster number of perforated holes and the total number of the perforated holes. By fine analyzing and evaluating the brittleness index of shale, selecting reasonable perforated hole parameters, conducting induced fracturing testing on each segment of a horizontal well, well controlling the major fracture net pressure and well controlling a diverting agent in the fracture, generation of network fractures or volume fractures is improved in the shale gas well fracturing process, accordingly the fracture stimulated reservoir volume is increased, and finally the fracture flow conductivity is improved after shale gas fracturing.

Owner:CHINA PETROLEUM & CHEM CORP +1

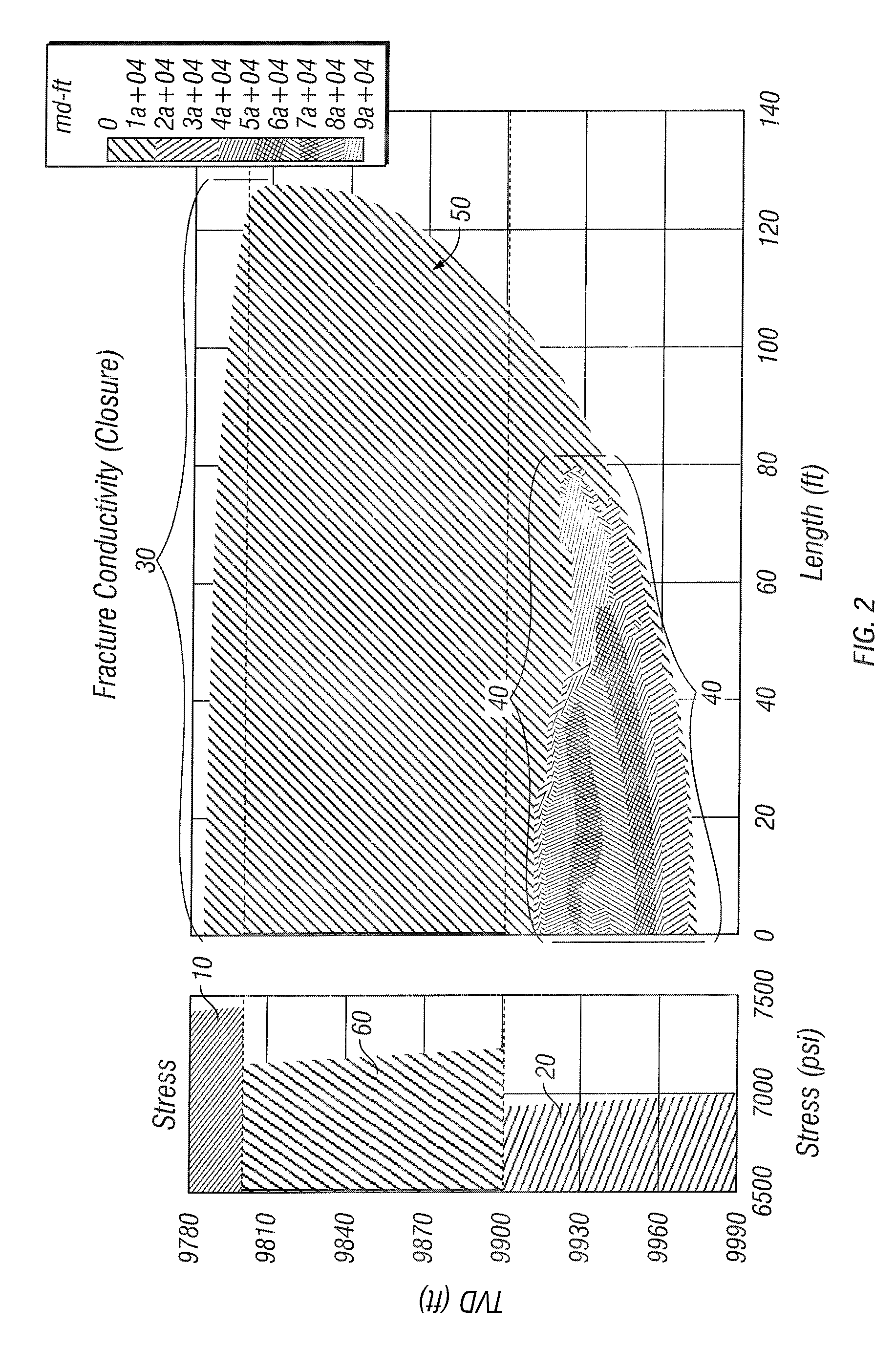

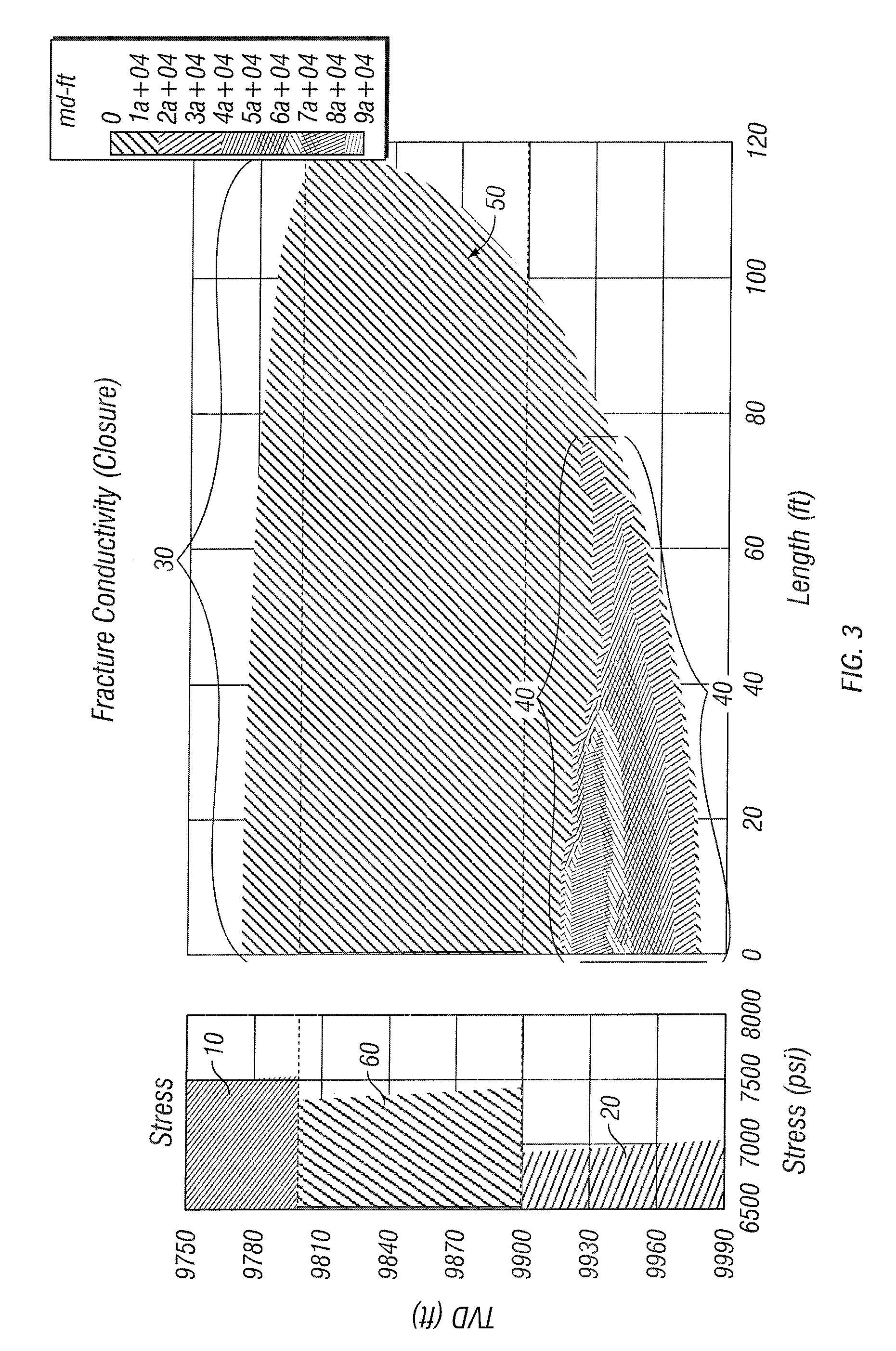

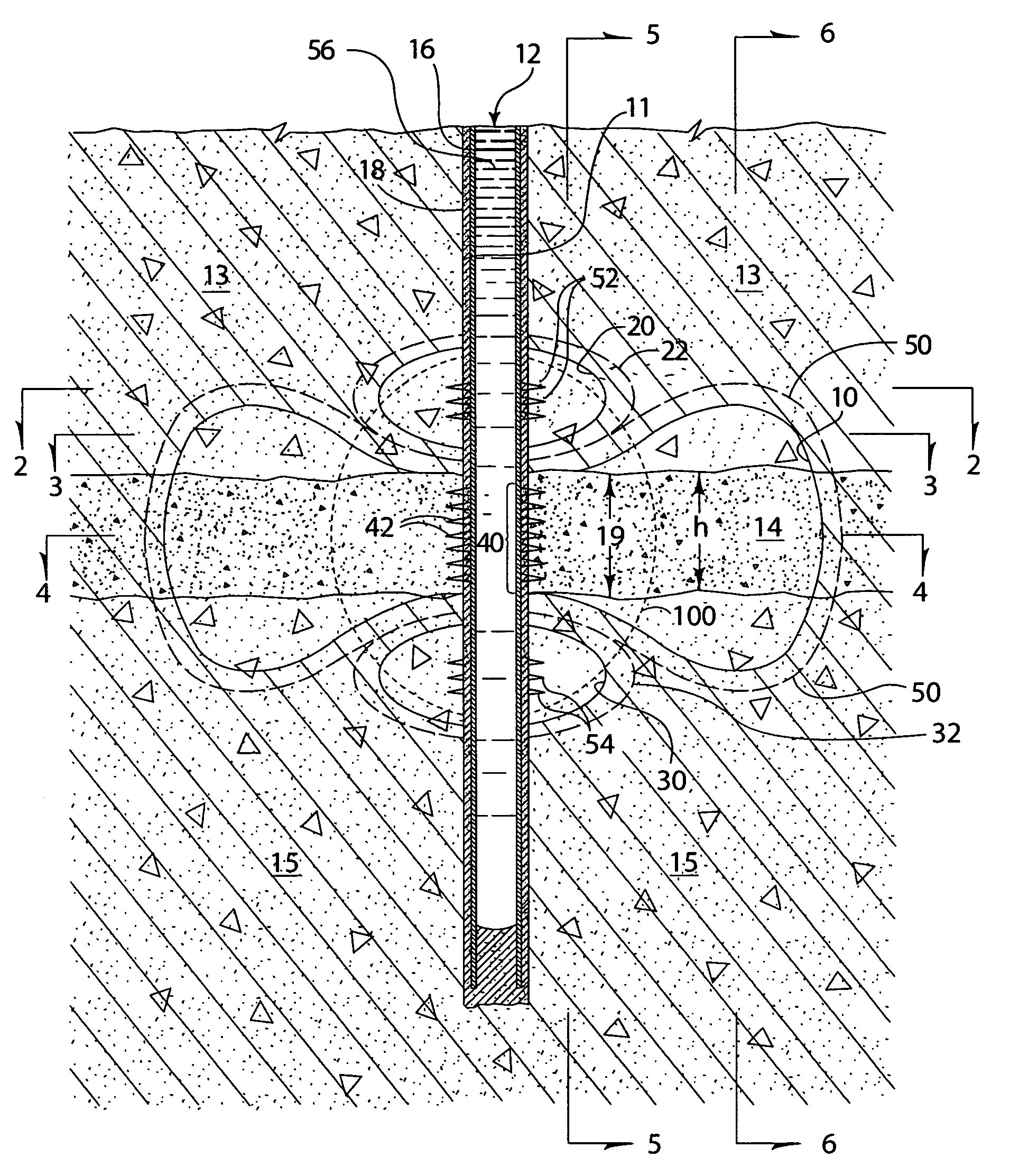

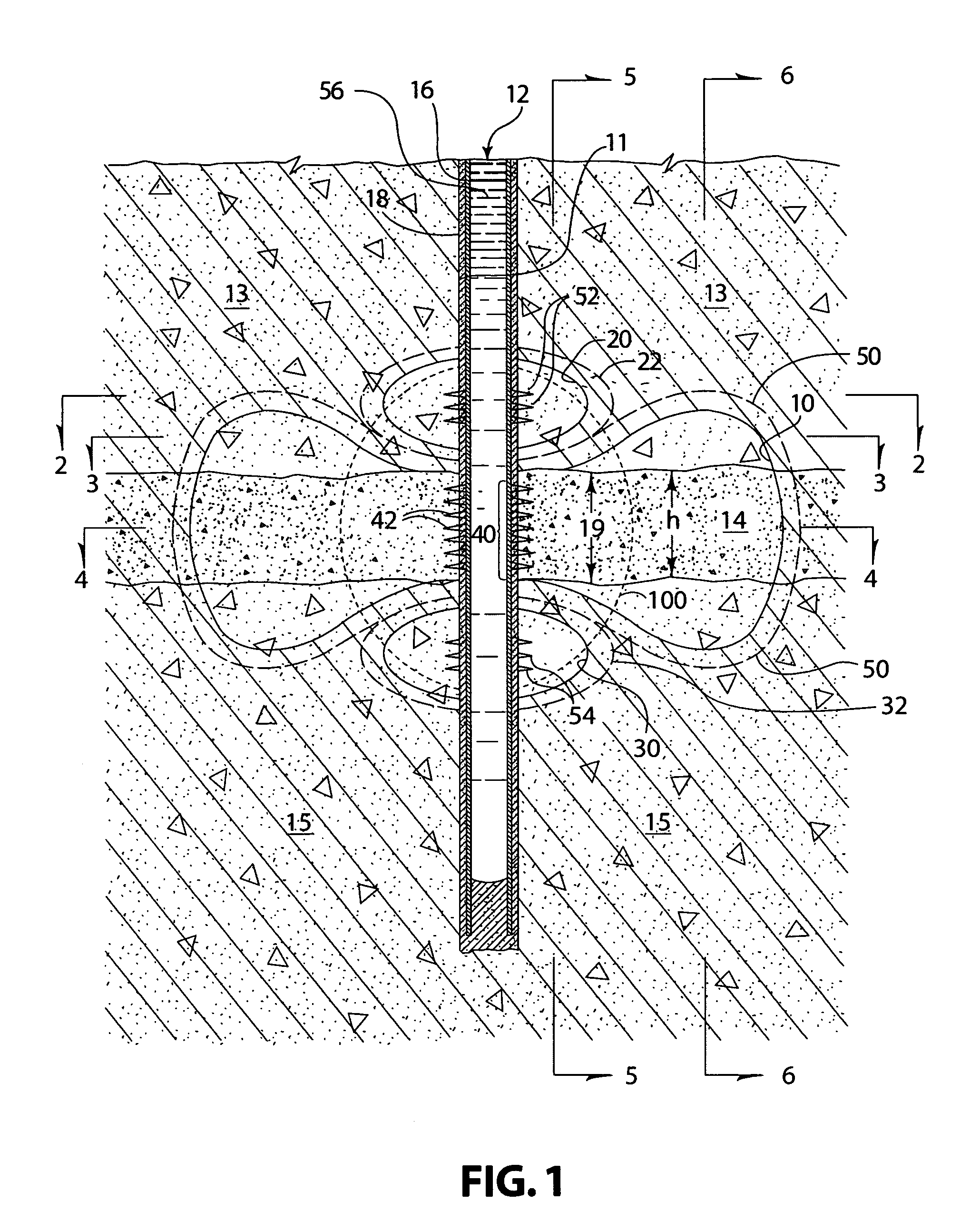

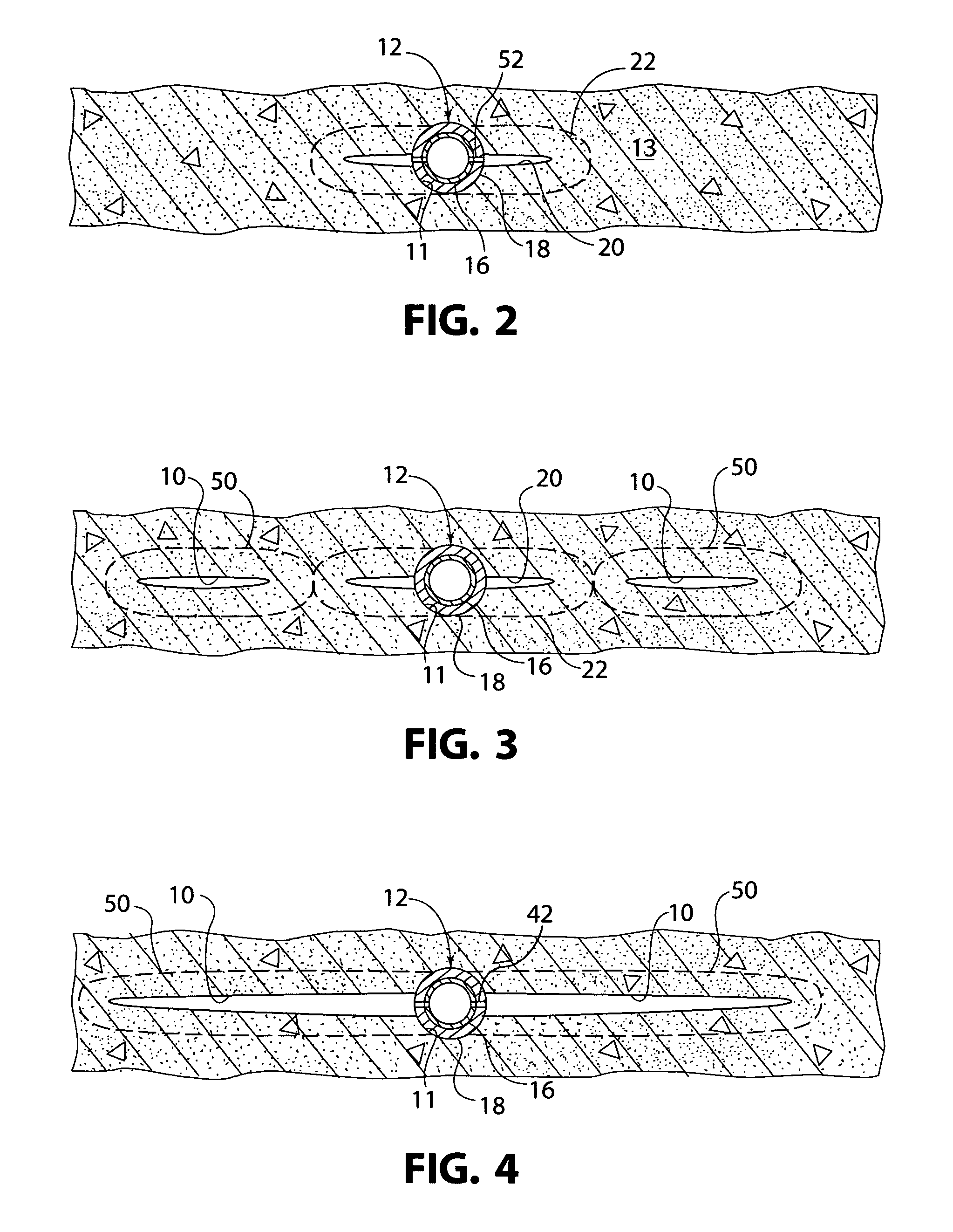

Method for increasing fracture penetration into target formation

InactiveUS7032671B2Reliable and goodReliable methodSurveyFluid removalFracturing fluidVertical growth

A method of propagating a fracture farther from a well-bore into an oil and / or gas-bearing zone of a target formation while inhibiting growth of the fracture into an adjacent water-bearing zone under or over the oil and / or gas-bearing zone, comprises creating a zone of increased in-situ stress a vertical distance adjacent a target interval and then creating a main fracture in the target interval by, for example, fracturing the target interval with enough fracture fluid and pressure to propagate the main fracture, inter alia, vertically to the zone of increased in-situ stress. When vertical growth of the main fracture reaches the limit set by the zone of increased stress, additional fracture fluid pumped into the target interval tends not to propagate the main fracture vertically beyond that limit and, instead, tends to propagate the main fracture more laterally and farther from the well. Such zone(s) of increased in-situ stress can be created above, below, or both above and below the target interval.

Owner:NEW IPT INC

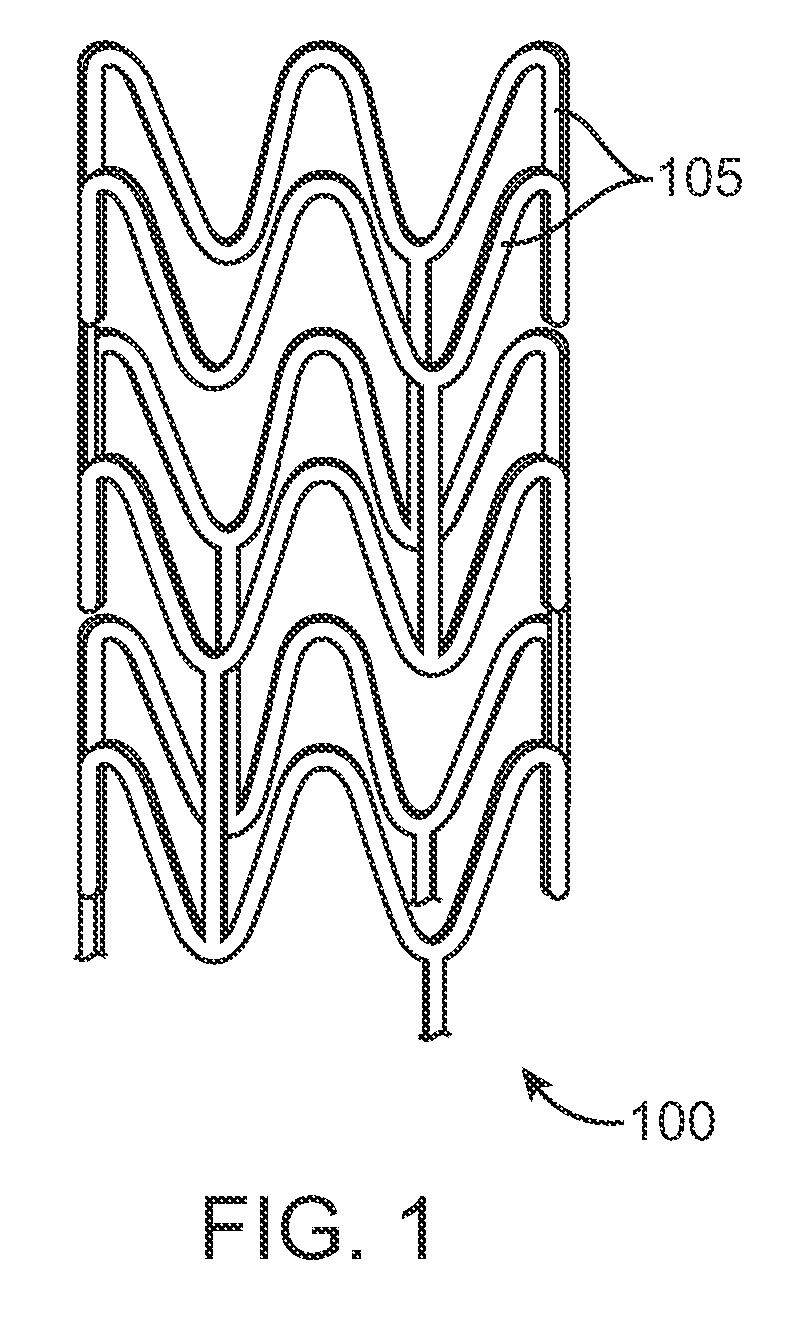

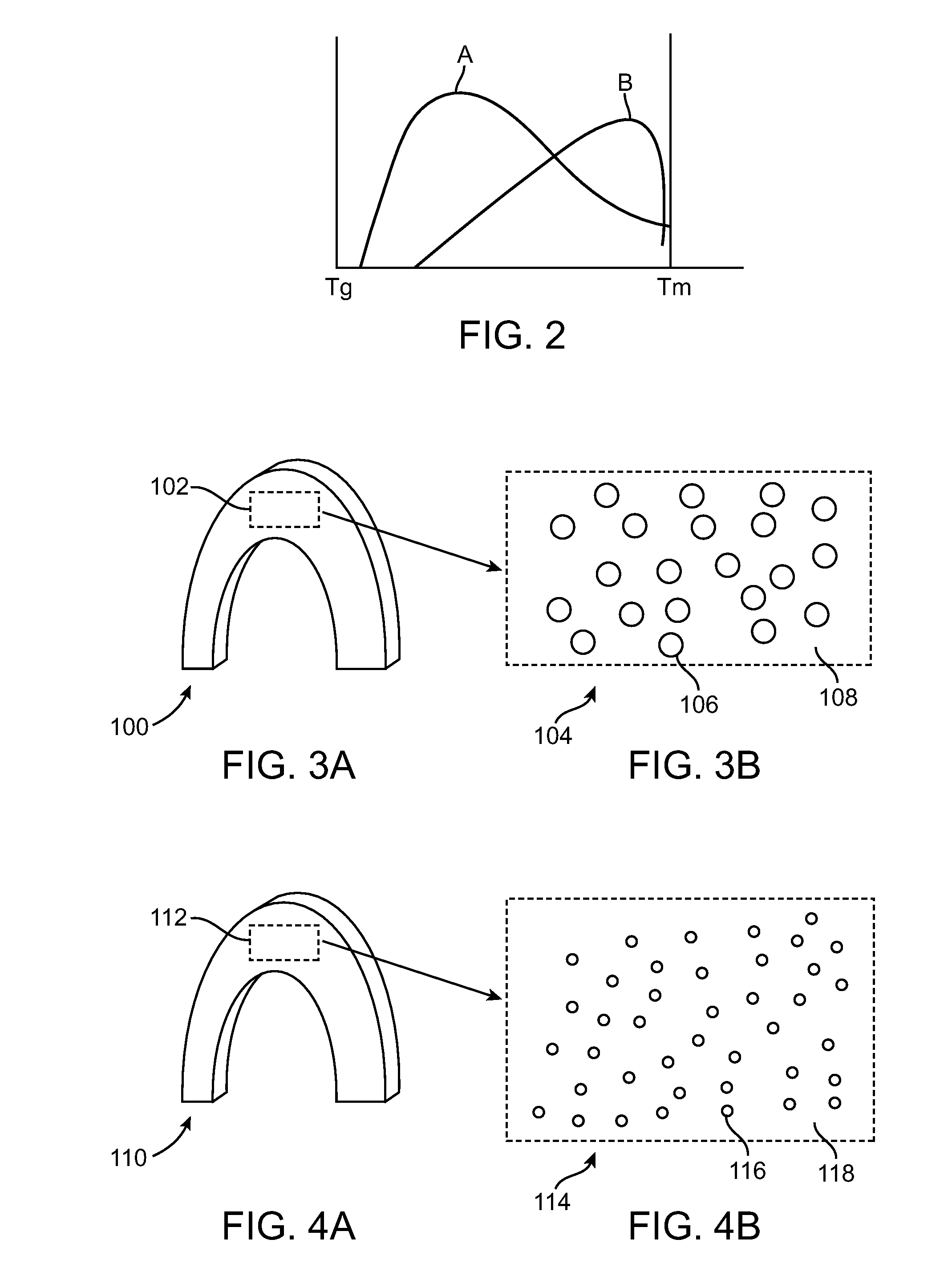

Fracture Toughness Of Medical Devices With A Stereocomplex Nucleating Agent

Methods of fabricating a polymeric implantable device from a PLLA / PDLA blend such as a stent with improved fracture toughness are disclosed. The blend is melt processed to allow formation of stereocomplex crystallites, which are nucleation sites for crystal growth. A polymer construct is formed from the melt processed blend and device is formed from the polymer construct. The stereocomplex crystallites result in an in increase in nucleation density and reduced crystal size, which increases fracture toughness of the formed device.

Owner:ABBOTT CARDIOVASCULAR

Method for slight fracture supporting, capable of increasing fracture stabilization period

ActiveCN107503729AImprove support efficiencyImprove fracturing effectFluid removalViscous fingeringStructure of the Earth

The invention discloses a method for slight fracture supporting, capable of increasing a fracture stabilization period. The method comprises the steps of (1) evaluation of a microstructure of reservoir rocks, (2) a first-stage injection phase, and (3) second-stage and third-stage injection phases. During the second step, (1) an ultralow-viscosity fracture solution carrying a micro-particle-diameter supporting agent is injected to communicate and extend natural fracture systems with micro scales, a low-viscosity fracture solution carrying a small-particle-diameter supporting agent is injected to communicate and extend natural fracture systems with large scales; a middle-viscosity fracture solution carrying a middle-particle-diameter supporting agent is injected to extend fracture systems with large scales; and (4) a high-viscosity fracture solution carrying a large-particle-diameter supporting agent is injected to extend fracture systems with the maximum scale. According to the invention, through fine evaluation of the microstructure of the reservoir rocks, alternate multi-stage injection, utilization of viscous fingering effects of various liquids with different viscosities, multi-scale sand adding and other methods, the fracture systems with the different scales within a full seam length scope of a main fracture can be fully expanded, extended and supported; and a "valid reshaping volume" of fractures and "supporting efficiency" of cracks are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

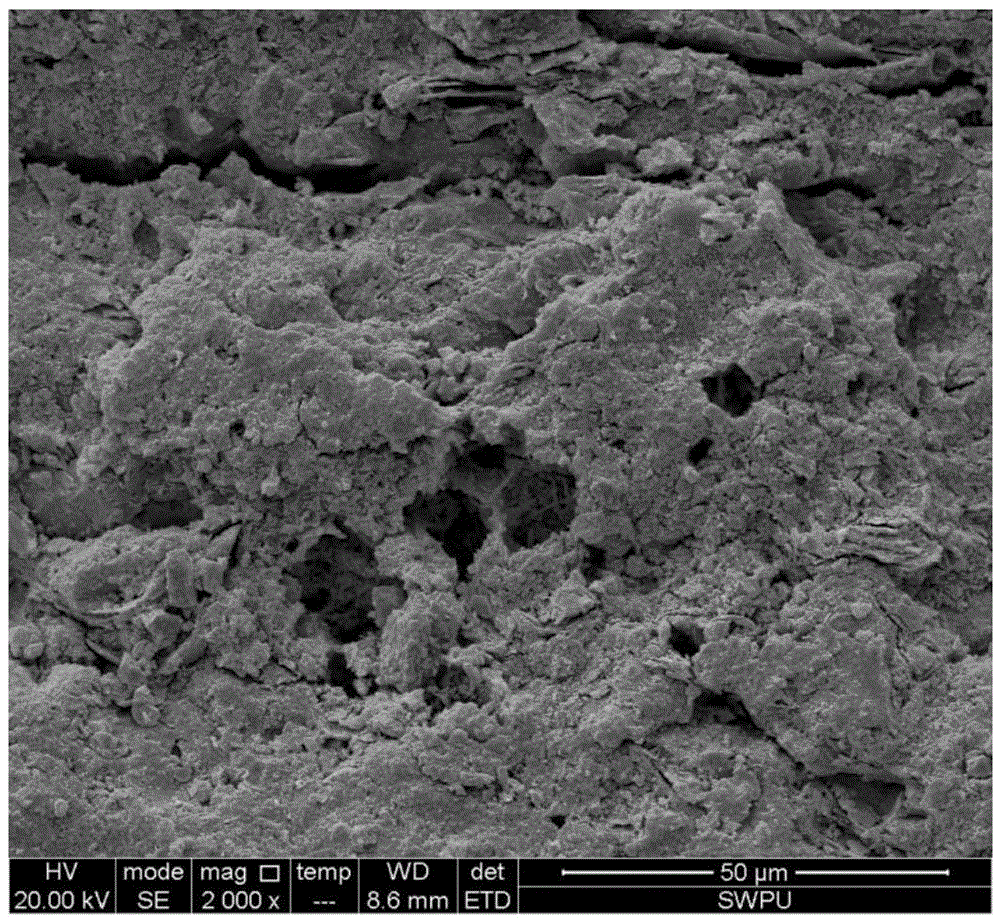

Method of increasing fracture network density for shale gas well fracturing improvement

Owner:SOUTHWEST PETROLEUM UNIV

Process for preparing polycarbonate/styrene-acrylonitrile copolymer alloy

InactiveCN1962759AImprove mechanical propertiesEasy to processManufacturing technologyPolymer science

The invention discloses a preparing method of PC / SAN alloy, which is characterized by the following: making segmented copolymer of hydrogenated butadiene rubber without double bond and phenylethene or segmented copolymer of hydrogenated polyisoprene and phenylethene directly with polycarbonate, phenylethene-acrylon copolymer and anti-oxidant in the double-screw squeezer to prepare the product; simplifying the manufacturing technology with good mechanic and manufacturing property; improving alloy phase rate of PC / ABS; increasing fracture growing rate by 300%.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for increasing fracture area

ActiveUS9140109B2Convenient treatmentIncrease the lengthFluid removalShortest distanceReservoir volume

A technique enables improvements in hydraulic fracturing treatments on heterogeneous reservoirs. Based on data obtained for a given reservoir, a fracturing treatment material is used to create complex fractures, which, while interacting with the interfaces and planes of weakness in the reservoir, develop fracture connectors, e.g. step-overs, which often grow for short distances along these planes of weakness. The technique further comprises closing or sealing at least one of the fracture connectors to enable reinitiation of fracturing from the truncated branches, and to subsequently develop additional connectors. As a result, the overall fracturing becomes more complex (more branches and more surface area per unit reservoir volume is created), which leads to an increase in the effective fracture area and improved fluid flow through the reservoir.

Owner:SCHLUMBERGER TECH CORP

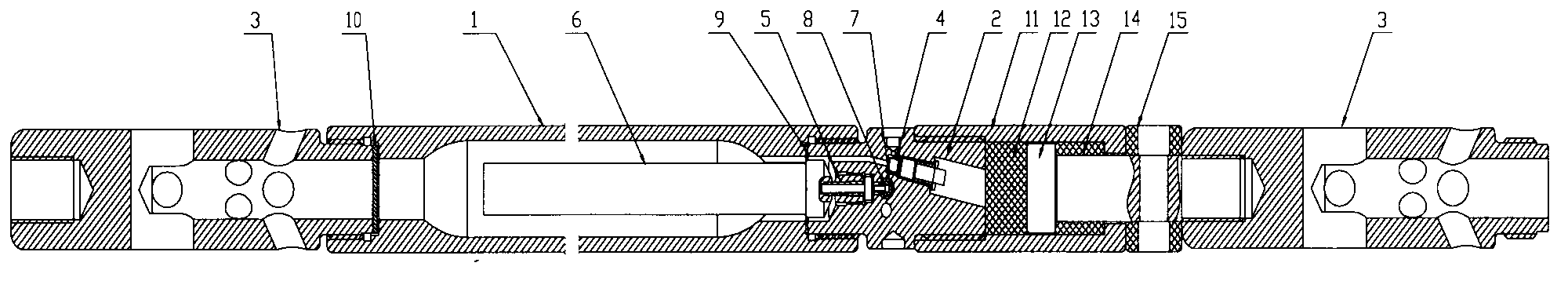

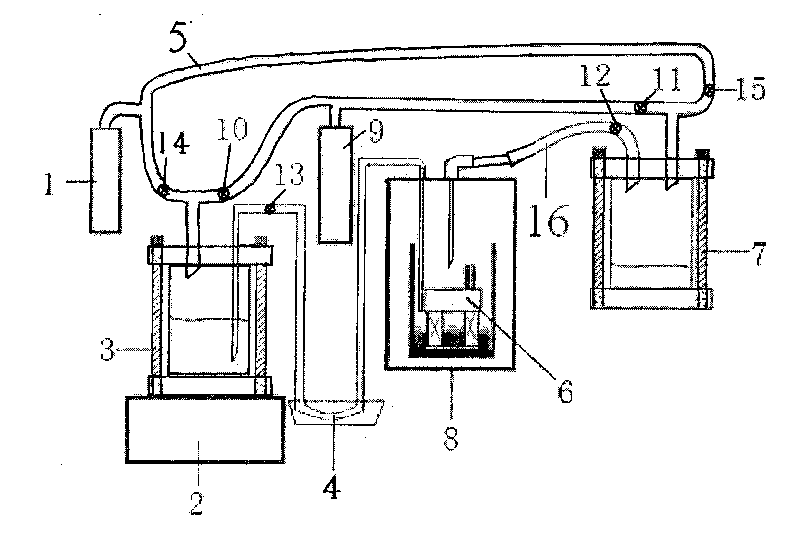

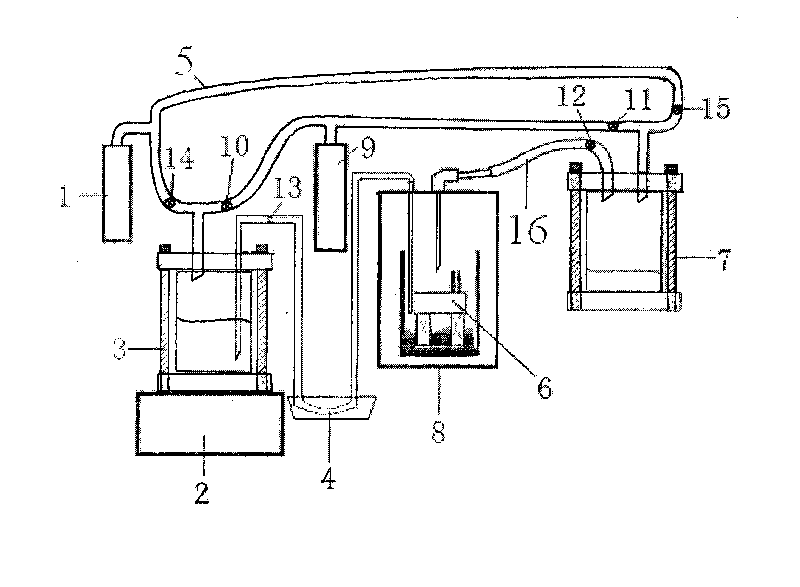

Gaseous phase fracturing device

The invention provides a gaseous phase fracturing device. The device can be used for regulating pressure and blasting speed, and comprises a buffer, a snifting valve, a supercharging device, an inflation valve, a fracturing pipe, a sealing ring and a shear plate, wherein the inflation valve and the snifting valve are connected to two end parts of the fracturing pipe through seal threads; the inflation valve comprises a valve and an electrode, the valve is opened and closed to realize the filling of the gaseous phase fracturing device, the electrode is connected with a main hole, and high pressure sealing is realized through the threads and a sealing gasket; meanwhile, a high-performance insulating material and the inflation valve are insulated from each other. The gaseous phase fracturing device is used for fracturing a pre-mining coal bed, increasing fractures of the coal bed and driving gas adsorbed by the coal bed, so that the gas is convenient to extract and the coal and gas outburst risk is eliminated. During use, open fire is avoided, and open fire explosion generated by the traditional detonator and dynamite blast is avoided. The device has the characteristics of safety, high efficiency, simple management and the like.

Owner:HENAN SHENHUA ENERGY ENG

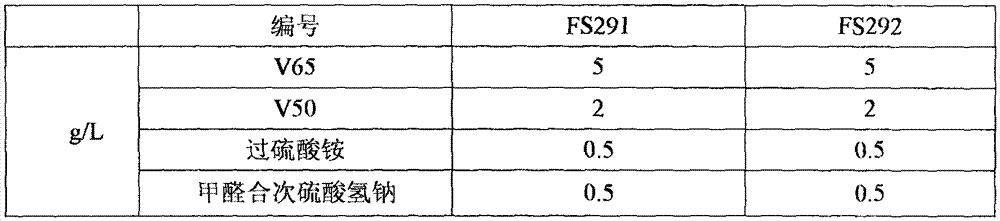

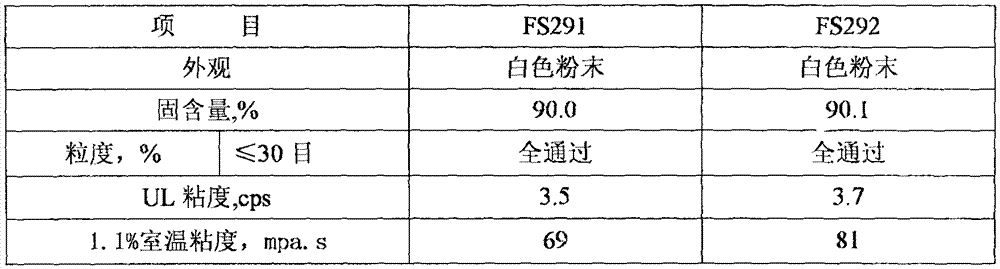

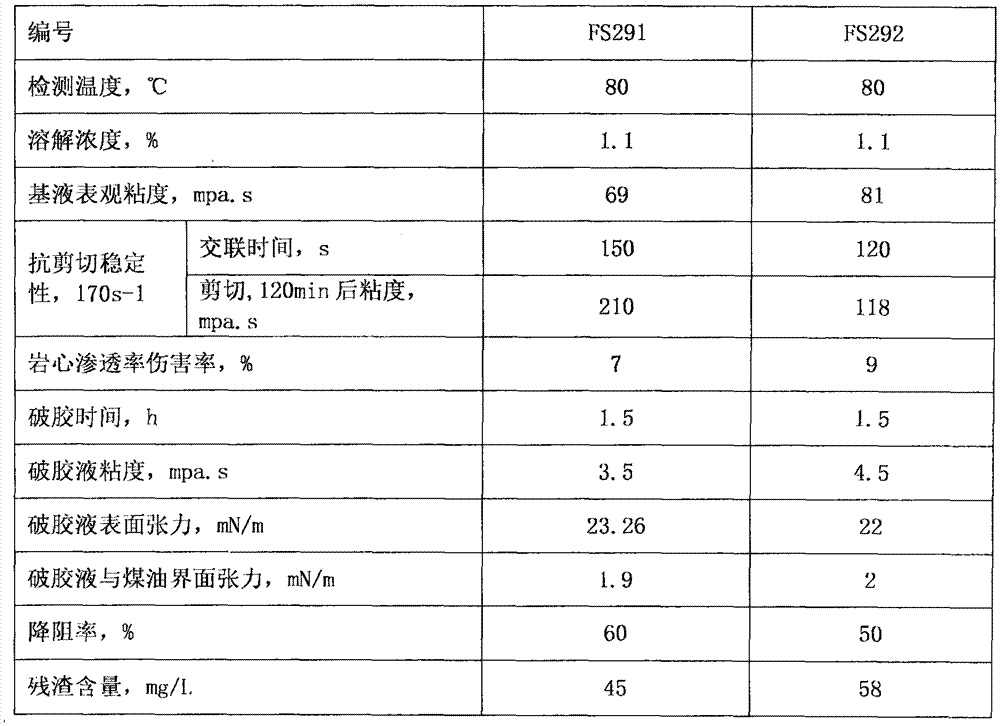

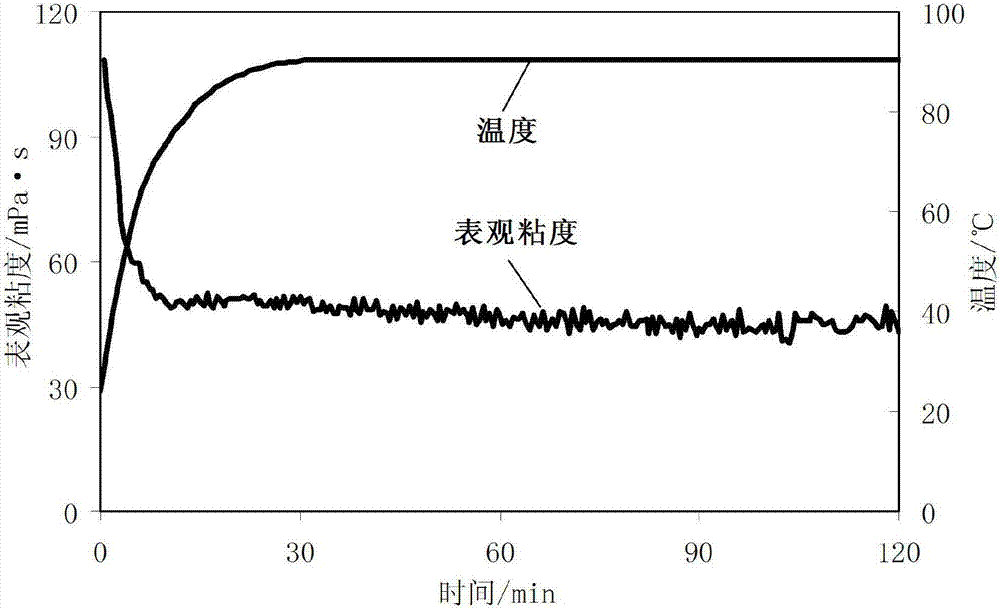

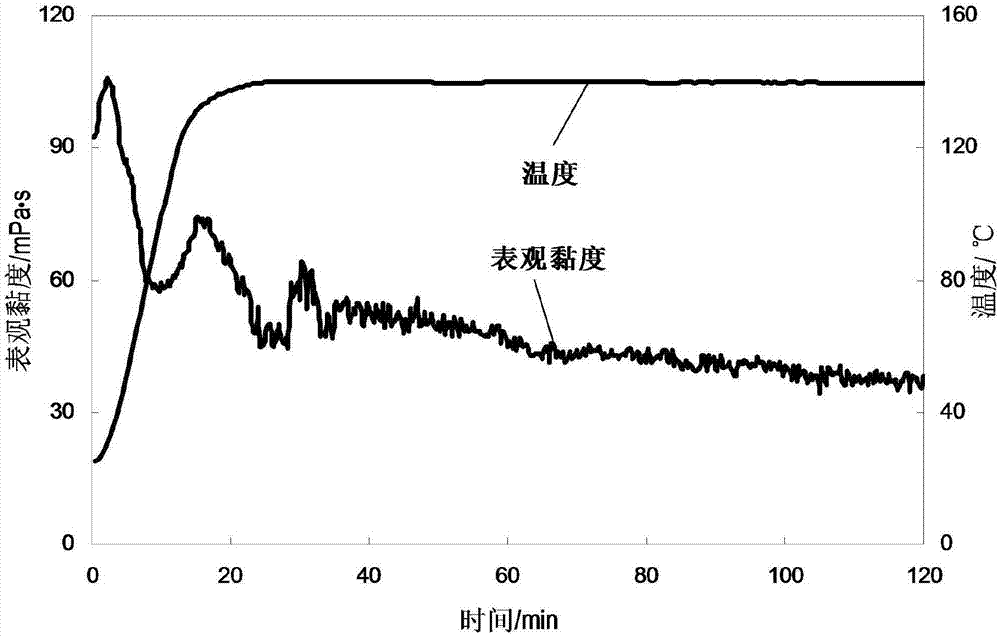

Polymer thickener for high-temperature-resistant water-based fracturing fluid and production method for polymer thickener

The present invention relates to a polymer thickener for a high-temperature-resistant water-based fracturing fluid and a production method for the polymer thickener. The thickener for the water-based fracturing fluid is a low molecular polymer which is good in temperature resistance, shear resistance and sand carrying performance in a hyperbranched structure and is used for a production-increasing fracturing operation in an oil field. The thickener is copolymerized by six monomers: acrylamide (AM), acrylic acid (AA), dimethyl diallyl ammonium chloride (DMDAAC), N,N'-methylenebisacrylamide (MBA), sodium p-styrenesulfonate (PSNN) and allyl polyoxyethylene ether (APEG). A production method for the thickener uses a thermal decomposition-type and redox-type initiator, so that the monomers are polymerized. The thickener provided by the present invention has the advantages of small amount of residues, low usage viscosity, good proppant carrying capacity, low cost and easy flow back and the like.

Owner:DOWNHOLE OPERATION CO OF CNPC WESTERN DRILLING ENG CO LTD +1

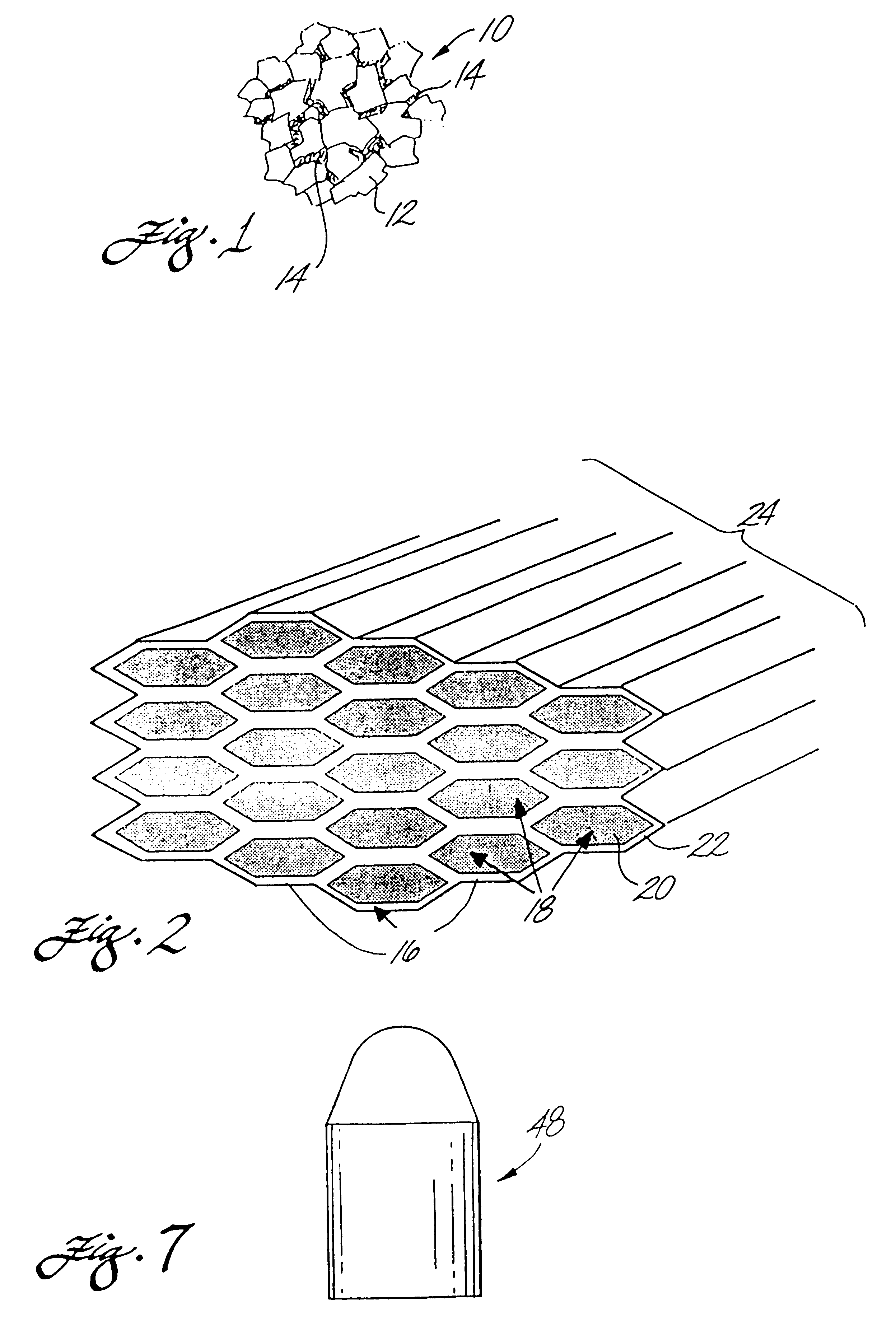

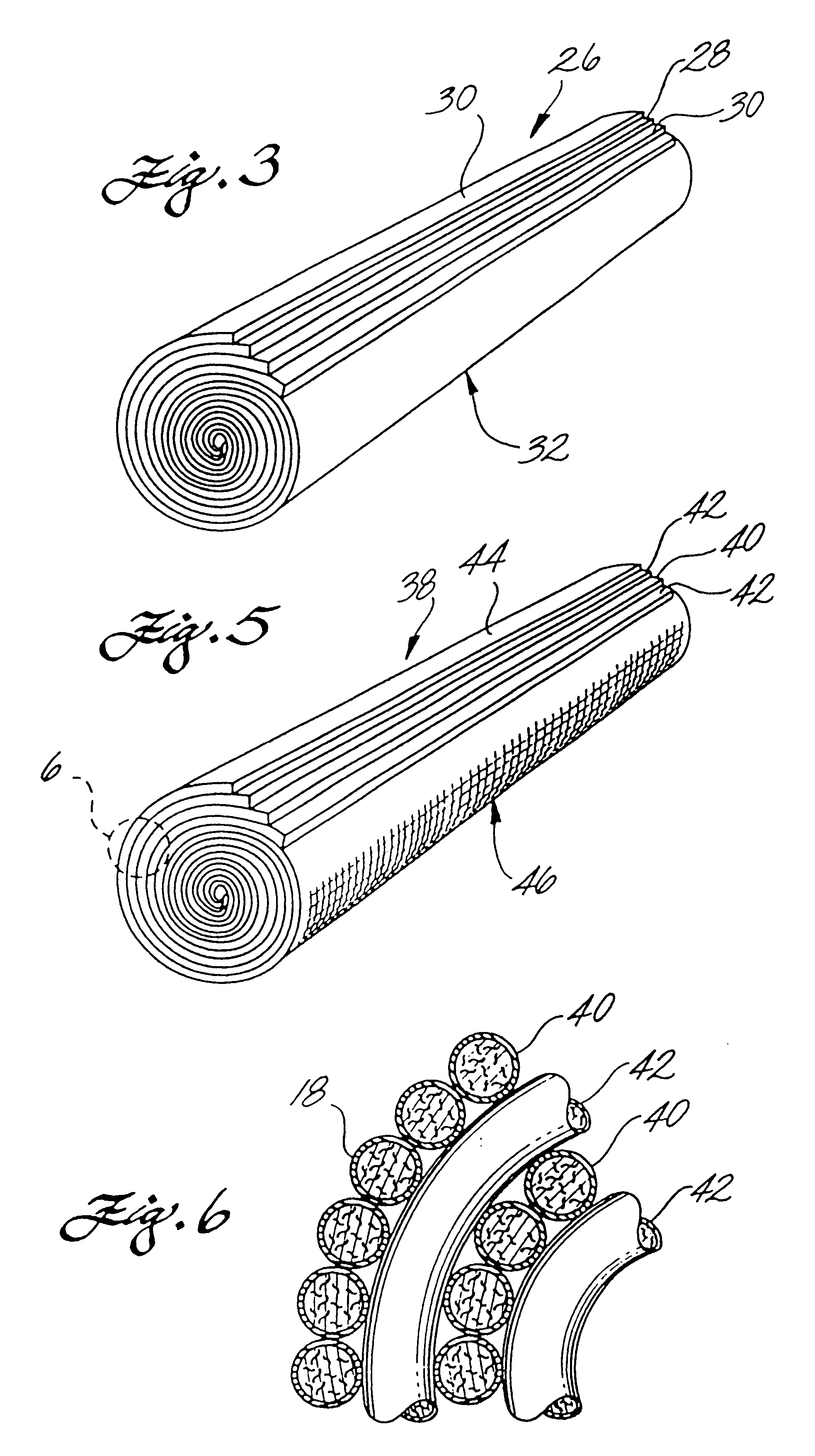

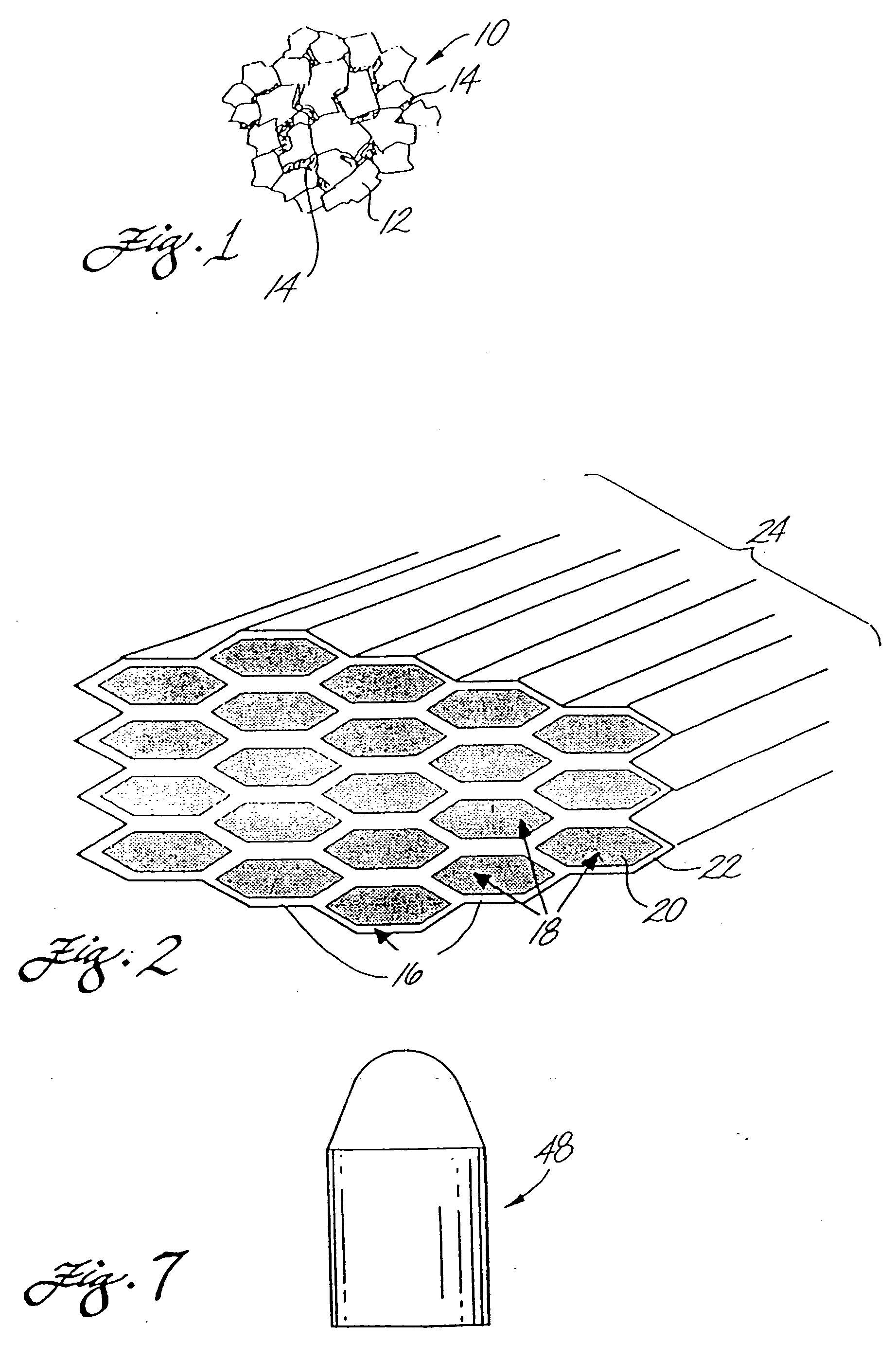

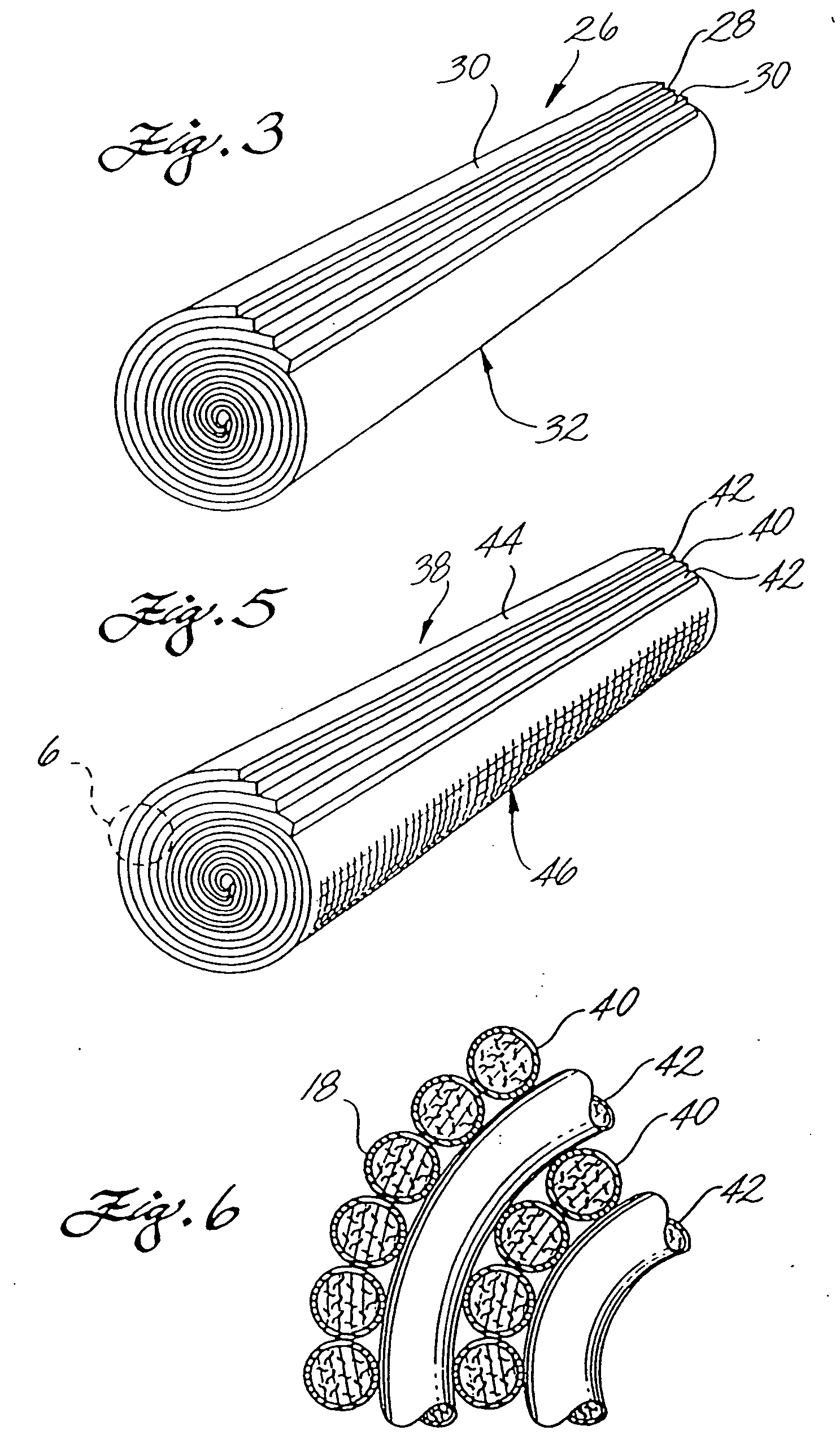

Composite constructions with oriented microstructure

InactiveUS6841260B2Improve propertiesImproved propertyDrill bitsConstructionsFiber bundleFibrous composites

In one embodiment, composite constructions of the invention are in the form of a plurality of coated fibers bundled together to produce a fibrous composite construction in the form of a rod. Each fiber has a core formed from a hard phase material, that is surrounded by a shell formed from a binder phase material. In another embodiment of the invention, monolithic sheets of the hard phase material and the binder phase material are stacked and arranged to produce a swirled composite in the form of a rod. In still another embodiment of the invention, sheets formed from coated fibers are arranged to produce a swirled composite. Inserts for use in such drilling applications as roller cone rock bits and percussion hammer bits, and shear cutters for use in such drilling applications as drag bits, that are manufactured using conventional methods from these composite constructions exhibit increased fracture toughness due to the continuous binder phase around the hard phase of the composites. These binder phases increase the overall fracture toughness of the composite by blunting or deflecting the tip of a propagating crack.

Owner:SMITH INT INC

Method for increasing fracturing volume in tight sandstone reservoir

ActiveCN110761762AIncrease in sizeImprove seepage capacityFluid removalMicro fractureHydraulic fracturing

The invention discloses a method for increasing the fracturing volume in a tight sandstone reservoir. The method includes the steps that (1) micro-fractures are formed in the tight sandstone reservoir; step (2) the micro-fractures are expanded and communicated; step (3) hydraulic fracturing is performed to form main fractures; and step (4) a proppant is turned from temporary blocking to form branch fractures. The method is suitable for fracturing transformation production increase operation of the tight sandstone reservoir with micro-fractures not developed. Through innovative process ideas, first, a large number of radial micro-fractures are artificially generated in a sandstone reservoir with the micro-fractures not developed and a dense matrix, then the main fractures penetrating through the micro-fractures are formed through hydraulic fracturing, and in the extension process, the main fractures are turned for multiple times, so that a complex fracture system is formed, and the fracturing transformation volume is increased and the production increase effect is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rubber combination for heavy-load tire tread and heavy-load inflating tyre employing combination on the tire tread

InactiveCN101113212AImprove fracture propertiesImprove chip resistanceSpecial tyresTyre tread bands/patternsOrganic acidCobalt salt

The invention aims at providing a rubber composition used on a face of a heavy load tyre with increased fracture physical properties and improved chipping resistance during the whole moving period from an initial stage to a long term period. The invention solves the problem by providing the rubber composition, namely the rubber composition used on the face of the heavy load tyre, and is characterized in that the invention comprises substances which are: (by weight) 100 portions of rubber that can be vulcanized and natural rubber and / or compound polyisoprene rubber is taken as the main part, 30-80 portions of carbon black and / or silicon dioxide with nitrogen adsorption specific surface area of over 70m2 / g and less than 1.0 proportion of organic acid cobalt salt that is counted basing on cobalt element.

Owner:YOKOHAMA RUBBER CO LTD

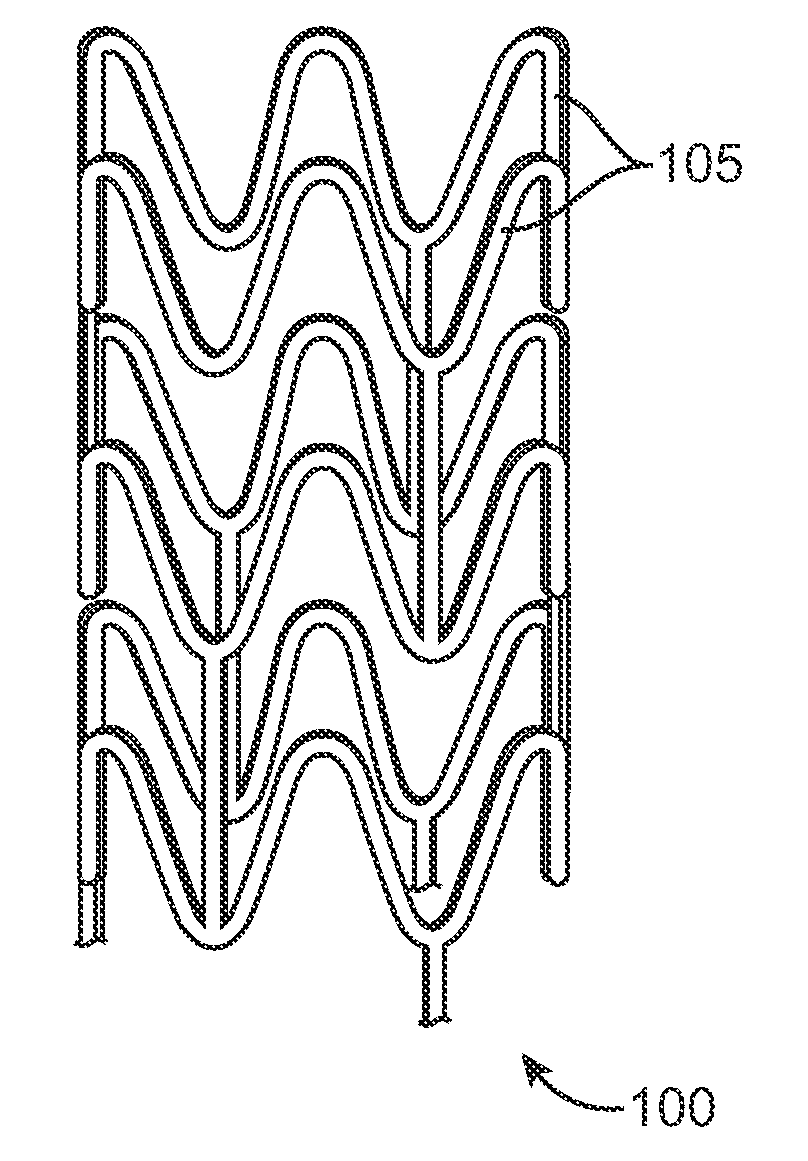

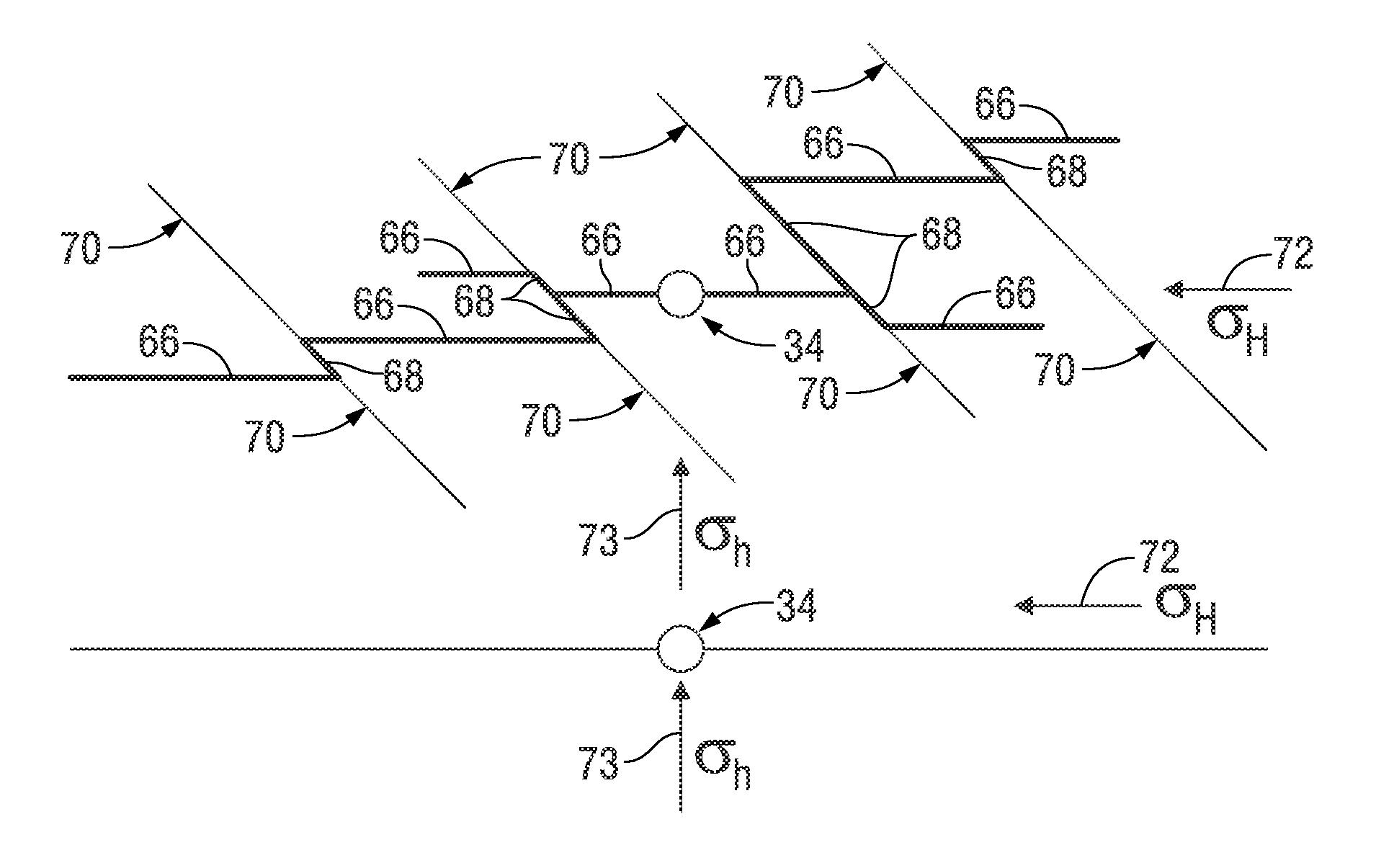

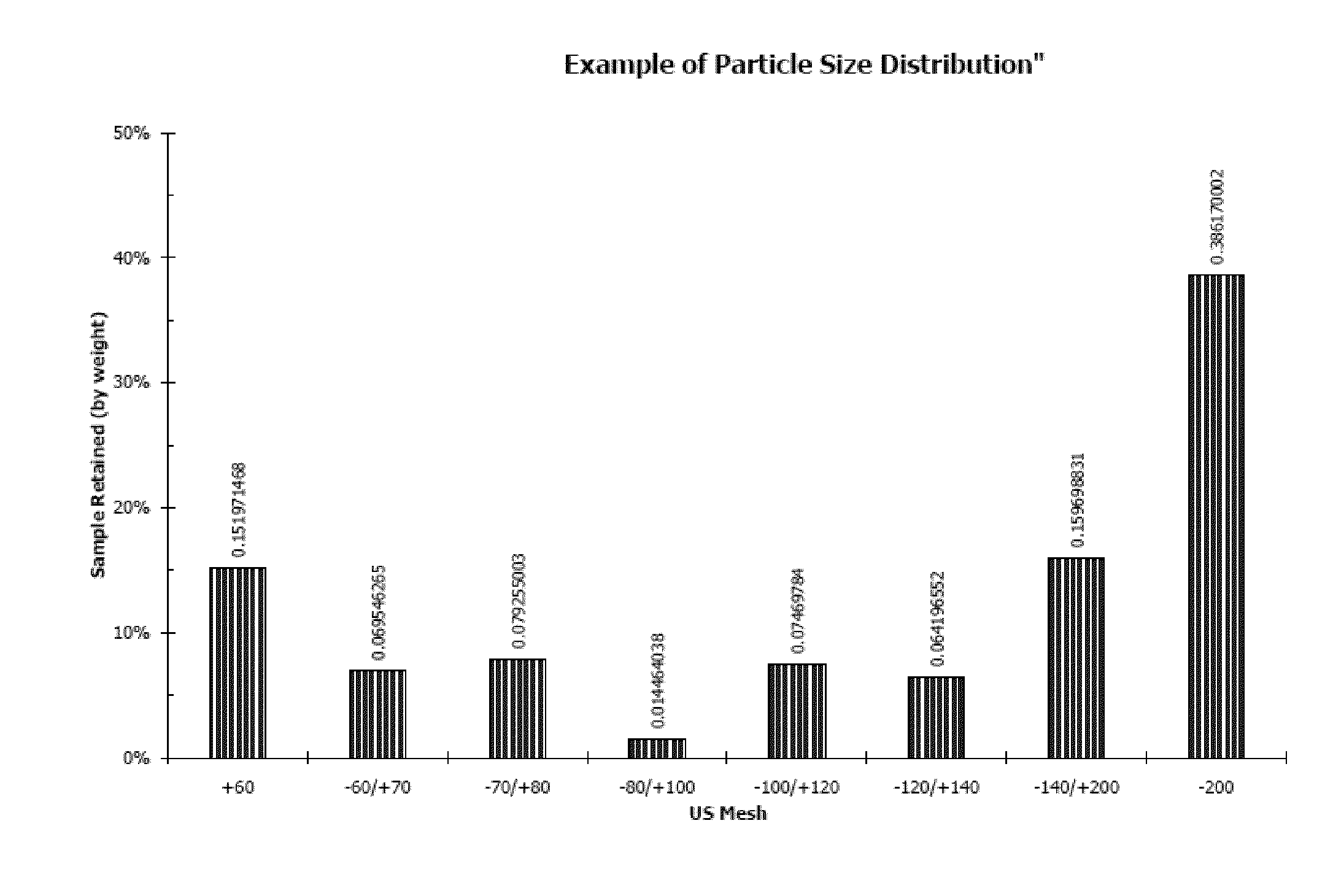

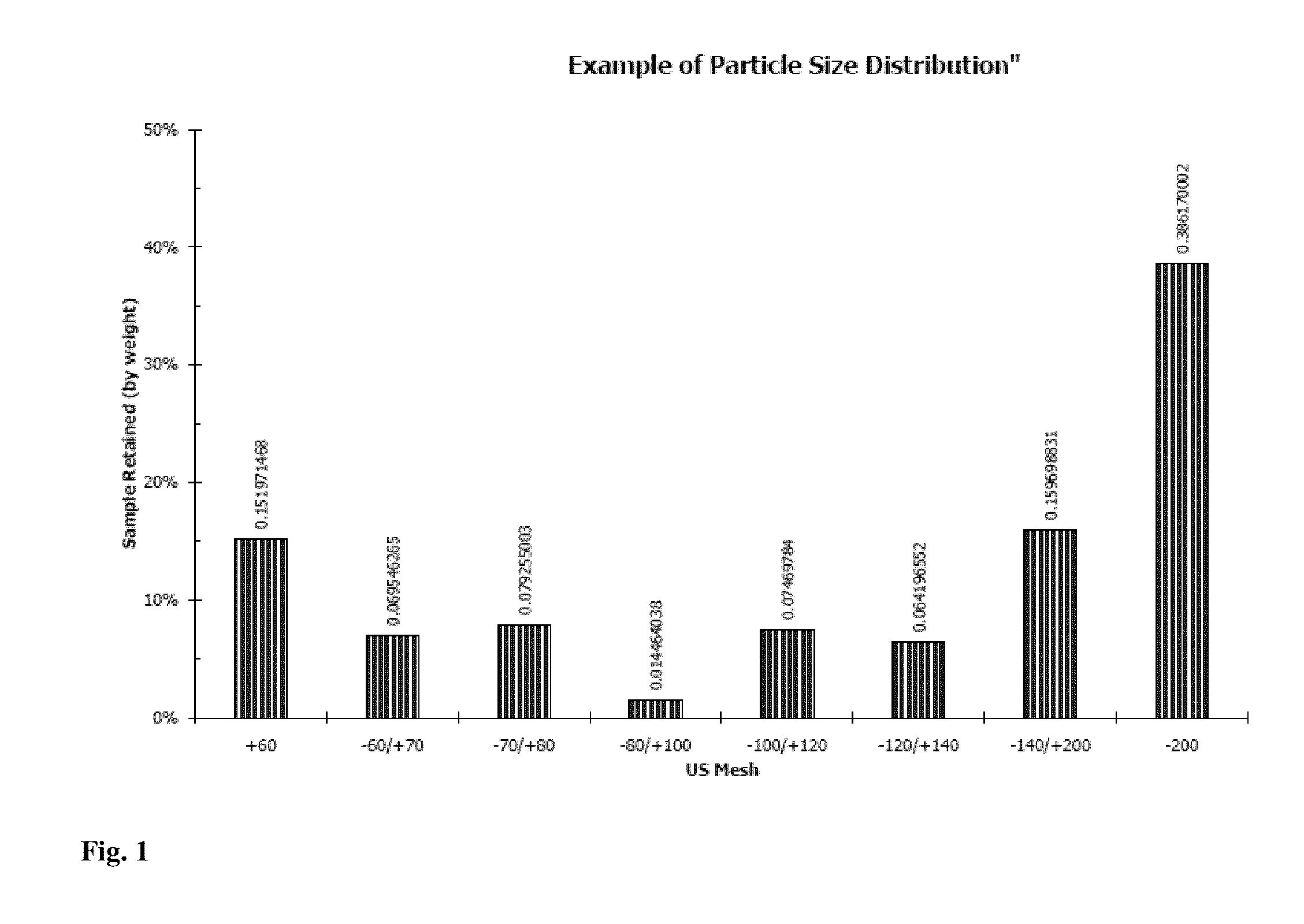

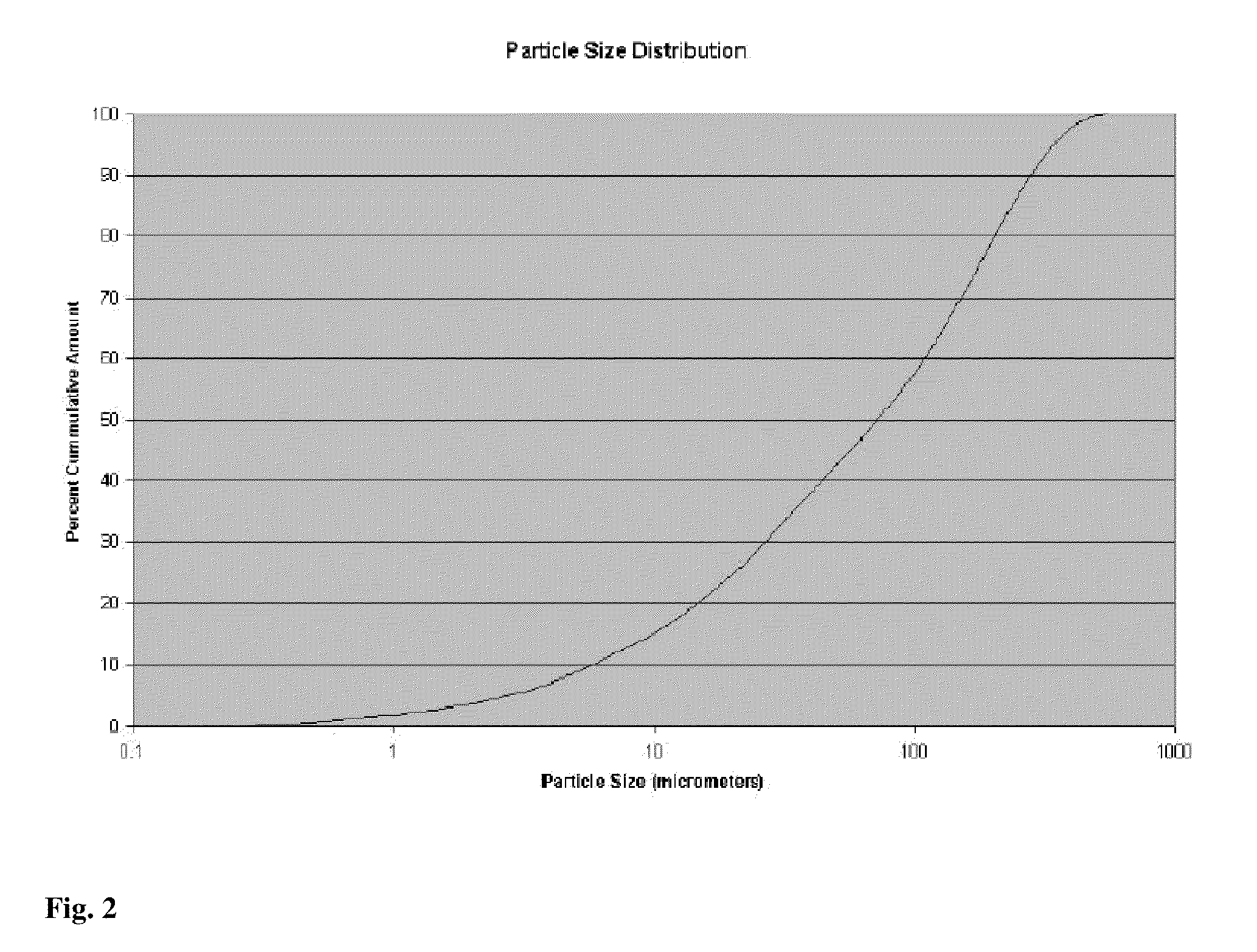

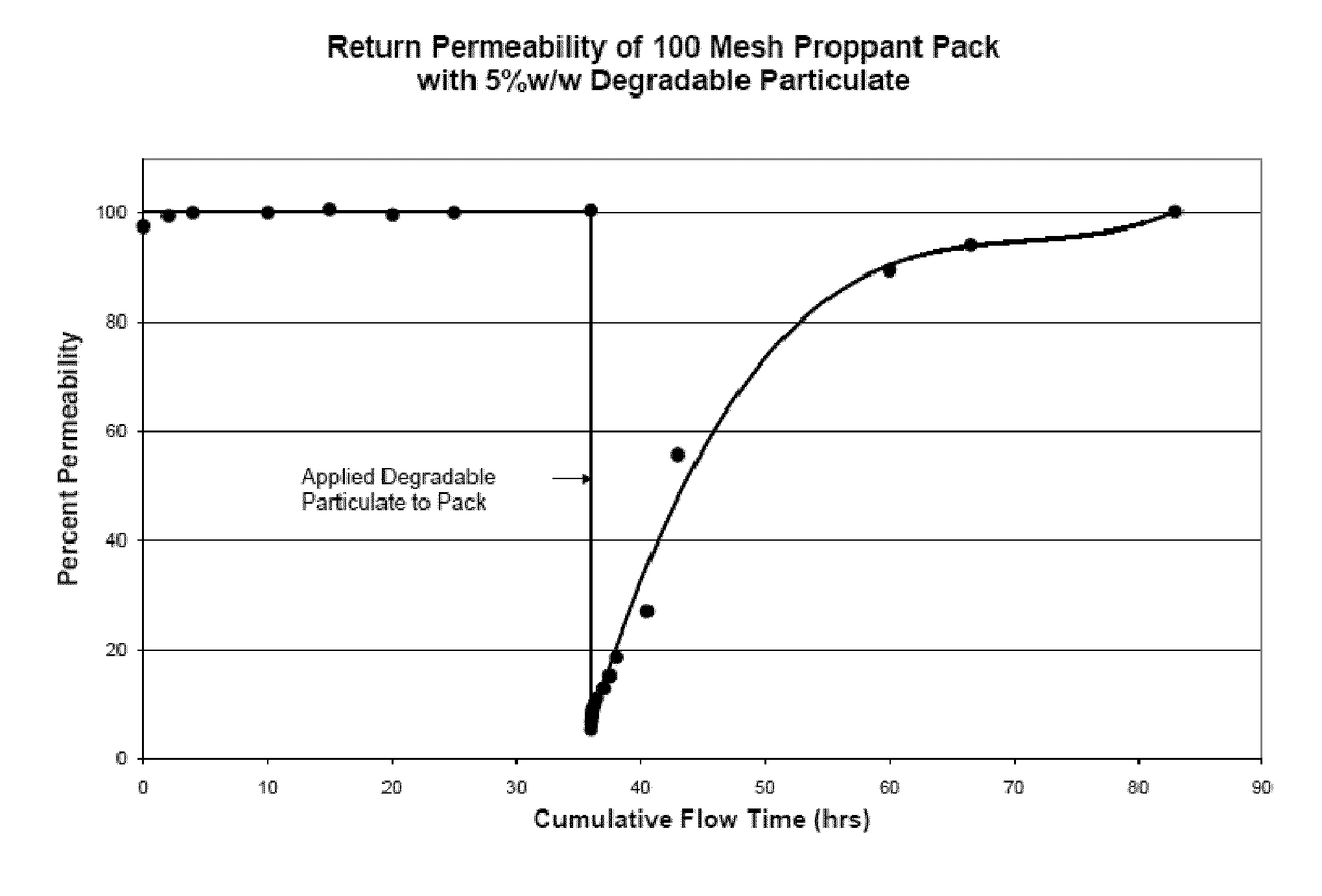

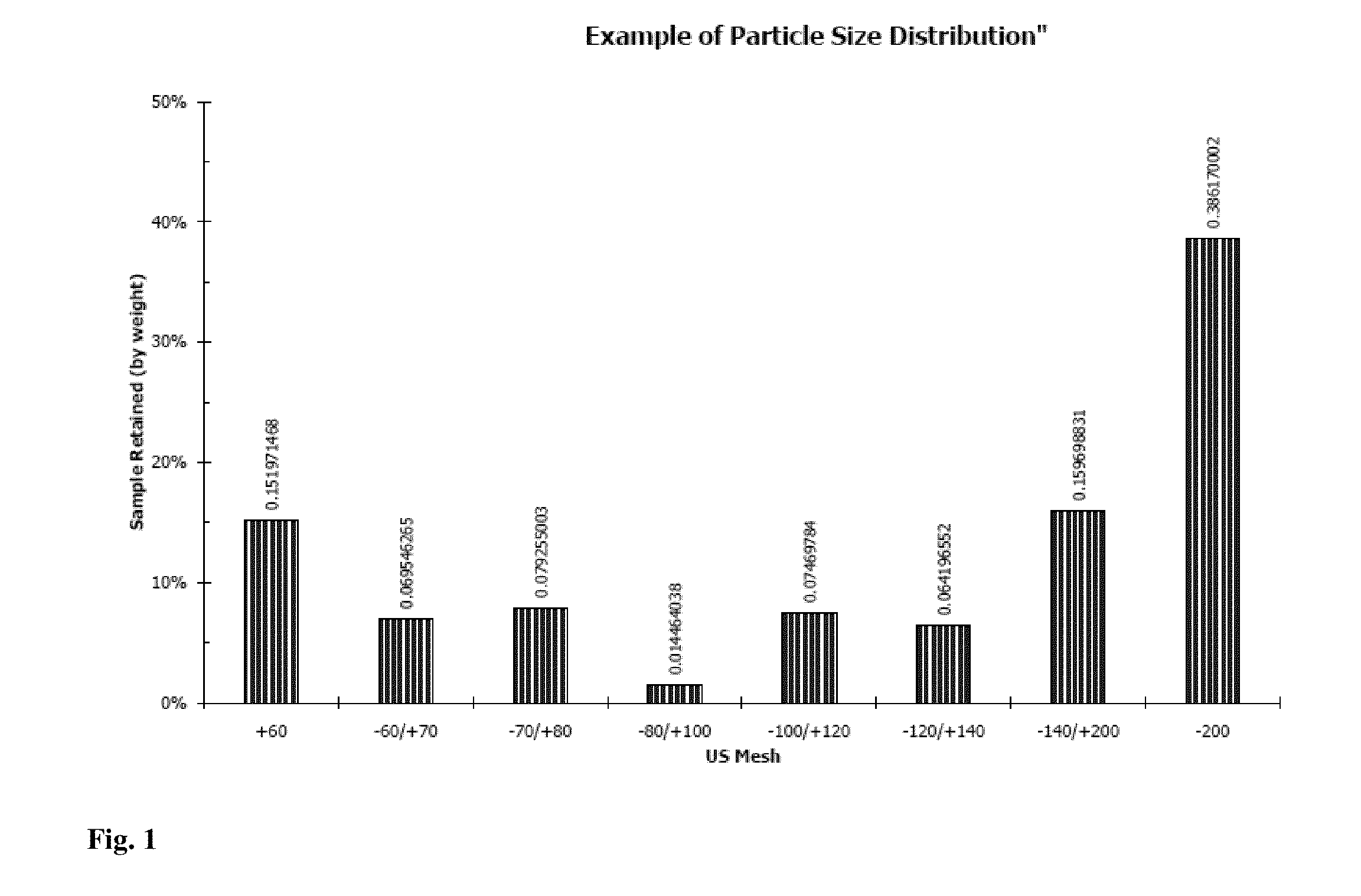

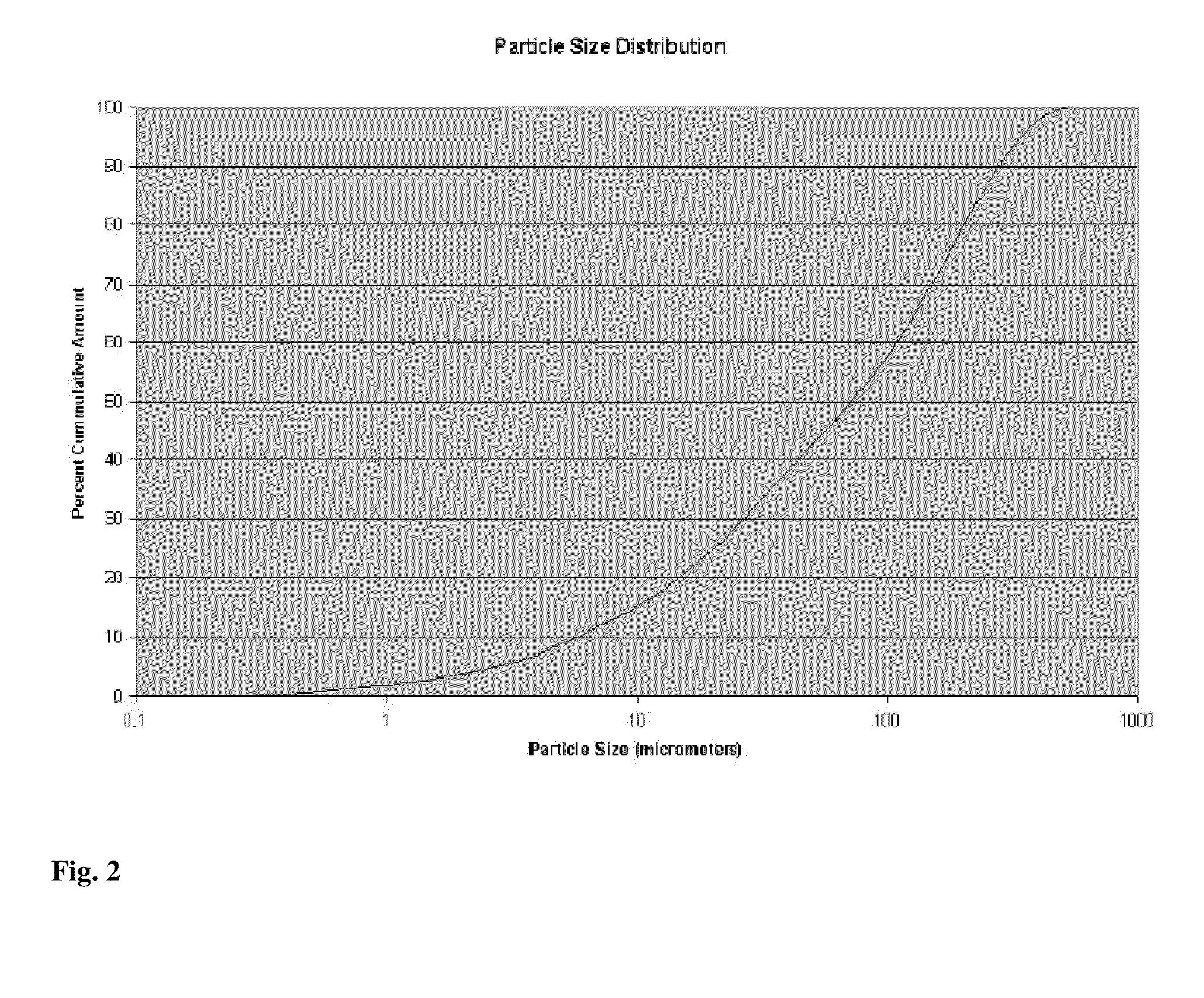

Increasing fracture complexity in ultra-low permeable subterranean formation using degradable particulate

A method of increasing the fracture complexity in a treatment zone of a subterranean formation is provided. The subterranean formation is characterized by having a matrix permeability less than 1.0 microDarcy. The method includes the step of pumping one or more fracturing fluids into a far-field region of a treatment zone of the subterranean formation at a rate and pressure above the fracture pressure of the treatment zone. A first fracturing fluid of the one or more fracturing fluids includes a first solid particulate, wherein: (a) the first solid particulate includes a particle size distribution for bridging the pore throats of a proppant pack previously formed or to be formed in the treatment zone; and (b) the first solid particulate comprises a degradable material. In an embodiment, the first solid particulate is in an insufficient amount in the first fracturing fluid to increase the packed volume fraction of any region of the proppant pack to greater than 73%. Similar methods using stepwise fracturing fluids and remedial fracturing treatments are provided.

Owner:HALLIBURTON ENERGY SERVICES INC

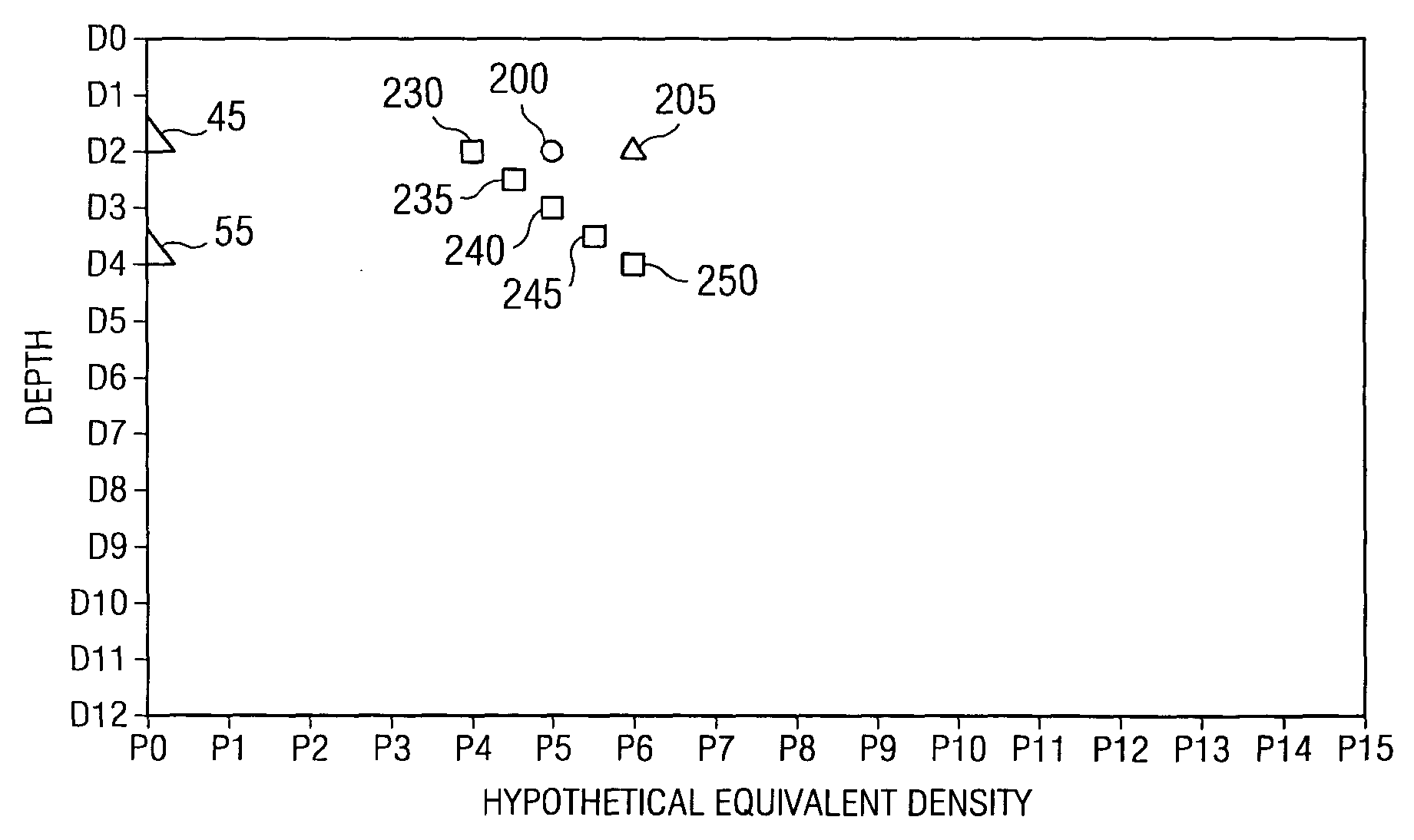

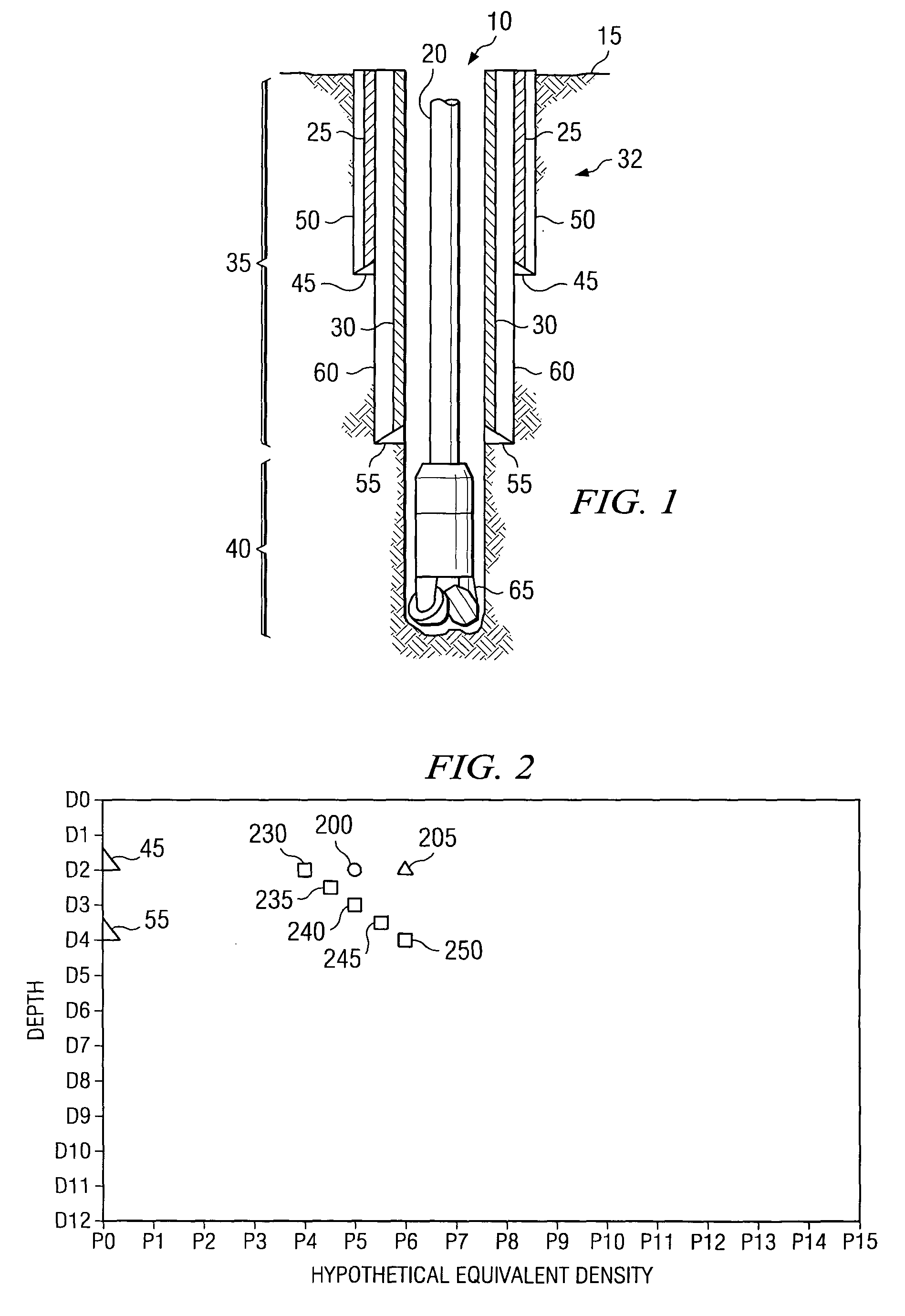

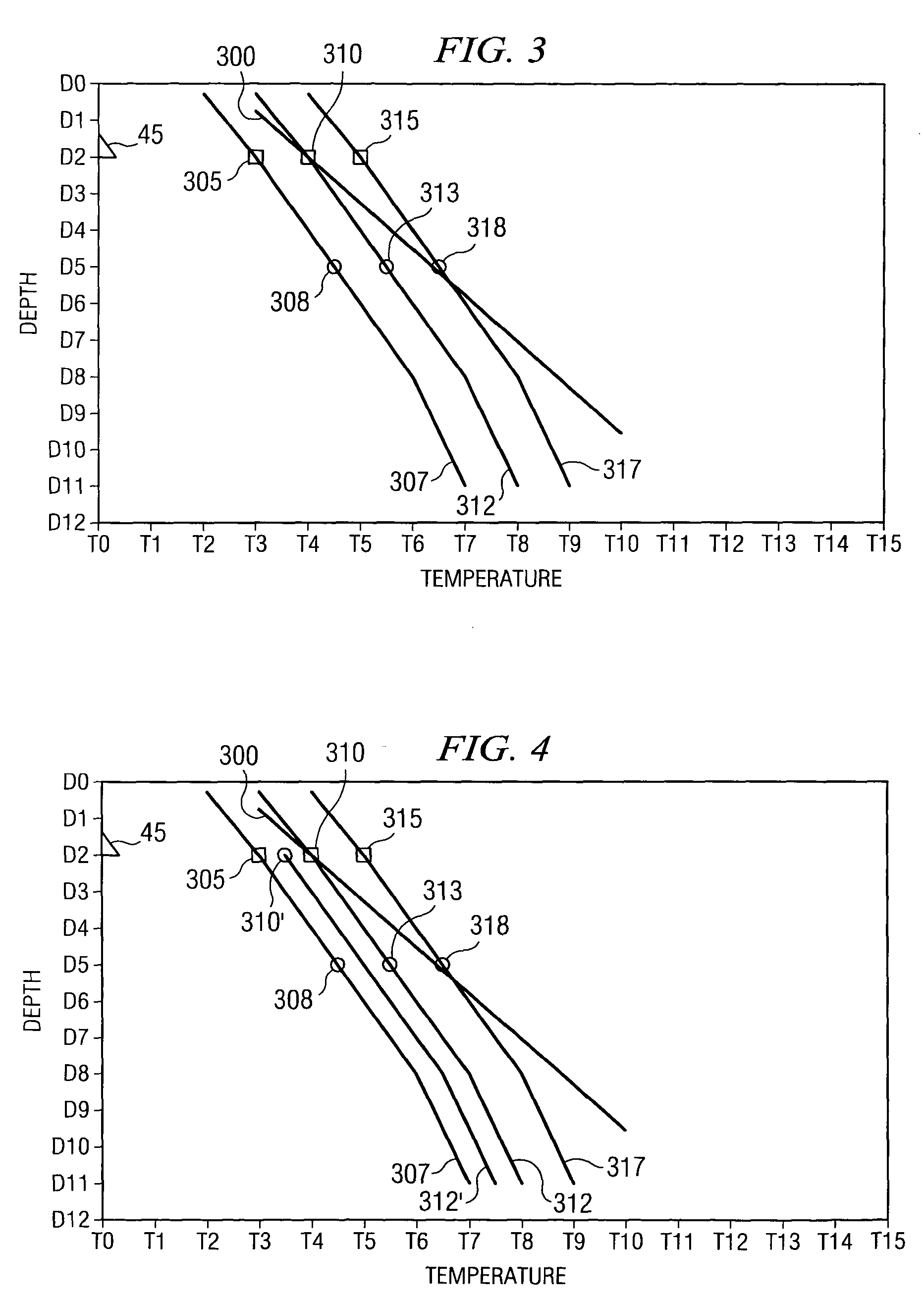

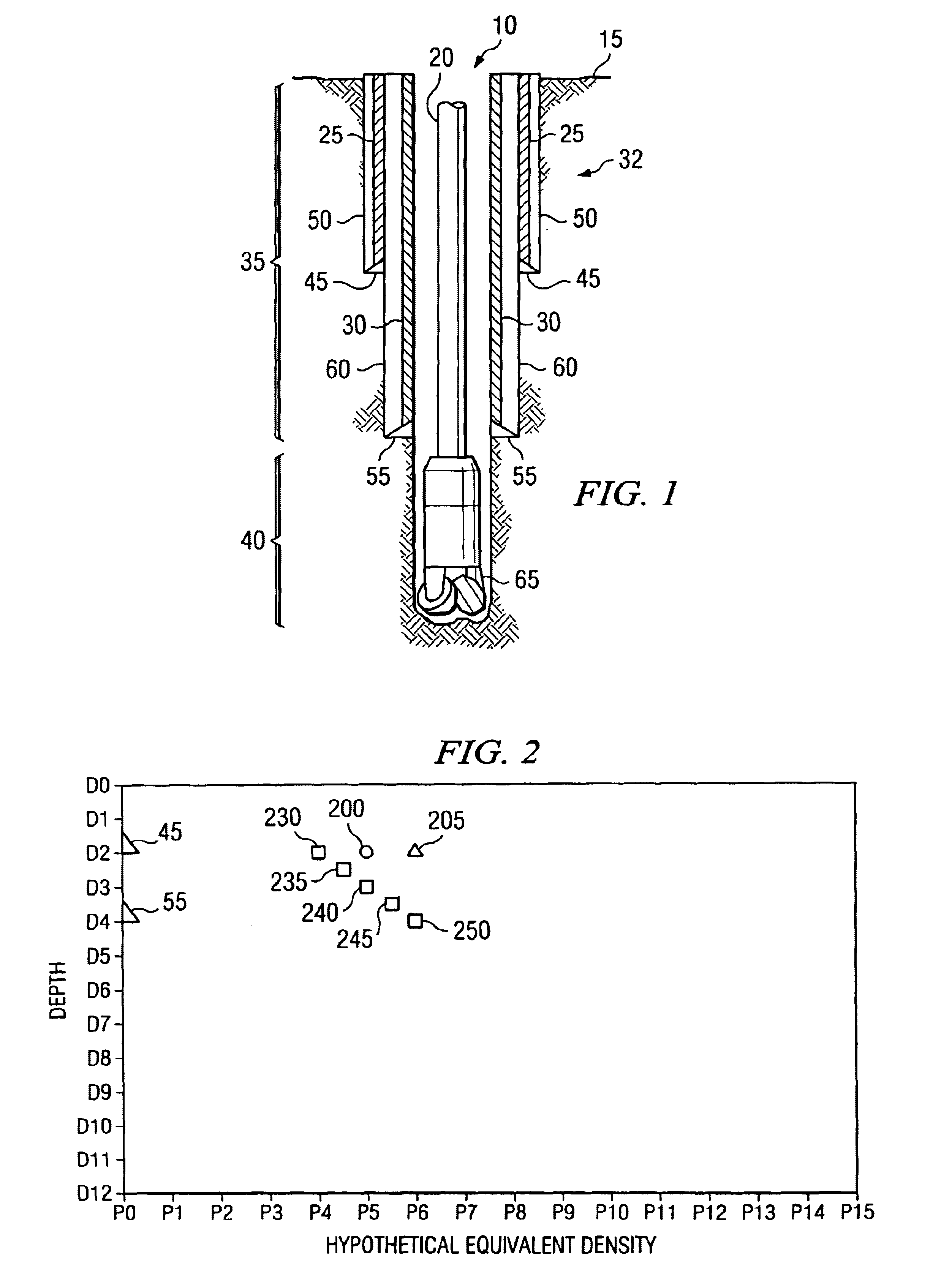

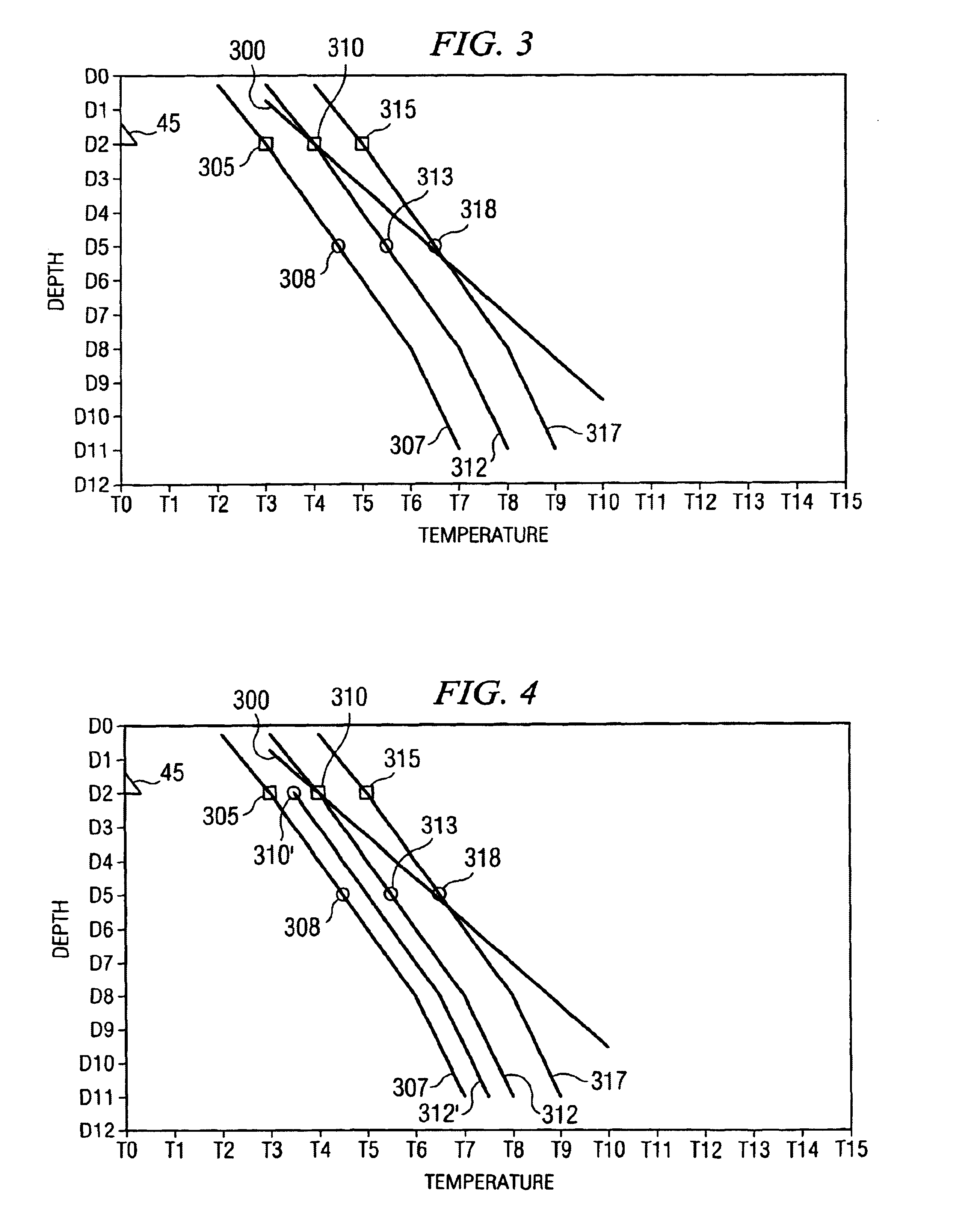

Using fluids at elevated temperatures to increase fracture gradients

ActiveUS20050034898A1Reduce the overall diameterIncreasing fracture gradientSurveyConstructionsCasing stringWellbore

A method for drilling a wellbore in a formation using a drilling fluid, wherein the drilling fluid has a first temperature, and wherein the wellbore has a first wellbore depth. In one embodiment, the method comprises determining at least one fracture gradient, wherein the fracture gradient is determined at about the first wellbore depth; increasing the temperature of the drilling fluid from the first temperature to a desired temperature at about the first wellbore depth; drilling into the formation at increasing wellbore depths below the first wellbore depth, wherein at least one equivalent circulating density of the drilling fluid is determined at about the first wellbore depth; and setting a casing string at a depth at which the equivalent circulating density is about equal to or within a desired range of the fracture gradient. In other embodiments, an automated system is used to maintain the temperature of the drilling fluid at about first wellbore depth.

Owner:HALLIBURTON ENERGY SERVICES INC

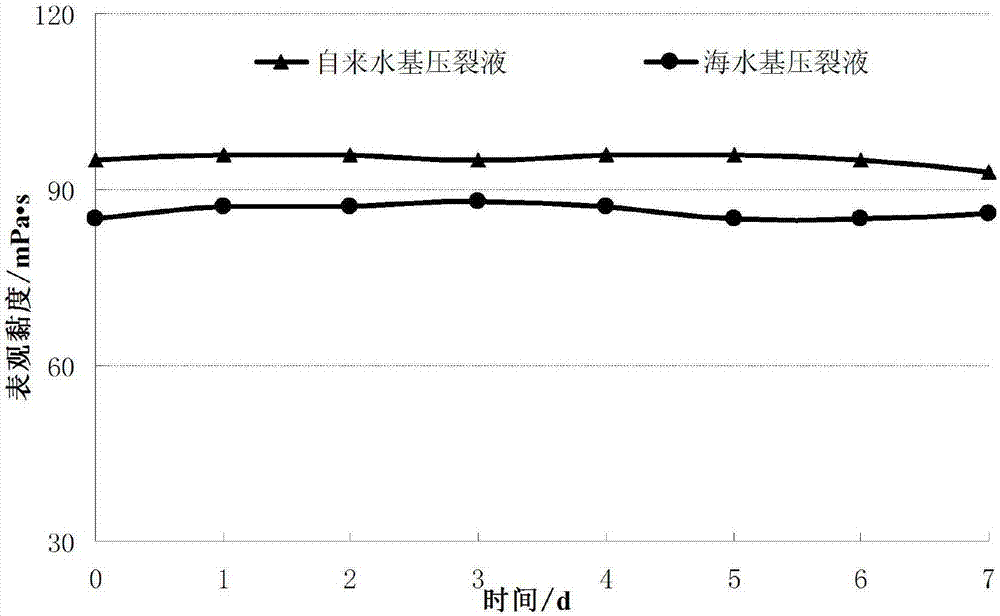

A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof

ActiveCN107474816AFast dissolutionImprove solubilityDrilling compositionPolymer scienceFracturing fluid

A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof are disclosed. The fracturing fluid includes 0.4-0.8 wt% of a thickening agent, 0.3-0.6 wt% of an auxiliary synergist, 0.2-0.4 wt% of an activating agent, 0.2-0.4 wt% of a metal ion stabilizer, and 0.3-0.4 wt% of a temperature stabilizer, with the balance being seawater. Beneficial effects of the fracturing fluid are that: a water-soluble multi-component copolymer is adopted as the thickening agent of the fracturing fluid system so that the fracturing fluid can rapidly swell in seawater having a high degree of mineralization; a low-viscosity high-elasticity fluid having a high space structure is formed through synergistic effects (non-crosslinking functions) with the auxiliary synergist; a sand-carrying property is good when the apparent viscosity is greater than 20 mPa.s; the prepared fracturing fluid is not eroded by bacteria, has characteristics of salt resistance, good temperature resistance and shearing resistance, low harm, no residue after cleaning, and the like, and can be prepared in batch or mixed continuously by adopting sea water; and the fracturing fluid can significantly reduce offshore fracturing construction costs and can increase fracturing construction efficiencies and reservoir yield-increasing effects.

Owner:SOUTHWEST PETROLEUM UNIV +1

Preparation method of Nb3Sn superconducting magnet with increased fracture resistance performance

ActiveCN101692367ABreak will notImprove fracture resistanceInductances/transformers/magnets manufactureSuperconducting magnets/coilsEpoxyNitrogen

The invention discloses a preparation method of Nb3Sn superconducting magnet with increased fracture resistance performance. The method comprises the following steps: firstly fully soaking Nb3Sn superconducting coil in epoxy resin under vacuum atmosphere, then using nitrogen for pressurization to ensure that epoxy resin is fully soaked in the Nb3Sn superconducting coil and finally solidifying to obtain Nb3Sn superconducting coil. When using the Nb3Sn superconducting coils prepared by the method of the invention for excitation, as the Nb3Sn superconducting coils are completely insulated, the Nb3Sn superconducting coils can not fracture.

Owner:西部超导材料科技股份有限公司

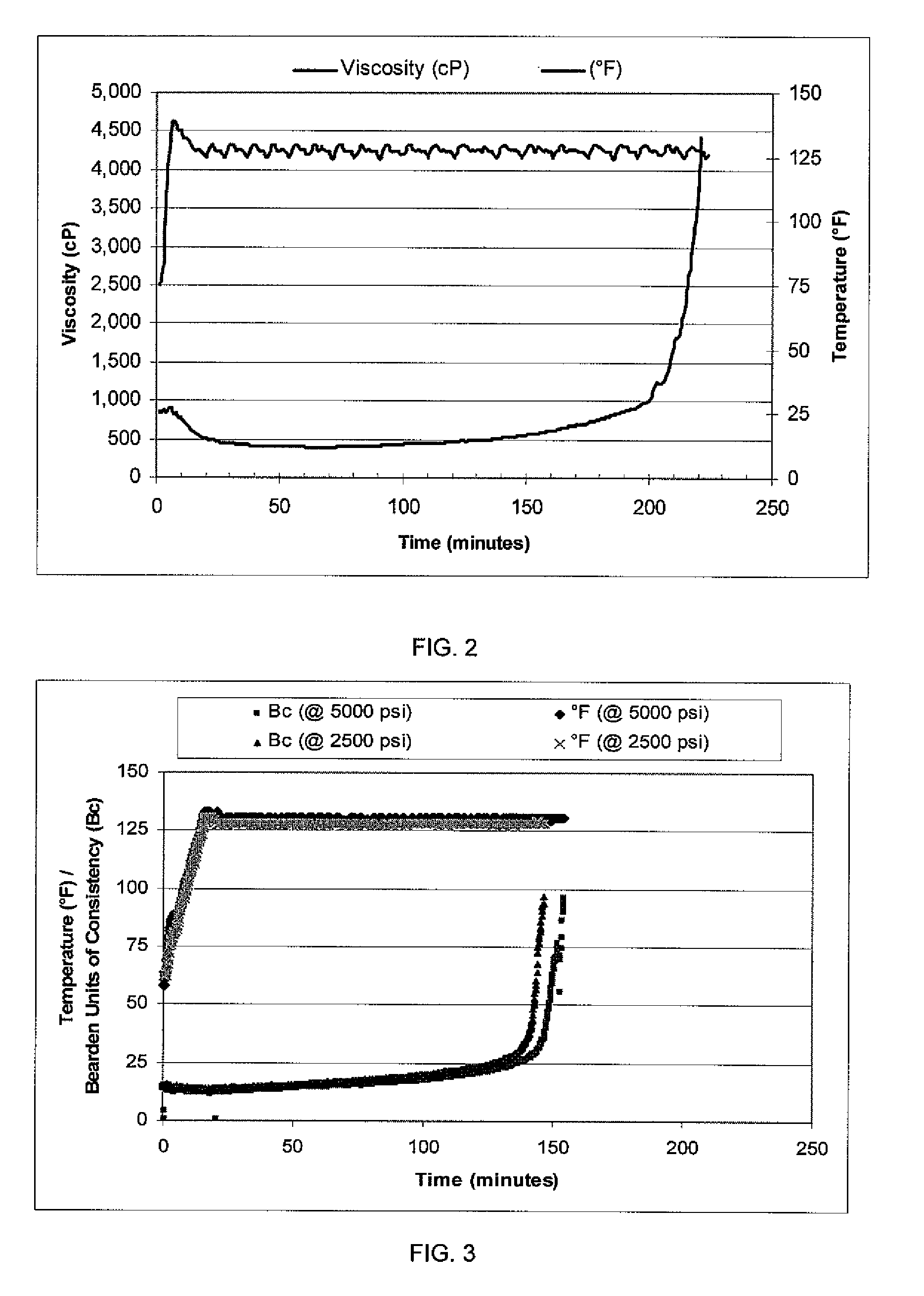

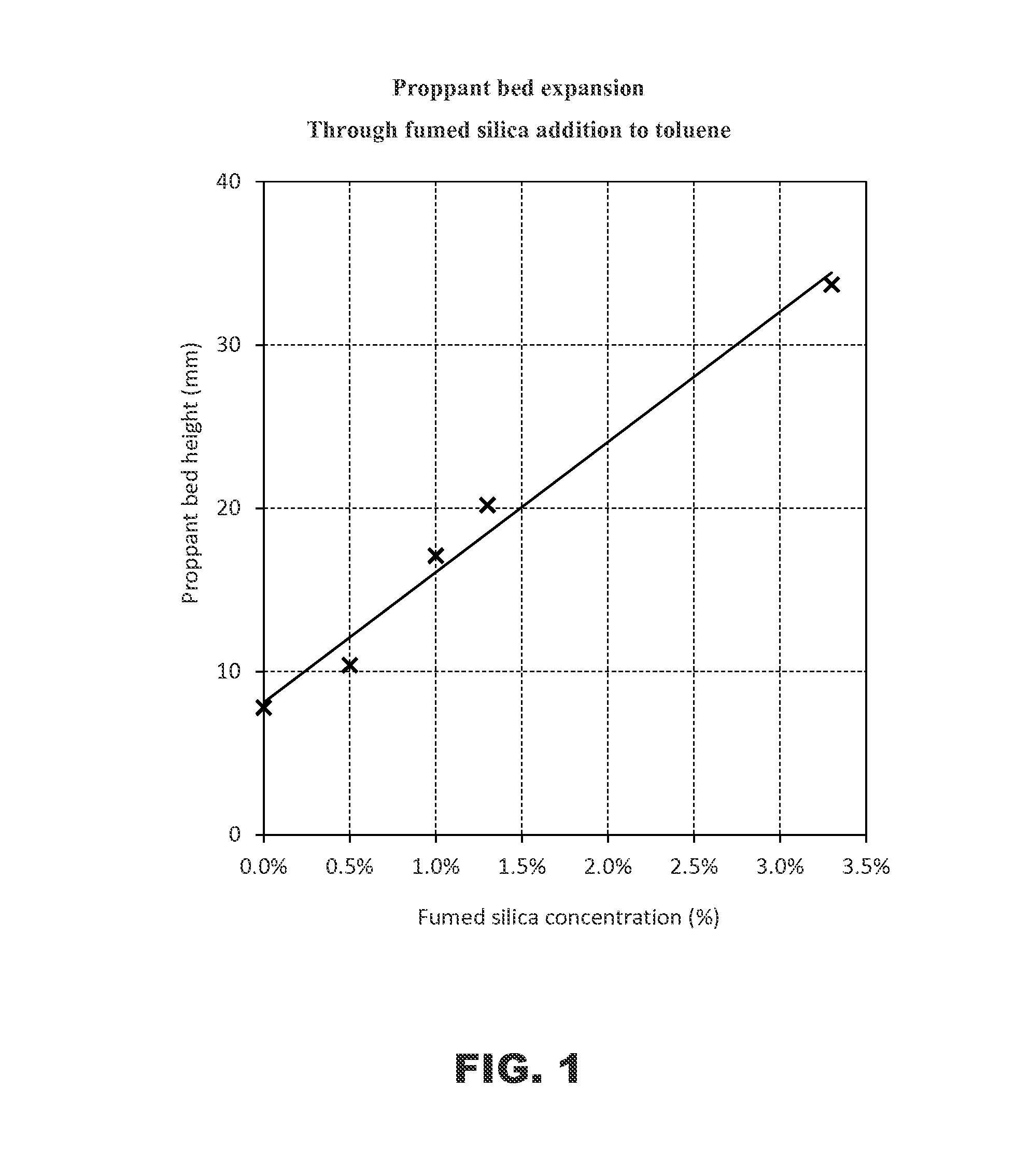

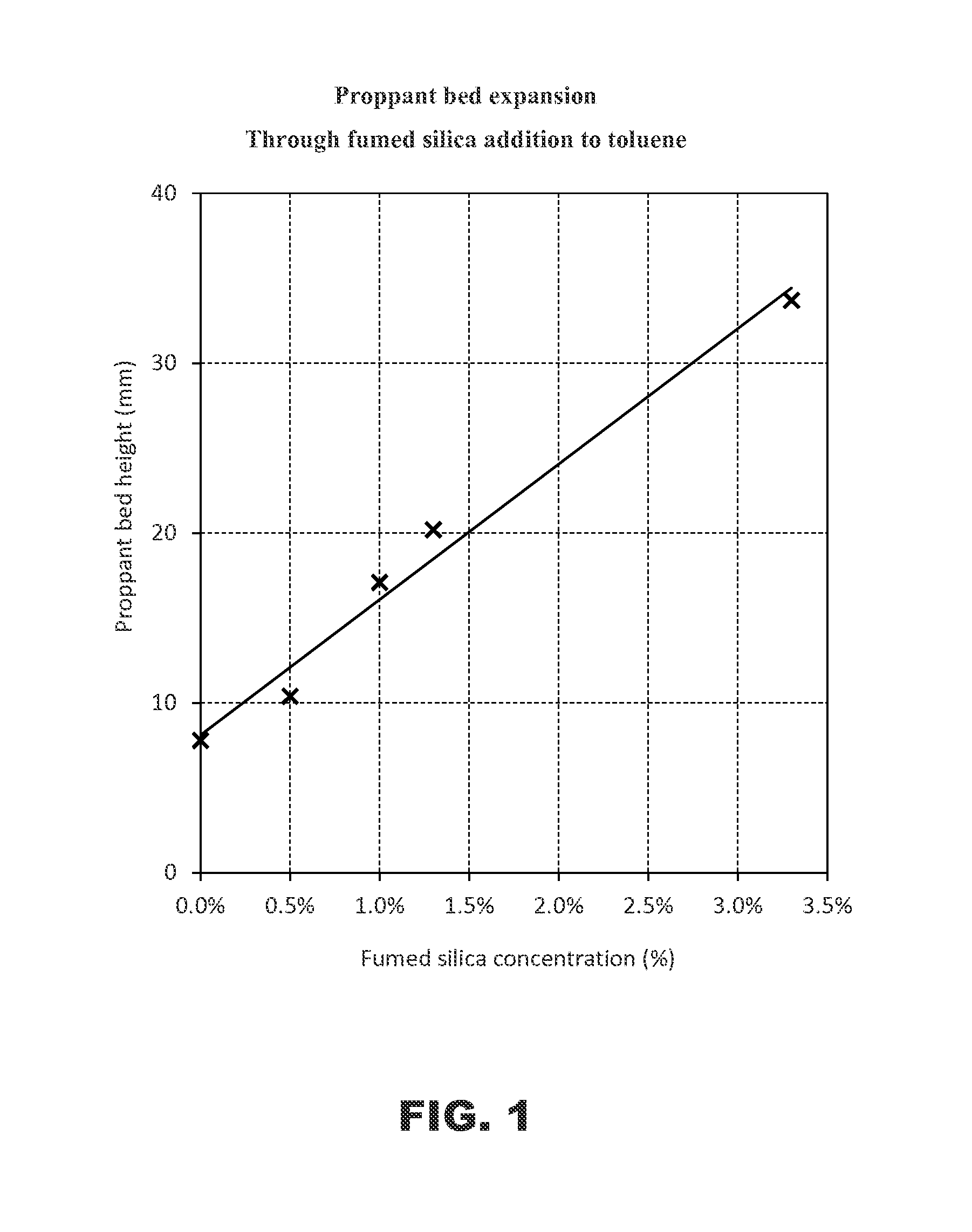

Fracturing fluid composition and method of using same in geological formations

InactiveUS20140378354A1Promote recoveryHigh viscosityFlushingDrilling compositionFracturing fluidLiquid carbon

A composition and method required for providing a fracturing fluid pumped down a well bore and into a subterranean formation under conditions of pressure that will fracture the subterranean formation is described. More specifically, the composition increases the recovery of hydrocarbons from a geological formation penetrated by a well bore, wherein the composition includes a fracturing fluid that is liquid carbon dioxide (LCO2) with proppant to aid transport of the proppant in suspension, and thereby create a fracture using a fracturing fluid which is the thickened composition containing fumed silica. When the composition is without a proppant, the viscosity of the composition is increased in order to improve the fracturing operation through aspects such as increased fracture width and reduced fluid leak-off.

Owner:PRAXAIR TECH INC

Using fluids at elevated temperatures to increase fracture gradients

InactiveUS6973977B2Reduce the overall diameterIncreasing fracture gradientSurveyConstructionsWell drillingCasing string

A method for drilling a wellbore in a formation using a drilling fluid, wherein the drilling fluid has a first temperature, and wherein the wellbore has a first wellbore depth. In one embodiment, the method comprises determining at least one fracture gradient, wherein the fracture gradient is determined at about the first wellbore depth; increasing the temperature of the drilling fluid from the first temperature to a desired temperature at about the first wellbore depth; drilling into the formation at increasing wellbore depths below the first wellbore depth, wherein at least one equivalent circulating density of the drilling fluid is determined at about the first wellbore depth; and setting a casing string at a depth at which the equivalent circulating density is about equal to or within a desired range of the fracture gradient. In other embodiments, an automated system is used to maintain the temperature of the drilling fluid at about first wellbore depth.

Owner:HALLIBURTON ENERGY SERVICES INC

Fracturing fluid composition and method of using same in geological formations

InactiveUS20140374094A1Increase viscosity of fluidPromote recoveryFluid removalFracturing fluidLiquid carbon

A composition and method required for providing a fracturing fluid pumped down a well bore and into a subterranean formation under conditions of pressure that will fracture the subterranean formation is described. More specifically, the composition increases the recovery of hydrocarbons from a geological formation penetrated by a well bore, wherein the composition includes a fracturing fluid that is liquid carbon dioxide (LCO2) with proppant to aid transport of the proppant in suspension, and thereby create a fracture using a fracturing fluid which is the thickened composition containing fumed silica. When the composition is without a proppant, the viscosity of the composition is increased in order to improve the fracturing operation through aspects such as increased fracture width and reduced fluid leak-off

Owner:PRAXAIR TECH INC

Increasing fracture complexity in ultra-low permeable subterranean formation using degradable particulate

A method of increasing the fracture complexity in a treatment zone of a subterranean formation is provided. The subterranean formation is characterized by having a matrix permeability less than 1.0 microDarcy. The method includes the step of pumping one or more fracturing fluids into a far-field region of a treatment zone of the subterranean formation at a rate and pressure above the fracture pressure of the treatment zone. A first fracturing fluid of the one or more fracturing fluids includes a first solid particulate, wherein: (a) the first solid particulate includes a particle size distribution for bridging the pore throats of a proppant pack previously formed or to be formed in the treatment zone; and (b) the first solid particulate comprises a degradable material. In an embodiment, the first solid particulate is in an insufficient amount in the first fracturing fluid to increase the packed volume fraction of any region of the proppant pack to greater than 73%. Similar methods using stepwise fracturing fluids and remedial fracturing treatments are provided.

Owner:HALLIBURTON ENERGY SERVICES INC

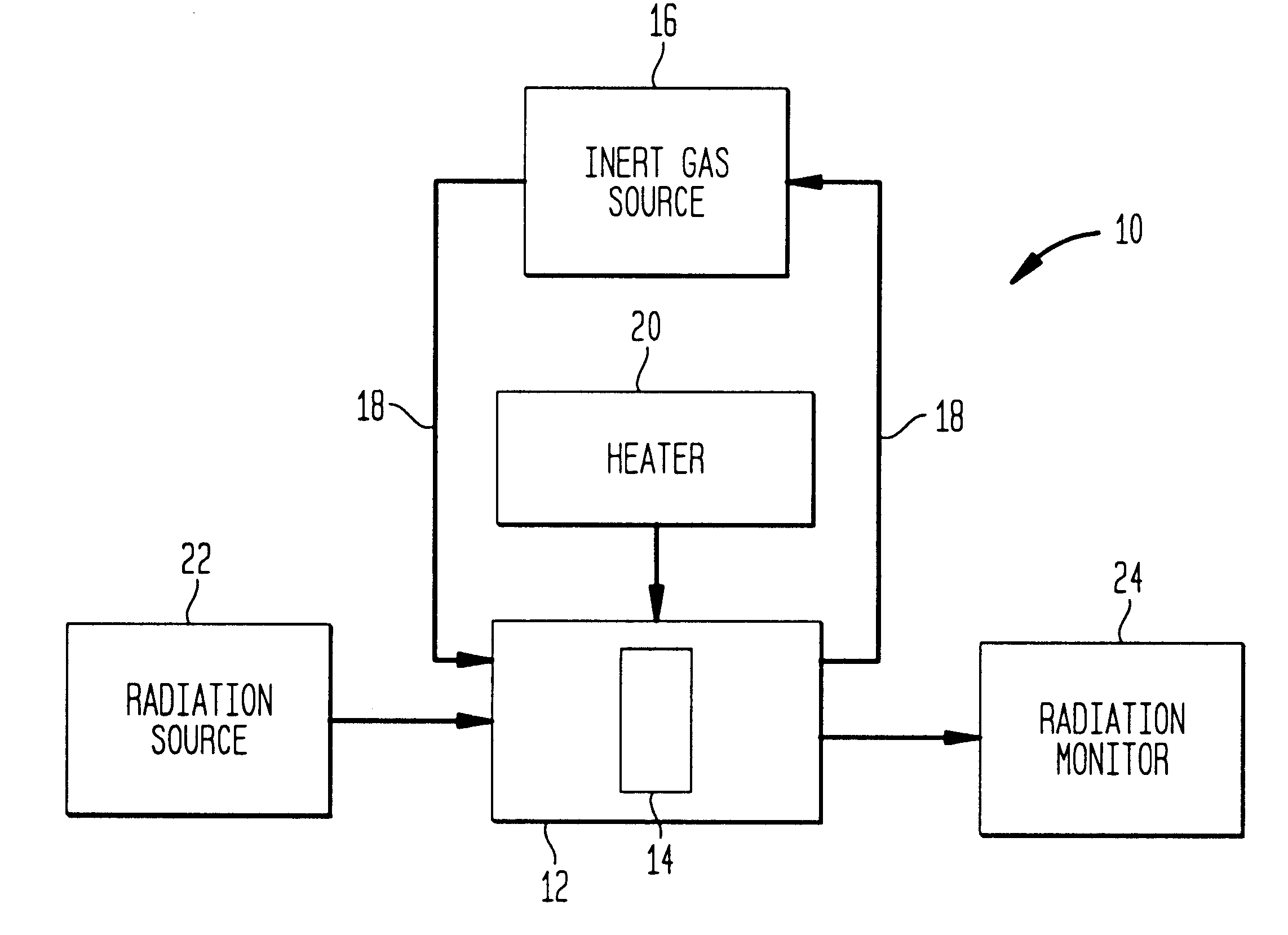

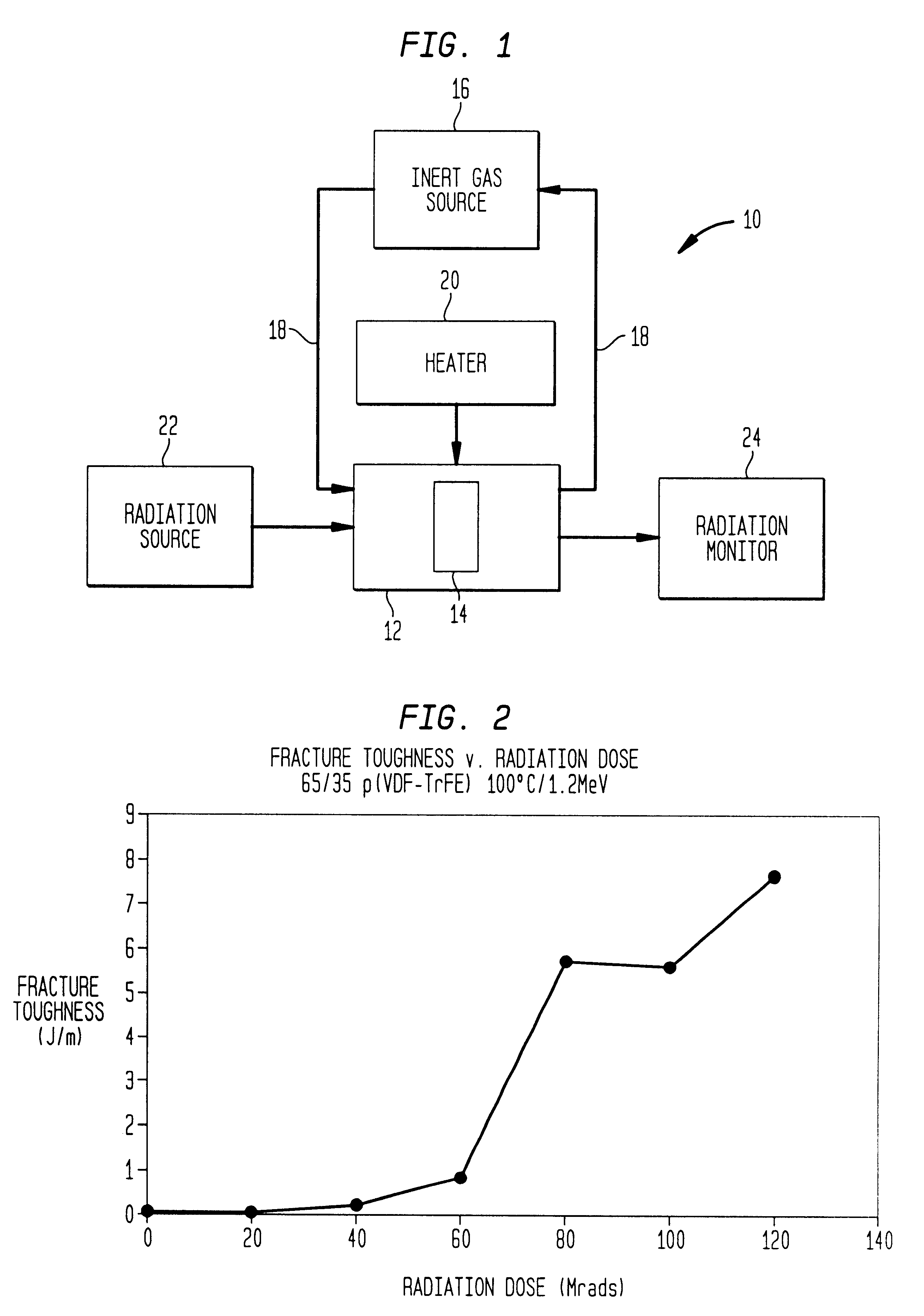

Method for increasing fracture toughness and reducing brittleness of ferroelectric polymer

InactiveUS6440755B1Piezoelectric/electrostrictive device manufacture/assemblySemiconductor/solid-state device manufacturingOxygenElectron

A method is provided that increases fracture toughness and reduces brittleness of a semi-crystalline ferroelectric polymer material while substantially maintaining ferroelectric properties of the material. The material is heated in an inert oxygen-free atmosphere to a temperature above the material's Curie transition but below its melting temperature. The material is then irradiated with beta particles to provide a desired level of fracture toughness that substantially maintains ferroelectric properties of the material. In the case of poly(vinylidene fluoride-trifluorethylene), the heating temperature is just above the material's Curie transition temperature, the beta particles have an energy level of approximately 2.5 mega electron volts (MeV), and the radiation dose should not exceed approximately 50 megarads (Mrads).

Owner:TOYOTA IND CORP +1

Improving fracture toughness of medical devices with a stereocomplex nucleating agent

Methods of fabricating a polymeric implantable device from a PLLA / PDLA blend such as a stent with improved fracture toughness are disclosed. The blend is melt processed to allow formation of stereocomplex crystallites, which are nucleation sites for crystal growth. A polymer construct is formed from the melt processed blend and device is formed from the polymer construct. The stereocomplex crystallites result in an in increase in nucleation density and reduced crystal size, which increases fracture toughness of the formed device.

Owner:ABBOTT CARDIOVASCULAR

Composite constructions with oriented microstructure

InactiveUS20050112396A1Improved propertyImprove fracture toughnessDrill bitsConstructionsComposite constructionFiber bundle

In one embodiment, composite constructions of the invention are in the form of a plurality of coated fibers bundled together to produce a fibrous composite construction in the form of a rod. Each fiber has a core formed from a hard phase material, that is surrounded by a shell formed from a binder phase material. In another embodiment of the invention, monolithic sheets of the hard phase material and the binder phase material are stacked and arranged to produce a swirled composite in the form of a rod. In still another embodiment of the invention, sheets formed from coated fibers are arranged to produce a swirled composite. Inserts for use in such drilling applications as roller cone rock bits and percussion hammer bits, and shear cutters for use in such drilling applications as drag bits, that are manufactured using conventional methods from these composite constructions exhibit increased fracture toughness due to the continuous binder phase around the hard phase of the composites. These binder phases increase the overall fracture toughness of the composite by blunting or deflecting the tip of a propagating crack.

Owner:SMITH INT INC

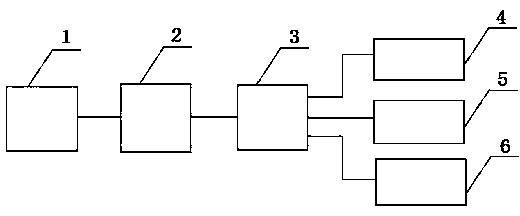

Multi-stage aging treatment method for aluminium-zinc-magnesium-copper 7000 series alloy thick plates

InactiveCN104313520AImprove mechanical propertiesImprove fracture toughnessRetention timeMechanical property

The invention belongs to a multi-stage aging treatment method for aluminium-zinc-magnesium-copper 7000 series alloy thick plates. The multi-stage aging treatment method is characterized by comprising the following steps of (a) putting the aluminium-zinc-magnesium-copper 7000 series alloy plates in a box type quenching furnace (1) to carry out quenching treatment, wherein a quenching temperature is increased to 477+ / -3 DEG C and a retention time is 80-100 min; (b) cooling the quenched in a water cooler (2); (c) carrying out multi-stage aging treatment in an aging furnace (3), wherein a first stage aging temperature is 120+ / -3 DEG C, a second stage aging temperature is 155+ / -3 DEG C and a third stage aging temperature is 120+ / -3 DEG C; and (d) processing into samples, stretching the samples on an electronic universal testing machine (4), observing microstructures and detecting changes of crystal grains under an optical microscope (5), and determining conductivity on an conductivity meter (6). The aluminium-zinc-magnesium-copper 7000 series alloy thick plates treated by the method increase mechanical properties of aluminium alloy materials and obviously increase fracture toughness.

Owner:DALIAN HUICHENG ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com