Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362 results about "Electrodischarge machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

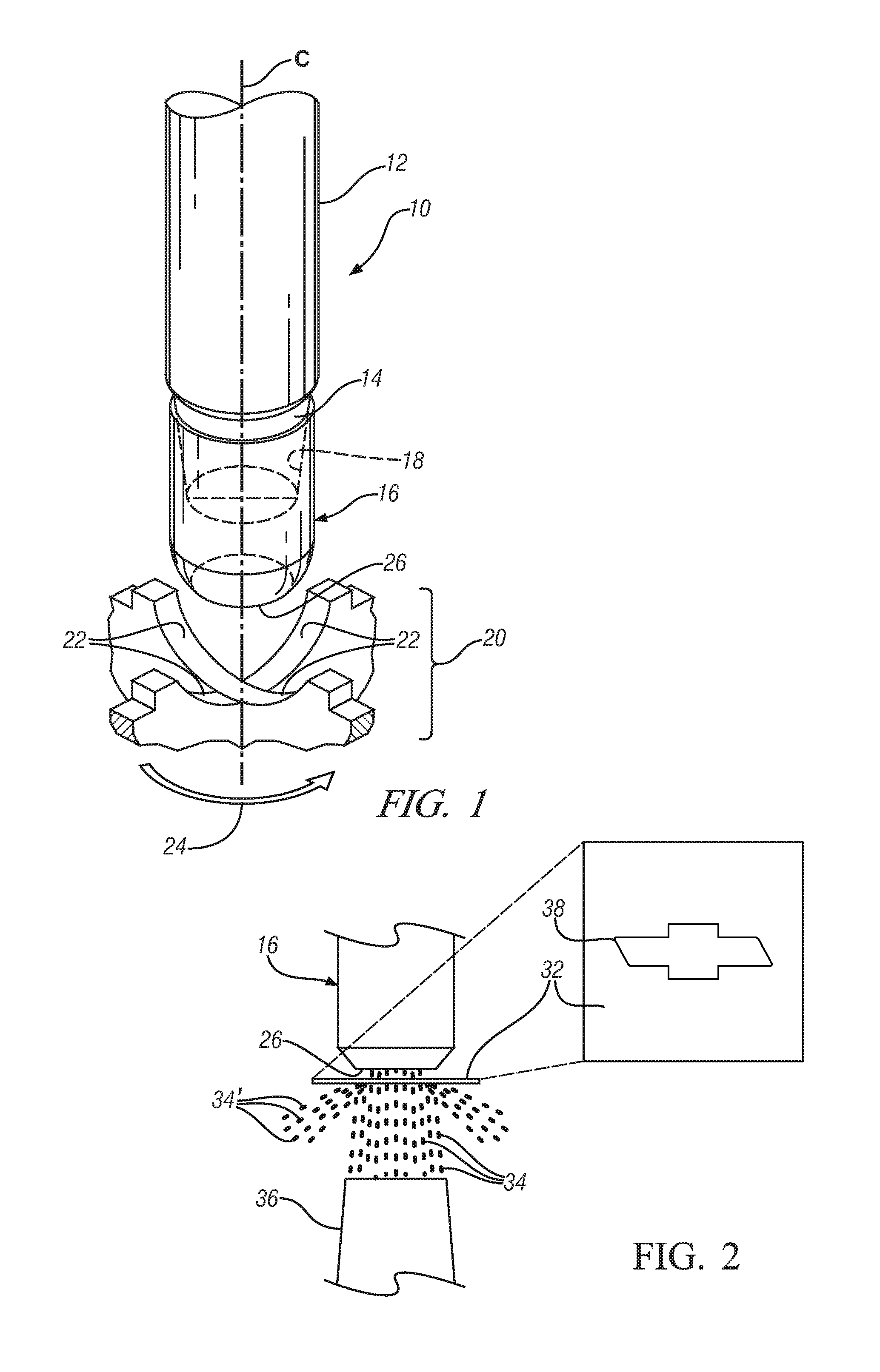

Methods for shaping and finishing prosthetic joint components including polycrystalline diamond compacts

InactiveUS6410877B1Less disruptiveImprove overall utilizationElectrode vibration holdersElectrical-based machining electrodesHeat-affected zoneElectric discharge

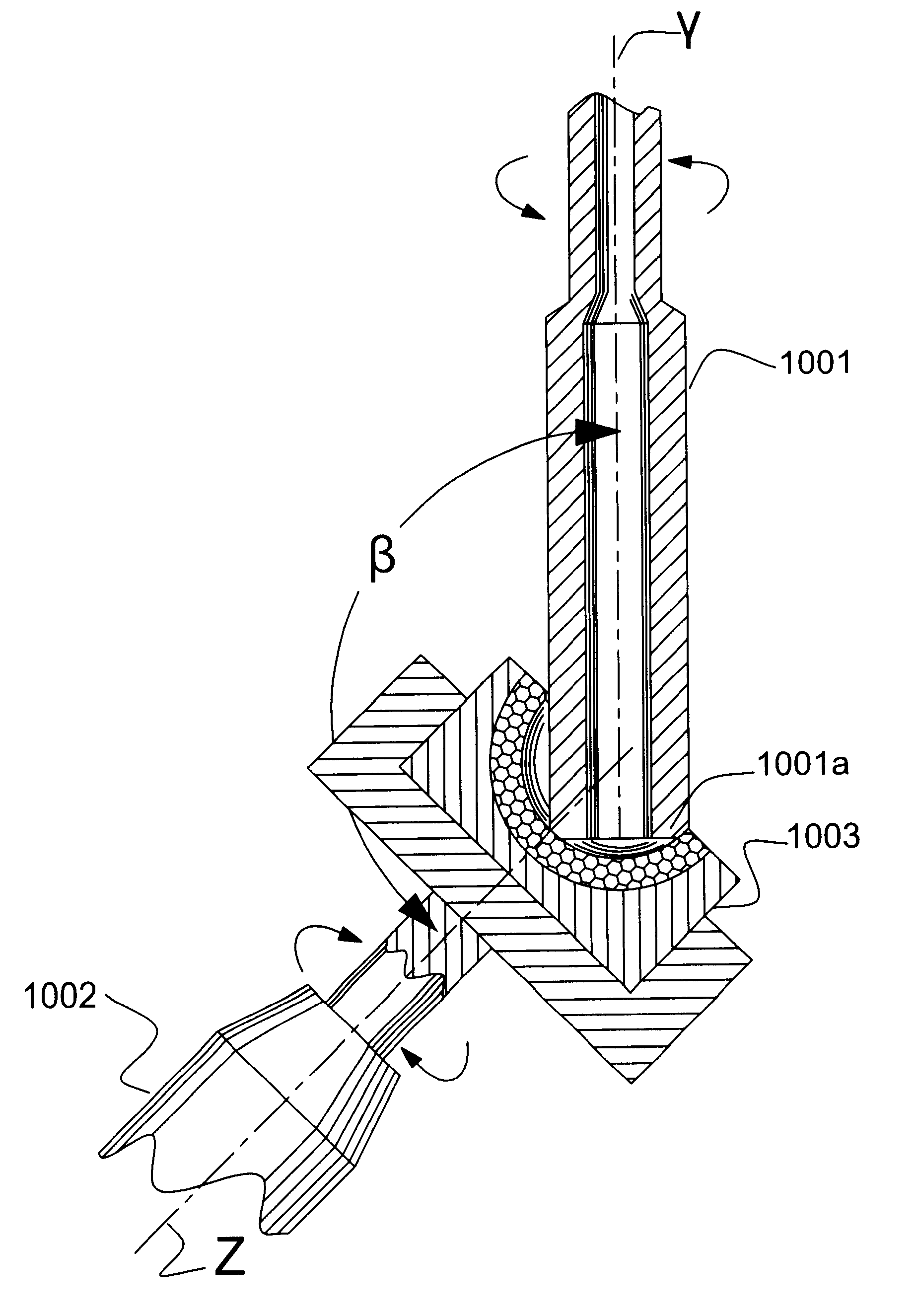

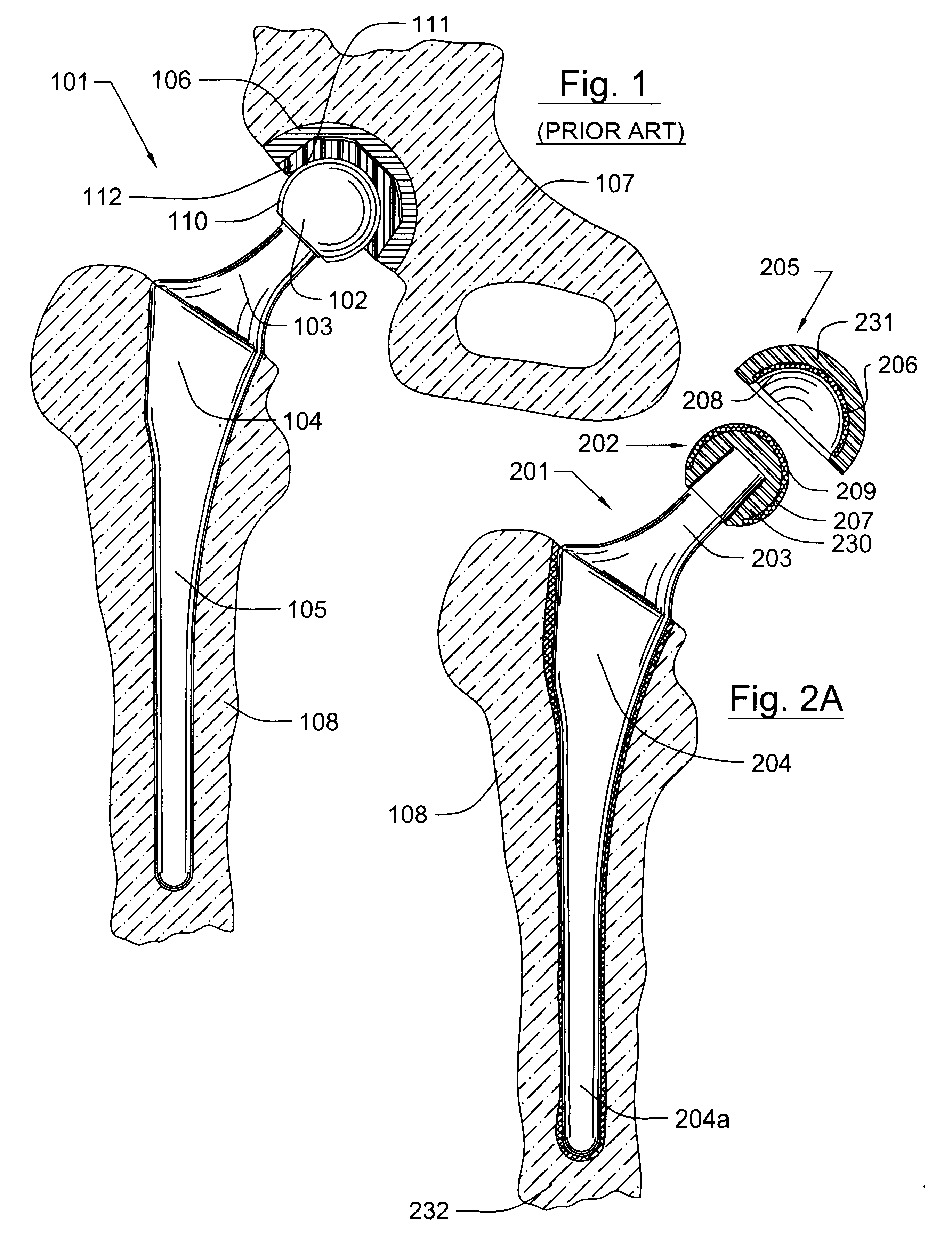

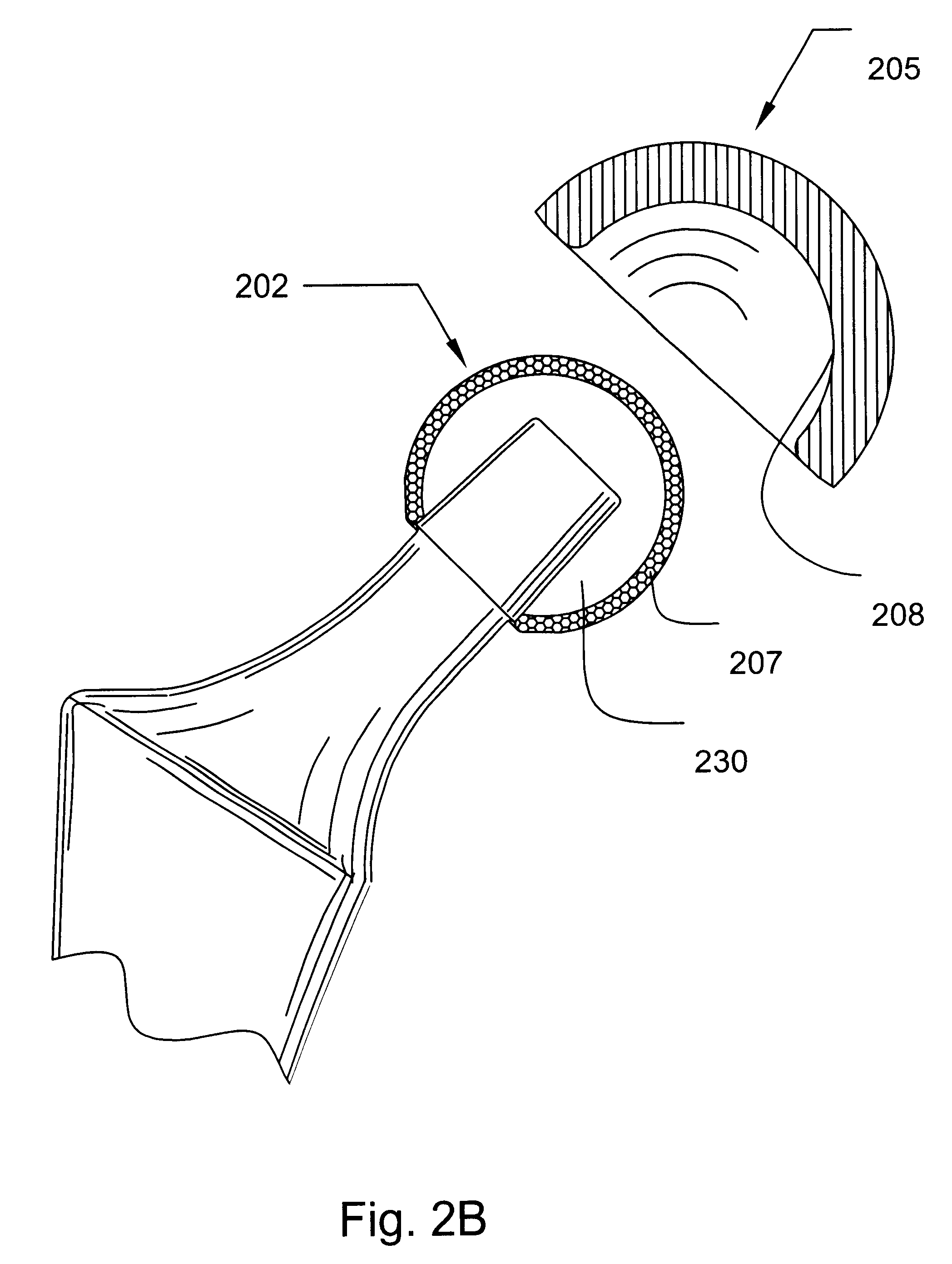

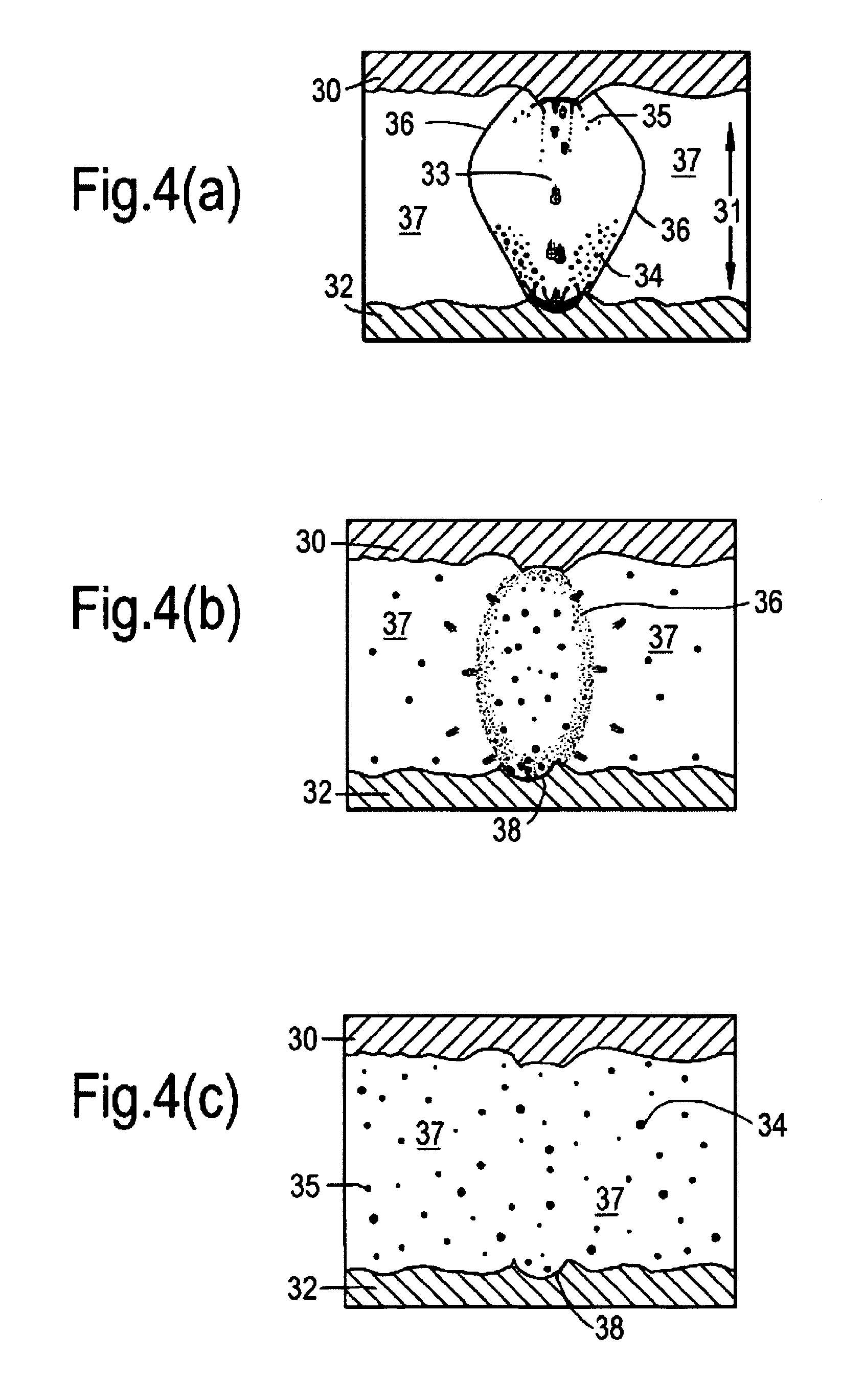

A method of rough shaping a prosthetic joint component that includes a generally spherical polycrystalline diamond compact by electric discharge machining is disclosed. The discharge machining electrode roughens a polycrystalline diamond compact sphere while the electrode and the sphere are rotating about different axes. By controlling the amount of discharge current, the depth and amount of the heat affected zone can be minimized. In the case of a polycrystalline diamond compact, the heat affected zone can be kept to about 3 to 5 microns in depth and is easily removable by grinding and polishing.

Owner:DIAMICRON

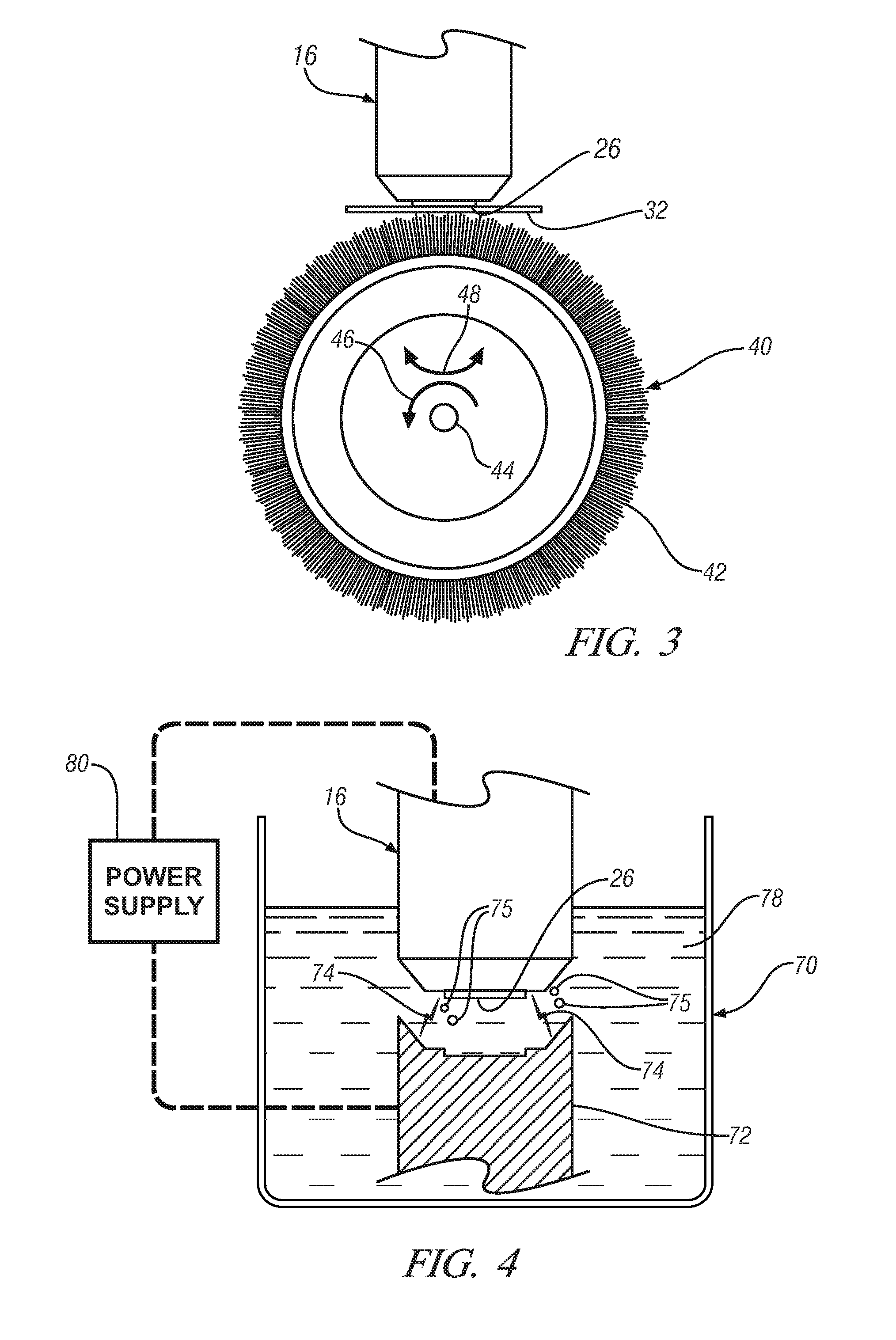

Rapid production of engineering tools and hollow bodies by integration of electroforming and solid freeform fabrication

InactiveUS6409902B1Stay in shapeAvoid insufficient thicknessAdditive manufacturing apparatusFoundry mouldsElectrolysisElement analysis

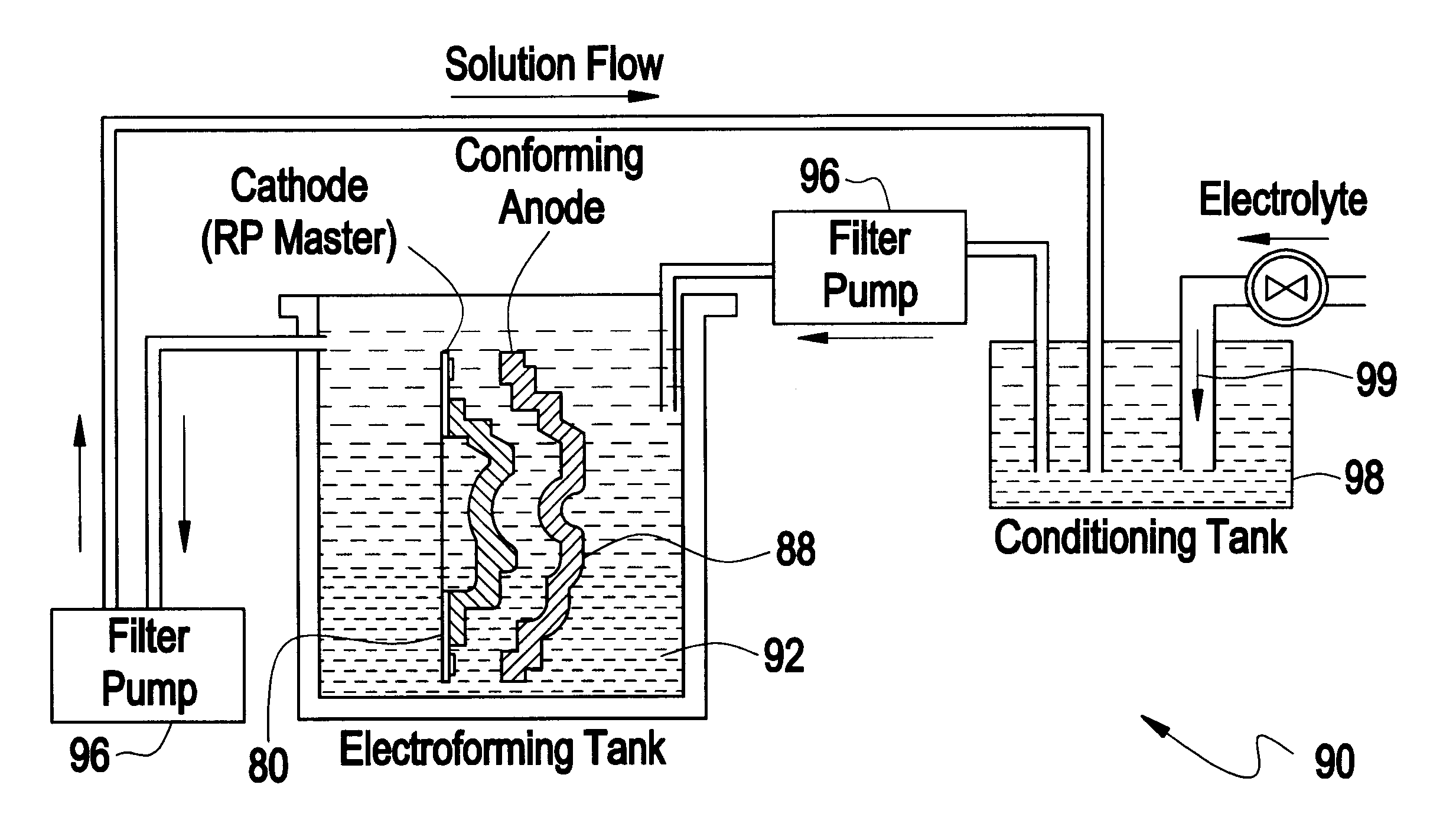

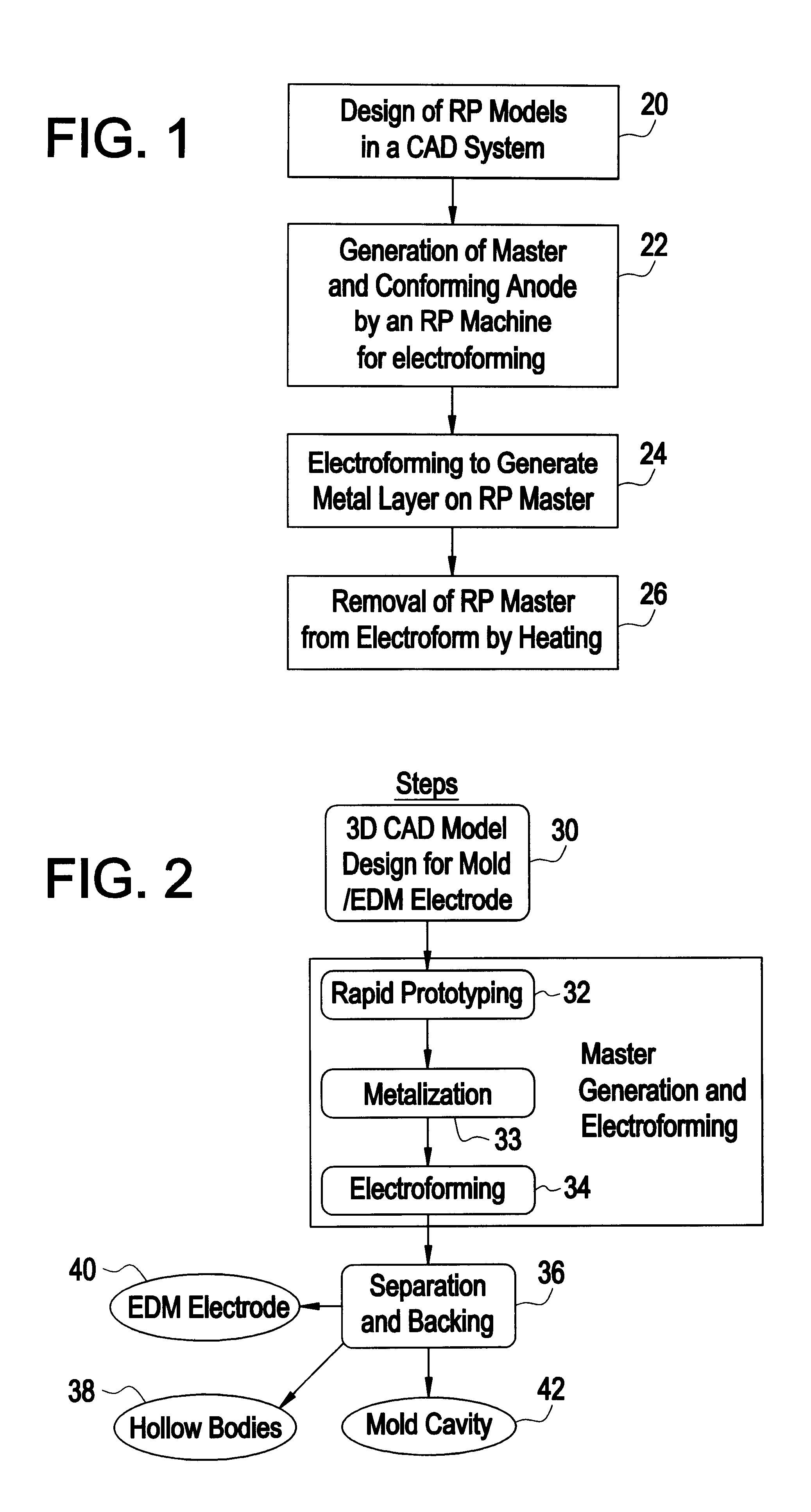

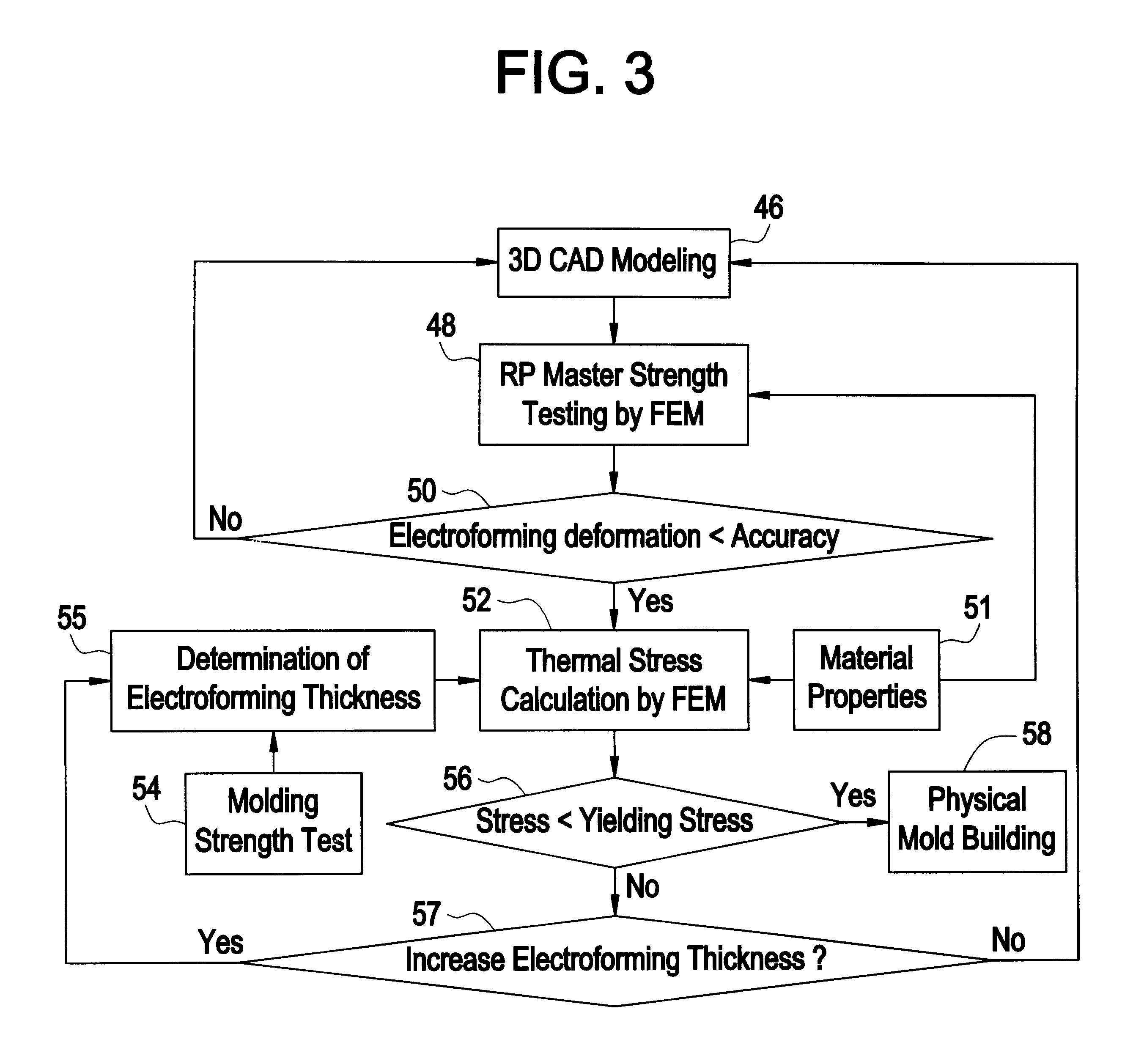

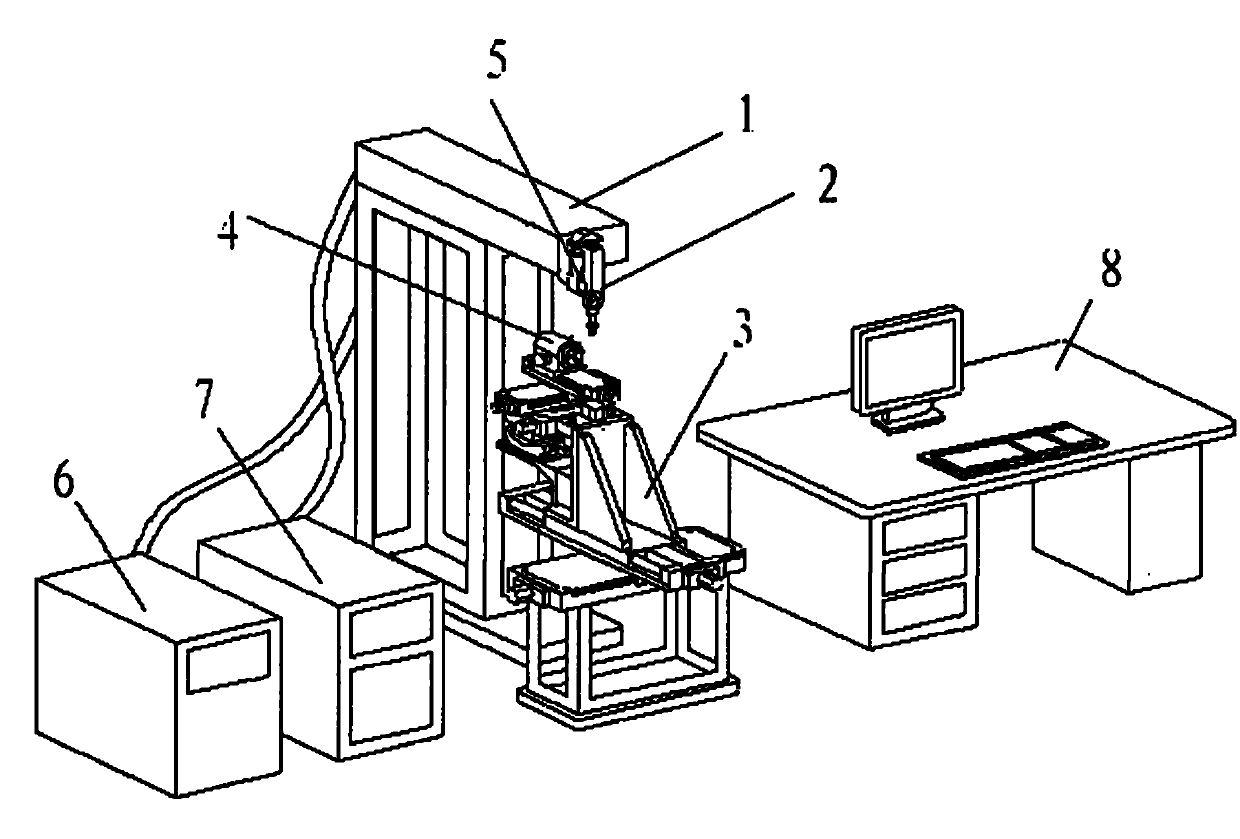

This invention describes a rapid tooling process that integrates solid freeform fabrication (SFF) with electroforming to produce metal tools including molds, dies, and electrical discharge machining (EDM) electrodes. An SFF part is metalized by electroless plating and then placed in an electroplating solution, where metal is deposited upon the part by electrolysis. When the desired thickness of metal has been reached, the SFF part is removed from the metal shell. The shell is then optionally backed with other materials to form a mold cavity, and EDM electrode, or other desired parts for tooling. Thermomechanical modeling and numerical simulation with finite element analysis (FEA) is used to determine the geometry of the SFF part and the electroform thickness for minimizing the manufacturing time and cost while satisfy the tooling requirement.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Laser tool grinding method and tool grinding machine

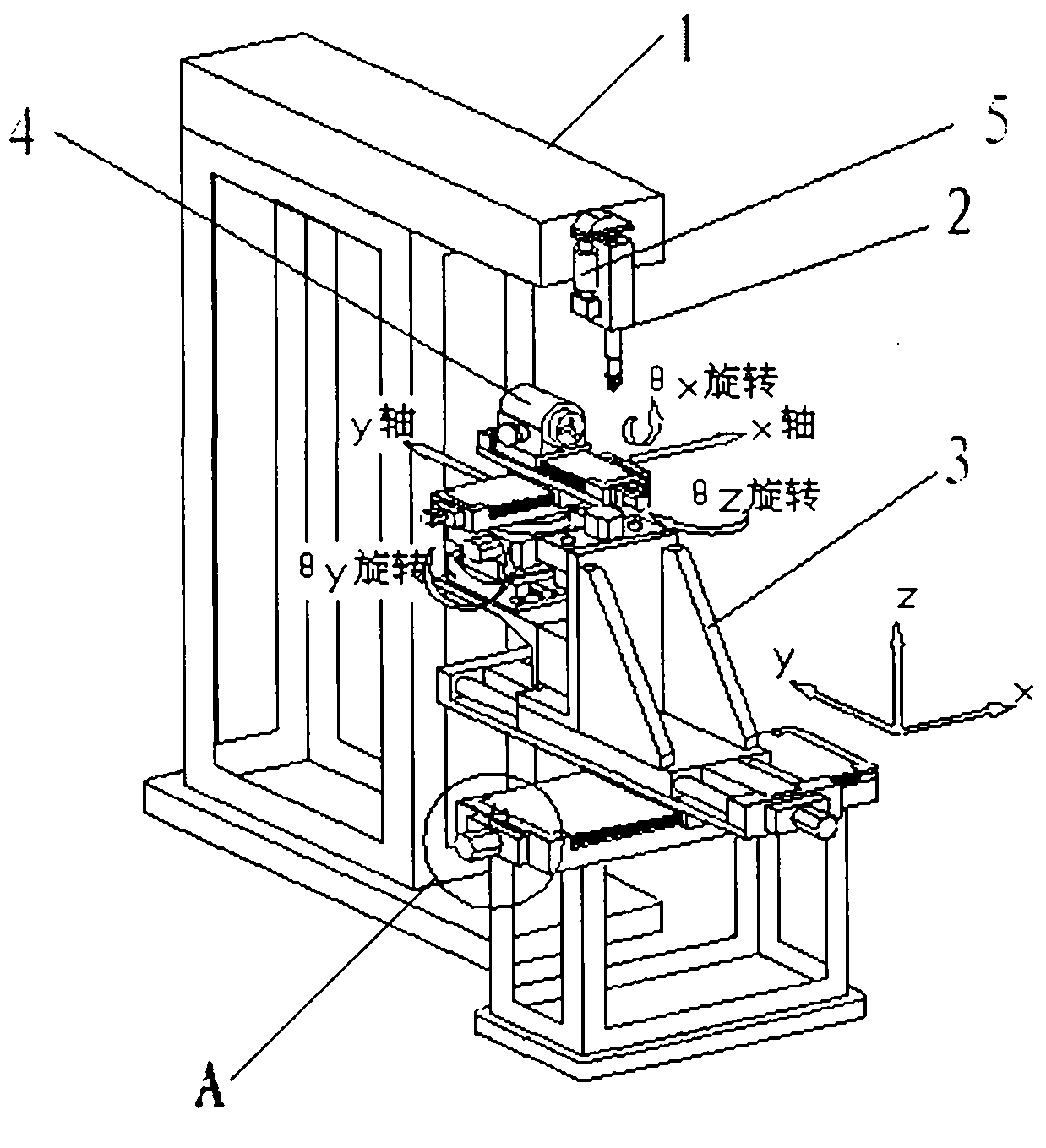

The invention discloses a laser tool grinding method and a laser tool grinding machine. High-quality laser replaces a grinding wheel or discharge machining and precisely machines tools, moulds and work pieces with the shape or mode similar to that of tools and moulds. The method comprises the following steps: a work piece is arranged in a fixture of a mounting tool, the position of the work piece to be machined is adjusted to an optimum angle and an optimum position; a point to be machined is arranged at a laser focus or a focal plane, laser and cooling air or cooling fluid are started, a high-precision multidimensional motion system is electrically or manually controlled to lead the machined region to move according to a fixed law, thus forming tool cutting edges of various shapes. Non-contact machining does not cause pressure and stress damage due to wheel grinding and does not cause discharge damage due to electrical discharge grinding, either. The method and the machine have high quality: when the laser quality is higher, cutting edges with smooth and clean mirror surfaces can be machined, and the efficiency and the quality are both superior to those of the electrical discharge grinding. The method and the machine have high efficiency: the efficiency of the laser grinding is far higher than that of the discharge grinding and the wheel grinding. Real-time monitoring is easy.

Owner:BEIJING WORLDIA DIAMOND TOOLS

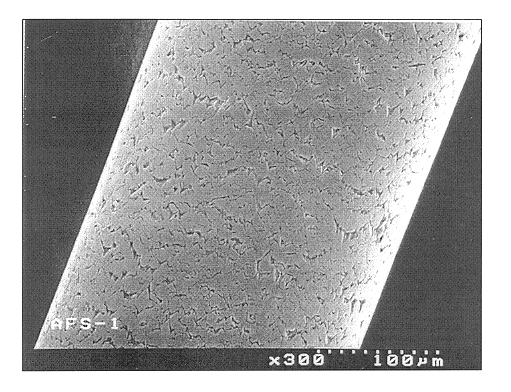

Method of manufacturing porous electrode wire for electric discharge machining and structure of the electrode wire

InactiveUS6306523B1Improve cooling effectNegative effectHot-dipping/immersion processesPretreated surfacesZincPorous electrode

The present invention relates to a porous electrode wire for use in electrical discharge machining and the method of manufacturing the same. The wire improves the machining speed at least 15% compared with a conventional zinc coated wire, which results from an increased cooling ability of the wire with a cooling liquid because of the increase in the surface area of the wire having porous surface morphology. Since the surface of the porous wire presents uniform profile of outer periphery rather than surface protrusions, it does not affect machining accuracy. Further, the porous nature of the wire is expected to improve flushability during the electrical discharge machining, providing spaces to eliminate particles of the machining. Therefore, in accordance with the method of the present invention, a zinc coated wire having improved performance of machining speed and flushability compared with a conventional coated wire can be provided without additional processes.

Owner:SEONG KI CHUL

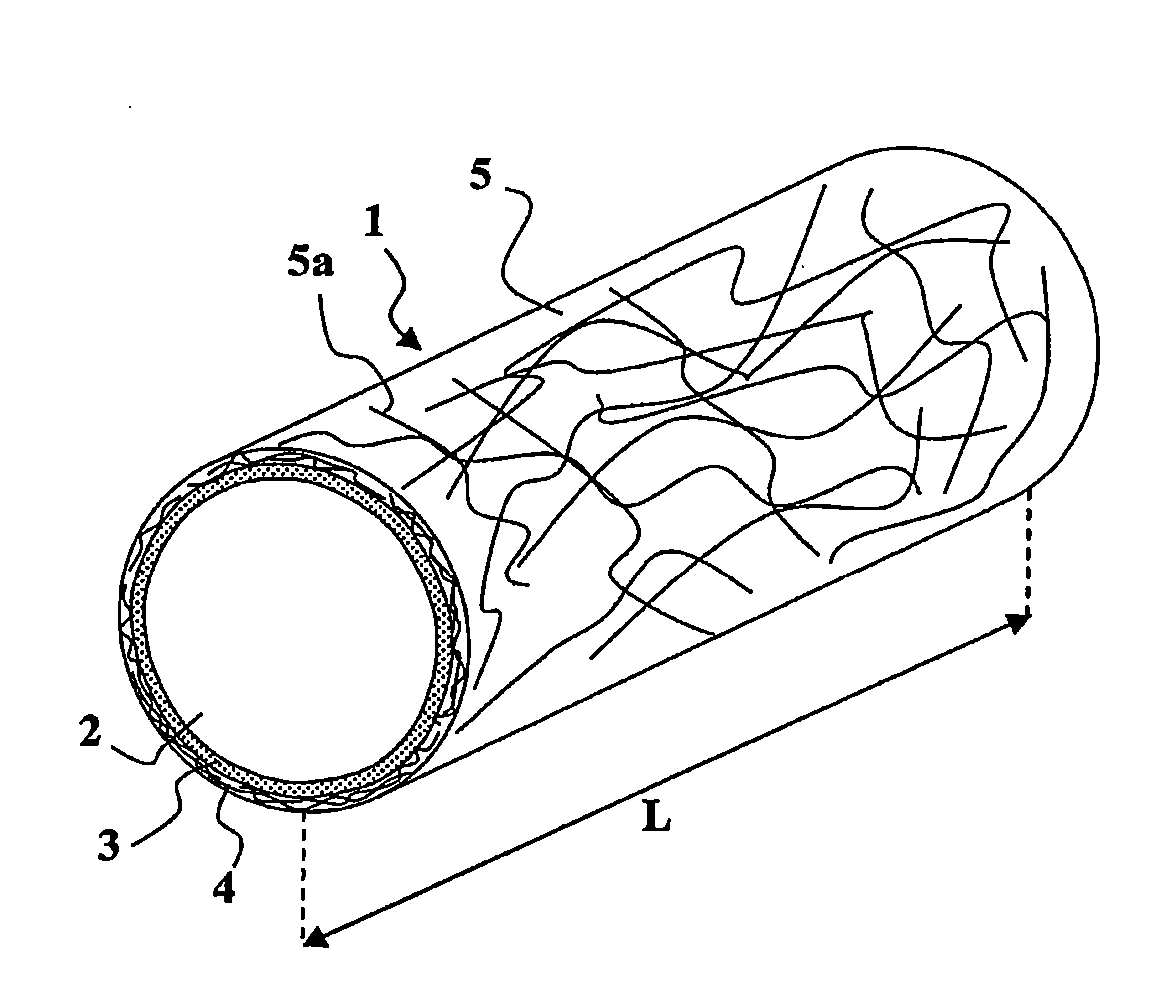

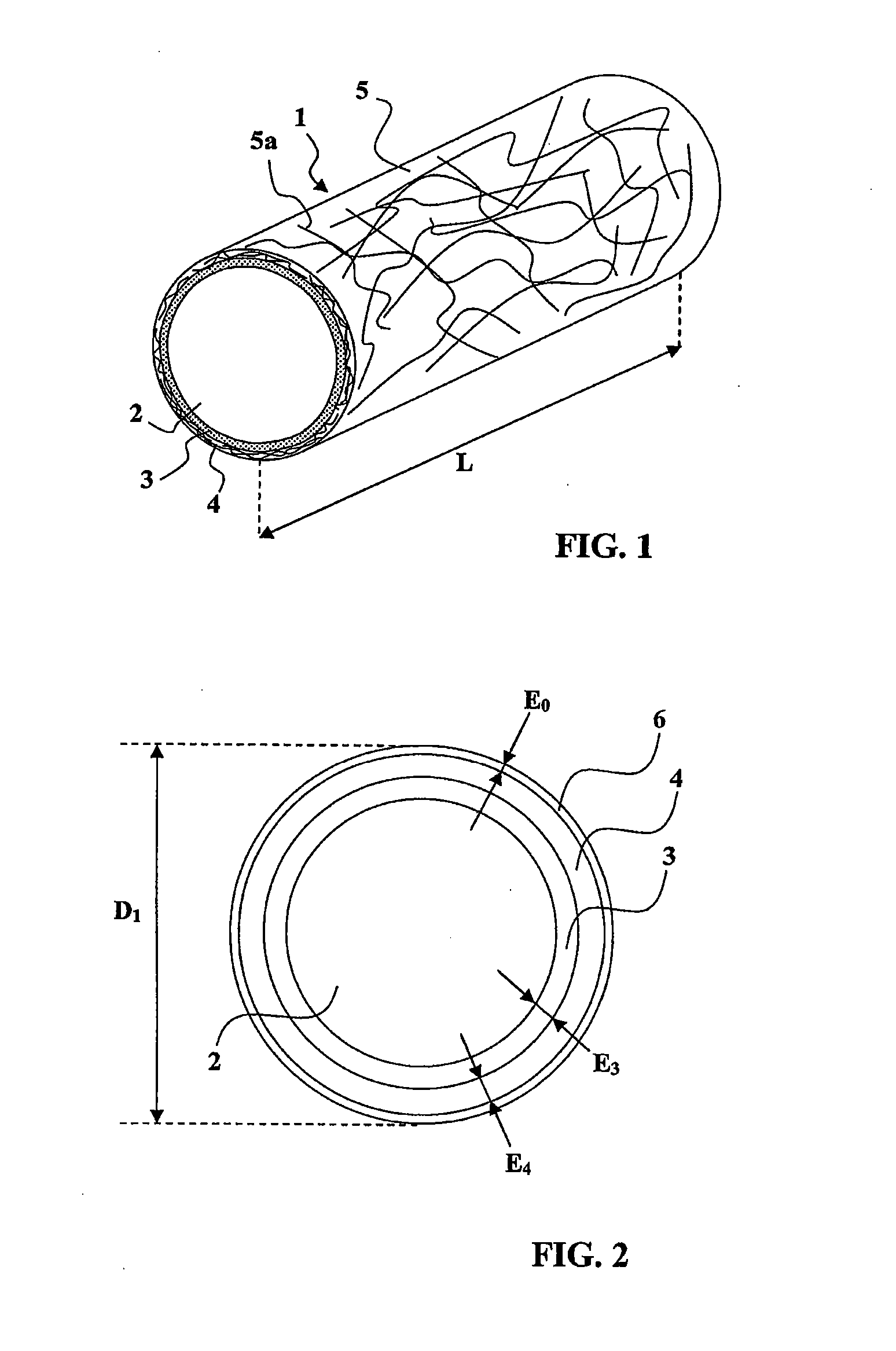

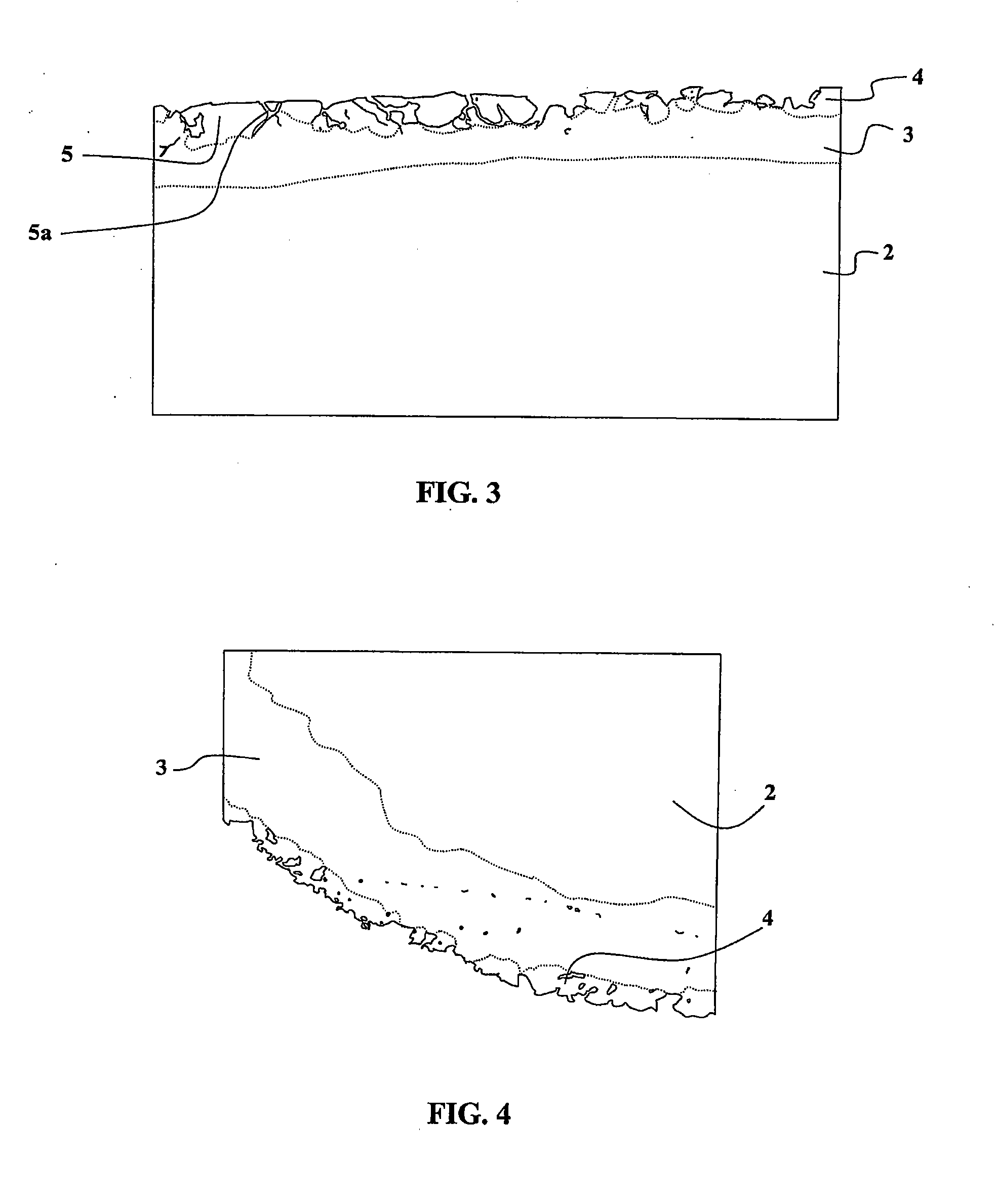

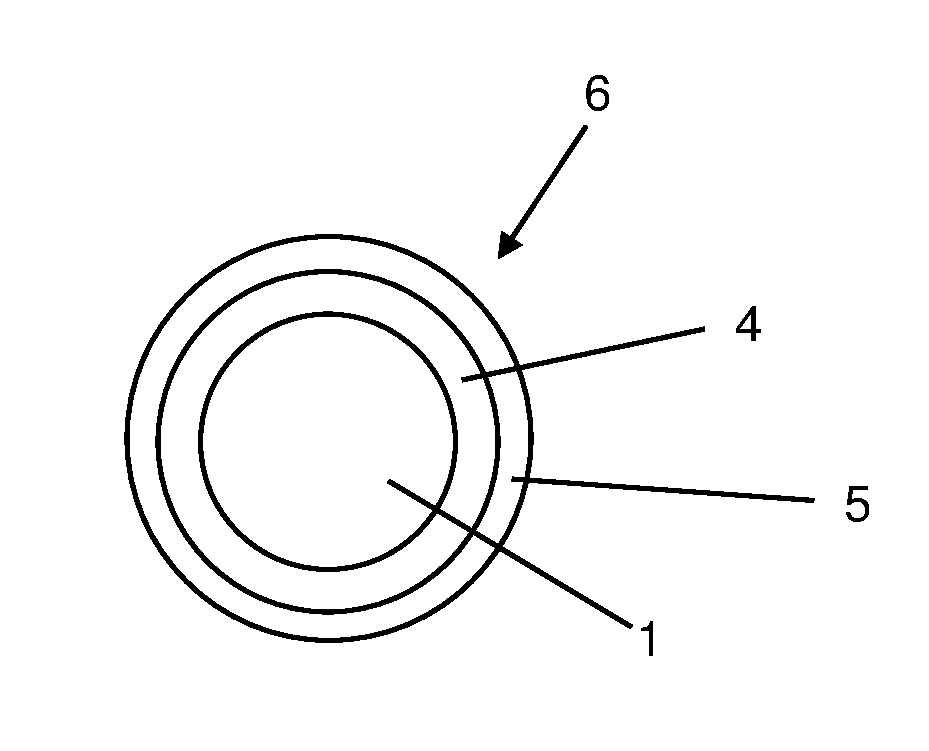

Composite Wire For Electrical Discharge Machining

ActiveUS20080061038A1Increase in EDM rateLow production costElectrical-based machining electrodesCopperMaterials science

The invention relates to a wire (1) which comprises a copper or pinchbeck core (2) surrounded by a pinchbeck coating consisting of a continuous pinchbeck sub-layer (3) in phase β and a superficial layer (4) with a fractured pinchbeck structure in phase ? enabling the appearance of pinchbeck in phase β in the fractures (5a). In this way, the electrical discharge machining speed is essentially increased.

Owner:THERMOCOMPACT

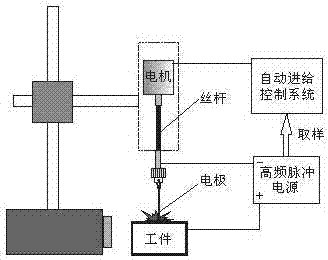

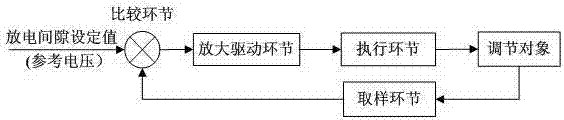

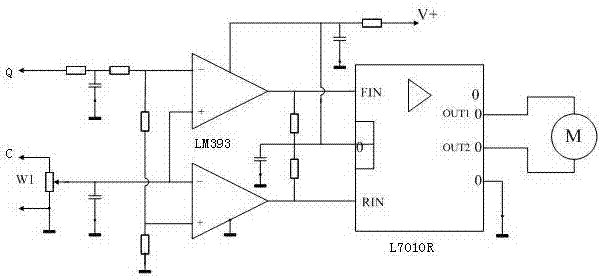

Method and control system of electric discharge machining processing feed automatic control

InactiveCN103084675AReduce weightReduce volumeElectric circuitsElectrostatic dischargeAutomatic control

The invention relates to the technical field of electric discharge machining processing feed automatic control, and discloses a method and a control system of the electric discharge machining processing feed automatic control. An electric discharge machining processing feed method utilizes a feed automatic control system to feed automatically. The feed automatic control system uses a comparison circuit which receives discharge gaps to be connected with an execution circuit through an amplification drive circuit, feed signals of the execution circuit are fed back to the comparison circuit through a controlled plant circuit and a sampling circuit and are in electric connection with the controlled plant circuit, the sampling circuit and the comparison circuit. The method and the control system of the electric discharge machining processing feed automatic control can control sizes of discharge gaps effectively, achieve the effect of electrical discharge machining, have the advantages of being light in weight, small in size, low in cost, stable in performance, simple to operate, high in response and long in service life, improve use ratios of pulsed power supply, avoid arcing and burning, enable electrosparking to achieve better processing performance, are suitable for use of portable spark machines, and reflect the features that the portable spark machines are portable, economical, popular and easy to operate.

Owner:LUOYANG XINCHENG PRECISION MACHINERY

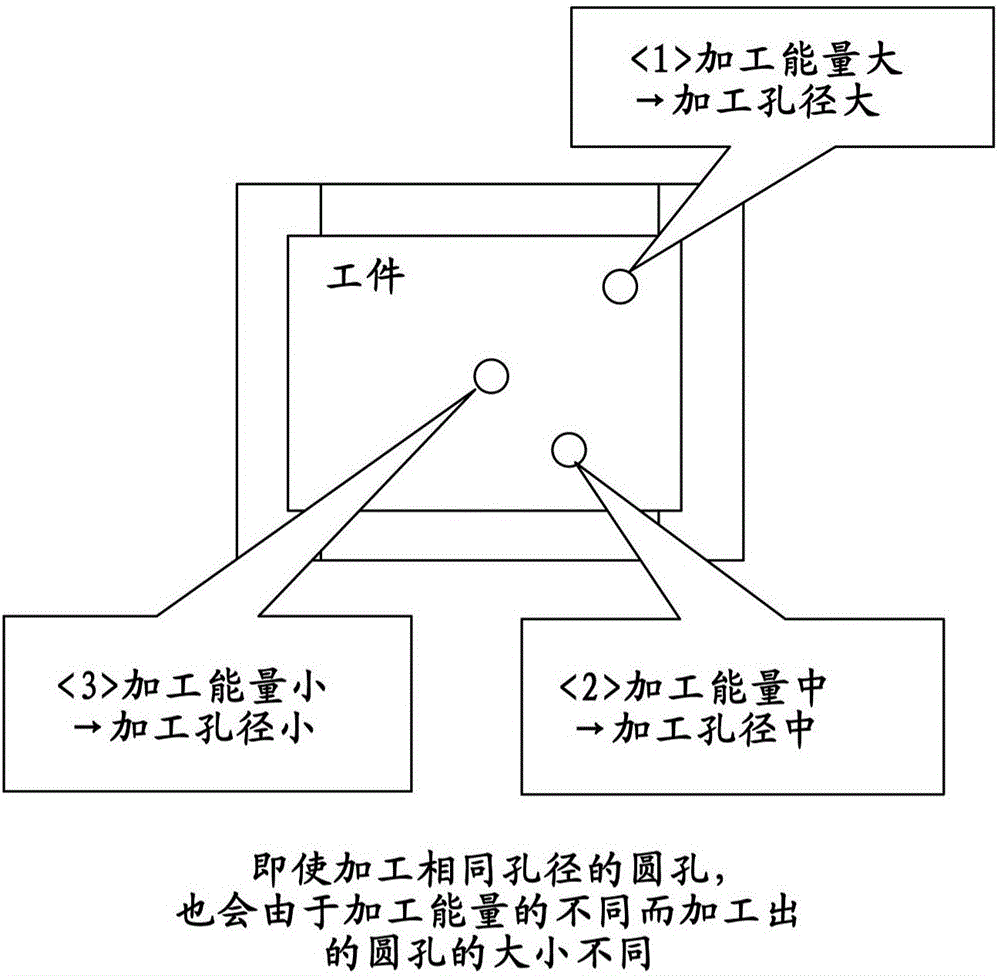

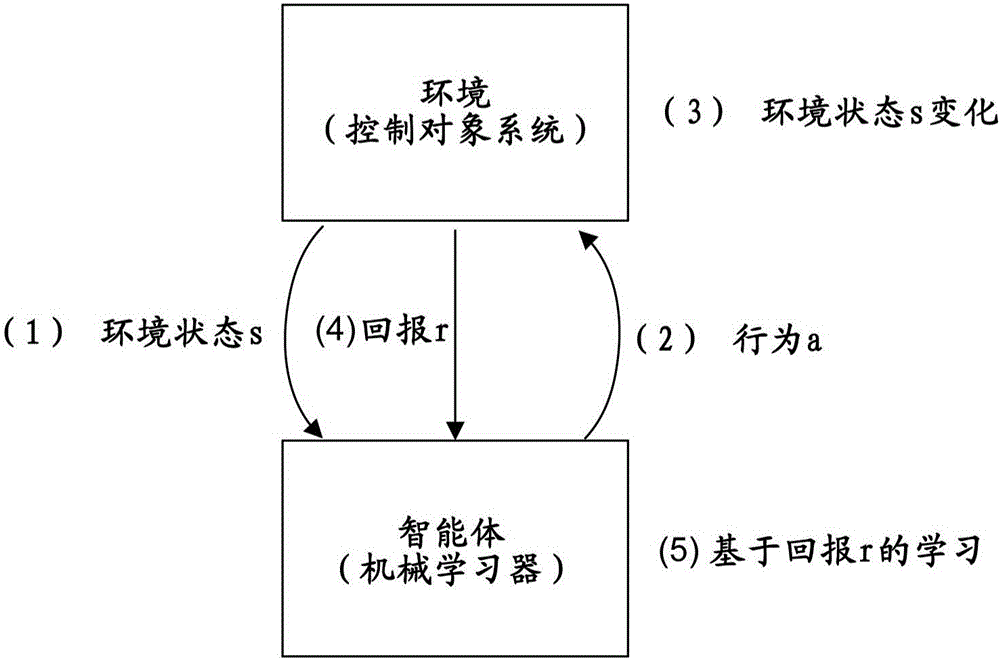

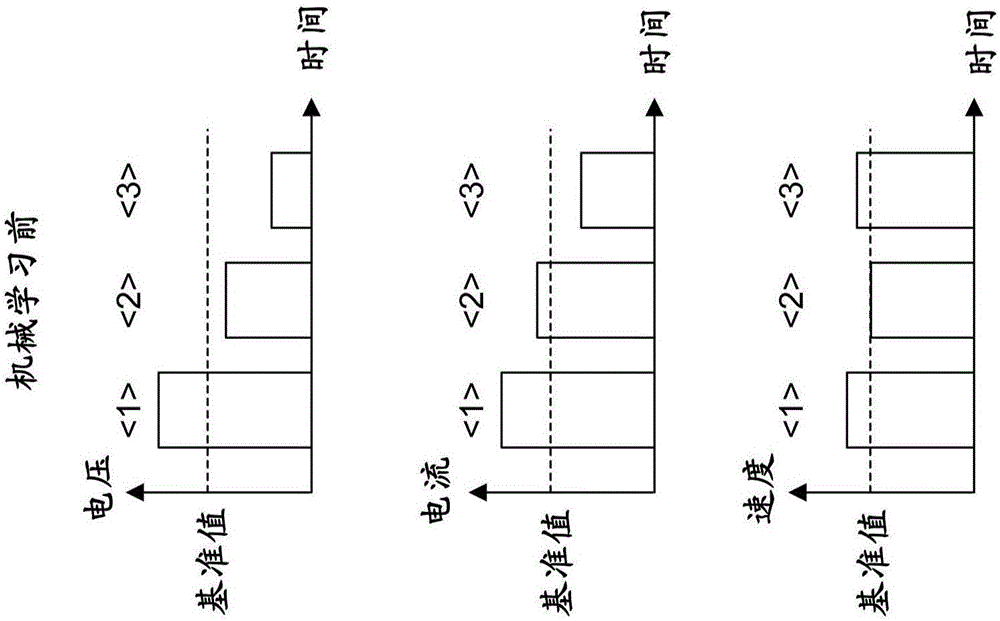

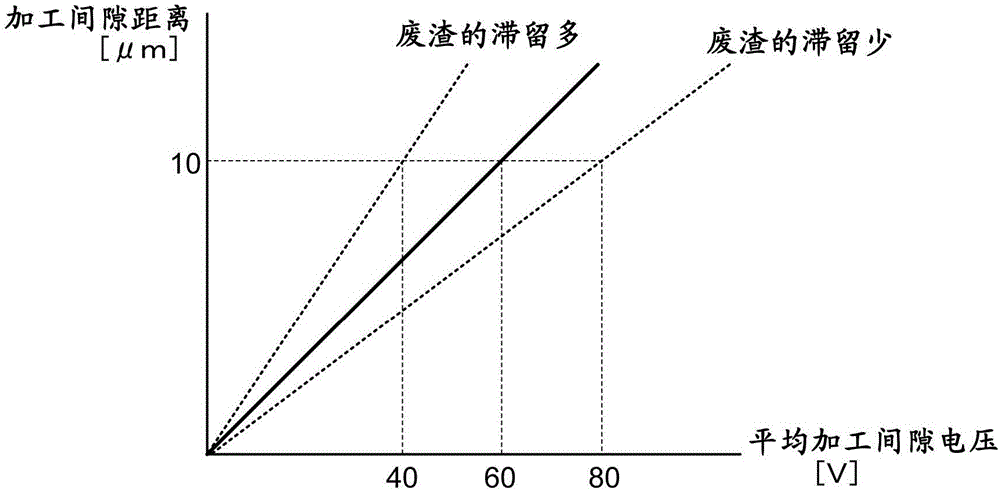

Wire electric discharge machine performing machining while adjusting machining condition

ActiveCN106475645AEliminate differences in processing energyImprove stabilityProgramme controlArtificial lifeLearning unitElectric discharge

A wire electric discharge machine according to the present invention includes a machine learning device which performs machine learning for adjustment of a machining condition of the wire electric discharge machine, the machine learning device includes a state observation unit which acquires data related to a machining state of a workpiece, a reward calculation unit which calculates a reward based on data related to a machining state, a machining condition adjustment learning unit which determines an adjustment amount of a machining condition based on a machine learning result and data related to a machining state, and a machining condition adjustment unit which adjusts a machining condition based on the determined adjustment amount of a machining condition, and the machining condition adjustment learning unit performs machine learning for adjustment of a machining condition based on the determined adjustment amount of a machining condition, data related to a machining state and acquired by the state observation unit, and a reward which is calculated by the reward calculation unit.

Owner:FANUC LTD

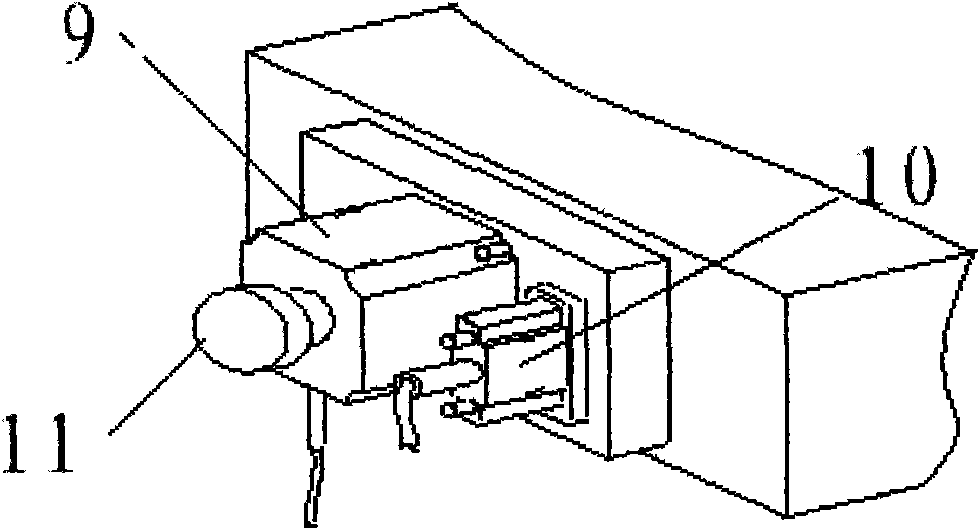

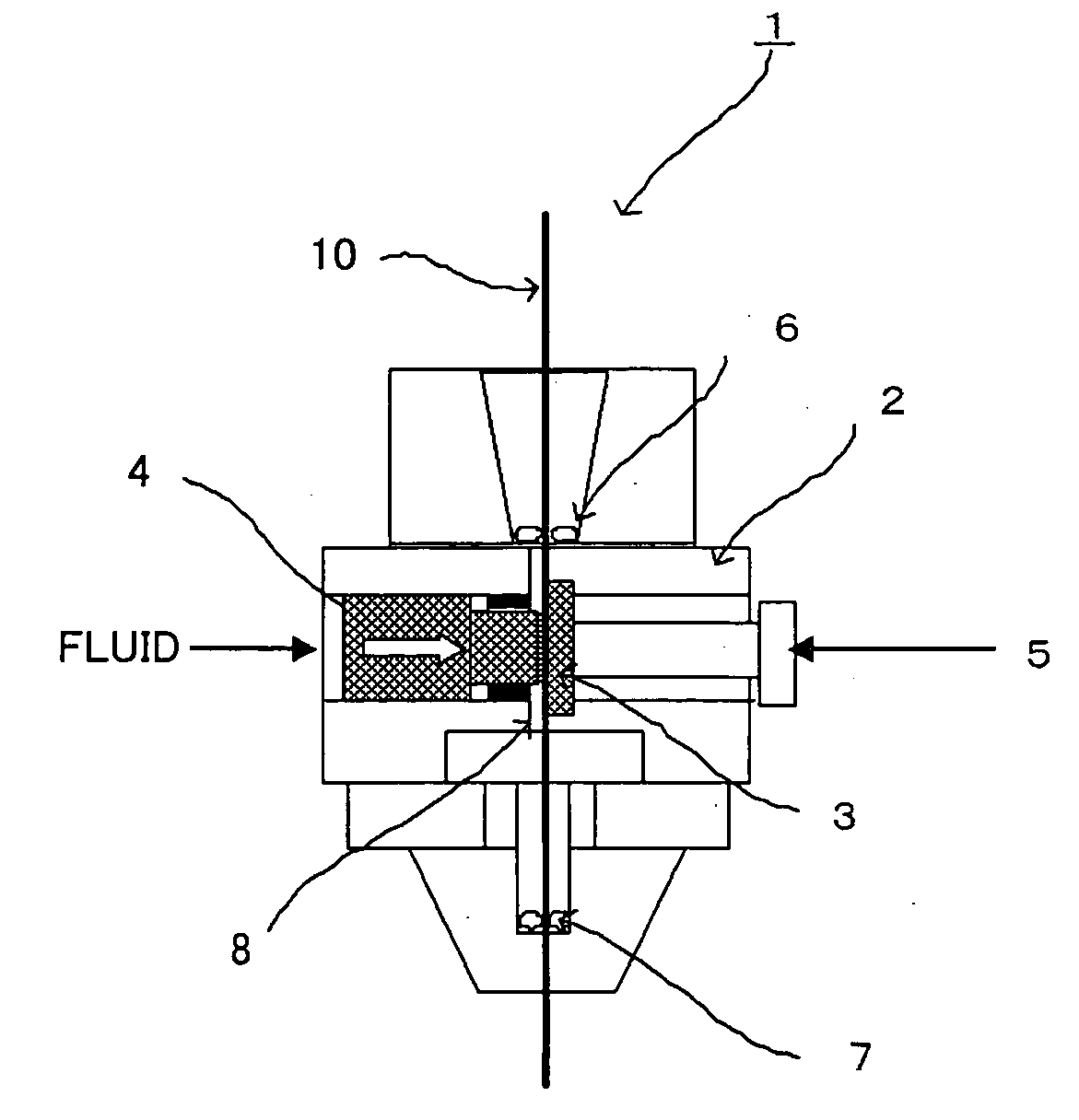

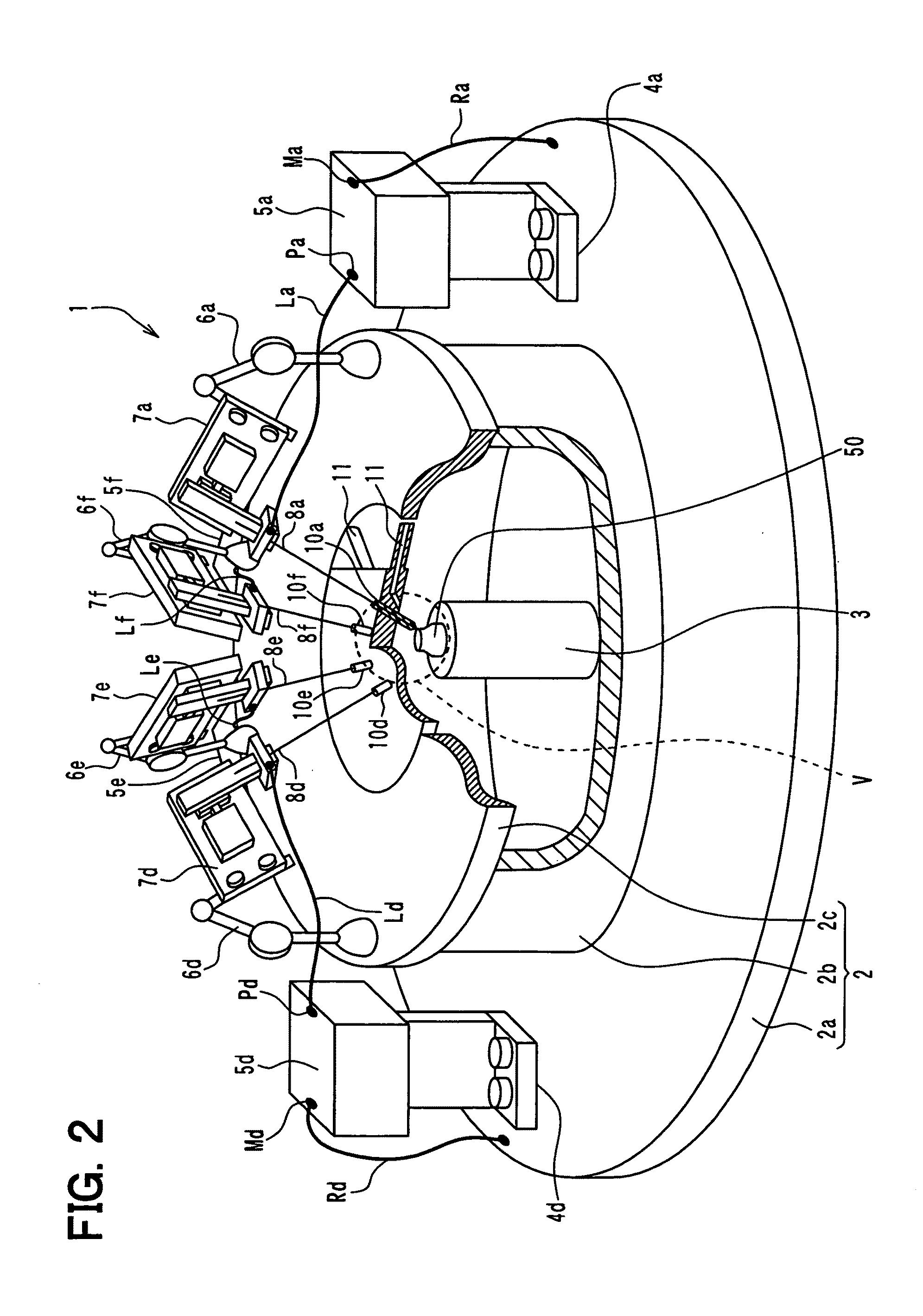

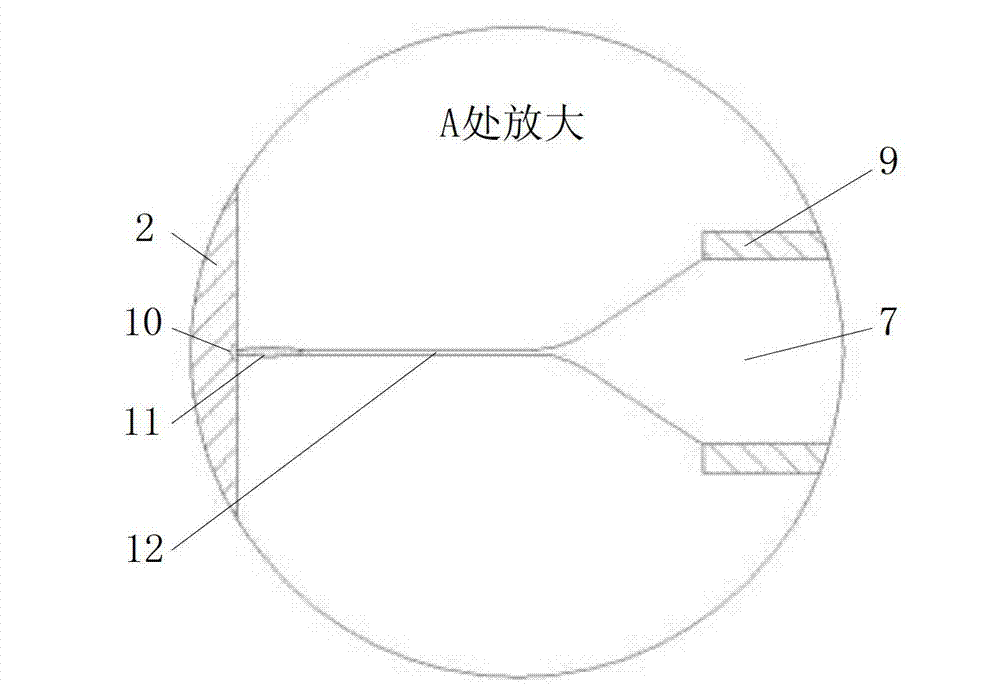

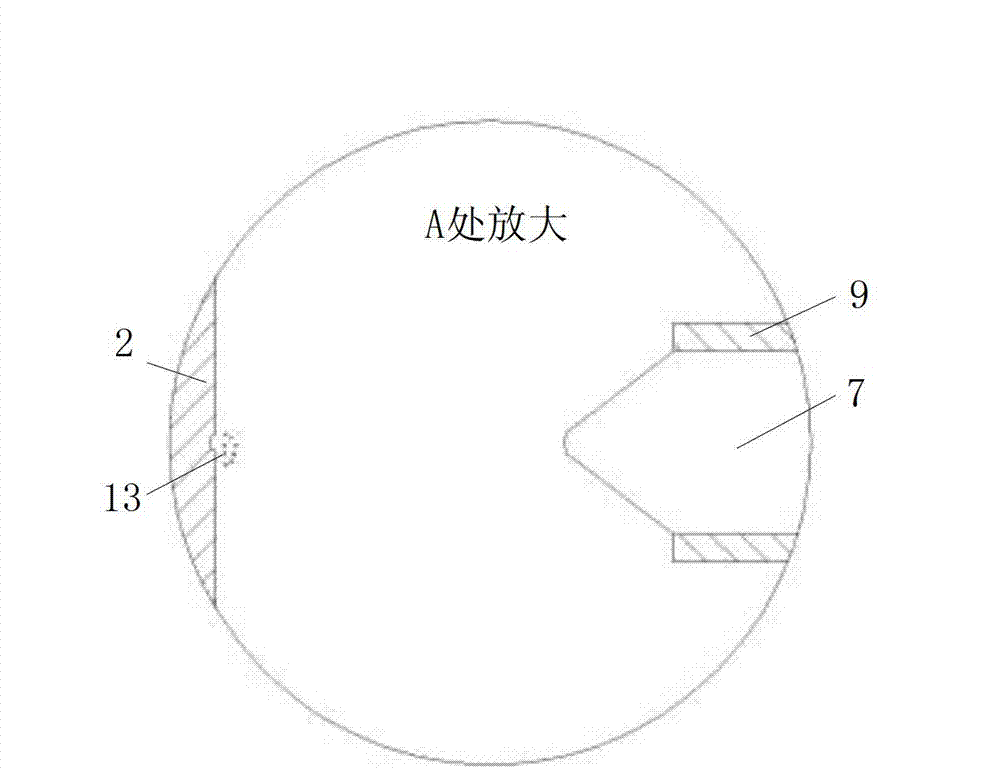

Electric discharge machining apparatus

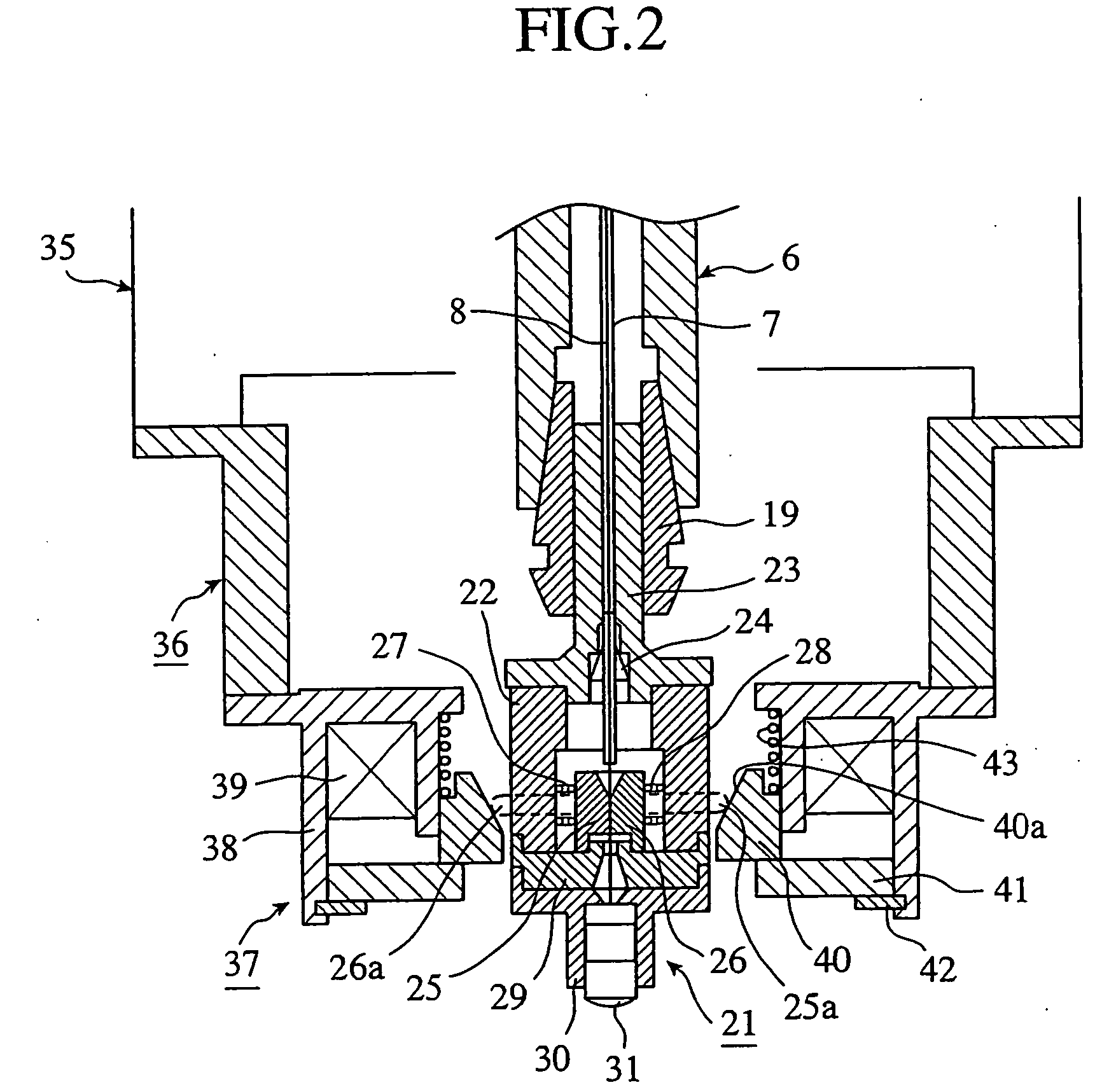

InactiveUS20070102402A1Prevent bucklingAvoid vibrationElectrode vibration holdersElectrical-based machining electrodesEngineeringFluid supply

An electric discharge machining apparatus includes: a guide electrode (7) that is shaped like a hollow bar and receives a small-diameter wire electrode (8) for electric discharge machining in such a way that the small-diameter electrode can freely slide and; guide electrode holding means (9, 19, 20) that holds this guide electrode (7) at a specified position; pressurized fluid supply means (10, 11) that supplies pressurized fluid into the guide electrode (7) to feed out the small-diameter wire electrode (8) from inside the guide electrode (7) to an electric discharge machining side; and small-diameter wire electrode holding means (21) that automatically holds the small-diameter wire electrode (8) fed out of the guide electrode (7).

Owner:MITSUBISHI ELECTRIC CORP

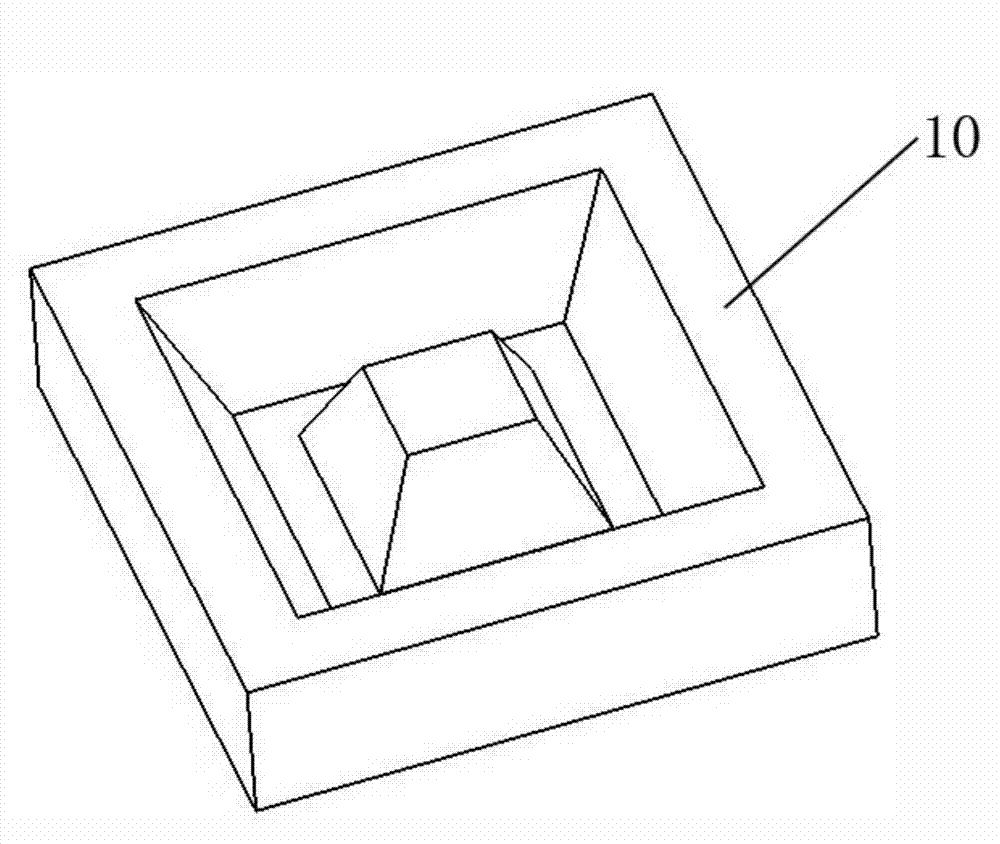

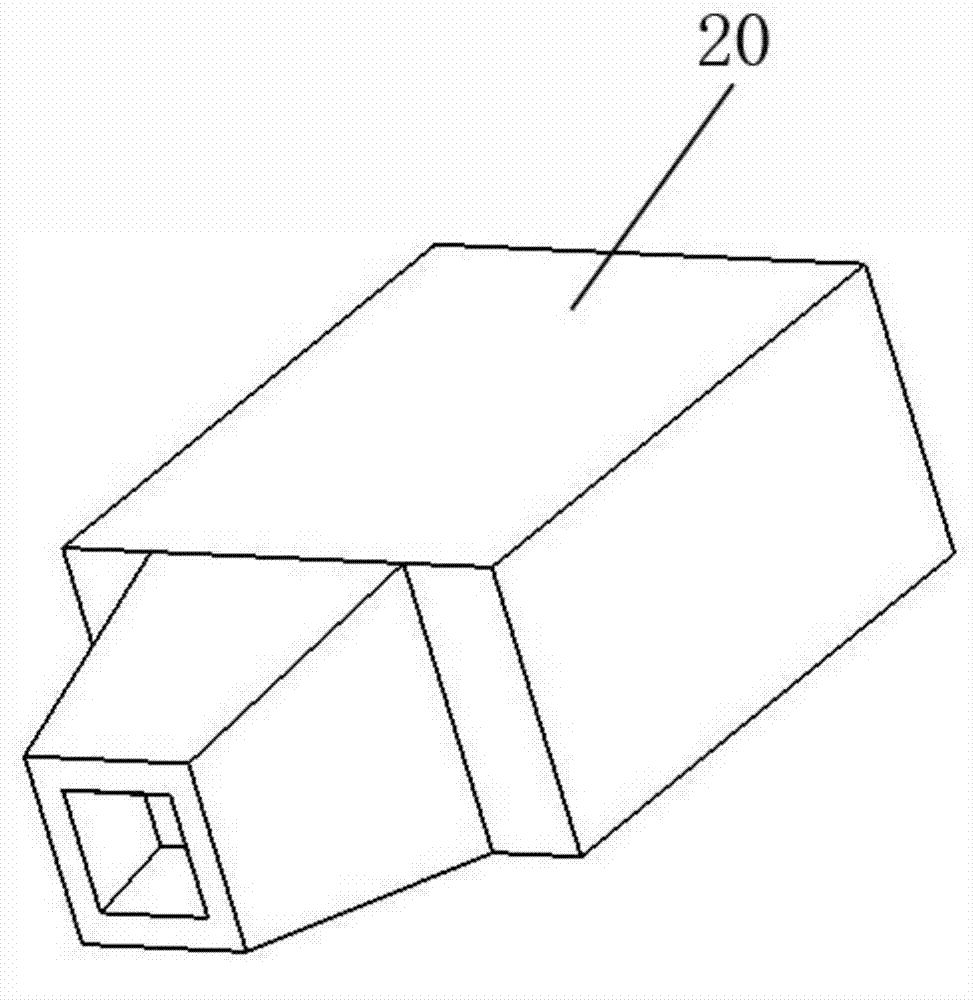

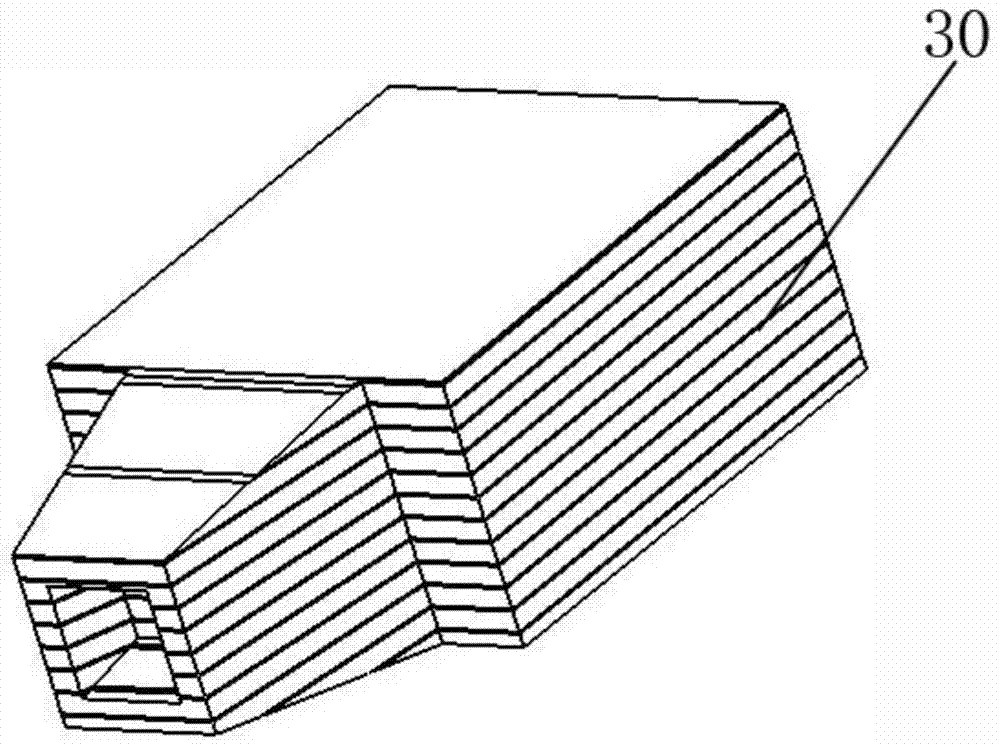

Processing method of three-dimensional microstructure prepared by minute electric sparks based on sheet electrodes

InactiveCN103480929AHigh fitting approximation accuracyAvoid stackingElectric dischargeGeometric modeling

The invention relates to a processing method of a three-dimensional microstructure prepared by minute electric sparks based on sheet electrodes. The processing method includes establishing three-dimensional microstructure CAD (computer-aided design) geometric models first, establishing three-dimensional minute electric spark electrode CAD geometric models corresponding to the established three-dimensional microstructure CAD geometric models, slicing the three-dimensional minute electric spark electrode CAD geometric models in dispersedness, transforming disperse slices geometric models into a group of slice electrode data models in mutually parallel, slicing corresponding slice electrodes on a slice electrode material one by one by a slice slicing system according to the slice electrode data models in a computer to acquire a group of slice electrode array, and performing minute electric spark machining. With the manufacturing method, electric discharge machining via large-size scanning and milling by layers of cylindrical microelectrodes is avoided when two-dimensional slice electrodes perform electric discharge machining, and an up and down type moving electric discharge mode can effectively increase machining efficiency and reduce microelectrode loss.

Owner:深圳市全达高分子材料科技有限公司

Wire electric discharge machine having estimation function for filter replacement timing

ActiveUS20160096231A1Water treatment parameter controlMachining working media supply/regenerationElectric dischargeReliability engineering

A wire electric discharge machine has a function of estimating the time for replacement of a filter based on a use situation for the machine. A time Tr during which the filter is serviceable is calculated according to an equation, Tr=|(Pd−Pn) / ΔP|, based on a fluid pressure variation amount ΔP, a current filter fluid pressure Pn, and a filter life pressure. A remaining available time Td for the filter which takes into account the operation rate of the machine is calculated according to an equation, Td=Tr / W.

Owner:FANUC LTD

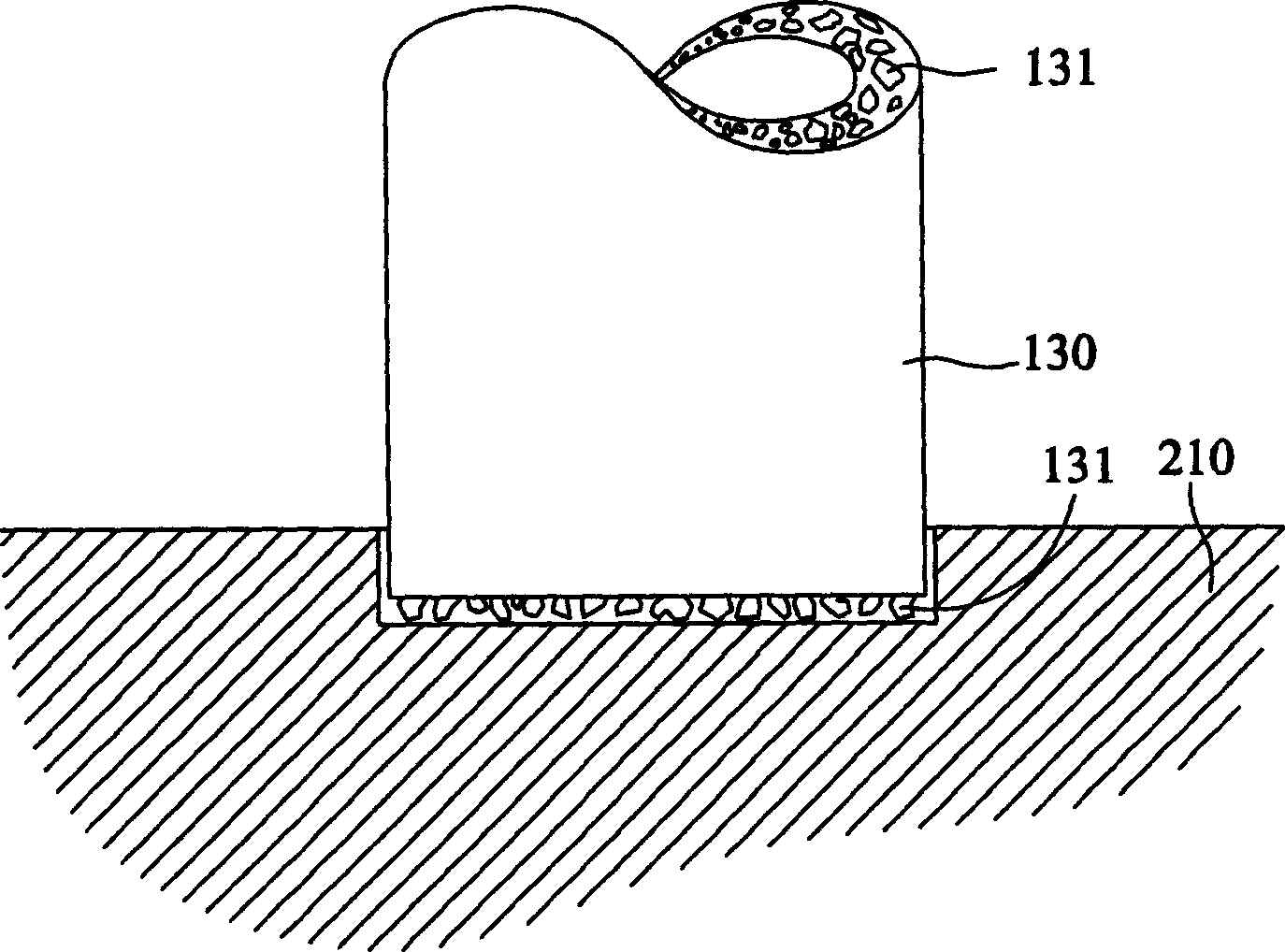

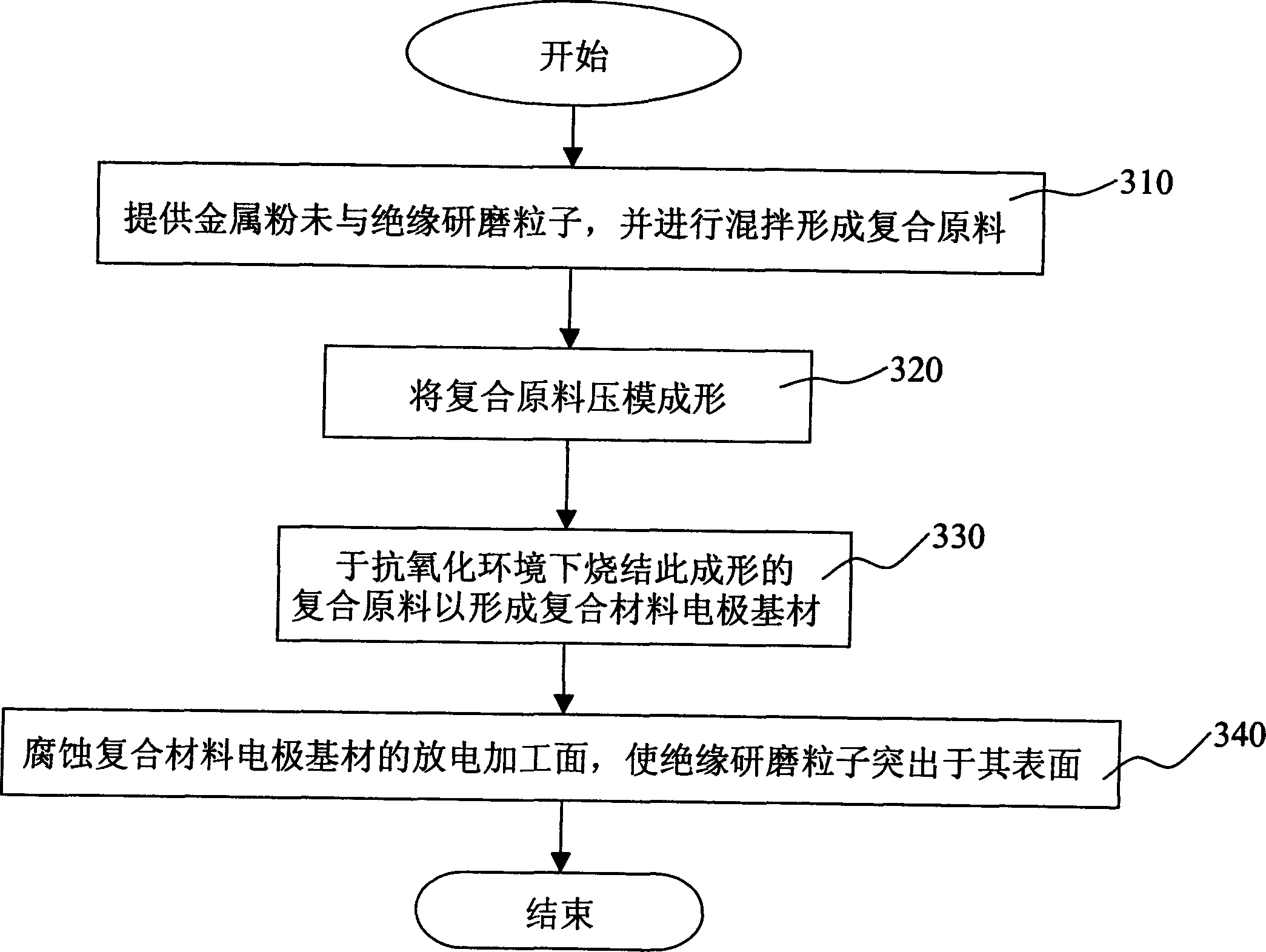

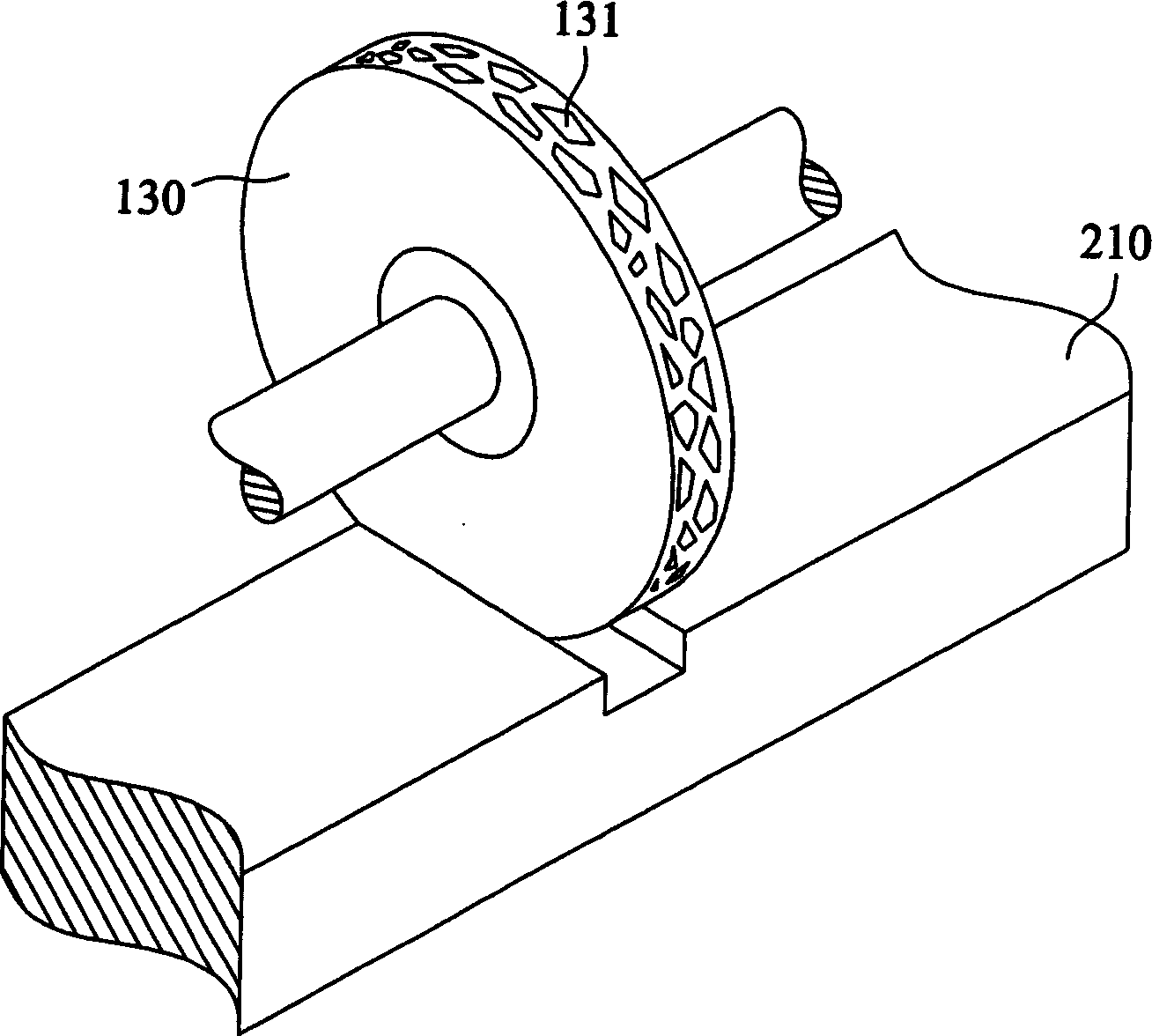

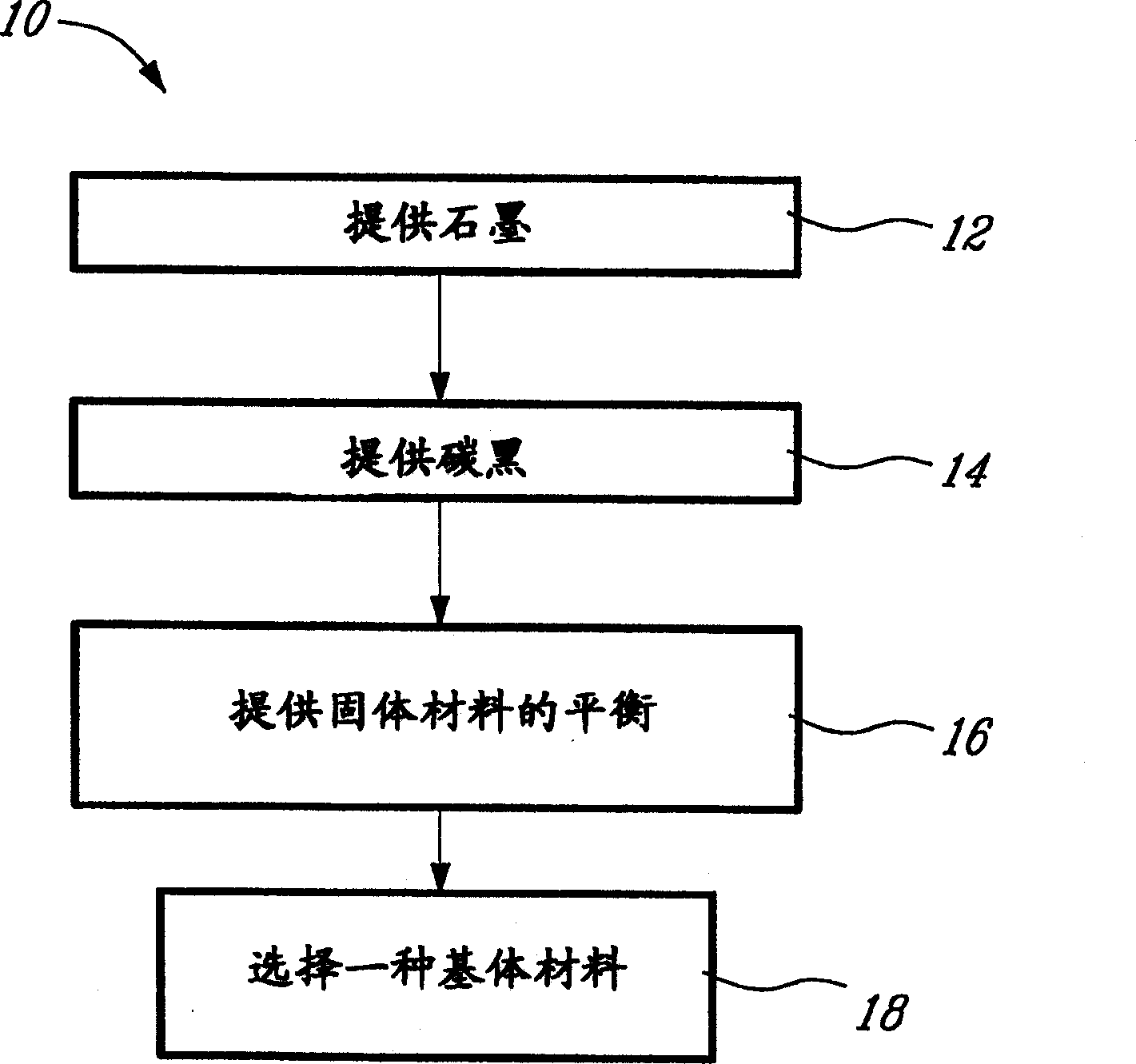

Combined material electrode for electrodischarge machining and is manufacturing method

InactiveCN1565786AIncrease EDM speedElectrical-based machining electrodesElectric dischargeMetal powder

The invention discloses a composite material electrode for electric discharge machining and the preparation method. The electric discharge machining surface for the composite material electrode comprises a bulgy hard insulating grinding particle. In the process of electric discharge machining, the bulge around the indent is removed by grinding. The processing method includes the following steps: sintering the metal powder and the nonconducting and fire-resistant grinding particles in a manner of powder metallurgy, making the insulating grinding particles higher than the electric discharge machining surface by corrosion.

Owner:涂肇嘉 +1

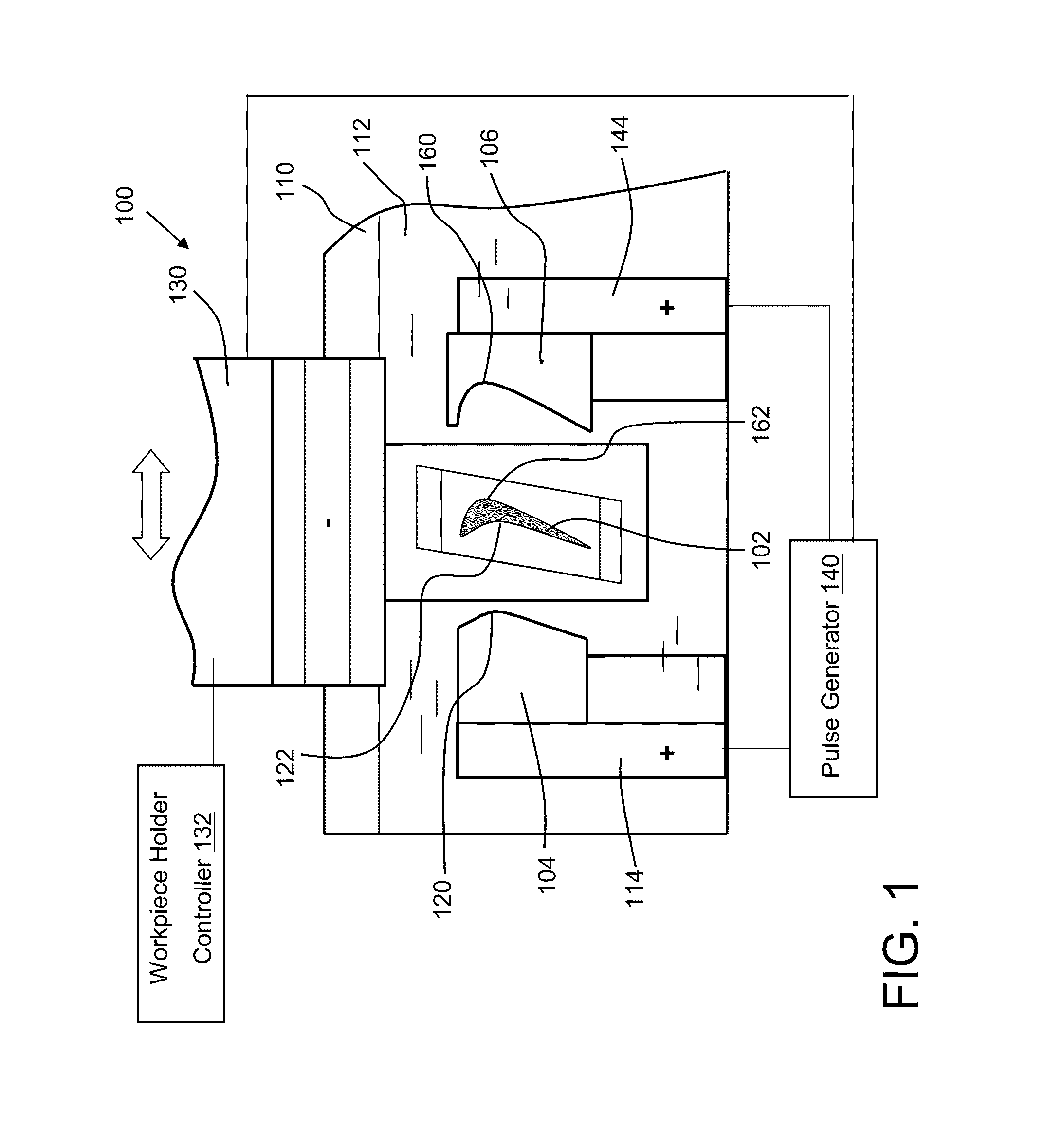

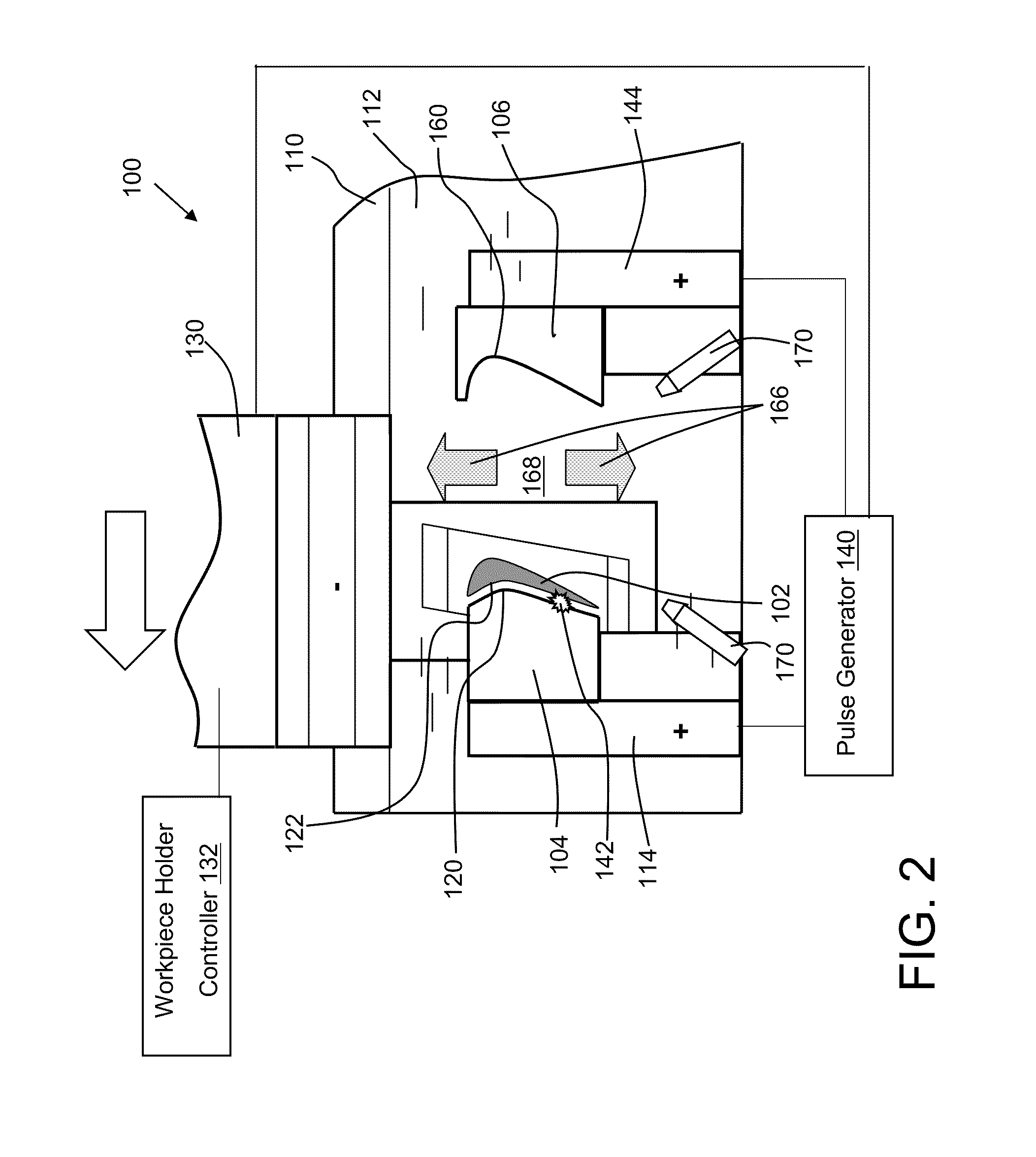

Electrical discharge machining

ActiveUS20130248495A1Large spark gap sizeEfficient removalElectrode vibration holdersElectrical-based auxillary apparatusLong axisEngineering

A method for electrical discharge machining a workpiece includes the steps of: presenting an elongate electrode to the workpiece with a spark gap therebetween; flowing a dielectric fluid in the gap; eroding the workpiece by electrical discharge between the tip of the electrode and the workpiece; displacing the electrode in a direction aligned with the long axis of the electrode to maintain the gap as the electrode wears and the workpiece is eroded; and simultaneously with the displacement, producing vibratory movement of the electrode, the vibratory movement being aligned with the long axis of the electrode.

Owner:ROLLS ROYCE PLC

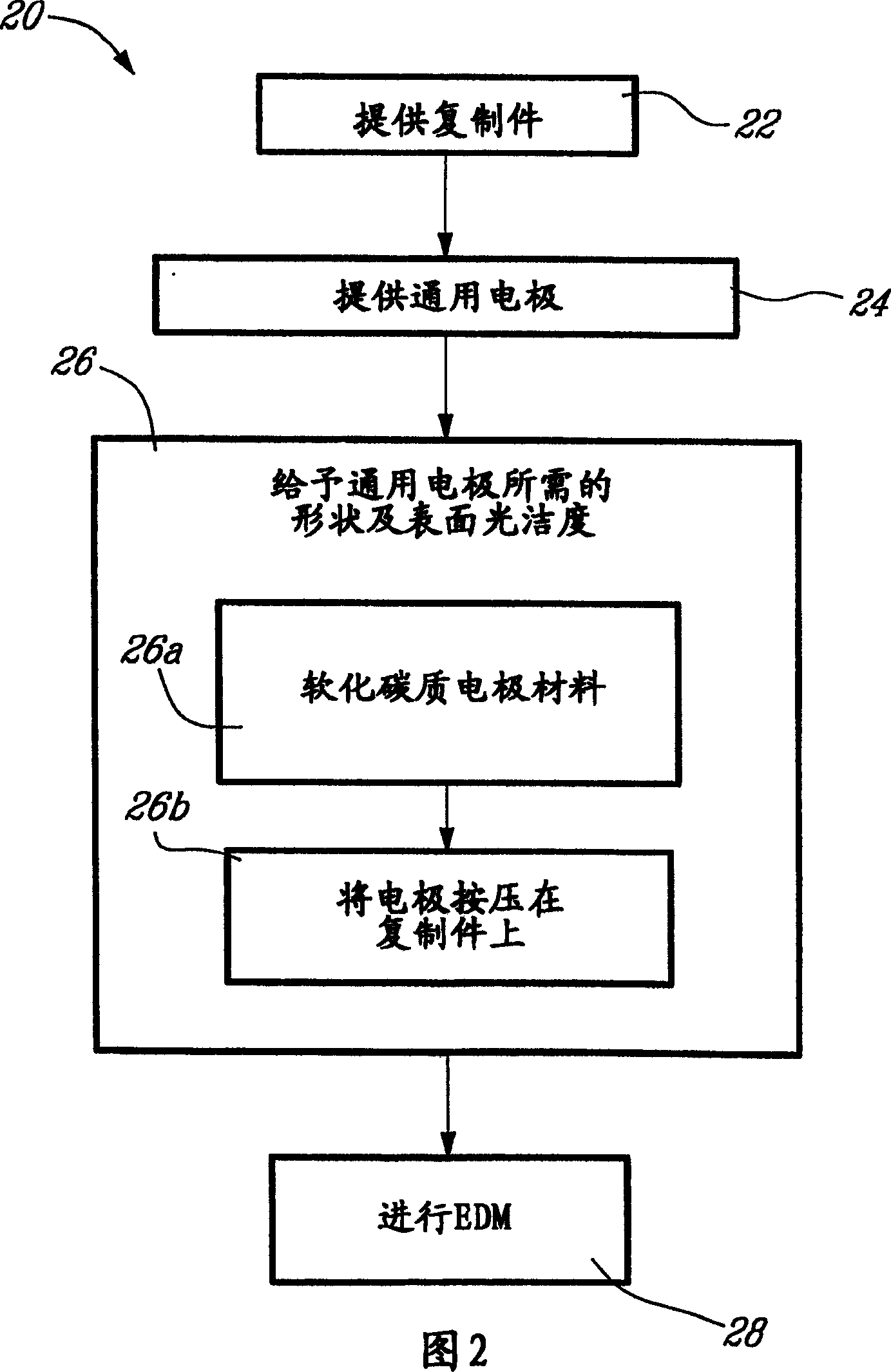

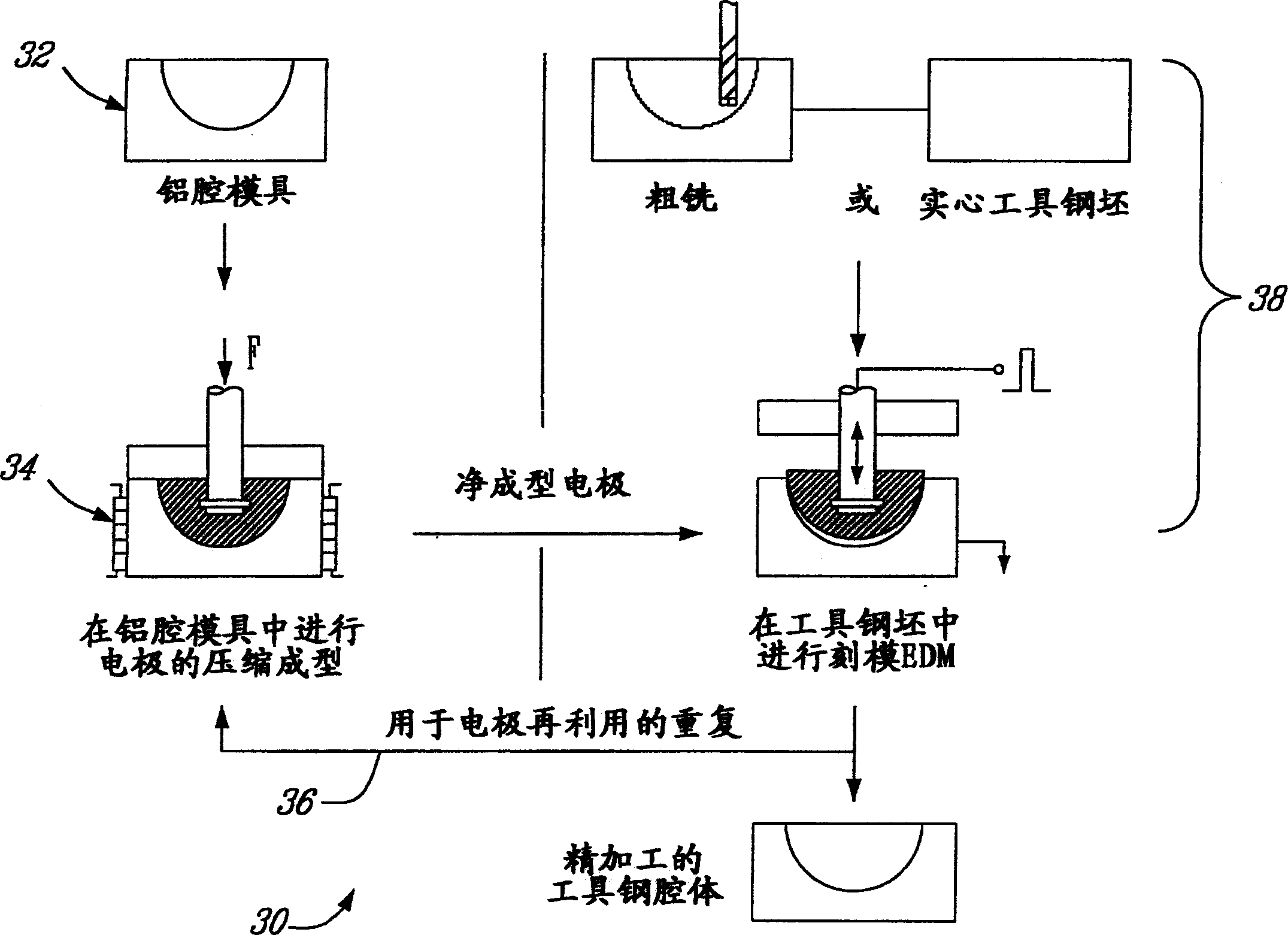

Electric discharge machining electrode and method

InactiveCN1607987AMaterial nanotechnologyElectrical-based machining electrodesSurface finishElectric discharge

A method of electrical discharge machining (EDM) using a malleable carbon electrode that automates roughing, finishing, finishing, and texturing operations on conductive materials. The EDM method involves the use of a moldable conductive electrode made of a carbon-polymer composite. Electrodes are made by uniformly heating a specified amount of said plastic electrode material at a temperature near the melting point of the polymer matrix prior to electrical discharge machining. Next, the composite material is formed into the desired electrode shape by pressing the soft material onto a template, a mold pattern, the workpiece, or a replica of a portion of the workpiece. The workpiece is then machined to the desired shape and surface finish using the formed electrodes using appropriate electrical discharge machining techniques. By adopting an initial softening and pressing procedure when the dimensions of the electrode and its surface have changed due to wear, the same electrode can be repaired quickly and repeatedly until the workpiece is complete.

Owner:UNIV LAVAL

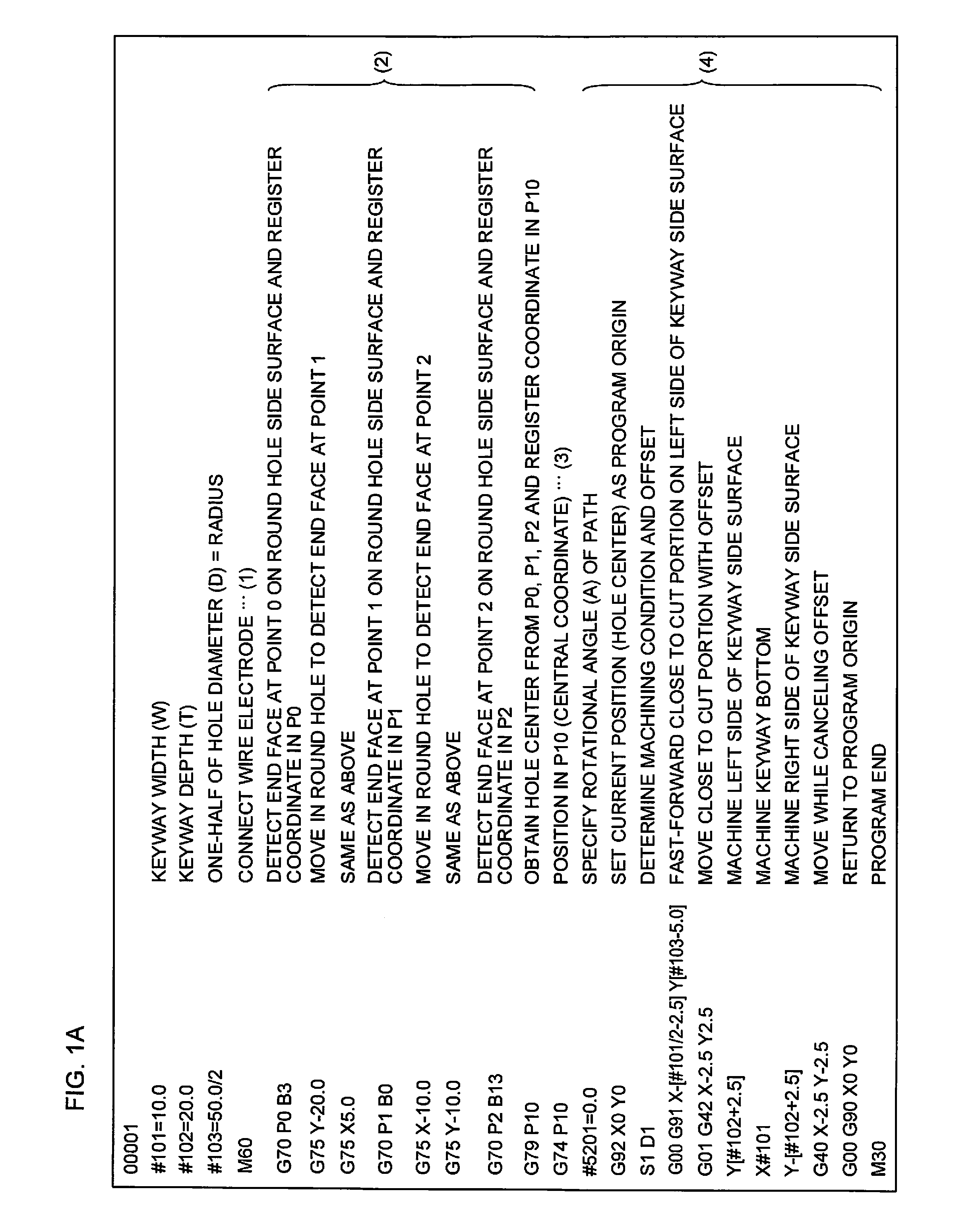

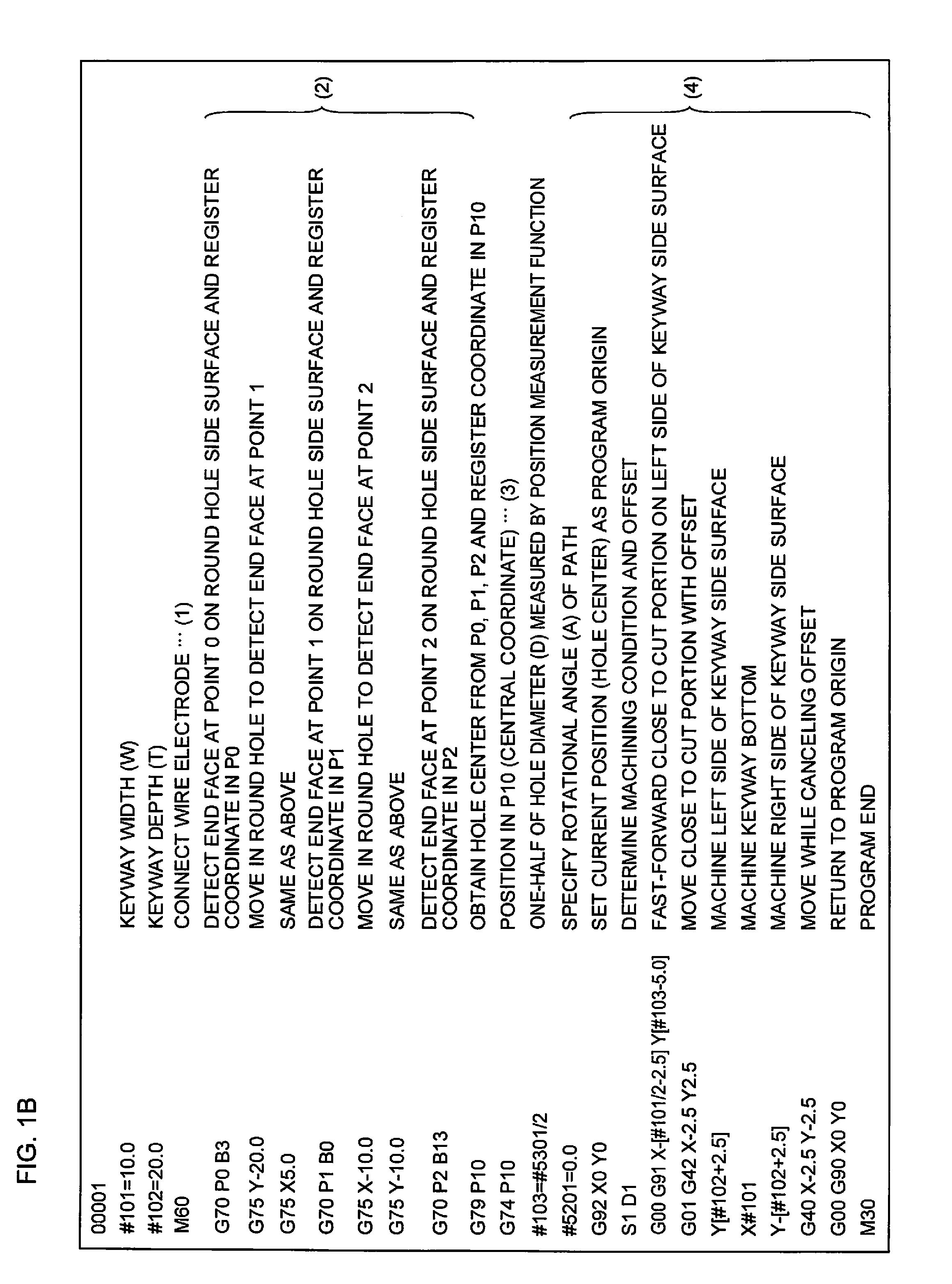

Machining program creating device for keyway milling for wire electric discharge machine

ActiveUS20150367436A1Improve productivityProgramme controlComputer controlElectric dischargeWire cutting

A machining program creating device for a wire electric discharge machine creates a machining program for machining a keyway on the side surface of a round hole in a workpiece, based on a previously specified diameter of the round hole, a center position of the round hole measured by bringing a wire electrode into contact with the workpiece, and a previously defined shape of the keyway.

Owner:FANUC LTD

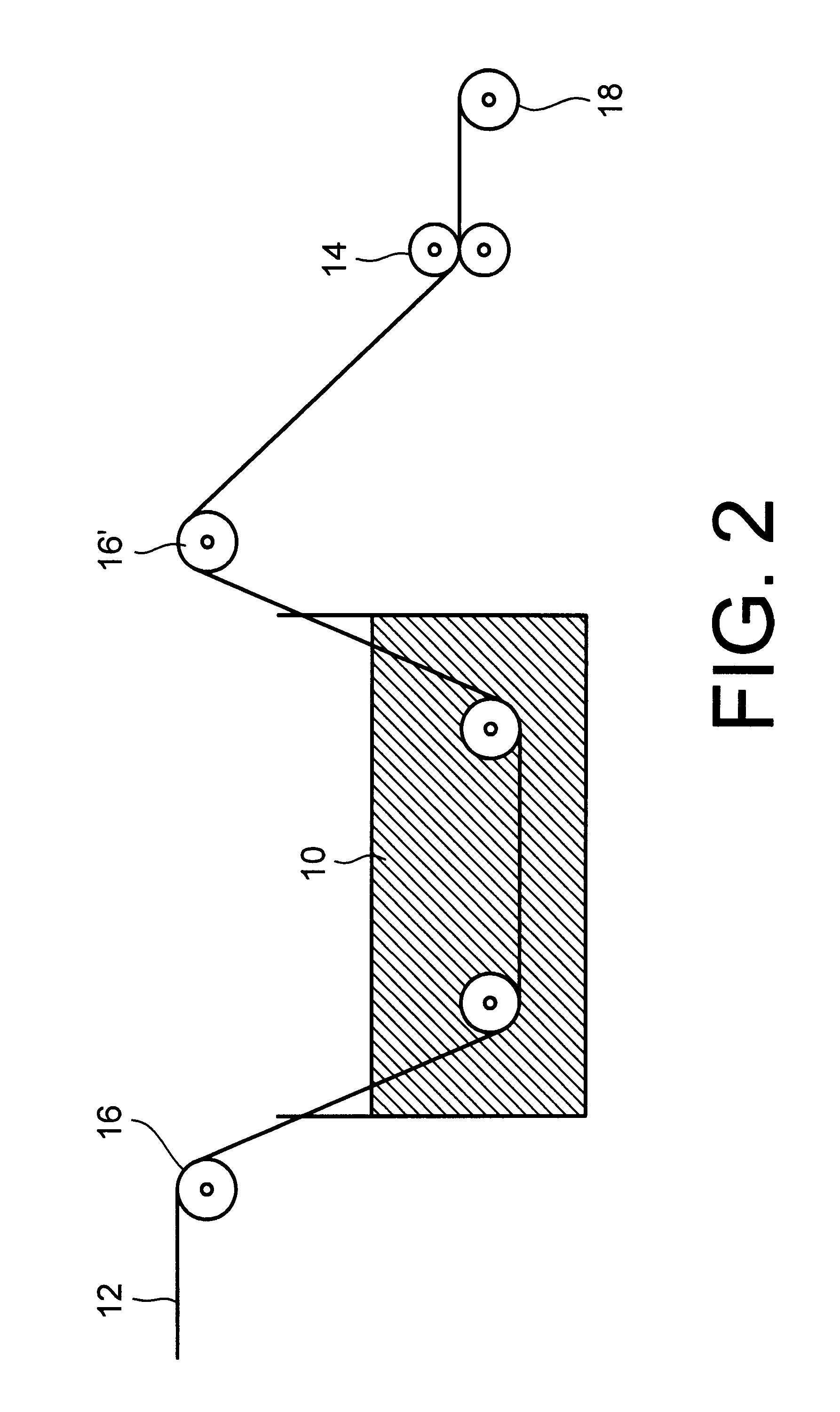

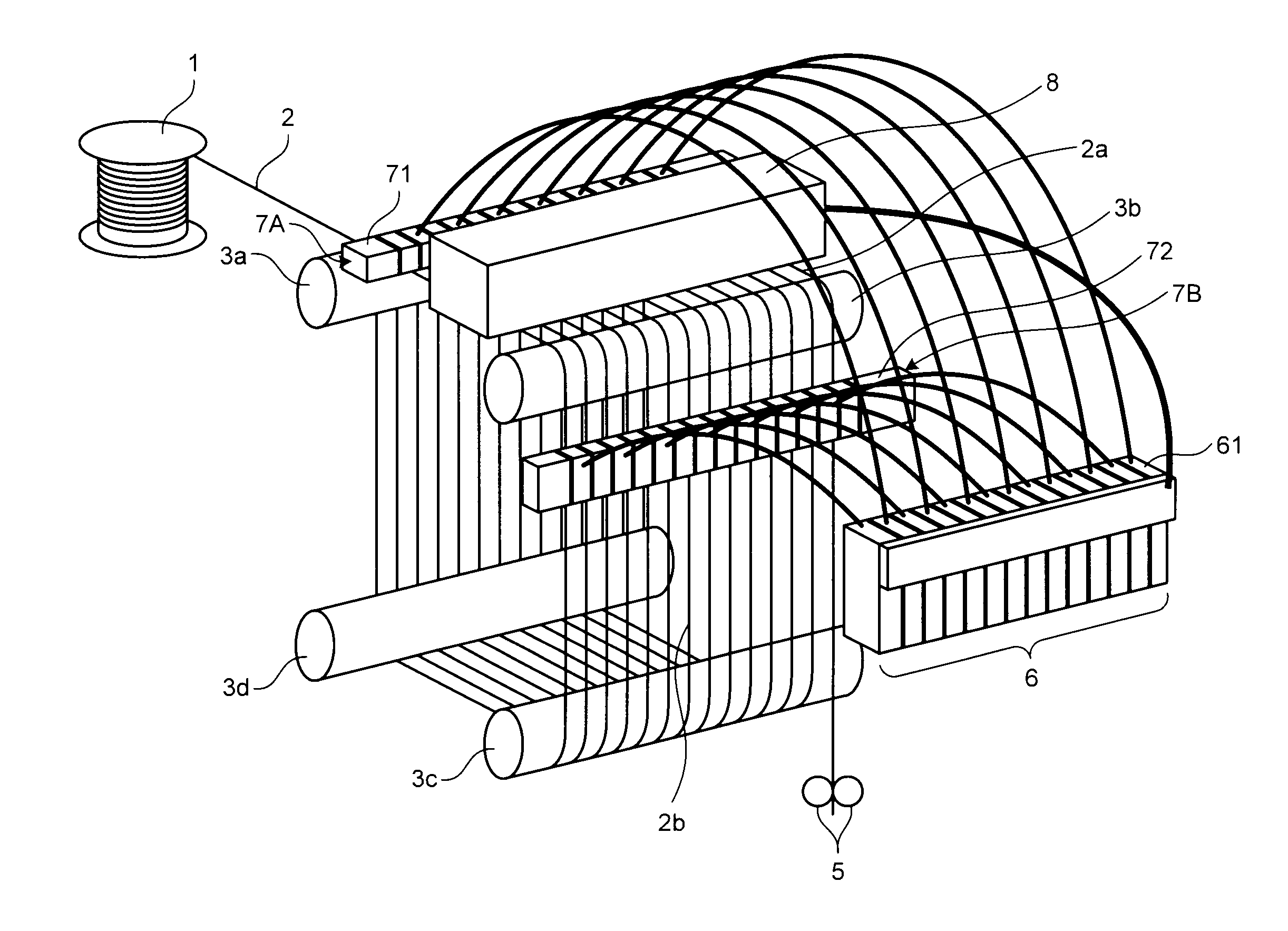

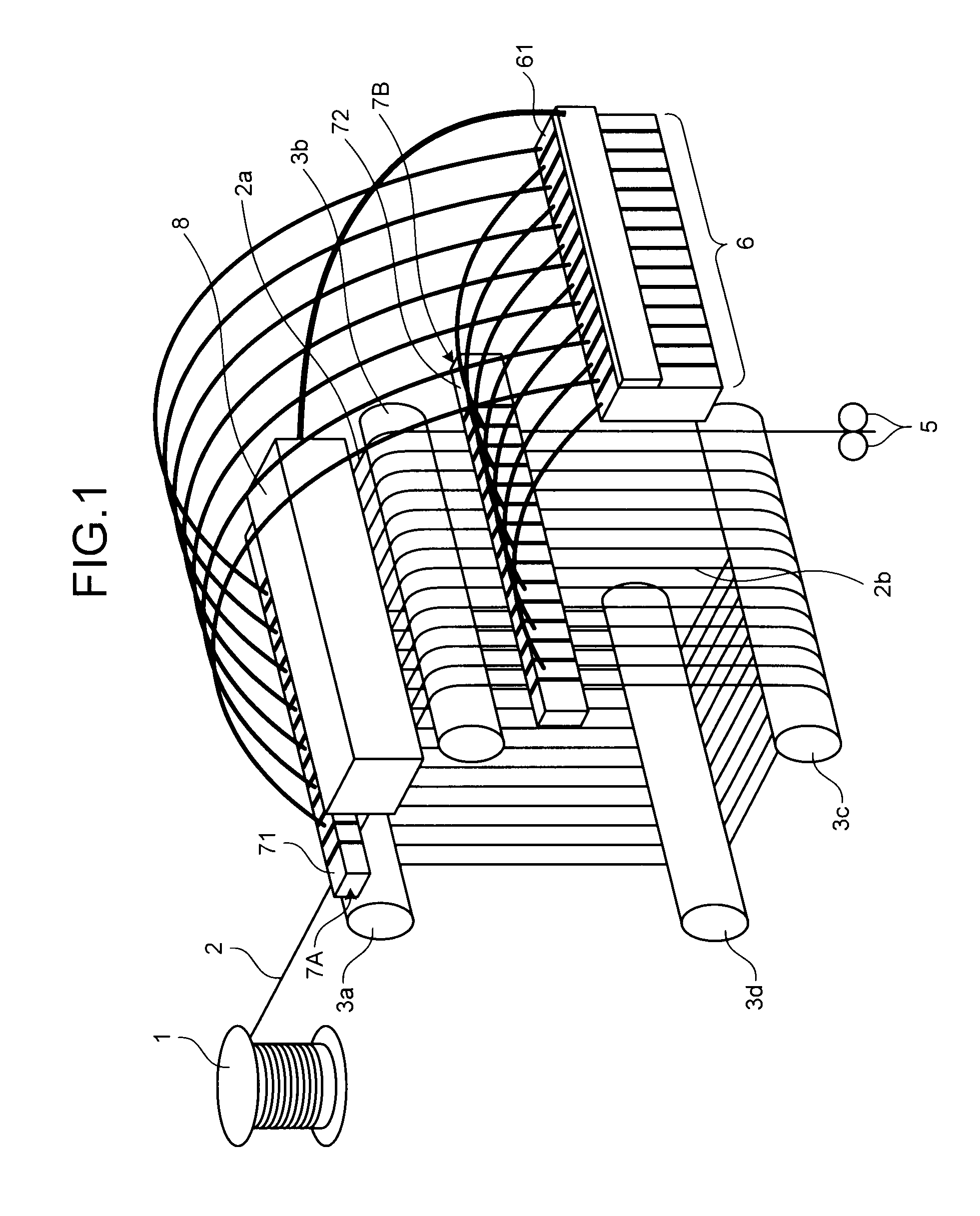

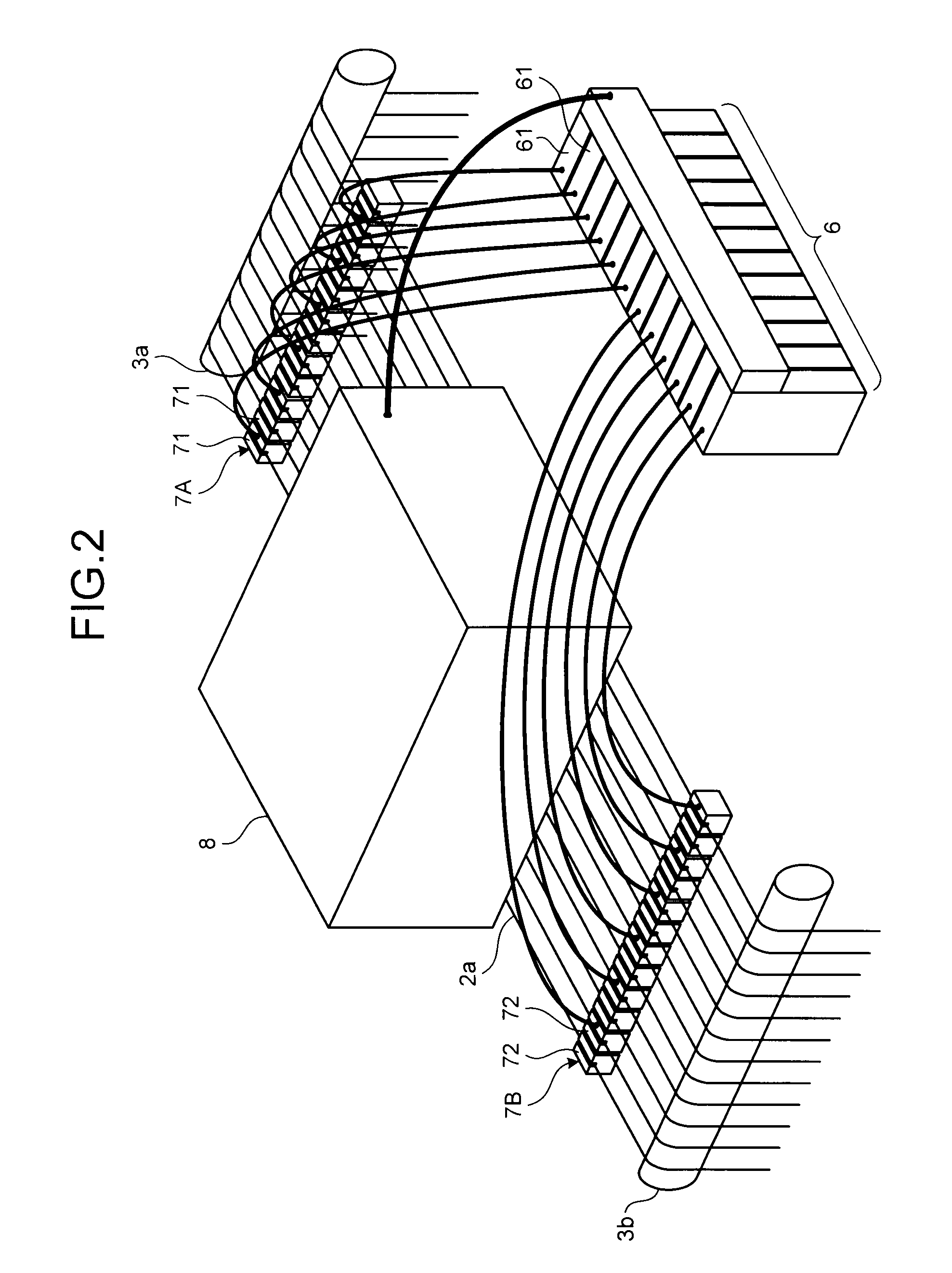

Wire discharge-machining apparatus and wire discharge-machining method, semiconductor wafer manufacturing apparatus and semiconductor wafer manufacturing method, and solar-cell wafer manufacturing apparatus and solar-cell wafer manufacturing method

ActiveUS20110092053A1Decrease in electromagnetic forceWarping of wire electrodes is suppressedSemiconductor/solid-state device manufacturingElectrical-based machining electrodesSolar cellSemiconductor wafer fabrication

A wire machining method includes: a wire electrode set as cutting wires provided in parallel with a distance between the cutting wires of which a predetermined regional part faces a workpiece; a machining power source that generates a pulse-shaped machining voltage; and plural feeder units that are electrically connected to the plural cutting wires respectively of the wire electrode and supply the machining voltage between the cutting wires and the workpiece respectively. The feeder units are arranged such that a direction of a current passed to at least a part of the cutting wires becomes a direction different from a direction of a current passed to other cutting wires.

Owner:MITSUBISHI ELECTRIC CORP

Wire-cut electric discharge machine

InactiveUS20060065637A1Smooth connectionInhibit productionElectrical-based machining electrodesElectric dischargeMachining

A wire-cut electric discharge machine which improves contact between a wire electrode and a conducting member without deforming the wire electrode to suppress production of minute electric discharges and reduce unnecessary loads on the wire electrode and the wire-cut electric discharge machine, and which makes it easy to make space on a wire traveling path to carry out automatic wire connection easily. In a wire-cut electric discharge machine having a conducting member for supplying an wire electrode with electric power for electric discharge machining, and making the wire electrode travel along a traveling path, sliding on the conducting member, a movable member capable of being moved nearer to and away from the conducting member is provided in a position opposite to the conducting member relative to the traveling path. By this arrangement, the contact between the wire electrode and the conducting member can be always kept without deforming the wire electrode.

Owner:FANUC LTD

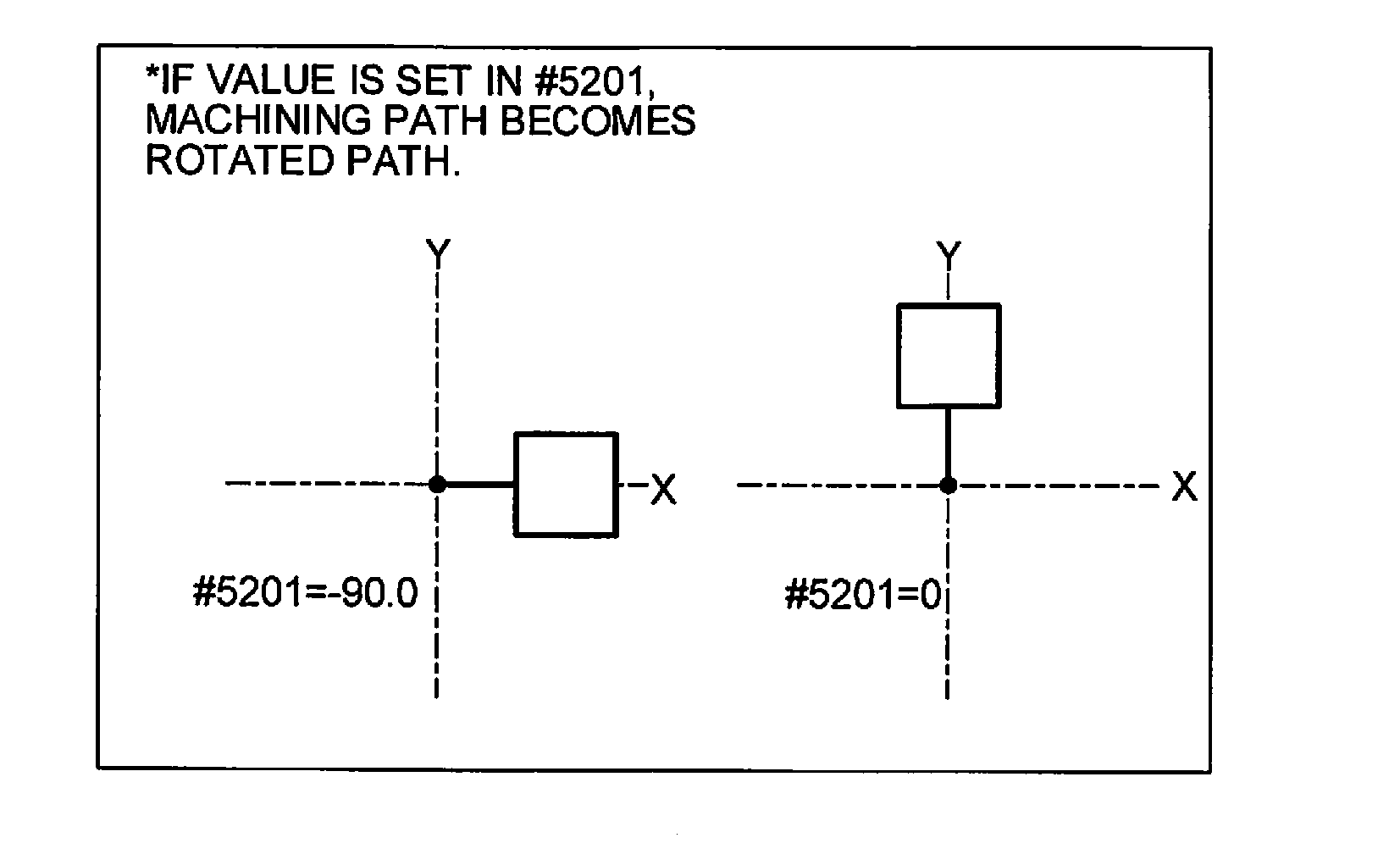

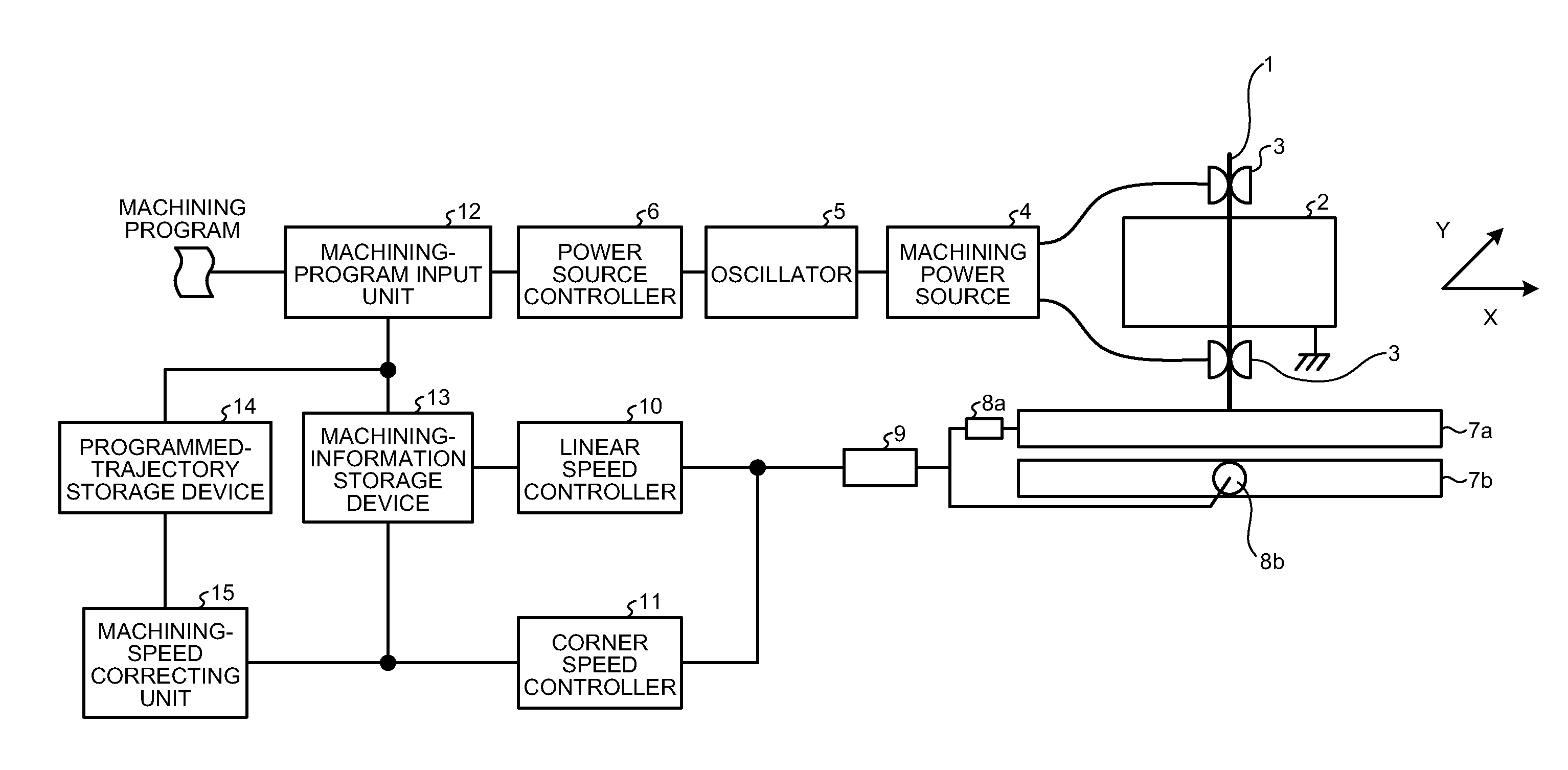

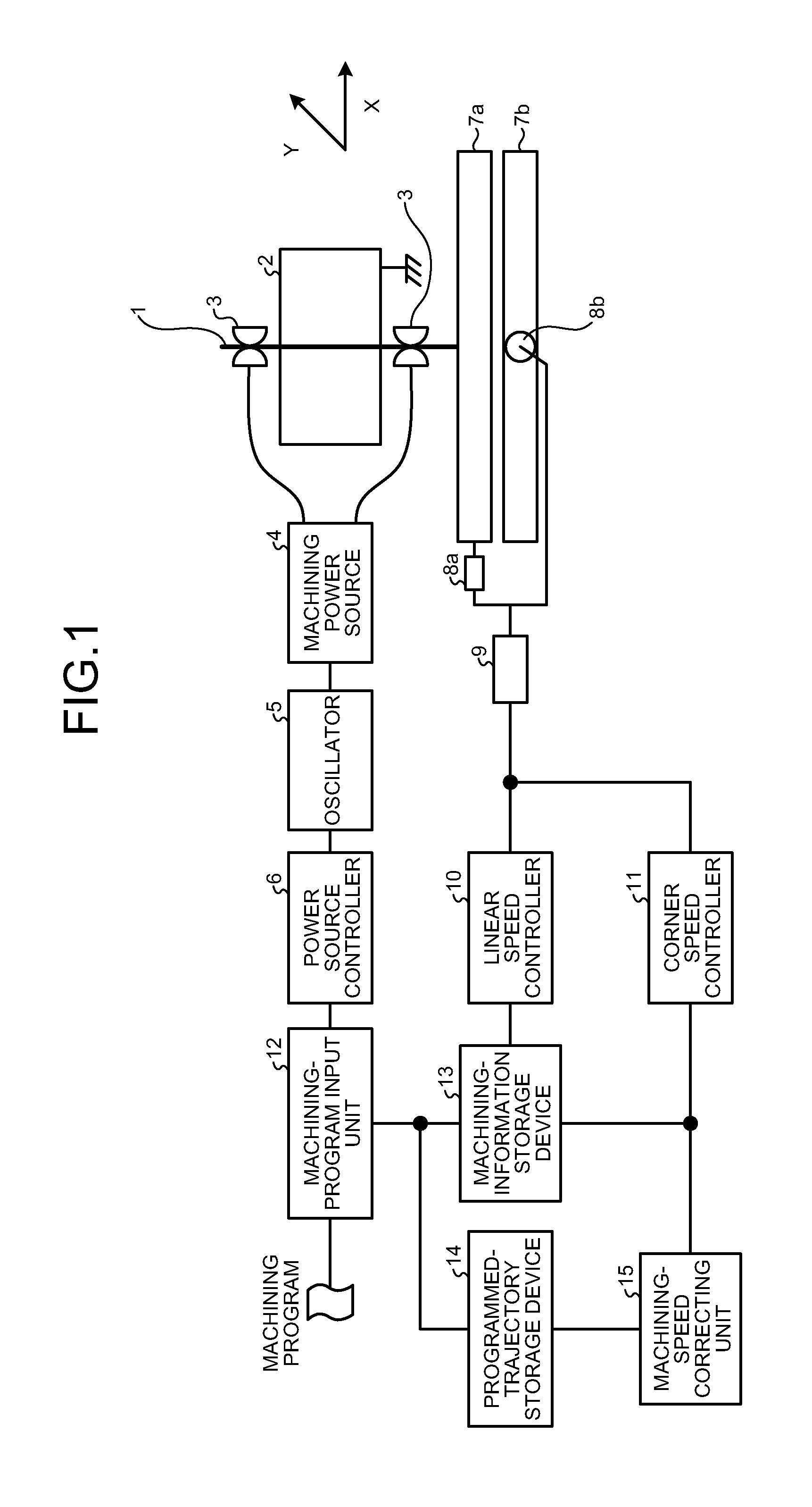

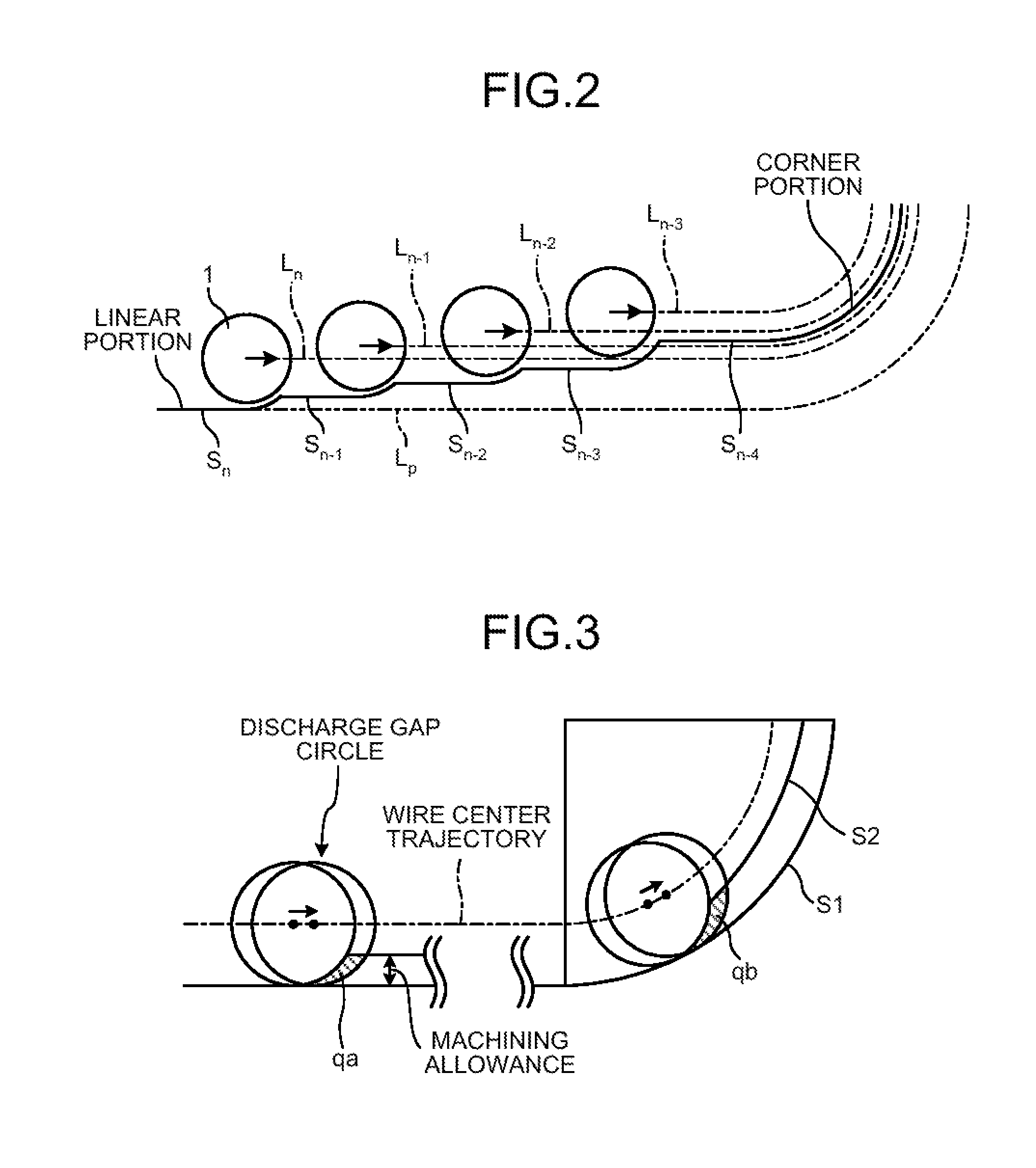

Wire electric discharge machining apparatus

An object is to enable highly accurate machining by correcting machining conditions by referring to a programmed trajectory to obtain a desired machining shape. A wire electric discharge machining apparatus includes a machining-condition correcting unit that corrects machining conditions in each machining stage corresponding to a circular arc radius of a portion corresponding to a corner portion of a programmed trajectory, in the corner portion formed by changing a direction of relatively moving a wire electrode, when the wire electrode is moved on a wire center trajectory, which is offset from the programmed trajectory prestored in order to obtain a desired machining shape to perform finish machining in each machining stage with an offset amount being changed.

Owner:MITSUBISHI ELECTRIC CORP

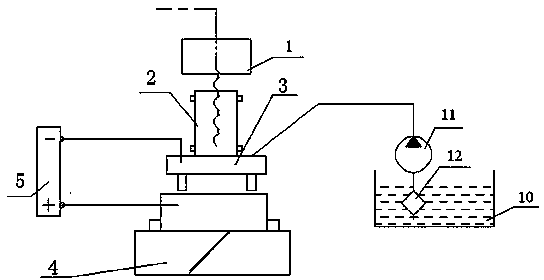

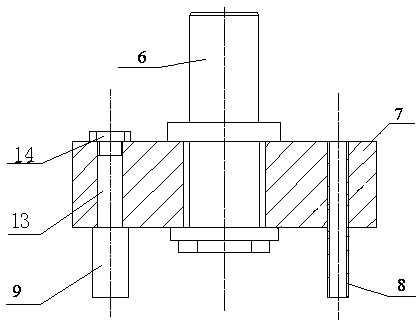

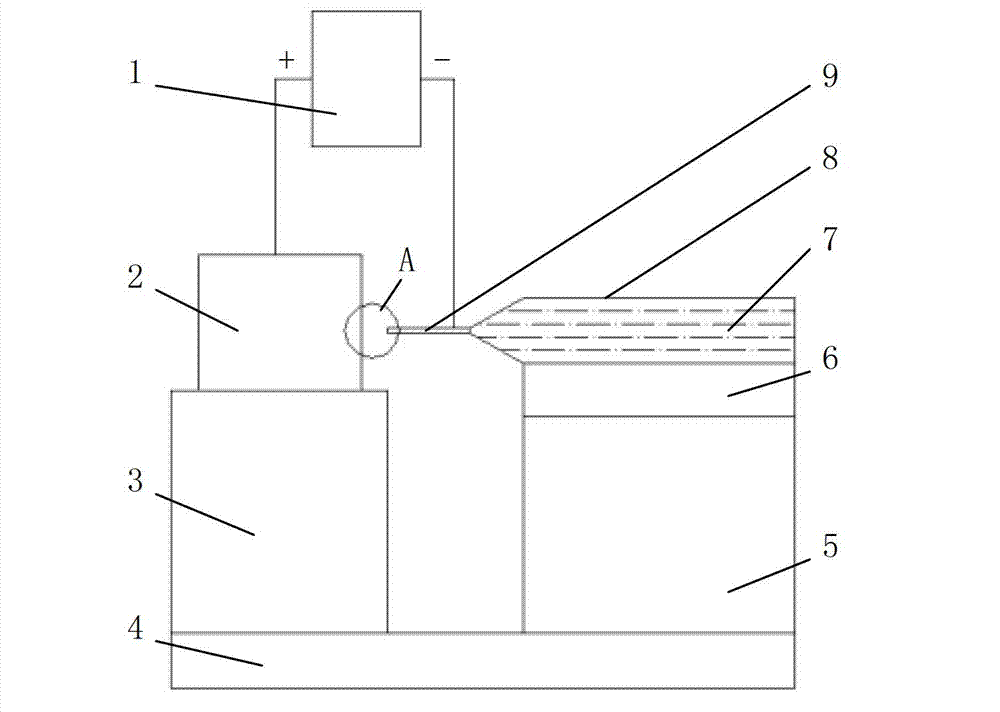

Electric spark milling and mechanical grinding combined machining device

The invention discloses an electric spark milling and mechanical grinding combined machining device. The combined machining device comprises a servo system (1), a milling machine chuck (2) connected with the servo system (1), a combined machining cutter (3) connected with the milling machine chuck (2), a rotary table (4) installed under the combined machining cutter (3) and a pulsed power supply (5) connected with the combined machining cutter (3). According to the combined machining device, discharge electrodes and material grinding rods are mounted on an electrode plate, mechanical grinding is carried out while electric discharge machining is conducted, no short out phenomena or arc discharge phenomena exist, electrode losses are even, quality of machining surfaces is good, compensation is easily achieved, machining efficiency is quite high, precision is high, the mirror surface effect can be achieved through machining, swarf removal is facilitated, and the combined machining device can be widely applied to machining insulators, semiconductors and other workpieces.

Owner:YANCHENG INST OF TECH

Graphene electrode

InactiveUS20160228964A1Outstanding propertyRequired propertyElectrolytic inorganic material coatingElectrophoretic coatingsGraphene electrodeCvd graphene

Owner:AGIE CHARMILLES

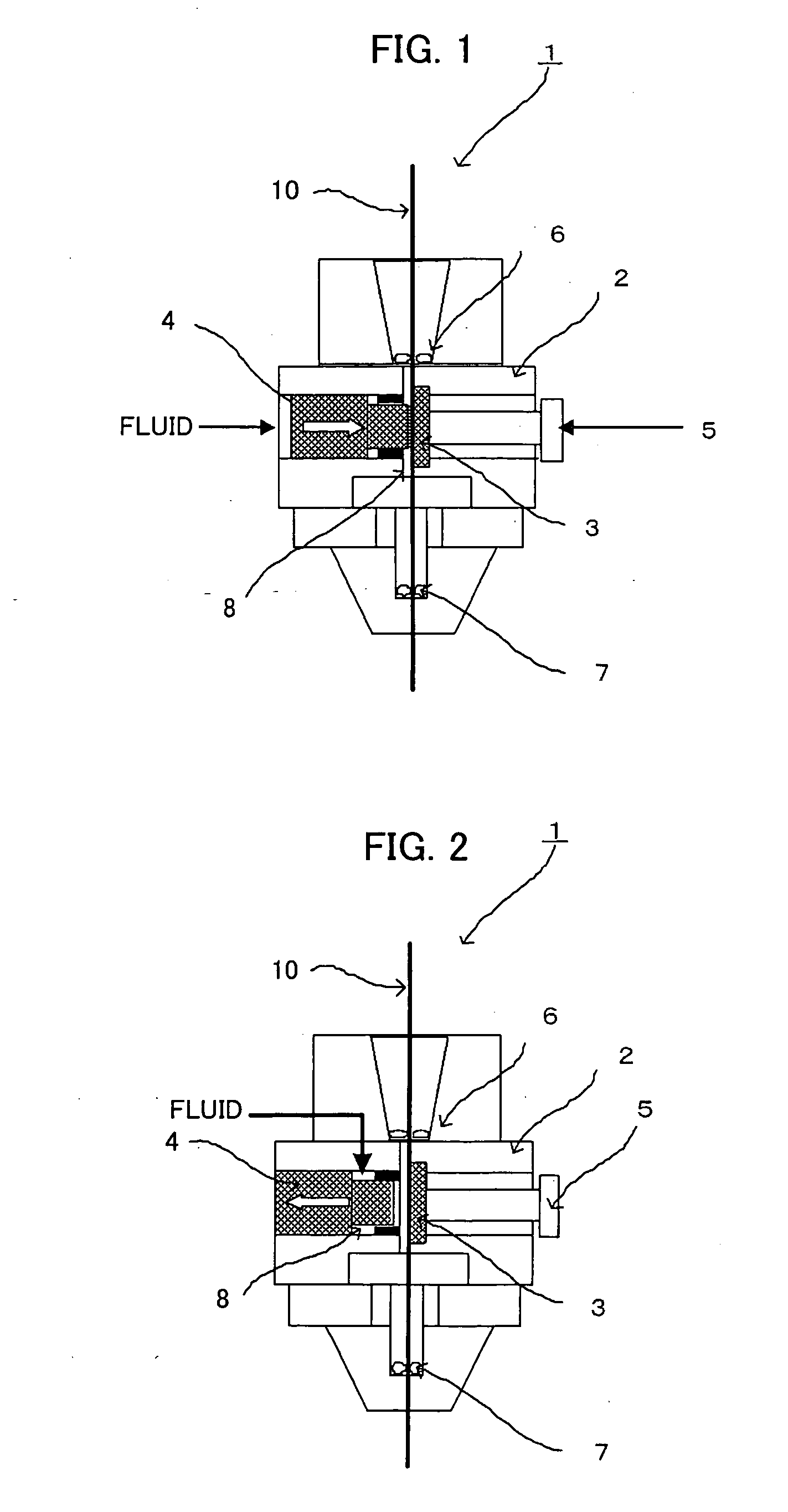

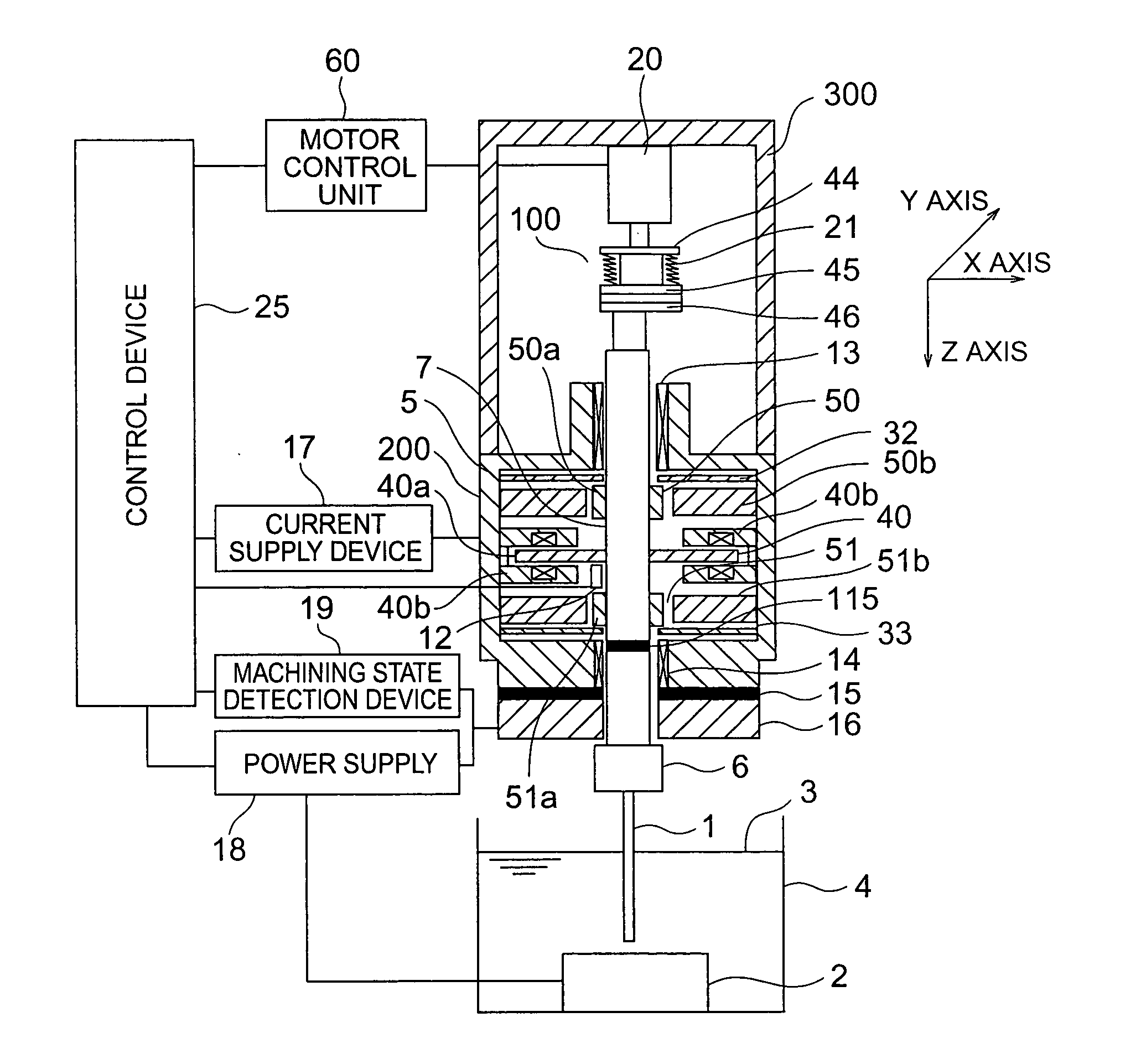

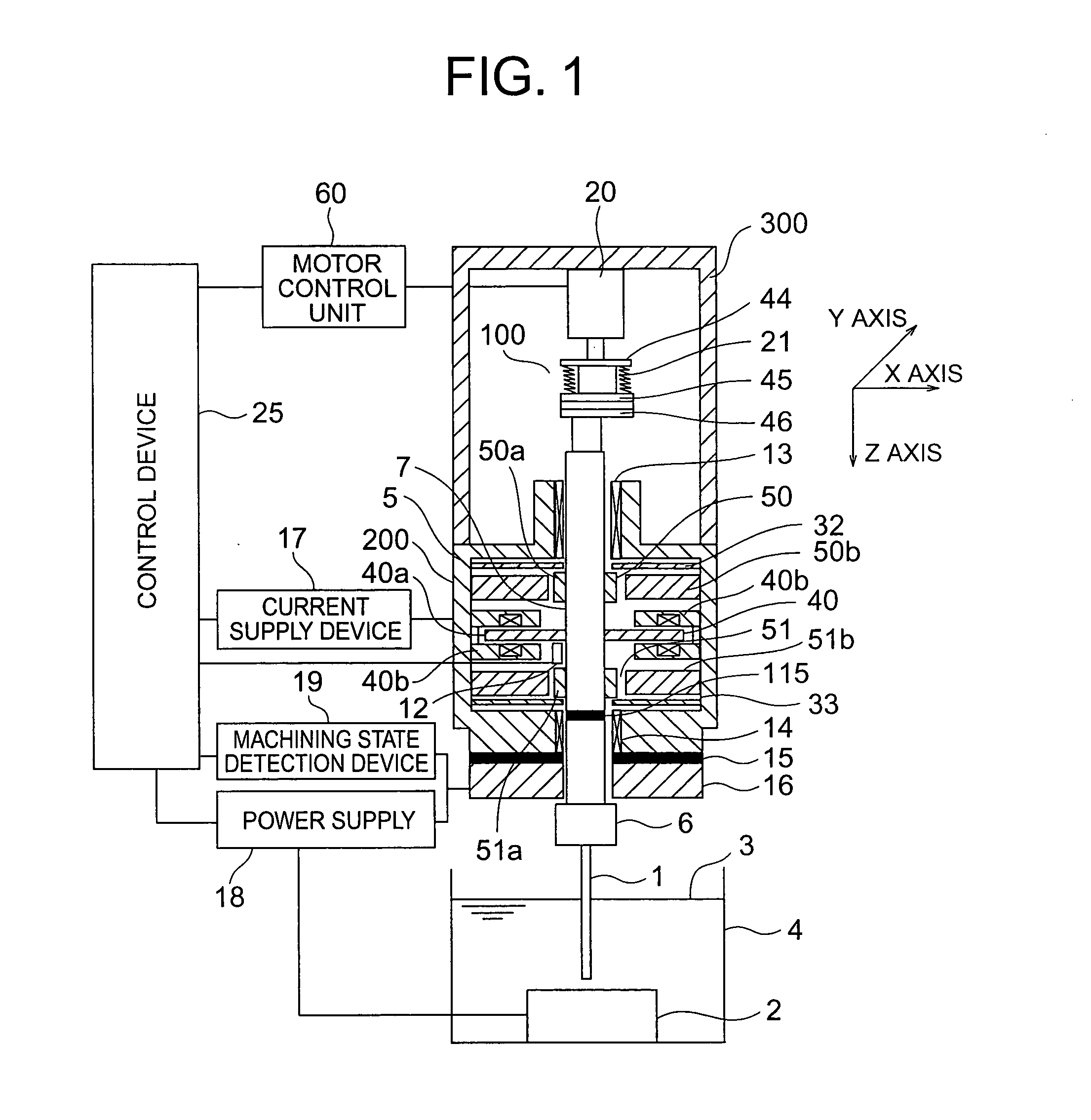

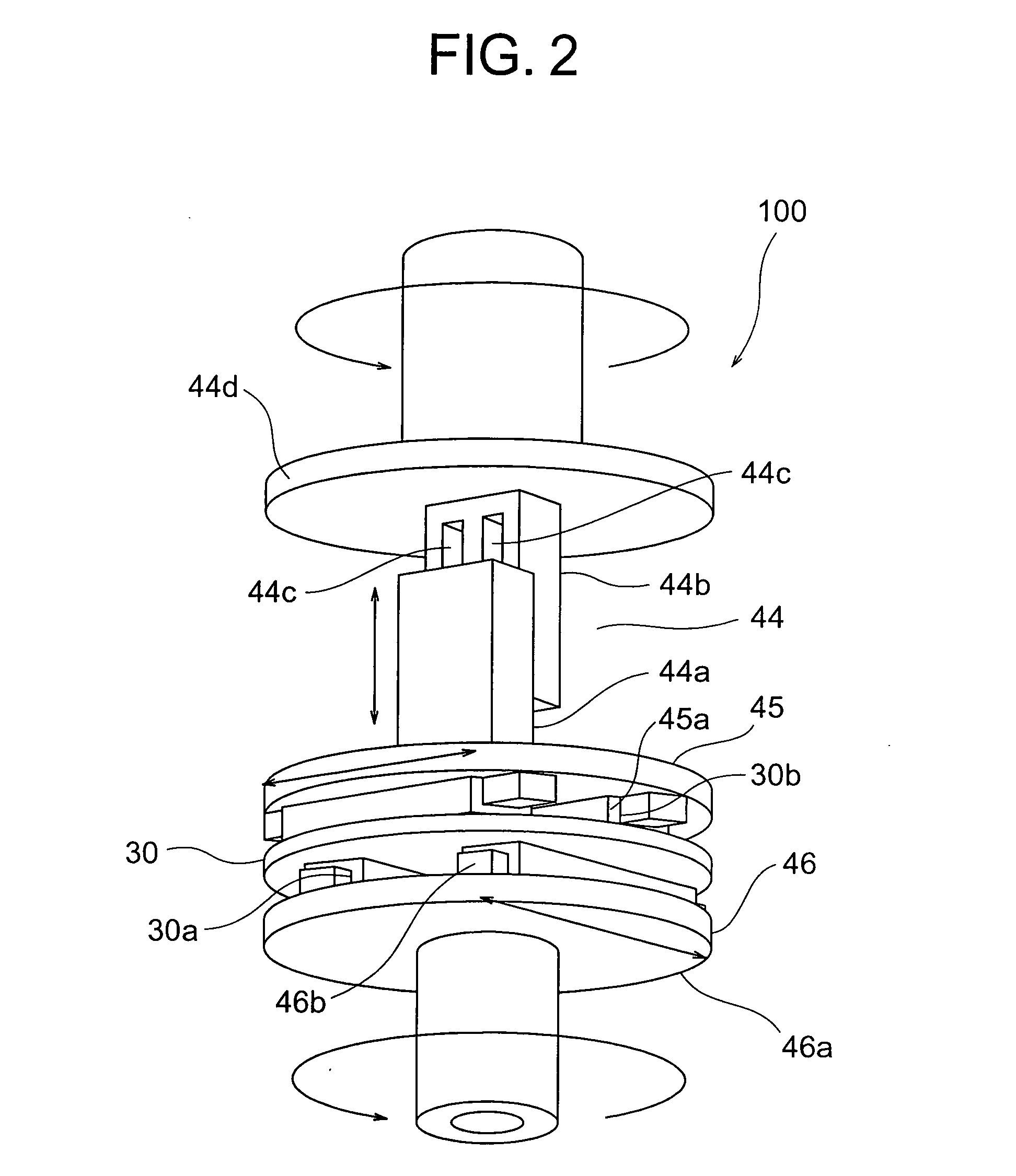

Electric discharge machining apparatus

InactiveUS20050016965A1Improve drivabilityIncrease machine speedElectrode vibration holdersResistance welding apparatusMagnetic bearingElectric discharge

An electric discharge machining apparatus has improved responsive drivability and improved machining speed. A tool electrode has a tip end directed toward a work piece, a voltage applied between the tool electrode and the work piece generating a discharge. A drive shaft is connected with the tool electrode. An electrode driving device has magnetic bearings for moving the drive shaft in three directions including a Z-axis direction which is an axial direction of the drive shaft, a Y-axis direction perpendicularly crossing the Z-axis direction, and an X-axis direction perpendicularly crossing the Y-axis direction and Z-axis direction, by supplying electric current to electromagnetic portions to control magnetic attraction. A movable coupling is connected with an end of the drive shaft and is movable in the three directions. An electric motor is connected with an end of the coupling for rotating the drive shaft through the coupling.

Owner:MITSUBISHI ELECTRIC CORP

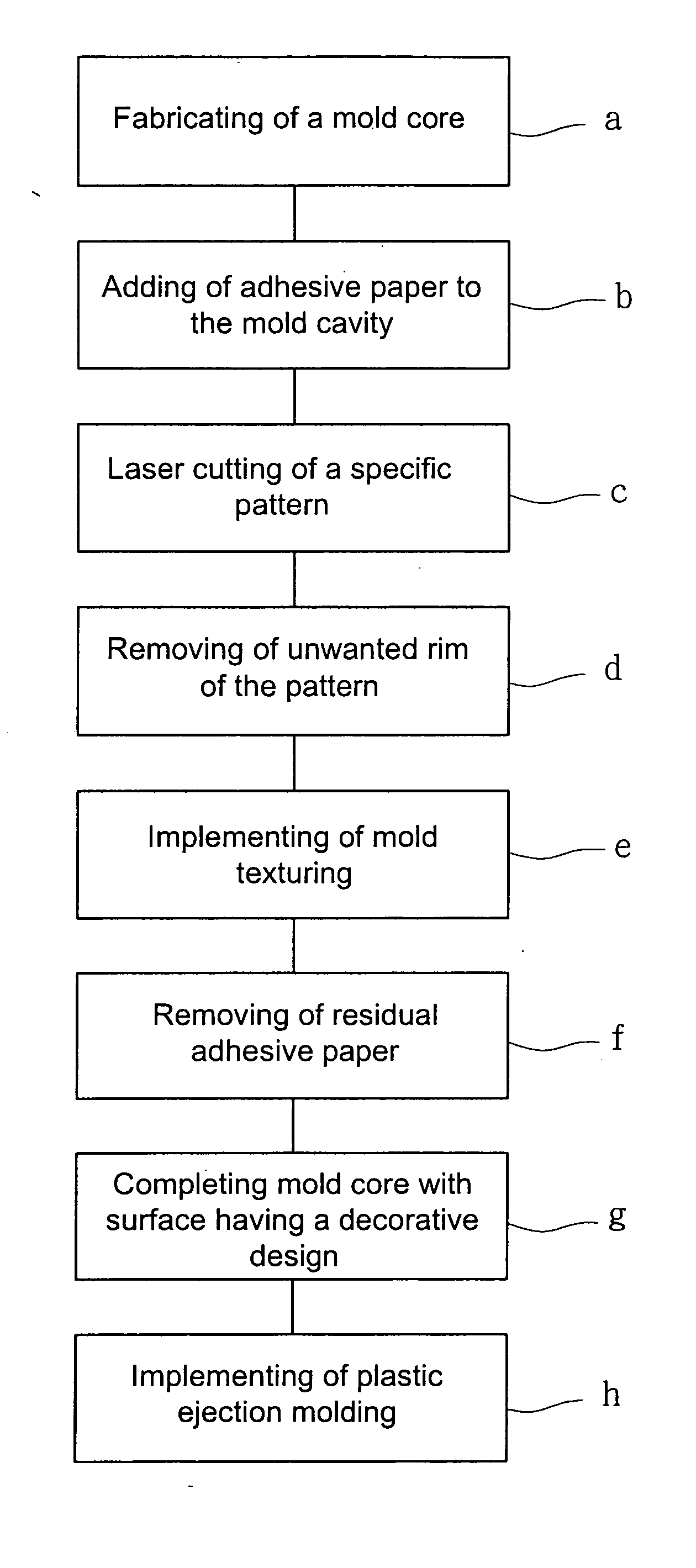

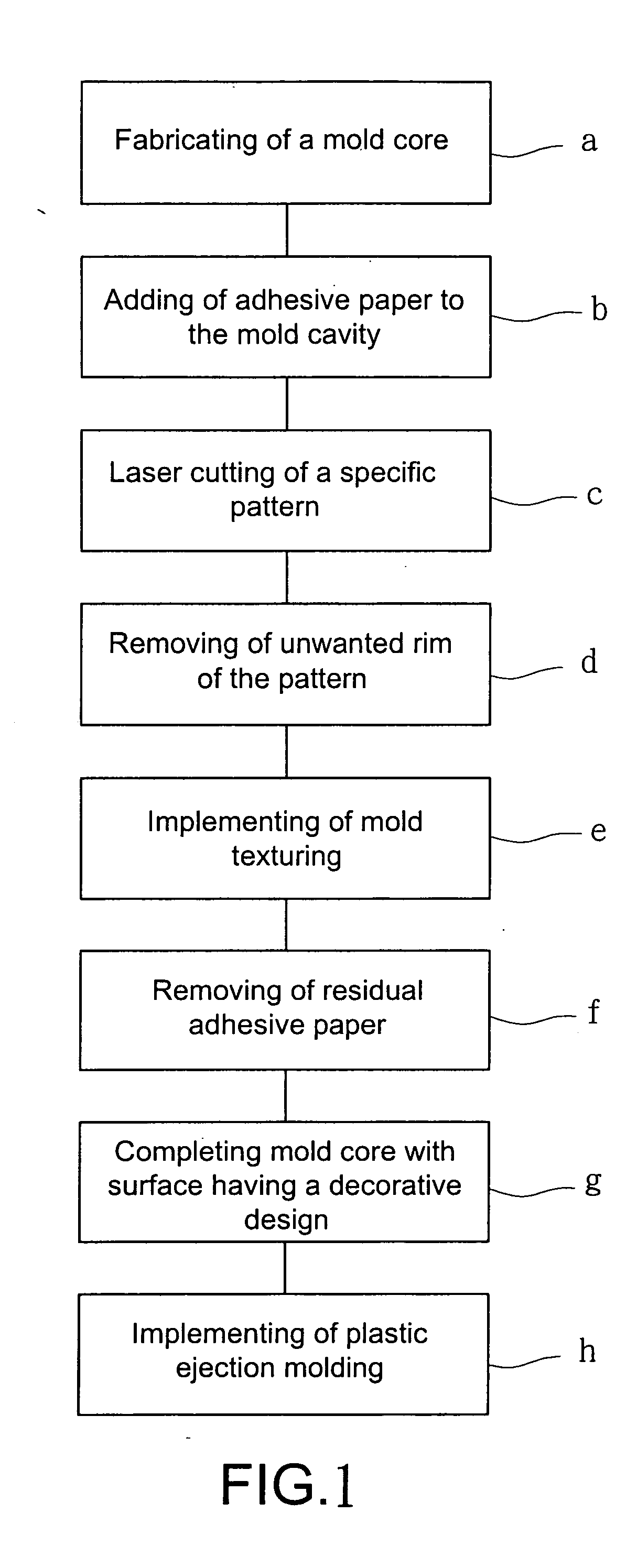

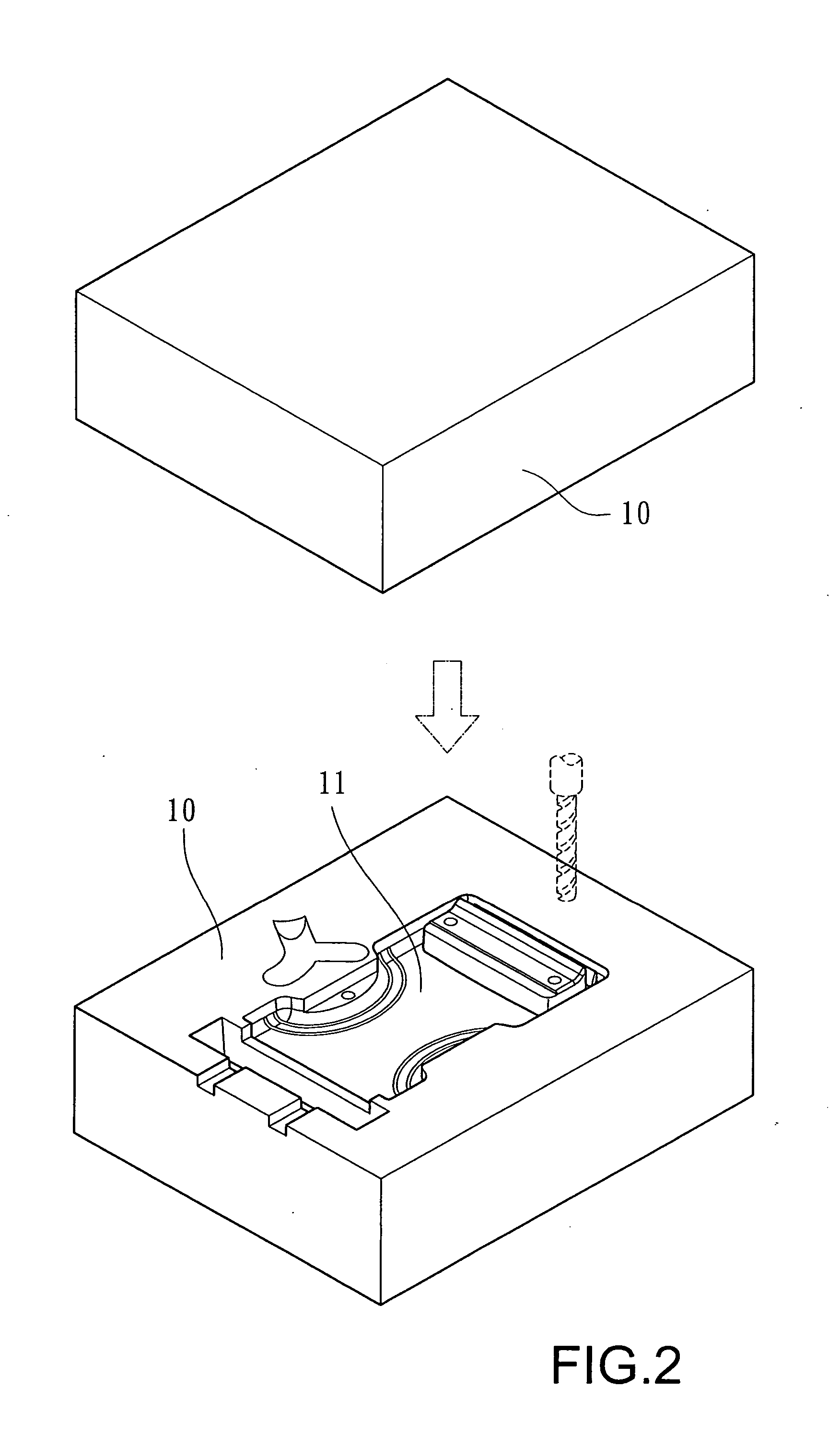

Method for forming a fine embossed pattern on a surface of a fastener member

InactiveUS20070262493A1Increasing aesthetic appeal thereofIncrease added valueDomestic articlesElectric/magnetic/electromagnetic heatingLaser engravingEngineering

A method for forming a fine embossed pattern on a surface of a fastener member, wherein a mold core is formed with a mold cavity having a fastener member shape, and a layer of adhesive paper is adhered to an area of the mold cavity desired to be fashioned with an embossed decorative design, then laser engraving machining technology is used to engrave out a specific pattern on the mold cavity. Adhesive paper out of the pattern is removed, and mold texturing (electrodischarge machining) is implemented. Finally, the residual adhesive paper is torn away to reveal a non-textured fine pattern in the mold cavity, and plastic ejection molding is implemented to manufacture a fastener member having a fine embossed pattern, thereby increasing aesthetic appeal of the fastener member.

Owner:UNIVERSAL TRIM SUPPLY CO LTD

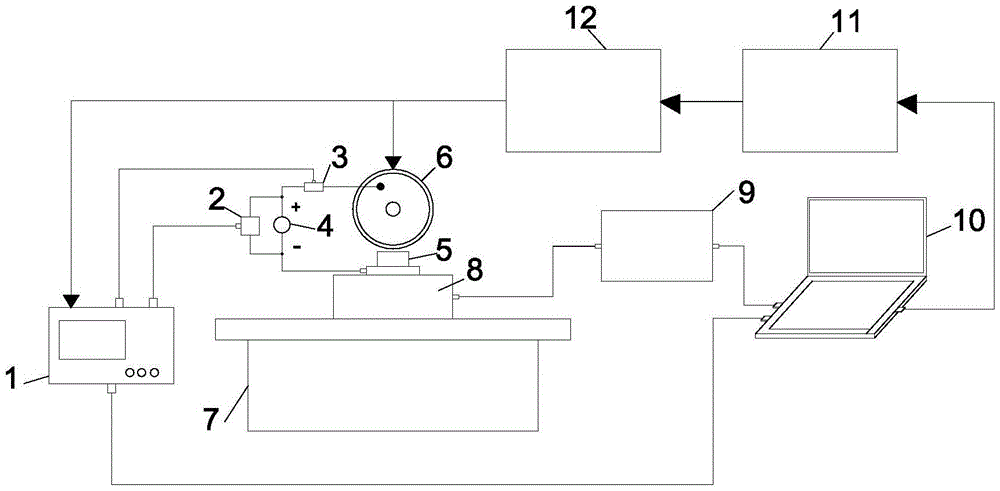

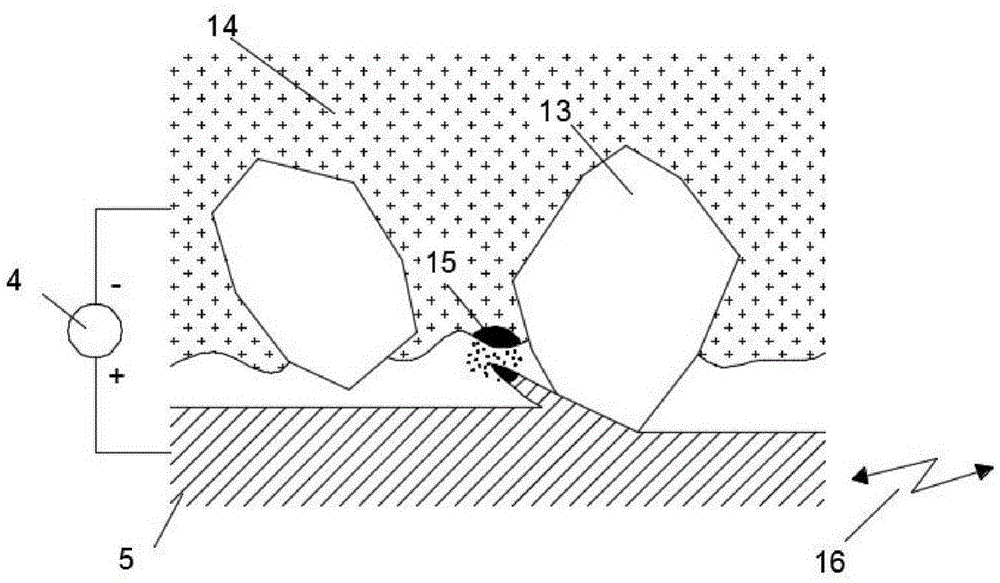

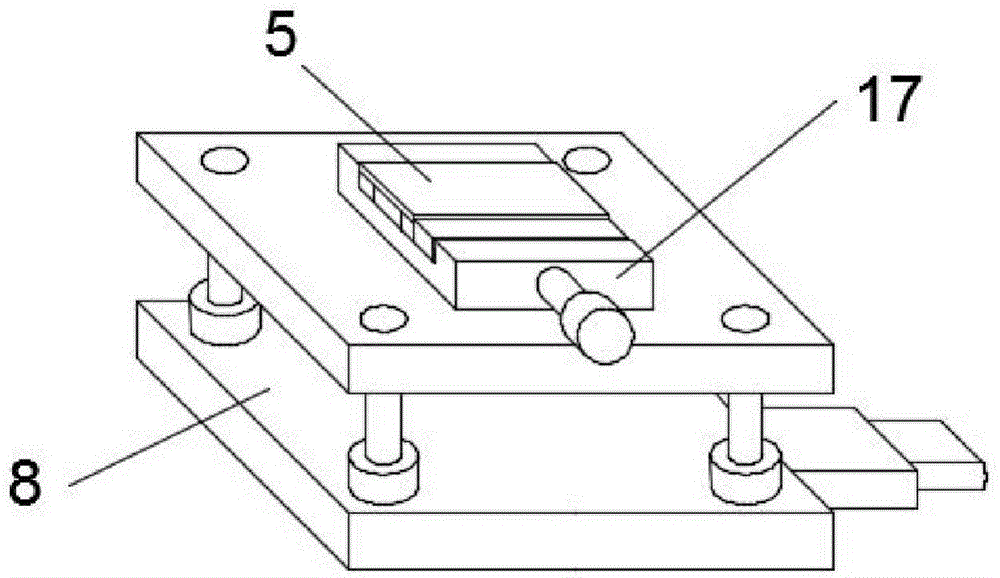

Ultrasonic-vibration-assisted discharging and grinding device and method

ActiveCN105458427AFacilitates the micro-crushing processHigh removal rateCollection systemControl system

The invention discloses an ultrasonic-vibration-assisted discharging and grinding device. The ultrasonic-vibration-assisted discharging and grinding device comprises an ultra-precision grinding machine, a pulse power supply, a pulse discharging parameter collection system, an ultrasonic vibration assistance device and a data processing and regulation system. The ultra-precision grinding machine is provided with a diamond abrasive wheel. The ultrasonic vibration assistance device is fixed to a working table of the ultra-precision grinding machine and used for installing a workpiece and making the workpiece vibrate in the axial direction. The data processing and regulating system is sued for analyzing vibration parameters of the ultrasonic vibration assistance device and obtaining pulse discharging parameters and grinding parameters in real time. The discharging parameters of the pulse power supply, the grinding parameters of the grinding machine and the vibration parameters of the ultrasonic vibration assistance device are regulated in a self-adaption manner through a grinding machine CNC system of the ultra-precision grinding machine so that ultrasonic-vibration-assisted discharging and grinding can be achieved. The invention further provides an ultrasonic-vibration-assisted discharging and grinding method. The gap between grinding particles of the abrasive wheel and the workpiece is regulated through axial ultrasonic vibration, and therefore spark discharging can be uniform, the phenomenon of intermittent discharging is reduced, discharging machining is improved, and the workpiece machining quality can be better.

Owner:SOUTH CHINA UNIV OF TECH

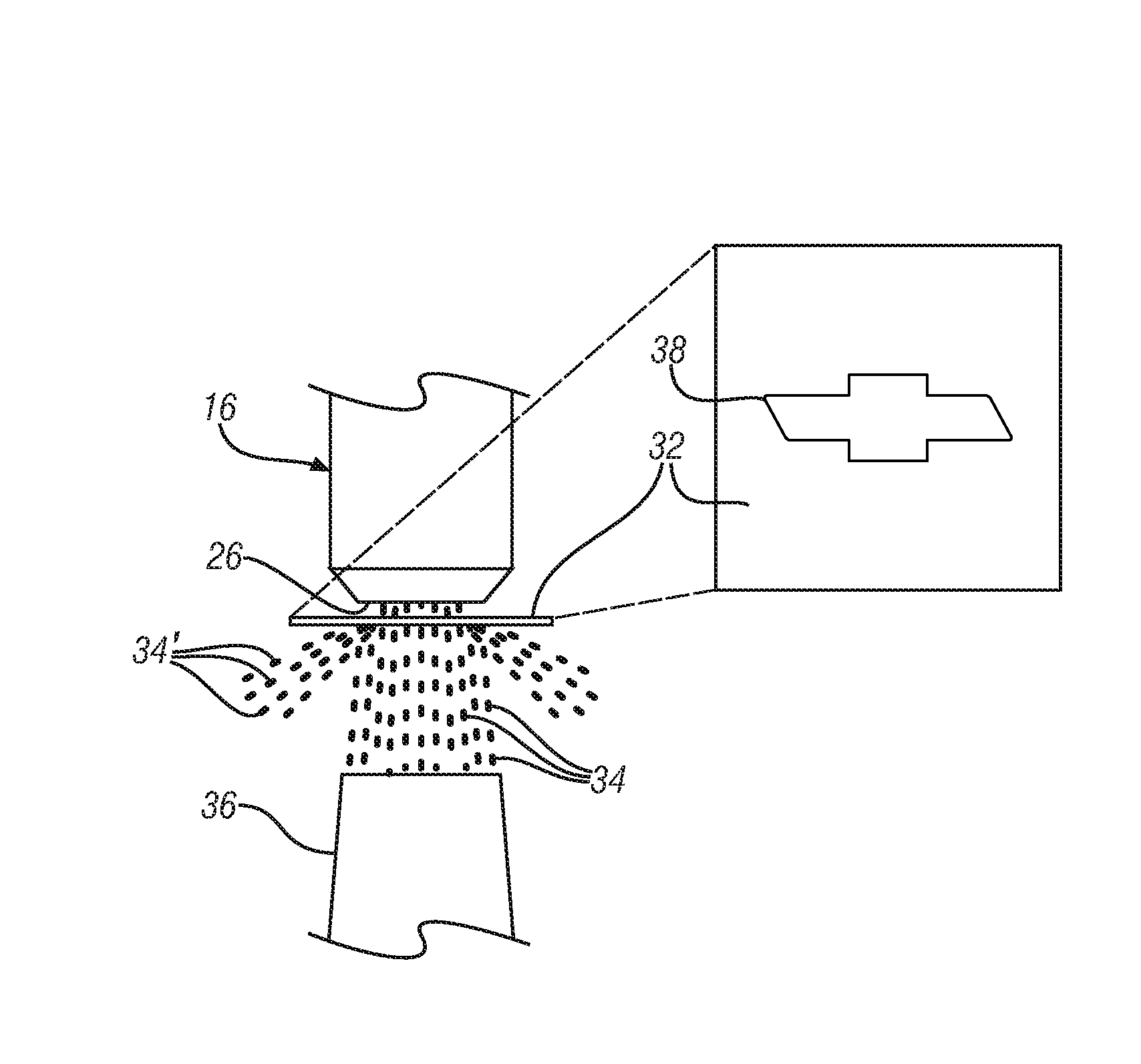

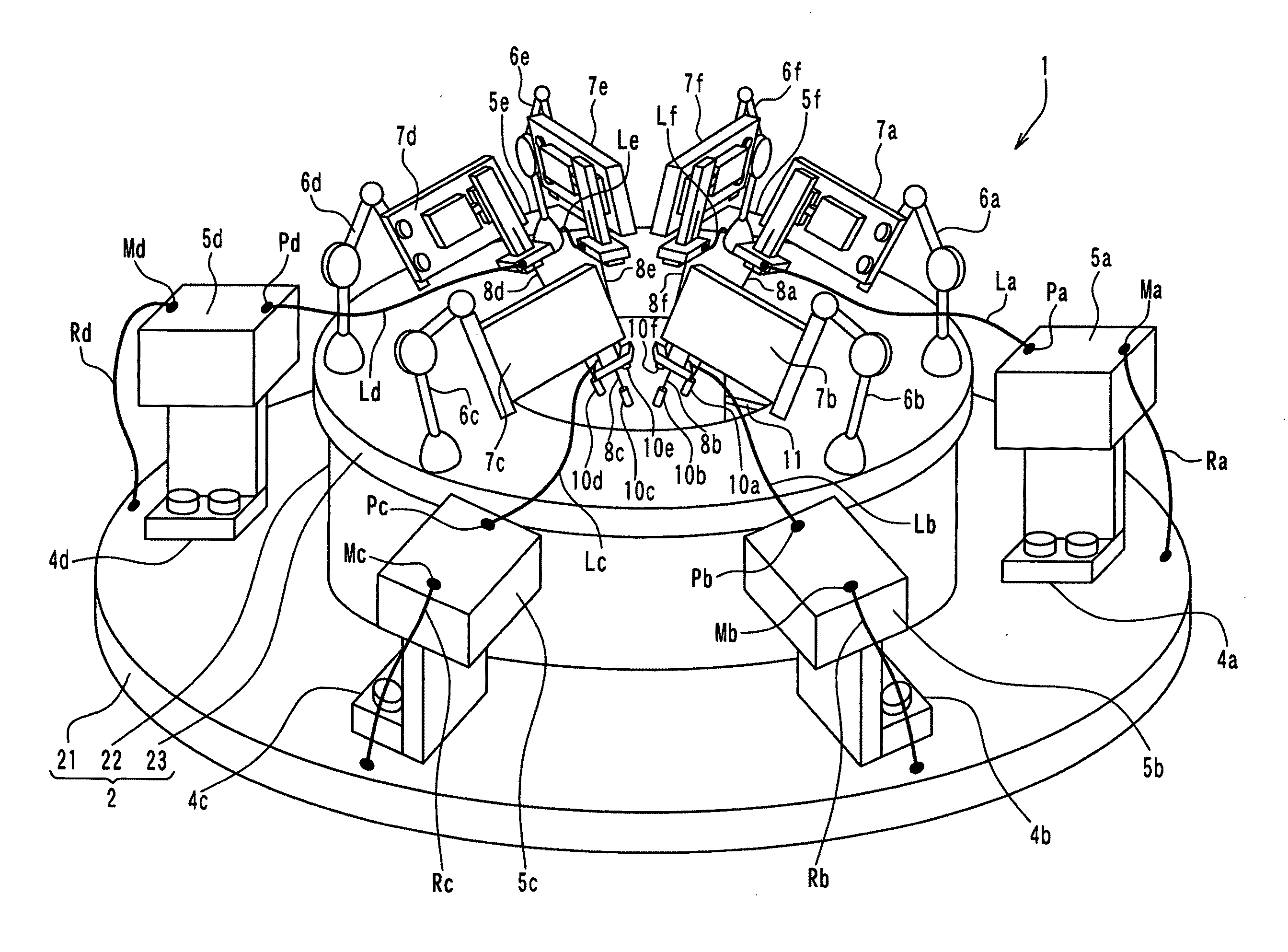

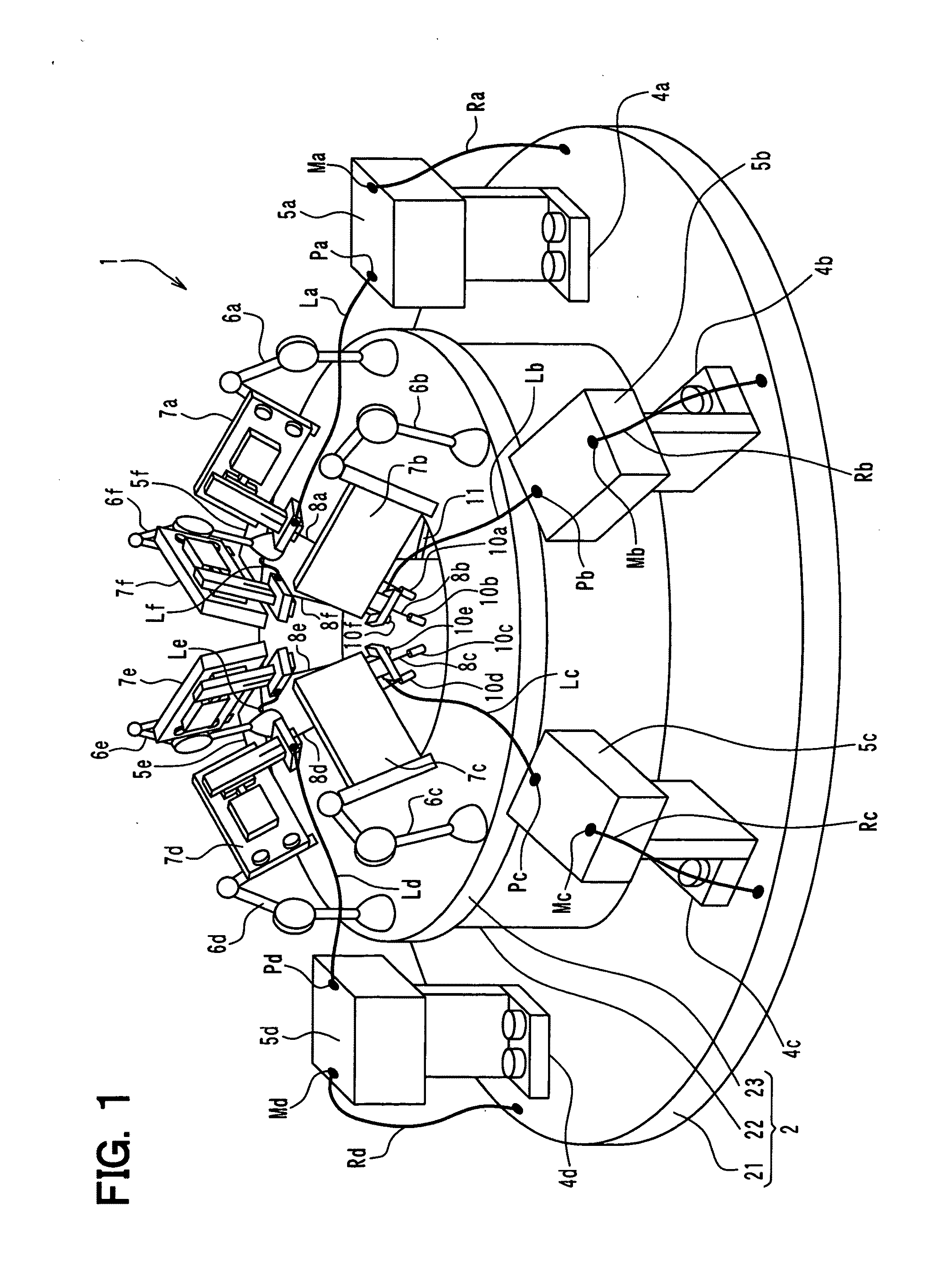

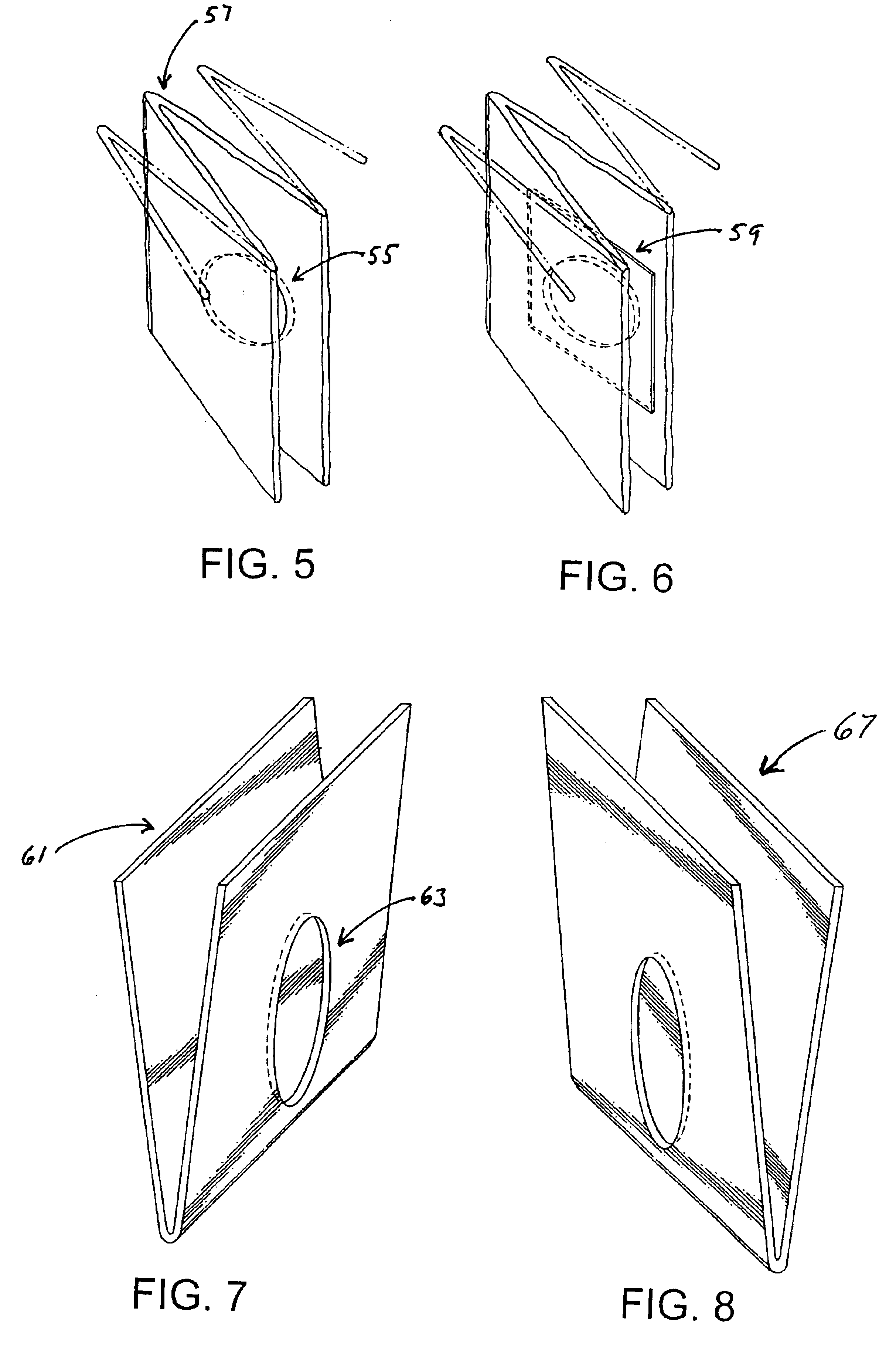

Application of surface relief to spot welding electrodes

ActiveUS8350179B2Avoid deformationPrevent removalArc welding apparatusPressure electrodesEngineeringSpot welding

The workpiece-contacting surface of the spot welding electrode may be suitably modified to incorporate a desired shape or form, generally comprising a depressed region outlining a recognizable shape, to form aesthetically-pleasing or functional features in the surface of a workpiece during resistance spot welding. Methods for creating the desired form in the spot welding electrode including abrasion, upsetting, and electrical discharge machining are disclosed. Preferably the electrode face is shaped and subsequently redressed during welding operations at the welding station.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electric discharge machine and method of producing nozzle body using the same

ActiveUS20110186551A1Reduce processing timeElectrode vibration holdersElectric circuitsElectric dischargeEngineering

An electric discharge machine to process a work piece includes a plurality of electrodes, and a plurality of discharge power supply units. The plurality of electrodes generate a plurality of discharges with the work piece, respectively. The plurality of discharge power supply units apply voltages for the plurality of electrodes, respectively and independently.

Owner:DENSO CORP

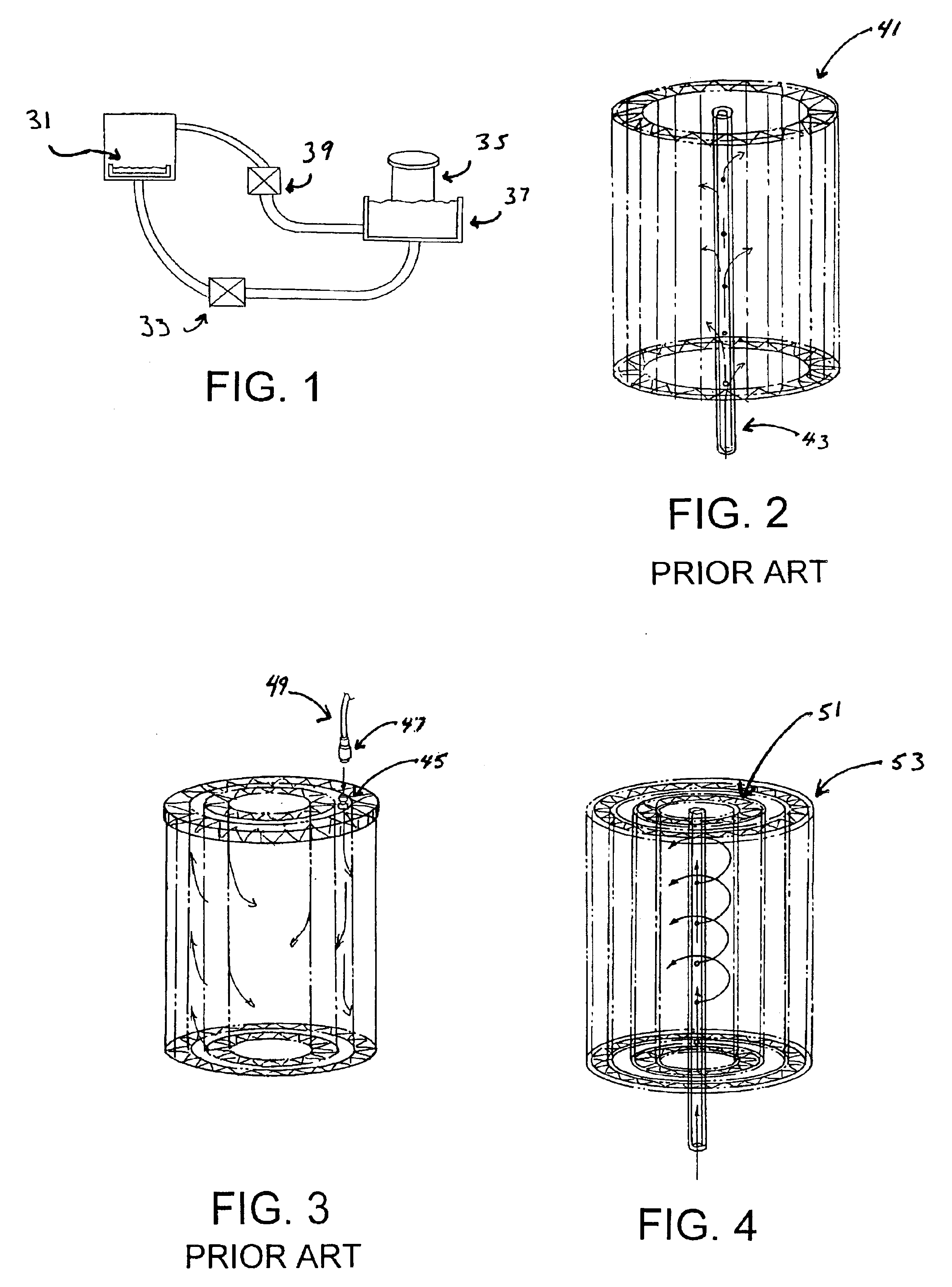

Multi-stage EDM filter

InactiveUS6881330B2Service lifeAvoid feesWater/sewage treatmentLoose filtering material filtersVertical tubeEngineering

A two-stage, retrofit filter is adapted for use with an electrical discharge machine (EDM) includes nested inner and outer filtering elements that may be placed as a unit in the same tank and over the apertured standpipe used for a one-stage filter, such that the fluid to be filtered now flows through each of the multiple filter elements. The retrofit EDM filter may be configured for flow in either direction, though the usual arrangement is one whereby the fluid being filtered flows up through the bottom of the tank, out the apertured standpipe, and into the inner filter element. Preferably, the filter elements are cylindrical, pleated elements composed of a technical grade filter paper. In the preferred embodiment, a pressure-operated release valve is provided in conjunction with the inner filter, such that when a predetermined pressure is reached due to the entrapment of contaminants by the inner filter, the valve opens to allow the fluid to be filtered to flow through the outer filter.

Owner:HOFF ENG

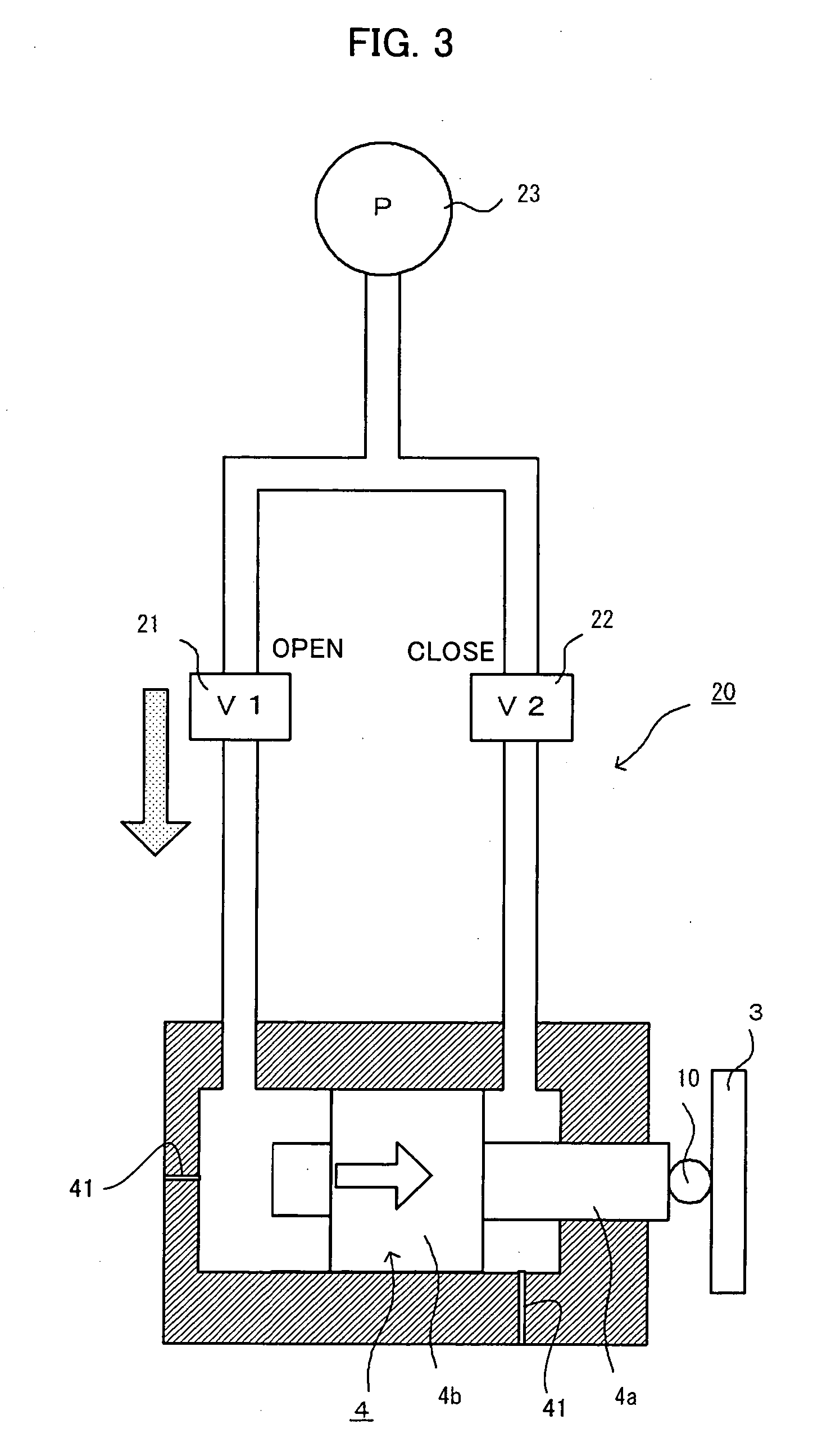

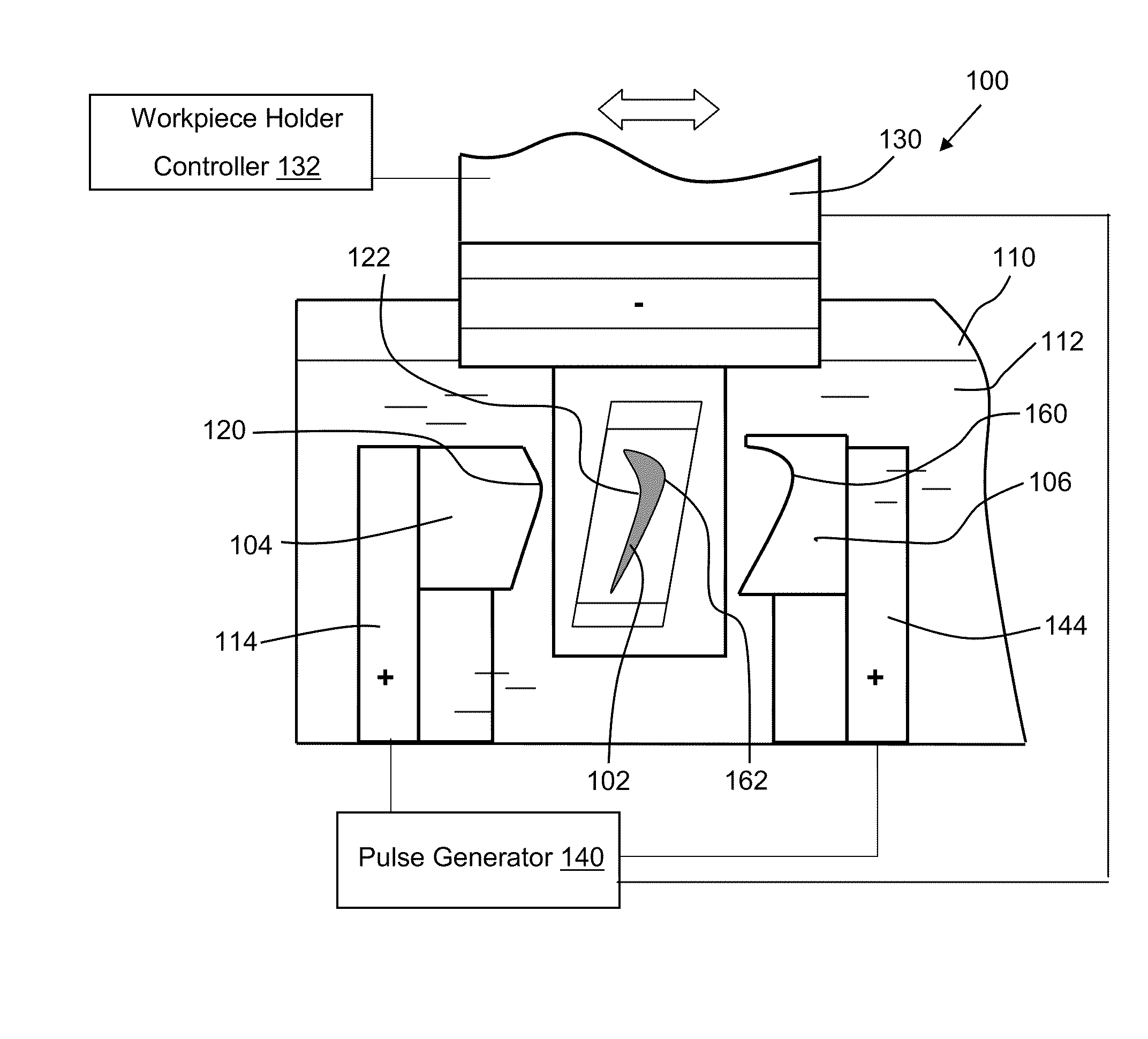

Electric discharge machining die sinking device

An EDM die sinking device includes a tank for holding a fluid, and at least one electrode in the tank having a shape for imparting to a first portion of a workpiece. A workpiece holder positions the workpiece at least partially immersed in the fluid and alternately moves the workpiece between an inoperable position and a first operable position of the first electrode at which electric discharge machining occurs on the first portion. A pulse generator creates an electric discharge between the first portion and the first electrode to remove material from the first portion in response to the workpiece being in the first operable position. Movement of the workpiece from the electrode flushes particle containing fluid away from the workpiece and the electrode. A segmented electrode includes a separate pulse generator for each segment may also be employed.

Owner:GENERAL ELECTRIC CO

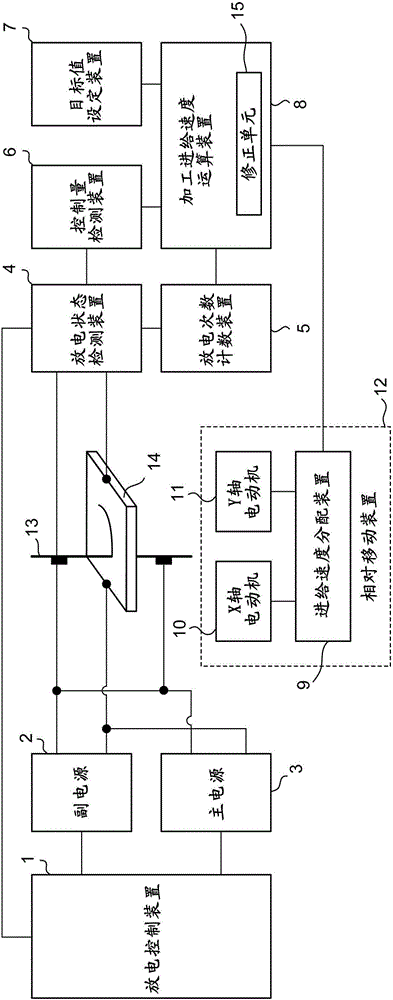

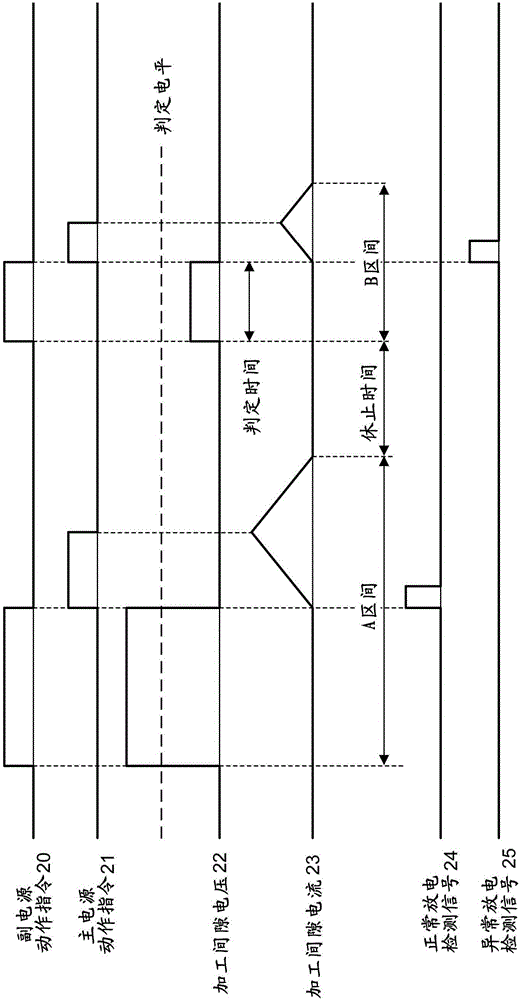

Wire electric discharge machine operating with constant inter-pole distance

ActiveCN106475646AConstant distanceProgramme controlElectric circuitsElectric dischargeControl theory

In a wire electric discharge machine of the present invention, a control variable detection apparatus is an inter-pole voltage detection apparatus and detects an average inter-pole voltage as a control variable correlating with an inter-pole distance. The wire electric discharge machine comprises a machining feed speed calculation apparatus determining a machining feed speed on the basis of a deviation between target voltage set by a target value setting apparatus and the average inter-pole voltage so as to eliminate the deviation. The wire electric discharge machine further comprises a feed speed distribution apparatus and a relative movement apparatus. The inter-pole distance can be kept constant by the relative movement of a wire electrode and a workpiece made on the basis of a command of thus determined machining feed speed.

Owner:FANUC LTD

Electric spark milling process method with mist

The invention relates to an electric spark milling method by mist, which pertains to special process technology domain. The invention takes mist as dielectric medium between work piece and instrument to make electrodischarge machining. Compared with gas and liquid medium, mist medium has a lower breakdown voltage and can reduce the cost of liquid, and with rotatable instrument pole it can accelerate decorporation of elaboration product. The invention has a fast process velocity and can produce product with good surface quality.

Owner:SHANGHAI JIAO TONG UNIV

Field jet flow micro electrical discharge machining method

ActiveCN103084674AAvoid easy cloggingThere is no installation errorElectrical-based machining electrodesMicro nanoElectric discharge

Provided is a field jet flow micro electrical discharge machining method of the micro-nano non-traditional machining field. The positive electrode and the negative electrode of a high direct voltage power supply are respectively connected with a machining workpiece and a jet mechanism, and direct voltage is applied, and a high voltage electric field is formed between the machining workpiece and the nozzle of the jet mechanism. Through the adjustment of the distance between the machining workpiece and the nozzle, an electrified liquid drop at the exit end of the jet mechanism is enabled to form Taylor cone and generate intermittent field jet flow at the tip end of the cone, further the gas medium between the jet flow tip end and the workpiece is punctured by the high voltage electric field and electric discharging and heat are generated, and therefore micro corrosion removing processing is achieved. The field jet flow micro electrical discharge machining method can achieve micro electric discharging corrosion removing processing of micron order and even smaller size, a micro electrode is free from being manufactured on line, and after the field jet flow breaks down in an electric discharging process, the field jet flow can be dynamically generated in next cycle, the process circulates repeatedly, the problem of the inherent electrode wear compensation of a normal electrical discharge machining does not exist.

Owner:SHANGHAI JIAO TONG UNIV

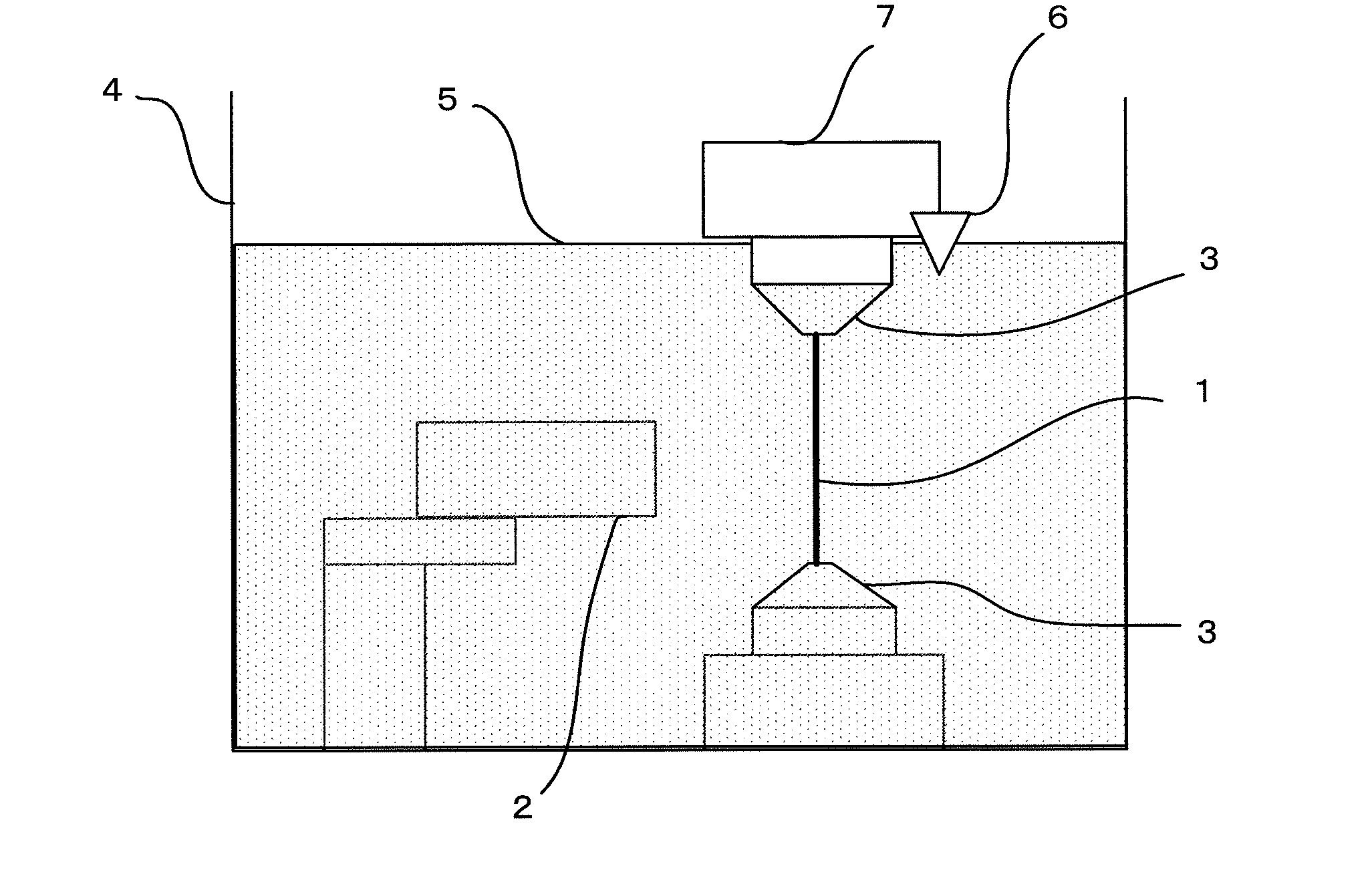

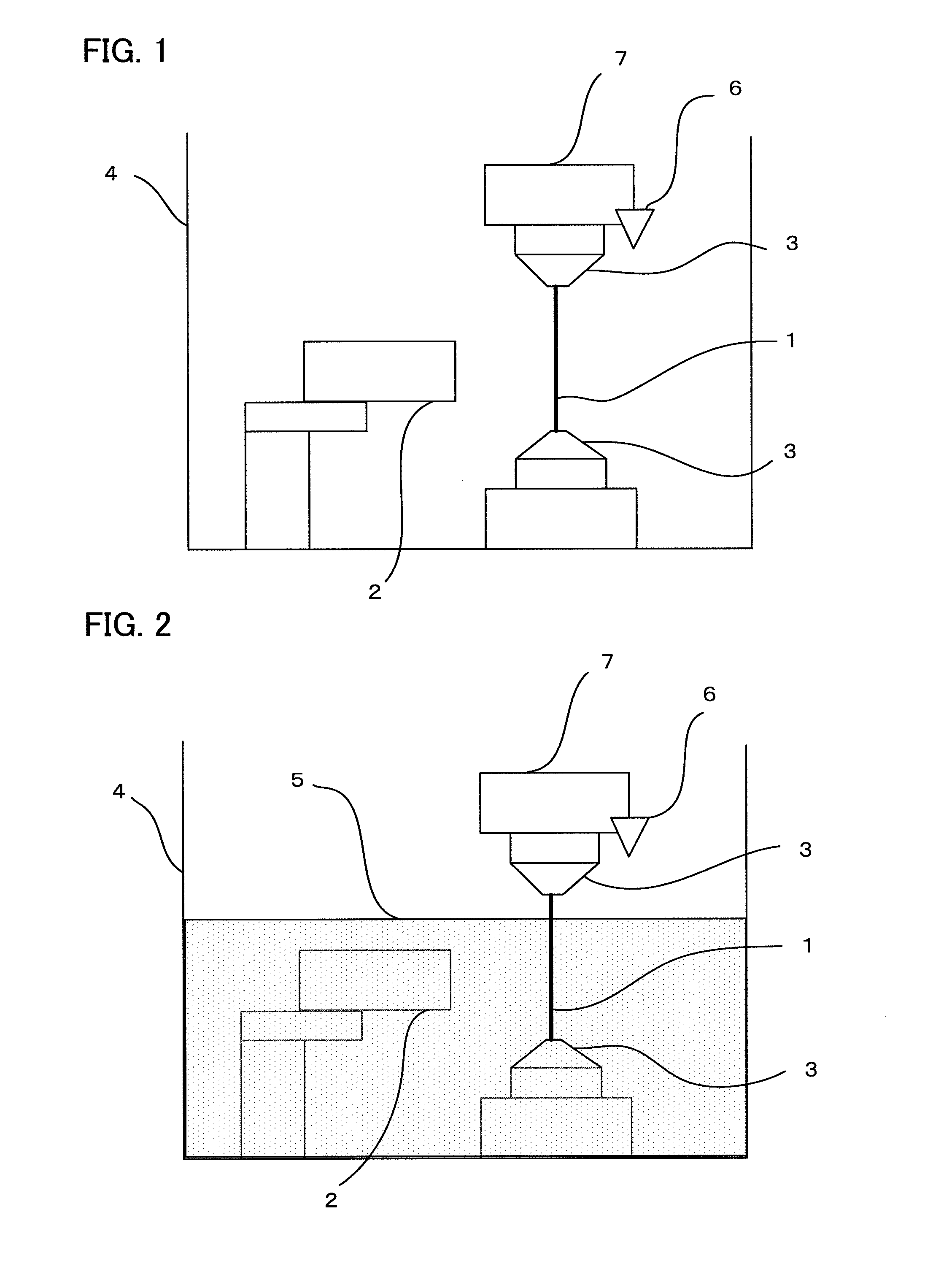

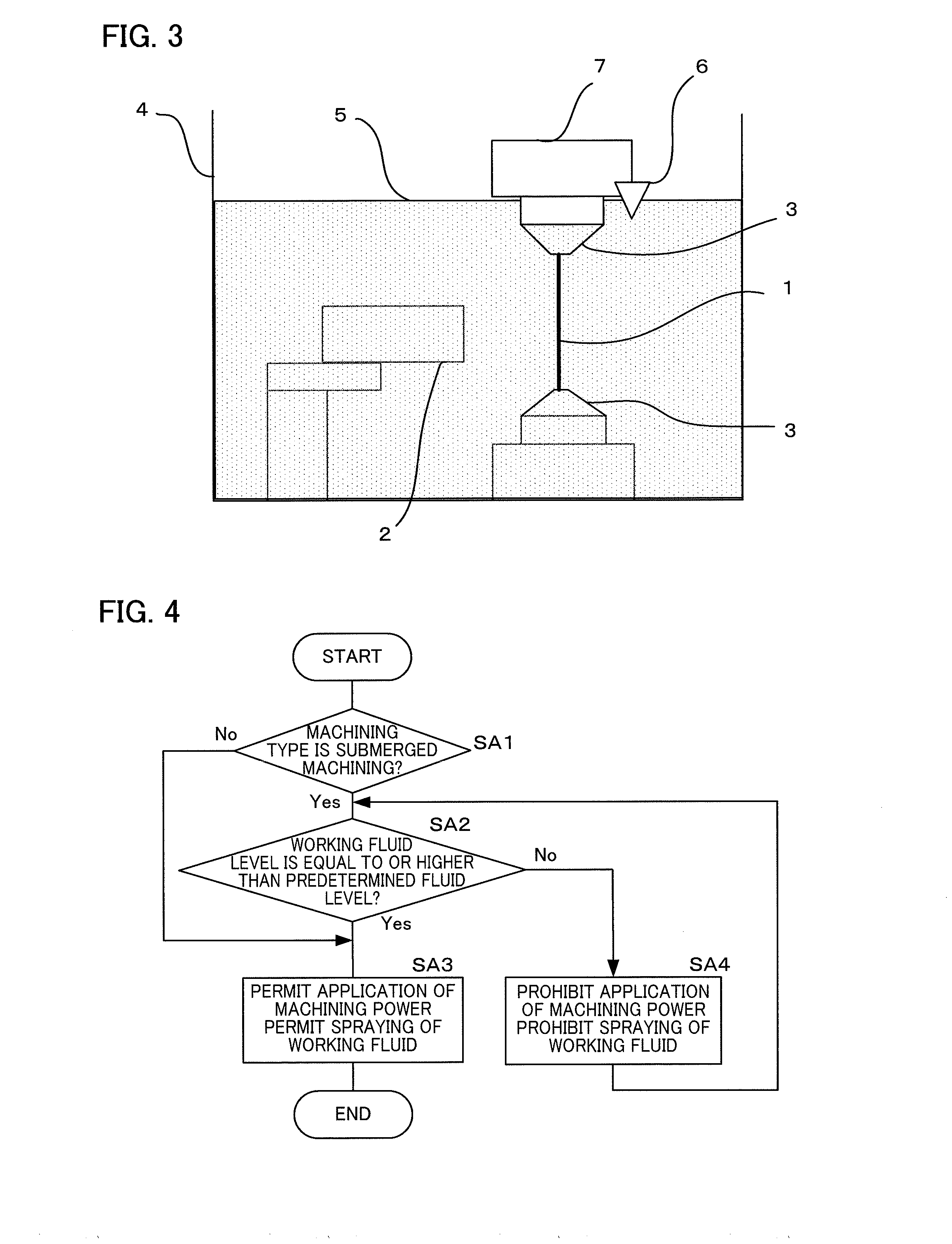

Wire electric discharge machine having function for discriminating state in work tank

The wire electric discharge machine determines whether machining is submerged machining or flushing machining. If the machining is the submerged machining, when a fluid level of working fluid is lower than a predetermined height, the wire electric discharge machine prohibits a machining power from being applied. Thus, it is possible to prohibit the machining power from applied in a state in which the working fluid is insufficient and the submerged machining cannot be appropriately performed, thereby preventing an electric shock due to contact with a wire electrode and machining parts of a workpiece and preventing the working fluid from scattering to the air, and improving safety.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com