Gaseous phase fracturing device

A pressurization device and gas phase technology, applied in safety devices, gas discharge, mining fluids, etc., can solve problems such as high cost of extraction, increase of coal seam cracks, slow boosting of hydraulic fracturing, etc., to improve the efficiency of gas extraction , increase air permeability, improve the effect of free state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

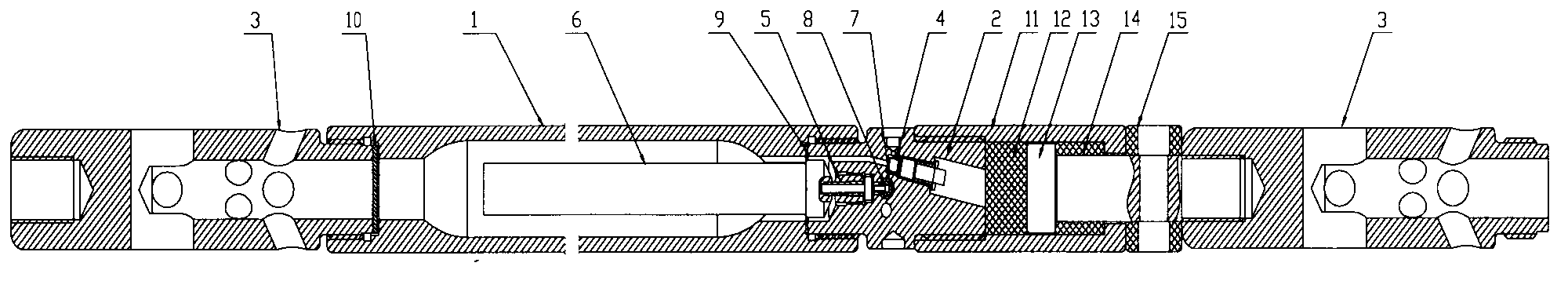

[0024] Such as figure 1 As shown, the gas-phase fracturing device of this embodiment includes a fracturing pipe 1, an inflation valve 2, an air injection valve 3, a sealing ring 9, a shear sheet 10, and a buffer 11; At both ends of the tube 4, the charging valve 2 is provided with a filling channel leading to the fracturing tube 1, and the air injection valve 3 is provided with an air injection channel. One end of the air injection channel leads to the filling chamber of the fracturing tube 1, and the other end leads to the Outside the fracturing device, the end of the air injection channel leading to the outside of the fracturing device has several air injection holes facing in different directions, and a shear sheet 10 is arranged in the seal between the air injection channel of the air injection valve 3 and the filling chamber of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com