Preparation method of Nb3Sn superconducting magnet with increased fracture resistance performance

A superconducting magnet, anti-fracture technology, used in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

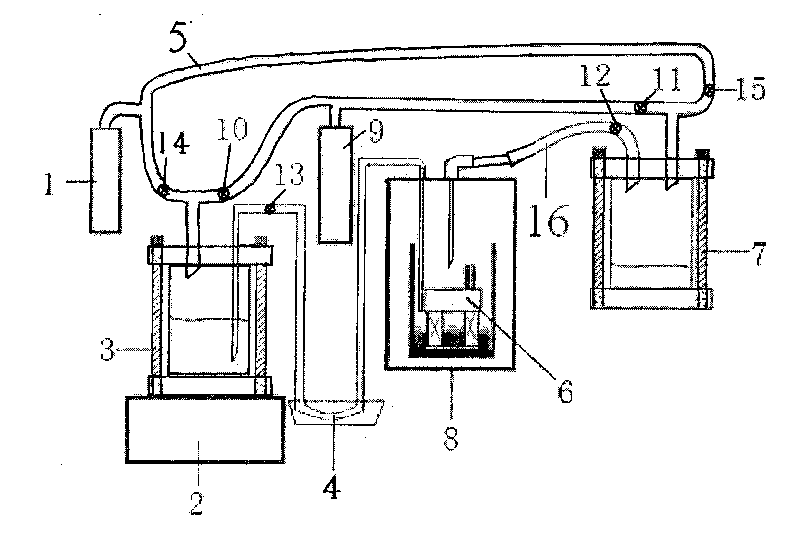

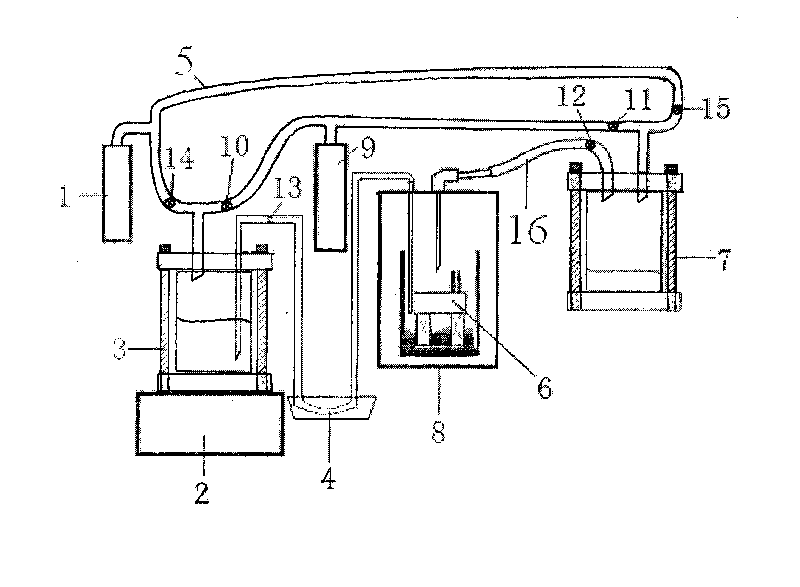

Image

Examples

preparation example Construction

[0018] The present invention Nb 3 The preparation method of Sn superconducting magnet specifically implements according to the following three steps:

[0019] 1. Wash Nb with acetone 3 Sn superconducting coil, then Nb 3 Put the Sn superconducting coil into the vacuum chamber; and configure the epoxy resin.

[0020] 2. Degas the epoxy resin by heating and stirring. The heating temperature is 60°C-80°C, and then put the epoxy resin into the vacuum chamber. The pressure of the vacuum chamber is 2000Pa-3000Pa, and the epoxy resin is fully immersed. Nb 3 After 30 minutes of the Sn superconducting coil, nitrogen gas is passed into the vacuum chamber so that the pressure of the vacuum chamber is 1.5 to 2 atmospheres, and the epoxy resin is squeezed into the Nb through nitrogen gas. 3 For the inner layer of the coil of the Sn superconducting coil, the time is 5 to 10 hours.

[0021] 3. The Nb fully impregnated in the previous step 3 The Sn superconducting coil is taken out from ...

Embodiment 1

[0037] Wash Nb with acetone 3 Sn superconducting coil, then Nb 3 Put the Sn superconducting coil into the vacuum chamber; record by weight, respectively take 50 parts of unmodified low-viscosity resin, 50 parts of polyethylene glycol diepoxide resin, and 28 parts of aromatic amine hardener. Mix the unmodified low-viscosity resin and polyethylene glycol diepoxide resin to obtain a mixed resin, and then drop a silicon antiform fluid (Silicon Antiform fluid) with a viscosity of 100 lipoise in every kilogram of the mixed resin. ) drop, followed by stirring the mixed resin to degas the mixed resin to obtain a degassed resin. Then filter the obtained aromatic amine hardener through a small-hole filter, pour it into the degassed resin, and stir it at the same time to obtain an epoxy resin. The epoxy resin is degassed by heating and stirring, the heating temperature is 60°C, and then the epoxy resin is passed into the vacuum chamber, the pressure of the vacuum chamber is 2000Pa, and...

Embodiment 2

[0039] Wash Nb with acetone 3 Sn superconducting coil, then Nb 3 Put the Sn superconducting coil into the vacuum chamber; record by weight, respectively take 50 parts of unmodified low-viscosity resin, 50 parts of polyethylene glycol diepoxide resin, and 28 parts of aromatic amine hardener. Mix the unmodified low-viscosity resin and polyethylene glycol diepoxide resin to obtain a mixed resin, and then drop a silicon antiform fluid (Silicon Antiform fluid) with a viscosity of 200 lipoises in every kilogram of the mixed resin. ) drop, followed by stirring the mixed resin to degas the mixed resin to obtain a degassed resin. Then filter the obtained aromatic amine hardener through a small-hole filter, pour it into the degassed resin, and stir it at the same time to obtain an epoxy resin. The epoxy resin is degassed by heating and stirring, the heating temperature is 80°C, and then the epoxy resin is passed into the vacuum chamber, the pressure of the vacuum chamber is 3000Pa, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com