Processing method of three-dimensional microstructure prepared by minute electric sparks based on sheet electrodes

A processing method and electric spark technology, which are applied in the field of processing micro-electric sparks to prepare three-dimensional microstructures, can solve the problems of serious micro-electrode loss, low processing efficiency, and difficulty in normal work for a long time, so as to reduce the micro-electrode loss and improve the The effect of processing efficiency and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

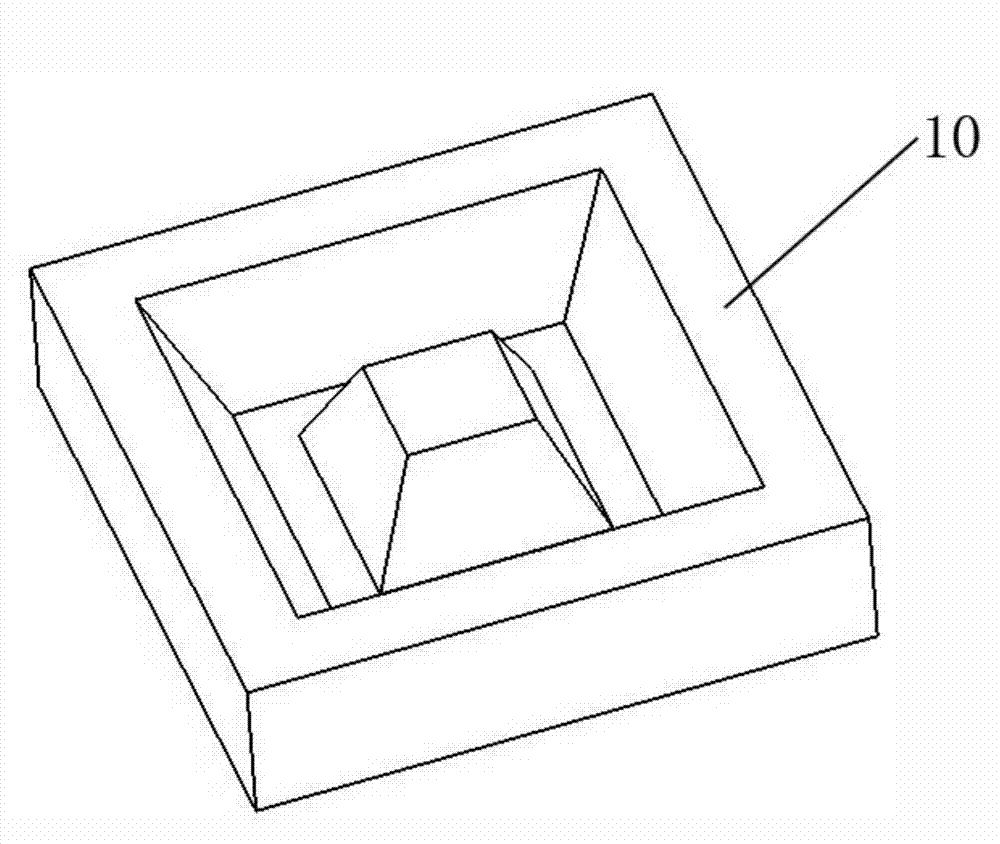

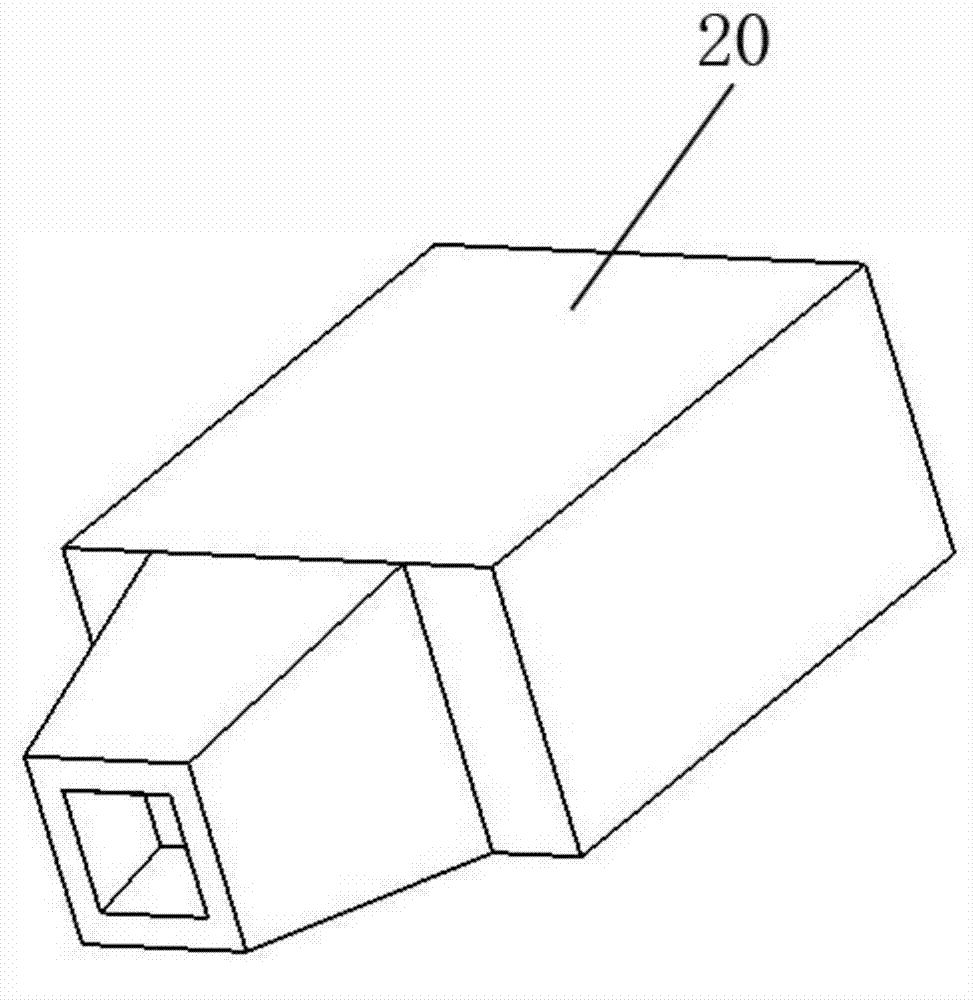

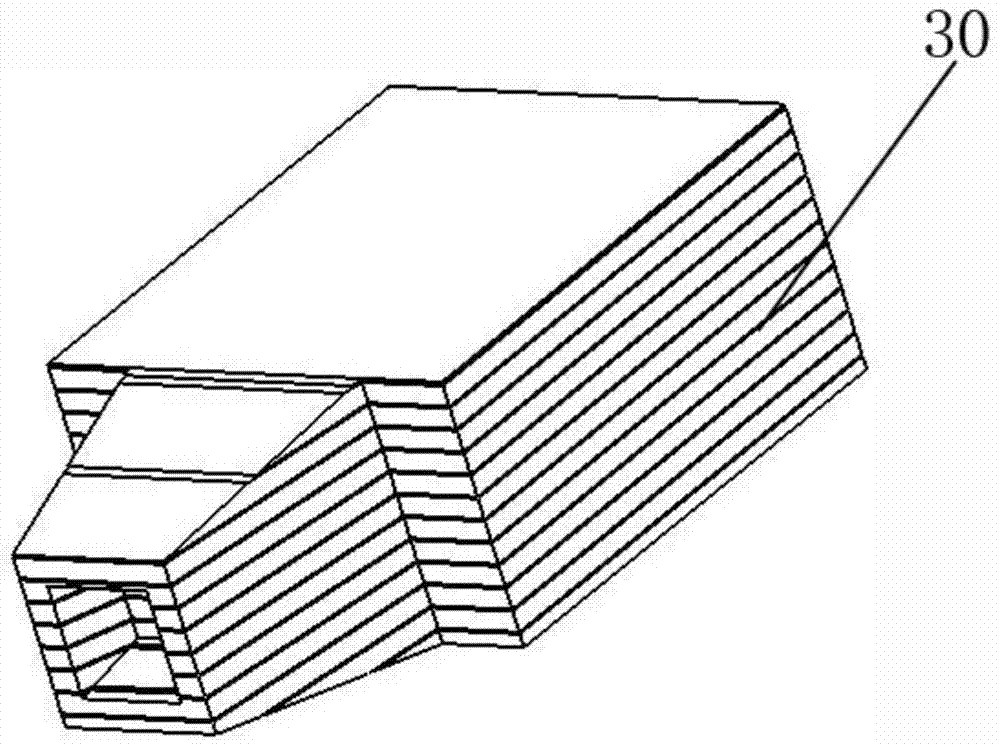

[0051] Such as Figure 1 to 4 As shown, taking the electrode sheet material of copper foil with a thickness of 0.02 mm as an example, the specific processing method for producing the three-dimensional microstructure of copper foil includes the following steps:

[0052] 1) First, establish a CAD geometric model of the three-dimensional microstructure of the material to be processed through the three-dimensional computer-aided design CAD software system;

[0053] 2) Establish the corresponding CAD geometric model of the 3D micro-EDM electrode according to the established 3D microstructure CAD geometric model, and perform discrete slices of the 3D microelectrode to obtain the discrete slice geometric model;

[0054] 3) Convert the discrete slice geometric model of the three-dimensional microelectrode into a set of parallel slice electrode data models;

[0055] 4) The laser cutting system cuts the corresponding slice electrodes one by one on a piece of copper foil with a thickness of 0.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com