Anti-fracture structure of folding plastic box folding line

A plastic box and foldable technology, which is applied to rigid containers, containers, packaging, etc., can solve the problems of affecting work efficiency, lack of aesthetic feeling of straight creasing and folding lines, and time-consuming and laborious packaging operations, so as to improve work efficiency and increase aesthetics , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

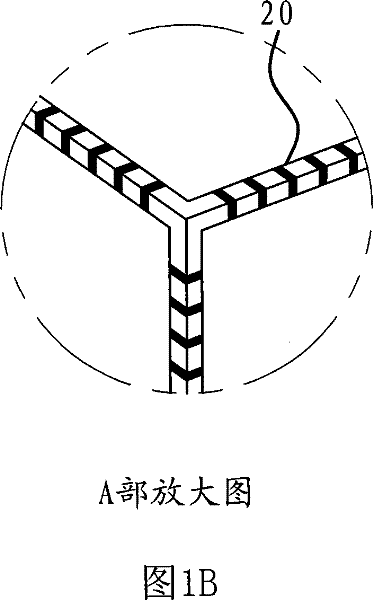

[0014] Referring to Fig. 1, Fig. 2, the anti-fracture structure of foldable plastic box fold line of the present invention comprises many plastic box sheets 10 and the fold line 20 between each box sheet, and described multi-sheet plastic box sheet 10 is transparent in the whole sheet or translucent plastic sheet with a special embossing knife to press out the folding line 20 to form the upper, lower, left, right, front and rear box pieces of the packaging box, and then fold them into a regular cube or a rectangular cube along each folding line. Shaped packing box, the thickness of plastic box sheet 10 is usually 0.17~1mm. The gist of the present invention is that the fold line 20 is an intermittent creasing line formed by a plurality of convex parts 21 and a plurality of concave parts 22 arranged alternately along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com